Honeywell M6284A1089-S, M6284D1032-F, M6284C1028-S, M6294F1017-F, M6285F1001-F Product Data

...Page 1

Put Bar Code Here

63-2629EF-01

Series 61 and Series 62

Modutrol IV™ Motors

FEATURES

• Replaces M644, M944B,E,G,H,J,K,R,S and

M945B,C,G,K,L,AD Motors.

• Integral junction box provides NEMA 3 weather

protection.

• Integral spring return returns motor to normal position

upon power failure.

• Motor and circuitry operate from 24 Vac. Models

available with factory installed transformer, or a field

added internal transformer.

• Quick-connect terminals are standard—screw terminal

adapter is available.

• Adapter bracket for matching shaft height of older

motors is available.

• Motors have field adjustable stroke (90° to 160°).

• Die-cast aluminum housing.

APPLICATION

The Series 61 and Series 62 Modutrol IV™ Motors are

three-wire spring return and non-spring return floating control

motors. Use these motors with controllers that provide a

switched spdt or floating output to operate dampers or valves.

The Series 62 motors have an internal electrically isolated

feedback potentiometer that provides indication of the motor

shaft position and can be used for slaving Series 90 Motors or

rebalancing an external control circuit.

• Integral auxiliary switches are available factory

mounted, or can be field added.

• Nominal timing standard of 30 seconds (90° stroke),

and 60 seconds (160° stroke). Other timings available.

• Spring return motors can operate valve linkages from

power end or auxiliary end shafts for normally closed

or normally open valve applications.

• All models have dual shafts (slotted and tapped on

both ends).

• All models have auxiliary switch cams.

• Fixed torque throughout the entire voltage range.

• Motors are designed for either normally open or

normally closed valves and dampers.

• Series 62 models include electrically isolated

potentiometer that provides shaft position indication.

• Series 62 TRADELINE models have linear feedback,

configurable for slaving Series 90 Motors.

PRODUCT DATA

SPECIFICATIONS

Models: TRADELINE models are selected and packaged to

provide ease of stocking, ease of handling and maximum

replacement value. TRADELINE model specifications are the

same as those of standard models unless specified otherwise.

Page 2

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

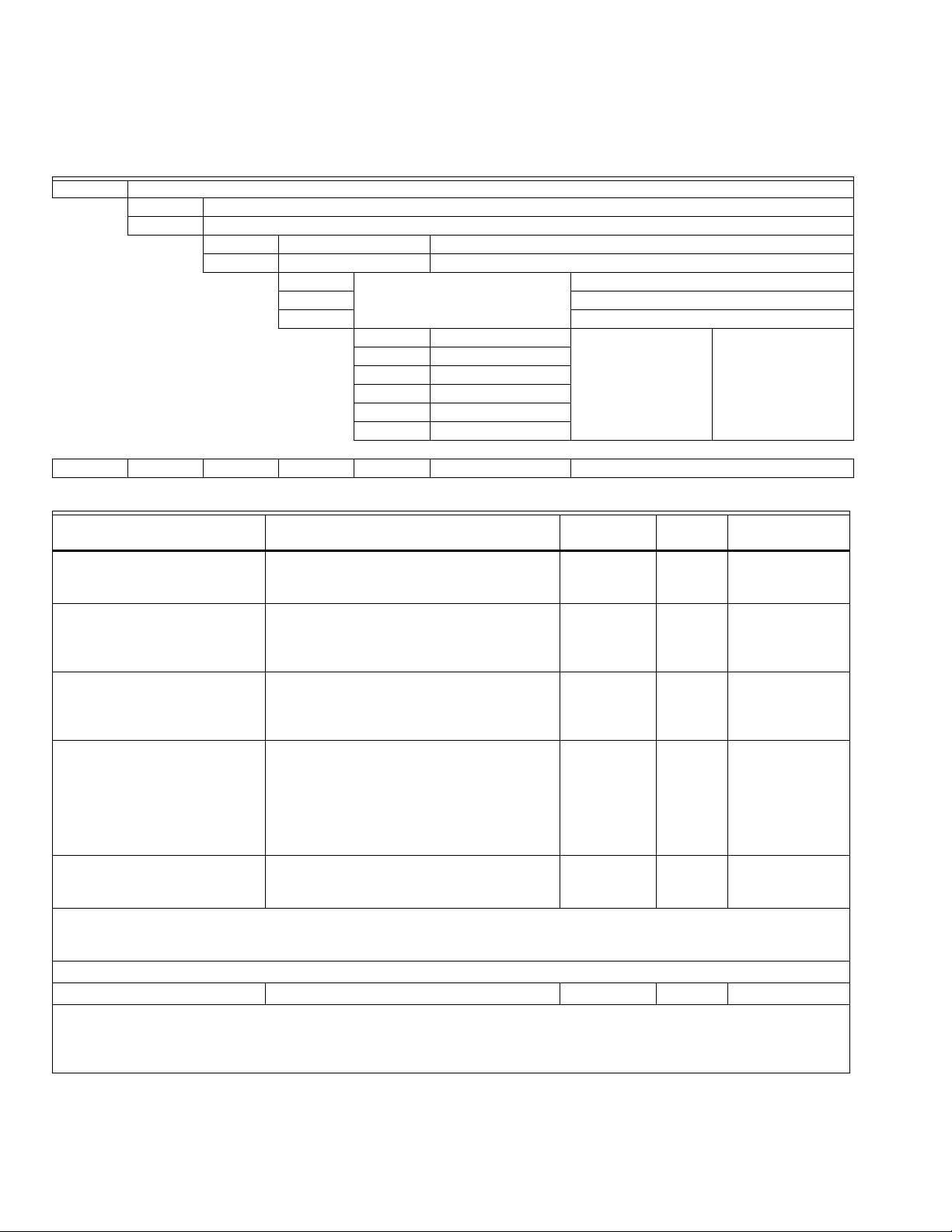

Modutrol IV Order Number Guide: See Table 1.

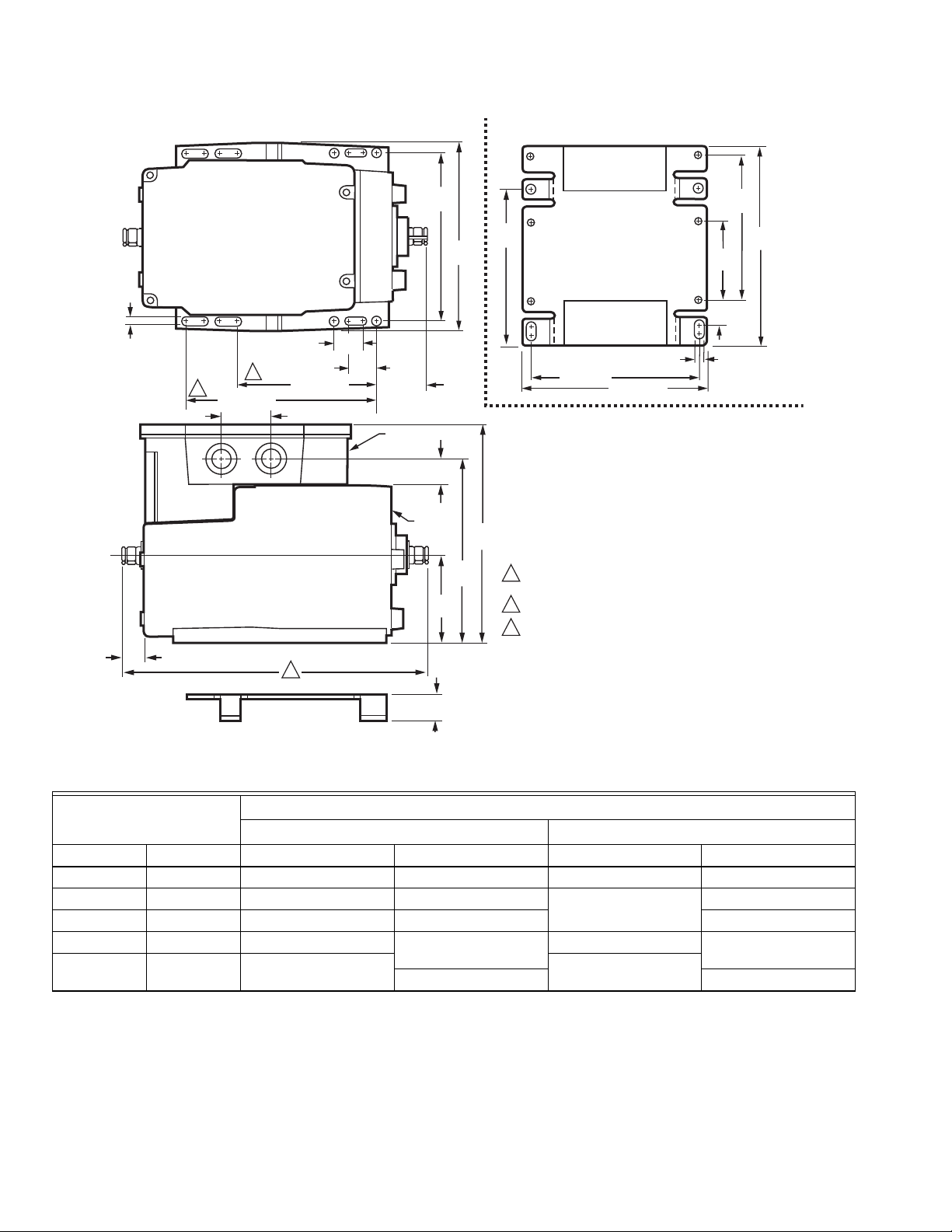

Dimensions: See Fig. 2.

Feedback See Table 2.

Electrical Ratings: See Table 4.

Table 1. Modutrol IV Series 2 Version Order Number Guide.

M Motor

61 Floating Control

62 Floating Control with feedback

8 60 lb-in. Spring Return 150 lb-in. Non-Spring Return

9 — 300 lb-in. Non-Spring Return

2 Dual-ended shaft Normally Closed Spring Return

4 Non-Spring Return

5 Normally Closed Spring Return

A 0 Auxiliary Switches Adjustable Stroke Normally Closed

B 1 Auxiliary Switch

C 2 Auxiliary Switches

D 0 Auxiliary Switch

E 1 Auxiliary Switch

F 2 Auxiliary Switches

M 61 8 4 A XXXX See Catalog for Complete O.S. Number

Table 2. Series 62 Feedback Characteristics

OS Number

M6284D1000-S, M6284D1026-S,

M6284D4004-S, M6285A1005-S,

M6285A1054-S, M6285A4009-S

M6274F1009-F, M6284F1070-F,

M6284F1078-F, M6285F1001-F,

M6294F1009-F, M6294F1017-F,

Feedback Resistance

(Resistance between terminals T, G, and Y)

TG = 370-2400-920 ohm curve (non-linear)

TY = 920-2400-370 ohm curve (non-linear)

YG = 600 ohms constant

TG = 0-10K ohm (linear)

TY = 10-0K ohm (linear)

YG = 10K ohms constant

Sensitivity

Adjustment

Linear

Feedback

Series 90 Slaving

Shunt Resistor

No No 187 Ohm

No Yes Not Available

M6284D1032-F

M6284A1071-S, M6284A1089-S,

M6284C1028-S

TG = 370-2350-630 ohm curve (non-linear)

TY = 630-2350-370 ohm curve (non-linear)

Yes No 274 Ohm

YG = 196 ohms constant for 160° stroke,

346 ohms constant for 90° stroke.

M6284A1030-S, M6284A1055-S,

M6284A1097-S, M6284B1004-S,

M6284C1010-S, M6284C1044-S,

M6284F1013-S, M6284F1039-S,

TG = 370-2300-550 ohm curve (non-linear)

TY = 550-2300-370 ohm curve (non-linear)

YG = 119 ohms constant for 160° stroke,

224 ohms constant for 90° stroke.

Yes No Not Necessary

M6285A1039-S, M6285A1047-S,

M6285C1001-S, M6294B1036-S,

M6294D1008-S

M6284F1062-S TG = 370-2800-1990 ohm curve (non-linear)

No No Not Available

TY = 1990-2800-370 ohm curve (non-linear)

YG = 1800 ohms constant

* All resistance ranges given in the "Feedback Resistance" column are for 160° motors. For a 90° motor that range will be

truncated to either the first half if it’s an asymmetrical motor (for example, a -F would go from 0-5K) or truncated to the middle half

if it's a symmetrical motor (for example, a -F motor would go from 2.5-7.5K).

“-S” Non-linear Feedback for Slaving Series 90 Mod IV Motor

“-F” 0-10K Feedback

Both the "-S" and the "-F" can be used as a voltage divider. When a constant voltage is applied to YG, a voltage signal can be

read over TG that varies linearly with the stroke of the motor from 4-96% of the constant voltage applied to YG, for a 160° motor

only. For 90° asymmetrical motor the signal from TG varies from 4-56% and for a 90° symmetrical motor the signal from TG

varies from 24-76%. A signal can also be read from TY which is the opposite of the signal from TG.

NOTE: Limited models available in Europe, check your local representative for the availability.

63-2629EF—01 2

Page 3

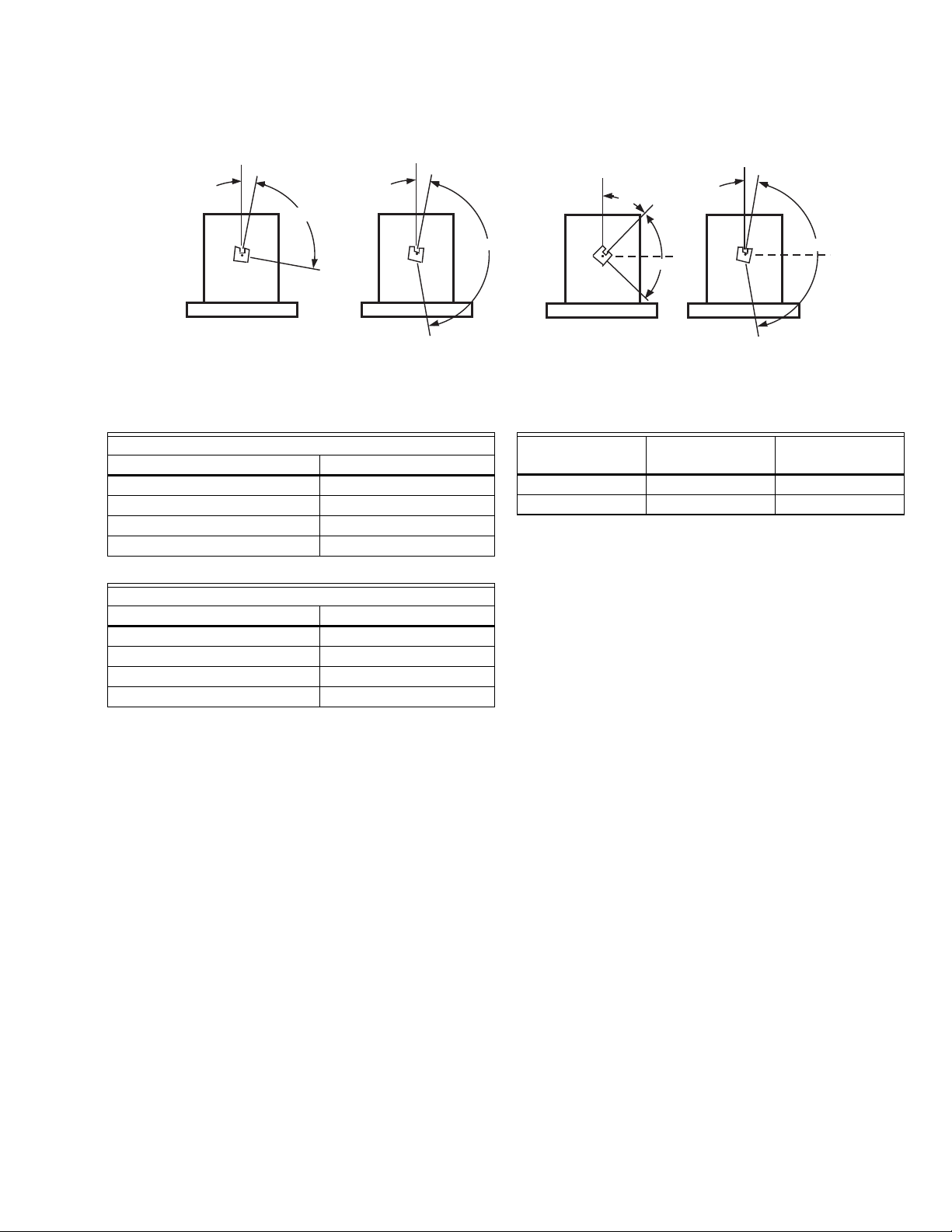

Fig. 1. Stroke

FULLY OPEN

90 DEGREE STROKE 160 DEGREE STROKE

M31079

VERTICAL

REFERENCE

FULLY CLOSED

160

10

VERTICAL

REFERENCE

FULLY CLOSED

90

10

FULLY OPEN

VERTICAL

REFERENCE

VERTICAL

REFERENCE

FULLY CLOSED

FULLY OPEN

FULLY

CLOSED

FULLY

OPEN

90 DEGREE STROKE 160 DEGREE STROKE

NON-SPRING RETURN MOTORS

160

10

90

45

SPRING RETURN MOTORS AND NON-SPRING RETURN MOTORS

ASYMMETRICAL MOTORS

SYMMETRICAL MOTORS

Table 3. Primary 50017460-001 Color Code.

Power Consumption

Lead Color Primary Voltage

Brown 24 VAC

White 120 VAC

Blue 230 VAC

Black Common

Table 4. Power Consumption Ratings.

Power Consumption

Model Number VA Rating

M6184A 15

M6184B 10

M6184D 15

M6184F 15

Auxiliary Switch Ratings: See Table 5.

Control Inputs:

Floating three-wire (Series 60): drive open, hold, drive closed.

Series 62 models include an internal, electrically isolated

feedback potentiometer that provides shaft position

indication.

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

Table 5. Auxiliary Switch Ratings.

Single Contact

a

Rating

120V (in Amps) 240V (in Amps)

Full Load 7.2 3.6

Locked Rotor 43.2 21.6

a

40 VA pilot duty, 120/240 Vac on opposite contact.

Ambient Temperature Ratings:

Maximum: 150°F (66°C) at 25% duty cycle.

Minimum: -40°F (-40°C).

Dead Weight Load On Shaft:

Power or Auxiliary End: 200 lb (90.8 kg) maximum.

Maximum Combined Load: 300 lb (136 kg).

Crankshaft: 3/8 in. (9.5 mm) square.

Stroke: Adjustable Stroke Models: Available field-adjustable

from 90° to 160°. (See Stroke Setting procedure.)

Timing And Torque: See Table 6.

Lifetime

60,000 Full Stroke Cycles

Repositions: 1.5 million

3 63-2629EF—01

Page 4

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

M18998B

4-7/8

(124)

5-1/2

(140)

13/16

(20)

4-1/16 (103)

1/4

(7)

1-1/2 (37)

4-1/16 (103)

JUNCTION

BOX

MOTOR

AUXILARY

END

POWER

END

ADAPTER

BRACKET

2-9/16

(66)

5-3/8

(137)

6-7/16

(164)

9/16 (15)

3/4

(19)

TOP VIEW OF BRACKET TOP VIEW

4-5/8

(116)

4-1/4

(107)

2-5/16

(58)

11/16

(17)

4-7/8 (124)

5-9/16 (141)

1/4 (7)

5-13/16

(148)

1

POWER END

2

3

1-1/2 (37)

3/4

(19)

SPRING RETURN MODEL SHOWN

FOR 60 LB-IN. SPRING RETURN MODELS 8-3/4 (222).

FOR NON-SPRING RETUIRN MODELS 7-5/16 (185).

FOR 60 LB-IN. SPRING RETURN MODELS (SHOWN).

FOR NON-SPRING RETURN MODELS.

1

2

3

13/16

(20)

honeyvell.energy

Fig. 2. Series 61 and 62 Modutrol IV Motor mounting dimensions in inches (mm).

Table 6. Series 61 and 62 Modutrol IV Motor Timing and Torque Ratings.

b

Rated Torque in lb-in. (N•m)

a

Nominal Timing

90° Stroke 160° Stroke Spring Return Non-Spring Return Spring Return Non-Spring Return

15 30 — 75 (8.5) — 150 (17.0)

30 60 60 (6.8) 35 (4.0) 120 (13.6) 70 (7.9)

in sec

60 120 300 (34.0) 600 (68.0)

120 240 —

a

Timings apply to all TRADELINE models. Some OEM models are available with non-standard timing/torque.

b

Torque ratings for dual-ended shaft motors are the sum of the shaft torques (power-end torque plus auxiliary-end torque).

c

Breakaway torque is the maximum torque available to overcome occasional large loads such as a seized damper or valve.

NOTE: Torque designation corresponds to torque rating

at standard timing (nominally 60 seconds for

160° and 30 seconds for 90° except for 300 lb-in.

motors that have timings of 2 or 4 minutes).

Normal Running Torque Breakaway Torque

150 (17.0) 300 (34.0)

150 (17.0) 300 (34.0)

—

IMPORTANT

Never use motor continuously at the Breakaway

Torque rating.

c

63-2629EF—01 4

Page 5

Feedback Potentiometer (Series 62 Models Only):

CAUTION

CAUTION

CAUTION

TRADELINE Models (Can be shunted for slaving a

Series 90 Motor).

Approvals:

Underwriters Laboratories Inc. Listed: File No. E4436, Guide

No. XAPX. For USA and Canada.

U.S. Patents: pending

Accessories:

220736A Internal Auxiliary Switch Kit; one switch, can be

field-installed.

220736B Internal Auxiliary Switch Kit; two switches, can be

field-installed.

220738A Adapter Bracket raises motor shaft height by 3/4

inch (19 mm) to match that of previous Modutrol Motor

models.

220741A Screw Terminal Adapter converts the standard

quick-connect terminals to screw terminals.

221455A Infinitely Adjustable Crank Arm, can rotate through

downward position and clear motor base without requiring

an adapter bracket.

4074ERU Weatherproofing Kit provides NEMA 3 rating for

Modutrol IV Motors mounted in position other than upright.

50017460-001 Internal Transformer; 24/120/230 Vac 50/60 Hz

primary, 24 Vac secondary, quick connect terminals.

50017460-003 Internal Transformer; 120 Vac 50/60 Hz pri-

mary, 24 Vac secondary, quick connect terminals.

7617ADW Crank Arm, can rotate through downward position

and clear motor base without requiring an adapter bracket.

Q100 Linkage connects Modutrol Motor to V51 Butterfly

Valve. Requires the 220738A Adapter Bracket.

Q181 Auxiliary Potentiometer for sequence or unison control

of 1 to 4 additional modulating (Series 90) motors.

Q5001 Bracket and Linkage Assembly connects Modutrol IV

Motor to water or steam valve.

Q605 Damper Linkage connects motor to damper. Includes

motor crank arm.

Q607 External Auxiliary Switch controls auxiliary equipment

as a function of motor position.

ES650-117 Explosion-Proof Housing encloses motor for use

in explosive atmospheres. Not for use with Q5001 (or any

other valve linkages). Order separately from Nelson Enclosures. To order, contact:

EGS Enclosures in Houston, TX

Karen Barfield 281-774-3763

Karen.Barfield@egseg.com

http://appletonelec.com

Part number ES-650-117

You need to order a 7617DM coupling assembly from

Honeywell to use with the cover.

INSTALLATION

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than one

disconnect.

Equipment Damage Hazard.

Can damage the motor beyond repair.

Never turn the motor shaft by hand or with a wrench.

Forcibly turning the motor shaft damages the gear

train and stroke limit contacts.

IMPORTANT

Always conduct a thorough checkout when

installation is complete.

Location

Allow enough clearance for accessory installation and motor

servicing when selecting a location (see Fig. 2). If located

outdoors, use liquid-tight conduit connectors with the junction

box to provide NEMA 3 weather protection. If mounted

outdoors in a position other than upright, install a 4074ERU

Weatherproofing Kit and liquid-tight connectors to provide

NEMA 3 protection.

Motor Damage Hazard.

Deteriorating vapors and acid fumes can damage

metal parts.

Install motor in areas free of acid fumes and other

deteriorating vapors.

In excessive salt environments, mounting base and screws

should be zinc or cadmium plated, not stainless steel or brass.

Use the 220738A Adapter Bracket for mounting on these

surfaces.

Mounting

Use the following guidelines for proper motor mounting:

• Always install motors with the crankshaft horizontal.

• Mounting flanges extending from motor housing base are

drilled for 1/4 inch (6.4 mm) machine screws or bolts.

• Non-Spring Return Motors are shipped from the factory in

the closed position (at the limit of counterclockwise

rotation, as viewed from the power end of the motor).

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

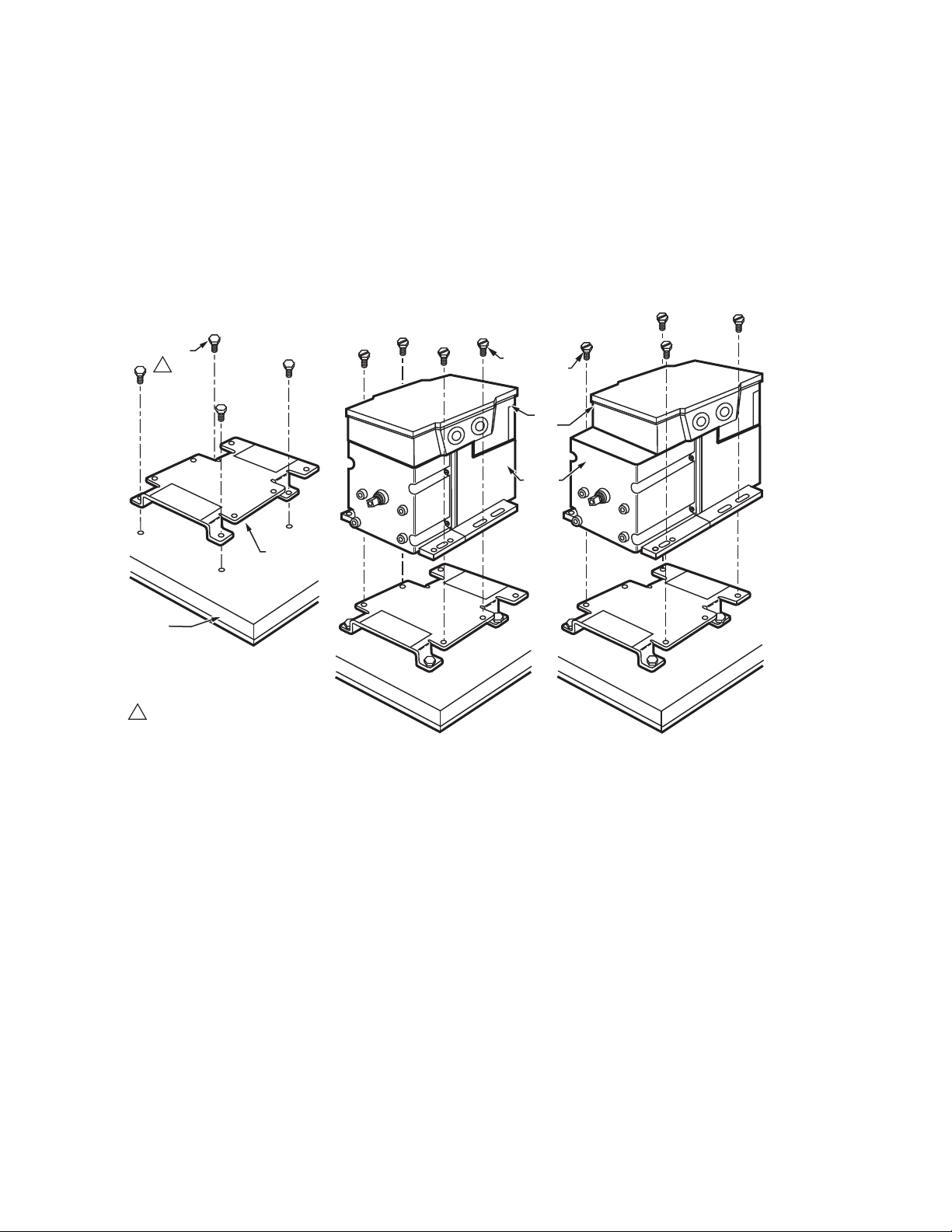

Adapter Bracket

The 220738A Adapter Bracket, positioned between the motor

and the equipment, raises motor shaft height by 0.75 in.

(19 mm) to match that of previous Modutrol Motor models.

The following applications require this bracket:

• Q607 External Auxiliary Switch.

• Damper linkage applications require added clearance to

allow:

5 63-2629EF—01

Page 6

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

M18999

EQUIPMENT

BASE

ADAPTER

BRACKET

STANDARD

BOLTS (4)

MOTOR

BOLTS

PROVIDED (4)

WIRING

BOX

NON-SPRING RETURN

SPRING RETURN

1 #12 OR 1/4" ZINC PLATED

MACHINE SCREWS OR BOLTS

1

PO

W

ER

END

POW

ER

END

POW

ER

END

— Crank arm rotation through the downward position.

— Sufficient damper linkage to reach the motor shaft.

• All valve linkages except the Q5001.

NOTE: When the bracket is not used in a replacement

application, the damper linkage requires adjustment for the new shaft position.

To mount the motor with the bracket:

1. Mount the bracket to the equipment with existing or

standard bolts.

2. Using the provided bolts, mount the motor to the bracket

threaded holes. See Fig. 3.

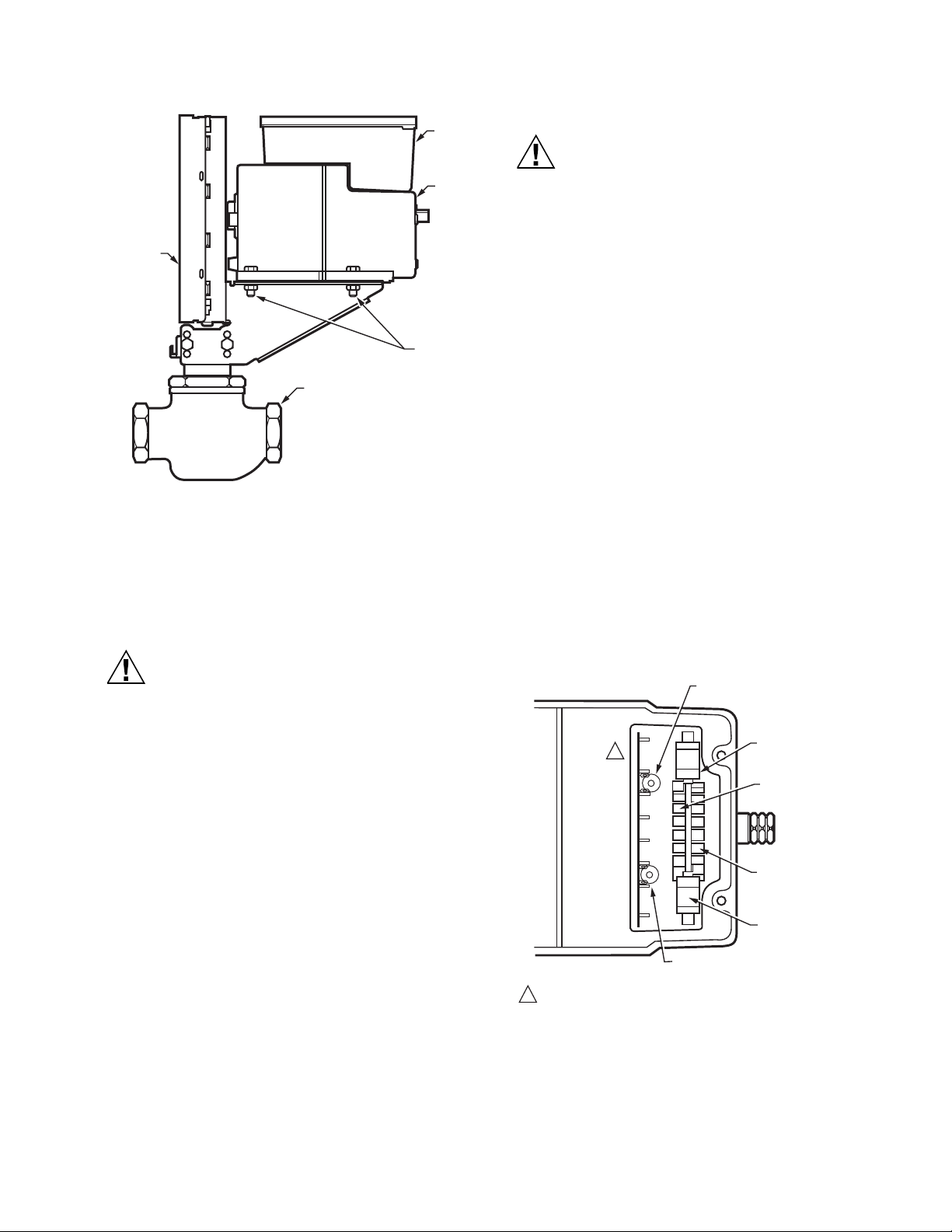

For valve linkage applications (other than the Q5001):

1. Mount the bracket to the linkage.

2. Position the motor on the bracket to align the motor

shaft with the linkage.

3. Attach the motor to the bracket with the four bolts

provided. See Fig. 4.

Fig. 3. Mounting the motor with an adapter bracket.

63-2629EF—01 6

Page 7

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

CAUTION

CAUTION

INNER AUXILIARY

SWITCH

INNER AUXILIARY

SWITCH CAM (BLUE)

POWER

END

OUTER AUXILIARY

SWITCH CAM (RED)

OUTER AUXILIARY

SWITCH

ADJUSTABLE STROKE

POTENTIOMETER

SERIES 62 TERMINAL DESIGNATIONS SHOWN.

NOTE: NOT ALL FEATURES AVAILABLE ON ALL MODELS.

M13600B

Y

T

G

R

4

2

1

3

1

1

SENSITIVITY POTENTIOMETER

(ON SOME SERIES 62 MODELS, SEE TABLE 5)

JUNCTION BOX

Q5001

VALV E

LINKAGE

POWER

END OF

MOTOR

VALV E

MOTOR

1/4-20 UNC

1 in. LONG

MOUNTING

BOLTS

M18994

Fig. 4. Mounting the motor on a Q5001 Valve Linkage.

Damper Linkages

The motor does not include a crank arm. Order the crank arm

separately (see Accessories in the Specifications section). For

detailed instructions on the assembly of specific linkages,

refer to the Installation Instructions packed with the linkage.

Wiring

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment circuitry.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than one

disconnect.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

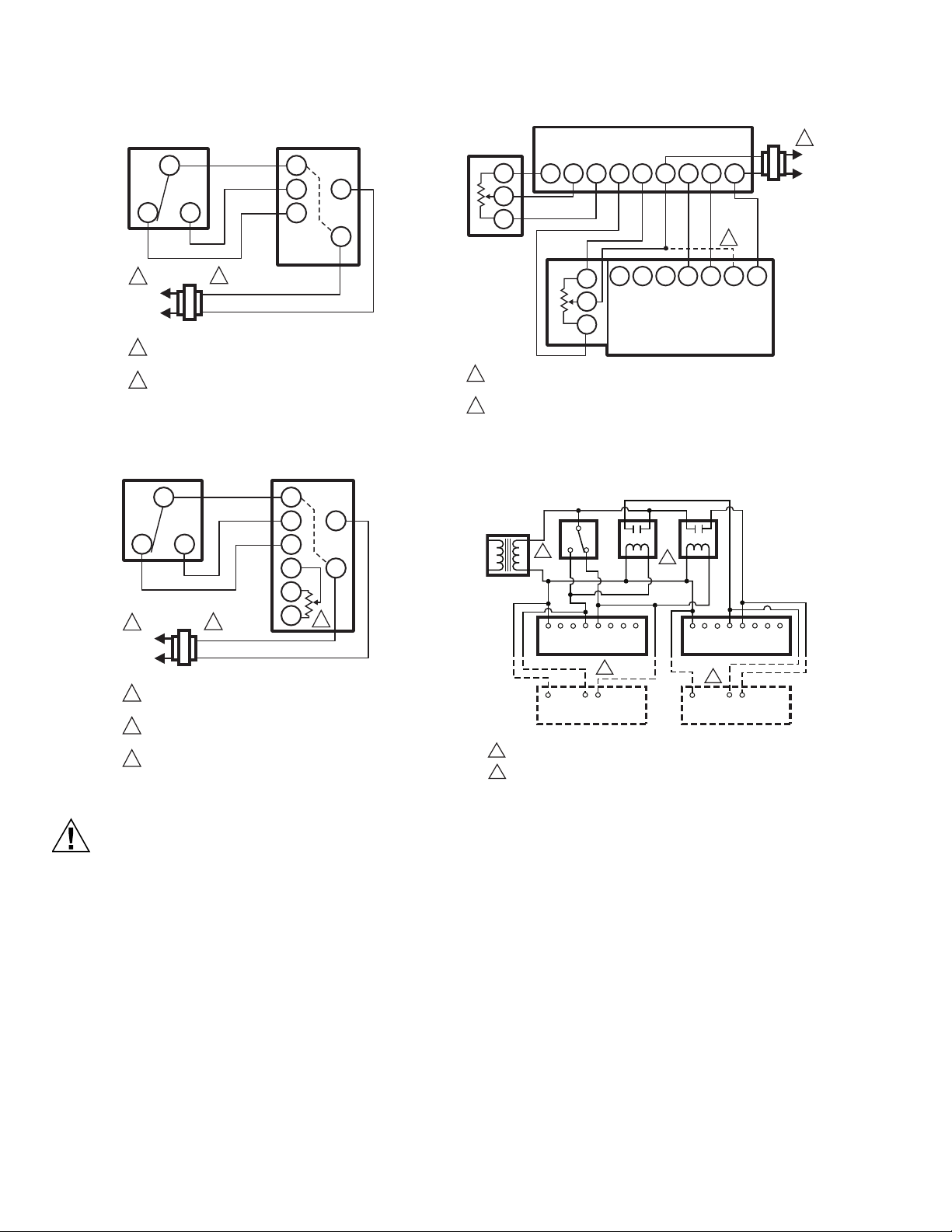

1. Ensure that the voltage and frequency stamped on the

motor correspond with the power supply characteristics.

2. When connecting several motors in parallel, ensure that

the power supply VA rating is large enough to provide

power to all motors used without overloading.

3. Fig. 5 shows that motor terminals are quick-connects

located on top of the printed circuit board.

4. To access the wiring compartment:

a. Remove the four screws from the junction box top.

b. Lift off the cover.

5. Refer to Fig. 6 and 7 for typical wiring, and Fig. 11 for

internal auxiliary switch connections.

NOTE: Reverse motor rotation by switching wires at

either the motor or panel. Reverse rotation on

Series 61 models by reversing wires at terminals

W and B. Reverse rotation on Series 62 models

by reversing wires at terminals 1 and 2 (to correct

motor rotation) and reverse wires at terminals Y

and G (to maintain a feedback signal that corresponds with shaft rotation),

Equipment Damage Hazard. Stalling a motor can

damage the drive shaft.

Ensure installation of motors and linkages allows the

motor to drive through full stroke without obstruction.

Valve Linkages

The Q100 Linkage requires a 220738A Adapter Bracket for all

valve applications. Applications with the Q5001 Valve Linkage

do not require the 220738A Adapter Bracket (see Fig. 4).

Junction Box

When used with liquid-tight conduit connectors, the junction

box provides NEMA 3 weather protection for the motor. The

junction box, standard with replacement motors, encloses the

terminals and provides knockouts for wiring conduits. Housing

an internal transformer or internal auxiliary switches requires

using a junction box.

Fig. 5. Terminals and adjustments.

7 63-2629EF—01

Page 8

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

CAUTION

R

B

W

R

W

B

T2

T1

(HOT) L1

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

TRANSFORMER MAY BE INTERNAL OR EXTERNAL

TO MOTOR.

M17095B

SERIES 60

CONTROLLER

SERIES 61

MOTOR

1

2

1

2

R

B

W

R

1

2

T

G

Y

4

3

(HOT) L1

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

TRANSFORMER MAY BE INTERNAL OR EXTERNAL

TO MOTOR.

FEEDBACK POTENTIOMETER.

M17096A

SERIES 60

CONTROLLER

SERIES 62

MOTOR

1

2

3

1

2

3

M27044

TRANS

R

C

M62 S2

M62 S1

3

4

R1

T

2

G

Y

3

4

R1

T

2

G

Y

R

W

B

K1

K2

WIRING DIAGRAM M62XX SERIES 1 AND SERIES 2 PARALLEL APPLICATION

SIZE RELAYS AND TRANSFORMER PER SYSTEM REQUIREMENTS.

ADDITIONAL SERIES 2 OR SERIES 1 MOTORS CAN BE ADDED IN

PARALLEL. DO NOT MIX SERIES 1 AND SERIES 2 IN THE SAME

LINE. ONLY WIRE SERIES 1 WITH SERIES 1 AND SERIES 2 WITH

SERIES 2 IN PARALLEL.

1

2

2

2

1

1

M62 S2

M62 S1

3

1

2

3

1

2

SERIES 90

CONTROLLER

W

R

B

R927C OR R9107A RELAY

W

B

R

1

L1 (HOT)

T

Y

G

T

1

2

2

L2

Fig. 6. Series 61 motor wiring.

Y

B

R

W

Q181A

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

CONNECTION REQUIRED ONLY FOR SPRING RETURN MOTORS.

160 STROKE SERIES 62 MOTOR

2

G

T

4

1

Fig. 8. Connections to R927C or R9107A Relay.

3

M17098A

Fig. 7. Series 62 motor wiring.

Ensure that L1(hot) on the transformer matches 4

(internal hot) on the motor and L2 matches 3

(internal ground) on the motor.

63-2629EF—01 8

Fig. 9. Series 1 and Series 2 Parallel Application

Page 9

R (HOT)

SERIES 60

CONTROLLER

R

B

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

The motors in the application need to be all symmetrical or all

asymmetrical. The M62 motor needs to be a “-S” slaving

model, as listed in Table 2. In order to get the correct response

the Series 62 needs the appropriate shunt resistor from Table

2. The motors' potentiometer settings are given in the

M6284

W

R

3

1

2

4

T

G

Y

configuration table (Table 7) below. When slaving more than

one Series 90 motor use the appropriate resistor table as

indicated by the configuration table and install two resistors to

ONE of the motors (Table 8 and 9). If the motor is the M62

master connect one resistor from terminals T to G and one

from T to Y. If the motor is one of the M90 slaves connect one

resistor from terminals R to B and one from R to W.

NOTE: More than 6 slaves is not recommended.

C

R (HOT)

C

W

R

B

M9184

T1

T2

M27035

Fig. 10. Series 60 and Series 90 in Slaving Application

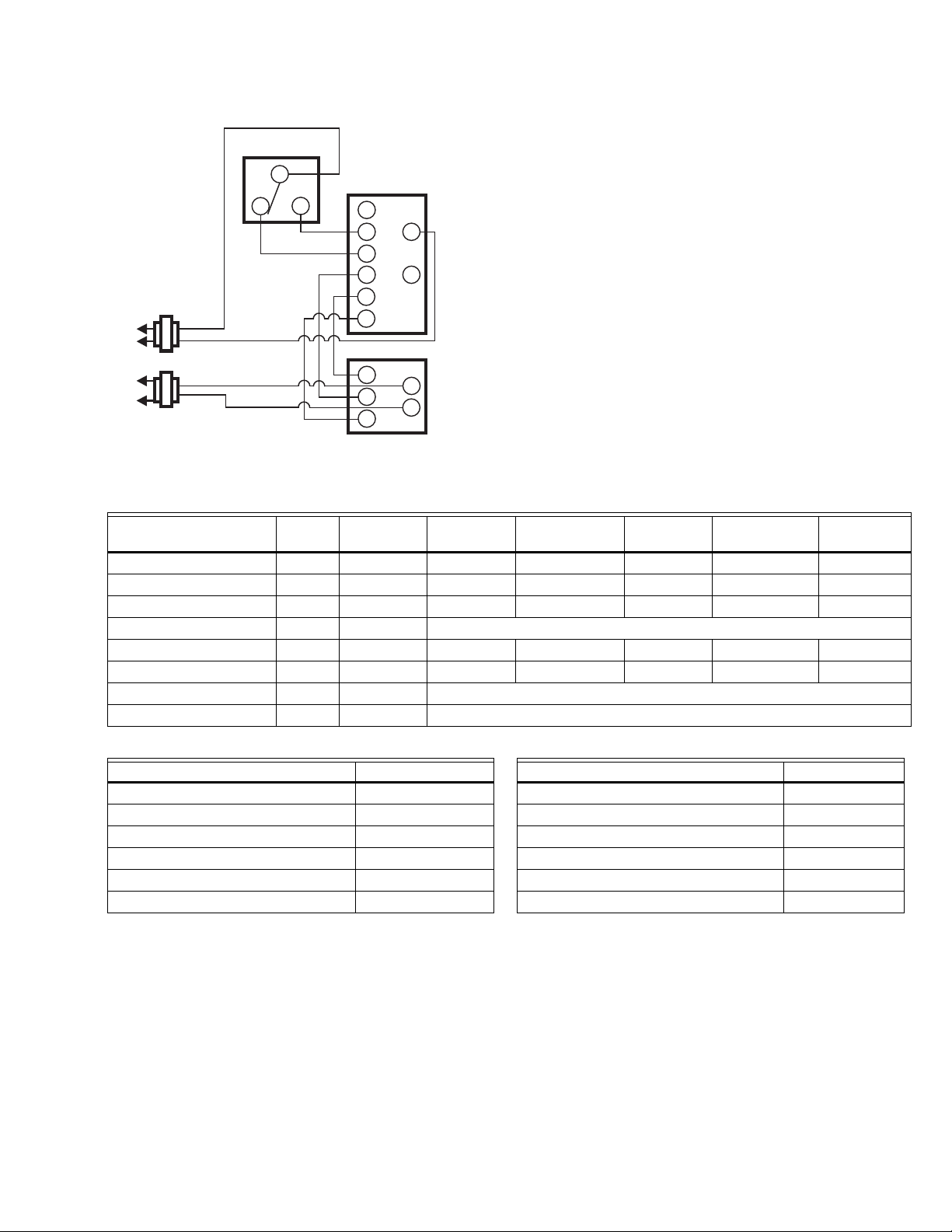

Table 7. Configuration Table

Symmetrical or

Asymmetrical

Master

Stroke

Slave

Stroke

Master

Stroke Pot

Master

Sensitivity Pot

Slave

Stroke Pot

Slave

Sensitivity Pot

Symmetrical 160 160 CW CW CW CW 1

Symmetrical 90 90 CCW CCW CCW CCW 2

Symmetrical 160 90 CCW CW CCW CCW 1

Symmetrical 90 160 Configuration not recommended

Asymmetrical 160 160 CW CW CW CW 1

Asymmetrical 90 90 CCW CW CW CW 1

Asymmetrical 160 90 Configuration not recommended

Asymmetrical 90 160 Configuration not recommended

Table 8. Resistor Table 1 Table 9. Resistor Table 2

Number of Slaves in Parallel Resistor Value

1NONE

2 3500 Ohms

3 2000 Ohms

4 1300 Ohms

5 1000 Ohms

6 800 Ohms

Number of Slaves in Parallel Resistor Value

1NONE

2 5000 Ohms

3 2400 Ohms

4 1700 Ohms

5 1400 Ohms

6 1200 Ohms

Resistor

Tabl e

NOTE: Vibration does not affect Modutrol IV Motor

performance (as it did in earlier Modutrol

Motors). When replacing a motor that was connected to an R927C or R9107A Relay, Honeywell

recommends performing a retrofit to remove the

relay and the old motor. Replace both with one

Series 90 Modutrol IV motor (that is, do not

replace the relay).

9 63-2629EF—01

Page 10

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

CAUTION

CAUTION

BLUE LEAD

YELLOW LEAD

RED LEAD

USE NEC CLASS 1 WIRING UNLESS POWER SUPPLY

MEETS CLASS 2 REQUIREMENTS. TAPE UNUSED LEADS.

ENSURE THE CURRENT DRAW OF THE EXTERNAL CIRCUIT

IS LESS THAN SWITCH CONTACT RATING.

ON TWO-SWITCH MOTORS, SECOND SWITCH HAS BLACK

LEADS WITH BLUE, YELLOW, AND RED TRACERS.

SOME AUXILIARY SWITCH ASSEMBLIES INCLUDE ONLY

RED AND YELLOW LEADS. SOME OTHERS DO NOT INCLUDE

THE YELLOW LEAD.

M17099

1

1

1

2

2

2

2

3

3

3

4

R

1

2

G

Y

M652

.

Fig. 11. Auxiliary switch schematic.

SETTINGS AND ADJUSTMENTS

Before Setting Stroke

1. Remove the top cover from the motor.

2. Disconnect the controller from the motor.

3. For models with an internal transformer (line voltage

motors), ensure that power (and nothing else) remains

connected to the motor.

IMPORTANT

Detach linkage from motor before adjusting stroke.

Adjustable Stroke

Equipment Damage Hazard.

Can damage the motor beyond repair.

Never turn the motor shaft by hand or with a wrench.

Forcibly turning the motor shaft damages the gear

train and stroke limit contacts.

ADJUSTABLE

STROKE

POTENTIOMETER

SENSITIVITY

POTENTIOMETER

(ON SOME SERIES 62

MODELS, SEE TABLE 5)

AUXILIARY

POWER END

OF MOTOR

SWITCH CAMS

M13601

Fig. 12. Stroke adjustments setup.

Feedback Potentiometer

Configuration (Series 62

TRADELINE

Select and install a shunt resistors to obtain the appropriate

feedback characteristic for your application. See the

Specifications section for details on feedback resistance

without a shunt resistor.

®

Motors Only)

Series 61 Adjustable Stroke

When viewing from the power end of the motor, the stroke

potentiometer is to the far left. To set the stroke to 160°

(maximum position) turn the potentiometer fully clockwise

, using a 1/8 in. straight-blade screwdriver. To set the

stroke at 90° (minimum position) turn the potentiometer fully

counter-clockwise . Setting the potentiometer anywhere

between fully clockwise and fully counter-clockwise will set the

stroke between 160° and 90°.

Series 62 Adjustable Stroke

When viewing from the power end of the motor, the stroke

potentiometer is to the far left. The sensitivity potentiometer is

to the far right. To set the stroke to 160° (maximum position)

turn both potentiometers fully clockwise , using a 1/8

inch straight-blade screwdriver. To set the stroke at 90°

(minimum position) turn both potentiometers fully counter-

clockwise . Setting the potentiometer anywhere between

fully clockwise and fully counter-clockwise will set the stroke

between 160° and 90°.

Careless Installation Hazard.

Use of excessive force while adjusting cams

damages the motor.

To avoid damaging motor end switches, set cams by

moving only the screwdriver top.

63-2629EF—01 10

NOTE: Due to circuit protection components, the resis-

tance cannot be read directly, use a voltage

divider to read the position of the motor.

• Linear feedback provides linear indication of shaft position

with no shunt resistor.

• Slaving a Series 90 Motor requires full-stroke feedback

resistance of 142 ohms. Select and attach the proper shunt

resistor across terminals Y and G (see Table 2 and Fig. 13).

Fig. 13. Attaching a shunt resistor to TRADELINE motors.

Page 11

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

Auxiliary Switches

Adjustable cams actuate the auxiliary switches. These cams

can be set to actuate the switches at any angle within the

motor stroke. Select switch differential of 1° or 10°.

Motors with factory-added auxiliary switches are shipped in

the closed position (fully counterclockwise, as viewed from the

power end). Auxiliary cam default actuates the switches 30°

from fully open with a 1° differential. With the motor in the

closed (fully counterclockwise) position, the auxiliary switch

breaks contacts R-B. See Fig. 11 (or the auxiliary switch

Installation Instructions) for auxiliary switch wiring.

NOTE: Series 2 Motors are shipped with auxiliary switch

cams that permit acceptance of 220736A,B Internal Auxiliary Switch Kits. Refer to Form no. 632228 for 220736A,B Installation Instructions.

Auxiliary Switch Adjustment

IMPORTANT

When adjusting the auxiliary switch cams use the

following procedure:

1.Insert 1/8 in. screwdriver blade into a slot on cam

and move the screwdriver top as far as possible in

the required direction. See Fig. 14.

2.Repeat step 1 in successive cam slots until the

cam is in the required position.

Use the following procedure to obtain the desired auxiliary

switch settings:

1. Remove the top cover from the motor to gain access to

the motor terminals and auxiliary cams.

2. Disconnect the controller from the motor.

3. Drive the motor to the position where the auxiliary

equipment is to be switched as follows:

a. For Non-Spring Return models without a transformer,

connect 24 Vac to terminals 2 and 3 to drive motor

open (clockwise as viewed from the power end), or to

terminals 1 and 3 to drive motor closed

(counterclockwise).

b. For Non-Spring Return models with a transformer,

jumper across terminals R and 2 to drive motor

open (clockwise as viewed from the power end), or

across terminals R and 1 to drive motor closed

(counterclockwise).

c. For Spring Return models, connect a jumper across

terminals 2 and 4 to drive the motor open, or across

terminals 1 and 4 to drive the motor closed.

4. Once motor reaches correct position, disconnect the

jumper.

5. For a switch differential of 1°, check continuity of auxiliary

switch contacts R-B and rotate the cam as follows:

a. If the contacts are open, rotate the cam clockwise

until the R-B contacts close.

b. If the contacts are closed, rotate the cam

counterclockwise until the R-B contacts open.

6. For a switch differential of 10°:

a. For Spring Return models, rotate the cam

approximately 180° so the slow-rise portion of the

cam actuates the switch. Then check continuity of

the auxiliary switch contacts R-B.

b. For Non-Spring Return models, check continuity of

the auxiliary switch contacts R-B.

7. Rotate the cam as follows:

a. If the contacts are open, rotate the cam

counterclockwise until the R-B contacts close.

b. If the contacts are closed, rotate the cam clockwise

until the R-B contacts open.

8. Check for the proper differential and switching of the

auxiliary equipment by driving the motor though the full

stroke in both directions.

9. Disconnect the jumper, reconnect the controller, and

replace the top cover on the motor.

NOTE: Changing the differential from 1° to 10° reverses

the switching action. For example, with a 10° differential, switch contacts R-B make and R-W

break on a

counterclockwise (closed) rotation. With a 1°

differential, switch contacts R-W make and R-B

break on a counterclockwise (closed) rotation.

11 63-2629EF—01

Page 12

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

RIGHT/INNER

AUXILIARY

SWITCH

FAST RISE

PORTION

(APPROX.

1 DIFF.)

SLOW RISE

PORTION

(APPROX.

10 DIFF.)

INNER

AUXILIARY

CAM

(BLUE)

NOTE: CAMS ARE OFFSET VERTICALLY TO

PROVIDE BETTER VIEW OF BACK CAM.

FAST RISE

PORTION

(APPROX.

1 DIFF.)

SLOW RISE

PORTION

(APPROX.

10 DIFF.)

MOTOR

OPEN

MOTOR

CLOSE

POWER

END

OUTER

AUXILIARY

CAM

(RED)

LEFT/OUTER

AUXILIARY

SWITCH

M13700

POWER END

OF MOTOR

OUTER AUXILIARY

CAM (RED)

INNER AUXILIARY

CAM (BLUE)

RIGHT/INNER

AUXILIARY SWITCH

LEFT/OUTER

AUXILIARY

SWITCH

MOVE SCREWDRIVER AT

TOP ONLY TO ADJUST CAM.

1/8 INCH

STRAIGHT-BLADE

SCREWDRIVER

OPERATION

Use Series 61 and 62 Modutrol IV Motors for standard Series

60 operation (drive open, hold, drive closed). Series 62

motors can also be used with the feedback potentiometer as

an input to the controller.

See Table 10 for details on motor response to controller

signals.

NOTE: Reverse the wires at either the motor or control-

To reverse the rotation direction of a non-spring return motor:

• Reverse the wires at terminals W and B.

Non-Spring Return

or Spring Return

Non-Spring Return

or Spring Return

Non-Spring Return Power

Spring Return Only Upon

63-2629EF—01 12

ler.

Table 10. Modutrol IV Motor Operation.

Terminal Connection

Motor Type

R-W R-1 ccw (closed)

R-B R-2 cw (open)

R-nothing R-nothing stops driving

Power

Failure

Power

Failure

Failure

Only Upon

Power

Failure

Fig. 14. Auxiliary switch adjustment.

CHECKOUT

After the installation and linkage adjustment, check the entire

motor and control hookup. Proper checkout ensures that:

• The motor operates the load (damper or valve) properly.

• The motor responds properly to the controller as the input

varies. See Table 10.

• The auxiliary switch, if used, operates at the desired point

of motor rotation.

1. Inspect motor, linkage, and valve or damper to ensure

all mechanical connections are correct and secure.

NOTE: In damper installations, the pushrod should not

2. Ensure that there is adequate clearance for the linkage

Resulting

ActionSeries 61 Series 62

stops (none)

spring return

(closed)

throughout the entire motor stroke without binding or

striking other objects.

3. Drive the motor fully open and fully closed. See Table

10.

NOTE: Refer to controller or system instructions for

M62 Checkout

The following procedure will verify that the M62 external

feedback potentiometer is working for a -F or -S model.

• Connect 24 VAC to terminals 3 and 4.

• Connect 5-10 VDC to terminals Y and G (connect +

to Y and - to G).

• Connect either a voltmeter or an oscilloscope to

terminals T and G (connect + to T and - to G).

• Connect terminal R to terminal 1 to drive the motor

towards the fully closed position.

extend more than a few inches past the ball

joints.

additional checkout procedures.

Page 13

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

• Connect terminal R to terminal 2 to drive the motor

towards the fully open position.

• Using the voltmeter or the oscilloscope, make sure

the DC voltage is linearly increasing throughout its

entire range.

• The range of Vout for a 90 degree asymmetrical

motor is 5-55% of Vin from closed to open.

• The range of Vout for a 90 degree symmetrical motor

is 25-75% of Vin from closed to open.

• The range of Vout for a 160 degree motor is 5-95% of

Vin from closed to open.

4. For spring return motors, ensure that the valve or

damper returns to its normal position upon power failure.

5. Return controller to the desired setting before leaving

the job.

REPLACEMENT

Damper Application

1. Turn off power and remove wiring from the old motor.

2. Remove the crank arm from the shaft of the old motor

and remove the old motor.

3. Determine mounting bracket necessity. If the linkage

can reach the new motor shaft position and the crank

arm has clearance for the necessary rotation, the

bracket is not required. Use the 220738A Adapter

Bracket or the 221455A Crank Arm if the crank arm

must rotate through the bottom plane of the motor.

a. If no bracket is required, mount the new motor

directly to the equipment and refer to the

Installation, Settings and Adjustments, and the

Operation and Checkout sections.

b. If the bracket is required, refer to the Adapter

Bracket section and Fig. 3 in addition to the

Installation, Settings and Adjustments, and the

Operation and Checkout sections.

4. Use No. 12 or 1/4 inch machine screws or bolts to

mount the new motor.

5. Mount damper crank arm and linkage to the new motor

shaft.

6. Use the Checkout procedures to test the crank arm and

linkage adjustment.

Valve Application

When replacing a motor in a valve application, the linkage

type determines the necessity for the 220738A Adapter

Bracket. With Q100, Q601 or Q618 Linkages, it is necessary

to use the 220738A to raise the motor shaft to the appropriate

height. Valve applications with a Q5001 Linkage do not

require the 220738A Adapter Bracket. To operate Honeywell

V5011 Two-way or V5013 Three-way Valves through full

stroke, use a 160° stroke motor.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2011 Honeywell International Inc.

63-2629EF—01 M.S. 10-11

Printed in United States

Page 14

Put Bar Code Here

63-2629EF-01

Servomoteurs Modutrol IV

Séries 61 et 62

CARACTÉRISTIQUES

• Remplacent les servomoteurs M644, M944B, E, G, H, J,

K, R, S et M945B, C, G, K, L, AD.

• Boîte de jonction intégrée assurant une protection

contre les intempéries selon la norme NEMA 3.

• Le ressort de rappel intégré ramène le moteur à la

position normale en cas de coupure de courant.

• Servomoteur et circuit alimentés en courant 24 V c.a. Il

existe des modèles comportant un transformateur

installé en usine et des modèles auxquels on peut

ajouter un transformateur interne sur place.

• Bornes standards à connexion rapide; adaptateur pour

bornes à vis également offert.

• Support d'adaptation permettant d'ajuster la hauteur

de l'arbre des anciens servomoteurs.

• Modèles à course réglable sur place (90

APPLICATION

Les servomoteurs Modutrol IVMC de séries 61 et 62 sont des

appareils trifilaires à régulation flottante, avec ou sans ressort

de rappel. Ils sont destinés à des régulateurs qui assurent la

commutation à sortie flottante, unipolaire et bidirectionnelle de

vannes ou de registres. Les servomoteurs de série 62 sont

équipés d'un potentiomètre d'asservissement électriquement

isolé qui indique la position de l'arbre et peut asservir d'autres

servomoteurs de série 90 ou rééquilibrer un circuit de

commande externe.

• Boîtier en aluminium moulé.

• Interrupteurs auxiliaires intégrés (installation en usine)

ou pouvant être ajoutés sur place.

• Durée nominale standard de la course de 30 secondes

• Les servomoteurs à ressort de rappel peuvent

• Tous les modèles possèdent des arbres doubles

• Tous les modèles sont équipés de cames

• Couple uniforme sur toute la plage de tension.

• Servomoteurs conçus pour des vannes et des

• Les modèles de série 62 comprennent un

• Les modèles TRADELINE de série 62 comportent un

o

et de 60 secondes à 160o. Autres durées

à 90

également offertes.

commander des accouplements de vanne du côté

commande ou du côté auxiliaire des arbres dans les

applications de vannes normalement ouvertes ou

normalement fermées.

(taraudés et à créneaux à chaque bout).

d'interrupteurs auxiliaires.

registres normalement ouverts ou normalement

fermés.

potentiomètre d'asservissement électriquement isolé

qui indique la position de l'arbre.

potentiomètre d'asservissement linéaire qui peut

asservir des servomoteurs de série 90.

MC

NOTICE TECHNIQUE

o

à 160o).

Page 15

SERVOMOTEURS MODUTROL IV

MC

SÉRIES 61 ET 62

CARACTÉRISTIQUES TECHNIQUES

Modèles : Les modèles TRADELINE® ont été choisis et

emballés pour faciliter le stockage et la manutention et offrir

une valeur de remplacement maximale. Leurs

caractéristiques techniques sont les mêmes que celles des

modèles standards, à moins d'avis contraire.

Tableau 11. Guide des numéros de pièce des Modutrol IV.

M Servomoteur

61 Régulation flottante

62 Régulation flottante avec asservissement

8 60 lb-po avec ressort de

9 — 300 lb-po sans ressort de rappel

rappel

2 Arbre à deux extrémités Normalement fermé à ressort de rappel

4 Sans ressort de rappel

5 Normalement fermé à ressort de rappel

A 0 interr. aux. Course réglable Normalement fermé

B 1 interr. aux.

C 2 interr. aux.

D 0 interr. aux.

E 1 interr. aux.

F 2 interr. aux.

Guide des numéros de pièce des Modutrol IV :

Voir le Tableau 1.

Encombrement : Voir la Figure 2.

Asservissement : Voir le Tableau 2.

Caractéristiques électriques nominales :

Voir le Tableau 3.

150 lb-po sans ressort de rappel

M 61 8 4 A XXXX Voir le catalogue pour le numéro complet du produit

Tableau 12. Caractéristiques de rétroaction Série 62

Résistance de

shunt asserv.

servomoteur

série 90

Numéro de pièce

M6284D1000-S, M6284D1026-S,

M6284D4004-S, M6285A1005-S,

M6285A1054-S, M6285A4009-S

M6274F1009-F, M6284F1070-F,

M6284F1078-F, M6285F1001-F,

M6294F1009-F, M6294F1017-F,

M6284D1032-F

M6284A1071-S, M6284A1089-S,

M6284C1028-S

M6284A1030-S, M6284A1055-S,

M6284A1097-S, M6284B1004-S,

M6284C1010-S, M6284C1044-S,

M6284F1013-S, M6284F1039-S,

M6285A1039-S, M6285A1047-S,

M6285C1001-S, M6294B1036-S,

M6294D1008-S

Résistance de rétroaction (résistance

entre les bornes T, G et Y)

TG = 370-2400-920 Courbe ohm (non

linéaire)

TY = 920-2400-370 Courbe ohm (non

linéaire)

YG = 600 Ohms constant

TG = 0-10K Ohm linéaire

TY = 10-0K Ohm linéaire

YG = 10K Ohms constant

TG = 370-2350-630 Courbe ohm (non

linéaire)

TY = 630-2350-370 Courbe ohm (non

linéaire)

YG = Ohms constants pour une course de

160°,

346 Ohms constants pour une course de

90°.

TG = 370-2300-550 Courbe ohm (non

linéaire)

TY = 550-2300-370 Courbe ohm (non

linéaire)

YG = 119 Ohms constants pour une course

de 160°,

224 Ohms constants pour une course de

90°.

Réglage de la

sensibilité

Non Non 187 Ohm

Non Oui Non disponible

Oui Non 274 Ohm

Oui Non Non nécessaire

Rétroaction

linéaire

15 63-2629EF—01

Page 16

SERVOMOTEURS MODUTROL IV

MC

SÉRIES 61 ET 62

Tableau 12. Caractéristiques de rétroaction Série 62

Résistance de

shunt asserv.

Résistance de rétroaction (résistance

Numéro de pièce

entre les bornes T, G et Y)

M6284F1062-S TG = 370-2800-1990 Courbe ohm (non

Réglage de la

sensibilité

Rétroaction

linéaire

servomoteur

série 90

Non Non Non disponible

linéaire)

TY = 1990-2800-370 Courbe ohm (non

linéaire)

YG = 1800 Ohms constant

* Toutes les plages de résistance listées dans la colonne « Résistance de rétroaction » sont pour des moteurs à 160°. Pour un

moteur de 90° la plage sera tronquée ou à la première moitié s'il s'agit d'un moteur asymétrique (par exemple un -F irait de 0 à 5

K) ou à la moitié du milieu s'il s'agit d'un moteur symétrique (par exemple un moteur F irait de 2,5 à 7,5 K).

-S : Rétroaction non-linéaire pour servomoteur Mod IV série 90 à asservissement

-F : Rétroaction 0 à 10 K

-S et -F peuvent tous deux être utilisé comme réducteur de tension. Lorsqu'une tension constante est appliquée à YG, un signal

de tension peut être lu sur TG qui varie de façon linéaire avec une course du moteur de 4 à 96 % de la tension constante

appliquée à YG, pour un moteur de 160° uniquement. Pour un moteur asymétrique de 90° le signal de TG varie de 4 à 56 % et

pour un moteur symétrique de 90° le signal de TG varie de 24 à 76 %. Un signal peut aussi être lu de TY qui est l'opposé du

signal TG.

REMARQUE : Un nombre limité de modèles est disponible en Europe; consultez vos représentants locaux pour les disponibilités.

10

MOTEURS ASYMÉTRIQUES

LIGNE DE

RÉFÉRENCE

VERTICALE

COMPLÈTEMENT

FERMÉ

90

LIGNE DE

RÉFÉRENCE

VERTICALE

10

COMPLÈTEMENT

FERMÉ

LIGNE DE

RÉFÉRENCE

VERTICALE

MOTEURS SYMÉTRIQUES

LIGNE DE

RÉFÉRENCE

COMPLÈTEMENT

FERMÉ

45

VERTICALE

10

COMPLÈTEMENT

FERMÉ

160

COMPLÈTEMENT

OUVERT

COURSE DE 90° COURSE DE 160°

MOTEURS AVEC RESSORTS DE RAPPEL ET SANS RESSORT DE RAPPEL

COMPLÈTEMENT

OUVERT

Fig. 15. Course

Tableau 13. Codes de couleurs 50017460-001 primaires.

Consommation d'énergie

Couleur du fil Tension primaire

Marron 24 V c.a.

Blanc 120 V c.a.

Bleu 230 V c.a.

Noir Commun

Tableau 14. Caractéristiques électriques nominales.

Consommation de courant

Numéro de modèle VA nominal

M6184A 15

M6184B 10

M6184D 15

M6184F 15

Caractéristiques électriques nominales des interrupteurs :

Voir le Tableau 4

160

90

COMPLÈTEMENT

OUVERT

COURSE DE 90° COURSE DE 160°E

MOTEURS SYMÉTRIQUES MOTEURS SANS RESSORT DE RAPPEL

COMPLÈTEMENT

OUVERT

MF31079

Entrées de commande :

Régulation flottante à trois fils (série 60) : ouverture, maintien,

fermeture.

Les modèles de série 62 comprennent un potentiomètre

d'asservissement intégré et électriquement isolé qui

indique la position de l'arbre.

Tableau 15. Caractéristiques électriques nominales des

interrupteurs.

Caractéristiques

électriques

nominales des

interrupteurs

a

120 V (en

ampères)

240 V (en

ampères)

Pleine charge 7,2 3,6

Rotor bloqué 43,2 21,6

a

Circuit de commande de 40 VA, 120/240 V c.a. à l'interrup-

teur opposé

Températures de service nominales :

Maximum : 66°C (150°F) à 25 % du cycle de fonctionnement.

63-2629EF—01 16

Page 17

SERVOMOTEURS MODUTROL IV

MF18998C

4-7/8

(124)

5-1/2

(140)

13/16

(20)

4-1/16 (103)

1/4

(7)

1-1/2 (37)

4-1/16 (103)

BOÎTE DE

JONCTION

MOTEUR

CÔTÉ

AUXILIAIRE

CÔTÉ

COMMANDE

SUPPORT

D'ADAPTATION

2-9/16

(66)

5-3/8

(137)

6-7/16

(164)

9/16 (15)

3/4

(19)

VUE DU DESSUS DU SUPPORT VUE DU DESSUS

4-5/8

(116)

4-1/4

(107)

2-5/16

(58)

11/16

(17)

4-7/8 (124)

5-9/16 (141)

1/4 (7)

5-13/16

(148)

1

CÔTÉ COMMANDE

2

3

1-1/2 (37)

3/4

(19)

MODÈLE À RESSORT DE RAPPEL

ILLUSTRÉ

POUR MODÈLES 60 LB-PO À RESSORT DE RAPPEL, 8 ¾ (222);

POUR MODÈLES SANS RESSORT DE RAPPEL, 7 5/16 (185).

POUR MODÈLES 60 LB-PO À RESSORT DE RAPPEL

(MODÈLE ILLUSTRÉ).

POUR MODÈLES SANS RESSORT DE RAPPEL.

1

2

3

13/16

(20)

MC

SÉRIES 61 ET 62

Minimum : -40°C (-40°F).

Poids neutre sur l'arbre (maximum) :

Côté commande ou auxiliaire : 90,8 kg (200 lb).

Charge combinée : 136 kg (300 lb).

Arbre moteur : 9,5 mm (3/8 po) carré.

Course : Modèles à course réglable : réglable sur place de

90° à 160° (Voir la marche à suivre pour le réglage de la

course).

Durée et couple : Voir le Tableau 5.

Durée de vie

60 000 cycles à pleine course

Repositionnements : 1,5 millions

Fig. 16. Encombrement des servomoteurs Modutrol IV de séries 61 et 62 en po (mm).

17 63-2629EF—01

Page 18

SERVOMOTEURS MODUTROL IV

MC

SÉRIES 61 ET 62

Tableau 16. Durée et couple des servomoteurs Modutrol de série 61 et 62.

rappel

b

c

Sans ressort de

rappel

Durée nominale

Course de

o

90

a

en sec

Course de

o

160

Couple nominal en N.m (lb-po)

Couple normal de service Couple de décollage

Avec ressort de

rappel

Sans ressort de

rappel

Avec ressort de

15 30 — 8,5 (75) — 17,0 (150)

30 60 6,8 (60) 4,0 (35) 13,6 (120) 7,9 (70)

17,0 (150) 34,0 (300)

60 120 34,0 (300) 68,0 (600)

120 240 —

—17,0 (150) 34,0 (300)

a

La durée de la course est la même pour tous les modèles TRADELINE. Certains modèles pour fabricants sont offerts avec

durée

b

et couple non standards

Le couple des modèles à arbre aux deux extrémités correspond à la somme des couples de l'arbre (couple côté commande et

.

couple côté auxiliaire).

c

Le couple de décollage est le couple maximum possible servant à surmonter les charges importantes et occasionnelles qui se

produisent par exemple lorsque le registre ou la vanne est coincé.

REMARQUE : La désignation du couple correspond au cou-

ple nominal à la durée standard de la course

(course nominale de 60 secondes pour 160

de 30 secondes pour 90

o

à l'exception des ser-

o

et

vomoteurs de 34 N.m (300 lb-po) dont la

course dure 2 ou 4 minutes).

IMPORTANT

Il ne faut jamais utiliser le servomoteur au couple de

décollage de façon continue.Potentiomètre d'asservissement (modèles de série 62 seulement):

Modèles TRADELINE (peuvent être shuntés pour

asservir un servomoteur de série 90).

Homologations :

o

Répertorié Underwriters Laboratories Inc. : n

E4436, guide n

o

XAPX. (Canada et États-Unis).

de dossier

En instance de brevet aux États-Unis.

Accessoires :

220736A Jeu d'interrupteur auxiliaire interne; un interrupteur,

peut être installé sur place.

220736B Jeu d'interrupteurs auxiliaires internes; deux inter-

rupteurs, peuvent être installés sur place.

220738A Support d'adaptation servant à augmenter la hau-

teur de l'arbre du servomoteur de 19 mm pour qu'elle corresponde à celle des modèles antérieurs de Modutrol.

220741A Adaptateur pour bornes à vis - transforme les

bornes standards à connexion rapide en bornes à vis.

221455A Bras de manivelle réglable à l'infini; il peut faire une

rotation vers le bas et dégager la base du servomoteur

sans qu'il soit nécessaire d'installer un support.

4074ERU Trousse d'étanchéisation, assure une protection

NEMA 3 aux servomoteurs Modutrol IV montés dans une

autre position qu'à la verticale.

50017460-001 Transformateur interne : primaire

24/120/230 V c.a., 50/60 Hz; secondaire 24 V c.a.; bornes

à connexion rapide.

50017460-003 Transformateur interne : primaire 120 V c.a.,

50/60 Hz; secondaire 24 V c.a.; bornes à connexion

rapide.

7617ADW Bras de manivelle, il peut faire une rotation vers le

bas et dégager la base du servomoteur sans qu'il soit

nécessaire d'installer un support d'adaptation.

Q100 Accouplement servant à raccorder un servomoteur

Modutrol à une vanne papillon V51. Nécessite un support

d'adaptation 220738A.

Q181 Potentiomètre auxiliaire pour la commande en

séquence ou en parallèle de 1 à 4 servomoteurs modulants additionnels (série 90).

Q5001 Ensemble support et accouplement servant à rac-

corder un servomoteur Modutrol IV à une vanne à eau ou à

vapeur.

Q605 Accouplement de registre; raccorde un servomoteur à

un registre; comprend le bras de manivelle du servomoteur.

Q607 Interrupteur auxiliaire externe - commande l'équipement

auxiliaire en fonction de la position du servomoteur.

ES650-117 Le boîtier antidéflagrant protège le moteur dans

les atmosphères explosives. Ne convient pas au Q5001

(ou à tout autre accouplement de vanne). Commander

séparément auprès de EGS Enclosures. Pour commander,

prière de s'adresser à : EGS Enclosures, (281) 774-3763;

ou communiquer par écrit avec :

EGS Enclosures de Houston, au Texas

Karen Barfield 281-774-3763

Karen.barfield@egseg.com

http://appletonelec.com/

Numéro de pièce ES-650-117

Il faut obtenir un ensemble d'accouplement 7617DM de

Honeywell qui sera utilisé avec le couvercle.

INSTALLATION

AVANT D'INSTALLER CET APPAREIL…

7. Lire attentivement les présentes instructions. Le fait de

ne pas les suivre risque d'endommager le produit ou de

constituer un danger

63-2629EF—01 18

Page 19

SERVOMOTEURS MODUTROL IV

CAUTION

CAUTION

CAUTION

MC

SÉRIES 61 ET 62

8. Vérifier les caractéristiques spécifiées dans les instruc-

tions et indiquées sur le produit, et s'assurer que celui-ci

correspond à l'application prévue.

9. L'installateur doit être un technicien d'expérience ayant

reçu une formation pertinente.

10. Après l'installation, vérifier le fonctionnement du produit

comme indiqué aux présentes instructions.

Risque de choc électrique et de dommage matériel

Peut donner un choc électrique ou court-circuiter

le circuit du matériel.

Couper toute alimentation électrique avant de

procéder à l'installation.

Les servomoteurs comportant des interrupteurs

auxiliaires peuvent avoir plus d'un dispositif de

coupure.

Risque de dommage matériel.Peut endommager le

servomoteur au point de le rendre inutilisable.

Ne jamais faire tourner l'arbre du servomoteur à la

main ou à l'aide d'une clé.

Faire tourner de force l'arbre du servomoteur

endommage le train d'engrenages et les interrupteurs

de fin de course.

IMPORTANT

Il faut toujours effectuer une vérification complète

une fois l'installation terminée.

Emplacement

Choisir un emplacement offrant suffisamment d'espace de

dégagement pour l'installation des accessoires et pour

l'entretien du servomoteur (voir la Fig. 2). Si le servomoteur

doit être installé à l'extérieur, utiliser des raccords de conduit

étanches aux liquides avec la boîte de jonction pour assurer

une protection anti-intempéries NEMA 3. Si le servomoteur

doit être installé à l'extérieur autrement qu'à la verticale,

installer une trousse d'étanchéisation 4074ERU et des

raccords étanches aux liquides pour procurer une protection

NEMA 3.

Dans les atmosphères très salines, la plaque de montage et

les vis devraient être plaquées au zinc ou au cadmium et non

en acier inoxydable ou en laiton. Utiliser le support

d'adaptation 220738A pour l'installation dans de telles

conditions.

Montage

Respecter les directives suivantes pour que le servomoteur

soit correctement installé :

• Toujours installer le servomoteur de façon à ce que l'arbre

de manivelle soit à l'horizontale.

• Les brides de fixation qui font saillie à la base du boîtier du

servomoteur sont percées pour recevoir des vis à métal ou

des boulons de 6,4 mm (1/4 po).

• Les servomoteurs sans ressort de rappel sont expédiés de

l'usine en position fermée (à la limite de la rotation dans le

sens antihoraire, vu du côté commande du servomoteur).

Support d'adaptation

Le support d'adaptation 220738A, placé entre le servomoteur

et le matériel, augmente la hauteur de l'arbre du servomoteur

de 19 mm (0,75 po) pour qu'elle corresponde à celle des

modèles antérieurs de servomoteurs Modutrol.

Le support d'adaptation doit être installé dans les applications

suivantes:

• Interrupteur auxiliaire externe Q607

• Les applications d'accouplement de registre exigent un

dégagement supplémentaire pour :

— La rotation du bras de manivelle jusqu'à la position

vers le bas.

— Permettre à l'accouplement de registre d'atteindre

l'arbre du servomoteur

• Tous les accouplements de vanne sauf le Q5001

REMARQUE : Lorsque le support n'est pas utilisé dans une

installation de rechange, il faut ajuster l'accouplement de registre pour qu'il corresponde à la

nouvelle position du registre.

Pour installer le servomoteur avec le support :

1. Fixer le support au matériel en utilisant des boulons

standards ou ceux qui sont déjà en place.

2. À l'aide des boulons fournis, fixer le servomoteur aux

ouvertures filetées du support. Voir la Fig. 3.

Risque de dommage au servomoteur.

Les vapeurs corrosives et acides peuvent endommager les

pièces métalliques.

Installer le servomoteur dans un endroit où on ne retrouve pas

de vapeurs acides et autres vapeurs corrosives.

Installations avec accouplement de vanne (sauf le Q5001) :

1. Fixer le support sur l'accouplement

2. Placer le servomoteur sur le support et aligner l'arbre

avec l'accouplement

3. Fixer le servomoteur au support avec les quatre bou-

lons fournis. Voir la Fig. 4.

19 63-2629EF—01

Page 20

SERVOMOTEURS MODUTROL IV

CAUTION

MF18999

BASE DE

L’APPAREIL

SUPPORT

D’ADAPTATION

BOULONS

STANDARDS (4)

MOTEUR

BOULONS

FOURNIS (4)

BOÎTE DE JONCTION

SANS RESSORT DE RAPPEL

AVEC RESSORT DE RAPPEL

1 VIS À MÉTAL OU BOULONS ZINGUÉS Nº 12 OU ¼ PO

1

POWER

END

POWER

END

POW

ER

END

BOULONS DE

MONTAGE

1/4-20 UNC 1 PO

LONGUEUR

Q5001

ACCOUPLEMENT

DE VANNE

MF18994

MOTEUR

BOÎTE DE

JONCTION

CÔTÉ

COMMANDE

DU MOTEUR

VAN NE

MC

SÉRIES 61 ET 62

Fig. 18. Fixation du servomoteur à un accouplement de

Fig. 17. Installation du servomoteur sur un support d'adaptation.

Pour des instructions détaillées sur les accouplements

particuliers, consulter les directives d'installation qui

accompagnent chaque accouplement.

Risque de dommage matériel. Bloquer un

servomoteur peut endommager l'arbre.

S'assurer que l'installation des servomoteurs et des

accouplements permet au servomoteur de parcourir

sa course complète sans obstruction.

Accouplement de vannes

Le support d'adaptation 220738A doit être utilisé avec

l'accouplement Q100 dans toutes les applications de vannes.

Le support d'adaptation n'est pas nécessaire avec

l'accouplement de vanne Q5001 (voir la Fig. 4).

Boîte de jonction

Utilisée avec des raccords de conduits étanches aux liquides,

la boîte de jonction procure au servomoteur une protection

contre les intempéries NEMA 3. La boîte de jonction, pièce

fournie avec les servomoteurs de remplacement, comprend

des ouvertures défonçables pour faire passer les conduits et

des bornes. Il faut utiliser une boîte électrique pour loger un

vanne Q5001.

transformateur interne ou des interrupteurs auxiliaires

internes.

Accouplements de registre

Le servomoteur ne comporte pas d'arbre de manivelle. Il faut

commander séparément le bras de manivelle (voir

Accessoires dans la section des caractéristiques techniques).

63-2629EF—01 20

Page 21

SERVOMOTEURS MODUTROL IV

CAUTION

R

B

W

R

W

B

T2

T1

(SOUS TENSION) L1

L2

ALIMENTATION. FOURNIR, AU BESOIN, UN DISPOSITIF

DE COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

LE TRANSFORMATEUR PEUT ÊTRE INTERNE OU EXTERNE.

MF17095B

RÉGULATEUR

DE SÉRIE 60

RÉGULATEUR

DE SÉRIE 61

1

2

1

2

MC

SÉRIES 61 ET 62

Raccordement

Risque de choc électrique et de dommage matériel.

Peut donner un choc électrique ou court-circuiter

le circuit du matériel. Couper toute alimentation

électrique avant de procéder à l'installation.

Les servomoteurs comportant des interrupteurs

auxiliaires peuvent avoir plus d'un dispositif de

coupure.

IMPORTANT

Tout le câblage doit être conforme aux codes et

règlements locaux.

1. S'assurer que la tension et la fréquence gravées sur le

servomoteur correspondent aux caractéristiques de

l'alimentation électrique.

2. Lors du raccordement de plusieurs servomoteurs en

parallèle, il faut s'assurer que la puissance (VA) de

l'alimentation électrique suffit à alimenter tous les

servomoteurs utilisés sans provoquer de surcharge.

3. La Fig. 5 montre que les bornes du servomoteur sont à

connexion rapide et sont situées sur le dessus de la plaquette de circuit imprimé.

4. Pour accéder au compartiment de câblage :

a. Retirer les quatre vis du dessus de la boîte de jonc-

tion.

b. Soulever le couvercle.

5. 5.Voir à la Fig. 6 le schéma de raccordement type et à la

Fig. 9, le raccordement des interrupteurs auxiliaires

internes.

REMARQUE : On peut inverser la rotation du servomoteur en

changeant les fils, soit au servomoteur, soit au

panneau. On peut inverser la rotation des

modèles de série 61 en inversant les fils aux

bornes W et B. On peut inverser la rotation des

modèles de série 62 en inversant les fils aux

bornes 1 et 2 (pour obtenir la rotation qui

convient) et en inversant les fils aux bornes Y

et G (pour maintenir un signal

d'asservissement qui correspond à la rotation

de l'arbre).

POTENTIOMÈTRE DE

SENSIBILITÉ (SUR CERTAINS

MODÈLES DE LA SÉRIE 62,

VOIR LE TABLEAU 5)

Y

1

G

T

2

1

R

4

3

POTENTIOMÈTRE DE

RÉGLAGE DE COURSE

LES DÉSIGNATIONS DES BORNES ILLUSTRÉES SONT CELLES

1

DES MODÈLES DE SÉRIE 62.

REMARQUE : TOUTES LES CARACTÉRISTIQUES NE FONT PAS

PARTIE DE TOUS LES MODÈLES.

INTERR. AUX.

CÔTÉ INTÉRIEUR

CAME (BLEUE)

INTERR. AUX.

CÔTÉ INTÉRIEUR

CÔTÉ

COMMANDE

CAME (ROUGE)

INTERR. AUX.

CÔTÉ EXTÉRIEUR

INTERR. AUX. CÔTÉ

EXTÉRIEUR

Fig. 19. Bornes et réglages.

MF13600C

Fig. 20. Raccordement d'un servomoteur de série 61.

21 63-2629EF—01

Page 22

SERVOMOTEURS MODUTROL IV

CAUTION

R

B

W

R

1

2

T

G

Y

4

3

(SOUS TENSION) L1

L2

ALIMENTATION. FOURNIR, AU BESOIN, UN DISPOSITIF

DE COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

LE TRANSFORMATEUR PEUT ÊTRE INTERNE OU EXTERNE.

POTENTIOMÈTRE D'ASSERVISSEMENT.

MF17096A

RÉGULATEUR

DE SÉRIE 60

RÉGULATEUR

DE SÉRIE 62

1

2

3

1

2

3

W

R

B

G

Y

T

ALIMENTATION. FOURNIR, AU BESOIN, UN DISPOSITIF DE

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

RACCORDEMENT REQUIS SEULEMENT POUR LES

MOTEURS À RESSORT DE RAPPEL.

MF17098

RÉGULATEUR

DE SÉRIE 90

RELAIS R927C OU R9107A

MOTEUR DE SÉRIE 62 À COURSE

DE 160 DEGRÉS

Q181A

2

1

T

1

2

2

L1

(SOUS

TENSION)

L2

1

R

W

Y

T

G

2

B

R

W

B

1

4

3

A

MC

SÉRIES 61 ET 62

SCHÉMA DE CÂBLAGE

– APPLICATION EN PARALLÈLE DU M62XX SÉRIE ET SÉRIE 2

Fig. 21. Raccordement d'un servomoteur de série 6.

S'assurer que L1 (sous tension) du transformateur

correspond à 4 (sous tension) du moteur et que le

L2 correspond à 3 (mise à la terre) du moteur.

TRANS

R

C

ÉTALONNER LES RELAIS ET LE TRANSFORMATEUR SELON

1

LES EXIGENCES DU SYSTÈME.

2

DES SERVOMEURS DE SÉRIE 1 OU 2 ADDITIONNELS PEUVENT

ÊTRE AJOUTÉS EN PARALLÈLE. NE PAS COMBINER LES APPAREILS

DE SÉRIE 1 ET DE SÉRIE 2 SUR LE MÊME CIRCUIT. RACCORDER

EN PARALLÈLE SEULEMENT DES APPAREILS DE SÉRIE 1

À D’AUTRES DE SÉRIE 1 ET DES APPAREILS DE SÉRIE 2 À D’AUTRES

DE SÉRIE 2.

1

3

M62 S2

3

M62 S2

R

K1

B

W

2

4

R1

T

2

2

1

K2

1

G

Y

3

4

M62 S1

3

M62 S1

R1

2

G

2

T

Y

2

1

MF27044

Fig. 23. Schéma de raccordement de l'interrupteur

auxiliaire

RÉGULATEUR

DE SÉRIE 60

R (SOUS

TENSION)

R

B

W

R

1

2

T

G

Y

M6284

3

4

Fig. 22. Raccordement à un relais R927C ou R9107A

63-2629EF—01 22

C

R (SOUS

TENSION)

C

Fig. 24. Application d'asservissement des servomoteurs

de série 60 et de série 90

W

R

B

M9184

T1

T2

MF27035

Page 23

Les moteurs de cette application doivent tous être

symétriques ou asymétriques. Le moteur M62 doit être de

modèle "-S" à asservissement, comme l'indique le Table 2.

Pour obtenir la réaction correcte, l'appareil de série 62 doit

être muni de la bonne résistance shunt, comme l'indique le

Table 2. Les réglages du potentiomètre du moteur sont

indiqués dans le tableau de configuration (Table 18) cidessous. Lorsque plus d'un moteur série 90 est asservi,

utiliser la bonne table de résistance, comme l'indique le

tableau de configuration, et installer deux résistances dans

UN des moteurs (Table 19 et 10). S'il s'agit du moteur maître

M62, raccorder une résistance des bornes T à G et l'autre des

bornes T à Y. s'il s'agit d'un des M90 asservis, raccorder une

résistance des bornes R à B et l'autre des bornes R à W.

SERVOMOTEURS MODUTROL IV

MC

SÉRIES 61 ET 62

REMARQUE : L'asservissement de plus de six moteurs est

déconseillé.

Tableau 17. Table de configuration

Pot.

Symétrique

ou asymétrique

Course

principale

Course

asservie

principal

course

Pot. principal

sensibilité

Pot. asservi

course

Pot. asservi

sensibilité

Symétrique 160 160 Horaire Horaire Horaire Horaire 1

Symétrique 90 90 Anti-horaire Anti-horaire Anti-horaire Anti-horaire 2

Symétrique 160 90 Anti-horaire Horaire Anti-horaire Anti-horaire 1

Symétrique 90 160 Configuration non recommandée

Asymétrique 160 160 Horaire Horaire Horaire Horaire 1

Asymétrique 90 90 Anti-horaire Horaire Horaire Horaire 1

Asymétrique 160 90 Configuration non recommandée

Asymétrique 90 160 Configuration non recommandée

Tableau 18. Table de résistance 1 Tableau 19. Table de résistance 2

Nombre d'asservissements en

parallèle

1 AUCUNE

2 3500 ohms

3 2000 ohms

4 1300 ohms

5 1000 ohms

6 800 ohms

Valeur de la

résistance

Nombre d'asservissements en

Valeur de la

parallèle

1 AUCUNE

2 5000 ohms

3 2400 ohms

4 1700 ohms

5 1400 ohms

6 1200 ohms

Tabl e de

résistance

résistance

REMARQUE : Les vibrations n'ont aucun effet sur le fonc-

tionnement des servomoteurs Modutrol IV

(comme c'était le cas pour les servomoteurs

Modutrol antérieurs). Lors du remplacement

d'un servomoteur qui était raccordé à un relais

R927C ou R9107A, Honeywell recommande

de moder- niser l'installation et de retirer le

relais et l'ancien servomoteur. Les deux doivent alors être remplacés par un servomoteur

Modutrol IV de série 90 (c'est-à-dire qu'il ne

faut pas remplacer le relais).

23 63-2629EF—01

Page 24

SERVOMOTEURS MODUTROL IV

CAUTION

CAUTION

FIL BLEU

FIL JAUNE

FIL ROUGE

UTILISER DU FIL DE CLASSE 1 NEC À MOINS QUE L'ALIMENTATION

ÉLECTRIQUE RESPECTE LES EXIGENCES DE LA CLASSE 2.

ENRUBANNER LES FILS INUTILISÉS. S'ASSURER QUE L'APPEL DE

COURANT DU CIRCUIT EXTERNE EST INFÉRIEUR AUX

CARACTÉRISTIQUES NOMINALES DE L'INTERRUPTEUR.

DANS LES MOTEURS À DEUX INTERRUPTEURS, LE DEUXIÈME

INTERRUPTEUR A DES FILS NOIRS AVEC DES REPÈRES BLEU,

JAUNE ET ROUGE.

CERTAINS MODÈLES COMPRENNENT SEULEMENT DES FILS JAUNE

ET ROUGE. CERTAINS MODÈLES N'ONT PAS DE FIL JAUNE.

1

1

1

2

2

2

2

3

3

MF13601A

CÔTÉ

COMMANDE

CAMES

D’INTERRUPTEURS

AUXILIAIRES

POTENTIOMÈTRE

DE SENSIBILITÉ

(SUR CERTAINS MODÈLES

DE LA SÉRIE 62,

VOIR LE TABLEAU 5)

POTENTIOMÈTRE DE

RÉGLAGE DE COURSE

MC

SÉRIES 61 ET 62

.

Fig. 25. Schéma de raccordement de l'interrupteur

auxiliaire

RÉGLAGES ET AJUSTEMENTS

Avant de régler la course

1. Retirer le couvercle du dessus du servomoteur.

2. Débrancher le régulateur du servomoteur.

3. Pour les modèles à transformateur interne (moteurs à

tension secteur), s'assurer que l'alimentation (et rien

d'autre) reste raccordée au servomoteur.

maximale du sens horaire et l'extrémité maximale du sens

antihoraire permet de régler la course à une position entre

160° and 90°.

À manipuler avec précautions.

L'usage excessif de la force lors de l'ajustement

des cames peut endommager le servomoteur.

Pour éviter d'endommager le servomoteur, régler les

cames en faisant tourner le tournevis par le haut

seulement.

Risque de dommage matériel.

Peut endommager le servomoteur au point de le

rendre inutilisable.

Ne jamais faire tourner l'arbre du servomoteur à la

main ou à l'aide d'une clé. Faire tourner de force

l'arbre du servomoteur endommage le train

d'engrenages et les interrupteurs de fin de course.

IMPORTANT

Détacher l'accouplement du servomoteur avant de

régler la course.

Course réglable

Course réglable des servomoteurs de série 61

Le potentiomètre de course est situé à l'extrême gauche du

servomoteur (vu du côté de l'arbre de commande). Pour

régler la course à 160° (position maximale), tourner le

potentiomètre jusqu'au bout dans le sens horaire , à

l'aide d'un tournevis à lame de 3 mm (1/8 po). Pour régler la

course à 90° (position minimale), tourner le potentiomètre

jusqu'au bout dans le sens antihoraire. . Tourner le

potentiomètre à une position entre l'extrémité maximale du

sens horaire et l'extrémité maximale du sens antihoraire

permet de régler la course à une position entre 160° and 90°.

Course réglable des servomoteurs de série 62

Le potentiomètre de course est situé à l'extrême gauche du

servomoteur (vu du côté de l'arbre de commande). Le

potentiomètre de sensibilité est situé à l'extrême droite. Pour

régler la course à 160° (position maximale), tourner les deux

potentiomètres jusqu'au bout dans le sens horaire , à

l'aide d'un tournevis à lame de 3 mm (1/8 po). Pour régler la

course à 90° (position minimale), tourner les deux

potentiomètres jusqu'au bout dans le sens antihoraire. .

Tourner le potentiomètre à une position entre l'extrémité

63-2629EF—01 24

Fig. 26. Réglage de la course des modèles sans ressort

de rappel.

Configuration du potentiomètre d'asservissement (Servomoteurs TRADELINE® de série 62 seulement)

Sélectionner et installer une résistance de shunt pour obtenir

les caractéristiques d'asservissement nécessaires à

l'application. Voir la section des caractéristiques techniques

pour connaître la résistance de rétroaction sans résistance de

shunt.

REMARQUE : En raison des organes de protection du circuit,

la résistance ne peut pas être directement lue,

et utiliser un réducteur de tension pour lire la

position du moteur.

• La rétroaction linéaire procure l'indication linéaire de la

position de l'arbre sans résistance de shunt.

• L'asservissement d'un servomoteur de série 90 requiert

une résistance de rétroaction de la course complète de

142 ohms. Sélectionner et fixer la résistance de shunt qui

convient entre les bornes Y et G (voir le Tableau 2 et la Fig.

13).

Page 25

SERVOMOTEURS MODUTROL IV

3

4

R

1

2

G

Y

M652

MC

SÉRIES 61 ET 62

3. Amener le servomoteur à la position où l'équipement

auxiliaire doit être commandé, comme suit :

a. Pour les modèles sans ressort de rappel et sans

transformateur, raccorder le courant 24 V c.a. aux

bornes 2 et 3 pour amener le servomoteur à la

position d'ouverture (dans le sens horaire, vu du côté

commande), ou aux bornes 1 et 3 pour amener le

servomoteur à la position de fermeture (dans le sens

antihoraire).

b. Pour les servomoteurs sans ressort de rappel avec

transformateur, installer un cavalier entre les bornes

R et 2 pour amener le servomoteur à la position

d'ouverture (dans le sens horaire, vu du côté commande), ou entre les bornes R et 1 pour amener le

servomoteur à la position de fermeture (dans le

sens antihoraire).

Fig. 27. Comment fixer une résistance de shunt aux

servomoteurs TRADELINE.

Interrupteurs auxiliaires

Les interrupteurs auxiliaires sont actionnés par des cames

réglables. Celles-ci peuvent être réglées de façon à actionner

les interrupteurs à n'importe quel angle de la course du

servomoteur. Le différentiel de commutation peut être réglé à

1° ou à 10°.

Les servomoteurs qui comportent des interrupteurs auxiliaires

ajoutés en usine sont expédiés en position fermée

(complètement dans le sens antihoraire, vu du côté

commande). La position par défaut de la came auxiliaire

actionne les interrupteurs à 30° de la position d'ouverture

complète avec un différentiel de 1°. Lorsque le servomoteur

est en position de fermeture (complètement dans le sens

antihoraire), le contact R-B de l'interrupteur auxiliaire s'ouvre.

Voir la Fig. 11 (ou les directives d'installation de l'interrupteur

auxiliaire) pour savoir comment raccorder l'interrupteur

auxiliaire.

c. Pour les modèles à ressort de rappel, installer un

cavalier entre les bornes 2 et 4 pour amener le servomoteur à la position d'ouverture, ou entre les

bornes 1 et 4 pour amener le servomoteur à la position de fermeture.

4. Lorsque le servomoteur atteint la position adéquate,

retirer le cavalier.

5. Pour obtenir un différentiel de commutation de 1°, vérifier

la continuité des contacts R-B de l'interrupteur auxiliaire

et faire tourner la came comme suit :

a. Si les contacts sont ouverts, faire tourner la came

dans le sens horaire jusqu'à ce que les contacts R-B

se referment.

b. Si les contacts sont fermés, faire tourner la came