Page 1

High-Performance

Process Manager

Planning

HP02-500

Page 2

Page 3

System Site Planning - 2

High-Performance

Process Manager

Planning

HP02-500

Release 530

CE Compliant

3/98

Page 4

Copyright, Notices, and Trademarks

© Copyright 1995 - 1998 by Honeywell Inc.

Revision 05 – March 20, 1998

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in its

written agreement with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special or consequential

damages. The information and specifications in this document are subject to

change without notice.

TotalPlant, TDC 3000, Process Manager, and SMARTLINE are U.S. registered

trademarks of Honeywell Inc.

Honeywell

Industrial Automation and Control

Automation College

2820 West Kelton Lane

Phoenix, AZ 85023

1-800-852-3211

ii HPM Planning 3/98

Page 5

About This Publication

This manual provides information necessary to properly plan the installation of a High-Performance

Process Manager (HPM) subsystem at a TPS system site. The subsystem encompasses the HighPerformance Process Manager and the Network Interface Module (NIM), which is resident on the

Universal Control Network (UCN), a network associated with the TPS system Local Control

Network (LCN). The amount of information that this publication provides depends on your

personal experience and the process that the High-Performance Process Manager will control and

monitor.

The experienced planner, a person involved in the installation of TPS system’s Basic or LCN

equipment, will find that some information is familiar. However, regardless of your past

experience, you must read Section 4 in this manual to enhance your knowledge of the process

control connections available, and also reference the TPS System Site Planning, Universal Control

Network Planning, and Universal Control Network Installation manuals to prepare yourself for the

connection of the High-Performance Process Manager to the Universal Control Network.

In some cases, control room expansion will be part of installing the High-Performance Process

Manager. If this is the case, use the LCN Planning and LCN Installation manuals to plan for

expansion of the network.

This publication supports TotalPlant Solution (TPS) system network software Release 530 or earlier

software releases. TPS is the evolution of TDC 3000X.

The publication supports CE Compliant equipment. Any equipment designated as “CE Compliant”

complies with the European Union EMC and its health and safety directives. All equipment entering

the European countries after January 1, 1996 require this type of compliance, denoted by the

“CE Mark.”

3/98 HPM Planning iii

Page 6

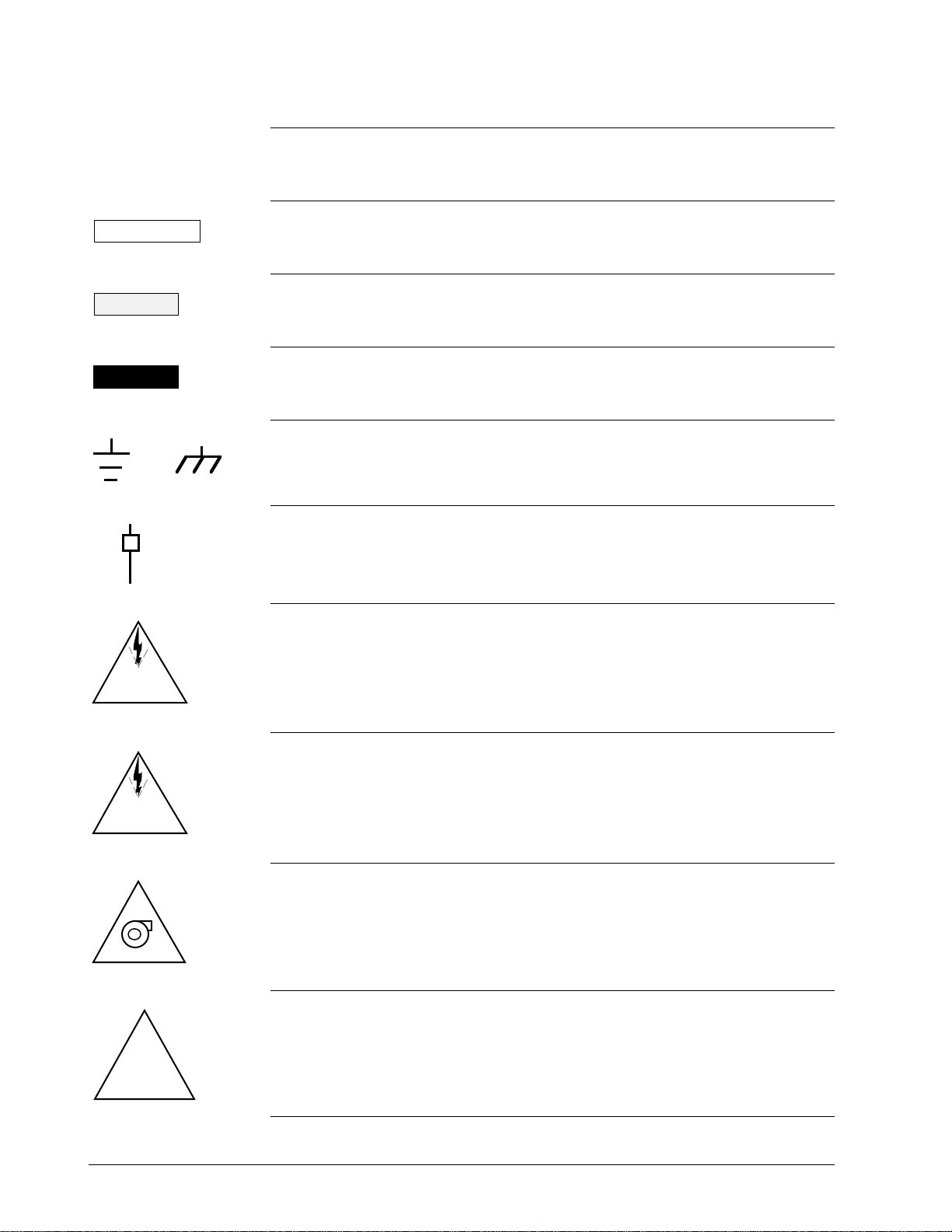

Standard Symbols

53896

Scope

ATTENTION

CAUTION

WARNING

OR

The standard symbols used in this publication are defined as follows.

Notes inform the reader about information that is required, but not

immediately evident.

Cautions tell the user that damage may occur to equipment if proper care is

not exercised.

Warnings tell the reader that potential personal harm or serious economic

loss may happen if instructions are not followed.

Ground connection to building safety ground.

53893

Ground stake for building safety ground.

53894

DANGER

SHOCK HAZARD

DANGER

HIGH VOLTAGE

!

Electrical Shock Hazard—can be lethal.

53895

Electrical Shock Hazard—can be lethal.

Rotating Fan—can cause personal injury.

53897

Caution—refer to the appropriate installation document.

iv HPM Planning 3/98

Page 7

Table of Contents

SECTION 1 – INTRODUCTION.................................................................................... 1

1.1 Overview.............................................................................................. 1

SECTION 2 – HPM DESCRIPTION.............................................................................. 3

2.1 Overview.............................................................................................. 3

2.2 Card Files ............................................................................................. 5

2.2.1 HPMM Card Files................................................................................... 6

2.2.2 Input/Output Processor (IOP) Card Files............................................... 12

2.3 Input/Output Processor (IOP) Cards..................................................... 16

2.3.1 IOP Redundancy................................................................................ 17

2.4 I/O Link Extender (Fiber Optic Link)...................................................... 19

2. 5 Field Termination Assemblies (FTAs).................................................... 24

2.6 Power Systems................................................................................... 36

2.7 Cabinet Configurations........................................................................ 41

SECTION 3 – POWER REQUIREMENTS.................................................................. 45

3.1 Overview............................................................................................ 45

3.2 Backup Strategy................................................................................. 46

3.3 Quality................................................................................................ 48

3.4 Power Draw ........................................................................................ 51

3.4.1 Typical 24 Vdc Power Draw Calculations ............................................... 53

3.4.2 Single Power System Calculation Example........................................... 58

3.4.3 Dual Power System Calculation Example .............................................. 59

3.4.4 HPM AC Power Draw........................................................................... 60

3.4.5 Crest Factor........................................................................................ 61

3.4.6 Inrush Current..................................................................................... 62

3.5 Substation Sizing................................................................................ 64

3.6 Circuit Breaker Sizing .......................................................................... 65

3.7 Custom UPS and Power Factor............................................................ 66

3.8 Automatic Bypass Switch..................................................................... 66

3. 9 Surge Protection ................................................................................ 67

3.10 Grounded Conductor .......................................................................... 68

3.11 Redundant Safety Grounds ................................................................. 68

3.12 Emergency Shutdown ........................................................................ 68

3.13 Trays and Conduits............................................................................. 68

3.14 Existing TPS System AC Power........................................................... 69

SECTION 4 – PROCESS WIRING.............................................................................. 71

4.1 Overview............................................................................................ 71

4.2 FTA Selection..................................................................................... 72

4.3 Cabinet Entry...................................................................................... 80

4.4 Signal Tray Wiring Compatibility............................................................ 81

4.5 Process Wiring Termination ................................................................. 82

SECTION 5 – HAZARDOUS ENVIRONMENT PLANNING........................................... 83

5.1 Overview............................................................................................ 83

5. 2 Hazardous Area Classifications............................................................. 84

5.3 Mounting and Operating the HPM in a Division 2 Location...................... 86

5.4 Field Wiring in Hazardous Locations ................................................... 100

SECTION 6 – CORROSION PROTECTION PLANNING ............................................ 103

6.1 Overview.......................................................................................... 103

6.2 Model Numbers................................................................................ 106

3/98 HPM Planning v

Page 8

Table of Contents

SECTION 7 – CE COMPLIANCE............................................................................. 115

7.1 Overview.......................................................................................... 115

7.2 Card Files ......................................................................................... 116

7.3 HPMM Cards..................................................................................... 117

7.4 IOPs................................................................................................. 117

7.5 FTAs................................................................................................ 120

7.6 I/O Link Extender.............................................................................. 129

7. 7 IOP to FTA Cables............................................................................. 130

7.8 Power Cables ................................................................................... 131

7.9 I/O Link Interface Cables.................................................................... 136

7.10 UCN Trunk Cable Taps...................................................................... 137

7.11 Cabinets........................................................................................... 139

SECTION 8 – MODEL MU-CBSM01/MU-CBDM01 CABINETS.................................. 141

8.1 Overview.......................................................................................... 141

8.2 Cabinet Description........................................................................... 144

8. 3 Card File and Power System Configurations........................................ 148

8. 4 Card File and Power System Description............................................. 150

8. 5 FTA Mounting Channel Description.................................................... 154

8.5.1 Vertical FTA Mounting Channels........................................................ 155

8.5.2 Horizontal FTA Mounting Channel...................................................... 159

8.6 Cabinet Floor Planning...................................................................... 163

SECTION 9 – MODEL MU-CBSX01/MU-CBDX01 CABINETS ................................... 165

9.1 Overview.......................................................................................... 165

9.2 Cabinet Description........................................................................... 169

9. 3 Card File and Power System Configurations........................................ 173

9. 4 Card File and Power System Description............................................. 175

9.5 FTA Mounting Channel Descriptions.................................................. 179

9.5.1 Vertical FTA Mounting Channels........................................................ 180

9.5.2 Horizontal FTA Mounting Channel...................................................... 184

9.6 Cabinet Floor Planning...................................................................... 188

SECTION 10 – REDUNDANCY PLANNING.............................................................. 189

10.1 Overview.......................................................................................... 189

10.2 Redundant HPMM Configurations...................................................... 189

10.3 Redundant IOP Placement ................................................................ 194

10.4 Redundancy Support........................................................................ 195

10.4.1 Power System.................................................................................. 195

10.4.2 HPMM to I/O ..................................................................................... 195

vi HPM Planning 3/98

Page 9

Table of Contents

SECTION 11 – I/O LINK EXTENDER PLANNING...................................................... 197

11.1 Overview.......................................................................................... 197

11.2 Description....................................................................................... 198

11.3 Fiber Optic Cable Routing.................................................................. 204

11.3.1 Direct Burial...................................................................................... 204

11.3.2 Aerial Lashing................................................................................... 204

11.3.3 Vertical Installations........................................................................... 205

11.3.4 Indoor Requirements........................................................................ 205

11.3.5 Loose Buffered Cable ....................................................................... 205

11.3.6 Number of Fibers.............................................................................. 206

11.3.7 Cable Installation............................................................................... 206

11.4 Indoor Cable Bend Radius................................................................. 207

11.5 Cable Construction........................................................................... 207

11.6 Cable Splices and Connections......................................................... 208

11.7 Signal Loss Budget........................................................................... 210

11.7.1 Standard I/O Link Extender................................................................ 210

11.7.2 Long Distance I/O Link Extender........................................................ 212

11.8 Power Level Measurement ................................................................ 213

SECTION 12 – LOW LEVEL MULTIPLEXER PLANNING.......................................... 215

12.1 Overview.......................................................................................... 215

12.2 LLMux Version................................................................................. 216

12.2.1 LLMux Configurations ....................................................................... 216

12.2.2 LLMux IOP Placement....................................................................... 219

12.2.3 LLMux Power Adapter Placement...................................................... 219

12.2.4 LLMux FTA Placement...................................................................... 219

12.2.5 Remote CJR Installation..................................................................... 222

12.3 RHMUX Version................................................................................ 223

12.3.1 RHMUX Configurations...................................................................... 223

12.3.2 RHMUX IOP Placement ..................................................................... 228

12.3.3 RHMUX Power Adapter Placement..................................................... 228

12.3.4 RHMUX FTA Placement..................................................................... 228

SECTION 13 – SERIAL DEVICE INTERFACE PLANNING......................................... 233

13.1 Overview.......................................................................................... 233

13.2 Serial Device Interface Configurations................................................ 233

13.3 Serial Device Interface IOP Placement................................................ 235

13.4 Power Adapter Placement................................................................. 235

13.5 IOP to Power Adapter Cabling............................................................ 235

13.6 Serial Device Interface FTA Placement............................................... 236

13.7 FTA to Power Adapter Cabling........................................................... 236

13.8 FTA Field Cabling.............................................................................. 238

13.9 Serial Device Interface FTA Models.................................................... 239

SECTION 14 – SERIAL INTERFACE PLANNING...................................................... 241

14.1 Overview.......................................................................................... 241

14.2 Serial Interface Configurations ........................................................... 241

14.3 Serial Interface IOP Placement........................................................... 247

14.4 Power Adapter Placement................................................................. 247

14.5 IOP to Power Adapter Cabling............................................................ 247

14.6 Serial Interface FTA Placement .......................................................... 248

14.7 FTA to Power Adapter Cabling........................................................... 248

14.8 FTA Field Cabling.............................................................................. 250

14.9 Serial Interface FTA Models............................................................... 251

14.10 Communications Interface Specifications............................................ 252

3/98 HPM Planning vii

Page 10

Table of Contents

SECTION 15 – GALVANICALLY ISOLATED FTA PLANNING.................................... 253

15.1 Overview.......................................................................................... 253

15.2 Description....................................................................................... 255

15.3 Features........................................................................................... 264

15.3.1 IOP Redundancy.............................................................................. 264

15.3.2 Analog and Digital Output Standby Manual Devices............................. 264

15.3.3 Auxiliary Inputs/Outputs.................................................................... 265

15.3.4 Power Requirements........................................................................ 267

15.3.5 Field Wiring Connections................................................................... 268

15.3.6 Ambient Temperature Limits.............................................................. 268

15.3.7 FTA Mounting Channels.................................................................... 269

15.4 Power Distribution............................................................................. 273

15.4.1 Power Distribution Assembly............................................................. 274

15.4.2 Cabling to Power Distribution Assemblies........................................... 275

15.4.3 Cabling to FTAs................................................................................ 275

15.4.4 Power Considerations ....................................................................... 276

15.5 High Level Analog Input (HLAI) FTAs.................................................. 277

15.5.1 Model MU-GAIH12/MU-GAIH82 FTA................................................... 277

15.5.1.1 Description....................................................................................... 277

15.5.1.2 Connectors...................................................................................... 277

15.5.1.3 Field Wiring Input Signals................................................................... 277

15.5.1.4 Auxiliary Connector Output................................................................ 278

15.5.1.5 Indicators.......................................................................................... 278

15.5.1.6 Current Consumption........................................................................ 278

15.5.1.7 Isolation and Safety........................................................................... 278

15.5.2 Model MU-GAIH13/MU-GAIH83 FTA................................................... 279

15.5.2.1 Description....................................................................................... 279

15.5.2.2 Connectors...................................................................................... 279

15.5.2.3 Field Wiring Input Signals................................................................... 280

15.5.2.4 Auxiliary Connector Output................................................................ 280

15.5.2.5 Indicators.......................................................................................... 280

15.5.2.6 Hand-Held Communicator.................................................................. 281

15.5.2.7 Current Consumption........................................................................ 281

15.5.2.8 Isolation and Safety........................................................................... 281

15.5.3 Model MU-GAIH14/MU-GAIH84 FTA................................................... 282

15.5.3.1 Description....................................................................................... 282

15.5.3.2 Connectors...................................................................................... 282

15.5.3.3 Field Wiring Input Signals................................................................... 283

15.5.3.4 Auxiliary Connector Output................................................................ 283

15.5.3.5 Indicators.......................................................................................... 283

15.5.3.6 Hand-Held Communicator.................................................................. 284

15.5.3.7 Current Consumption........................................................................ 284

15.5.3.8 Isolation and Safety........................................................................... 284

15.5.4 Model MU-GAIH22/MU-GAIH92 FTA................................................... 285

15.5.4.1 Description....................................................................................... 285

15.5.4.2 Connectors...................................................................................... 285

15.5.4.3 Field Wiring Input Signals................................................................... 286

15.5.4.4 Auxiliary Connector Output................................................................ 286

15.5.4.5 Indicators.......................................................................................... 286

15.5.4.6 Current Consumption........................................................................ 287

15.5.4.7 Isolation and Safety........................................................................... 287

viii HPM Planning 3/98

Page 11

Table of Contents

15.6 24 Vdc Digital Input FTAs................................................................... 288

15.6.1 Model MU-GDID12/MU-GDID82 FTA................................................... 288

15.6.1.1 Description....................................................................................... 288

15.6.1.2 Connectors...................................................................................... 288

15.6.1.3 Field Wiring Input Signals................................................................... 289

15.6.1.4 Line-Fault Detection.......................................................................... 289

15.6.1.5 Auxiliary Connector Output................................................................ 289

15.6.1.6 Indicators.......................................................................................... 290

15.6.1.7 Current Consumption........................................................................ 290

15.6.1.8 Isolation and Safety........................................................................... 290

15.6.2 Model MU-GDID13/MU-GDID83 FTA................................................... 291

15.6.2.1 Description....................................................................................... 291

15.6.2.2 Connectors...................................................................................... 291

15.6.2.3 Field Wiring Input Signals................................................................... 291

15.6.2.4 Indicators.......................................................................................... 292

15.6.2.5 Current Consumption........................................................................ 292

15.6.2.6 Isolation and Safety........................................................................... 292

15.7 Analog Output FTAs......................................................................... 293

15.7.1 Model MU-GAOX02/72 and MU-GAOX12/82 FTAs.............................. 293

15.7.1.1 Description....................................................................................... 293

15.7.1.2 Connectors...................................................................................... 293

15.7.1.3 Field Wiring Output Signals................................................................ 293

15.7.1.4 Line-Fault Detection.......................................................................... 294

15.7.1.5 Calibration........................................................................................ 294

15.7.1.6 Indicators.......................................................................................... 294

15.7.1.7 Current Consumption........................................................................ 294

15.7.1.8 Isolation and Safety........................................................................... 295

15.8 24 Vdc Digital Output FTAs................................................................ 296

15.8.1 Model MU-GDOD12/MU-GDOD82 FTA............................................... 296

15.8.1.1 Description....................................................................................... 296

15.8.1.2 Signal Connectors............................................................................ 296

15.8.1.3 Field Wiring Output Signals................................................................ 296

15.8.1.4 Auxiliary Connector........................................................................... 297

15.8.1.5 Indicators.......................................................................................... 297

15.8.1.6 Standby Manual Device Connector.................................................... 297

15.8.1.7 Current Consumption........................................................................ 298

15.8.1.8 Isolation and Safety........................................................................... 298

15.8.2 Model MU-GDOL12/MU-GDOL82 FTA............................................... 299

15.8.2.1 Description....................................................................................... 299

15.8.2.2 Signal Connectors............................................................................ 299

15.8.2.3 Field Wiring Output Signals................................................................ 299

15.8.2.4 Auxiliary Connector........................................................................... 300

15.8.2.5 Indicators.......................................................................................... 300

15.8.2.6 Standby Manual Device Connector.................................................... 301

15.8.2.7 Current Consumption........................................................................ 301

15.8.2.8 Isolation and Safety........................................................................... 301

15.9 Combiner Panel................................................................................ 302

15.10 Marshalling Panel.............................................................................. 303

15.10.1 Description....................................................................................... 303

15.10.2 Configurations.................................................................................. 304

15.10.2.1 High Level Analog Input FTAs............................................................ 304

15.10.2.2 Digital Input FTAs.............................................................................. 305

15.10.2.3 Digital Output FTAs........................................................................... 306

3/98 HPM Planning ix

Page 12

Figures

Figure 2-1 Nonredundant HPMM Cabinet Layout................................................. 4

Figure 2-2 Left 7-Slot HPMM Card File................................................................. 7

Figure 2-3 Right 7-Slot HPMM Card File............................................................... 9

Figure 2-4 15-Slot HPMM Card File.................................................................... 11

Figure 2-5 Left 7-Slot IOP Card File................................................................... 13

Figure 2-6 Right 7-Slot IOP Card File................................................................. 14

Figure 2-7 15-Slot IOP Card File........................................................................ 15

Figure 2-8 HLAI FTA with Redundant HLAI IOPs................................................ 17

Figure 2-9 Analog Output FTA with Redundant Analog Output IOPs................... 18

Figure 2-10 Standard I/O Link Extender Interconnections

with Nonredundant HPMM................................................................ 20

Figure 2-11 Standard I/O Link Extender Interconnections

with Redundant HPMMs................................................................... 21

Figure 2-12 Long Distance I/O Link Extender Interconnections

with Nonredundant HPMM................................................................ 22

Figure 2-13 Long Distance I/O Link Extender Interconnections

with Redundant HPMMs................................................................... 23

Figure 2-14 Field Termination Assembly (FTA) Sizes............................................ 28

Figure 2-15 Typical Vertical FTA Mounting Channel Layout................................... 30

Figure 2-16 Typical FTA Compression Terminal Connector................................... 31

Figure 2-17 Typical FTA Fixed-Screw Terminal Connector .................................... 32

Figure 2-18 Typical FTA Removable-Screw Terminal Connector............................ 32

Figure 2-19 Crimp-Pin Galvanic Isolation Module Terminal Connector.................... 33

Figure 2-20 Compression-Type Galvanic Isolation Module .................................... 34

Figure 2-21 FTA Marshalling Panel Assembly Layout............................................ 35

Figure 2-22 Standard Power System—Model MU-PSRX03................................... 37

Figure 2-23 Standard Power System—Model MU-PSRX04................................... 38

Figure 2-24 AC Only Power System—Not for CE Compliant Applications............... 40

Figure 2-25 Single Cabinet with Redundant HPMMs............................................ 42

Figure 2-26 Complexed Cabinets with Redundant HPMMs................................... 43

Figure 2-27 Local Complexed Cabinets with Redundant HPMMs .......................... 44

Figure 3-1 Subsystem AC Power and Ground Connections—

Multi-Ground System........................................................................ 49

Figure 3-2 Subsystem AC Power and Ground Connections—

Single-Ground System ..................................................................... 50

Figure 4-1 Field Termination Assembly (FTA) Sizes............................................ 73

Figure 4-2 Field Termination Assembly (FTA) Mounting Dimensions.................... 74

Figure 6-1 Conformal Coating Symbol............................................................. 105

Figure 7-1 I/O Link Extender Adapter Kit.......................................................... 129

Figure 7-2 Two-Port UCN Cable Tap................................................................ 137

Figure 7-3 Four-Port UCN Cable Tap............................................................... 138

Figure 7-4 Eight-Port UCN Cable Tap.............................................................. 138

Figure 8-1 Single-Access Cabinet ................................................................... 142

Figure 8-2 Dual-Access Cabinet...................................................................... 143

Figure 8-3 Single-Access Cabinet Bottom Cable Entry Slots ............................. 144

Figure 8-4 Dual-Access Cabinet Bottom Cable Entry Slots................................ 145

Figure 8-5 Cabinet Interior Dimensions............................................................ 147

Figure 8-6 Typical Single-Access Cabinet Assembly Layout.............................. 148

Figure 8-7 Typical Dual-Access Cabinet Assembly Layout................................. 149

Figure 8-8 7-Slot Card File Installation Dimensions............................................ 150

Figure 8-9 15-Slot Card File Installation Dimensions.......................................... 151

Figure 8-10 Installation of 7-Slot and 15-Slot Card Files....................................... 152

Figure 8-11 Power System Installation Dimensions............................................. 153

Figure 8-12 Typical Vertical FTA Mounting Channel Configurations..................... 156

Figure 8-13 Vertical FTA Mounting Channel Dimensions .................................... 157

Figure 8-14 Vertical FTA Mounting Channel Installation Holes............................. 158

Figure 8-15 Horizontal FTA Mounting Channel Cabinet Layout ........................... 160

Figure 8-16 Horizontal FTA Mounting Channel Dimensions ................................ 161

x HPM Planning 3/98

Page 13

Figures

Figure 8-17 Horizontal FTA Mounting Channel Installation Holes......................... 162

Figure 8-18 Cabinet Floor Planning Template .................................................... 163

Figure 9-1 Single-Access Cabinet................................................................... 166

Figure 9-2 Dual-Access Cabinet...................................................................... 167

Figure 9-3 Cabinet Base Panel Grounding Procedure ...................................... 168

Figure 9-4 Cabinet Panel and Door Grounding Procedure ................................ 168

Figure 9-5 Single-Access Cabinet Bottom Cable Entry ..................................... 169

Figure 9-6 Dual-Access Cabinet Bottom Cable Entry........................................ 170

Figure 9-7 Cabinet Interior Dimensions............................................................ 172

Figure 9-8 Typical Single-Access Cabinet Assembly Layout.............................. 173

Figure 9-9 Typical Dual-Access Cabinet Assembly Layout................................. 174

Figure 9-10 7-Slot Card File Installation Dimensions............................................ 175

Figure 9-11 15-Slot Card File Installation Dimensions.......................................... 176

Figure 9-12 Installation of 7-Slot and 15-Slot Card Files....................................... 177

Figure 9-13 Power System Installation Dimensions............................................. 178

Figure 9-14 FTA Mounting Channel Configurations............................................ 181

Figure 9-15 FTA Mounting Channel Dimensions ................................................ 182

Figure 9-16 FTA Mounting Channel Mounting FTA Installation Holes................... 183

Figure 9-17 Horizontal FTA Mounting Channel Cabinet Layout ........................... 185

Figure 9-18 Horizontal FTA Mounting Channel Dimensions ................................ 186

Figure 9-19 Horizontal FTA Mounting Channel Installation Holes......................... 187

Figure 9-20 Cabinet Floor Planning Template .................................................... 188

Figure 10-1 Single Cabinet with Redundant HPMMs.......................................... 191

Figure 10-2 Dual Cabinets with Redundant HPMMs............................................ 192

Figure 10-3 Redundant HPMM Configuration Cabling ........................................ 193

Figure 10-4 Local/Remote Cabinet Configuration............................................... 196

Figure 11-1 Standard I/O Link Extender Interconnections

with Single HPMM.......................................................................... 199

Figure 11-2 Standard I/O Link Extender Interconnections

with Redundant HPMMs................................................................. 200

Figure 11-3 Long Distance I/O Link Extender Interconnections

with Single HPMM.......................................................................... 201

Figure 11-4 Long Distance I/O Link Extender Interconnections

with Redundant HPMMs................................................................. 202

Figure 11-5 Remote Site Multi-IOP Card File I/O Link Interface Cabling................. 203

Figure 11-6 ST-Type Connector....................................................................... 209

Figure 12-1 LLMux Configuration Interconnections – CE Compliant.................... 218

Figure 12-2 Remote CJR Installation.................................................................. 222

Figure 12-3 Nonincendive RHMUX Configuration Interconnections..................... 226

Figure 12-4 Intrinsically Safe RHMUX Configuration Interconnections.................. 227

Figure 13-1 Serial Device Interface Interconnections.......................................... 234

Figure 14-1 Serial Interface FTA to Modbus Device EIA-232 and EIA-422/485

Interconnections............................................................................ 243

Figure 14-2 Serial Interface FTA to Modbus Device EIA-422/485

Interconnections............................................................................ 244

Figure 14-3 Serial Interface FTA to Peripheral Device EIA-422/485

Interconnections............................................................................ 245

Figure 14-4 Serial Interface FTA to Allen-Bradley Device EIA-232

Interconnections............................................................................ 246

Figure 15-1 Typical Galvanically Isolated FTA...................................................... 259

Figure 15-2 Galvanic Isolation Module................................................................ 260

Figure 15-3 Crimp-Type Galvanic Isolation Module Terminal Connector................ 261

Figure 15-4 Compression-Type Galvanic Isolation Module Terminal Connector .... 262

Figure 15-5 Galvanically Isolated FTA with Auxiliary Connector............................ 266

Figure 15-6 Cabinet with Horizontally Installed FTA Mounting Channels............... 270

3/98 HPM Planning xi

Page 14

Tables

Table 2-1 Card File Models ................................................................................ 5

Table 2-2 Standard Field Termination Assembly Types...................................... 25

Table 2-3 Galvanically Isolated Field Termination Assembly Types...................... 27

Table 3-1 HPM Assembly 24 Vdc Power Usage ................................................ 54

Table 3-2 Single Power System Calculation Example ........................................ 58

Table 3-3 Dual Power System Calculation Example (Power System 1)................ 59

Table 3-4 Dual Power System Calculation Example (Power System 2)................ 60

Table 4-1 Standard FTAs and Associated Assemblies....................................... 75

Table 4-2 Galvanically Isolated FTAs and Associated Assemblies ....................... 78

Table 5-1 Hazardous Area Classifications.......................................................... 84

Table 5-2 HPM Equipment Approved for Use in a Division 2 Area....................... 87

Table 5-3 Nonincendive FTA Types ............................................................... 101

Table 5-4 FTA Cable and Load Parameters..................................................... 102

Table 6-1 Environment Minimum Equipment Requirement .............................. 103

Table 6-2 Harsh Environment Definitions from ANSI/ISA-S71.04-1985............ 104

Table 6-3 Conformally Coated Assembly Model Numbers................................ 107

Table 7-1 Card Files ...................................................................................... 116

Table 7-2 IOPs—Nonconformally Coated ....................................................... 118

Table 7-3 IOPs—Conformally Coated............................................................. 119

Table 7-4 Field Termination Assemblies—Nonconformally Coated................... 120

Table 7-5 Field Termination Assemblies—Conformally Coated......................... 125

Table 7-6 IOP to FTA Cables.......................................................................... 130

Table 7-7 Non-CE Compliant Subsystem Power Cables .................................. 133

Table 7-8 CE Compliant Subsystem Power Cables.......................................... 134

Table 7-9 Power Cables without I/O Link Protector Module.............................. 135

Table 7-10 I/O Link Interface Cable Sets........................................................... 136

Table 11-1 Minimum Bend Radius for Indoor Cable ........................................... 207

Table 11-2 Standard Optical Power Loss.......................................................... 211

Table 11-3 Standard Fiber Optic Cable Losses (@ 850 nm) ............................... 211

Table 11-4 Long Distance Optical Power Loss.................................................. 213

Table 11-5 Long distance Fiber Optic Cable Losses (@ 1300 nm)...................... 213

Table 12-1 LLMux Assembles......................................................................... 216

Table 12-2 RHMUX Assemblies ....................................................................... 223

Table 14-1 Serial Interface FTAs ...................................................................... 241

Table 14-2 Serial Interface EIA-232 Specifications ............................................ 252

Table 14-3 Serial Interface EIA-422/485 Specifications ..................................... 252

Table 15-1 CE Compliant Galvanically Isolated FTAs—Nonconformally Coated ... 256

Table 15-2 CE Compliant Galvanically Isolated FTAs—Conformally Coated ......... 257

Table 15-3 Galvanically Isolated FTA Power Requirements................................ 267

xii HPM Planning 3/98

Page 15

Acronyms

AC.................................................................................................. Alternating Current

ANSI.................................................................... American National Standards Institute

AO........................................................................................................ Analog Output

AWG........................................................................................... American Wire Gauge

CJR........................................................................................ Cold Junction Reference

CMOS ........................................................ Complementary Metal Oxide Semiconductor

DC.......................................................................................................... Direct Current

DISOE........................................................................ Digital Input Sequence of Events

DI............................................................................................................... Digital Input

DO.......................................................................................................... Digital Output

EIA.............................................................................. Electronic Industries Association

EMI.................................................................................. Electromagnetic Interference

FM................................................................................... Factory Mutual Research, Inc.

FTA.................................................................................... Field Termination Assembly

GI ....................................................................................................... Galvanic Isolation

HLAI......................................................................................... High Level Analog Input

HPM...................................................................... High-Performance Process Manager

HPMM....................................................... High-Performance Process Manager Module

IS........................................................................................................... Intrinsic Safety

I/O............................................................................................................ Input/Output

IEC................................................................ International Electrotechnical Commission

IEEE.................................................... Institute of Electrical and Electronic Engineering

ISA.................................................................................. Instrument Society of America

ISO....................................................................... International Standards Organization

LCN............................................................................................ Local Control Network

LFD............................................................................................... Line Fault Detection

LLAI ......................................................................................... Low Level Analog Input

LLMux..................................................................... Low Level Analog Input Multiplexer

MRG...................................................................................... Master Reference Ground

NE........................................................................................... National Electrical Code

NEMA....................................................... National Electrical Manufacturer’s Association

NFPA........................................................................... National Fire Protection Agency

NiCad................................................................................................... Nickel Cadmium

NIM....................................................................................... Network Interface Module

PI............................................................................................................... Pulse Input

PSM........................................................................................... Power Supply Module

PS ......................................................................................................... Power System

PVC.................................................................................................. Polyvinyl Chlorine

PV ..................................................................................................... Process Variable

RHMUX ....................................... Remote Hardened Low Level Analog Input Multiplexer

RTD................................................................................ Resistive Temperature Device

RTU............................................................................................ Remote Terminal Unit

SDI............................................................................................. Serial Device Interface

SI.......................................................................................................... Serial Interface

STI....................................................................................... Smart Transmitter Interface

STIM ................................................................. Smart Transmitter Interface Multivariable

TC......................................................................................................... Thermocouple

UCN...................................................................................... Universal Control Network

UV.............................................................................................................. Ultra Violet

3/98 HPM Planning xiii

Page 16

References

Publication

Title

High-Performance Process Manager

Specification and Technical Data

High-Performance Process Manager

Installation

High-Performance Process Manager

Checkout

High-Performance Process Manager

Service

Process Manager I/O Specification and

Technical Data

Process Manager I/O Installation

TPS System Site Planning

Publication

Number

HP03-500 System Summary - 2 TPS 3010-2

HP20-500 Implementation/

High-Performance Process

Manager - 3

HP20-510 Implementation/

High-Performance Process

Manager - 3

HP13-500 PM/APM/HPM Service - 1 TPS 3061-1

IO03-500 System Summary - 2 TPS 3010-2

PM20-520 Implementation/

High-Performance Process

Manager - 3

SW02-550 System Site Planning - 1 TPS 3020-1

Binder

Title

Binder

Number

TPS 3066-3

TPS 3066-3

TPS 3066-3

Universal Control Network Specification

and Technical Data

Universal Control Network Planning

Universal Control Network Installation

Universal Control Network Guidelines

Local Control Network Planning

LCN System Installation

LCN System Checkout

LCN Guidelines - Implementation,

Troubleshooting, and Service

UN03-500 System Summary - 2 TPS 3010-2

UN02-501 System Site Planning - 1 TPS 3020-1

UN20-500 Installation/Universal Control

Network

UN12-510 Installation/Universal Control

Network

SW02-501 System Site Planning - 1 TPS 3020-1

SW20-500 LCN Installation TPS 3025

SW20-510 LCN Installation TPS 3025

LC09-510 LCN Installation TPS 3025

TPS 3041

TPS 3041

xiv HPM Planning 3/98

Page 17

1.1 Overview

Section 1 – Introduction

Section contents

1. 1 Overview............................................................................................... 1

The manual’s purpose

The manual’s contents

The topics covered in this section are:

Topic See Page

This manual is intended for planning the installation of a High-Performance

Process Manager (HPM) subsystem at a TPS

system site. The

High-Performance Process Manager subsystem is a device on the Universal

Control Network (UCN) that includes the Network Interface Module

(NIM). Process Managers (PMs), Advanced Process Managers (APMs),

and Logic Managers (LMs) may also be resident on the network.

Planning includes the consideration of the High-Performance Process

Manager cabinet layout, process wiring techniques, Division 2 environment

equipment approval, conformal coating of the assemblies to protect against

a corrosive environment, HPMM and IOP redundancy, and unique

hardware features, such as fiber optic I/O Link Extenders, Low Level

Analog Input Multiplexer FTAs, Serial Device Interface FTAs, Serial

Interface FTAs, and Galvanically Isolated FTAs.

Information not covered

Neither installation, power on checkout, or service of the

High-Performance Process Manager, nor planning for the Local Control

Network (LCN) is addressed in this manual. See the related reference

documentation for information about these topics.

3/98 HPM Planning 1

Page 18

2 HPM Planning 3/98

Page 19

2.1 Overview

Section 2 – HPM Description

Section contents

2. 1 Overview............................................................................................... 3

2.2 Card Files.............................................................................................. 5

2.2.1 HPMM Card Files ................................................................................... 6

2.2.2 Input/Output Processor (IOP) Card Files................................................ 13

2. 3 Input/Output Processor (IOP) Cards...................................................... 17

2.3.1 IOP Redundancy ................................................................................. 18

2. 4 I/O Link Extender (Fiber Optic Link)....................................................... 20

2.5 Field Termination Assemblies (FTAs) .................................................... 25

2.6 Power Systems................................................................................... 36

2. 7 Cabinet Configurations ........................................................................ 41

HPM major assemblies

The topics covered in this section are:

Topic See Page

The High-Performance Process Manager subsystem (HPM) consists of

major assemblies described in the following subsections. The major

High-Performance Process Manager assemblies are

• High-Performance Process Manager Module (HPMM) card file

• Input/Output Processor (IOP) card file

• Input/Output Processor (IOP) card

• I/O Link Extender

• Field Termination Assembly (FTA)

• Power System

Continued on next page

3/98 HPM Planning 3

Page 20

2.1 Overview, Continued

P

P

P

Digital

P

P

P

High L

l

Anal

L

l

Digital

P

Digital

P

P

P

P

High L

l

Anal

L

l

Digital

P

Digital

P

P

P

P

High L

l

Anal

L

l

Digital

P

P

Digital

P

P

P

High L

l

Anal

L

l

Digital

P

Digital

P

P

P

P

High L

l

Anal

L

l

Digital

P

Digital

P

P

P

P

High

High

L

l

Digital

P

P

Nonredundant HPM

cabinet layout

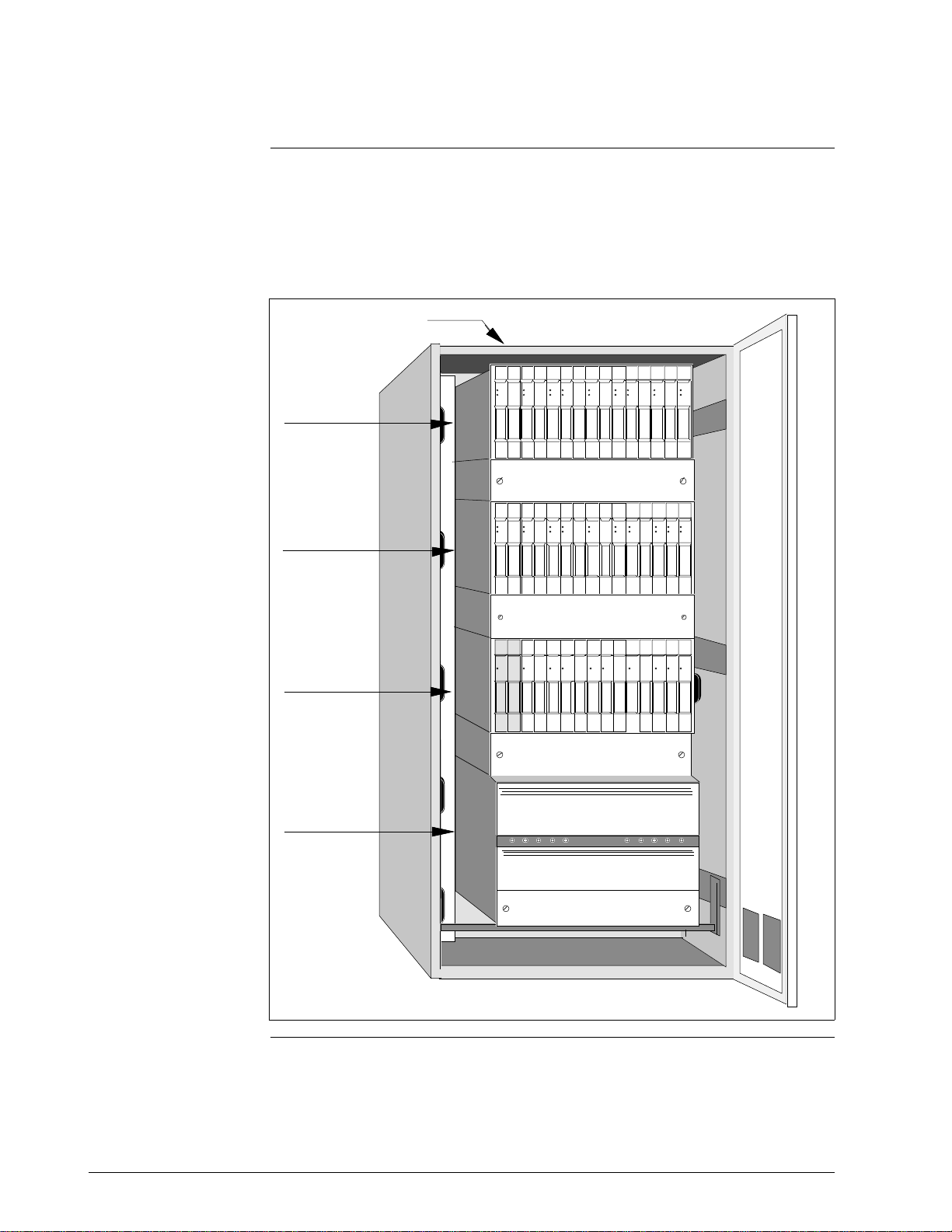

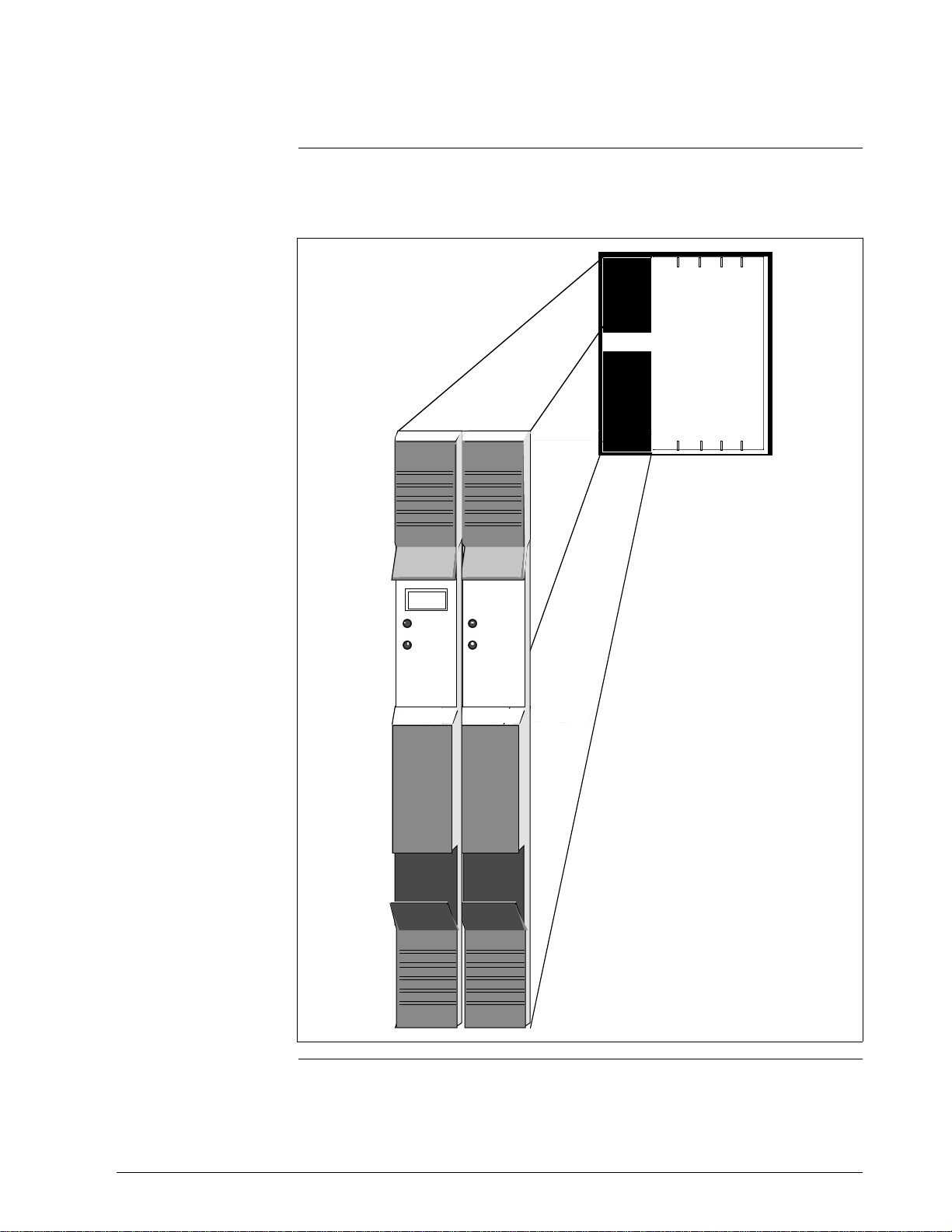

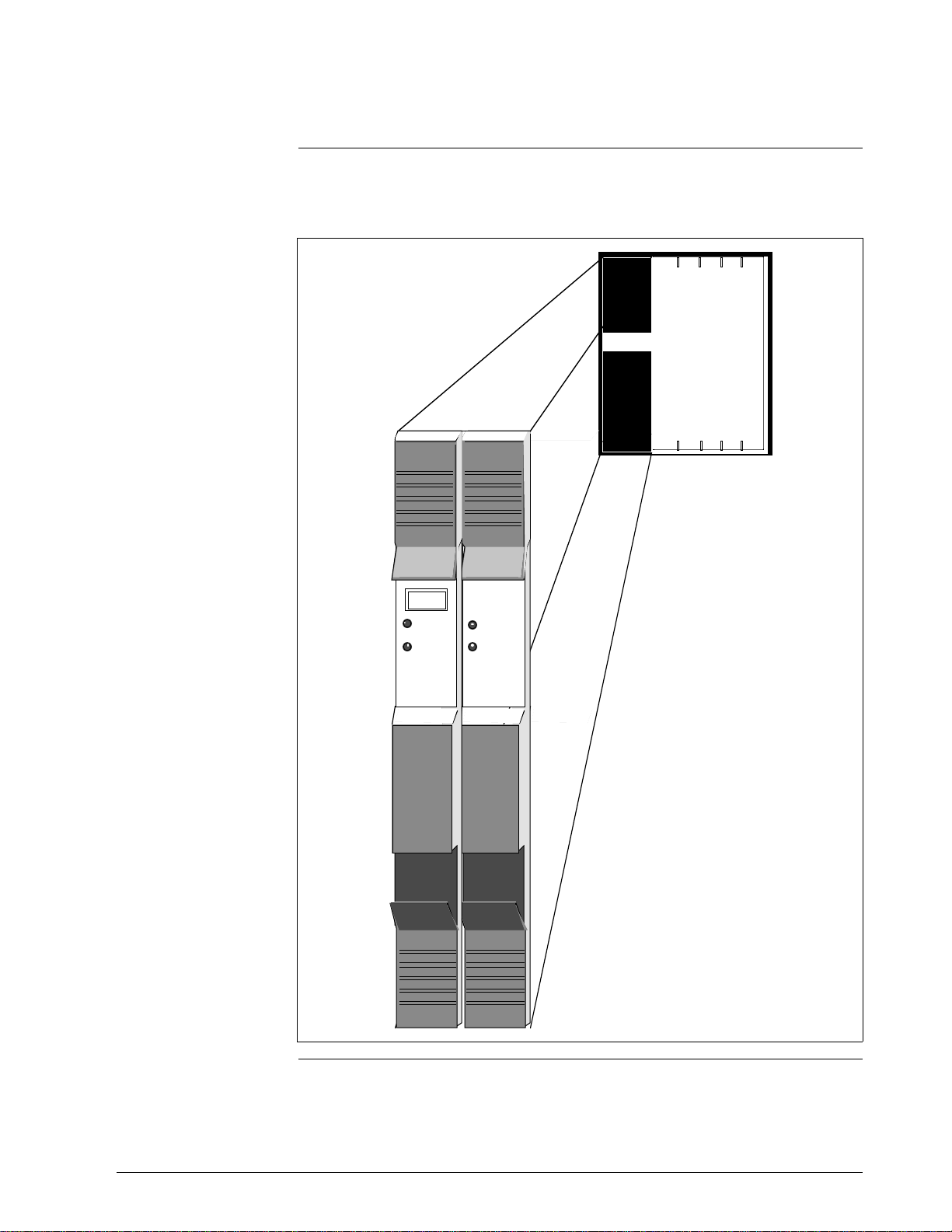

Figure 2-1 is an illustration of a single High-Performance Process Manager

cabinet containing a nonredundant High-Performance Process Manager

Module (HPMM) with supporting assemblies. The HPMM cards (2) and

the IOPs cards are installed in 15-Slot HPMM card files. IOP cards occupy

the IOP card files.

Figure 2-1 Nonredundant HPMM Cabinet Layout

FTAs are installed in the

rear on an FTA Mounting

Channel.

ower

Power

Power

Power

Status

Status

Status

Status

Analog

Low Level

Digital

Digital

Output

Analog

Input

Output

Input

ower

ower

ower

ower

Status

Status

Status

Status

og

ow Leve

Output

Input

Analog

Output

Input

IOP Card File #2

IOP Card File #1

ower

ower

Power

Power

Status

Status

High Level

Analog

Analog

Input

Output

ower

ower

Status

Status

eve

og

Output

Analog

Input

Power

Power

Power

Status

Status

Status

Status

Status

Low Level

Analog

Input

ower

Status

ow Leve

Analog

Input

Analog

High Level

Digital

Digital

Output

Analog

Input

Output

Input

ower

ower

ower

ower

Status

Status

Status

Status

eve

og

Output

Analog

Input

Output

Input

Power

Power

Power

Power

Status

Status

Status

Status

Low Level

High Level

Digital

Digital

Analog

Analog

Input

Output

Input

Input

ower

ower

ower

ower

Status

Status

Status

Status

eve

ow Leve

Analog

Input

Analog

Output

Input

Input

HPMM Card File

Power System

Performan

Comm/Cntl

ower

ower

ower

ower

ower

ower

ower

ower

ower

ower

ower

ower

Status

Status

Status

Status

Status

ow Leve

Analog

Input

Performan

Analog

Output

I/O Link

Input

Input

ower

Status

Status

Status

Status

Status

eve

og

ow Leve

Output

Analog

Input

Analog

Output

Input

Input

ower

Status

eve

ower

Status

Status

Status

Status

og

ow Leve

Output

Input

Analog

Output

Input

32747

4 HPM Planning 3/98

Page 21

2.2 Card Files

Introduction

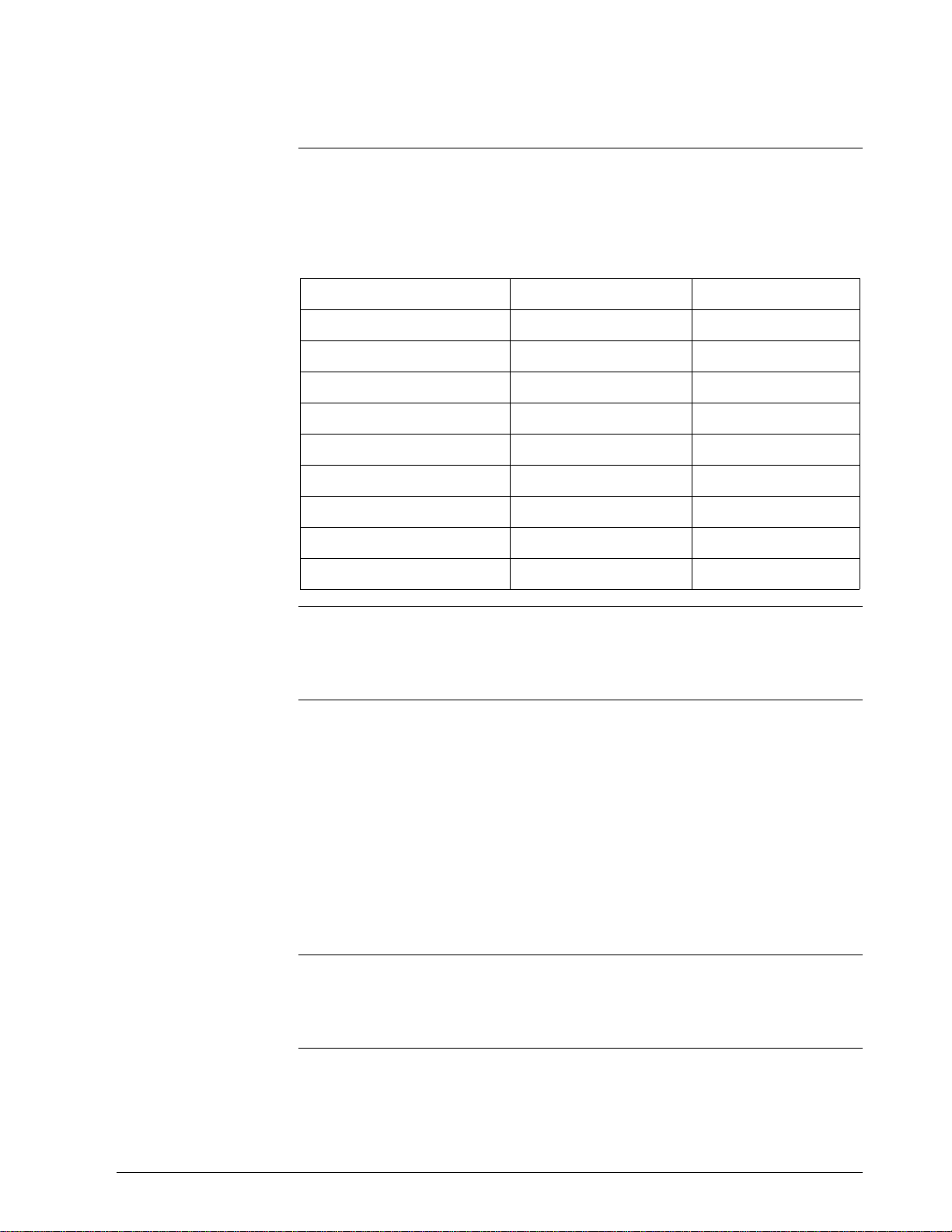

There are nine card file models. Three models are not CE Compliant and

six models are CE Compliant. Table 2-1 lists the nine card file models. All

models are also available with conformal coating (a model number with a

prefix of MC, rather than MU).

Table 2-1 Card File Models

Card File Description CE Compliant Non-CE Compliant

Left 7-Slot HPMM or IOP N/A MU-HPFH01

Right 7-Slot HPMM or IOP N/A MU-HPFH11

15-Slot HPMM or IOP N/A MU-HPFX02

Left 7-Slot HPMM MU-HPFH03 N/A

Right 7-Slot HPMM MU-HPFH13 N/A

15-Slot HPMM MU-HPFX03 N/A

Left 7-Slot IOP MU-HPFI03 N/A

Right 7-Slot IOP MU-HPFI13 N/A

15-Slot IOP MU-HPFI23 N/A

Non-CE Compliant card

file models

CE Compliant card file

models

Conversion kit

The non-CE Compliant card file models can be designated as an HPMM

card file or an IOP card file by either installing an HPMM card set in the

two left-most card slots or installing IOP cards.

Unlike the non-CE Compliant card file models, the CE Compliant card file

models are designated either an HPMM card file or an IOP card file because

even though their is no electrical difference in the backpanel, they differ

mechanically. The addition of a ground plate and filtered IOP connectors in

the two left-most slots prohibits the installation of an HPMM card set.

The card file is designated an IOP card file when the ground plate and

filtered connectors are present.

The card file is designated an HPMM card file when the ground plate and

filtered connectors are absent.

A CE Compliant HPMM card file can be converted to an IOP card file with

a model MU-ZPFI03 upgrade kit. The kit adds 2 filtered IOP adapter

connectors to the two left-most card slots and a ground plate extension.

3/98 HPM Planning 5

Page 22

2.2.1 HPMM Card Files

Three types of HPM

card files

HPMM description

There are three types of HPMM card files. The two left-most slots of each

type are populated by the three assemblies that comprise the HPMM. The

remaining slots accommodate IOPs.

If the card file is a non-CE Compliant card file, the two left-most slots of

each type can also accommodate IOPs with no alterations. The card file is

then designated an IOP card file.

The High-Performance Process Manager Module (HPMM) is composed of

two card assemblies that install in the two left-most slots in a 7-Slot or

15-Slot card file, and a UCN interface module that mounts and connects to

the 50-pin connector that is directly below the left-most card.

The three HPMM assemblies are identified as follows:

• High-Performance Communications/Control (High-Performance

Comm/Control) card

• High-Performance I/O Link Interface (High-Performance I/O Link) card

• High-Performance UCN Interface (HPM UCN Interface) module

The HPM UCN Interface module connects to the 50-pin connector below

the High-Performance Comm/Control card.

Left 7-Slot HPMM card

file description

The Left 7-Slot card file accepts the two HPMM cards and the HPM UCN

Interface module that comprise the HPMM, and accommodates up to five

IOP cards. The card slots are numbered 1 through 7, starting at the

left-most position.

The High-Performance Comm/Control and High-Performance I/O Link

cards occupy slots 1 and 2, while the HPM UCN Interface module mounts

below slot 1 and connects to its 50-pin connector.

Slots 3 through 7 can accommodate IOP cards. The IOP card slots assume

numerical I/O Link Interface addresses of 3 through 7 and binary I/O Link

Interface addresses of 2 through 6.

Continued on next page

6 HPM Planning 3/98

Page 23

2.2.1 HPMM Card Files, Continued

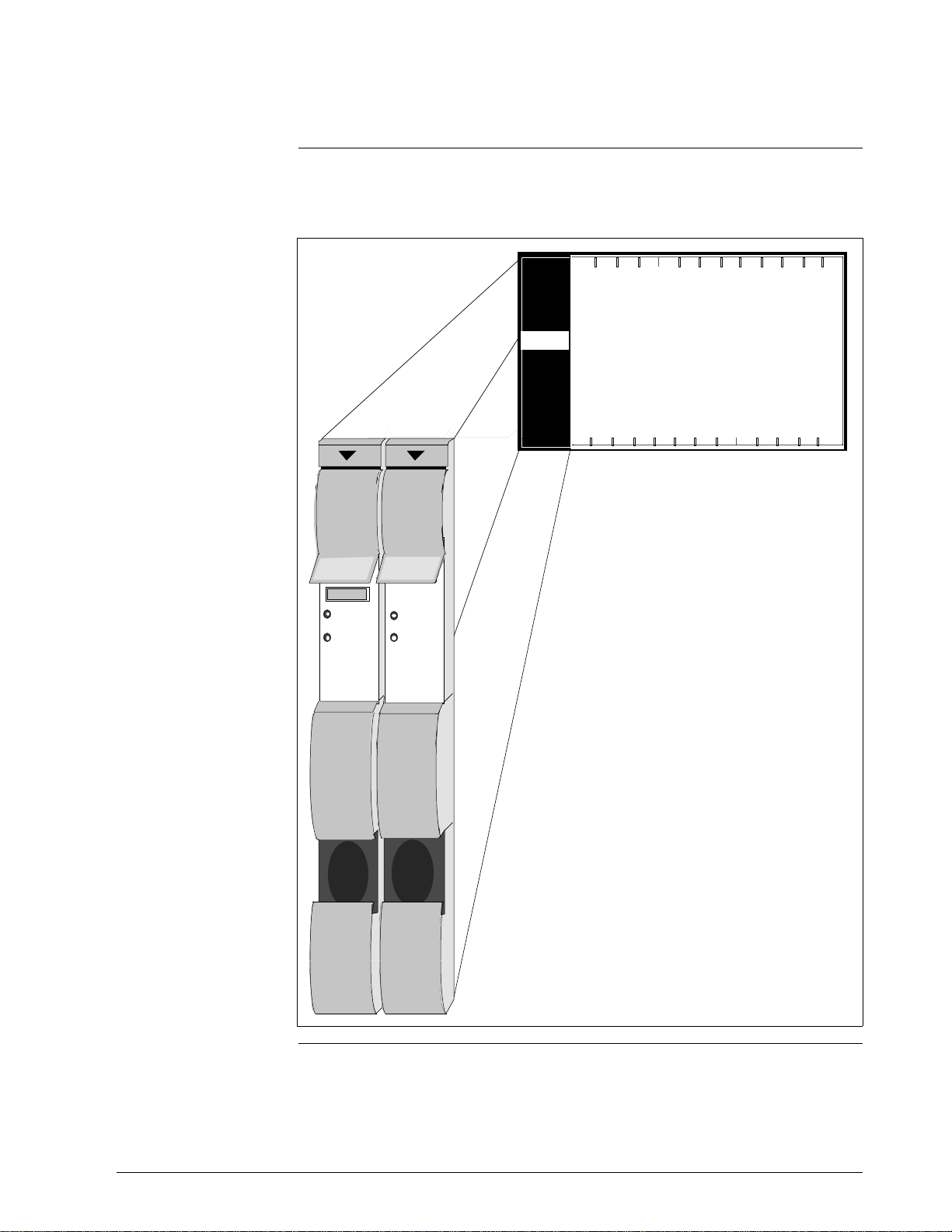

Left 7-Slot HPMM

card file illustration

Figure 2-2 is an illustration of a Left 7-Slot HPMM card file and the two

HPMM cards that occupy slots 1 and 2.

Figure 2-2 Left 7-Slot HPMM Card File

1A15

Power

Status

High

Performance

Comm/Cntrl

Power

Status

High

Performance

I/O Link

HPMM

1 2 3 4 5 6 7

IOPs

16000

Continued on next page

3/98 HPM Planning 7

Page 24

2.2.1 HPMM Card Files, Continued

Right 7-Slot HPMM card

file description

The description of the Right 7-Slot HPMM card file is identical to the Left

7-Slot HPMM card file, except the two HPMM cards and the UCN

interface module occupy slots 9 and 10. The card slots are numbered

9 through 15.

Slots 11 through 15 accommodate IOP cards. The IOP card slots assume

numerical I/O Link Interface addresses of 11 through 15 and binary

I/O Link Interface addresses of 10 through 14.

Continued on next page

8 HPM Planning 3/98

Page 25

2.2.1 HPMM Card Files, Continued

Right 7-Slot HPMM

card file illustration

Figure 2-3 is an illustration of a Right 7-Slot HPMM card file and the two

HPMM cards that occupy slots 9 and 10.

Figure 2-3 Right 7-Slot HPMM Card File

1A15

Power

Status

High

Performance

Comm/Cntrl

Power

Status

High

Performance

I/O Link

HPMM

9 10 11 12 13 14 15

IOPs

16001

Continued on next page

3/98 HPM Planning 9

Page 26

2.2.1 HPMM Card Files, Continued

15-Slot HPMM card file

description

The 15-Slot card file accepts the two HPMM cards and the UCN interface

module that comprise the HPMM, and accommodates up to thirteen IOP

cards. The card slots are numbered 1 through 15, starting at the left-most

position.

The High-Performance Comm/Control and High-Performance I/O Link

cards occupy slots 1 and 2, while the HPM UCN Interface module mounts

below slot 1 in its 50-pin connector.

Slots 3 through 15 can accommodate IOP cards. The IOP card slots

assume numerical I/O Link Interface addresses of 3 through 15 and binary

I/O Link Interface addresses of 2 through 14.

When populated with the HPMM cards, the card file is designated a 15-Slot

HPMM card file.

Continued on next page

10 HPM Planning 3/98

Page 27

2.2.1 HPMM Card Files, Continued

r

s

r

s

15-Slot HPMM

card file illustration

Figure 2-4 is an illustration of a 15-Slot HPMM card file and the two

HPMM cards that occupy slots 1 and 2.

Figure 2-4 15-Slot HPMM Card File

Powe

Statu

High

Performance

Comm/Cntrl

Powe

Statu

High

Performance

I/O Link

HPMM

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

IOPs

32745

Continued on next page

3/98 HPM Planning 11

Page 28

2.2.1 HPMM Card Files, Continued

7-Slot HPMM card file

usage

15-Slot HPMM card file

usage

HPMM functionality

The two types of 7-Slot HPMM card files are intended to be used in a small

HPM subsystem.

When the subsystem consists of nonredundant HPMMs, a Left 7-Slot

HPMM card file must be installed. For a subsystem that requires redundant

HPMMs, Left and Right 7-Slot HPMM card files are installed. Both card

files are assigned the same the same I/O Link Interface address. There is no

slot 8 because the card file slots are numbered 1 through 7 and 9 through

15.

The 15-Slot HPMM card file is intended for use in a larger HPM

subsystem, either with nonredundant or redundant HPMMs. Unlike the

7-Slot HPMM card file, there is no “loss” of a card slot.

The HPMM provides the following functions:

• Communications with the Local Control Network (LCN) Network

Interface Module (NIM) through the Universal Control Network (UCN)

• A Communications processor ( Motorola 68LC040)

• Communications through the I/O Link Interface with Input/Output

Processors (IOPs) and I/O Link Extenders

• A Control processor (Motorola 68040)

• Separate and shared memory for the Communications and Control

processors

• An I/O Link processor (Intel 80C32) with SRAM

• HPMM redundancy control

2.2.2 Input/Output Processor (IOP) Card Files

IOP card file

descriptions

Non-CE Compliant card

files

CE Compliant card files

The 7-Slot and 15-Slot IOP card files are electrically identical to the HPMM

card files, except that an HPMM card set is not installed in the card file.

IOPs can be installed in the two left-most card slots.

Non-CE Compliant HPMM and IOP card files differ only in the application.

Electrically and mechanically, their backpanels are the same. The card file

model numbers are the same.

CE Compliant HPMM and IOP card files differ mechanically. IOP card

files have filtered IOP connectors and connector ground plates. Electrically,

their backpanels are the same. The card file model numbers are different.

Continued on next page

12 HPM Planning 3/98

Page 29

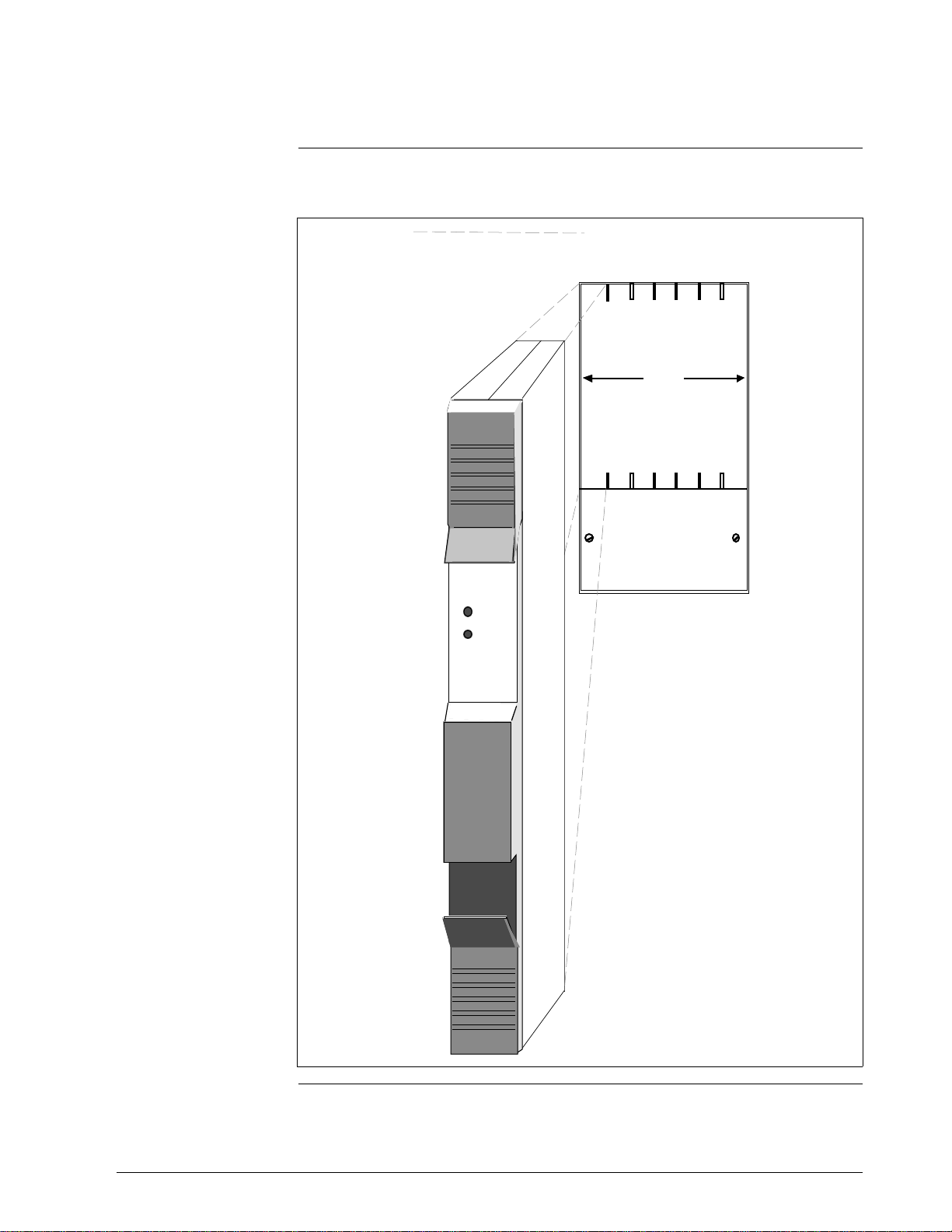

2.2.2 Input/Output Processor (IOP) Card Files, Continued

Left 7-Slot IOP card file

Figure 2-5 illustrates a Left 7-Slot IOP card file.

Figure 2-5 Left 7-Slot IOP Card File

7 IOPs

1234567

Power

Status

Analog

Output

16004

Continued on next page

3/98 HPM Planning 13

Page 30

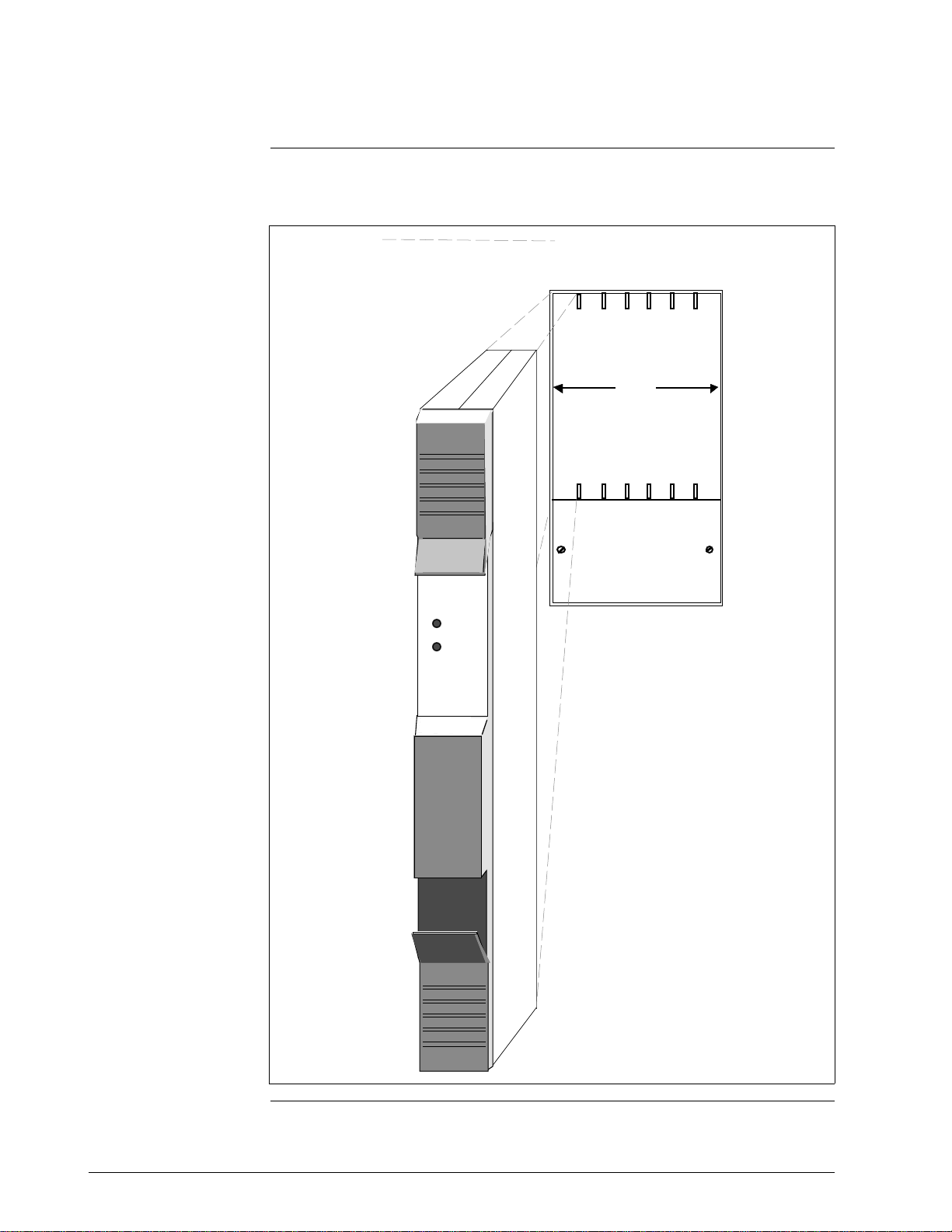

2.2.2 Input/Output Processor (IOP) Card Files, Continued

5

Right 7-Slot IOP card

file

Figure 2-6 illustrates a Left 7-Slot IOP card file.

Figure 2-6 Right 7-Slot IOP Card File

7 IOPs

9 10111213141

Power

Status

Analog

Output

16005

Continued on next page

14 HPM Planning 3/98

Page 31

2.2.2 Input/Output Processor (IOP) Card Files, Continued

15-Slot IOP card file

Figure 2-7 illustrates a 15-Slot IOP card file.

Figure 2-7 15-Slot IOP Card File

15 IOPs

123456789101112131415

Power

Status

Analog

Output

32962

3/98 HPM Planning 15

Page 32

2.3 Input/Output Processor (IOP) Cards

Types of Input/Output

Processors (IOPs)

Card file configurations

There are thirteen types of Input/Output Processor (IOP) card assemblies.

Some IOP card types interface with more than one type of Field

Termination Assembly (FTA). The functional types of IOPs are

• High Level Analog Input (HLAI)

• Low Level Analog Input (LLAI)

• Low Level Analog Multiplexer (LLMux)

• Remote Hardened Low Level Analog Multiplexer (RHMUX)

• Digital Input (DI)

• Analog Output (AO)

• Digital Output (DO)

• Smart Transmitter Interface (STI)

• Smart Transmitter Interface Multivariable (STIM)

• Pulse Input (PI)

• Digital Input Sequence of Events (DISOE)

• Serial Device Interface (SDI)

• Serial Interface (SI)

Additional IOP card file slots can be added to any High-Performance

Process Manager subsystem. Each IOP card file accommodates up to 7 or

15 IOPs as illustrated in Figures 2-5 through 2-7. A total of eight 15-Slot

card files or 7-Slot card file pairs (Left and Right), including HPMM card

files, can exist in a High-Performance Process Manager subsystem.

However, the limit is eight because each 15-Slot card file and pair of 7-Slot

card files must be assigned an I/O Link Interface address between 0 and 7.

IOP card files can be installed at remote locations with the use of fiber optic

I/O Link Extenders, as well as locally in the cabinet or cabinet complex

containing the HPMM card file(s).

A total of 40 primary IOPs, 40 secondary (redundant) IOPs, and 3 I/O Link

Extenders (a maximum of 8 I/O Link Extender cards) can exist in a single

High-Performance Process Manager subsystem.

16 HPM Planning 3/98

Page 33

2.3.1 IOP Redundancy

IOP redundancy

Redundant HLAI IOPs

The HPM subsystem supports IOP redundancy for the following types of

IOPs:

• High Level Analog Input (HLAI)

• Smart Transmitter Interface (STI or STIM)

• Analog Output (AO)

• Digital Input (DI)

• Digital Input Sequence of Events (DISOE)

• Digital Output (DO)

Presently, not all Digital Input and Digital Output IOP models support

redundancy.

A pair of IOPs can be connected in a redundant configuration with both

IOPs connected by separate cables to the same FTA. Figure 2-8 illustrates

an HLAI FTA that interfaces with a pair of HLAI IOPs that are installed in

separate card files.

Figure 2-8 HLAI FTA with Redundant HLAI IOPs

Primary

HPMM Card File

Secondary

HPMM Card File

J15

J1

Field Wiring

Terminals

Model HLAI FTA

3/98 HPM Planning 17

J2

Redundancy

J15

32755

Continued on next page

Page 34

2.3.1 IOP Redundancy, Continued

Redundant AO IOPs

Output type FTAs can also interface with two IOPs with separate cables,

and an automatic selector switch on the FTA selects which IOP’s output

drives the field wiring terminal connectors on the FTA. Figure 2-9 is an

illustration of an Analog Output (AO) FTA interface with two Analog

Output IOPs.

Figure 2-9 Analog Output FTA with Redundant Analog Output IOPs

Primary

HPMM Card File

J15

Secondary

HPMM Card File

J15

Field Wiring

Terminals

J1

J2

J3

Redundancy Model

Analog Output FTA

32756

18 HPM Planning 3/98

Page 35

2.4 I/O Link Extender (Fiber Optic Link)

Introduction

Features

Remote card files

Fiber optic cable length

The I/O Link Extender provides the ability to locate 7-Slot or 15-Slot IOP

card files and associated FTAs up to 8 kilometers (5 miles) from the

HPMM(s). Two types of I/O Link Extenders and their associated fiber

optic couplers are available, the “Standard” I/O Link Extender that provides

up to a 1.3 kilometer (4000 feet) link, and the “Long Distance” I/O Link

Extender which provides up to an 8 kilometers (5 miles) link. The

connection is made using a pair of fiber optic transmission cables, driven

and terminated by a fiber optic coupler that mates with the connector located

directly below the card file slot in which the I/O Link Extender card is

installed.

An I/O Link Extender consists of two pairs I/O Link Extender cards, one

for Link A and one for Link B, and associated fiber optic couplers at each

end of the fiber optic link. The I/O Link Extender cards and their fiber optic

couplers occupy two slots in an HPMM or IOP card file.

Every remote card file, or complex of IOP card files, requires two I/O Link

Extender cards and two fiber optic couplers, one for Link A and one for

Link B.

The maximum fiber optic cable length is dependent upon the number of

splices and quality of the cable (dB loss per meter of cable). This maximum

can be between 0.98 and 1.3 kilometers for the Standard I/O Link Extender

and 8 kilometers for the Long Distance I/O Link Extender.

I/O Link Extender

planning

Standard I/O Link

Extender

I/O Link Extender planning can be found in Section 11 in this manual.

Each Standard I/O Link Extender card has an associated fiber optic coupler

that can drive up to three pair of fiber optic cables. Each cable pair is

terminated by a fiber optic coupler that terminates one fiber optic pair.

The Standard I/O Link Extender card will drive and terminate Link A or

Link B, depending upon the card file number and slot number number. If

the card file number and slot number number are both odd or both even, the

card will drive Link A. If the card file number and slot number number are

not both odd or both even, the card will drive Link B.

Two Standard I/O Link Extender cards, connecting up to six remote card

files, can be installed in a HPMM card file, but the maximum number of

primary IOPs is still 40 (plus 40 redundant IOPs).

Continued on next page

3/98 HPM Planning 19

Page 36

2.4 I/O Link Extender (Fiber Optic Link), Continued

e

Standard I/O Link

Extender connections

nonredundant HPMM

Figure 2-10 illustrates the interconnections for a Standard I/O Link Extender

in a High-Performance Process Manager that contains a nonredundant

HPMM.

Figure 2-10 Standard I/O Link Extender Interconnections with Nonredundant HPMM

Central Site

HPMM Card Fil

B

A

B

IOP Card Files

Remote Site 1

A

Remote Site 2

A

B

Remote Site 3

B

A

NOTE

The following High-Performance Process Manager subsystem configuration is assumed.

1. The HPMM card file is configured as card file #1 (I/O Link address of 0).

2. Remote Site #1's IOP card file is configured as card file #2 (I/O Link address of 1).

3. Remote Site #2's IOP card file is configured as card file #3 (I/O Link address of 2).

4. Remote Site #3's IOP card file is configured as card file #4 (I/O Link address of 3).

Continued on next page

32777

20 HPM Planning 3/98

Page 37

2.4 I/O Link Extender (Fiber Optic Link), Continued

e

J42

J43

Standard I/O Link

Extender connections

Figure 2-11 illustrates the interconnections for a Standard I/O Link Extender

in a High-Performance Process Manager that contains redundant HPMMs.

redundant HPMMs

Figure 2-11 Standard I/O Link Extender Interconnections with Redundant HPMMs

Central Site

Redundant HPMM Card File

B

Primary HPMM Card Fil

I/O Link

Cables

IOP Card Files

A

B

B

Remote Site 1

Remote Site 2

A

J42

J43

A

A

B

NOTE

The following High-Performance Process Manager subsystem configuration is assumed.

1. The lower HPMM card file is configured as card file #1 (I/O Link Address of 0).

2. The upper HPMM card file is configured as card file #2 (I/O Link Address of 1).