Page 1

HMR4007

SENSOR PRODUCTS

HMR4007

Linear Position Sensor

User’s Guide

Solid State Electronics Center

• www.magneticsensors.com • (800) 323-8295 • Page 1

Page 2

HMR4007

SENSOR PRODUCTS

INTRODUCTION

The Honeywell HMR4007 is an electronic linear position sensing solution for use in commercial and industrial

application environments. A stationary array of Honeywell’s magnetoresistive (MR) sensors is utilized to quickly and

accurately monitor the position of a small magnet attached to a moving object such as a valve stem or hydraulic

cylinder. The use of a sensor array makes the solution highly insensitive to many environmental influences such as

magnet strength, alignment, run out, and temperature. This solution is easily integrated into systems using a highly

reliable serial interface or a 12-bit analog output (with over-range error indication).

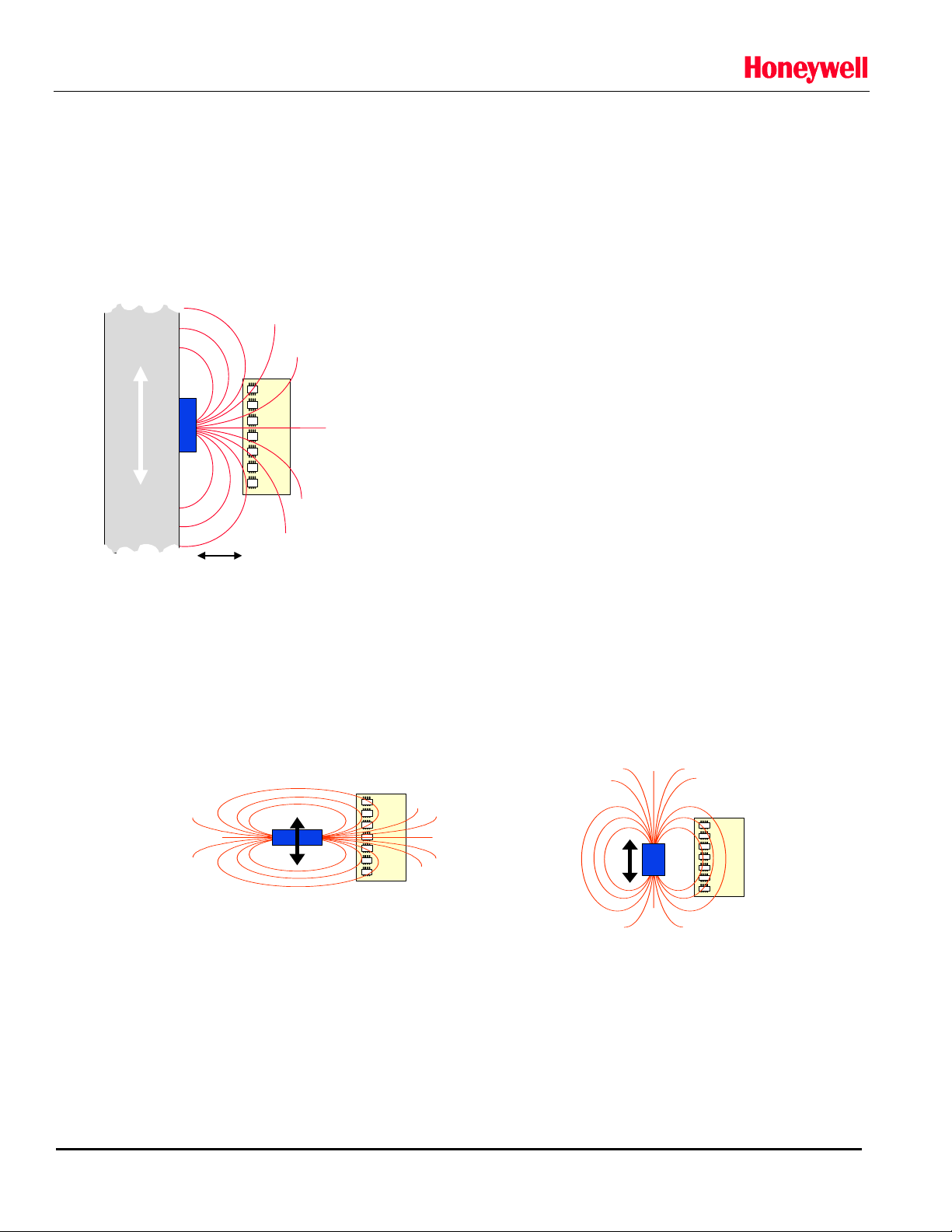

In normal operation, a small target magnet is mounted to the

moving object whose position is to be monitored and the sensor

array is held stationary. The exact standoff distance (gap) is

arbitrary (between 1/2” to 1-1/2”) as the embedded software is

highly tolerant of this gap. The sensed axis is parallel to the long

axis of the sensor board. The embedded software then

calculates the position of the magnetic center of the target

moving object

N

stationary sensor card

~0.5 - 1.5”

magnet as a function of its distance along the axis of the board.

The result is expressed as a 12-bit unsigned integer (or as a 12bit analog voltage). In the example to the left, if the center of the

magnet was aligned with the center of the bottom-most sensor in

the array, the result would be interpreted as a position of “0” while

alignment with the top-most sensor would be interpreted as a

position of “4095”. To convert the reading to engineering units,

the reported position is divided by 4095 and then multiplied by the

span of the sensors (69.7mm or 2.75”). If we call the reported

position “x”, then the position in engineering units would be:

Position in mm = (x / 4095) * 69.6

Position in inches = (x / 4095) * 2.75

The above example shows a magnet oriented in what is called the “radial” mode, where the magnetic poles point

towards the sensor card. The embedded software is also capable of operating with a magnet oriented in the axial

mode where the magnet poles point along the axis of the sensor as seen below. The sensor card, however, does

not automatically detect the magnet mode, and a status bit in the embedded code must be set to configure the

HMR4007. Software tools are available from Honeywell to easily accomplish this.

N

S

Radial mode magnet “Axial” mode magnet

The orientation of the north and south poles is arbitrary, and the embedded software is highly tolerant of the magnet

geometry so that rectangular bar magnets or cylindrical magnets can be used equally well. Cylindrical magnets in

the axial mode are particularly attractive because the magnetic field is symmetrical with respect to rotation about the

center axis without loss of position accuracy.

The magnet should have a minimum length of 23mm (0.91 inches) along the axis of the travel. Shorter magnets,

however, can be used with some increase in the minimum gap between the magnet and sensor board as long as a

minimum field strength of 80 gauss and an apparent magnet length of 23 mm is maintained at the sensor board.

More on apparent magnet length can be found in the application notes at the end of this document.

N

S

Solid State Electronics Center

• www.magneticsensors.com • (800) 323-8295 • Page 2

Page 3

HMR4007

SENSOR PRODUCTS

SPECIFICATIONS

Characteristics Conditions

Min Typ Max Units

General

Accuracy 0.2 0.1 mm

Resolution 0.1 mm

Hysteresis 0.01 mm

Repeatability 0.01 0.1 mm

Update Rate 10 30 Hz

Standoff

Magnetic Field

Range magnetic field at the sensor array 80(note 1) gauss

length apparent magnet length at sensor array 23

Orientation Axial (note 2)

Electrical

Input Voltage Unregulated 6 28 VDC

Current 15 20 mA

Digital Interface

Baud Rate nonstandard synchronous serial interface 1000 21,000 Bits / sec.

Signaling Level TTL levels ( “1” )

Connector In-Line 6-Pin Block (0.1” spacing)

Analog Interface

Analog Output D/A output 0 2.5 VDC

Update Rate 10 30 Hz

Signaling Level TTL levels ( “1” )

Connector In-Line 4-Pin Block (0.1” spacing)

Physical

Dimensions Circuit Board Assembly

Weight HMR4007 16.5 grams

Environment

Temperature Operating

Note 1: The standoff distance between the sensor board and the target magnet is highly variable. A magnet of sufficient strength,

however, must be used to maintain a magnetic field strength of 80 gauss (min.) at the sensor array and an apparent

magnet length of 23 mm.

Note 2: Sensor boards are factory calibrated in the axial mode using a 27mm cylindrical magnet. Operation in the radial mode

must be configured by the user.

Note 3: cf. "Magnet Considerations" (pg. 8)

Distance (gap) between the target

magnet and the sensor board

( “0” )

( “0” )

(including connectors)

Storage

0.1 5

(note 3)

3.5

-0.3

3.5

-0.3

40.0 x 80.0 x

12.0

-40

-55

-

-

(note 1)

5.0

1.5

5.0

1.5

+70

+125

mm

mm

VDC

VDC

VDC

VDC

mm

°C

Solid State Electronics Center

• www.magneticsensors.com • (800) 323-8295 • Page 3

Page 4

HMR4007

SENSOR PRODUCTS

PIN CONFIGURATION

Pin Number Pin Name Description

Digital Interface

1 RTS Serial Clock Output

2 Data_Out Serial Data Output

3 Data_In Serial Data Input

4 CTS Serial Clock Input

5 Power Unregulated Power Input (+6 to +28 VDC) (see note 1)

6 GND Power and Signal Ground

Analog Interface

1 Power Unregulated Power Input (+6 to +28 VDC) (see note 2)

2 Analog Out 0 - 2.5 VDC analog output

3 Position Valid TTL level (0 = position invalid, 1 = position valid)

4 GND Power and Signal Ground

Jumper Block #1

2-5 Note 1 Analog Output port selected as power source

3-6 Note 1 Serial Communications port selected as power source

Note 1: The board contains three interface connectors for digital and/or analog communications. Power is supplied to the board

through any one of these connectors and is selected by jumper block #1. All of the ground connections on all three

ports are common to the circuit ground and are not affected by the jumper position. Only ONE of the three positions on

JP1 should be shorted at a time. Shorting more than one may result in excessive power supply currents and board

damage.

CIRCUIT DESCRIPTION

The HMR4007 Linear Position Sensor circuit board includes all of the basic sensors and electronics to provide a

digital indication of position of a target magnet. The HMR4007 starts with an array of seven Honeywell HMC1501

single axis magnetoresistive (MR) sensors to determine the field geometry and direction of a target magnet attached

to the moving part of a device under test. These sensors are supplied power by a constant voltage source, and the

use of an array of sensors helps to maintain accuracy over temperature and run-out. The sensor outputs are routed

to a multiplexed Analog to Digital Converter (ADC) integrated circuit. A microcontroller integrated circuit periodically

queries the multiplexed ADC and performs sensor offset and gain corrections and computes the position of the target

magnet as a function of the distance of travel along the long axis of the sensor board. The position data, along with

an error bit, is available thought the serial interface or is present on the Digital to Analog Converter (DAC) output port.

The serial interface is not needed in order to use the board’s stand-alone analog output. The microcontroller

also performs the external serial data interface and other housekeeping functions. An onboard EEPROM integrated

circuit is employed as a nonvolatile storage to retain necessary data and configuration variables for best performance.

The HMR4007 uses an on-board low drop out (LDO) +5 volt regulator so that a regulated +5 volt power supply or an

unregulated power supply in the range of +6VDC to +28VDC can be used. The power is supplied to the board

through one of the three user ports being (serial, analog, or USB) and a jumper is used to select which port is the

power source. Only one jumper should be in place at any one time as the board does not have over current

protection and use of more than one jumper can result in excessive power supply currents and board damage.

Solid State Electronics Center

• www.magneticsensors.com • (800) 323-8295 • Page 4

Page 5

HMR4007

)

)

2

3

SENSOR PRODUCTS

PHYSICAL CHARACTERISTICS

The circuit board for the HMR4007 Linear Position Sensor is approximately 340mm by 80mm. A 6-pin right angle

connector (J1) and two 4-pin connectors (J2, J3) protrude from the back of the board for user connections.

Components on the top-side have a maximum height of 12mm. Figure 1 shows a typical circuit board with

dimensions.

PARTS PLACEMENT

xx

x

Not used

leave all OPEN

xxx

1

JP1

Whe r e 1 = J3 (U SB)

2 = J2 (Analog out put)

3 = J1 (di gital communicati ons) - shown above

Sensed axis

Sensor Board

J2 pin uP pin f unction

1 Vcc power input (5 -28VDC)

2 RA4 status (TTL output) Logic 0 = ou tput not valid

3 D/A Output analog output(0 - 2.25V

4 GND powe r ground

Logic 1 = output valid

Figure 1 – Sensor board layout and connector pin designations

MATING PARTS

4 5 6

1 2 3

4 5 6

1 2 3

4-40NF mounting holes

(connected to ground plane)

6 5 4 3 2 14 3 2 1

USB port

not used

PC (parallel port) Sens or Board

LPT bit LPT pin J 1 pin uP bit function c olor

S3 15

S4 13

D1 3

D0 2

--

-19

Sx = status (LPT port base address + 1, Bit x)

Dx = d at a(LPTport base address + 0, Bit x

<>

<>

1RA3Tx_CLK(gray)

<

2 RA2 Tx (y ello w )

<

3RA1 Rx(blue)

>

4RA0Rx_CLK(white)

>

5Vcc+5-28 VDC(red)

6 GND power gnd (black)

Connectors J1, J2, and J3 mate with GC/Waldom C-Grid crimp-style shells and terminals. Polarized shells (with a

locking tab) or unpolarized shells are available. The applicable GC/Waldom part numbers are:

Connector pins Polarized shell Unpolarized shell Crimp terminals

J1 6 50-57-9406 50-57-9006 16-02-0097

J2 4 50-57-9404 50-57-9004 16-02-0097

J3 4 50-57-9404 50-57-9004 16-02-0097

Solid State Electronics Center

• www.magneticsensors.com • (800) 323-8295 • Page 5

Page 6

HMR4007

SENSOR PRODUCTS

APPLICATION NOTES

USING THE HMR4007 AS A STAND ALONE SENSOR

Introduction

The HMR4007 can be used as a stand-alone sensor without the need for any digital communications. The board is

configured at the factory to provide a 0-2.5 VDC analog output (axial magnet) and status signal that represents the

position of the magnet along the long axis of the device. All power and signals are available on connector J2.

Connector J2 General Description

When used in a stand-along mode, only connector J2 needs to be used. Connector J2 is a 4-pin socket header that is

used to supply power (pin 1), ground (pin 4), analog position (pin 3), and status (pin 2). When power is supplied to

the board though J2, a jumper must be placed on pins 2-5 (center pair) in jumper block JP2. The power supply can

be regulated 5VDC or unregulated 6-28VDC. If connector J2 is used in combination with the communications port,

only ONE of the ports should be used to supply power to the board.

Analog Outputs

The analog output (J2, pin 3) represents the position of the magnet along the long axis of the sensor board as seen in

Figure 2 below. In the given example, the center of the magnet lies between sensors 3 and 4. The resulting output

voltage is 1.20 volts which corresponds to a position of 33.4 mm.

69.6

33.4 mm

N

S

position (mm)

34.8

1.20 vdc

0

0

1.25 2.50

Output (volts, DC)

Figure 2. Position sensing example.

An effort should be made to keep the angle of the magnet with respect to the sensor board reasonably constant along

the length of travel. The sensor, however, is quite tolerant to changes in distance (gap) between the sensor and

magnet along the length of travel.

Status Pin

Pin 2 (on port J2) is a TTL logic-level status output bit. This pin will be logic high (+5VDC) whenever the position

output is valid. Logic level low (ground) indicates that the sensor cannot calculate a magnet position. The most likely

causes of a position error signal are:

1. The magnet is beyond the sensed range of the device.

2. The magnet is too short or too weak for the sensors to track.

3. The gap between the sensor and magnet is too large.

4. The magnet is not present.

Solid State Electronics Center

• www.magneticsensors.com • (800) 323-8295 • Page 6

Page 7

HMR4007

SENSOR PRODUCTS

USING THE HMR4007 IN DIGITAL COMMUNICATIONS MODE

Introduction

The HMR4007 is capable of communicating with a higher-level system through a proprietary communications port

(J1). This port uses a bit-clocked serial protocol for higher speed and higher data integrity than standard serial

protocols. Signal levels are standard TTL compatible. For convenience, a windows-based DLL (dynamic link library)

and sample Visual Basic demonstration program are available from Honeywell that communicates with the sensor

through a PC's parallel port. Interested developers should contact their Honeywell representatives or the factory for

details of the communications protocol and command structure. The communications port can be used independently

or in combination with the analog output described earlier. When used in combination with the analog port, only ONE

port should be used to supply power to the board. Sensor configuration, such as changing the magnet mode from

axial to radial, is available only through the communications port and DDL calls are supplied to support these basic

functions.

Connector J1 General Description

J1 is a 6-pin header which is wired to a PC parallel port for digital communications with the Honeywell demonstration

DLL software (or other user application) using the following connections:

PC (parallel port) Sensor Board

LPT pin data

direction

15 <-- 1 RTS (gray)

13 <-- 2 Data_Out (yellow)

3 --> 3 Data_In (blue)

2 --> 4 CTS (white)

- <> 5 +5-28 VDC (red)

19 <> 6 power gnd (black)

Demonstration Software

Two programs are included with this board to demonstrate its operation.

HMR4007.dll is a dynamic link library that performs low level communications between the host PC's parallel port

and the sensor board to query the current, measured position and support operating mode changes. Several

functions are visible to the user using the following Visual Basic header formats:

Declare Function InitPort Lib "HMR4007.dll" (ByVal ADD As Integer, ByVal TOut As Long) As Integer

Declare Function CurrentPosition Lib "HMR4007.dll" () As Integer

Declare Function SetAxialMode Lib "HMR4007.dll" () As Integer

Declare Function SetRadialMode Lib "HMR4007.dll" () As Integer

Declare Function EnableDAC Lib "HMR4007.dll" () As Integer

Declare Function DisableDAC Lib "HMR4007.dll" () As Integer

J1 pin function color

The first function, "InitPort", is used to setup the PC's parallel port base address (default is 0x378) and timeout value.

This function must be called before any calls to the operating functions.

The port base address (ADD) is the address of the computer's parallel (printer) adapter and used by the software

as a base address to send and receive data to the sensor card through the parallel port adapter. The value is

passed as a 16-bit integer. Setting this value to -1 re-initializes the port with the previous value (or default value)

retained.

The timeout value (Tout) is used as an internal loop counter to return to the calling program after a fixed time if

for some reason the sensor board fails to respond. A value of 10,000 is the default and works well on a 100MHz

Pentium-class machine. Higher values will be needed for faster machines. The parameter is passed as a 32-bit

long integer. Passing a value of -1 sets the value to the previous (or default) value.

The function returns a 16-bit integer "0" to indicate that the port is active.

Solid State Electronics Center

• www.magneticsensors.com • (800) 323-8295 • Page 7

Page 8

HMR4007

SENSOR PRODUCTS

The second function, "CurrentPosition", is used to query the current position of the magnet. The following 16-bit

integer values are returned:

0-1024 normal position response where 1024 represents full scale response.

-1, -2 communications failure. The sensor failed to respond to the PC quickly enough. This is

usually caused by improper wiring, improper power settings, a timeout value too small for

the PC speed, or the DLL not being initialized before attempting to get the position.

-3 position error. The sensor communicated correctly, but the sensor card was not able to

calculate a valid position. A position error is usually caused by the magnet being off the end

of the board or not present.

The functions "SetAxialMode" and "SetRadialMode" are used to configure the sensor to use magnets in either the

axial mode or radial (see the introduction for a description of axial and radial modes). The sensor is shipped with the

axial mode selected. Once set into an operating mode, that mode is retained in nonvolatile RAM.

The functions "EnableDAC" and "DisableDAC" are used to enable and disable the digital to analog (DAC) output on

port J2. The sensor is shipped with the DAC enabled. Once set into an operating mode, that mode is retained in

nonvolatile RAM.

HMR4007.exe: This is a simple Visual Basic 5.0 executable that demonstrates the use of the DLL and shows a

simple graphical display of the current position. Source code for the program is available and can be modified as

desired. The position window will turn yellow in the event of a communications failure, or turn red in the event of a

position error.

MAGNET CONSIDERATIONS

The choice of magnet to be used with the HMR4007 is critical to its accuracy. Because a magnet's field extends

beyond the boundaries of the material, a magnet has two dimensions to consider: its physical (material) length and its

apparent (magnetic) length. The heart of the HMR4007 is Honeywell's HMR1501 magnetoresistive (MR) sensor that

responds to the angle between the chips' sensitive axis and the magnetic field. The HMR1501 has a maximum

response when this angle is +/-45 degrees. We can, therefore, define the magnet's apparent length as the distance

between the +45 and -45 degree points at the gap distance.

B

HMR1501

x

response

B

4

= f(4)

As the gap between the magnet and the sensor array increases, the

apparent length of the magnet increases as well. A general rule of

thumb for a cylindrical bar magnet is that the apparent length will

increase by the amount of the gap. A twenty-five millimeter long

magnet for example will appear to be thirty-five millimeters long at a

gap of 10 millimeters. Since magnetic fields are highly nonlinear and

subject to the exact geometry and properties of the material, this is only

a general guide.

N

S

physical

length

apparent

length

The HMR4007 uses three sensors in its array at all times in order to

calculate position. It automatically selects the sensors closest to the

magnet for this purpose. The apparent magnet length must, therefore

be greater than he spacing between three sensors, and this distance is

23.2mm for the HMR4007.

The disadvantage of increasing the gap between the sensor and

magnet in order to increase its apparent length is that a magnet's field

strength decreases exponentially with gap. In order to maintain the MR

sensor's response the magnetic field at the sensor must be greater

than 35 gauss. Unless extremely strong rare earth magnets are

gap

economically feasible or a large gap is required because of restrictions

on where the magnet and array can be mounted, it is usually better to

keep the gap to a minimum and use a longer magnet.

Figure 3. Magnet apparent length

900301 01-03 Rev. A

Solid State Electronics Center

• www.magneticsensors.com • (800) 323-8295 • Page 8

Loading...

Loading...