Page 1

Solid State Sensors GT1 Series

Hall Effect Gear Tooth Sensors

TYPICAL APPLICATIONS

Automotive and Heavy Duty Vehicles:

1

Camshaft and crankshaft speed/

position

1

Transmission speed

1

Tachometers

1

Anti-skid/traction control

Industrial:

1

Sprocket speed

1

Chain link conveyor speed and

distance

1

Stop motion detector

1

High speed low cost proximity

1

Tachometers, Counters

GT1 ORDER GUIDE

Catalog Listing Description

1GT101DC Gear Tooth Sensor

FEATURES

1

Senses ferrous metal targets

1

Digital current sinking output (open

collector)

1

Better signal-to-noise ratio than

variable reluctance sensors, excellent

low speed performance, output

amplitude not dependent on RPM

1

Sensor electronically

slight variations in runout and

variations in temperature, simplifying

installation and maintenance

1

Fast operating speed – over 100 kHz

1

EMI resistant

1

Reverse polarity protection and

transient protection (integrated into

Hall I.C.)

1

Wide continuous operating

temperature range (–40

short term to 160

self-adjusts

°

C

°

to 150°C),

GENERAL INFORMATION

1GT1 Series Gear Tooth Sensors use a

magnetically biased Hall effect integrated

circuit to accurately sense movement of

ferrous metal targets. This specially designed I.C., with discrete capacitor and

bias magnet, is sealed in a probe type

package for physical protection and cost

to

effective installation.

Units will function from a 4.5 to 24 VDC

power supply. Output is digital, current

sinking (open collector). Reverse polarity

protection is standard. If power is inadvertently wired backwards, the sensor will

not be damaged. Built-in protection

against pulsed transients to

is also included.

Optimum sensor performance is dependent on the following variables which must

be considered in combination:

1

Target material, geometry, and speed

1

Sensor/target gap

1

Ambient temperature

1

Magnetic material in close proximity

PDFINFO pag e -05 2

+

60V, –40V

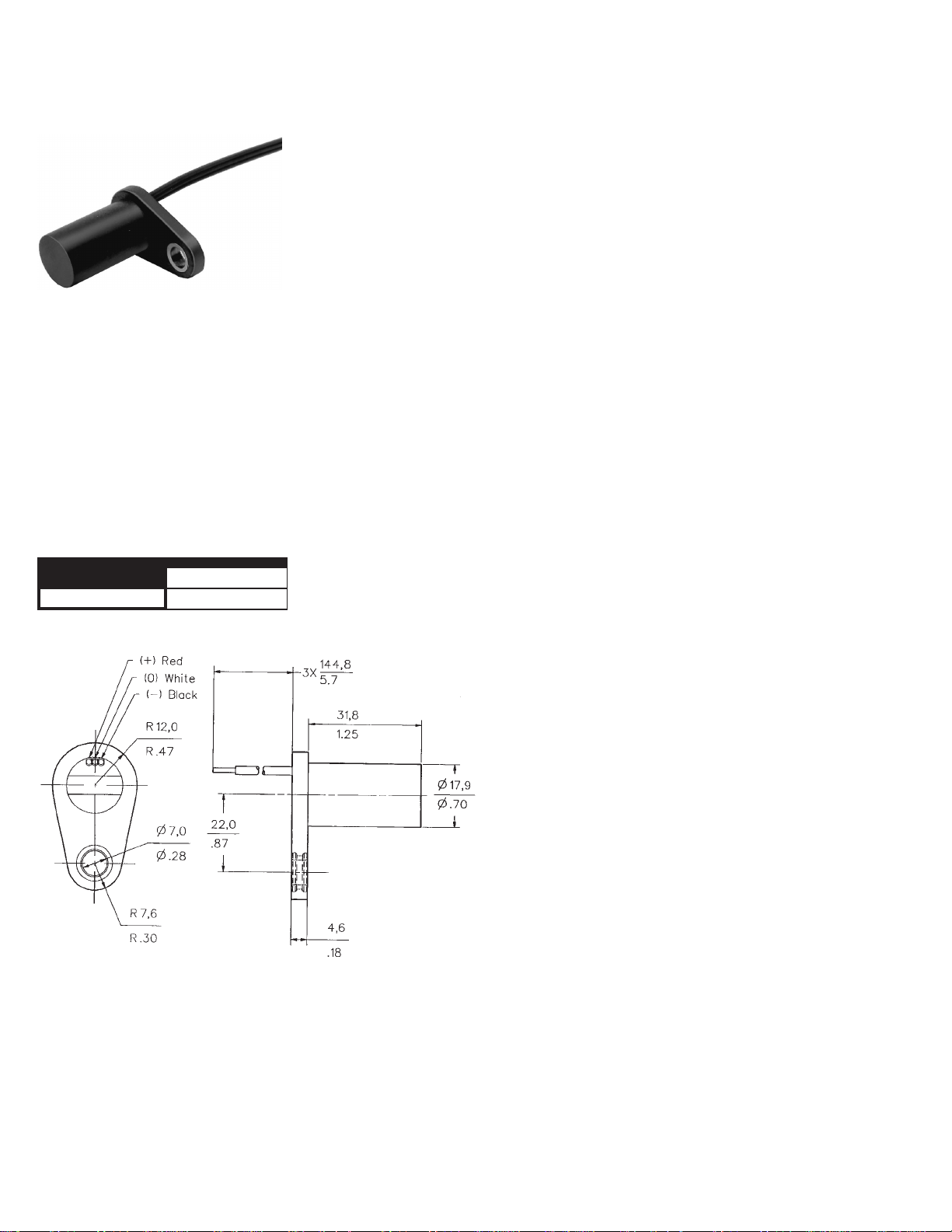

MOUNTING DIMENSIONS (For reference only)

52 Honeywell 1 MICRO SWITCH Sensing and Control11-800-537-6945 USA 1F1-815-235-6847 International 11-800-737-3360 Canada

Page 2

Solid State Sensors GT1 Series

Hall Effect Gear Tooth Sensors

SENSOR SPECIFICATIONS

All values were measured using 1 K pull-up resistor.

Electrical

Characteristics

Absolute

Maximum

Ratings*

Switching

Characteristics**

* As with all solid state components, sensor performance can be expected to deteriorate as

rating limits are approached; however, sensors will not be damaged unless the limits are

exceeded.

** See Reference Target table.

Supply Voltage 4.5 to 24 VDC

Supply Current 10 mA typ., 20 mA max.

Output Voltage (output low) 0.4 V max.

Output Current (output high) 10 µA max. leakage into sensor

Switching Time

Rise (10 to 90%) 15 µsec. max.

Fall (90 to 10%) 1.0 µsec. max.

Supply Voltage (Vs) ±30 VDC continuous

Voltage Externally Applied

To Output (output high) –0.5 to +30 V

Output Current 40 mA sinking

Temperature Range

Storage –40 to 150°(–40 to 302°F)

Operating –40 to 150° C(–40to302°F)

Operate Point 3.7±1.25° (3,28±1,13 mm)

Release Point 4.7±2.50 ° (4,16±2,21 mm)

Differential Travel 8.4±3.70° (7,45±3,34 mm)

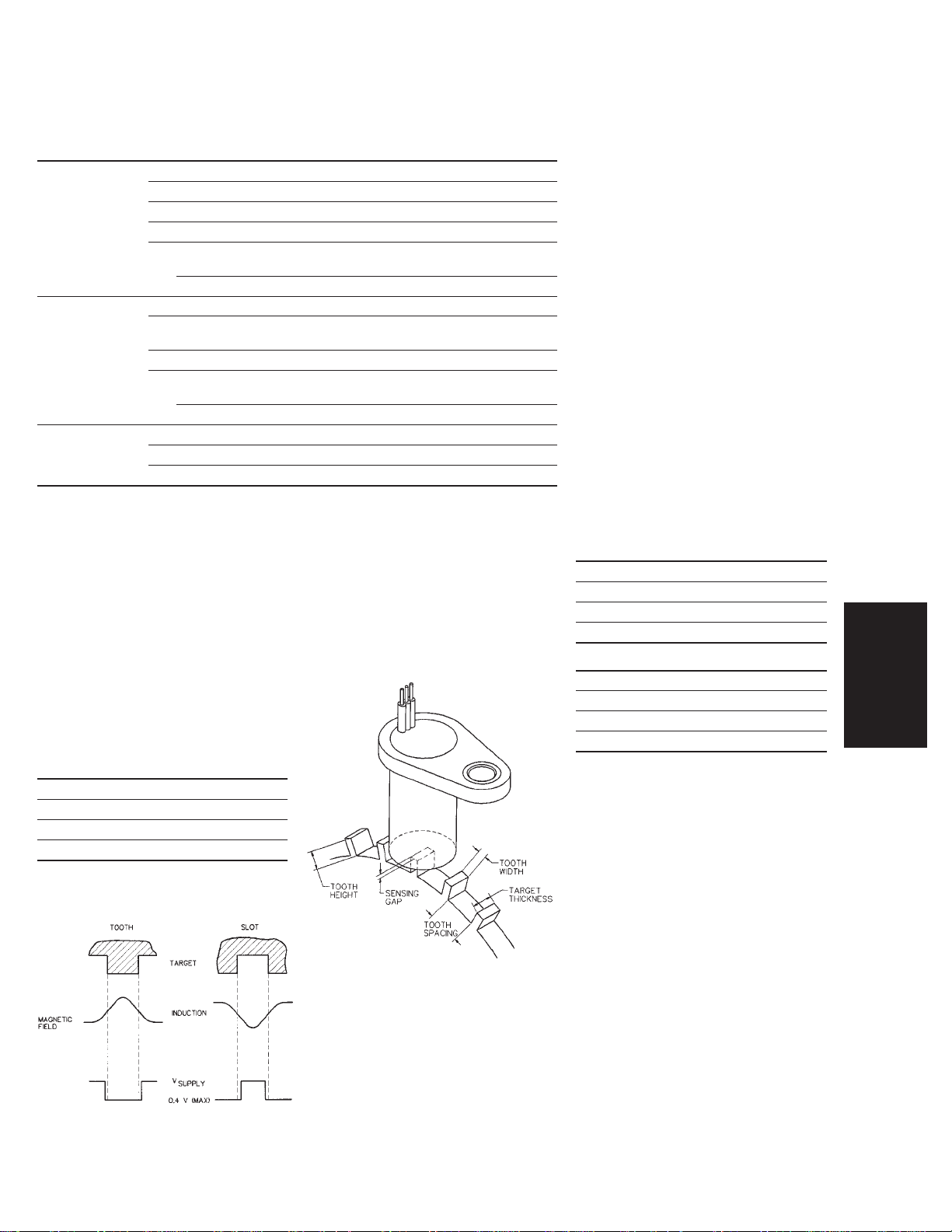

TARGET GUIDELINES

The Target Guidelines table provides basic parameters whenan application is not

restricted to a specific target.

Any target wheel that exceeds the following minimum specifications can be

sensed over the entiretemperature range

of –40

°

to 150°C with any sensing gap up

to .080 in.(2,0 mm).This data is based on

a 4 in. (102 mm) diameter wheel, rotating

10 to 3600 RPM.

Reference Target Dimensions

Tooth Height: .200 in. (5,06 mm) min.

Tooth Width: .100 in. (2,54 mm) min.

Tooth Spacing: .400 in. (10,16 mm) min.

Target Thickness: .250 in. (6,35 mm)

Sensor Output (with pull-up resistor added to output circuit)

REFERENCE TARGET/CONDITIONS

Characteristics will varydue to target size,

geometry, location, and material. Sensor

specifications were derived using a coldrolled steel reference target. See table,

right, for reference target configuration

and evaluation conditions.

Target

Diameter: 4 in. (101,6 mm)

Tooth Width: .350 in. (8,89 mm)

Thickness: .250 in. (6,35 mm)

Test Conditions

Air Gap: .040 to .080 in. (1,02 to 2,03 mm)

V Supply: 4.5 to 24 V

RPM: 10 min., 3600 max.

Integral Magnet

PDFINFO p a g e - 0 5 3

Honeywell 1 MICRO SWITCH Sensing and Control11-800-537-6945 USA 1F1-815-235-6847 International 11-800-737-3360 Canada 53

Loading...

Loading...