Page 1

GSS Series

Global Safety Switch

FEATURES

• EN 50041 and EN 50047 mounting and

characteristics

• Designed to IEC electrical standard for

world-wide use in guarding applications

• Positive opening operation of NC

(Normally Closed) contacts conforming

to IEC /EN 60947-5-1-3

• Available with a wide range of positive

opening contacts

• Rugged housing (Zinc Die-cast)

• Tamper resistant design uses TORX®

head security screw

• Full range of actuator heads and levers

suitable for safety applications

• Sealing up to IP 67, NEMA 1, 4, 12 & 13

• Snap action and slow action basic

switches

• International conduit sizes

• Galvanically isolated contacts

• UL listed; CSA and CE certified, BG

approved

• Red body colour for easy safety

recognition

BENEFITS

• Standard mounting and characteristics

• Globally available and accepted

• Welded NC contacts will separate – vital

security in safety applications

• Range of actuation methods for

detecting safety conditions in guarding

and machine status applications

• Wiring and body flexibility

• Suitable for inductive switching and

safety relay interfaces

• Signalling and power/safety circuits may

be different polarities or voltages

• Immediately recognisable in the

application as a safety component

GSS Series products may be used alone as Category 1 per EN 954-1 safety component. In conjunction with other safety switches and our complete range of safety

control modules, it is possible to construct comprehensive protection schemes

with Category 2, 3 or 4 compliance per EN 954-1.

Honeywell’s design experience has resulted in a brand new patented concept in

safety switching techniques. The sequential safety switch incorporates positive

opening on the downward stroke of each NC sequence point. This allows the user to

have both a warning signal and a stop signal. With this information a door can be

closed before it stops a machine or settings adjusted to stop excessive movement

thus avoiding down time.

LOW ENERGY SWITCHING

In today’s demanding age of low energy controls, electromechanical switches are

frequently used to interface directly with safety relays, PLCs and other low energy

devices. To accommodate this requirement GSS offers gold plated contact versions

of the standard basic switch. This improves reliability of switching at low currents

and voltages, by protecting the contact surfaces from contamination during operation or storage prior to use.

Standard silver contacts have a disadvantage in that the contact surface may tarnish under certain environmental conditions e.g. in the presence of moisture.

Low energy basic switches are rated as follows:

Operating Voltage U

Operating Current I

e

e

1 to 50 Vac or Vdc

1 µA to 100 mA

GSS

GSS Series

!

WARNING

MISUSE OF DOCUMENTATION

• The information presented in this product sheet (or catalogue) is for reference only. DO NOT USE this document as system

installation information.

• Complete installation, operation and maintenance information is provided in the instructions supplied with each product.

Failure to comply with these instructions could result in death or serious injury.

•

Industrial Safety Products

• 197

Page 2

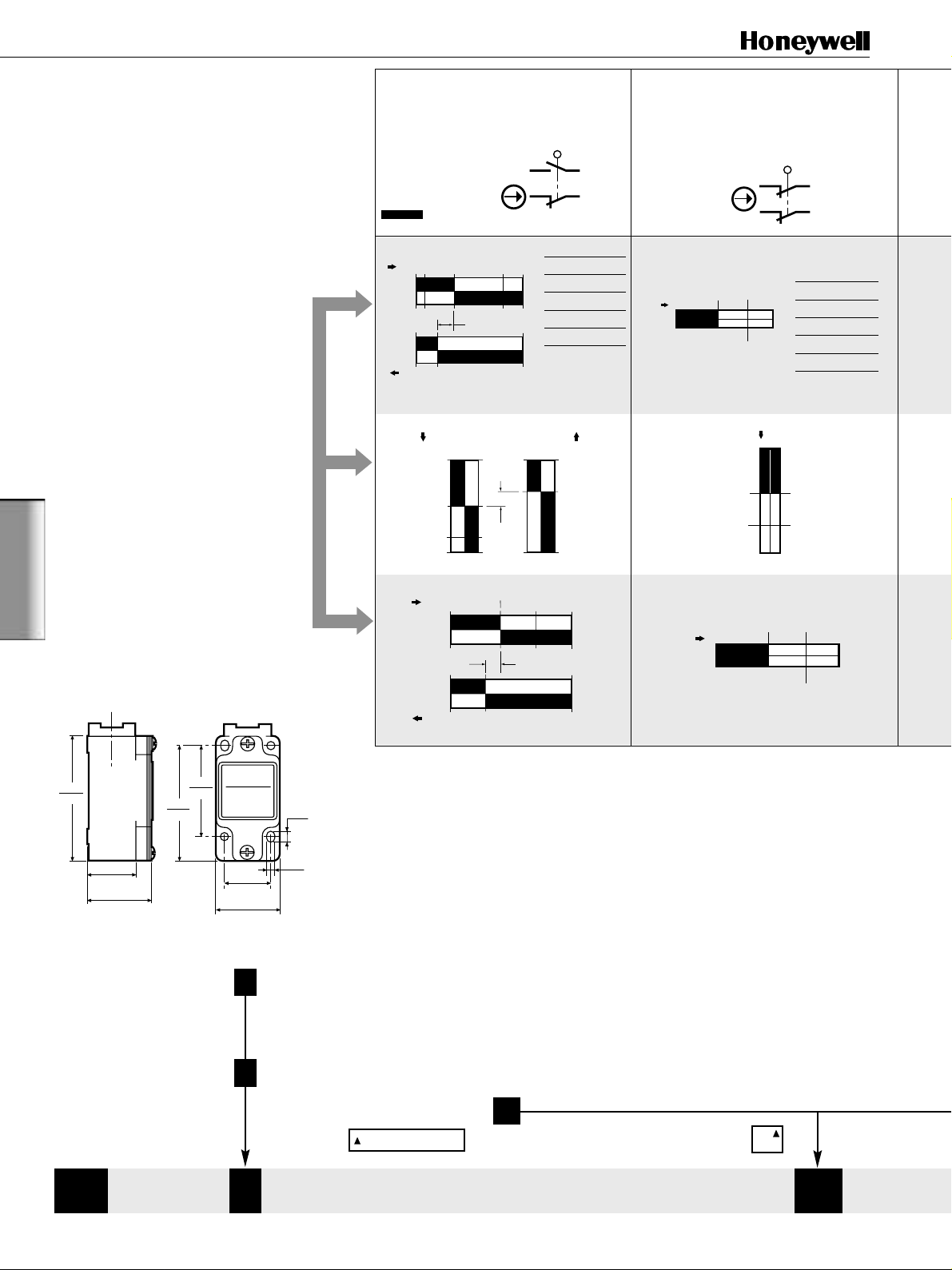

GSA EN 50041

-3,6 mm

20

32

FP

OT

21-22

11-12

*

Safety Metal

Snap-Action Contacts Slow-Action Contacts

1 NORMALLY CLOSED/ 2 NORMALLY CLOSED

1 NORMALLY OPEN

Standard

Technical Data

Mechanical up to 15 million

life operations

Degree of IP 67

protection NEMA/UL

type 1, 4, 12, 13

Temperature

range -25 °C to +85 °C /

Approvals* IEC 60947-5-1

Vibration 10 g conforming to

GSS

Shock 50 g conforming to

Terminal marking to EN 50013

*See Standards (page 179)

Dimensions in mm / in

Operating:

-13 °F to +185 °F

Storage:

-40 °C to +85 °C /

-40 °F to +185 °F

EN 60947-5-1

ac15 A300/A600

dc13 Q300

UL & CSA

IEC 68-2-6

IEC 68-2-27

Circuit closed

*Positive opening to IEC/EN 60947-5-1-3

56

OP OT

*

DT = 12 mm

21-22

13-14

FP

DT =

0,9 mm

*

OT

(max.)

15

13,2 RP

1,8 DT

21-22

13-14

21-22

13-14

-3,6

FP

37,5 mm

OP 35 mm

33 mm

30,5 mm

21-22

13-14

21-22

13-14

20 mm

RP = 8 mm

11,3 mm

FP

13

Zb

21

(F.P.) 0°

(O.P.) 26°

(R.P.) 14°

(D.T.) 12°

(*) 55°

(O.T.) 71° to 85°

21-22

13-14

35,9 mm

RP

18,3

OT

*

14

22

21-22

11-12

37,5 mm

35 mm

33 mm

30,5 mm

11,3 mm

FP

21

11

21-22

11-12

FP

OT

(max.)

15

22

2Y

12

(F.P.) 0°

(O.P.) 26°

(R.P.)

(D.T.)

(*) 38°

(O.T.) 71° to 85°

*

18,3

OT

*

75,8 /

2.98

60 /

2.36

30 /

1.18

1.65

42 /

7,3 /

0.29

5,3 /

0.21

82 /

3.23

31,5 /

1.24

42 /

1.65

Conduit

Thread

= 1/2" NPT

A

= 20 mm

C

Low Energy Contacts

Ordering:

198 •

Example: GSA C 01 B

* Point from which the positive opening is assured

** Positive opening occurs at operating position. But to meet IEC/EN 60947-5-3

which requires a dielectric gap of 2,5 kV, positive opening is assured at*.

01

Note: See page 197

Industrial Safety Products

•

36

XXXGSA

GSS Series

Page 3

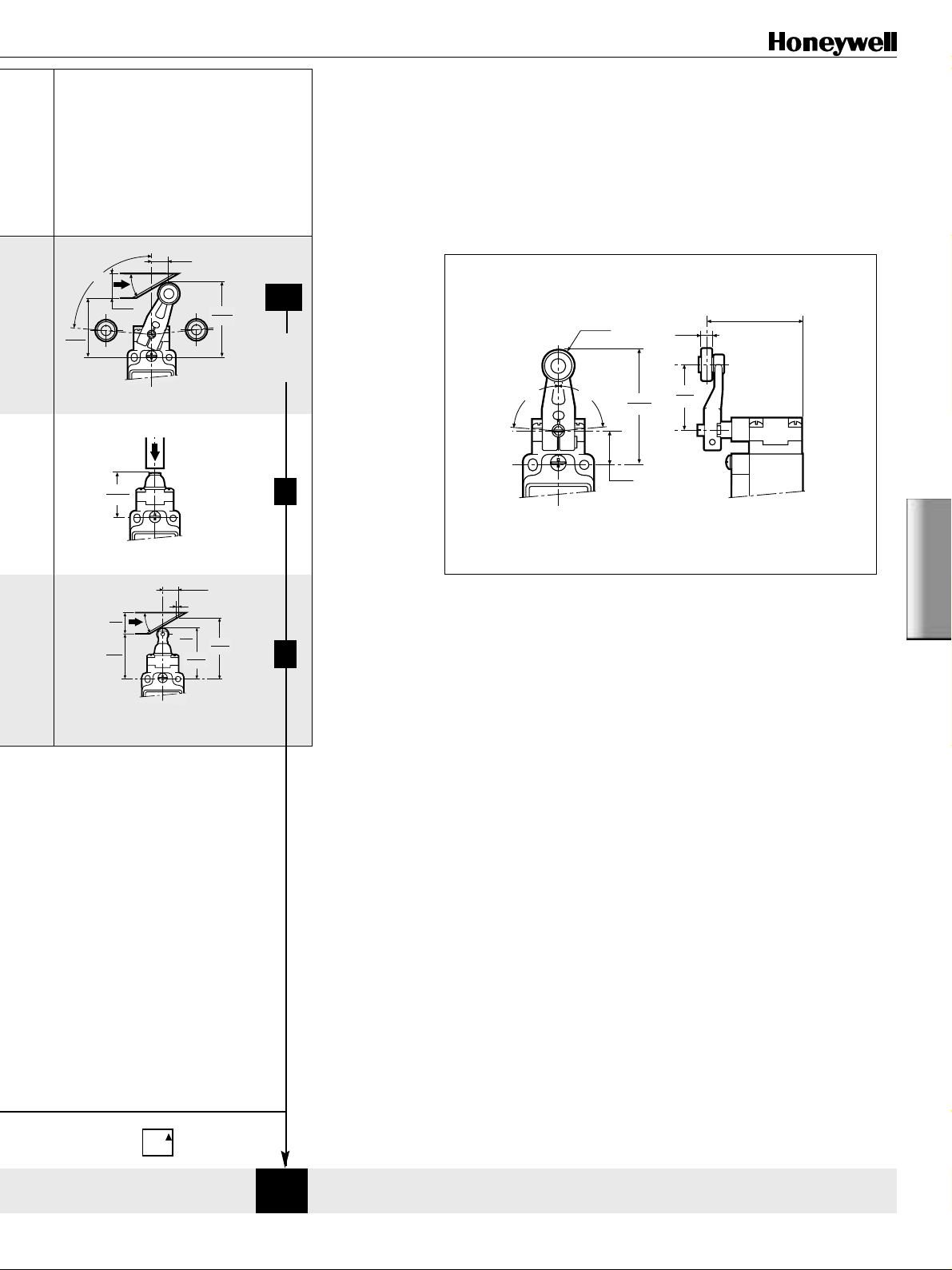

Actuator Types

OP

30˚

58 /

2.28

20 /

0.79

15 /

±2,5

0.59

±0.1

50,5 /

1.99

DP

44 /

1.73

ø12,4 /

0.49

FP

85˚

20 /

0.79

52 /

2.05

Side Rotary, metal roller

37,5 /

1.48

Top pin plunger

0.79

30˚

20 /

OP

67 /

2.64

A1B

Additional

levers

available

(see page 208)

B

Additional Lever Types

For use with all Side Rotary Head Styles.

Figure 1 illustrates standard lever types which conform to EN 50041.

All dimensions are in mm / in

GSA

56 /

2.2

Figure 1

85˚

ø19,1 /

0.75

85˚

6,4

0.25

38,1 /

70 /

1.5

2.76

20 /

0.79

Side Rotary Roller Lever

A1B Metal Roller

Top roller plunger

GSS

C

GSS Series

47

XXX

•

Industrial Safety Products

• 199

Page 4

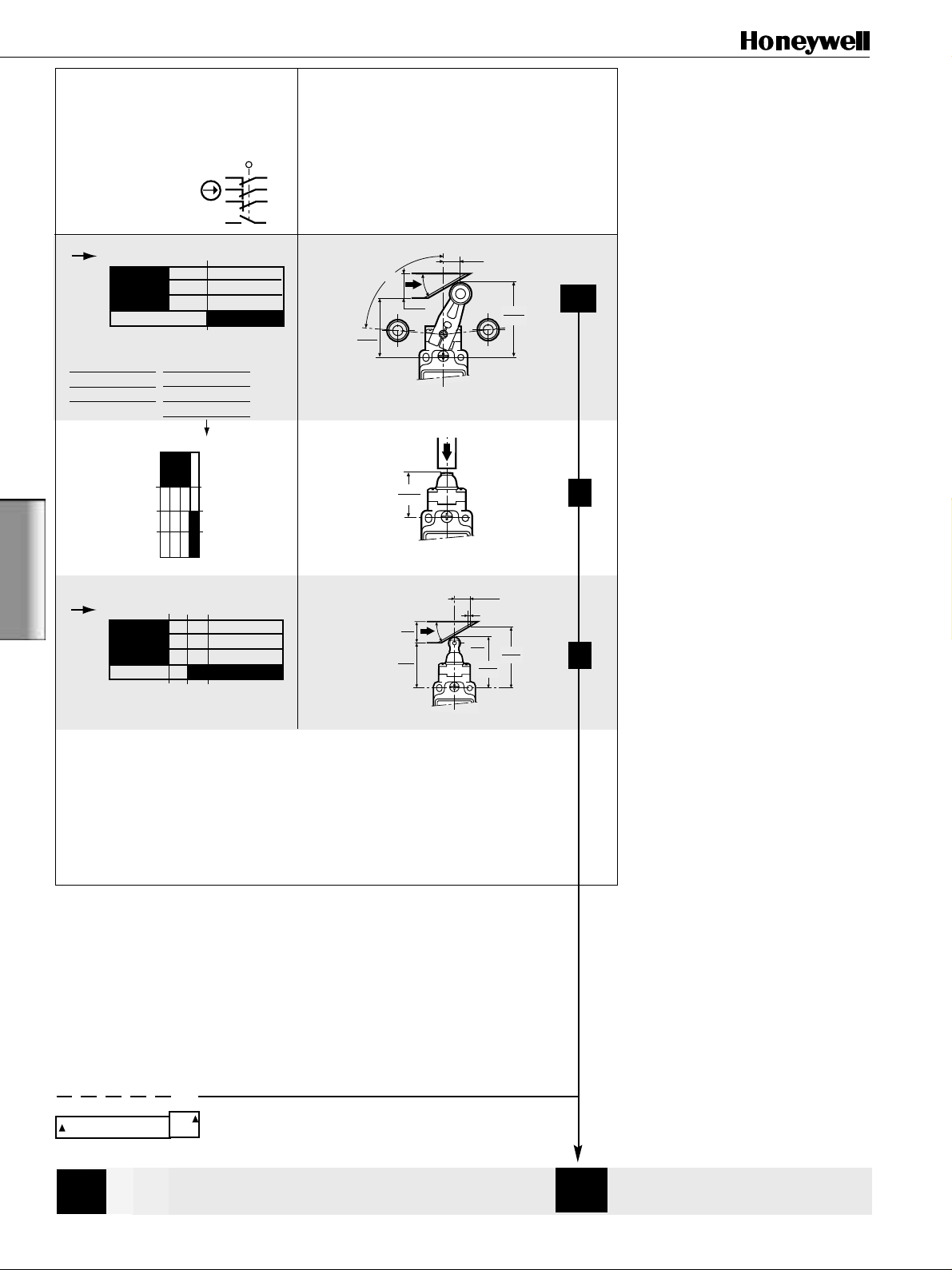

Slow-Action Contacts

3 NORMALLY CLOSED/

1 NORMALLY OPEN

BREAK BEFORE MAKE

11

21

31

43

Actuator Types

12

2Y

22

32

Zb

44

GSS

-3,6

11-12

21-22

31-32

43-44

(F.P.) 0°

(O.P.1) 26°

(O.P.2) 32°

11,3

11-12

21-22

31-32

43-44

37,5 mm

33 mm

30,5 mm

20 32

(R.P.)

(D.T.)

(*) 38°

(O.T.) 71° to 85°

11-12

21-22

31-32

43-44

*

15

18,3

16,8

*

35 mm

34 mm

OT

(MAX)

*

OT

52 /

2.05

Side Rotary, metal roller

Top pin plunger

OT

Top roller plunger

20 /

OP

85˚

20 /

0.79

37,5 /

1.48

20 /

0.79

44 /

1.73

0.79

30˚

67 /

2.64

A1B

B

±2,5

15 /

OP

±0.1

0.59

FP

DP

30˚

ø12,4 /

58 /

0.49

50,5 /

1.99

2.28

C

Low Energy Contacts

Note: See page 197

47

GS

200 •

Industrial Safety Products

XXX

•

GSS Series

Page 5

GSS

GSS Series

•

Industrial Safety Products

• 201

Page 6

GSC EN 50047

Safety Metal

Snap-Action Contacts Slow-Action Contacts

1 NORMALLY CLOSED/ 2 NORMALLY CLOSED

1 NORMALLY OPEN

Standard

Technical Data

Mechanical up to 15 million

life operations

Degree of IP 66

protection NEMA/UL

type 1, 4, 12, 13

Temperature

range -25 °C to +85 °C /

Approvals* IEC 60947-5-1

Vibration 10 g conforming to

GSS

Shock 50 g conforming to

Terminal marking to EN 50013

*See Standards (page 179)

Dimensions in mm / in

24,75 /

0.97

Operating:

-13 °F to +185 °F

Storage:

-40 °C to +85 °C /

-40 °F to +185 °F

EN 60947-5-1

ac15 A300

dc13 Q300

BG, UL & CSA

IEC 68-2-6

IEC 68-2-27

3 /

0.12

2,15 /

R

0.08

13

14

21

Zb

22

*

10,5

21

(F.P.)

(O.P.) 26˚

(R.P.) 14,5˚

(D.T.) 11,5˚

(*) 54˚

(O.T.) 61˚ to 75˚

21-22

13-14

13,9

*

1,6 DT

0˚

18,9 mm

RP

21-22

11-12

(F.P.) 0˚

(O.P.) 26˚

(R.P.)

21-22

11-12

-4,4

FP

15 mm

21 mm

18 mm

16,5 mm

15 mm

5,3 mm

FP

Circuit closed

*Positive opening to IEC/EN 60947-5-1-3

-4,4

15 mm 43,3

21-22

13-14

FP OP OT

21-22

13-14

21 mm

OP 18 mm

16 mm

15 mm

21-22

13-14

22 /

0.87

20 /

0.78

55 /

2.16

21-22

13-14

DT = 9,8 mm

RP = 5,2 mm

21-22

13-14

FP

DT =

0,9 mm

*

OT

(max.)

5,3 mm

FP OT

8,9 RP

22

2Y

12

11

36,5

*

(D.T.)

(*) 46,5˚

(O.T.) 61˚ to 75˚

21-22

11-12

FP

OT

(max.)

10,5 13,5

OT

*

OT

*

30,5 /

14,5 /

0.57

30 /

1.18

conduit

thread

Note: Incorporates safety screws

Ordering:

202 •

Example: GSC C 01 B

1.20

ø 23 /

ø 0.9

0.138

19,8 /

0.78

3,5 /

Conduit

Thread

= 1/2" NPT

A

= 20 mm

C

Low Energy Contacts

Note: See page 197

* Point from which the positive opening is assured

** Positive opening occurs at operating position. But to meet IEC/EN 60947-5-3

which requires a dielectric gap of 2,5 kV , positive opening is assured at*.

01

Industrial Safety Products

•

36

XXXGSC

GSS Series

Page 7

Actuator Types

75˚

20 /

0.79

30˚

40 /

1.57

Side Rotary, metal roller

15 ± 3 /

0.39 ± 0.8

DT

ø19 /

0.748

55 /

2.17

OP

A1B

Additional

levers

available

(see page 208)

Additional Lever Types

For use with all Side Rotary Head Styles.

All dimensions are in mm / in

Figure 2 illustrates standard lever types

which conform to EN 50047.

GSC

45 /

1.77

40 /

1.07

1.58

27 /

0.24

6 /

75˚

ø19 /

0.74

75˚

46,5 /

1.83

ø 9,9 /

0.39

FP

OT

21 /

(max.)

0.827

15 /

0.591

Top pin plunger

20 /

0.787

25 /

0.984

Top roller plunger

DT

10 ± 1,5 /

0.394

ø12,4 /

0.49

OP

18 ± 0,5 /

0.709

DT

OP

30˚

35 /

1.378

15 /

B

Figure 2

Side Rotary Roller Lever

0.59

A1B Metal Roller

GSS

C

GSS Series

XXX

•

Industrial Safety Products

• 203

Page 8

GSD EN 50047

Safety Double Insulated

Snap-Action Contacts Slow-Action Contacts

1 NORMALLY CLOSED/ 2 NORMALLY CLOSED

1 NORMALLY OPEN

Standard

Technical Data

Mechanical up to 15 million

life operations

Degree of IP66

protection NEMA/UL

type 1, 12, 13

Temperature

range -25 °C to +85 °C /

Approvals* IEC 60947-5-1

Vibration 10 g conforming to

GSS

Shock 50 g conforming to

Terminal marking to EN 50013

*See Standards (page 179)

Dimensions in mm / in

24,75 /

0.97

Operating:

-13 °F to +185 °F

Storage:

-40 °C to +85 °C /

-40 °F to +185 °F

EN 60947-5-1

ac15 A600

dc13 Q300

BG, UL & CSA

IEC 68-2-6

IEC 68-2-27

3 /

0.12

2,15 /

R

0.08

13

14

Zb

22

21

Circuit closed

*Positive opening to IEC/EN 60947-5-1-3

-4,4

15 mm 43,3

21-22

13-14

FP OP OT

21-22

13-14

RP = 5,2 mm

21 mm

OP 18 mm

16 mm

15 mm

5,3 mm

21-22

13-14

FP OT

22 /

0.87

20 /

0.78

* Point from which the positive opening is assured

55 /

2.16

** Positive opening occurs at operating position. But to meet IEC/EN 60947-5-3

which requires a dielectric gap of 2,5 kV, positive opening is assured at*.

21-22

13-14

DT = 9,8 mm

21-22

13-14

FP

DT =

0,9 mm

*

OT

(max.)

8,9 RP

*

10,5

1,6 DT

0˚

(F.P.)

(O.P.) 26˚

(R.P.) 14,5˚

(D.T.) 11,5˚

(*) 54˚

(O.T.) 61˚to 75˚

21-22

13-14

18,9 mm

RP

13,9

*

21-22

11-12

(F.P.) 0˚

(O.P.) 26˚

(R.P.)

21-22

11-12

-4,4

FP

16,5 mm

5,3 mm

FP

21

11

15 mm

21 mm

18 mm

15 mm

22

2Y

12

36,5

*

(D.T.)

(*) 46,5˚

(O.T.) 61˚ to 75˚

21-22

11-12

FP

*

OT

(max.)

10,5 13,5

*

OT

OT

30,5 /

14,5 /

0.57

30 /

1.18

conduit

thread

Note: Incorporates safety screws

Ordering:

1.20

ø 23 /

ø 0.9

0.138

19,8 /

0.78

3,5 /

Conduit

Thread

= 1/2" NPT

A

= 20 mm

C

Low Energy Contacts

Note: See page 197

Example: GSD C 01 B

204 •

01

Industrial Safety Products

36

XXXGSD

•

GSS Series

Page 9

Actuator Types

75˚

20 /

0.79

30˚

40 /

1.57

Side Rotary, metal roller

ø 9,9 /

0.39

FP

OT

21 /

(max.)

0.827

15 /

0.591

15 ± 3 /

0.39 ± 0.8

DT

ø19 /

0.748

DT

OP

55 /

2.17

OP

18 ± 0,5 /

0.709

A1B

Additional

levers

available

(see page 208)

B

Additional Lever Types

For use with all Side Rotary Head Styles.

All dimensions are in mm / in

Figure 2 illustrates standard lever types

which conform to EN 50047.

GSD

45 /

1.77

40 /

1.07

1.58

27 /

0.24

6 /

75˚

ø19 /

0.74

75˚

46,5 /

1.83

15 /

0.59

Top pin plunger

20 /

0.787

25 /

0.984

Top roller plunger

10 ± 1,5 /

0.394

DT

ø12,4 /

0.49

OP

30˚

35 /

1.378

Side Rotary Roller Lever

A1B Metal Roller

Figure 2

GSS

C

GSS Series

XXX

•

Industrial Safety Products

• 205

Page 10

GSE EN 50047 Compatible

11

12

21

22

31

32

2Y

Zb

43

44

Safety 3 Conduit Metal

Standard

Technical Data

Mechanical up to 15 million

life operations

Degree of IP66

protection NEMA/UL

type 1, 4, 12, 13

Temperature

range -25 °C to +85 °C /

Approvals* IEC 60947-5-1

Vibration 10 g conforming to

GSS

Shock 50 g conforming to

Terminal marking to EN 50013

*See Standards (page 179)

Dimensions in mm / in

24,75 /

12,5 /

0.49

12 /

0.47

0.97

0.12

R

13,75 /

0.54

2,5 /

0.1

30 /

1.18

conduit

thread

Operating:

-13 °F to +185 °F

Storage:

-40 °C to +85 °C /

-40 °F to +185 °F

EN 60947-5-1

ac15 A300

dc13 Q300

BG, UL & CSA

IEC 68-2-6

IEC 68-2-27

42 /

1.65

40 /

1.57

22 /

0.87

20 /

0.79

3 /

2,15 /

0.08

52 /

2.05

57 /

2.24

65 /

2.56

60 /

2.37

4 /

0.16

Slow-Action Contacts Actuator Types

3 NORMALLY CLOSED/

1 NORMALLY OPEN

BREAK BEFORE MAKE

37,5 mm

33 mm

30,5 mm

20 32

*

(R.P.)

(D.T.)

(*) 38°

(O.T.) 71° to 85°

11-12

21-22

31-32

*

15

18,3

16,8

*

43-44

35 mm

34 mm

OT

(MAX)

OT

40 /

1.57

Side Rotary, metal roller

21 /

0.82

FP

OT

(max.)

15 /

0.59

Top pin plunger

OT

Top roller plunger

0.98

75˚

30˚

20 /

0.79

25 /

-3,6

11-12

21-22

31-32

43-44

(F.P.) 0°

(O.P.1) 26°

(O.P.2) 32°

11,3

11-12

21-22

31-32

43-44

* Point from which the positive opening is assured

** Positive opening occurs at operating position. But to meet IEC/EN 60947-5-3

which requires a dielectric gap of 2,5 kV, positive opening is assured at*.

15 ±3 /

0.39 ±0.08

DT

DT

15 ±3 /

0.59 ±0.12

DT

OP

55 /

2.17

OP

18 ±0,5 /

0.709 ±0.02

OP

30˚

35 /

1.38

A1B

Additional

levers

available

(see page 208)

B

C

23,8 /

0.94

ø 23 /

ø 0.9

Note: Incorporates safety screws

Conduit

Thread

= 1/2" NPT

A

= 20 mm

C

Low Energy Contacts

Ordering:

206 •

Example: GSE C 20 B

Note: See page 201

47

XXXGSE

Industrial Safety Products

XXX

•

GSS Series

Page 11

Additional Lever Types

For use with all Side Rotary Head Styles.

All dimensions are in mm / in

Figure 2 illustrates standard lever types

which conform to EN 50047.

GSE

45 /

1.77

40 /

Figure 2

1.07

1.58

27 /

6 /

0.24

75˚

Side Rotary Roller Lever

A1B Metal Roller

ø19 /

0.74

75˚

46,5 /

1.83

15 /

0.59

GSS

GSS Series

•

Industrial Safety Products

• 207

Page 12

GSS

208 •

Industrial Safety Products

•

GSS Series

Loading...

Loading...