Page 1

M

TTM

IInntteelllliiPPaatth

h

AAuuttoo--sseelleeccttss OOppttiimmuumm GGSSMM ppaatthh –– 22GG,, 33GG,, oorr 44G

SSeerriieess 44GG GGSSMM CCoommmmuunniiccaattoorr

G

GSS

G

M

M

V44

V

G

G

/

GSS

/

M

V

C

G

M

V

ssuuppppoorrttss ttwwoo--wwaayy vvooiiccee

C

N44

N

G

G

Installation and Setup Guide

800-11119 1/12 Rev. E

Page 2

Page 3

Table of Contents

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

SECTION 1: General Information .................................................................................................................. 1-1

System Overview ...................................................................................................................................... 1-1

Introduction ....................................................................................................................................... 1-1

General Information .......................................................................................................................... 1-1

System Features ....................................................................................................................................... 1-1

Encryption ................................................................................................................................................ 1-2

Remote Services ....................................................................................................................................... 1-2

Modes of Operation .................................................................................................................................. 1-2

ECP Mode ........................................................................................................................................... 1-2

Zone Trigger Mode ............................................................................................................................. 1-3

4204 Mode and Two-4204 Mode ....................................................................................................... 1-3

Supervision Features ............................................................................................................................... 1-3

Antenna .............................................................................................................................................. 1-4

Specifications ............................................................................................................................................ 1-5

Compatibility ............................................................................................................................................ 1-6

Compliance ............................................................................................................................................... 1-6

SECTION 2: Mounting and Wiring ................................................................................................................ 2-1

Determine the Signal Strength and Select a Location .......................................................................... 2-1

Mounting the Communicator .................................................................................................................. 2-2

Mounting Procedure, GSMV4G (no rear tamper switch) ............................................................... 2-2

Mounting Procedure, GSMVCN4G (with rear tamper switch) ..................................................... 2-3

Wiring the Communicator ....................................................................................................................... 2-4

Wiring for two-way voice ................................................................................................................... 2-4

Wiring for ECP, 4204 and Two-4204 Modes .................................................................................... 2-5

Wiring for Zone Trigger Mode .......................................................................................................... 2-5

Wiring the Fault Relay ...................................................................................................................... 2-6

Power Connections and Options ............................................................................................................. 2-7

Powering the Communicator ............................................................................................................ 2-7

Backup Battery Connection .............................................................................................................. 2-8

Initial Power-Up Sequence ............................................................................................................... 2-8

SECTION 3: Programming the Communicator .......................................................................................... 3-1

General Information ................................................................................................................................ 3-1

Using the AlarmNet Direct Website ................................................................................................ 3-1

Using a 7720P Programming Tool .................................................................................................... 3-1

Using the Control Panel Programming Mode ................................................................................. 3-2

Programming Conventions ............................................................................................................... 3-3

ECP Mode Programming ......................................................................................................................... 3-3

ECP Status Codes .............................................................................................................................. 3-7

Alternative Mode Programming (Zone Trigger, 4204 and Two-4204) .................................................. 3-8

Zone Trigger Mode ............................................................................................................................. 3-8

4204 Emulation Mode ....................................................................................................................... 3-8

4204 Emulation Mode Options ......................................................................................................... 3-8

Alternative Mode Programming ........................................................................................................... 3-10

Exiting Programming Mode .................................................................................................................. 3-18

Setting Factory Defaults ................................................................................................................. 3-18

SECTION 4: Registration ................................................................................................................................. 4-1

Registering the Communicator ............................................................................................................... 4-1

Registering through AlarmNet Direct Website ............................................................................... 4-1

i

Page 4

GSMV4G/GSMVCN4G Installation and Setup Guide

Register using the Tamper Switch ................................................................................................... 4-2

Register using the Programming Tool ............................................................................................. 4-2

Replacing an existing communicator ............................................................................................... 4-3

Register by Phone .............................................................................................................................. 4-3

SECTION 5: Programmer Keyboard Commands ....................................................................................... 5-1

Programmer Keyboard Commands ......................................................................................................... 5-1

Identification Displays ...................................................................................................................... 5-1

GSM Status Displays ........................................................................................................................ 5-2

System Status Displays..................................................................................................................... 5-4

Appendices ......................................................................................................................................................... A-1

Appendix A : Summary of LED Operation ............................................................................................. A-1

Appendix B : Central Station Messages ................................................................................................. B-1

Appendix C : Glossary .............................................................................................................................. C-1

Summary of Connections Diagram…………………………………………………………..……….Inside Back Cover

ii

Page 5

UL / ULC

ULC

SECTION 1

General Information

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

System Overview

Introduction

Congratulations on your purchase of Honeywell's GSMV4G GSM Communicator (referred to

as the GSMV4G, or GSMVCN4G in Canada). It represents the latest and most innovative

communication technology for the security industry and uses sophisticated encryption to

ensure the highest level of security for your customer.

The new 4G connectivity brings faster GSM data transfers with lower latency (response

time); together it results in speedier data transfers.

The communicator requires an AlarmNet–i account. For new installations, please obtain the account

information from the central station prior to programming this communicator. For replacement

installations, the AlarmNet-i account is created automatically when the communicator is registered

(based on the existing account).

In addition to alarm reporting, the communicator provides two-way voice communications

with the central station (when used with Honeywell’s AVS Audio Verification System

provides upload/downloading capability of Honeywell's control panel data over the Internet

(via the AlarmNet-G network), using GSM (Global System for Mobile) technology.

) and

NOTE: Two-way voice is not compatible with Honeywell Commercial Control Panels (such

as the VISTA-128/250 series).

Due to Honeywell's continuing effort to improve our products, your device may look slightly

different than pictured.

General Information

The communicator transmits signals to the AlarmNet-G network (GSM cellular network,

using GPRS) and forwards them to your central station.

If the GPRS network is unavailable, the communicator (if enabled by the dealer) will attempt

to send the transmission via SMS (Short Message Service) and/or email.

The communicator also provides support for AlarmNet Remote Services. These services

allow users remote access to their security systems and provide the ability for users to be

notified of system events via email.

ULC

System Features

Basic features of the communicator include:

• Remote Services allow the end user to access their security system from their computer

via a website. Availability of this service is controlled by the dealer via the web-based

programming tool on the AlarmNet Direct website. Once enabled, remote access can be

programmed via web or 7720P programming tool.

• Quick connection to compatible Honeywell series control panels

Two-way voice has not been evaluated by UL/ULC.

SMS has not been evaluated for ULC central station communication.

The GSMVCN4G is only employed for supplemental use. A listed DACT is required to be

used in conjunction with the GSMVCN4G to provide passive communication for fire and

Level P2 channel security for burglary.

1-1

Page 6

GSMV4G/GSMVCN4G Installation and Setup Guide

UL

ULC

UL

• Simple programming using a 7720P programming tool

• Reports fire, burg, and status messages via wireless network

• Allows uploading and downloading of control panel data via the wireless network

• Supports remote control of alarm systems via Remote Services feature

• Two-way voice capability

Encryption

The communicator uses 256 bit AES (Rijndael) encryption (which is required for certain

government installations). The AlarmNet-i AES Encryption Software Module Version 1.0

contained in the Honeywell products has NIST approval. Listings for this approval can be

found at http://csrc.nist.gov/groups/STM/cavp/documents/aes/aesval.html and search for

“Certificate number 979.”

Remote Services

Honeywell now offers a new series of web based services that provides consumers with the

ability to communicate with their security system remotely in a number of ways. These new

web services will allow users to:

• Access their security system from a computer via a website (Remote Access feature)

• Receive email and text message notifications of system events (Multi-Mode feature)

• Perform system functions and receive confirmations using text messages (SMS feature)

Dealers will initially enroll their customers for web services during account programming

through the AlarmNet Direct website. The features that can be enabled include Remote

Access and Multi-Mode. Once enabled, the specific programming fields associated with

these features can be programmed into the communications device either remotely using

the AlarmNet Direct website or locally using the 7720P local keypad programming tool.

Remote Access and Multi-Mode have not been evaluated by UL.

Modes of Operation

The communicator provides four modes of operation so it can be used with various types of

control panels, as summarized below.

ECP Mode

• This mode is for Honeywell control panels that support ECP communication

• The communicator connects to the control panel’s keypad terminals and provides 2-way

communication with the control panels using ECP messaging

• The control panel treats the communicator as an ECP device, so ensure to program the

control panel with the communicator’s device address

• Reports are sent in Contact ID format

• The communicator also supports two hardwire zone trigger inputs (zones 6 and 7)

UL

Only ECP Mode has been approved for ULC installations.

Only ECP Mode and Zone Trigger Mode have been evaluated.

• Opening and Closing ring back is fully supported.

• Only the V+ inverted, V– non-inverted, and EOL options have been evaluated.

1-2

Page 7

UL

Zone Trigger Mode

• This mode is for use with control panels that do not support ECP communication nor 4204

Relay Modules

• The communicator provides six input zones

• Each zone can be configured for +V, –V, or EOLR triggering

UL: For the communicator, only the V+ inverted, V– non-inverted, and EOL options have

been evaluated.

• Each zone can be programmed for inverted operation, delayed reporting, and restoral

reporting

• Zone 1 input can distinguish between pulsed and steady signals and report fire or

burglary alarms respectively

• Zone 1 can also be programmed to report LYNX panic (if used with LYNX control)

UL: This feature has not been evaluated by UL.

• Reports are sent in ADEMCO High-Speed format

Section 1: General Information

Opening and Closing ring back is supported by the control panel’s digital dialer.

4204 Mode and Two-4204 Mode

• This mode is for use with Honeywell control panels that do not support ECP communica-

tion, but do support 4204 Relay Modules

• The communicator connects to the control panel’s keypad terminals

• The control panel treats the communicator as 4204 Relay Module(s), so program the

control panel accordingly, including setting the communicator’s proper 4204 device

address

• 4204 mode provides up to four zone inputs, plus two optional trigger zones, depending on

options programmed

• Two-4204 mode provides up to eight zone inputs, depending on options programmed

• Each 4204 zone can be programmed for delayed reporting and restoral reporting

• Reports are sent in ADEMCO High-Speed format

UL

Supervision Features

The communicator provides the following types of supervision and communicator fault

detection:

• Network communication failure

supervisory message from the communicator within a specified time (“Supervision” option,

24 hours, 30 days, or none), AlarmNet notifies the central station of a communication

failure.

• Communication path failure

failure, both the Central Station and the control panel can be notified of the trouble

condition. The failure is considered a true fault when the fault time has expired ("GSM

Fault Time" option) provided it has been set to a non-zero value. Notification is sent to

the central station upon this expiration.

• Opening and Closing ring back is supported by the control panel’s digital dialer.

• 4204 Mode and Two-4204 Mode has not been evaluated by UL.

: In the event the AlarmNet network does not hear a

: In the event the module detects a communication path

1-3

Page 8

GSMV4G/GSMVCN4G Installation and Setup Guide

UL / ULC

• Fault output: Terminal 11 can serve as a fail-safe trigger for communicator fault

conditions.

If used, the fault relay will trip when the following conditions occur: tamper*, power loss*,

low battery*, battery charger fault*, loss of network connectivity*, the device is not

registered and the device is remotely disabled by AlarmNet.

* Alarm reporting for the noted condition must be enabled for it to trigger the fault relay.

• Primary power loss and low battery conditions (“Pwr Loss Rpt,” “Low Bat Rpt” options).

• Cover tamper condition (“Tamper Rpt” option).

Antenna

The communicator comes equipped with an internal antenna. This feature provides

additional security to the installation by making the device tamper resistant.

External antenna has not been evaluated by UL.

AMPS antennas, such as the 7825-OC antenna, cannot be used with this product.

1-4

Page 9

Specifications

Input Power:

16.5VAC, 40VA transformer, or for ULC installations 12VDC from

Backup Battery:

6V, 3.1AH, (Honeywell # K14139 included with GSMV4G only.)

ful life of the battery at 25ºC (77ºF) is approximately 4 years.

RF Output Power:

Operating temperature: –20º to +55ºC, for UL/ULC installations 0ºC

Altitude: to 10,000 ft. operating, to 40,000 ft. storage

Mechanical: Dimensions: 8.4" x 8.0" x 1.5" Weight: 2.4 lbs., with battery

Current Drain: 220mA standby, 380mA active

Fault Relay Output: Open collector, 12VDC, 0.25W max.

Section 1: General Information

the control panel.

(Honeywell transformer # 1361 included with GSMV4G.)

(Honeywell transformer # 1361CN not included with the

GSMVCN4G.)

Expected Battery Life: 5 Years (approx.)

Note: The sealed lead acid battery used for backup will have

reduced life expectancy when exposed to elevated temperatures.

The use

At 35ºC (95ºF) this will drop to 2 years and at 45ºC (113ºF) 1 year.

Battery life expectancy should be taken into account when locating

the radio.

Positive Trigger

6V or greater = positive trigger. (4V or less = restore.)

Level:

Negative Trigger

4V or less = negative trigger. (6V or greater = restore.)

Level:

RF Frequency:

2G GSM/GPRS/EDGE Quad Band, 850/900/1800/1900 MHz

3G/4G UMTS/HSPA+ Band V, Band II

2G GPRS +33dBm, GMSK modulation

EDGE +27dBm, 8-PSK modulation

3G UMTS +24dBm, QPSK modulation

WCDMA +24dBm, QPSK modulation

4G HSPA+ +24dBm, 64 QAM modulation

WCDMA +24dBm, 64 QAM modulation

Environmental:

to +49ºC

Storage temperature: –40º to +70ºC

Humidity: 0 to 95% relative humidity, non-condensing

for UL installations 0% to 85%; for ULC installations 0% to 93%

1-5

Page 10

GSMV4G/GSMVCN4G Installation and Setup Guide

MX8000 (UL – can be used for secondary reporting in ECP mode and Zone

7810iR-ENT (UL – must be the primary alarm receiver.)

Ademco 685

Compatibility

For a list of control panels that are compatible with various features of this device, go to:

https://mywebtech.honeywell.com/.

After logging on, select the applicable communication product, and then select “Compatibility

Chart” under Essential Docs.

For UL installations and ULC Commercial Burglary Installations, any compatible UL or ULC (respectively)

Listed Control Panel may be used. Note, that any control panel that does not communicate via Honeywell's

ECP data bus is compatible using zone Trigger Mode. For ULC Commercial Fire Installations, only ULC

Listed Subscriber's Unit Panels which use Honeywell's ECP data bus are compatible.

For UL and ULC Fire and Burglary installations, compatible receivers are:

•

Trigger mode. Shall be used for opening and closing ring back with the

control panel dialer)

•

•

UL

ULC

The Automation System must be UL1981 listed.

The GSMV4G has been evaluated for connection to police station receivers.

The GSMVCN4G has only been evaluated for communication with listed Model 7810iR-ENT

internet receiver and Model MX8000 central station receiver.

Compliance

This device complies with the following ULC Installation Codes and Standards:

1. The Canadian Electrical Code, Part I, Safety Standard for Electrical Installations,

CSA C22.1.

2. National Building Code (NBC).

3. Standard for Installation and Services for Fire Signal Receiving Centers and

Systems, CAN/ULC-S561-03.

4. Standard for Installation of Fire Alarm Systems, CAN/ULC-S524-06.

5. Standard for Installation and Classification of Burglar Alarm Systems for Financial

and Commercial Premises, Safes and Vaults, CAN/ULC-S302-M91.

1-6

Page 11

SECTION 2

Mounting and Wiring

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Determine the Signal Strength and Select a Location

The communicator must be mounted indoors within the protected premises. When choosing

a suitable mounting location, understand that signal strength is very important for proper

operation. For most installations using the supplied antenna, mounting the unit as high as

practical, and avoiding large metal components provides adequate signal strength for proper

operation.

You will use the communicator to determine signal strength in order to find a suitable

mounting location.

Note: If the SIM is already activated, the RSSI signal strength indicators will indicate

signal strength.

If the SIM has not been activated, the firmware in the communicator enables it to

communicate with the cellular network towers (without the SIM being activated) so that

signal strength measurements can be determined. In this case, you can display the signal

strength by simultaneously pressing the MODE and TAMPER switches.

Allow at least 60 seconds for a reading to establish.

RF Exposure

Warning – The internal or external antenna(s) used with this product must be installed to

provide a separation distance of at least 7.8 in. (20 cm) from all persons and must not be

co-located or operating in conjunction with any other antenna or transmitter except in

accordance with FCC multi-transmitter product procedures.

Mise en Garde

Exposition aux Frequences Radio: L'antenne (s) utilisée pour cet émetteur doit être

installée à une distance de séparation d'au moins 7,8 pouces (20 cm) de toutes les

personnes.

Note: The communicator must be installed in accordance with the National Fire Alarm

Code, ANSI/NFPA 72.

Unshielded, 22 AWG cable is recommended for the communicator power/data wires.

1. Unpack the communicator and open the case by pushing in the two bottom tabs with a

screwdriver while separating the case front.

2. Temporarily connect the communicator to the AC transformer or battery.

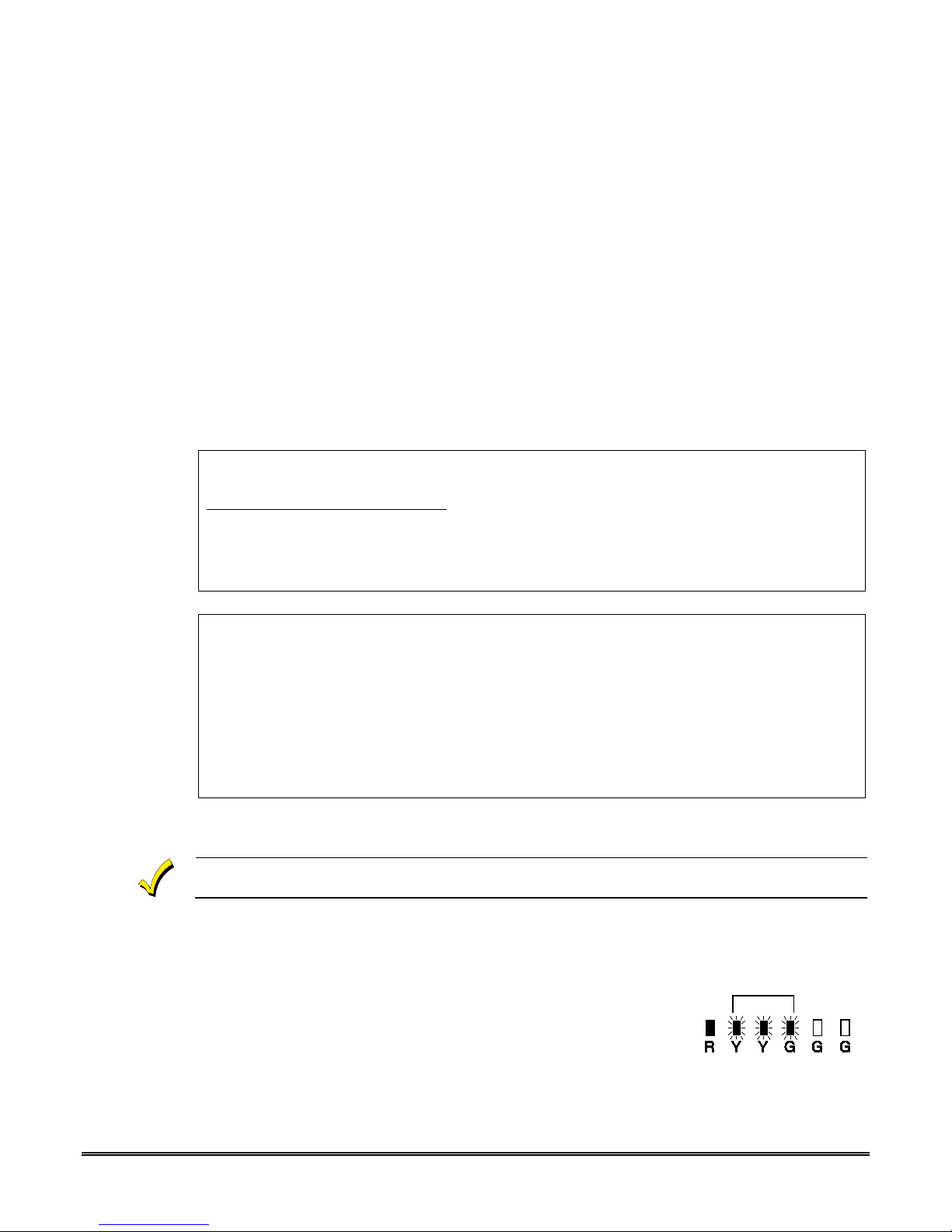

3. Choose the installation site with the best signal strength by

observing the signal strength (RSSI) bar graph (refer to

Appendix A for information about signal strength and status

indications). Signal strength should be within 3-5 bars. The

best signal strength is usually found at the highest point in

the building, near a window.

4. Mark the location for the communicator.

2-1

Page 12

GSMV4G/GSMVCN4G Installation and Setup Guide

UL

Mounting the Communicator

The communicator can be mounted in two ways depending on the installation requirements.

ULC NOTES:

For Commercial Fire installations, the communicator must be mounted to a single or double

gang box.

1. Locate the Drilling Template (provided) and align with case back. Drill at the appropriate locations for either single or double gang box.

2. Locate the gang box into the mounting surface, align case back over mounting surface

and install using the screws provided. Pass wires/cables through the opening in the gang

box and then through the opening in the case back.

3. When all wiring is completed, attach the case front of the communicator to the case back.

Attach the top first then press the bottom section inward until it snaps into place. Secure

cover using supplied screw.

4. For Commercial Burglary installations

The cover must be secured with the supplied screw.

Mounting Procedure, GSMV4G (no rear tamper switch)

1. Locate the case back over selected mounting position such that the opening in the case

back is aligned with the wire/cable opening on the mounting surface.

2. Pass the wires/cable through the opening in the case back, or route through the

removable knockouts located on the back cover.

3. Secure the case back to the mounting surface using four screws (supplied).

4. When all wiring is completed, attach the case front. Position the top first, then press the

bottom section until it snaps in place. Secure bottom using the supplied cover screw.

(This is required for UL installations.)

, you must install the rear tamper switch.

2-2

Standard Mounting

Page 13

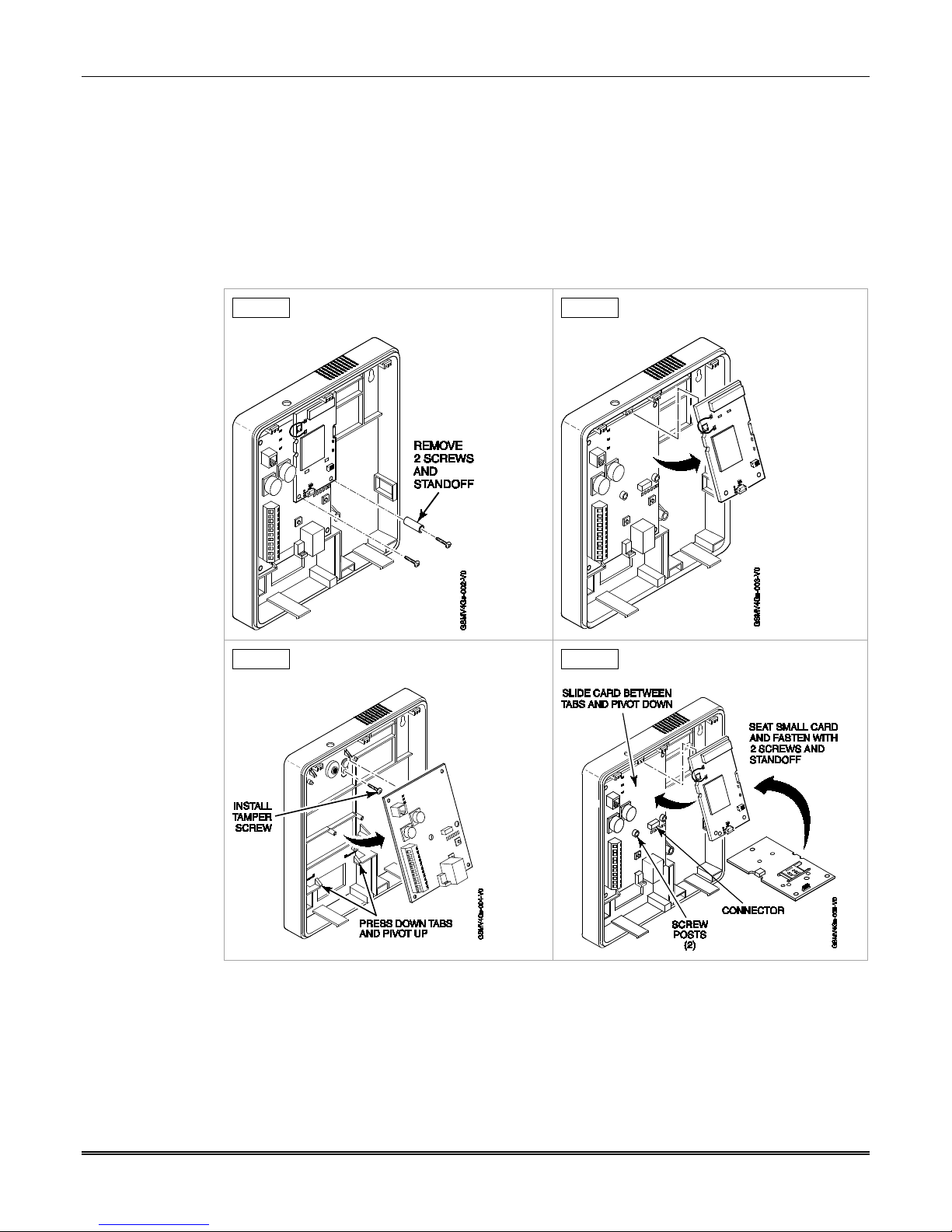

Mounting Procedure, GSMVCN4G (with rear tamper switch)

For Canadian installations where the rear tamper switch is used, this procedure requires the

removal of the printed circuit boards and installation of the tamper screw.

1. Remove the two mounting screws, and standoff from the daughter card, as shown in

Step A below.

2. Remove the daughter card by pivoting upward, as shown in Step B below.

3. Remove the lower printed circuit board by pushing down on the lower tabs and pivoting

the board upward, as shown in Step C below.

STEP A STEP B

Section 2: Mounting and Wiring

STEP C STEP D

4. Locate the case back over selected mounting position such that the opening in the case

back is aligned with the wire/cable opening on the mounting surface.

5. Pass the wires/cable through the opening in the case back, or route through the

removable knockouts located on the back cover.

6. Secure the case back to the mounting surface using four screws (supplied).

7. Install the tamper screw (provided), as shown in Step C above.

2-3

Page 14

GSMV4G/GSMVCN4G Installation and Setup Guide

UL

8. Replace lower printed circuit board and then daughter card, as shown in Step D above.

Be sure to engage receptacle pins by pushing in before securing the daughter card with

mounting screws.

When all wiring is completed, attach the case front. Position the top first, then press the

bottom section until it snaps in place. Secure bottom using the supplied cover screw.

Wiring the Communicator

• Installation must be in accordance with the National Electrical code and UL681, Installation and

Classification for Burglar and Hold-Up Alarm Systems.

• The communicator must be connected to a UL Listed dry contact or voltage trigger outputs of a UL

Listed compatible control panel.

• All interconnecting wires between the UL Listed control panel and the communicator must be less

than 3 feet in length contained in the same room. All interconnecting wiring must be installed in rigid

or EMT (where exposed on interior walls) or in flexible metal tubing if run in the walls or ceiling.

• Requires dialer reporting with a UL Listed control panel. Reporting occurs over both paths.

• A UL listed control panel must monitor the radio fault output of the communicator. A No. 659 or other

UL listed Telco Line Fault Monitor’s output must be connected to an input zone on the communicator.

Premises openings and closings should be sent via the UL listed control panel.

ULC

For ULC Commercial Fire and Burglary installations, only use the ULC wiring specified in the “Power

Connections and Options” topic.

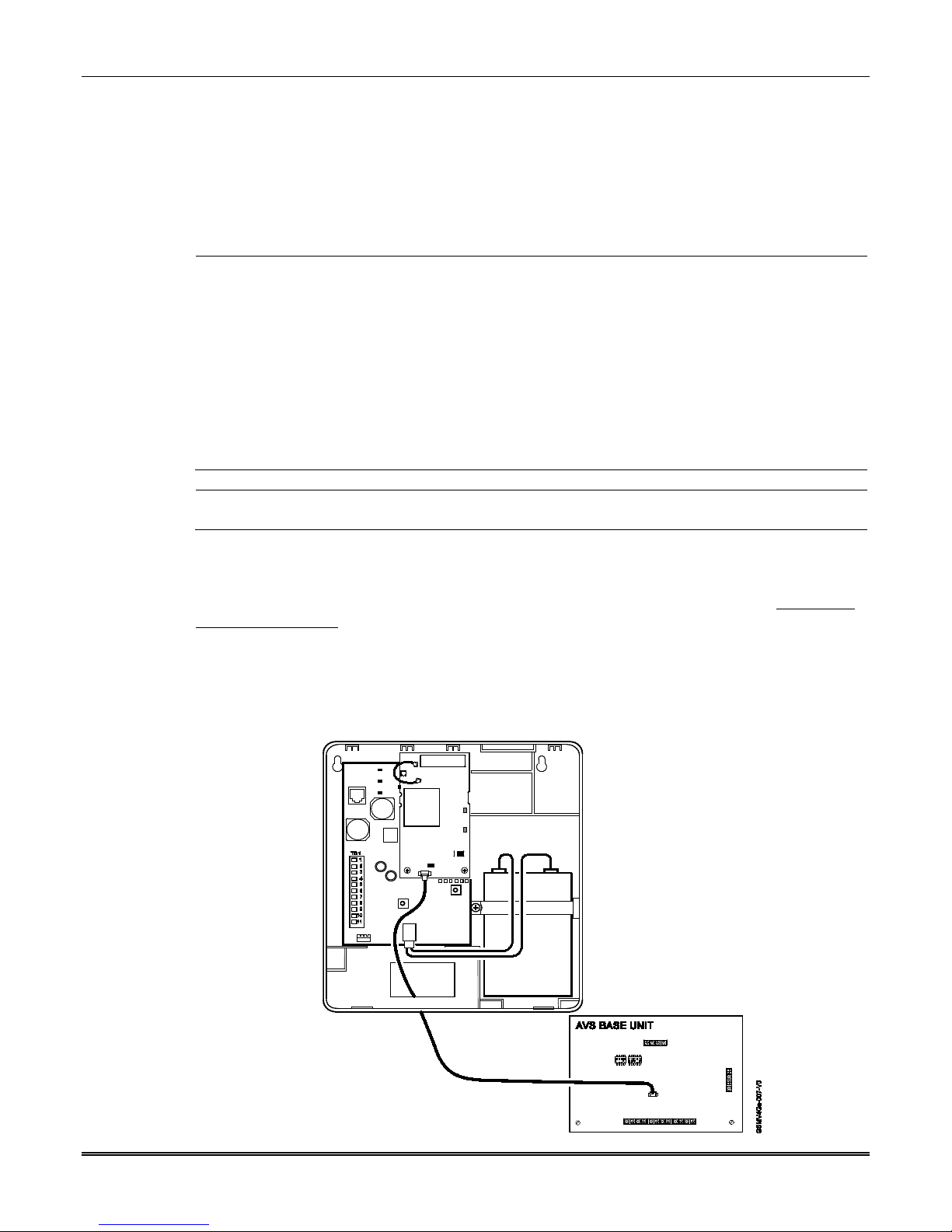

Wiring for two-way voice

The GSMV4G requires an optional audio cable (GSMV-AUDIO, grey) to support two-way

voice using the AVS Base Unit. Note the AVS Base Unit is part of Honeywell’s AVS Audio

Verification System. This system consist of the AVS Base Unit, Remote Station, and the

Remote Station PC board. For detailed information, refer to the AVS Audio Verification

System documentation. Follow the guidelines below for connecting the audio cable.

1. Power down the communicator, control panel and AVS Audio Verification System.

(When the communicator is fully wired up, restore power to the communicator, control

panel and AVS Audio Verification System.)

2-4

Page 15

2. Connect one end of the audio cable to the audio connector located on the small PC board.

3. Route the audio cable to the connector on the AVS Base Unit and connect the cable.

4. Ensure the audio cable ends are secured with tie wraps to reduce strain.

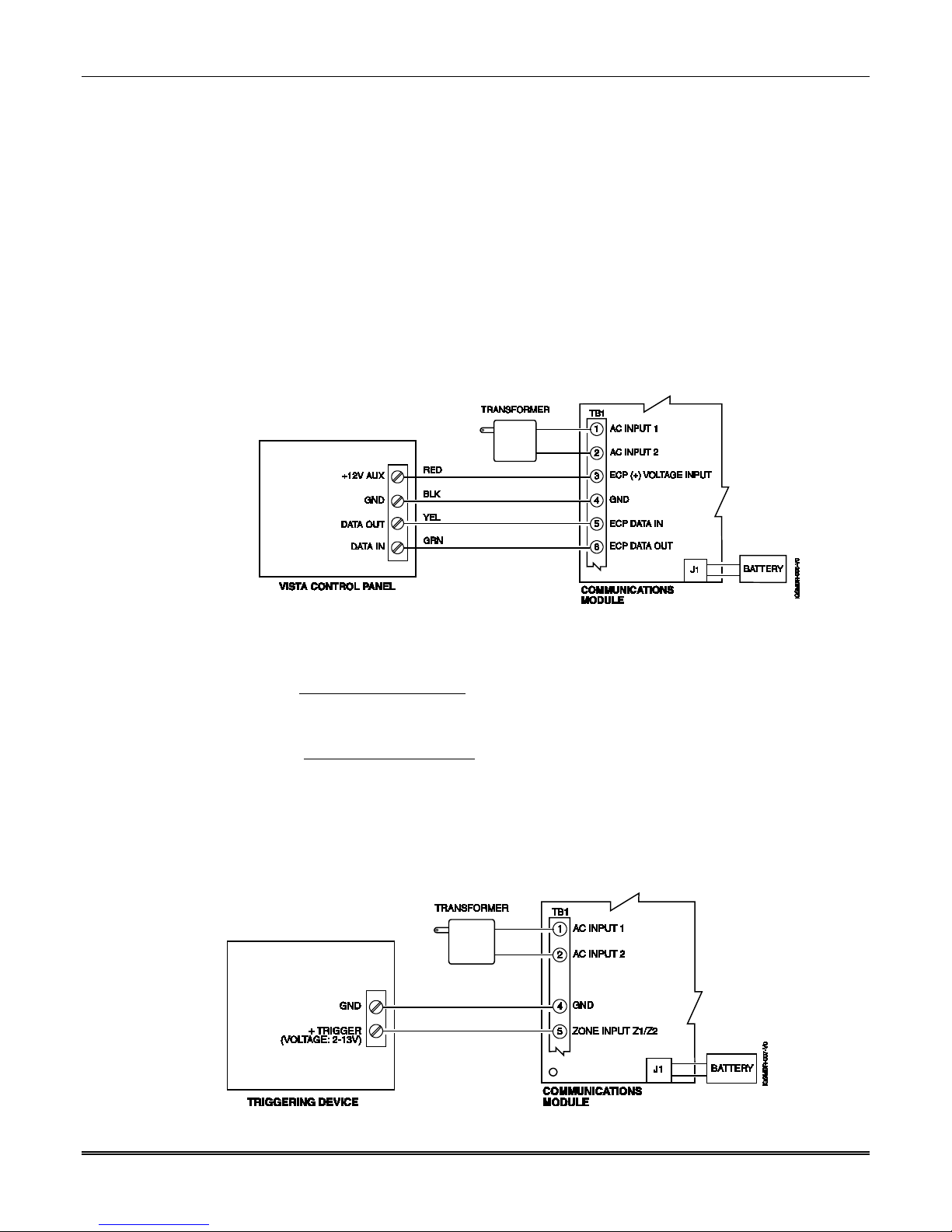

Wiring for ECP, 4204 and Two-4204 Modes

Most Honeywell ADEMCO control panels support ECP data communication, (e.g., VISTA10P, VISTA-15P, VISTA-20P, VISTA-128BP and VISTA-128FBP). However, there are some

panels that do not. Check the Installation and Setup Guide for the control panel you are

using to see if it supports ECP communication.

Connect the communicator to a compatible Honeywell VISTA control panel's ECP terminals,

in parallel with keypads and other peripheral devices such as RF receiver, VIP module, etc.

Wire length/gauge limitations are the same for the communicator as they are for keypads

and other peripheral devices. To wire the communicator for ECP or 4204 modes, see the

figure below and make the following connections:

Section 2: Mounting and Wiring

Wiring a VISTA for ECP Mode or 4204 Modes

Wiring for Zone Trigger Mode

To trip a zone using a positive trigger

, the voltage level must be:

6V or greater = positive trigger. (Levels above +14V may cause damage to the unit.)

4V or less = restore.

To trip a zone using a negative trigger

, the voltage level must be:

4V or less = negative trigger.

6V or greater = restore. (Levels above +14V may cause damage to the unit.)

Note: Remember to program the communicator’s zone for the desired trigger type.

Connect a wire from the triggering source (bell output, voltage trigger, etc.) of the control

panel to the zone input of the communicator, and connect a common ground between the

communicator and control panel. Examples of zone connections follow:

Wiring the Zone 1 Input for a Positive (+) Trigger

2-5

Page 16

GSMV4G/GSMVCN4G Installation and Setup Guide

UL / ULC

Wiring the Zone 1 Input for a Ground (-V) Trigger

UL

• Zones should use EOL resistors, and be pro-

grammed as V+ Inverted or V– Inverted

operation such that a cut line results in an

alarm.

• Do not use zones 1 and 2 for UL installations.

Wiring the Zone 1 Input for EOL Supervised N.O./N.C. Triggers

Wiring the Fault Relay

You may wire and program the communicator's fault output trigger for fail-safe mode (see

the question "FLT REL ON Y/N").

To sense a communicator fault at the control panel, see the figure below and make the

following connections. Include the proper EOL resistor required by the control panel.

A 24 hour supervisory zone must be assigned on the control panel, with the communicator's fault

relay wired to that zone.

Wiring the Fault Relay to a Control Panel Zone for Normally Closed Fault

2-6

Page 17

Power Connections and Options

Standard

ULC Commercial

Fire and Burglary

Compliant

Installation

Powering the Communicator

There are three ways to power the communicator (see illustrations below):

Standard Installation

transformer.

ULC Commercial Fire and Burglary Compliant Installation

powered by the control panel.

Shared Transformer Installation

transformer may be used to power both the communicator and the control panel under the

following conditions:

• You must use the Honeywell 1361 Transformer.

• This configuration ONLY applies to the VISTA-10P, VISTA-15P, VISTA-20P control

panels when used with the GSMV4G communicator.

• DO NOT use this configuration with any other control panel.

• DO NOT use this configuration if using two-way voice.

• This configuration has not been evaluated by UL.

For all installations the control panel ground (GND) must be connected to TB1-4 GND on the

communicator. In addition, if using ECP communication, you must connect the +12VDC

AUX voltage output on the control panel (9.6V-13.8V typical) to TB1-3 on the communicator.

Section 2: Mounting and Wiring

– The communicator is powered by the supplied AC plug-in

– The communicator must be

– In this installation the supplied AC plug-in

Installation

2-7

Page 18

GSMV4G/GSMVCN4G Installation and Setup Guide

NOTE:

Shared

Transformer

Installation

When calculating the total load on the auxiliary power output of the control panel, budget 10mA

for the communicator when using ECP mode.

Backup Battery Connection

The included battery (K14139) is used for backup in the event of power loss to the communicator. It does not provide power to the control panel.

In ULC installations this battery is not connected

, and all backup power is supplied by the

control panel.

• The battery can provide over 24 hours of system life in the event of a power failure.

• A programmable power loss message can alert the AlarmNet Control Center when system

power is lost (power loss messages are reported within 1-3 hours of actual loss).

• The communicator transmits a low-battery message (programmable) when the battery

reaches 5.7V ±5%, indicating subsequent messages may not be transmitted.

• The system shuts down when the battery reaches 5.1V, and radio transmissions are no

longer possible.

• If system power is restored before the communicator shuts down, a power restore message

is sent within 1-3 hours after power is restored, and the battery is recharged using the

communicator’s built-in battery charger. If system power is restored after the

communicator has shut down, a power-on reset condition exists, the communicator

initializes itself and the battery will recharge.

Install the battery as follows, and refer to the Summary of Connections diagram at the end of

this document.

1. Place the battery inside the case back.

2. Snap the right side of the battery clip onto the inside of the case back and secure the

left side with the screw provided.

Do not plug the battery in until after you have powered-up the communicator.

Initial Power-Up Sequence

Before connecting power, check that the following have been completed:

• If using ECP, 4204 or 2-4204 Mode, terminal block TB1 V+ and GND terminals are

connected to the control panel’s auxiliary power output: 12VDC nominal.

• Plug in the transformer. Then connect the red and black battery cables to the battery

terminals. Connect battery cable to connector J1.

• Power up the control panel. (Initially, all communicator programming options are set to

the factory default settings.)

2-8

Page 19

UL

SECTION 3

Programming the Communicator

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

General Information

The communicator is designed to deliver alarms via the GSM network to an AlarmNet

central station when it is registered with a valid AlarmNet account.

The communicator requires an AlarmNet–i account. For new installations, please obtain the account

information from the central station prior to programming this communicator. For replacement

installations, the AlarmNet-i account is created automatically when the communicator is registered.

You can program the communicator by one of the following methods:

• Through the AlarmNet Direct website

• Through use of a 7720P Programming Tool

• Through a programming mode in the control panel on panels that support this option

(e.g., VISTA-128BP and FBP)

Only ECP and Zone Trigger modes have been evaluated by UL.

Using the AlarmNet Direct Website

To program the communicator via the website (if you are already signed up for this service),

go to: https://services.alarmnet.com/AlarmNetDirect/userlogin.aspx

If you are not signed up for this service, click on “Dealer Sign-Up.”

Log in and follow the on-screen prompts.

Please have the following information available when programming the communicator:

1. Primary City ID (two-digit number)

2. Primary Central Station ID (two-digit hexadecimal number)

3. Primary Subscriber ID (four-digit number)

4. MAC ID and MAC CRC number (located on the box and inside the communicator)

After programming is complete, you must transfer the data to the communicator and the

communicator must be registered. Refer to Section 4: Registration, for further instructions.

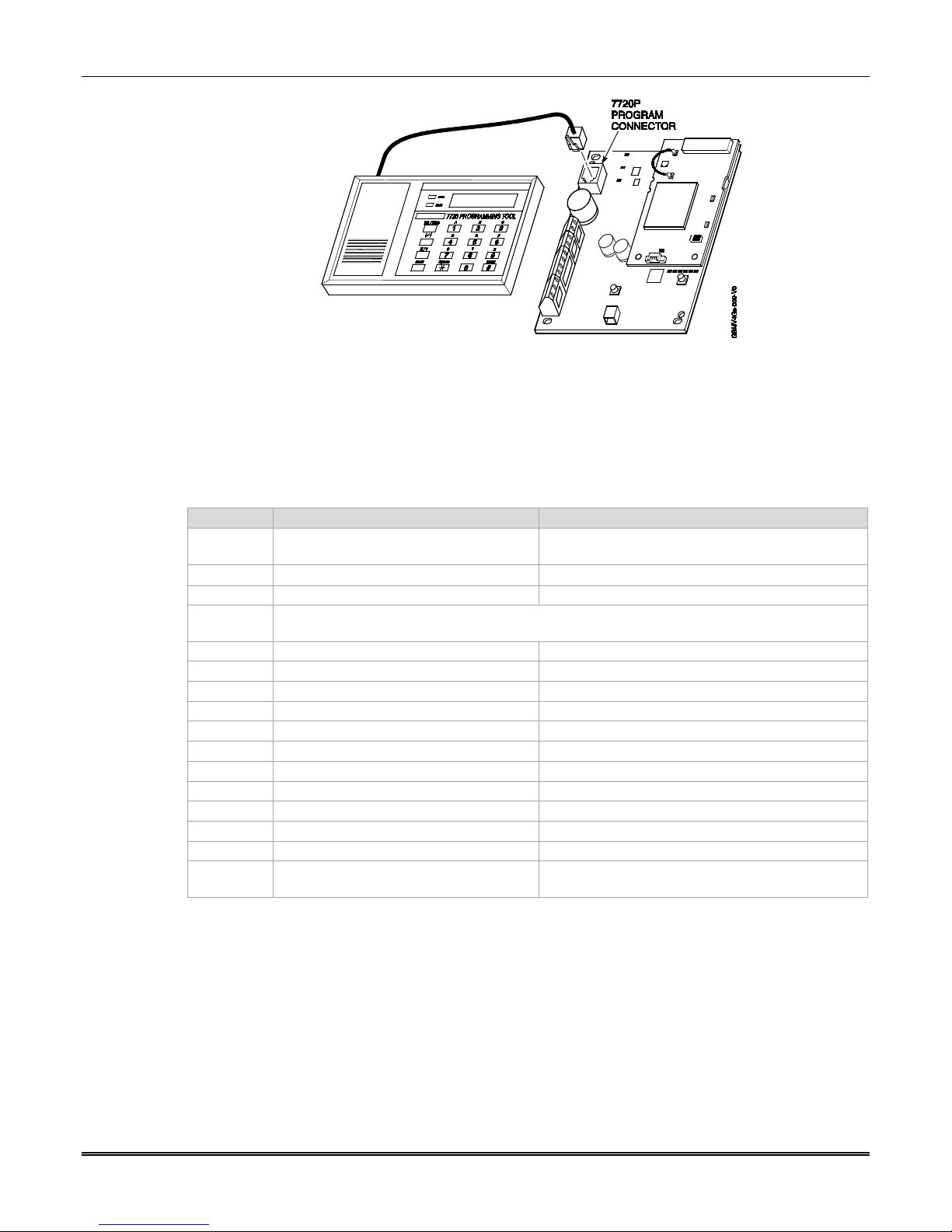

Using a 7720P Programming Tool

Connect the 7720P Programming Tool as shown below. The communicator powers the 7720P

Programming Tool via the programming jack, and automatically senses the presence of the

7720P when it is plugged in.

3-1

Page 20

GSMV4G/GSMVCN4G Installation and Setup Guide

KEY

NORMAL KEY FUNCTION

SHIFT KEY FUNCTION

BS/ESC

[BS]: Press to delete entry

[ESC]: Press to quit program mode; also can reset

programming defaults*

[↓]: Scroll down programming

[↑]: Scroll up programming

N/Y

[N]: Press for "NO" answer

[Y]: Press SHIFT-Y for "YES" answer

SHIFT

Press before pressing a SHIFT key function. Will light SHIFT LED. LED goes out once a key

is pressed. Press again for each SHIFT function desired.

1/A

[1]: For entering the number 1

[A]: For entering letter A

2/B

[2]: For entering the number 2

[B]: For entering letter B

3/C

[3]: For entering the number 3

[C]: For entering letter C

4/D

[4]: For entering the number 4

[D]: For entering letter D

5/E

[5]: For entering the number 5

[E]: For entering letter E

6/F

[6]: For entering the number 6

[F]: For entering letter F

7/S

[7]: For entering the number 7

[S]: For entering letter S

8/T

[8]: For entering the number 8

[T]: For entering letter T

9/X

[9]: For entering the number 9

[X]: For entering letter X

SPACE

[SPACE]: For scrolling option list

No SHIFT function

0

[0]: For entering the number 0

No SHIFT function

#/ENTER

[#/ENTER]: Starts programming mode;

Press to accept entries

No SHIFT function

7720P Programmer Tool Connection

Each key of the 7720P has two possible functions: a normal function and a Shift function.

To perform a normal key function, simply press the desired key.

To perform a Shift function, press the [Shift] key, and then press the appropriate key.

The prompts in this document reflect use of the 7720P Programming Tool. Table 3-1 below

lists each normal and shift key function.

Table 3-1. 7720P Normal and Shift Key (shift LED lit) Functions

↓/↑

*Active only when the "Exit Programming Mode" prompt is displayed.

Using the Control Panel Programming Mode

Some control panels support programming of the communicator through the control

panel programming mode (e.g., Vista-128BP). If programming through the control

panel, only the ECP Mode programming options are available. The "mode" questions

will not be displayed, and the mode cannot be changed. For a description of key

functions on the control panel keypad, and how they map to the 7720P Programming

tool, refer to the control panel's Programming Guide.

3-2

Page 21

Programming Conventions

ULC

[Y], [N]

Enters programming mode.

[0-9, A-F, N, S,

If a password has been previously assigned, this prompt appears.

[Y], [N]

To begin programming the communicator, press [Y] and go to

"Change Password."

[Y], [N]

Passwords can be used to protect account and programming

Password."

[Y], [N]

If a password has already been assigned, this prompt appears after

Programming is accomplished by answering a series of prompts (questions). Most prompts

require only a [Y]es or [N]o response, while others require a numerical response (ID

numbers, etc.).

The current value is displayed on the second line in parentheses ( ). A "?" indicates an

invalid entry.

Use the [ENTER] key to accept the current entry and proceed to the next prompt. If the

entered value is invalid, pressing [ENTER] re-displays the prompt; the next prompt is not

displayed until a valid answer is entered.

Use the up/down arrow keys to scroll through the programming questions without changing

any values. Press the [ESC] key to go to the end of the list of questions.

ECP Mode Programming

The communicator supports ECP messaging to communicate with the control panel.

Likewise the control panel sends Contact ID format alarms to the communicator via the ECP

bus. Not all control panels support the communicator interface on ECP, so be sure to check

the Installation and Setup Guide of the control panel to see if it supports this feature.

Only ECP Mode has been approved for ULC installations.

Refer to Table 3-2 for ECP Mode programming and follow the prompts.

Press the [ENTER] key to begin programming.

Section 3: Programming the Communicator

NOTE: The central station can remotely block access to local device

programming. If this has been done, the following prompt appears:

NOTE: The default programming values for ECP mode are listed in the prompts below.

Table 3-2. Programming the communicator for ECP mode only.

PROMPTS OPTIONS DESCRIPTION

Strt Prog Mode?

1

(Y/N)_

Enter Password

2

Program Device?

3

(Y/N)_

Create Password?

4

(Y/N)_

T, X, Y]

Enter a 4-digit password (0-9, A-F, N, S, T, X, Y).

The next prompt appears.

Prompt 9: "Device Mode."

To create a password if none has been assigned, press [N] and go to

Prompt 4: "Create Password."

To change an existing password, press [N] and go to Prompt 5:

information.

If no password has been assigned, this prompt appears after

pressing [N] at the "Program Device?" prompt.

If a password is desired, press [Y] and go to Prompt 6: "Enter

Access to Prog

Mode Denied

Change

5

Password?

(Y/N)_

pressing [N] at the "Program Device?" prompt.

Press [Y] if you want to change the password.

NOTE: To clear an existing password, without entering a new one,

answer [Y] to the "Change Password?" prompt, then press the

[Enter] key when prompted for the new password and its

confirmation.

3-3

Page 22

GSMV4G/GSMVCN4G Installation and Setup Guide

PROMPTS

OPTIONS

DESCRIPTION

[0-9, A-F, N, S,

[0-9, A-F, N, S,

Re-enter the password as confirmation.

displayed followed by the "Exit Prog. Mode?" prompt:

Otherwise, the "Exit Prog. Mode?" prompt is displayed directly.

[Y], [N]

Exits program mode.

Refer to the Exiting Programming Mode paragraph in this section.

ECP

Press the [space] key to scroll through the modes of operation. Press

Multi-Mode (email notification) is intended as a convenience for the user, and does not replace

UL / ULC

[01-30]

This address must be programmed if using the Multi- Mode feature.

panels. See Important Information above.

Important Information Regarding Primary and Secondary Accounts (Questions 12-18)

account reporting, you will need secondary account information. The City ID, CS ID or Subscriber ID of the

Enter Password

6

Verify Password

7

Exit Prog. Mode?

8

(Y/N)_

T, X, Y]

T, X, Y]

[ESC]

This prompt is displayed if [Y] was pressed in Prompt 4 or 5.

Enter a 4-digit password (0-9, A-F, N, S, T, X, Y).

If the password doesn't match the first entry, the following is

Verify Not OK

PSWD not created

Press [N] to go back to Prompt 3.

Press [ESC] to load factory defaults.

Device Mode

9

(ECP)_

NOTE: In order for the Multi Mode

must be created in the AlarmNet Direct website and “Remote Access” must be enabled for the comm device.

Users can receive email notification of system events by using the Multi-Mode feature. In ECP mode, this is

accomplished through emulation of a 4204 relay module, or two 4204 relay modules.

• When “4204-sourced” is selected, the user can be notified of up to four events, plus two additional events if using

the optional communication device zones of 6 and 7.

• When “2-4204-sourced” is selected, the user can be notified of up to eight events. The Multi-Mode address must

match the address of a relay module enabled in the control panel (although you don’t actually connect a module).

If using “2-4204-sourced,” the address of the second module is automatically assigned the next device address

after the first 4204.

• When “Enhanced Reports” is selected, a device address of 25 should be selected.

Make sure the addresses are also enabled in the control panel. Program outputs to trigger on system events the

user would like to be notified of through Output Device (Relay) programming in the control panel.

These events are configured at the AlarmNet Total Connect website at: https://services.alarmnet.com/TotalConnect

Central Station reporting of critical events (alarms, troubles, etc.).

Multi-Mode has not been evaluated by UL or ULC.

Multi Mode

10

(Disabled)_

Multi Mode Addr

11

(12)_

•

• Zone Trig.

• 4204 Emu

• Two 4204s

Important Information Regarding Multi-Mode Options

, Remote Access, and Keypad Address programming fields to appear an account

• Disabled

• 4204 Sourced

• 2-4204 Sourced

• Enhanced

Reports

[ENTER] to select ECP mode.

IMPORTANT, if either Zone Trig, 4204 Emu, or Two 4204s device

mode is desired, use Table 3-4 for programming.

Enable if you want system events sent by email to the user. Select

"4204 Sourced" to send up to four events (plus two additional reports

triggered by optional hardwire zones 6 and 7), or "2-4204 Sourced"

to send eight events.

Disable for normal alarm processing and go to Prompt 12: "Primary

City ID".

Select “Enhanced Reports” to enable reporting to TC2 web services.

Note, to use “Enhanced Reports” ensure the control panel is Total

Connect 2.0 Ready.

The address must be unique from the normal communicator (or

LRR) device address, and the Keypad Address used for Remote

Access or Direct Wire downloading. The address used must also be

enabled as a 4204 relay module in Vista and First Alert control

3-4

Account information is provided by the central station administrator. If the control panel supports secondary

Page 23

Section 3: Programming the Communicator

PROMPTS

OPTIONS

DESCRIPTION

secondary account must differ from that of the primary account.

[01-99]

[01-FE]

Enter the 2-digit primary central station ID number, 01-FE (HEX).

[0001-9999]

Applicable only if control panel supports Central Station #1 and #2

Enter the 2-digit secondary city ID, 01-99 (decimal).

In ECP mode, the GSMV4G communicates with the control panel

entered in Prompt 22.

UL / ULC

Press [Y] to allow the end user to access their system via a website.

based programming tool on the AlarmNet Direct website.

Applies only to VISTA-128BP/250BP and FBP Series control panels,

programmed

30 Day

The AlarmNet network must hear at least one supervisory message

UL/ULC: Must be set to 24 hours.

Primary City ID

12

(??)_

Primary CS ID

13

(???)

Primary Sub ID

14

(????)

En. 2nd CS Y/N

15

(N)_

2nd City ID

16

(??)_

2nd CS ID

17

(??)_

2nd Sub ID

18

(????)_

Device Address

19

(03)_

[Y], [N]

[01-99]

[01-FE]

[0001-9999]

[01-30]

Enter the 2-digit primary city ID, 01-99 (decimal).

Enter the 4-digit subscriber account number, 0001-9999 (decimal).

Category Enable reporting for the communicator device (e.g.,

VISTA-128BP, FA1660C).

Used if reporting to a second central station is desired.

If [N], go to Prompt 19: "Device Address."

Enter the 2-digit second central station's ID number, 01-FE (HEX).

Enter the 4-digit subscriber account number for the second central

station, 0001-9999.

using the ECP bus. Enter the appropriate ECP device address. For

VISTA-10 and VISTA-20 series control panels, use address 03. For

other control panels, see the their Installation and Setup Guide.

NOTES:

1. When programming the control panel, enable the communicator

(or LRR) output.

2. The device address must be unique from the "Keypad Address"

Remote access has not been evaluated by UL or ULC.

Remote Access Y/N

20

(N)_

Direct Wire Y/N

21

(N)_

[Y], [N]

[Y], [N]

Availability of this service is controlled by the dealer via the web-

and FA1660C and 1700C Series control panels.

If [N], and if Prompt 20: “Remote Access” is disabled, skip to Prompt

23: "Supervision."

Keypad Address

22

(28)_

[01-30]

Must be

Direct Wire downloading.

NOTES:

1. This address must be programmed as an alpha keypad in the

2. This address must be unique from the "Device Address" entered

in Prompt 19.

Supervision

23

(24 Hours)_

•

• 24 Hour

• None

from the communicator during this supervision period; otherwise,

AlarmNet notifies the central station that a communication failure

has occurred. (If the supervision period is changed after registration,

you must re-register the communicator.)

Press the [space] key to scroll through choices.

if using either the Remote Access feature or

control panel (Device Programming Mode). If using Remote

Access, the keypad must also be enabled as an AUI (advanced

user interface) keypad. DO NOT connect an actual keypad (or

any other device) assigned to this address.

3-5

Page 24

GSMV4G/GSMVCN4G Installation and Setup Guide

PROMPTS

OPTIONS

DESCRIPTION

•10 Minutes

• 24 Hours

The old alarm time sets how long an undeliverable alarm is retried

In the event the communicator detects a communication path

UL/ULC: Must be one (01) minute.

If enabled, the fault open collector output is normally energized to

Sends a primary power loss report to the central station within 1-3

Sends a low-battery report when a low battery condition exists.

[Y], [N]

Sends a tamper report when the communicator detects a tamper

Set V+ to inverted, and V– as non-inverted.

NOTE: Optional hardwire zones report in ADEMCO High-Speed

format.

Old Alarm Time

24

10 Minutes_

GSM Flt Time

25

(00 mins)_

Flt Rel ON Y/N

26

(N)_

Pwr Loss Rpt Y/N

27

(Y)_

• 4 Hours

• 15 Minutes

• 8 Hours

• 30 Minutes

• 12 Hours

• 1 Hour

• 24 Hours

• 2 Hours

• 4 Hours

• 8 Hours

• 12 Hours

[00-99]

[00] = not used

[Y], [N]

[Y], [N]

for delivery to the central station. If the message is not validated, it

is retried until the old alarm time is reached or the message is

validated.

Press the [space] key to scroll through choices.

UL/ULC: Must be set to 10 minutes.

failure, enter the time delay (in minutes) before the communicator

notifies the control panel with a trouble message (and trips the

Fault Output if used; (terminal 11) see next prompt). The control

panel can then notify the central station.

ground, and de-energizes (open circuit) in the event of a

communicator fault. For conditions that trip the fault relay refer to

Supervision Features in Section 1.

Set to [Y] if fail-safe mode is desired.

See Wiring the Fault Relay in Section 2.

UL/ULC: Must be set to "Y."

hours after its detection. A restore report is sent within 1-3 hours

after power is restored.

UL/ULC: Must be set to "Y."

Low Bat Rpt Y/N

28

(Y)_

[Y], [N]

UL/ULC: Must be set to "Y."

Tamper Rpt Y/N

29

(Y)_

condition. A tamper restore is automatically sent when the tamper

condition clears.

UL/ULC: Must be set to "Y."

Important Information Regarding Zone Input Options

ECP mode supports two optional hardwire zone input triggers by making connections to the communicator’s zone 6

and/or zone 7 terminals and programming the appropriate zone trigger options below.

Each zone input can be programmed to cause an alarm under one of the following conditions:

• (V+), where a positive voltage causes an alarm for normally low connections (voltage trigger, NO, NC)

• (V–), where a ground trigger causes an alarm for normally high connections (open collector, NO, NC)

• (EOLR) End of Line Resistor, where the input is supervised by a 2K EOL resistor. The zone can be triggered

by open collector, voltage trigger, NO, NC.

UL:

In addition to the above, zones can be programmed for an Inverted Trigger, where the alarm and normal states of

the zones are inverted; this can serve a fail-safe supervisory purpose for certain installations.

These zone inputs can also be programmed for restore reporting, and for delayed reporting, which allows time for

the user to abort false alarms.

3-6

Page 25

PROMPTS

OPTIONS

DESCRIPTION

[Y], [N]

Enables alarm reporting for zone 6.

(V+)

(EOLR)

Selects the triggering method for this zone input.

[Y], [N]

Inverts the alarm and normal states of the zone 6 trigger; otherwise

Enables restore reporting for zone 6.

[01-15]

Defines the reporting delay in seconds for zone 6.

[Y], [N]

(V+)

(EOLR)

Selects the triggering method for this zone input.

Inverts the alarm and normal states of the zone 7 trigger; otherwise

[Y], [N]

Enables restore reporting for zone 7.

UL/ULC: Must be set to “Y.”

[01-15]

Defines the reporting delay in seconds for zone 7.

Reviewing Programming Mode Entries

UL

STATUS CODE

DESCRIPTION

0000

Control panel lost communication with communicator.

0880

Communicator tamper detected (cover removed).

0005

Communicator has lost contact with AlarmNet-G network.

000F

Communicator is not registered; account not activated.

Enable Zn6 Y/N

30

(N)_

Zn6 Trigger Type

31

(V+)_

Invert Zn6 Y/N

32

(N)_

Restore Zn6 Y/N

33

(Y)_

Delay Zn6 (secs)

34

(00)_

•

• (V–)

•

[Y], [N]

[00] = no delay

Section 3: Programming the Communicator

If [N], skip to Prompt 35: "Enable Zn7."

Press the [space] key to scroll through choices.

uses normal input signal.

UL/ULC: Must be set to “Y.”

UL/ULC: Must be set to “00.”

Enable Zn7 Y/N

35

(N)_

Zn7 Trigger Type

36

(V+)_

•

• (V–)

•

Invert Zn7 Y/N

37

[Y], [N]

(N)_

Restore Zn7 Y/N

38

(Y)_

Delay Zn7 (secs)

39

(00)_

Review? Y/N

40

[00] = no delay

[Y] = review

[N] = exit

ECP Status Codes

When the communicator is configured for ECP mode, it sends status messages to the control

panels for battery, power, tamper, and network connectivity failures. Some of the control

panels, (e.g., VISTA-10P, VISTA-15P and VISTA-20P Series) display these on the keypad as

“LngRng Radio” followed by a 4-digit code (listed below). In addition, the Contact ID codes

(listed in Appendix B) for these conditions are sent to the central station by the

communicator.

Enables alarm reporting for zone 7.

If [N], skip to Prompt 40: "Review."

Press the [space] key to scroll through choices.

uses normal input signal.

UL/ULC: Must be set to “00.”

To review the programming options, press [Y]. The programming

prompts are displayed again. Use the up/down arrow keys to scroll

through the program fields without changing any of the values. If a

value requires change, simply type in the correct value. When the

last field is displayed, the “REVIEW?” prompt again appears.

To exit the programming mode, press [N] in response to the

"REVIEW?" prompt, and refer to Exiting Programming Mode

paragraph at the end of this section.

The information in the following table is based on the VISTA-20 which has not been evaluated

with this communicator.

Table 3-3. Common ECP Keypad Display Status Codes

3-7

Page 26

GSMV4G/GSMVCN4G Installation and Setup Guide

0019

Communicator shutdown.

0400

Communicator power on / reset AND the control panel lost communications with

0C80

Communicator power on / reset AND tamper detected.

0C8F

Communicator power on / reset AND tamper detected AND not registered.

08E0

Communicator tamper detected AND communicator battery low.

3000

Primary power loss (will only be displayed in conjunction with another event).

8000

Battery charger failure (will only be displayed in conjunction with another event).

0060

Low battery (will only be displayed in conjunction with another event).

UL / ULC

NOTE:

UL

the communicator.

Alternative Mode Programming (Zone Trigger, 4204 and Two-4204)

The LYNX controls have not been evaluated with this communicator.

Zone Trigger Mode

There are six input zones available on the communicator. Each zone is selectable for +V, -V,

or EOLR trigger. The first zone input can detect both pulsed and steady signals if connected

to a bell output.

When using Zone Trigger mode, messages are sent in ADEMCO High-Speed format.

Zones 3, 4, 5, 6 and 7 are voltage trigger inputs located on TB1 pins 6-10.

Refer to Table 3-4 for Zone Trigger Mode programming and follow the prompts that pertain

to Zone Trigger Mode.

4204 Emulation Mode

In 4204 Emulation Mode, the GSMV4G communicates with a compatible Honeywell VISTA

series or First Alert control panel as though it were a 4204 Relay Module. If two 4204s are

enabled in the communicator, it acts as two 4204s at consecutive device addresses. The

control panel must be configured to recognize one or two 4204 relay modules accordingly. On

VISTA-32FB (or higher) control panels and First Alert equivalents, addresses 6 and 13

should not be used when the secondary 4204 is enabled. Messages are sent in ADEMCO

High-Speed format.

See your control panel Installation and Setup Guide for the number of 4204 modules

supported.

4204 Emulation Mode Options

For control panels that do not support ECP communication, the 4204 Emulation modes

provide a means of sending up to eight unique reports based on defined system conditions.

In 4204 mode, the communicator functions as a logical 4204 Relay Module, where each relay

number, referred to in the communicator as zone number, can be programmed to send a

report based on the output function programmed in the control panel for that relay. Each

relay-zone can be programmed to; send a restore message of the reported condition, delay the

transmission of messages, and to send reports only when a conditional zone is triggered

(armed). See "Important Information Regarding Zone Input Options" later in this section.

In single 4204 mode, the communicator supports up to four relay-zones. In Two-4204 mode,

the communicator functions as two 4204 modules, supporting up to eight relay-zones.

4204 Mode and Two-4204 Mode has not been evaluated.

3-8

Page 27

Section 3: Programming the Communicator

First 4204 Zones

(device address entered in Prompt 14):

Second 4204 Zones

(device address entered in Prompt 14, plus 1):

Relay 1 = Zone 1

Relay 1 = Zone 5

4204 Relay Outputs map to communicator zones as follows:

Relay 2 = Zone 2

Relay 3 = Zone 3

Relay 4 = Zone 4 or conditional zone trigger if

“report only if armed” is selected in any zone 1-3

when using single 4204 mode.

NOTE: Zone 4 status is not reported when being

used as the conditional (arming) trigger zone.

Relay 2 = Zone 6

Relay 3 = Zone 7

Relay 4 = Zone 8 or conditional zone trigger if

“report only if armed” is selected in any zone 1-7

when using Two-4204 mode.

NOTE: Zone 8 status is not reported when being

used as the conditional (arming) trigger zone or if

tamper reporting is enabled.

When using the communicator in 4204 Emulation Mode, DO NOT enable the communicator

(or LRR) in control panel programming. Instead, enable the module device address(es) and

program the appropriate relay activation functions for the relay-zones being used. In some

control panels, it is called “relay programming” and in others it is called “output device

programming.” It is recommended that “close and stay closed” (usually choice 2) action is

selected. Selection of momentary activation will cause the communicator to generate an

alarm and NOT a restore, even if the communicator is programmed to send a restore for the

given zone.

In 4204 mode, messages are reported in ADEMCO High-Speed format. Zone alarms

(status 7) are reported with “1” (alarm) or “3” (restore) displayed in the zone position for the

respective zone (e.g. alarm on zone 2: 5155 5555 7; restore 5355 5555 7). A supervision fault

trouble message is automatically sent if the communicator detects no activity on its connection to the control panel. The message is: 5555 5515 5; restore message is: 5555 5535 5.

Refer to Table 3-4 for 4204 Emulation Mode programming and follow the prompts that

pertain to 4204 or Two-4204 mode. A “X”

indicates whether the prompt applies to that mode.

3-9

Page 28

GSMV4G/GSMVCN4G Installation and Setup Guide

TRIG.

4204/

[Y], [N]

Enters programming mode.

[0-9, A-F, N, S,

If a password has been previously assigned, this

[Y], [N]

To begin programming the communicator, press [Y]

Prompt 5: "Change Password."

[Y], [N]

Passwords can be used to protect account and

6: "Enter Password."

[Y], [N]

If a password has already been assigned, this

[0-9, A-F, N, S,

If [Y] was pressed in Prompt 4 or 5, this prompt

[0-9, A-F, N, S,

Re-enter the password as confirmation.

Mode?" prompt:

Otherwise, the "Exit Prog. Mode?" prompt is

displayed directly.

[Y], [N]

Exits program mode.

in this Section.

Alternative Mode Programming

Press the [ENTER] key to begin programming and follow the prompts for the mode of

operation being programmed.

NOTE: The central station can remotely block access to local

device programming. If this has been done, the following

Table 3-4. Programming for Zone Trigger, 4204 Emulation, or Two-4204 Emulation modes.

PROMPTS

prompt appears:

ZONE

2-4204

OPTIONS DESCRIPTION

Access to Prog

Mode Denied

Strt Prog Mode?

1

(Y/N)_

Enter Password

2

Program Device?

3

(Y/N)_

Create Password?

4

(Y/N)_

Change Password

5

(Y/N)

Enter Password

6

Verify Password

7

?

X X

X X

X X

X X

X X

X X

X X

T, X, Y]

T, X, Y]

T, X, Y]

prompt appears. Enter a 4-digit password (0-9, A-F,

N, S, T, X, Y).

The next prompt appears.

and go to Prompt 9: "Device Mode."

To create a password if none has been assigned,

press [N] and go to Prompt 4: "Create Password."

To change an existing password, press [N] and go to

programming information.

If no password has been assigned, this prompt

appears after pressing [N] at the "Program Device?"

prompt.

If a password is desired, press [Y] and go to Prompt

prompt appears after pressing [N] at the "Program

Device?" prompt.

Press [Y] if you want to change the password.

NOTE: To clear an existing password, without

entering a new one, answer [Y] to the "Change

Password?" prompt, then press the [Enter] key

when prompted for the new password and its

confirmation.

appears.

Enter a 4-digit password (0-9, A-F, N, S, T, X, Y).

If the password doesn't match the first entry, the

following is displayed followed by the "Exit Prog.

Verify Not OK

PSWD not created

Exit Prog. Mode?

8

X X

(Y/N)_

3-10

[ESC]

Press [N] to go back to Prompt 3.

Press [ESC] to load factory defaults.

Refer to the Exiting Programming Mode paragraph

Page 29

Section 3: Programming the Communicator

TRIG.

4204/

ECP

Press the [space] key to scroll through the modes of

Table 3-2 for programming.

Multi-Mode (email notification) is intended as a convenience for the user, and does not replace Central

UL

Enabled

Enable if you want all events sent by email to the

Important Information Regarding Primary Account (Questions 11-13)

Account information is provided by the central station administrator.

(??)_

[01-99]

Enter the 2-digit primary city ID, 01-99 (decimal).

[01-FE]

[0001-9999]

The GSMV4G communicates with the control panel

UL / ULC

Press [Y] to allow the end user to access their

PROMPTS

Device Mode

9

(ECP)_

NOTE: In order for the Multi Mode

must be created in the AlarmNet Direct website and “Remote Access” must be enabled for the comm device.

In Zone Trigger mode, the options for Multi-Mode are "Enabled" or "Disabled." If enabled, whenever a zone on the

communication device is triggered, a corresponding email message is sent INSTEAD of normal central station

reports. Cover tamper will send email event 8. All communication device system events (such as power loss, low

battery, Telco, etc.) are still sent to AlarmNet.

Events used to send email messages are defined on the Honeywell Total Connect web site, and must correspond to

events triggering the hardwired zones.

Station reporting of critical events (alarms, troubles, etc.).

Multi-Mode has not been evaluated by UL.

ZONE

X X

2-4204

OPTIONS DESCRIPTION

•

• Zone Trig.

• 4204 Emu

• Two 4204s

operation.

Press [ENTER] to select the mode of operation.

IMPORTANT, if ECP device mode is desired, use

Important Information Regarding Multi-Mode Options

, Remote Access, and Keypad Address programming fields to appear an account

10

Multi Mode

X

(Disabled)_

Primary City ID

11

X X

12

Primary CS ID

X X

(???)

Primary Sub ID

13

X X

(????)

Device Address

14

X

(12)_

•

• Disabled

[01-15]

user. Disable for normal alarm processing.

Enter the 2-digit primary central station ID

number, 01-FE (HEX).

Enter the 4-digit subscriber account number, 00019999 (decimal).

as a 4204 relay module. Enter the appropriate

address. For VISTA-10P and FA130CP Series

control panels, this must be address 12. For other

control panels, see their Installation and Setup

Guide.

NOTES:

1. The 4204 protocol limits address range to 01-15.

If using 2-4204 mode, the communicator assigns

the second 4204 to the next higher device address

(e.g., if entering address 12 for the first 4204, then

address 13 is automatically assigned to the second

4204 module). Program the control panel

accordingly.

2. The device address(es) must be unique from the

"Keypad Address" entered in Prompt 17 and any

other address used on the control panel.

Remote access has not been evaluated by UL or ULC.

Remote Access

15

Y/N

(N)_

X

[Y], [N]

system via a website. Availability of this service is

controlled by the dealer via the web-based

programming tool on the AlarmNet Direct website.

3-11

Page 30

GSMV4G/GSMVCN4G Installation and Setup Guide

TRIG.

4204/

Applies only to VISTA-128BP/250BP and FBP

This address must be programmed if using either

30 Day

The AlarmNet network must hear at least one

• 10 Min

24 Hrs

Sets how long an undeliverable alarm is retried for

[00-99]

In the event the communicator detects a

If enabled, the fault open collector output is

PROMPTS

ZONE

2-4204

OPTIONS DESCRIPTION

16

Direct Wire Y/N

X

(N)_

Keypad Address

17

X

(28)_

18

Supervision

X X

(24 Hours)_

Old Alarm Time

19

10 Minutes_

GSM Flt Time

20

X X

X X

(00 mins)_

Flt Rel ON Y/N

21

(N)_

X X

3-12

[Y], [N]

[01-30]

•

• 24 Hrs

• None

• 15 Min

• 30 Min

• 1 Hr

• 2 Hrs

• 4 Hrs

• 8 Hrs

• 12 Hrs

•

[00] = not used

[Y], [N]

Series control panels.

If [N], and if Prompt 15: Remote Access is disabled,

skip to Prompt 18: "Supervision."

the Remote Access feature or Direct Wire

downloading.

NOTES:

1. This address must be programmed as an alpha

keypad in the control panel (Device Programming

Mode). If using Remote Access, the keypad must

also be enabled as an AUI (advanced user

interface) keypad. DO NOT connect an actual

keypad (or any other device) assigned to this

address.

2. This address must be unique from the "Device

Address" entered in Prompt 14, and cannot equal

that device address plus 1 (one) if using 2-4204

mode.

supervisory message from the communicator during

this supervision period; otherwise, AlarmNet

notifies the central station that a communication

failure has occurred. (If the supervision period is

changed after registration, you must re-register the

communicator.)

Press the [space] key to scroll through choices.

UL/ULC: Must be set to 24 hours.

delivery to the central station. If the message is not

validated, it is retried until the old alarm time is

reached or the message is validated.

Press the [space] key to scroll through choices.

UL/ULC: Must be set to 10 minutes.

communication path failure, enter the time delay (in

minutes) before the communicator notifies the

control panel with a trouble message (and trips the

Fault Output if used (terminal 11); see next

question). The control panel can then notify the

central station.

UL/ULC: Must be one (01) minute.

normally energized to ground, and de-energizes

(open circuit) in the event of a communicator fault.

For conditions that trip the fault relay refer to

Supervision Features in Section 1.

Set to [Y] if fail-safe mode is desired.

See Wiring the Fault Relay in Section 2.

UL/ULC: Must be set to "Y".

Page 31

TRIG.

4204/

Sends a primary power loss report to the central

[Y], [N]

Sends a low-battery report when a low battery

[Y], [N]

Sends a tamper report when the communicator

[Y], [N]

Applies only if used with a Lynx, LynxR or

• (V+), where a positive voltage causes an alarm for normally low connections (voltage trigger, NO, NC)

PROMPTS

Pwr Loss Rpt Y/N

22

(Y)_

ZONE

X X

2-4204

Section 3: Programming the Communicator

OPTIONS DESCRIPTION

[Y], [N]

station within 1-3 hours after its detection. A

restore report is sent within 1-3 hours after power is

restored.

UL/ULC Standard Installations

transformer and battery): Must be set to "Y" unless

used with a LynxR-I series control. Must be set to

"N" when using a LynxR-I series control.

ULC Commercial Fire & Burglary Installations

(powered from the control panel): Must be set to "N."

(using

Low Bat Rpt Y/N

23

(Y)_

X X

condition exists. A low-battery restore is

automatically sent when the low battery condition

clears.

Alternate Installations

(powered from the control

panel): Must be set to "N."

UL/ULC Standard Installations

(using

transformer and battery): Must be set to "Y" unless

used with a LynxR-I series control. Must be set to

"N" when using a LynxR-I series control.

ULC Commercial Fire & Burglary Installations

(powered from the control panel): Must be set to "N."

Tamper Rpt Y/N

24

(Y)_

X X

detects a tamper condition. A tamper restore is

automatically sent when the tamper condition

clears.

UL/ULC: Must be set to "Y."

Lynx Panic Y/N

25

(N)_

X

LynxR-EN controls where the communicator (or

LRR) trigger is connected to the communicator’s

zone terminal.

Reports a Panic alarm on zone 3 when the

communicator detects a single pulse on zone 1.

No restores are generated for a Panic alarm.

Important Information Regarding Zone Input Options

If desired, 4204 mode supports two optional hardwire zone input triggers by making connections to the