Page 1

Ui 300V ac/dc metal

Ui 300 Vdc/600 Vac plastic

UL EN 50047

EN6094751

CCC GB 14048.5 - 2001*

EN455452 HL 3 (GLC & GLE Series switches only)

81521

Installation Instructions for the MICRO SWITCH Global Limit Switches (GLS MINDIN Series)

Instrucciones de instalación para los MICRO SWITCH interruptores limite global (serie GLS MINDIN)

Einbauanweisungen für den MICRO SWITCH Global Endschalter (Serie GLS MINDIN)

Instructions d’installation du MICRO SWITCH fin de course mondiales (série GLS MINDIN)

Istruzioni per l’installazione del MICRO SWITCH finecorsa globali (Serie GLS MINDIN)

Instruções de Instalação para o MICRO SWITCH de limite global (Série GLS MINDIN)

MICRO SWITCH 全球限位开关(GLS MINDIN 系列)安装指南

Issue 10

m WARNING

IMPROPER INSTALLATION

• Consult with local safety agencies and their

requirements when designing a machine-control link,

interface, and all control elements that affect safety.

• Strictly adhere to all installation instructions.

Failure to comply with these instructions could result in

death or serious injury.

MOUNT, WIRE, AND SEAL THE SWITCH

m WARNING

IMPROPER OPERATION

• Ensure switch actuator achieves sufficient travel for

positive opening of normally closed (NC) contacts to

occur.

Failure to comply with these instructions could result in

death or serious injury.

1. Refer to:

• Page 5 for adjustments

• Pages 8 to 12 for specific travel distances for each

switch code and specifications

• Page 5 for proper application of limit switches

• Page 13 to 18 for switch mounting dimensions

2. Perform adjustments (if desired):

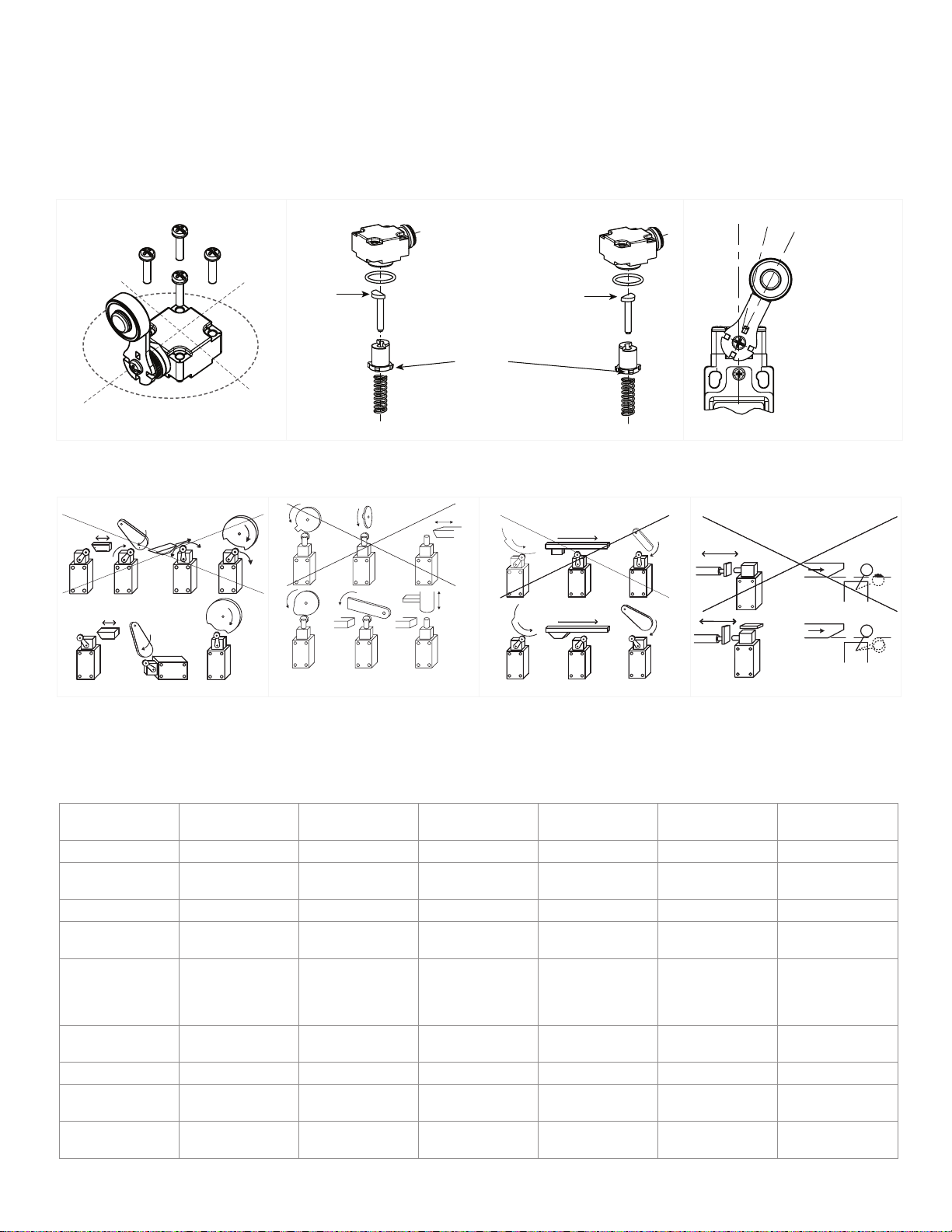

• Head orientation (Figure 1, page 5)

• Actuation direction (Figure 2, page 5)

• Side rotary switches with 36 drive lever positions

(Figure 3, page 5):

3. Mount switch at top corners of switch using two M4 or #8

screws. For GLD products torque screws to 2,7 Nm to 3,4

Nm [24 in-lb to 30 in-lb]. For GLC & GLE products torque

screws to 3,1 Nm to 3,7 Nm [27 in-lb to 33 in-lb].

4. Remove screws on cover plate.

5. Connect stranded wire (0,75 mm2 to 2,3 mm2, 1814 AWG)

or solid wire (0,75 mm2 to 1,5 mm2, 1816 AWG) to contact

block terminals (use 90 °C wire when ambient temperature

is over 75 °C). Torque switch terminal screws to 0,8 Nm to

1,0 Nm [7 in-lb to 9 in-lb].

6. Seal conduit opening according to instructions in PK

80112.

7. Reassemble cover plate, and torque cover screws to 0,5 Nm

[4.4 in-lb].

m ADVERTENCIA

INSTALACIÓN INCORRECTA

• Consulte las normas de seguridad y sus requisitos al

realizar el diseño del enlace de control de una máquina,

la interfaz, y los elementos de control que afecten a la

seguridad.

• Siga estrictamente todas las instrucciones para la instalación.

El incumplimiento de estas recomendaciones puede

ocasionar lesiones graves o peligro de muerte.

MONTAJE, CABLEADO Y SELLADO DEL

INTERRUPTOR

m ADVERTENCIA

FUNCIONAMIENTO INCORRECTO

• Asegúrese que el actuador del interruptor tenga la

suficiente carrera para que se produzca la apertura positiva

de los contactos normalmente cerrados (NC)..

El incumplimiento de estas recomendaciones puede

ocasionar lesiones graves o peligro de muerte.

1. Consulte:

• Página 5 para obtener información sobre ajustes

• Páginas 8 a 12 para obtener las distancias específicas

de carrera para cada código de interruptor y especificaciones

• Página 5 para obtener información sobre la aplicación

correcta de los interruptores de final de carrera

• Página 13 a 18 para obtener las dimensiones de montaje del interruptor

2. Realice ajustes (si lo desea):

• Orientación del cabezal (Figura 1, página 5)

• Dirección del accionamiento (Figura 2, página 5)

• Interruptores de rotación lateral con 36 posiciones de

la palanca de impulsión (Figura 3, página 5):

3. Monte el interruptor colocando dos tornillos M4 o N.º 8 en

sus ángulos superiores. Para los productos GLD, ajuste los

tornillos empleando un torque de 2,7 Nm a 3,4 Nm [de 24

in-lb a 30 in-lb]. Para los productos GLC y GLE, ajuste los

tornillos empleando un torque de 3,1 Nm a 3,7 Nm [de 27

in-lb a 33 in-lb].

4. Retire los tornillos de la tapa.

5. Conecte cable trenzado (de 0,75 mm2 a 2,3 mm2, 1814

AWG) o sólido (de 0,75 mm2 a 1,5 mm2, 1816 AWG) en

los terminales del bloque de contactos (utilice cable de 90

°C cuando la temperatura ambiente es mayor de 75 °C).

Ajuste los tornillos empleando un torque de 0,8 Nm a 1,0

Nm [de 7 in-lb a 9 in-lb].

6. Selle la entrada del conducto según las instrucciones

incluidas en PK 80112.

7. Vuelva a montar la tapa y ajuste empleando un torque de

0,5 Nm [4,4 in-lb].

Sensing and Internet of Things

Page 2

Installation Instructions for

MICRO SWITCH GLS Min-Din Limit Switches

ISSUE 10 81521

m WARNUNG

UNSACHGEMÄSSER EINBAU

• Beraten Sie sich mit den zuständigen

Sicherheitsbehörden beim Entwurf von Verbindungen zu

Maschinensteuerungen, Schnittstellen und sämtlichen

Steuerelementen, welche die Sicherheit betreffen.

• Halten Sie sich genau an die EinbauAnweisungen.

Das Nichtbeachten dieser Anweisungen könnte zum Tod oder

zu schweren Verletzungen führen.

SCHALTER MONTIEREN, ANSCHLIESSEN

UND ABDICHTEN

m WARNUNG

UNSACHGEMÄSSER BETRIEB

• Sicherstellen, daß der Betätiger genügend Laufweg hat, um

die Öffnerkontakte (NC) zwangszuöffnen.

Das Nichtbeachten dieser Anweisungen könnte zum Tod oder

zu schweren Verletzungen führen.

1. Weitere Informationen:

• Einstellungen auf Seite 5

• Spezifische Laufwege für jeden Schaltercode und

Spezifikationen auf Seiten 8 bis 12

• Sachgemäße Anwendung von Positionsschaltern auf

Seite 5

• SchaltermontageAbmessungen auf Seiten 13 bis 18

2. Einstellungen vornehmen (falls gewünscht):

• Ausrichtung des Kopfes (Abbildung 1, Seite 5)

• Betätigungsrichtung (Abbildung 2, Seite 5)

• Schalter mit seitlichem Schwenkhebel mit 36 Antriebshebelpositionen (Abbildung 3, Seite 5):

3. Den Schalter an den oberen Ecken mit Hilfe von zwei M4

Schrauben oder Schrauben Nr. 8 montieren. Für GLD

Produkte Schrauben auf 2,7 Nm bis 3,4 Nm [24 in-lb bis

30 in-lb] anziehen. Für GLC & GLEProdukte Schrauben

auf 3,1 Nm bis 3,7 Nm [27 in-lb bis 33 in-lb] anziehen.

4. Die Schrauben auf der Deckplatte entfernen.

5. Den Litzendraht (0,75 mm2 ... 2,3 mm2, 18 ... 14 AWG) oder

Draht (0,75 mm2 ... 1,5 mm2, 18 ...16 AWG) an die SicherheitskontaktblockKlemmleisten anschließen (wärmebeständige Aderleitung 90 °C verwenden, wenn die Umgebungstemperatur über 75 °C liegt). Klemmenleistenschrauben

auf 0,8 Nm bis 1,0 Nm [7 in-lb bis 9 in-lb] anziehen.

6. Die Kabeleinführung entsprechend den Anweisungen in PK

80112 versiegeln.

7. Bringen Sie die Abdeckplatte wieder an, und schrauben

Sie diese mit einem Anzugsmoment von 0,5 Nm [4,4 in-lb]

fest.

m AVERTISSEMENT

INSTALLATION INCORRECTE

• Faites appel à des emperatu locaux de sécurité et prenez

en compte leurs exigences lorsque vous concevez une

liaison de commande ou interface de machine, ou tout

autre dispositif de commande mettant en jeu la sécurité.

• Respectez scrupuleusement l’ensemble des instructions

d’installation.

L’inobservation de ces instructions peut entraîner la mort ou

de graves blessures.

MONTEZ, CABLEZ ET ETANCHEIFIEZ

L’INTERRUPTEUR

m AVERTISSEMENT

MAUVAIS FONCTIONNEMENT

• Veillez à ce que l’actionneur de l’interrupteur parcourt une

course suffisante afin de permettre une ouverture positive

des contacts normalement fermés (NF).

L’inobservation de ces instructions peut entraîner la mort ou

de graves blessures.

1. Consultez :

• la page 5 pour les réglages.

• les pages 8 à 12 pour connaître les longueurs de

courses pour chaque code d’interrupteur et les caractéristiques techniques.

• la page 5 pour une utilisation correcte des interrupteurs de fin de course.

• les pages 13 à 18 pour les cotes de montage de

l’interrupteur.

2. Effectuez les réglages (le cas échéant) :

• Orientation de la tête (figure 1, page 5)

• Sens de commutation (figure 2, page 5)

• Interrupteurs à rotation latérale avec 36 positions de

leviers (figure 3, page 5) :

3. Montez l’interrupteur en vissant deux vis M4 ou n° 8 sur sa

partie supérieure. Pour les produits GLD, exercez sur les vis

un couple de 2,7 Nm à 3,4 Nm [24 in-lb à 30 in-lb]. Pour

les produits GLC et GLE, exercez sur les vis un couple de

3,1 Nm à 3,7 Nm [27 in-lb à 33 in-lb].

4. Retirez les vis du couvercle.

5. Connectez du fil souple (0,75 mm2 à 2,3 mm2, 18 à 14

AWG) ou rigide (0,75 mm2 à 1,5 mm2, 18 à 16 AWG) aux

bornes du bloc de contacts (utilisez du fil 90 C lorsque la

température ambiante est supérieure à 75 C). Exercez sur

les vis des bornes de l’interrupteur un couple de 0,8 Nm à

1,0 Nm [7 in-lb à 9 in-lb].

6. Réalisez l’étanchéité de l’ouverture du conduit conformément aux instructions données en PK 80112.

7. Replacez le couvercle et serrez les vis avec un couple de 0,5

Nm [4,4 in-lb].

2 sensing.honeywell.com

Page 3

Installation Instructions for

MICRO SWITCH GLS Min-Din Limit Switches

ISSUE 10 81521

m ATTENZIONE

INSTALLAZIONE SCORRETTA

• Consultare gli enti locali in materia di antinfortunistica

e le rispettive normative nel momento in cui ci si avvia

alla progettazione di un qualsiasi collegamento controllo

macchina, o di un’interfaccia ,o di tutti gli elementi di

controllo che possano influire sulla sicurezza.

• Attenersi rigorosamente a tutte le istruzioni relative

all’installazione.

L’inosservanza di tali istruzioni può essere causa di gravi

lesioni, con conseguenze addirittura fatali.

MONTARE, CABLARE E SIGILLARE

L’INTERRUTTORE

m ATTENZIONE

FUNZIONAMENTO SCORRETTO

• Accertarsi che la corsa dell’attuatore dell’interruttore sia

sufficiente a consentire l’apertura forzata dei contatti

normalmente chiusi (NC).

L’inosservanza di tali istruzioni può essere causa di gravi

lesioni, con conseguenze addirittura fatali.

1. Consultare:

• Pagina 5, per le regolazioni

• Pagine da 8 a 12, per gli specifici valori relativi a ciascun codice di interruttore e per i dati tecnici

• Pagina 5, per il corretto uso degli interruttori finecorsa

• Pagine da 13 a 18, per le dimensioni di montaggio

dell’interruttore

2. Eseguire le regolazioni (in base alle esigenze):

• Orientamento testa (Figura 1, pagina 5)

• Direzione di attuazione (Figura 2, pagina 5)

• Interruttori a rotazione laterale con leve di azionamento a 36 posizioni (Figura 3, pagina 5):

3. Montare l’interruttore negli angoli superiori dell’interruttore

mediante due viti M4 o #8. Per i prodotti GLD, serrare le viti

con una coppia compresa tra 2,7 Nm e 3,4 Nm [da 24 in-lb

a 30 in-lb]. Per i prodotti GLC e GLE, serrare le viti con una

coppia compresa tra 3,1 Nm e 3,7 Nm [da 27 in-lb a 33 inlb].

4. Rimuovere le viti dalla piastra di copertura.

5. Collegare cavi flessibili (da 0,75 mm2 a 2,3 mm2, 1814

AWG) o cavi rigidi (da 0,75 mm2 a 1,5 mm2, 1816 AWG)

ai morsetti dei connettori (se la temperatura ambiente

supera i 75 °C, utilizzare cavi che hanno una temperatura

di esercizio pari a 90 °C). Serrare le viti dei morsetti con una

coppia compresa tra 0,8 Nm e 1,0 Nm [da 7 in-lb a 9 in-lb].

6. Sigillare l’apertura pressacavo in base alle istruzioni riportate in PK 80112.

7. Rimontare il coperchio e serrare le viti con una coppia di

0,5 Nm [4,4 in-lb].

m ADVERTÊNCIA

INSTALAÇÃO INCORRETA

• Consulte as agências de segurança local e seus requisitos

ao projetar unidades de conexão ou interface para controle

de máquinas, bem como todos os elementos de controle

que possam afetar a segurança

• Obedeça rigorosamente todas as instruções de segurança.

Desobediência a essas instruções pode resultar em morte ou

ferimentos graves.

MONTAGEM, FIAÇÃO E VEDAÇÃO DO

SWITCH

m ADVERTÊNCIA

INSTALAÇÃO INCORRETA

• Certifique-se de que o atuador do switch atinja um percurso

suficiente para que ocorra a abertura positiva de contatos

normalmente fechados (NC, normally closed).

Desobediência a essas instruções pode resultar em morte ou

ferimentos graves.

1. Consulte:

• A página 5 para ajustes.

• As páginas 8 e 12 para distâncias de percurso para

cada código de chave e especificações

• A página 5 para saber a aplicação correta das chaves

de fim de curso

• As páginas 13 a 18 para dimensões de instalação do

switch

2. Faça os ajustes necessários (se desejado):

• Orientação do cabeçote (Figura 1, página 5)

• Direção de atuação (Figura 2, página 5)

• Chaves laterais giratórias com 36 posições da alavanca de acionamento (Figura 3, página 5):

3. Instale dois parafusos M4 ou Nº 8 na parte superior para

montar a chave. Para produtos GLD, aperte os parafusos

com torque de 2,7 a 3,4 Nm [24 a 30 lb-pol.]. Para produtos GLC e GLE, aperte os parafusos com torque de 3,1 a

3,7 Nm [27 a 33 lb-pol.].

4. Remova os parafusos da tampa de cobertura.

5. Conecte o fio desfiado (0,75 mm2 a 2,3 mm2, 18 AWG

14 AWG) ou fio sólido (0,75 mm2 a 1,5 mm2, 18 AWG16

AWG) aos terminais do conector (use fiação para até 90

ºC quando a temperatura ambiente for superior a 75 °C.).

Aperte os parafusos de terminal com torque de 0,8 a 1,0

Nm [7 a 9 lb-pol.].

6. Vede as aberturas do conduíte de acordo com as instruções encontradas no PK 80112.

7. Monte novamente a tampa de cobertura e aperte os parafusos com torque de 0,5 Nm [4,4 lb-pol.].

Sensing and Internet of Things 3

Page 4

Installation Instructions for

MICRO SWITCH GLS Min-Din Limit Switches

m 警告

安装不当

• 设计机器控制链接、接口以及所有影响安全的控制元件时,

请咨询当地安全机构,了解相关要求。

• 严格遵守安装指南。

如果不遵守以上说明,则有可能造成死亡或重伤。

开关的安装、接线和密封

m 警告

操作不当

• 确保开关驱动器有足够的移动行程,能让常闭 (NC) 触点正极

开启。

如果不遵守以上说明,则有可能造成死亡或重伤。

1. 请参阅:

• 第 5 页,了解如何进行调节

• 第 8 至 12 页,了解各开关编码对应的具体移动行程和规格

• 第 5 页,了解限位开关的正确应用

• 第 13 至 18 页,了解开关的安装尺寸

2. 根据需要进行调节:

• 操作头方向(第 5 页“图 1”)

• 动作方向(第 5 页“图 2”)

• 侧旋转开关,带 36 个驱动杆位置(第 5 页“图 3”):

3. 用 M4 或 #8 螺钉安装开关顶部的各角。对于 GLD 产品,向螺钉

施加 2.7 - 3.4 Nm [24 - 30 in-lb] 的扭动力。对于 GLC 和 GLE

产品,向螺钉施加 3.1 - 3.7 Nm [27 - 33 in-lb] 的扭动力。

4. 拆下盖板上的螺钉。

5. 将绞合线(0.75 mm2 至 2.3 mm

(0.75 mm

(环境温度超过 75 °C 时,使用 90 °C 的线)。向开关端子

螺钉施加 0.8 - 1.0 Nm [7 - 9 in-lb] 的扭动力。

6. 按照 PK 80112 中的说明密封导线孔。

7. 重新装上盖板,向盖板上的螺钉施加 0.5 Nm [4.4 in-lb] 的扭

动力。

2

至 1.5 mm

2

,1816 AWG)连接至接触块端子

2

,1814 AWG)或单股线

ISSUE 10 81521

4 sensing.honeywell.com

Page 5

Installation Instructions for

90°

90°

90°

Half-moon of

internal plunger

to back

(as shown) or

front:

CW/CCW

Actuation.

Half-moon of

internal plunger

to right

(as shown):

CCW only

Actuation.

Half-moon of

internal plunger

to left:

CW only

Actuation

The four ribs

on the external plunger

must be aligned

to the slots

in the metal body

when re-inserting.

10°

emental

positions of the

ISSUE 10 81521

MICRO SWITCH GLS Min-Din Limit Switches

FIELD ADJUSTABLE HEAD CAMPO DE CABEZA AJUSTABLE 现场可调节操作头

FIELD VERSTELLBAREM KOPF TÊTE DE CHAMP RÉGLABLE

CAMPO TESTA REGOLABILE CABEÇA CAMPO AJUSTÁVE

1.

90°

2.

3.

OPERATION REQUIREMENTS REQUISITOS DE FUNCIONAMIENTO 操作要求

ANFORDERUNGEN AN DEN BETRIEB EXIGENCES DE FONCTIONNEMENT

REQUISITI PER L’ESERCIZIO REQUISITOS DE OPERAÇÃO

10°

10° x 36

(36 incr

lever.)

TERMS CONDICIONES 术语

BEDINGUNGEN TERMES

TARIFFE CONDIÇÕES

Contact Closed Contacto cerrado Kontakt geschlos-

Contact Open Contacto abierto Kontakt offen Contact ouvert Contatto aperto Contato Aberto

Differential Travel Carrera diferencial Differenzwinkel Course différen-

Free Position Posición libre Freistellung Position libre Posizione libera Posição Livre

Operating Position 1

Positive Opening

1 to IEC 94751

Differential Travel 1Carrera diferen-

Over Travel Sobrecarrera Nachlaufweg Surcourse Oltre corsa Sobrepercurso

Maximum Operating Force

Maximum Disconnect Force

Posición de funcionamiento 1

Apertura positiva

1 según IEC 947

51

cial 1

Fuerza de funcionamiento máxima

Fuerza de desconexión máxima

sen

Schaltpunkt 1 Position de com-

Zwangsöffnung 1

gemäß IEC 947

51

Differenzweg 1 Course différenti-

Maximale Betätigungskraft

Maximale Öffnungskraft

Contact fermé Contatto chiuso Contato Fechado

tielle

mutation 1

Ouverture positive

1 selon CEI 947

51

elle 1

Force de commutation maximum

Force de déconnexion maximum

Corsa differenziale Percurso Diferen-

Posizione di funzionamento 1

Apertura forzata

1 Conforme alla

norma IEC 947

51

Corsa differenziale 1

Forza massima di

intervento

Forza massima di

scollegamento

cial

Posição de Operação 1

Abertura Positiva

1 para IEC 947

51

Percurso Diferencial 1

Força Máxima de

Operação

Força Máxima de

Desconexão

Sensing and Internet of Things 5

触点已闭合

触点已开启

差动行程

自由位置

工作位置 1

正极开启 1 至

IEC 94751

差动行程 1

超程

最大操纵力

最大切断力

Page 6

Installation Instructions for

MICRO SWITCH GLS Min-Din Limit Switches

ISSUE 10 81521

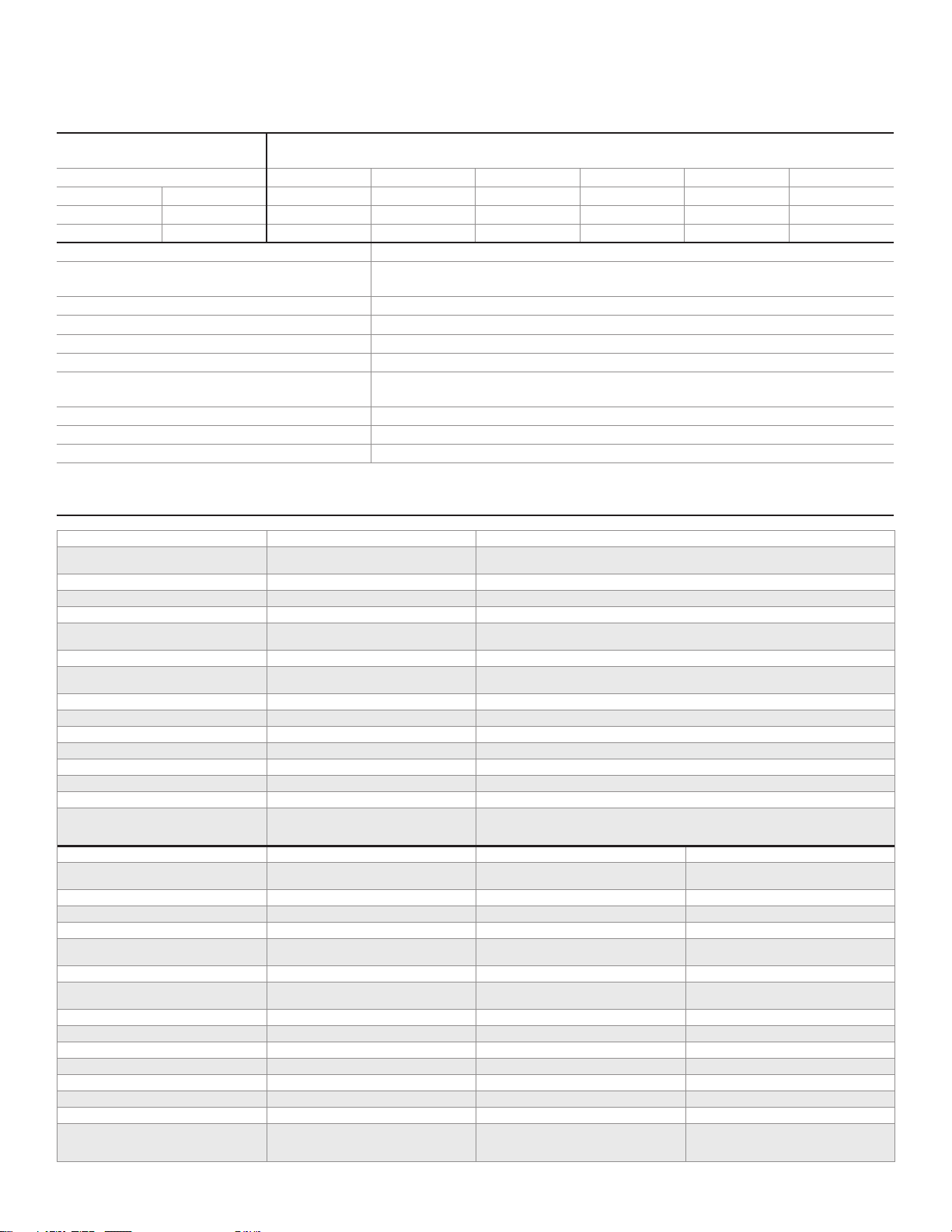

Designation and Utilization

Rated Operational Current Ie (A) at Rated Operational Voltage Ue (V)

Category

24 V 120 V 240 V 380 V 480 V 600 V

ac15 A300 – 6 A 3 A – – –

ac15 A600 – 6 A 3 A 1.9 A 1.5 A 1.2 A

dc13 Q300 2.8 A 0.55 A 0.27 A – – –

Rated thermal current (Ith) 10 A

Sealing

GLC/GLE: IP66; NEMA 1, 4, 12, 13

GLD: IP67; NEMA 1, 4X, 12, 13 (4X indoor use only)

Rated impulse withstand (Uimp) 2500 V

Pollution degree 3

Rated insulation voltage (Ui) 300 V, 600 V

Operating temperature range 40 °C to 85 °C [40 °F to 185 °F]

Short-circuit protective device (type/maxi-

mum rating)

Class J fuse (10 A/600 V)

Expected mechanical life up to 10,000,000 operations

Conditional short-circuit current 1000 A

Electrical rating for gold-plated contacts 10 mA to 100 mA, 1 Vac/Vdc to 50 Vac/Vdc

• Low Voltage Directive 2006/95/EC

• Machinery Directive 2006/42/EC only as directives relate to the components being used in a safety function

• IEC/EN 6094751

Designation and utilization category Categoría de designación y utilización Bezeichnung und Verwendungskategorie

Rated operational current Ie (A) at rated operational

voltage Ue (V)

Rated thermal current (Ith) Corriente térmica nominal (Ith) Nominaler thermischer Strom (Ith)

Rated impulse withstand (Uimp) Resistencia de impulso nominal (Uimp) Nominale Impulsspannung (Uimp)

Rated insulation voltage (Ui) Voltaje de aislamiento nominal (Ui) Nominale Isolationsspannung (Ui)

Short-circuit protective device (type/maximum

rating)

Conditional short-circuit current Corriente condicional de cortocircuito Bedingter Kurzschlußstrom

Electrical rating for gold-plated contacts Clasificación eléctrica para contactos bañados

Sealing Sellado Schutzart

Pollution degree Nivel de contaminación Emissionsgrad

Operating temperature range Límites de temperatura de funcionamiento Betriebstemperaturbereich

Expected mechanical life Vida mecánica esperada Erwartete mechanische Lebensdauer

Operations Operaciones Schaltspiele

Complies with: Cumple con: Entspricht:

• Low Voltage Directive 2006/95/EC • Directiva de bajo voltaje 2006/95/EEC • NiederspannungsRichtlinie 2006/95/EG

• Machinery Directive 2006/42/EC only as the

directives relate to the components being used in a

safety function.

Désignation et catégorie d’utilisation Denominazione e categoria d’impiego Categoria de designação e utilização

Courant de fonctionnement nominal Ie (A) à la

tension de fonctionnement nominale Ue(V)

Courant thermique nominal (Ith) Corrente termica nominale (Ith) Corrente térmica nominal (Ith) 额定热电流 (Ith)

Tension nominale de tenue au choc (Uimp) Resistenza agli impulsi nominale (Uimp) Resistência nominal ao impulso (Uimp) 额定冲击耐受 (Uimp)

Tension d’isolement nominale (Ui) Tensione di isolamento nominale (Ui) Tensão de isolamento nominal (Ui) 额定绝缘电压 (Ui)

Dispositif de protection contre les courts-circuits

(type/valeur nominale maximum)

Courant de court-circuit conditionnel Corrente di cortocircuito condizionale Corrente condicional de curto-circuito

Caractéristiques électriques de contacts plaqués or Classificazione elettrica per contatti placcati oro Cl assificações elétricas para contatos banhados

Etanchéité Grado di protezione Vedação

Indice de pollution Grado di inquinamento Grau de poluição

Gamme de températures de fonctionnement Temperature di esercizio Faixa de temperaturas de operação

Durée mécanique prévue Durata meccanica prevista Vida mecânica esperada

Utilisation Operazioni Operações

Conforme à: Conforme con: Em conformidade com:

• Directive Basse tension 2006/95/CEE • Direttiva Bassa tensione 2006/95/CEE • Diretiva de baixa tensão 2006/95/EEC • 2006/95/EC 低电压指令

• Directive Machine 2006/42/EEC limitée à ce qui

concerne les composants utilisés dans une fonction

de sécurité.

Corriente operativa nominal Ie (A) a voltaje operativo nominal Ue (V)

Dispositivo de protección contra cortocircuito

(tipo/valor nominal)

en oro

• Directiva de maquinarias 2006/42/EEC solo en

lo que se refiere a componentes que se utilizan en

una función de seguridad.

Corrente nominale di esercizio Ie (A) alla tensione

nominale di esercizio Ue (V)

Dispositivo di protezione per cortocircuito (valore

nominale tipico/massimo)

• Direttiva macchine 2006/42/CEE solo nella misura in cui la direttiva fa riferimento ai componenti

da utilizzare con funzioni di sicurezza.

Nominaler Betriebsstrom Ie (A) bei nominaler Betriebsspannung Ue (V)

KurzschlußSchutzeinrichtung (Typ/Maximalleistung)

Schaltvermögen von vergoldeten Kontaken

• MaschinenRichtlinie 2006/42/EG, soweit sich diese auf die Komponenten bezieht, die als Sicherungsvorrichtungen verwendet werden.

体系及应用类别

Corrente operacional nominal Ie (A) na tensão

operacional nominal Ue (V)

Dispositivo protetor contra curto-circuito (tipo/

nominal máxima)

a ouro

• Diretiva de maquinário 2006/42/EEC somente

no que se refere aos componentes usados em

função de segurança.

额定工作电压 Ue (V) 下的额定工作电流 Ie (A)

短路保护器件(类型/最大等级)

限制短路电流

镀金触点电气额定值

密封

污染程度

工作温度范围

预期机械寿命

操作

符合:

• 机械指令 2006/42/EC,仅限与安全功能中

使用的元件相关的指令。

6 sensing.honeywell.com

Page 7

Installation Instructions for

Contact Closed

Contact Open Diff. Travel

**Positive Opening to IEC 947-5-1

SNAP-ACTION CONTACTS

>

<

13-14

20°

56°**

12° Differential travel

GL

NOTE: not all combinations of model code ar

Please contact your Honeywell pr

for assistance.

L

A

MICRO SWITCH GLS Min-Din Limit Switches

Figure 4. Reading Operating Specifications

ISSUE 10 81521

Catalog

listing Contact block diagram

GL**01A

SINGLE POLE

GL**07A

Zb

Ç Ç Ç Ç Ç Ç Ç Ç

Catalog

Listing

Code

PRODUCT NOMENCLATURE

Switch Type

GLS Series

Global

Limit

Switch

Contact Block Diagram

Shows the circuit con-

figuration of the internal

contact block.

C

Body

Metal,

C

MIN-DIN

Plastic,

D

MIN-DIN

Metal,

E

Pancake

Nominal travels and related terminals

21-22

Show the state of the contacts relative to the

A

Conduit

1/2-14

A

NPT

PG 13.5

B

20 mm

C

e available.

ovider/representative

Operating Bar Charts

position of the actuator.

01

Basic Switch

SPDT

01

snap action

SPDT, BBM

03

slow acting

SPDT, MBB

04

slow acting

DPST, 2NO

05

slow acting

DPST, 2NC

06

slow acting

SPDT, snap

07

action, gold cont.

DPDT, snap

24

action, Body E

DPDT, snap

action, gold cont.

32

Body E

SPDT, BBM

slow acting,

33

gold contacts

SPDT, MBB

slow acting,

34

gold contacts

DPST, 2NO

slow acting,

35

gold contacts

DPST, 2NC

slow acting,

36

gold contacts

A1A

A1B

A2A

A2B

A4J

A4L

A5A

A5B

A9A

B

C

D

Operating force

max.

9,7 N

[2.2 lb]

A1A

Head/Actuator

Side rotary,

fixed, 19 x 6

nylon roller

Side rotary,

fixed, 19 x 6

steel roller

Side rotary,

adjust., 19 x 6

nylon roller

Side rotary,

adjust., 19 x 6

steel roller

Side rotary,

adjust., 140 mm

aluminum rod

Side rotary,

adjust., 200 mm

aluminum rod

Side rotary,

offset, 19 x 6

nylon roller

Side rotary,

offset, 19 x 6

steel roller

Side rotary,

conveyor

lever

Top pin

plunger

Top roller

plunger

Top roller

lever

Disconnect force,

max.

11,4 N

[2.6 lb]

Operating degrees,

max.

0,85 M/S

[33.5 in/S]

Operating Specifications

Wobble,

E7A

plastic stick

Wobble,

E7B

coil

Wobble,

E7D

cat whisker

Adj. top roller

lever, Ø27,3 x

F

5 POM roller

Cat whisker,

K8A

140 mm

Cat whisker,

K8B

190 mm

Wobble,

K8C

cat whisker

Side rotary,

fixed,

A1

no roller

Side rotary,

adjustable,

A2

no roller

Side rotary,

fixed, 50 x 10

A1Y

rubber roller

Side rotary,

adj., 50 x 10

A2Y

rubber roller

Operating degrees,

min.

8,5 mm/S

[0.33

in/S]

Modification Codes

A1A, A1B, A2A, A2B, A4J, A5B, A9

CW rotation

1

only

CCW rotation

2

only

Lever to

3

right

Lever to

4

left

Lever to

5

mounting surf.

for

Actuator/Material C

Roller

perpendicular

6

to mtg. surf.

for

Actuator/Material D

Lever to

right, hinge

6

to left

Max. operate fre-

250

quency ops/min

Sensing and Internet of Things 7

Page 8

Installation Instructions for

Contact Closed

Contact Open Diff. Travel

**Positive Opening to IEC 947-5-1

13

21

14

22

Zb

OP = 26°

Total Travel = 70° min.

-4.4 15 mm 43,3

13-14

Zb

21

13

22

14

13-14

* = 36.5°

25,9 mm

13

22

14

13-14

OT

* = 50.5°

40 mm

23

14

24

2X

23-24

13-14

OT = 61° to 75°

-4.4 24,6 mm 53.5

21

12

22

11-12

36,5 mm

5

21

22

Za

Za

21-22

13-14

OP

FP

FP = 0°

DT = 8°

OP = 26°

* = 54°

-4.4 15 mm

43.3

23-24

11-12

21-22

13-14

23-24

11-12

DT=6,6 mm

RP=8,4 mm

RP = 18°

Total travel = 70° min.

OP +10°/-5°

MICRO SWITCH GLS Min-Din Limit Switches

ISSUE 10 81521

Figure 5. Head Code: A

Side Rotary Angular Operating Characteristics

Notes:

• Free position, operate point, over travel and pre-travel all to EN 50047

• Operating characteristics apply to counter clockwise (CCW) and clock wise (CW) actuation

• Refer to page 6 for instructions on how to read operating characteristics and specifications

• Contact block terminal designation to EN 50013

• Tightening torque GLC/GLD: 0,5 Nm [4.4 in-lb] max.

• Tightening torque GLE: 0,339 Nm [3 in-lb] max.

Catalog

listing Contact block diagram

Snap action

GL**01A

GL**07A

Nominal travels and related terminals

21-22

13-14

21-22

FP

FP = 0°

OP

DT=9,8 mm

RP=14.5°

Operating torque

max.

0,120

Nm

[1.1

in-lb]

0,140

Nm

[1.3

in-lb]

Disconnect torque,

max.

OP

RP

Operating degrees,

max.

Operating degrees,

360° 10°

OP2

min.

Operating velocity,

2,0

mm/s

min.

Operating velocity,

200

mm/s

max.

Max. operate fre-

250

quency ops/min

GL**03A

GL**33A

GL**04A

GL**34A

GL**05A

GL**35A

GL**06A

GL**36A

GLE*24A

GLE*32A

BBM, slow action

MBB, slow action

21

Zb

2 NO, slow action

13

2 NC, slow action

11

2Y

2 NC/2 NO, snap

action

13

14

12

11

24

23

-4.4 15 mm

21-22

FP

FP = 0°

OP = 26°

-4.4 15 mm

21-22

FP = 0°

OP = 26°

FP = 0°

OP = 39°

-4.4 15 mm

21-22

FP

FP = 0°

OP = 26°

27,9

OP

OP2

OP2 = 39°

Total Travel = 70° min.

OP2OPFP

OP2 = 39°

OT = 61° to 75°

OPFP

* = 46.5°

OT = 61° to 75°

0,110

Nm

[1.0

in-lb]

53.527.9

0,110

Nm

[1.0

in-lb]

0,110

OT

Nm

[1.0

in-lb]

53.

OTOP

0,110

Nm

[1.0

in-lb]

0,165

Nm

[1.6

in-lb]

0,160

Nm

[1.5

in-lb]

0,170

Nm

[1.6

in-lb]

0,150

Nm

[1.4

in-lb]

0,150

Nm

[1.4

in-lb]

0,165

Nm

[1.6

in-lb]

360° 10°

360° 10°

360° 10°

360° 10°

10°

2,0

mm/s

2,0

mm/s

2,0

mm/s

2,0

mm/s

2,0

mm/s

200

mm/s

200

mm/s

200

mm/s

200

mm/s

200

mm/s

250

250

250

250

250

8 sensing.honeywell.com

Page 9

Installation Instructions for

Contact Closed

Contact Open Diff. Travel

**Positive Opening to IEC 947-5-1

13

21

14

22

Zb

16 mm

RP=18,9 mm

DT=0,9 mm

Zb

21

13

22

14

15 mm

21 mm

OT max.

17,2 mm

13

22

14

15 mm

17 mm

21 mm

OT max.

16,2 mm

23

14

24

2X

15 mm

17 mm

21 mm

OT max.

21

12

22

15 mm

18 mm

21 mm

OT max.

16,5 mm

21

22

Za

Za

15 mm

18 mm

21 mm

RP=18,6 mm

DT=0,6 mm

ential travel

15,0 max. [0.59 max.]

Overtravel

MICRO SWITCH GLS Min-Din Limit Switches

Figure 6. Head Code: B

Pin Plunger Operating Characteristics

Notes:

• Free position, operate point, overtravel, and pretravel all to

21,0

[0.83]

Free position

0,9 [0.04]

Differ

18,0 ±0,5 [0.71]

Operating point

EN 50047

• Refer to page 6 for instructions on how to read operating

characteristics and specifications

• Contact block terminal designation to EN 50013

ISSUE 10 81521

Catalog

listing Contact block diagram

Snap action

GL**01B

GL**07B

BBM, slow action

GL**03B

GL**33B

MBB, slow action

GL**04B

GL**34B

21

Zb

2 NO, slow action

13

GL**05B

GL**35B

Nominal travels and related terminals

21 mm

18 mm

15 mm

21-22

18 mm

17 mm

13-14

FP

OT

max.

21-22

21-22

13-14

13-14

FP

OP

13-14

FP

18 mm

23-24

21-22

13-14

FP

OP

Operating force

16 N

[3.6 lb]

14 N

[3,2 lb]

16 N

[3.6 lb]

13 N

[2.9 lb]

max.

Disconnect force,

23 N

[5,2 lb]

24 N

[5,4 lb]

27 N

[6.1 lb]

23 N

[5.2 lb]

max.

Operating velocity,

100

mm/S

[3.9

in/S]

100

mm/S

[3.9

in/S]

100

mm/S

[3.9

in/S]

100

mm/S

[3.9

in/S]

max.

Operating velocity,

min.

1,0 mm/S

[0.04

in/S]

1,0 mm/S

[0.04

in/S]

1,0 mm/S

[0.04

in/S]

1,0 mm/S

[0.04

in/S]

Max. operate fre-

250

250

250

250

quency ops/min

GL**06B

GL**36B

GLE*24B

GLE*32B

2 NC, slow action

11

2Y

2 NC/2 NO, snap action

13

11

23

21-22

11-12

FP

OP

23-24

21-22

11-12

13-14

14

12

24

FP

OT max.

13 N

[2.9 lb]

13 N

[2.9 lb]

23 N

[5.2 lb]

24 N

[5.4 lb]

100

mm/S

[3.9

in/S]

100

mm/S

[3.9

in/S]

1,0 mm/S

[0.04

in/S]

1,0 mm/S

[0.04

in/S]

250

250

Sensing and Internet of Things 9

Page 10

Installation Instructions for

Contact Closed

Diff. Travel

**Positive Opening to IEC 947-5-1

13

21

14

22

Zb

OT

RP=8,9 mm

Zb

21

13

22

14

OT

FP

12,2

13

22

14

OT

FP

Contact Closed

Diff. Travel

**Positive Opening to IEC 947-5-1

23

14

24

2X

OT FP

OP

21

12

22

OT FP

3

21

22

Za

Za

21-22

OT

23-24

RP=9,5 mm

ential travel

25,0 max. [0.98 max.]

Overtravel

MICRO SWITCH GLS Min-Din Limit Switches

Figure 7. Head Code: C

Roller Plunger Operating Characteristics

Notes:

31,0

[1.22]

Free position

Differ

RP

28,0 ±1,0 [1.10]

Operating point

• Free position, operate point, overtravel, and pretravel all to

EN 50047

• Refer to page 6 for instructions on how to read operating

characteristics and specifications

• Contact block terminal designation to EN 50013

ISSUE 10 81521

Contact

block dia-

gram

Catalog listing

Snap

action

GL**01C | GL**07C

BBM, slow

action

GL**03C | GL**33C

MBB, slow

action

21

GL**04C | GL**34C

Nominal travels and related

terminals

Contact Open

Contact

Nominal travels and related

terminals

Contact Open

block dia-

Operating force max.

Disconnect force, max.

Operating velocity, max.

Operating velocity, min.

Max. operate frequency ops/min

Catalog listing

gram

Operating force max.

Disconnect force, max.

Operating velocity, max.

Operating velocity, min.

Max. operate frequency ops/min

FP

OT

21-22

21-22

13-14

FP

OP

OT max.

11,9

13-14

FP

28 mm

26,2 mm

OT max.

12,2

21-22

13-14

RP=28,9 mm

DT=0,9 mm

27,2 mm

13,6

16 N [3.6 lb]

14 N [3.2 lb]

17,3

16 N [3.6 lb]

17,3

23 N [5,2 lb]

100 mm/S [3.9 in/S]

1,0 mm/S [0.04 in/S]

24 N [5.4 lb]

100 mm/S [3.9 in/S]

1,0 mm/S [0.04 in/S]

27 N [6.1 lb]

100 mm/S [3.9 in/S]

1,0 mm/S [0.04 in/S]

250

250

250

21-22

13-14

31 mm

OP 28 mm

26 mm

25 mm

max.

5,3 mm

21-22

13-14

DT=1,6 mm

21-22

13-14

21-22

13-14

Zb

21-22

13-14

10,5 13,9 17,3

FP

31 mm

28 mm

27 mm

25 mm

10,5

5,3 mm

31 mm

27 mm

25 mm

5,3 mm

10,5

2 NO, slow

action

13

GL**05C | GL**35C

2 NC, slow

action

11

2Y

GL**06C | GL**36C

2 NC/2

NO, snap

action

13

11

23

GLE*24C | GLE*32C

23-24

13-14

FP

31 mm

27 mm

OP

25 mm

OT max.

13-14

31 mm

28 mm

25 mm

FP

OT

max.

10,5

12,2

11-12

21-22

FP

OP

26,5 mm

OT max.

DT=0,6 mm

5,3 mm

13-14

23-24

5,3 mm

21-22

11-12

11-12

31 mm

28 mm

26

25 mm

5,3 mm

11-12

14

13-14

21-22

12

23-24

DT=1,0 mm

11-12

13-14

21-22

23-24

FP

24

13,6

RP=28,6 mm

13,910,5

17,3

17,

17,3

13 N [2.9 lb]

23 N [5.2 lb]

13 N [2.9 lb]

23 N [5.2 lb]

13 N [2.9 lb]

24 N [5.49 lb]

250

100 mm/S [3.9 in/S]

1,0 mm/S [0.04 in/S]

250

100 mm/S [3.9 in/S]

1,0 mm/S [0.04 in/S]

250

100 mm/S [3.9 in/S]

1,0 mm/S [0.04 in/S]

10 sensing.honeywell.com

Page 11

Installation Instructions for

Contact Closed

Diff. Travel

**Positive Opening to IEC 947-5-1

13

21

14

22

Zb

OT

RP=6,7 mm

23

Zb

21

13

22

14

OT

FP

14,4

13

22

14

OP

OT

23

Contact Closed

Diff. Travel

**Positive Opening to IEC 947-5-1

23

14

24

2X

OT FP

12

22

OT

FP

21

22

Za

Za

OT

RP=8,0

]

RP

MICRO SWITCH GLS Min-Din Limit Switches

Figure 8. Head Code: D

Top Roller Lever Operating Characteristics

Notes:

35,8 ±0,8 [1.41

Operating point

• Free position, operate point, overtravel, and pretravel all to

• Refer to page 6 for instructions on how to read operating

• Contact block terminal designation to EN 50013

ISSUE 10 81521

EN 50047

characteristics and specifications

Contact

block dia-

Catalog listing

action

GL**01D | GL**07D

BBM, slow

action

GL**03D | GL**33D

MBB, slow

action

GL**04D | GL**34D

gram

Snap

21

Zb

Nominal travels and related

terminals

Contact Open

OP 35,8 mm

-0,3 mm

21-22

13-14

DT=3,6 mm

21-22

13-14

-0,3 mm

21-22

13-14

-0,3 mm

21-22

13-14

21-22

10,4 18,3

FP

OP 35,8 mm

34,2

10,4

34,2

FP 10,4

13-14

OP

21-22

OP

21-22

13-14

13,6

13-14

35,8 mm

14,4

DT=1,3 mm

OP

34,5

32,9

21-22

13-14

RP=37,1 mm

17,6

23

Operating force max.

Disconnect force, max.

Operating velocity, max.

100 mm/s

10 N [2.2 lb]

13 N [3.0 lb]

100 mm/s

9 N [2.0 lb]

16 N [3.6 lb]

100 mm/s

10 N [2.2 lb]

17 N [3.8 lb]

Operating velocity, min.

1,0 mm/s

1,0 mm/s

1,0 mm/s

Max. operate frequency ops/min

250

250

250

Contact

block dia-

gram

Catalog listing

2 NO, slow

action

13

GL**05D | GL**35D

2 NC, slow

action

11

2Y

21

GL**06D | GL**36D

2 NC/

2 NO, snap

action

13

11

23

GLE*24D | GLE*32D

Nominal travels and related

terminals

Contact Open

Operating force max.

Disconnect force, max.

Operating velocity, max.

Operating velocity, min.

Max. operate frequency ops/min

13-14

23-24

FP

34,2

OP

35,8

10,4

OP

21-22

13-14

23-24

10,4 18,3

OP

21-22

OT

14,4

OP

11-12

FP

OP

33,1

OT

DT=0,9

16,5

RP=36,7

-0,3 mm

13-14

23-24

-0,3 mm

21-22

11-12

11-12

OP=35,8

-0,3 mm

11-12

14

13-14

21-22

12

23-24

DT=2,4

11-12

13-14

21-22

23-24

FP

24

23

23

23

8 N [1.8 lb]

13 N [3.0 lb]

8 N [1.8 lb]

13 N [3.0 lb]

3,2 N [0.72 lb]

6,0 N [1.35 lb]

250

1,0 mm/s

100 mm/s

250

1,0 mm/s

100 mm/s

250

1,0 mm/s

100 mm/s

Sensing and Internet of Things 11

Page 12

Installation Instructions for

Contact Closed

Contact Open Diff. Travel

**Positive Opening to IEC 947-5-1

13

21

14

22

Zb

.

35°

0° 16°

RP=6°

Zb

21

13

22

14

max.

35°

0° 16° 27°

13

22

14

max.

35°

0° 16° 27°

23

14

24

2X

max.

35°

0° 27°

22

max.

35°

0° 16°

Za

Za

.

RP=9°

[3.94]

ISSUE 10 81521

MICRO SWITCH GLS Min-Din Limit Switches

Figure 9. Head Code: K

Wobble Stick Angular Actuation Operating Characteristics

Notes:

• Free position, operate point, over travel and pre-travel all to

EN 50047

• Refer to page 6 for instructions on how to read operating

characteristics and specifications

• Contact block terminal designation to EN 50013

Nominal travels and related terminals

Catalog

listing Contact block diagram

OT

35°

max.

Operating torque

max.

Operating degrees,

max.

16° ±5°

OP

10°

DT

100,0

Operating degrees,

min.

Operating velocity,

max.

Operating velocity,

min.

Max. operate fre-

quency ops/min

Snap action

GL**01K

GL**07K

BBM, slow action

GL**03K

GL**33K

MBB, slow action

GL**04K

GL**34K

21

Zb

2 NO, slow action

13

GL**05K

GL**35K

2 NC, slow action

GL**06K

GL**36K

11

2Y

21

2 NC/2 NO, snap action

GLE*24K

GLE*32K

12 sensing.honeywell.com

13

11

23

21

14

12

24

22

21-22

13-14

FP

21-22

13-14

21-22

13-14

FP

21-22

13-14

FP

13-14

23-24

FP

11-12

21-22

11-12

13-14

21-22

23-24

11-12

13-14

21-22

23-24

FP

FP

12

OP

DT=10°

OP

OP

OP

OP

16°0°

OP OT

DT=7°

OT

max

OT

OT

OT

OT

35°

max

1,3 N

[0.29

lb]

1,1 N

[0.25

lb]

1,2 N

[0.27

lb]

1,1 N

[0.25

lb]

1,1 N

[0.25

lb]

1,1 N

[0.25

lb]

360° 10°

360° 10°

360° 10°

360° 10°

360° 10°

360° 10°

13

rad/s

13

rad/s

13

rad/s

13

rad/s

13

rad/s

13

rad/s

0.13

rad/s

0.13

rad/s

0.13

rad/s

0.13

rad/s

0.13

rad/s

0.13

rad/s

100

100

100

100

100

100

Page 13

Installation Instructions for

3,5 mm [0.14 in] for PG 13,5 and M20 conduit threads.

MICRO SWITCH GLS Min-Din Limit Switches

ISSUE 10 81521

Figure 1. GLC Side Rotary • A1, A1A, A1B, and A1Y

Figure 2. GLC Side Rotary • A2, A2A, A2B, and A2Y

Figure 4. GLC Side Rotary • A5A and A5B

7,2 mm [0.28 in] for 0.5-14 NPT conduit threads.

Figure 5. GLC Side Rotary • A9A

Figure 3. GLC Side Rotary Rod • A4J (140 mm) & A4L (200 mm)

3,5 mm [0.14 in] for PG 13,5 and

M20 conduit threads. 7,2 mm [0.28 in] for

0.5-14 NPT conduit threads.

Figure 6. GLC Top Pin Plunger

3,5 mm [0.14 in] for PG 13,5 and M20 conduit threads.

7,2 mm [0.28 in] for 0.5-14 NPT conduit threads.

3,5 mm [0.14 in] for PG 13,5 and M20 conduit threads.

7,2 mm [0.28 in] for 0.5-14 NPT conduit threads.

Sensing and Internet of Things 13

Page 14

Installation Instructions for

threads.

MICRO SWITCH GLS Min-Din Limit Switches

ISSUE 10 81521

Figure 7. GLC Top Roller Plunger

Figure 8. GLC Top Roller Arm

3,5 mm [0.14 in]

for PG 13,5 and

M20 conduit

threads.

7,2 mm [0.28 in]

for 0.5-14 NPT

conduit threads.

Figure 9. GLC Wobble • E7B

Figure 10. GLC Wobble • K8A/K8B

3,5 mm [0.14 in]

for PG 13,5 and

M20 conduit threads.

7,2 mm [0.28 in] for

0.5-14 NPT conduit

threads.

3,5 mm [0.14 in]

for PG 13,5 and

M20 conduit threads.

7,2 mm [0.28 in] for

0.5-14 NPT conduit

Figure 11. GLC Conduit

3,5 mm [0.14 in]

for PG 13,5 and

M20 conduit threads.

7,2 mm [0.28 in] for

0.5-14 NPT conduit

threads.

or

or

14 sensing.honeywell.com

Page 15

Installation Instructions for

MICRO SWITCH GLS Min-Din Limit Switches

ISSUE 10 81521

Figure 12. GLD Side Rotary • A1, A1A, A1B, and A1Y

3,5 mm [0.14 in]

for PG 13,5 and

M20 conduit threads.

7,2 mm [0.28 in] for

0.5-14 NPT conduit

threads.

Figure 13. GLD Side Rotary • A2, A2A, A2B, and A2Y

Figure 15. GLD Side Rotary • A5A and A5B

M20 conduit threads.

Figure 16. GLD Side Rotary • A9A

3,5 mm [0.14 in]

for PG 13,5 and

7,2 mm [0.28 in] for

0.5-14 NPT conduit

threads.

Figure 14. GLD Side Rotary Rod • A4J (140 mm) & A4L (200 mm)

3,5 mm [0.14 in] for PG 13,5 and M20 conduit threads.

7,2 mm [0.28 in] for 0.5-14 NPT conduit threads.

Figure 17. GLD Top Pin Plunger

3,5 mm [0.14 in]

for PG 13,5 and

M20 conduit threads.

7,2 mm [0.28 in] for

0.5-14 NPT conduit

threads.

3,5 mm [0.14 in]

for PG 13,5 and

M20 conduit threads.

7,2 mm [0.28 in] for

0.5-14 NPT conduit

threads.

Sensing and Internet of Things 15

Page 16

Installation Instructions for

MICRO SWITCH GLS Min-Din Limit Switches

ISSUE 10 81521

Figure 18. GLD Top Roller Plunger

Figure 19. GLD Top Roller Arm

3,5 mm [0.14 in]

for PG 13,5 and M20

conduit threads.

7,2 mm [0.28 in] for

0.5-14 NPT conduit threads.

Figure 20. GLD Wobble • E7B

Figure 21. GLD Wobble • K8A/K8B

3,5 mm [0.14 in] for PG 13,5 and M20 conduit threads.

7,2 mm [0.28 in] for 0.5-14 NPT conduit threads.

3,5 mm [0.14 in] for PG 13,5 and M20 conduit threads.

7,2 mm [0.28 in] for 0.5-14 NPT conduit threads.

Figure 22. GLD Conduit

16 sensing.honeywell.com

Page 17

Installation Instructions for

MICRO SWITCH GLS Min-Din Limit Switches

ISSUE 10 81521

Figure 23. GLE Side Rotary • A1, A1A, A1B, and A1Y

Figure 24. GLE Side Rotary • A2, A2A, A2B, and A2Y

Figure 26. GLE Side Rotary • A5A and A5B

Figure 27. GLE Side Rotary • A9A

Figure 25. GLE Side Rotary • A4J and A4L

Figure 28. GLE Top Pin Plunger

Sensing and Internet of Things 17

Page 18

Installation Instructions for

MICRO SWITCH GLS Min-Din Limit Switches

ISSUE 10 81521

Figure 29. GLE Top Roller Plunger

Figure 30. GLE Top Roller Arm

Figure 31. GLE Wobble • E7B

Figure 32. GLE Wobble • K8A

18 sensing.honeywell.com

Figure 33. GLE Conduit Adapter for 0.514 NPT

Page 19

Installation Instructions for

MICRO SWITCH GLS Min-Din Limit Switches

ISSUE 10 81521

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free of defective

materials and faulty workmanship. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please

refer to your order acknowledgement or consult your local sales office

for specific warranty details. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its

option, without charge those items it finds defective. The foregoing is

buyer’s sole remedy and is in lieu of all other warranties, expressed

or implied, including those of merchantability and fitness for a

particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages.

While Honeywell may provide application assistance personally,

through our literature and the Honeywell web site, it is up to the customer to determine the suitability of the product in the application.

Specifications may change without notice. The information we supply

is believed to be accurate and reliable as of this printing. However, we

assume no responsibility for its use.

GARANZIA/RISARCIMENTO

Honeywell garantisce che i propri prodotti sono esenti da difetti nei

materiali e nella manodopera. Rimane valida la garanzia di prodotto

standard Honeywell, se non diversamente concordato dalla stessa per

iscritto. Fare riferimento alla ricevuta dell’ordine o rivolgersi all’ufficio

vendite della propria zona, per ulteriori dettagli sulla garanzia. Durante

il periodo di validità della garanzia, Honeywell provvederà alla riparazione o alla sostituzione, a sua discrezione e senza alcun addebito degli

articoli restituiti e riscontrati difettosi. Tale azione costituisce l’unico

risarcimento per l’acquirente e sostituisce tutte le altre garanzie, esplicite o implicite, incluse quelle della commerciabilità e

dell’idoneità ad uno scopo particolare. In nessun caso Honeywell è

da ritenersi responsabile per danni conseguenti, speciali o indiretti.

Honeywell fornisce assistenza in merito alle applicazioni tramite il

proprio personale, il proprio materiale informativo ed il proprio sito Web;

tuttavia è responsabilità del cliente verificare l’idoneità del prodotto

all’applicazione.

I dati tecnici sono soggetti a modifica senza alcun preavviso. Le informazioni fornite nel presente documento sono da ritenere accurate

ed affidabili. Tuttavia, Honeywell non si assume alcuna responsabilità

in merito al loro impiego.

GARANTIE UND HAFTUNGSANSPRÜCHE

Honeywell garantiert für seine hergestellten Produkte fehlerfreies

Material und Qualitätsarbeit. Es gilt die durch Honeywell schriftlich

mitgeteilte StandardProduktgarantie von Honeywell. Informationen zu

Garantiedetails finden Sie auf Ihrer Auftragsbestätigung bzw. erhalten

Sie von Ihrer örtlichen Niederlassung. Wenn Produkte mit Garantie

innerhalb der Garantiefrist an Honeywell zurückgesendet werden,

ersetzt oder repariert Honeywell die als fehlerhaft angesehen Teile nach

eigenem Ermessen kostenlos. Das Vorangegangene gilt als einzige

Entschädigung des Käufers und ersetzt alle anderen ausdrücklichen oder stillschweigenden Garantien, einschließlich Qualitätsund Sachmängelhaftung. In keinem Fall haftet Honeywell für

mittelbare, indirekte oder Sondeschäden.

Obwohl Honeywell persönliche und schriftliche Anwendungshilfe sowie

Informationen über die Honeywell Website bietet, ist es die Entscheidung des Kunden, ob das Produkt sich für die entsprechende Anwendung eignet.

Änderungen der technischen Daten ohne Vorankündigung sind vorbehalten. Die hier gegebenen Informationen sind nach unserem Wissen

zum Zeitpunkt der Drucklegung korrekt. Wir übernehmen dennoch

keinerlei Verantwortung für deren Verwendung.

GARANTIE/RECOURS

Honeywell garantit que les articles de sa fabrication sont exempts

de défauts de pièces et main d’œuvre. La garantie standard sur les

produits Honeywell est d’application sauf indication contraire écrite et

approuvée par Honeywell. Veuillez vous reporter au récépissé de votre

commande ou consulter votre bureau de vente local pour obtenir des

détails spécifiques sur la garantie. Si les articles garantis sont retournés

à Honeywell pendant la période de couverture, Honeywell réparera ou

remplacera, à sa discrétion, gratuitement ceux qui auront été trouvés

défectueux. Ce qui précède constitue le seul recours de l’acheteur

et se substitue à toutes autres garanties, explicites ou implicites, y

compris celles relatives à la commercialisation ou la compatibilité

avec une application particulière. Honeywell ne peut être en aucun

cas tenu responsable de tout dommage indirect, spécial ou accessoire.

Bien que nous fournissions une assistance aux applications par le biais

de notre bibliographie et le site Web Honeywell, il appartient au client

de déterminer l’aptitude du produit pour son application.

Les caractéristiques techniques peuvent changer sans préavis. Les

informations que nous diffusons sont réputées précises et fiables au

moment de leur impression. Nous n’assumons cependant aucune

responsabilité pour leur usage.

CLAUSULA DE GARANTÍA

Honeywell garantiza que todos los productos que fabrica están libres

de defectos de mano de obra o materiales. La garantía del producto

estándar de Honeywell se aplica a menos que Honeywell haya acordado lo contrario por escrito; consulte a su confirmación de orden o a

su oficina de ventas local para detalles específicos de garantía. Si se

devuelven productos con garantía a Honeywell durante el período de

cobertura, Honeywell los reparará o reemplazará, de manera opcional, si determina que están defectuosos. Esta cláusula de garantía

sustituye a cualquier otra garantía, ya sea explícita o implícita. En

ningún caso Honeywell será responsable por daños consecuentes,

especiales o indirectos.

Aunque Honeywell ofrece asistencia personal para las aplicaciones

por medio de sus publicaciones y páginas web, es el cliente quien debe

determinar la idoneidad del producto en la aplicación.

Las especificaciones pueden cambiar sin previo aviso. La información

suministrada es considerada correcta y fiable en el momento de esta

impresión. No obstante, no asumimos la responsabilidad por su uso.

GARANTIA/SOLUÇÕES

A Honeywell garante seus produtos contra defeitos de material e de

fabricação. A garantia padrão de produto da Honeywell se aplica a

menos que haja um acordo diferente por escrito com a Honeywell;

consulte a sua confirmação de encomenda ou consulte o escritório

de vendas local para obter detalhes específicos da garantia. Quando

produtos dentro do período de cobertura da garantia forem devolvidos

à Honeywell, esta se compromete a reparar ou substituir, de acordo

com a opção da empresa, por um novo aqueles produtos que considerar defeituosos. O acima estipulado é a única solução oferecida ao

comprador e substitui quaisquer outras garantias, expressas ou implícitas, inclusive garantias de comerciabilidade e adequação a um

fim específico. Em hipótese alguma a Honeywell deve ser responsabilizada por danos conseqüenciais, especiais ou indiretos.

Embora a Honeywell proporcione assistência pessoal, através de literatura e de seu site na web, cabe ao cliente determinar qual produto é

mais adequado à sua aplicação.

Sensing and Internet of Things 19

Page 20

Installation Instructions for

MICRO SWITCH GLS MinDin Limit Switches

Especificações podem ser alteradas sem aviso prévio. Acreditamos que

as informações aqui contidas eram as mais precisas e confiáveis no

momento da impressão desta publicação. No entanto, não assumimos

qualquer responsabilidade pelo uso destas.

保证/补救

霍尼韦尔保证,本公司所制造的产品不存在任何有缺陷的材料和工艺上的缺

陷。如霍尼韦尔未另外以书面形式同意,则适用霍尼韦尔的标准产品保证;

请参阅订单确认书或咨询当地销售处了解具体保修细节。如果用户在保修期内

将产品退回公司,霍尼韦尔将负责免费维修或更换存在缺陷的零部件。上述条

款是购买人所能获得的唯一补救方法,并取代所有其他明示或暗指的保证,包

括有关针对某一特定目的的适销性和适用性的保证。霍尼韦尔对衍生性损害、

特殊损害与间接损害概不负责。

尽管我们可以派专人、通过我们的技术资料和霍尼韦尔网站等方式提供应用支

持,但确定产品在应用中是否适合则取决于用户自身。

技术规格若有改动,恕不另行通知。本文所提供的信息自印刷之日起均视为准

确、可靠。但是,我们不对本文的使用承担任何责任。

ISSUE 10 81521

For more information

Honeywell Sensing and Internet of

Things services its customers through a

worldwide network of sales offices and

distributors. For application assistance,

current specifications, pricing or the

nearest Authorized Distributor, visit

sensing.honeywell.com or call:

Asia Pacific +65 63552828

Europe +44 1698 481481

USA/Canada +18005376945

Honeywell Sensing and Internet of Things

9680 Old Bailes Road

Fort Mill, SC 29707

www.honeywell.com

PK 8152110MLa | 10 | 04/19

© 2019 Honeywell International Inc. All rights reserved.

Loading...

Loading...