Page 1

User’s Manual

ENTIS R121.1

Page 2

PREFACE

About this Guide

This manual describes how to operate the ENTIS system. It has been written for

operators, as well as system supervisors, to provide them with all the information

required to operate the system.

For installation details refer also to the ENTIS Installation Guide.

Safety and prevention of damage

‘Cautions’, and ‘Notes’ have been used throughout this manual to bring special

matters to the immediate attention of the reader.

A Caution draws attention to an action which may damage the

equipment.

A Note points out a statement deserving more emphasis than the

general text, but does not deserve a “Warning” or a “Cauti on”.

Additional information

Contact Honeywell, or its representative, if you require additional information.

Also, refer to the list of related documents in Appendix for more information.

Legal aspects

The information in this manual is copyright property of Honeywell, Netherlands.

Honeywell disclaims any responsibility for personal injury or damage to

equipment caused by:

Deviation from any of the prescribed procedures

Execution of activities that are not clearly documented

Copyright 2020 Honeywell. All rights reserved.

Reproduction in any form without the prior consent of Honeywell is not allowed.

This manual is for information only. The contents, descriptions and specifications

are subject to change without notice. Honeywell accepts no responsibility for any

errors that may appear in this manual.

The warranty terms and conditions applicable in the country of purchase in

respect to Honeywell products are available from your supplier. Please retain

them with your proof of purchase.

ii ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 3

ETDOC-X615-en-101A

September 2019 (1st Release)

ETDOC-X615-en-110.1

December 2019 (R110.1)

ETDOC-X615-en-120.1

June 2020 (R120.1)

ETDOC-X615-en-121.1

September 2020 (R121.1)

ETDOC-X612-en-R121.1

ENTIS Quick Start Guide

ETDOC-X613-en-R121.1

ENTIS Installation and C on f iguratio n Guide

EHDOC-X136-en-510A

Experion HS Software Installation Users Guide

EHDOC-XX75-en-510A

Network and Security Guide

Support

For support, contact your local Honeywell Process Solutions Customer Contact Centre (CCC). To

find your local CCC visit the website,

US/contactus/pages/default.aspx

https://www.honeywellprocess.com/en-

Revision History

ENTIS Installation and Configuration Guide (This document)

Documentation References

The following list identifies publications that may contain information relevant to

the information in this document.

ENTIS Hub page for documentation and videos: https://www.honeywellprocess.com/en-

US/online_campaigns/terminals/Pages/Terminals-HUB.aspx.

Experion HS Network and Security Guide:

http://hpsvault.honeywell.com/sites/HPSVaultSupportLibrary/Documents/Experion_HS/R51

1.1/Network-and-Security-Planning-Guide-EHDOC-XX75-en-511A.pdf

ENTIS documentation on HPS web:

US/explore/products/terminal-operations/tank-storage/Pages/tank-inventory-systems.aspx.

https://www.honeywellprocess.com/en-

Contacts

See back page for details

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual iii

Page 4

Contents

PREFACE ........................................................................................................................................ ii

INTRODUCTION ............................................................................................................................. 1

Real Time Inventory ............................................................................................................... 1

Numerical & Graphical Displa y ............................................................................................... 1

Networking ............................................................................................................................. 1

Alarm System ......................................................................................................................... 1

Hot Standby & CIU Redundancy Support ............................................................................... 1

ENTIS Redundancy Support .................................................................................................. 2

Dual Gauges Support ............................................................................................................. 2

954 Servo Test Alarm Support ............................................................................................... 2

50 Point Density Profile Support ............................................................................................. 2

Reporting Enhancements ....................................................................................................... 2

ENTIS Language Support ...................................................................................................... 2

Experion Alarms & Events Screen Language Support ............................................................ 2

INTERFACE GUIDELINES .............................................................................................................. 4

Help ........................................................................................................................................ 4

Data Status ............................................................................................................................ 4

SECURITY CONSIDERATIONS ..................................................................................................... 5

General Guidelines ................................................................................................................. 5

Signed Assemblies ................................................................................................................. 5

Network Shares ...................................................................................................................... 6

Access Control List ................................................................................................................. 6

Backup & Restore .................................................................................................................. 6

User Accounts and Roles ................................................................................................

Physical and Environmental Considerations ........................................................................... 7

System Monitoring .................................................................................................................. 7

Vulnerability Reporting ........................................................................................................... 7

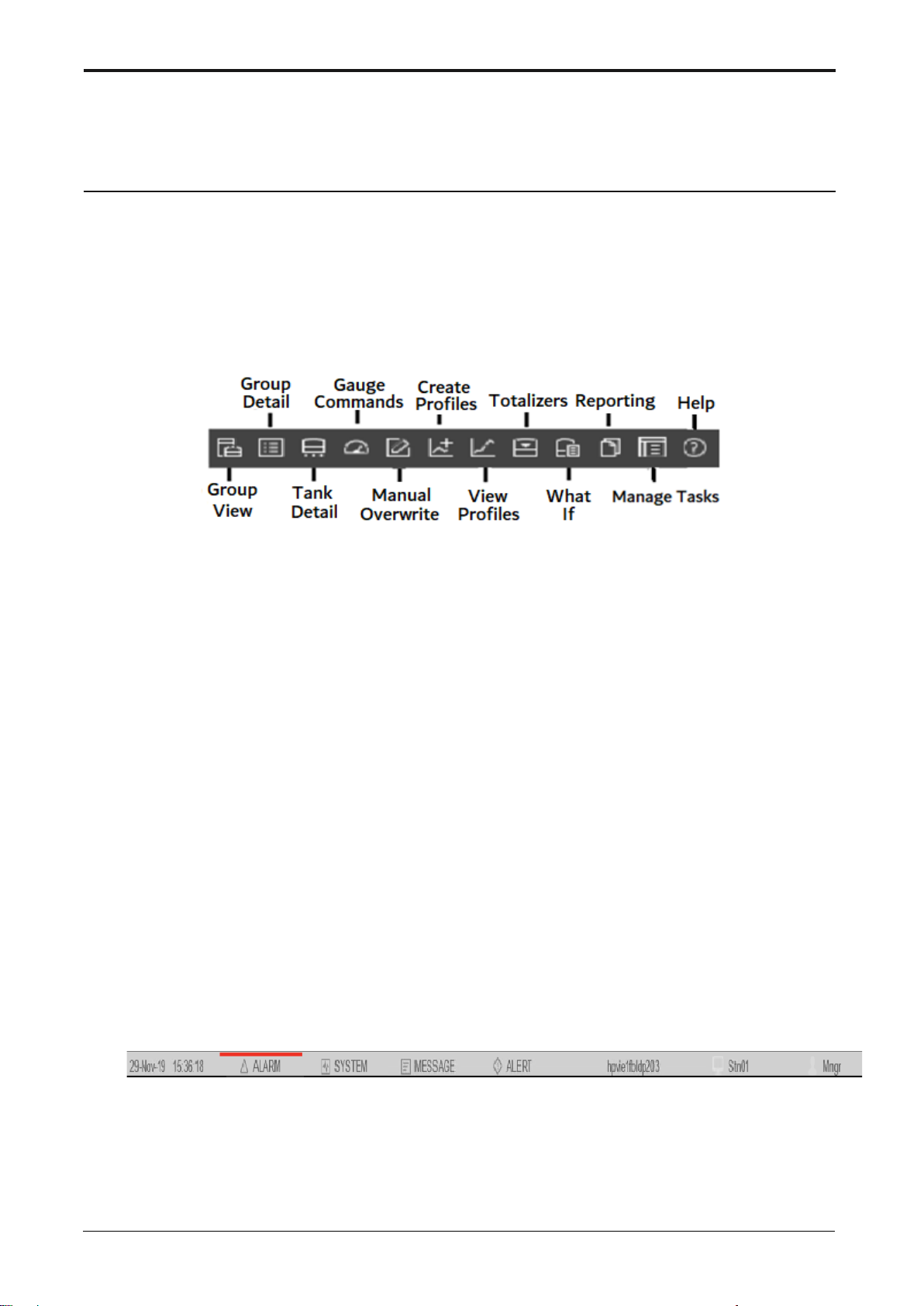

TOOLBAR ....................................................................................................................................... 8

Toolbar ................................................................................................................................... 8

Status bar ............................................................................................................................... 8

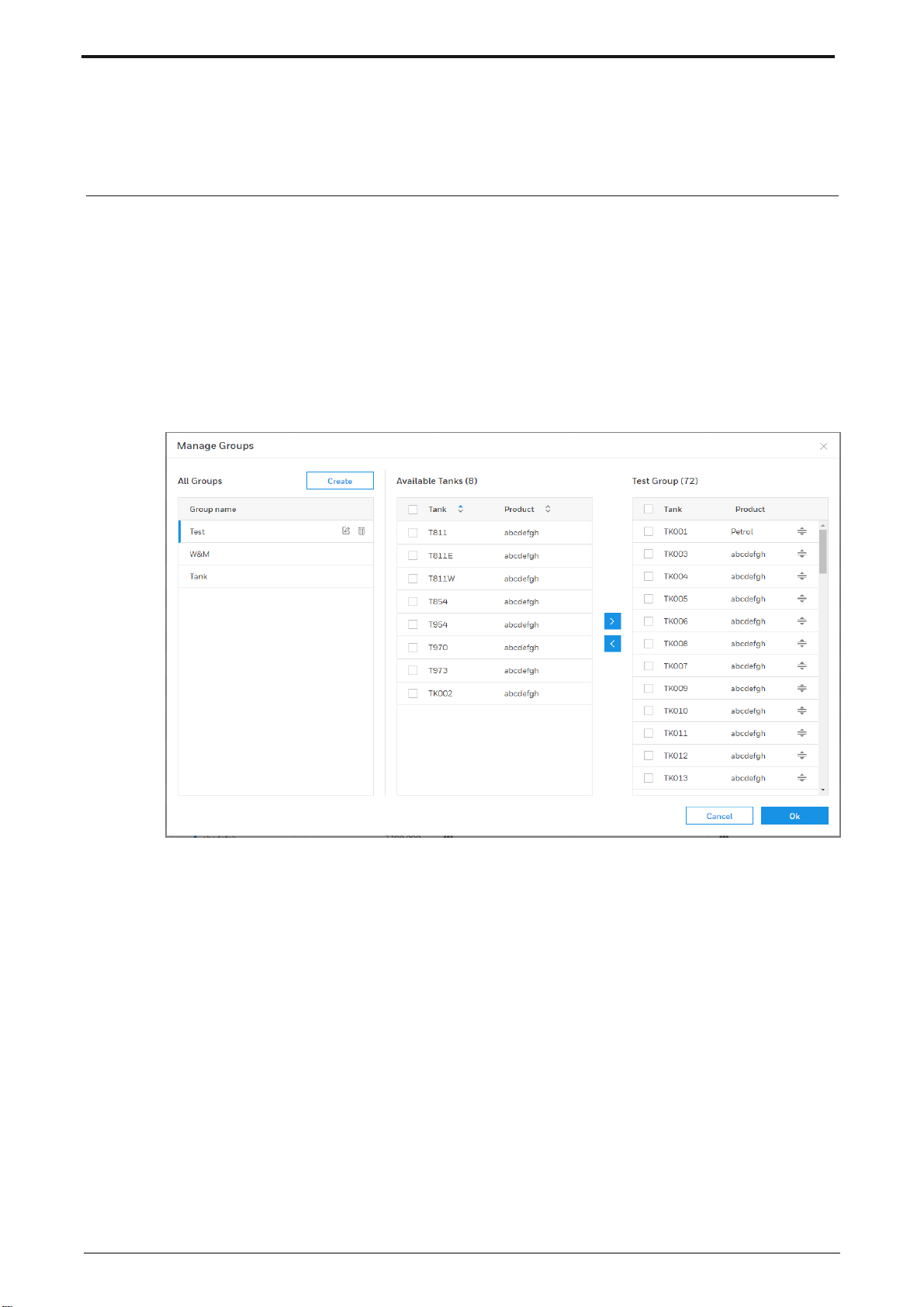

MANAGE DISPLAYS .................................................................................................................... 10

Manage Group ..................................................................................................................... 10

Manage Views ...................................................................................................................... 12

Manage Filters ...................................................................................................................... 15

GROUP VIEW .............................................................................................................................. 17

GROUP DETAIL ............................................................................................................................ 18

Delta column ........................................................................................................................ 20

Critical / Operation PAL Column ........................................................................................... 23

Remark Column ................................................................................................................... 28

TANK DETAIL ............................................................................................................................... 31

GAUGE COMMANDS ................................................................................................................... 36

Running Dipping Commands ................................................................................................ 40

Running Displacer Commands ............................................................................................. 41

Scheduling Gauge Command ............................................................................................... 42

MANUAL OVERWRITE ................................................................................................................. 44

Performing a Manual Overwrite ............................................................................................ 45

PROFILES..................................................................................................................................... 48

Profile screen examples ....................................................................................................... 51

....... 7

iv ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 5

MOVEMENT .................................................................................................................................. 54

TOTALIZER ................................................................................................................................... 60

WHAT IF ........................................................................................................................................ 62

REPORTS ..................................................................................................................................... 66

Report Printing ..................................................................................................................... 66

Report Scheduling ............................................................................................................... 70

Templates ............................................................................................................................ 72

MANAGE TASKS ........................................................................................................................... 77

HELP ............................................................................................................................................. 79

SETTINGS ..................................................................................................................................... 80

ALARMS .............................................................................................................................. 80

Product Color Code ............................................................................................................. 82

Clock Sync ........................................................................................................................... 83

Manage Files ....................................................................................................................... 83

Reporting ............................................................................................................................. 84

HOT STANDBY & REDUNDANCY SUPPORT ENT IS ................................................................... 85

Hot Standby & Redundancy Support (CIU 888) ................................................................... 87

How to Perform Manual Switch Over ................................................................................... 88

ALARMS ........................................................................................................................................ 89

CONFIGURE ALARMS ........................................................................................................ 89

VIEW ALARMS .................................................................................................................... 92

EVENTS ........................................................................................................................................ 96

96

Viewing Events .................................................................................................................... 96

HISTORICAL AND REALTIME TRENDING ................................................................................. 100

INDEX .......................................................................................................................................... 109

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual v

Page 6

Table of Tables

Table 1: Data Status ........................................................................................................................ 4

Table 2: Displacer Commands....................................................................................................... 38

Table 3: Entity Fields ..................................................................................................................... 45

Table 4: Configuration Alarms ....................................................................................................... 89

vi ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 7

Table of Figures

Figure 1: Tool bar ............................................................................................................................ 8

Figure 2: Status bar ......................................................................................................................... 8

Figure 3: Manage Groups ............................................................................................................. 10

Figure 4: Reset Views ................................................................................................................... 12

Figure 5: Manage Views ............................................................................................................... 13

Figure 6: Manage Filters ............................................................................................................... 15

Figure 7: Group View .................................................................................................................... 17

Figure 8: Group Detail ................................................................................................................... 19

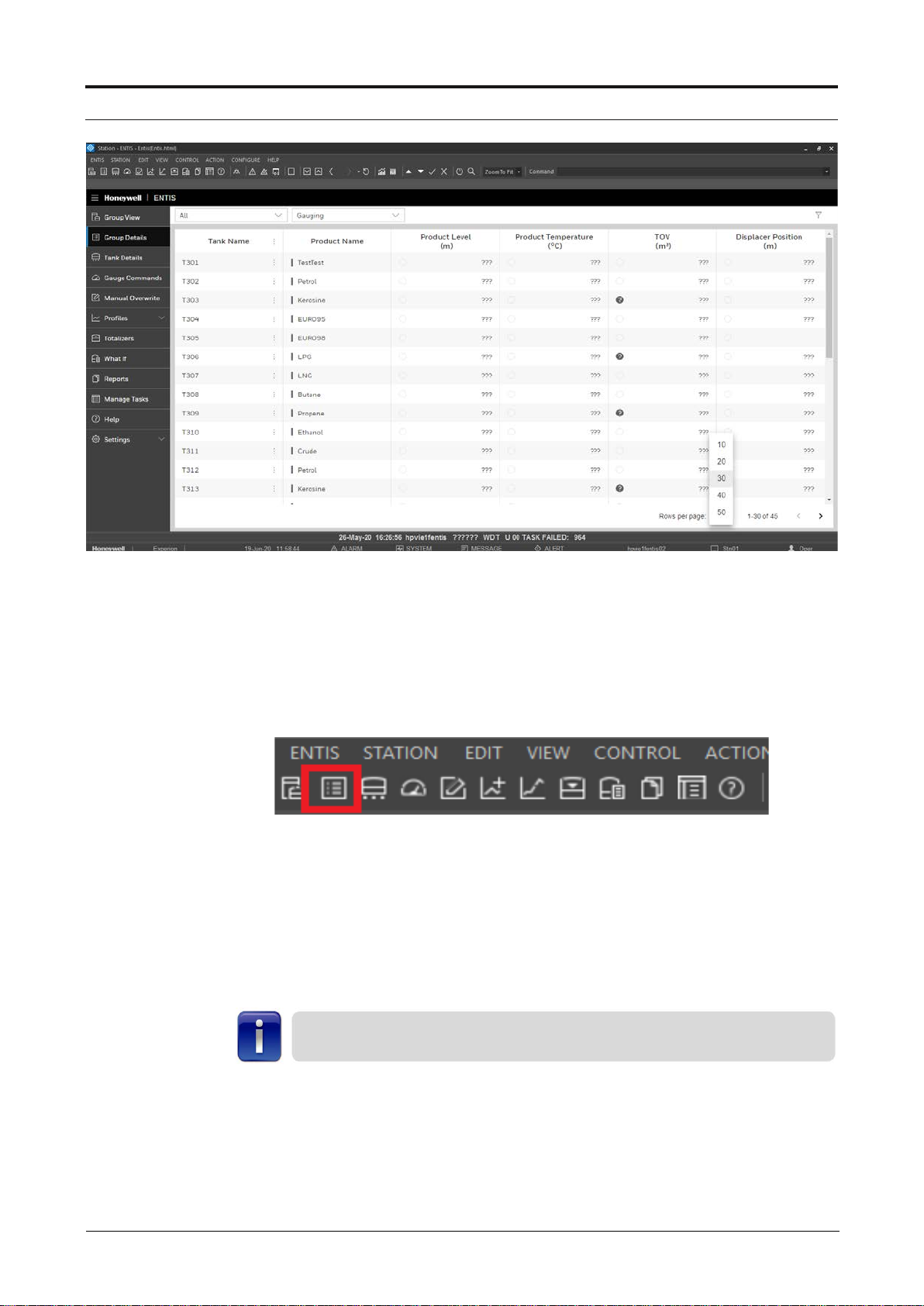

Figure 9: Delta Column ................................................................................................................. 20

Figure 10: Delta Column Group..................................................................................................... 21

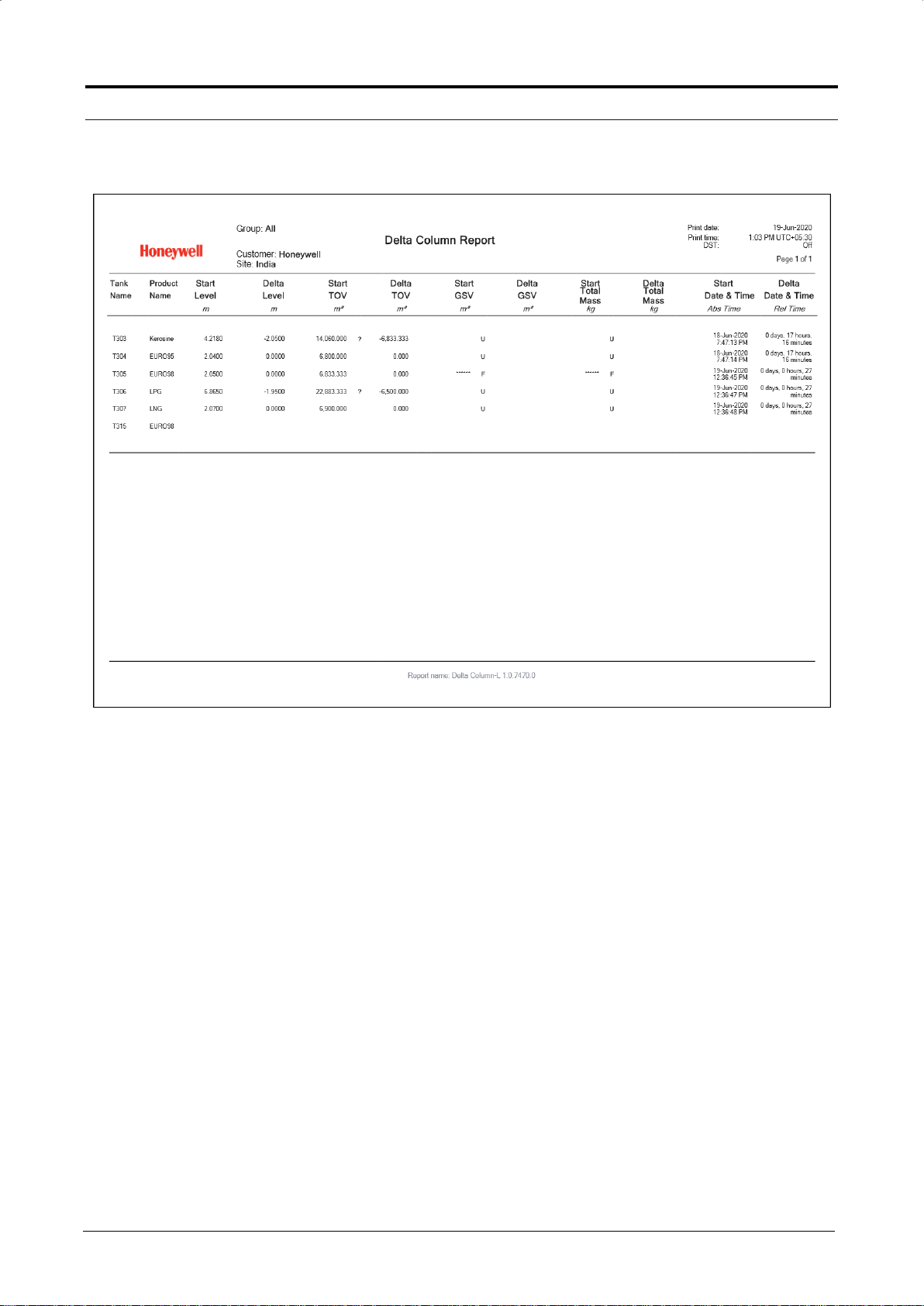

Figure 11: Delta Column Report .................................................................................................... 22

Figure 12: Alarm Column .............................................................................................................. 23

Figure 13: Alarm Column Views .................................................................................................... 24

Figure 14: Group Detail Alarm Column .......................................................................................... 25

Figure 15: Alarm Column HA ........................................................................................................ 26

Figure 16: Alarm Column HA Ack .................................................................................................. 26

Figure 17: Alarm Column LA ......................................................................................................... 27

Figure 18: Remarks Column ......................................................................................................... 28

Figure 19: Remarks Views ............................................................................................................ 29

Figure 20: Remarks Views edit...................................................................................................... 30

Figure 21: Remarks Views with history .......................................................................................... 30

Figure 22: Tank Detail ................................................................................................................... 32

Figure 23: Tank Detail Floating ..................................................................................................... 33

Figure 24: Tank Detail Sphere....................................................................................................... 34

Figure 25: Tank Detail Icon ........................................................................................................... 35

Figure 26: Gauge Commands ....................................................................................................... 36

Figure 27: Dipping Command ....................................................................................................... 37

Figure 28: Displacer command...................................................................................................... 38

Figure 29: Tank Gauge Alarm ....................................................................................................... 39

Figure 30: Displacer ...................................................................................................................... 40

Figure 31: Displacer ...................................................................................................................... 41

Figure 32: Schedule Command Screen ......................................................................................... 42

Figure 33: Scheduling screens ...................................................................................................... 43

Figure 34: Manual Overwrite ......................................................................................................... 44

Figure 35: Manual Overwrite Parameter ........................................................................................ 46

Figure 36: Create Profile ............................................................................................................... 49

Figure 37: Profile ready ................................................................................................................. 50

Figure 38: Temperature profile ...................................................................................................... 51

Figure 39: Density Profile .............................................................................................................. 52

Figure 40: Interface Profile ............................................................................................................ 53

Figure 41: Density and Temperature profile .................................................................................. 53

Figure 42: Density profile .............................................................................................................. 53

Figure 43: Totalizer ....................................................................................................................... 60

Figure 44:Totalizer_All .................................................................................................................. 60

Figure 45: Totalizer Icon................................................................................................................ 61

Figure 46: What If ......................................................................................................................... 62

Figure 47: What – If layout ............................................................................................................ 63

Figure 48: What – If Start .............................................................................................................. 64

Figure 49: What – If Reload .......................................................................................................... 65

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual vii

Page 8

Figure 50: Reports ......................................................................................................................... 66

Figure 51: Reporting icon .............................................................................................................. 67

Figure 52: Tank detail report .......................................................................................................... 67

Figure 53: Browse Reports ............................................................................................................ 69

Figure 54: Schedule report ............................................................................................................ 70

Figure 55: Schedule report screens ............................................................................................... 71

Figure 56: Group detail report ........................................................................................................ 72

Figure 57: Tank detail .................................................................................................................... 73

Figure 58: Delta column report ...................................................................................................... 74

Figure 59 - What if .. report ............................................................................................................ 75

Figure 60: Manage Tasks .............................................................................................................. 77

Figure 61: Scheduling screen ........................................................................................................ 78

Figure 62: Confirmation Dialog ...................................................................................................... 78

Figure 63: Help .............................................................................................................................. 79

Figure 64: Help icon ...................................................................................................................... 79

Figure 65: Alarm Settings .............................................................................................................. 81

Figure 66: Product Color Code ...................................................................................................... 82

Figure 67: Clock Sync ................................................................................................................... 83

Figure 68: File Cleanup ................................................................................................................. 83

Figure 69: Reporting Settings ........................................................................................................ 84

Figure 70: Configuration screen ..................................................................................................... 90

Figure 71: Alarm Configuration screen .......................................................................................... 91

Figure 72: View Alarms ................................................................................................................. 92

Figure 73: View Events .................................................................................................................. 97

Figure 74: Trends ........................................................................................................................ 105

Figure 75: Configure Trends ........................................................................................................ 106

Figure 76: Select the point ........................................................................................................... 106

Figure 77: Select the parameter .................................................................................................. 107

Figure 78: View Trend ................................................................................................................. 107

Figure 79: Historical Trend .......................................................................................................... 108

viii ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 9

INTRODUCTION

ENTIS is a unique Tank Inventory Management System developed for Windows

10 Enterprise, and powered by the Experion platform, to display Tank inventory

data.

Real Time Inventory

ENTIS is a Windows 10 Enterprise application. Data is retrieved via dedicated

Communication Interface Units (CIU’s) and processed through to the open ENTIS

database. Various displays are available for inventory management. These

displays include bar graphs, tabular data, iconized tanks, and a whole range of

modules such as trending, report printing, and a “what if” tank calculator.

Numerical & Graphical Display

The graphical displays provide a quick overview of tank data. The numerical

displays can be customized to suit your own particular needs. These displays can

be either tank or group related. Several graphical displays are also available, and

tank images can be customized per tank if required.

Networking

The network facilities of the Experion system allow you to integrate ENTIS into

your plant’s networks.

Alarm System

ENTIS provides you with an array of programmable alarm set points. Privileged

users can create their own alarms for all measured and calculated data. During

inactive periods, tanks can be put into a leak detection mode. Alarms and

acknowledgements, together with all tank information, are stored and recorded for

future review and traceability.

Hot Standby & CIU Redundancy Support

The ENTIS system can be enhanced for use in critical applications with hot

standby and CIU redundancy support. CIU redundancy support can cover the

unlikely event of a network failure, providing sustained and reliable data to your

management system. After the occurrence of an error, the second CIU will

automatically start and take over the lost functionality. Following the switch over,

all gauge data will be rescanned and recalculated to ensure data reliability.

ETDOC-X615–R121.1 ENTIS R121.1 User’s Manual 1

Page 10

ENTIS Redundancy Support

The ENTIS system can now be used in a redundant server mode, with automatic

failover capabilities.

Dual Gauges Support

ENTIS can now work with the CIU to support dual gauge systems, allowing for

two product levels to be used to generate a difference alarm.

954 Servo Test Alarm Support

ENTIS can be used to generate test alarms for the 954 servo.

50 Point Density Profile Support

ENTIS can now work with the 954 servo to support 50 point density profiles.

Reporting Enhancements

ENTIS reporitng now allows for the use of customized customer name, sites and

logos, on the standard and Legal Metrology-approved report set.

ENTIS license now gives you the option to start with 5, 10, 15, 20, …310, 315,

320...400 tanks.

ENTIS Language Support

ENTIS now supports either of English, French, Italian, Dutch, Chinese, Spanish

or Russian language. ENTIS will appear in the language as being set at

commissioning. User with Admin rights can change the language of ENTIS when

required. Experion menu items are available in English, French, Italian, Dutch,

Chinese, Spanish or Russian language.

Refer the instructions provided in section 6.1 of

Guide for changing the languag e.

Experion Alarms & Events Screen Language Support

ENTIS now allows user to view the alarm and event description in either of

English, French, Italian, Dutch, Spanish language.

ENTIS Installation and Configuration

2 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 11

Tank hooks to address a specific tank from Experion

From ENTIS it is possible to see the tank details of a specific tank by selecting

the “Tank Detail” screen and by selecting the required tank.In some cases it is

very useful to have a direct link to the tank “Tank Detail” screen and the selected

tank.For example when you have a HMIWeb page in Experion and you want to

link the tank details from this page.

%HwProgramData%\Experion

PKS\Client\MenusAndToolbars\EntisHTML\Entis.HTML?tab=tank-details\T111

In case of linking anther tank instead of T111 you need to replace the tank name

at the end of the link.

The part between the brackets below needs to be replaced with the tan k name:

%HwProgramData%\Experion

PKS\Client\MenusAndToolbars\EntisHTML\Entis.HTML?tab=tankdetails\[TankName]

To test the link in Experion Station you can execute the link in the Experion

“Command” bar.

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 3

Page 12

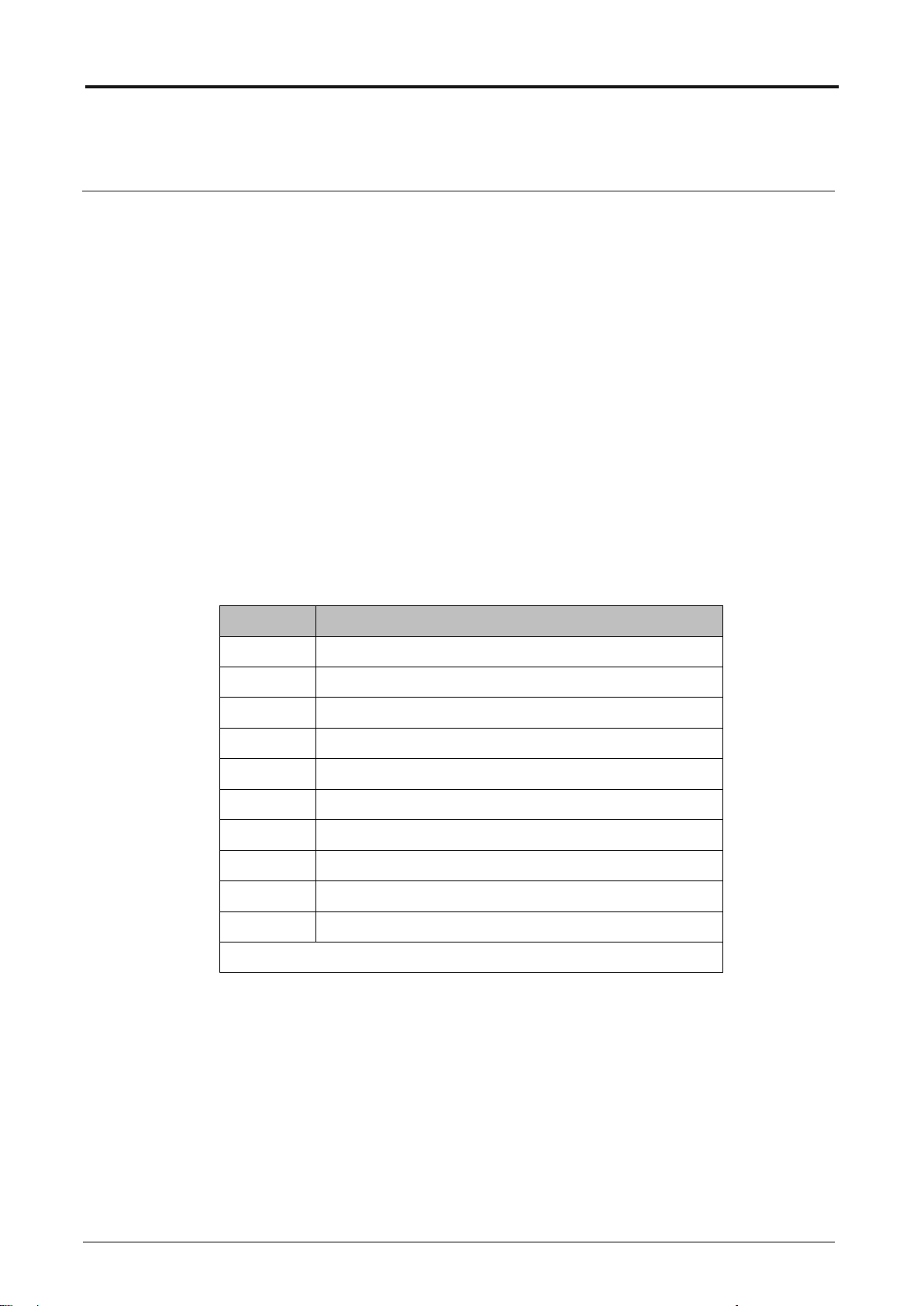

Sign

Description

&

Data is manually overwritten

S

Data is stored and not approved

#

Data is not approved f or Legal Metro lo g y use

?

Data has reduced accuracy and is not approved

F

Data is in fail

K

Data is not being scanned (formerly called ‘killed’)

˄

Data is over range

˅

Data is under range

U

Data is uninitialized

S&W, Liq/Vol Ratio and Molar Weight are always manually entered

INTERFACE GUIDELINES

The ENTIS user interface consists of a set of inter-related graphical objects

together with a set of rules governing their deployment, such as windows, dialog

boxes, task icons, colours and others.

Although ENTIS is a Windows application, there are certain additional

conventions used in ENTIS that will be described in this chapter. This chapter

also describes a basic set of rules to help the user learn how to use ENTIS

Help

ENTIS supports the displaying of the PDF of the User’s Manual. Navigating to the

Help menu item will open the pdf version of the ENTIS User’s Manual.

Data Status

Measured and calculated data is indicated by a status sign.

The statuses are shown in the following table:

Table 1: Data Status

Data is actual and approved

4 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 13

SECURITY CONSIDERATIONS

General Guidelines

ENTIS runs on the Experion HS platform; therefore, Experion’s security

guidelines / recommendations should be followed in any ENTIS deployment.

Experion HS provides a comprehensive Network and Security Guide (ID:

EHDOC-XX75-en-510A) that should be reviewed prior to an ENTIS deployment.

It contains numerous guidelines to help ensure a secure deployment.

In addition to the information provided in that manual, this section provides some

additional security-related details.

This information is ENTIS-specific and is meant only to augment the Experion

documentation.

Signed Assemblies

Digitally signing files allows users to confirm that those files were provided by

Honeywell.

Honeywell has digitally signed the assemblies that it provides with ENTIS. Note

that this does not include third-party assemblies that are not maintained as a part

of the ENTIS product line.

Users can confirm that their ENTIS assemblies are signed by bringing up the

assembly properties via Windows Explorer.

Users can check for signing by right-clicking on the dll/exe, and selecting

Properties from the context menu.

If the ensuing dialog has a Digital Signatures tab, and there is a “Honeywell

Limited” signer listed, then your assembly has been properly signed by

Honeywell.

ENTIS R121.1 User’s Manual ETDOC-X615–R121.1 5

Page 14

Security Considerations

ENTISRepository

C:\ProgramData\Ho

Server

Used by File Replication

Broker

C:\Program Files

Server

Used to exchange the

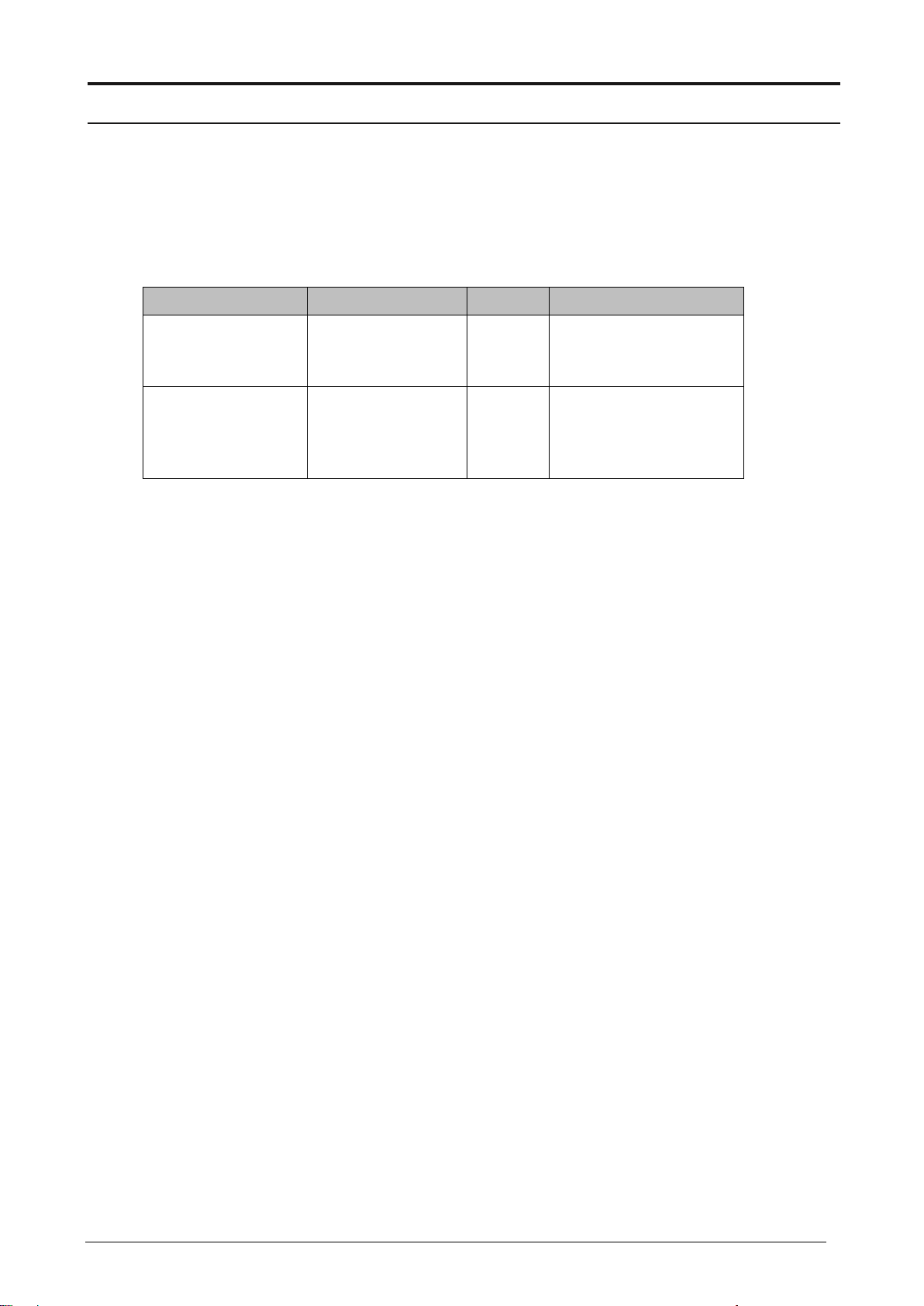

Network Shares

ENTIS creates the following network shares beyond what Experion

configures, and documents, in their Network and Security Guide.

Shares created by Server-Client install are as follows:

Name Location Nodes Usage

neywell\ENTIS

(x86)\Mosquitto

to replicate contents to a

redundant server

certificate and

configuration file with a

redundant server.

Access to the shares is limited to users of the groups Administrators,

Product Administrators and Local servers.

Access Control List

ENTIS will set up the appropriate access controls on its files for the

application to run securely.

This ACL configuration step is run automatically as a part of the

installation process.

In addition to the ENTIS-specific ACL settings, ENTIS also relies on

the standard Experion ACL implementation, as is described in the

Experion Network and Security Guide.

6 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Backup & Restore

For the backup and restoration process for the node, please refer to

the following sections of the Experion PKS Backup and Restore

User's Guide, EPDOC-X111-en-431K on Honeywellprocess.com.

Backups on a physical node.

1. Backups on a virtual node.

2. Restoring Physical Nodes.

3. Restoring Virtual Nodes.

Page 15

SECURITY CONSIDERATIONS

User Accounts and Roles

User roles define the set of operations that a user is allowed to perform. ENTIS

leverages the Experion platform and its user roles. For information on the roles,

please refer to the “User accounts and Experion user roles” section in the

Network and Security Guide (ID: EHDOC-XX75-en-510A). Note that the Legal

Metrology user roles are ENTIS specific and explained in more detail in the

ENTIS Sealing guide.

Physical and Environmental Considerations

While the security issues for ENTIS on Experion are largely the same as for any

IT server, the physical access of a tank information system can be particularly

important. For physical and environmental considerations, please see the

Physical and Environmental Considerations section in the Network and Security

Guide (ID: EHDOC-XX75-en-510A).

System Monitoring

ENTIS and Experion provide a number of ways to detect potential evidence of

intrusion. The System Monitoring section of the Network and Security Guide (ID:

EHDOC-XX75-en-510A) provides details on this subject. In addition to the information

in that guide, it should be added that ENTIS wll write events into the ENTIS event log,

which is available through the Windows event viewer.

Vulnerability Reporting

In the previously mentioned Network and Security Guide (ID: EHDOC-XX75-en510A), please refer to the section titled “How to report a security vulnerability” for

information pertaining to reporting potential security vulnerabilities against

Honeywell products.

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 7

Page 16

TOOLBAR

Toolbar

The toolbar is present in Experion Station. It offers a fast navigation

tool for ENTIS displays. Based on their access level, users can

navigate to ENTIS screens by clicking on the associated menu icons.

Figure 1: Tool bar

Status bar

The status bar includes the following display areas:

DateTime

Displays the current system date and time.

Alarms

Whenever an alarm is raised, the alarm icon will start blinking in red.

Clicking on the icon will open the Alarm display.

System

If it is blinking in blue, the system status is ok. If any system related

issues come up, it will start blinking in red. Click on it to open the

system status vie w.

Message, Alert

Any message or alert logged by Experion will be available here.

Figure 2: Status bar

8 ENTIS R121.1 User’s manual ETDOC-X615– R121.1

Page 17

Toolbar

Server Name

Server to which Experion Station is connected. Click on the icon to view details.

Station Name

The connected Station name will be displayed here.

Role

Displays the logged-in user role. Click on it to enter the credentials and change

the role.

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 9

Page 18

MANAGE DISPLAYS

Manage Group

Tank groups can be defined to allow for easier navigation between subsets of

tanks.

The Manage Groups dialog can be opened from the Group View, Group Detail, or

Totalizers screen.

Figure 3: Manage Groups

This dialog displays the following main sections:

• On the left side, all created tank groups are displayed.

• In the middle part, the available tanks to be added to the tank group are

shown.

• At the right side, the tanks which are a member of the selected tank group

are displayed.

10 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 19

Manage Displays

Creating a Group

1. Log on as a user with SUPV permissions (or higher).

2. Click the Manage Groups icon from either the Group View or the Group

Detail display. The Manage Groups dialog opens.

3. Click on Create:

An edit field opens where you can enter the tank group name.

4. Enter the tank group name and click Create.

The tank group is added to the list of created Tank Groups.

5. In the middle part of the screen, select the tanks that you want to add to

the group.

6. Click on

The selected tanks are moved from the middle panel to the right part of the

dialog.

7. Click OK

The dialog closes.

The newly created group can be selected in the Group selector dropdown

box on the various UI screens.

8. Similarly, to remove tanks from a group, select the tanks in the right part of

the screen and click on

Note that the “All” group is available by default and cannot be removed or altered.

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 11

Page 20

Manage Displays

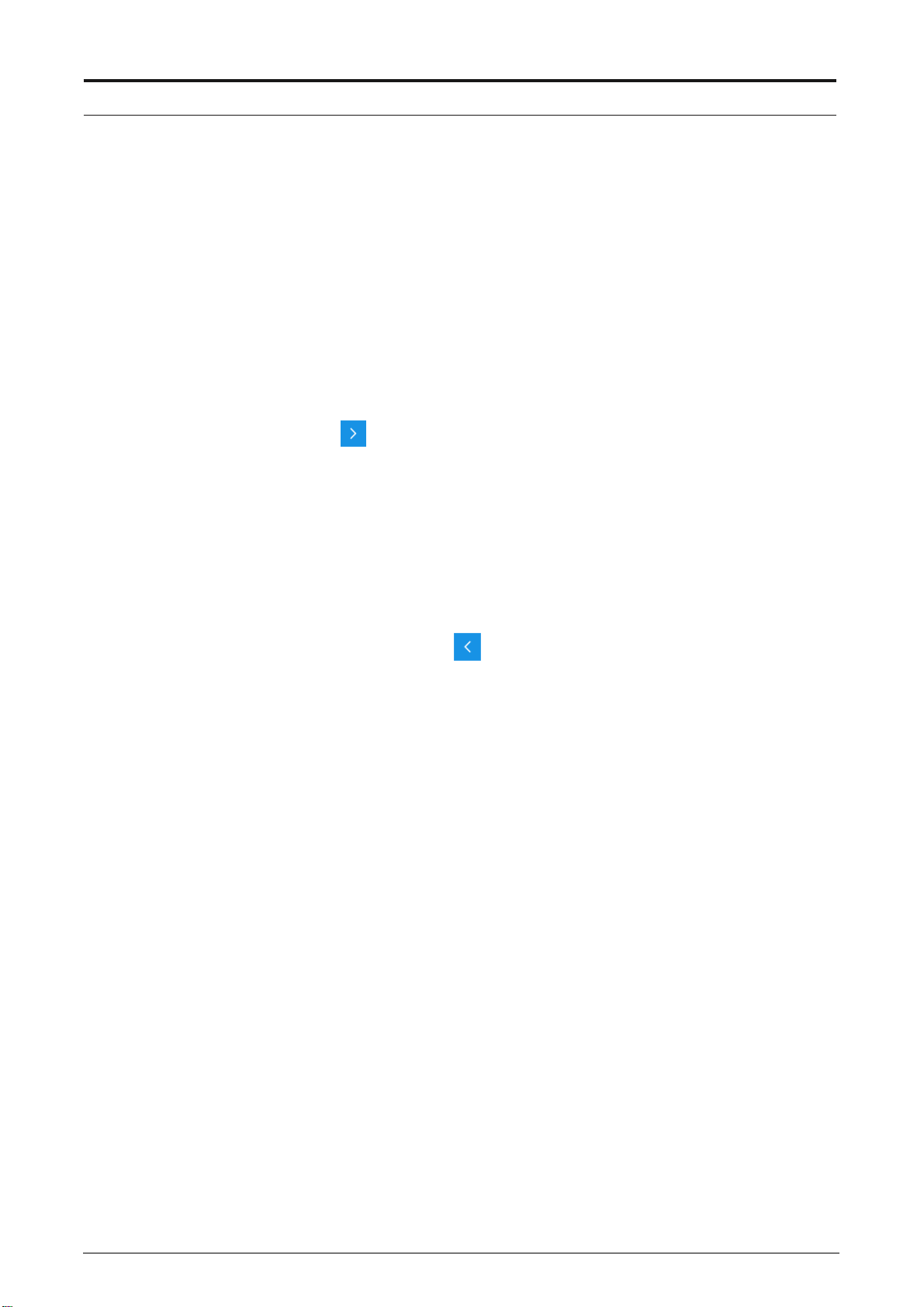

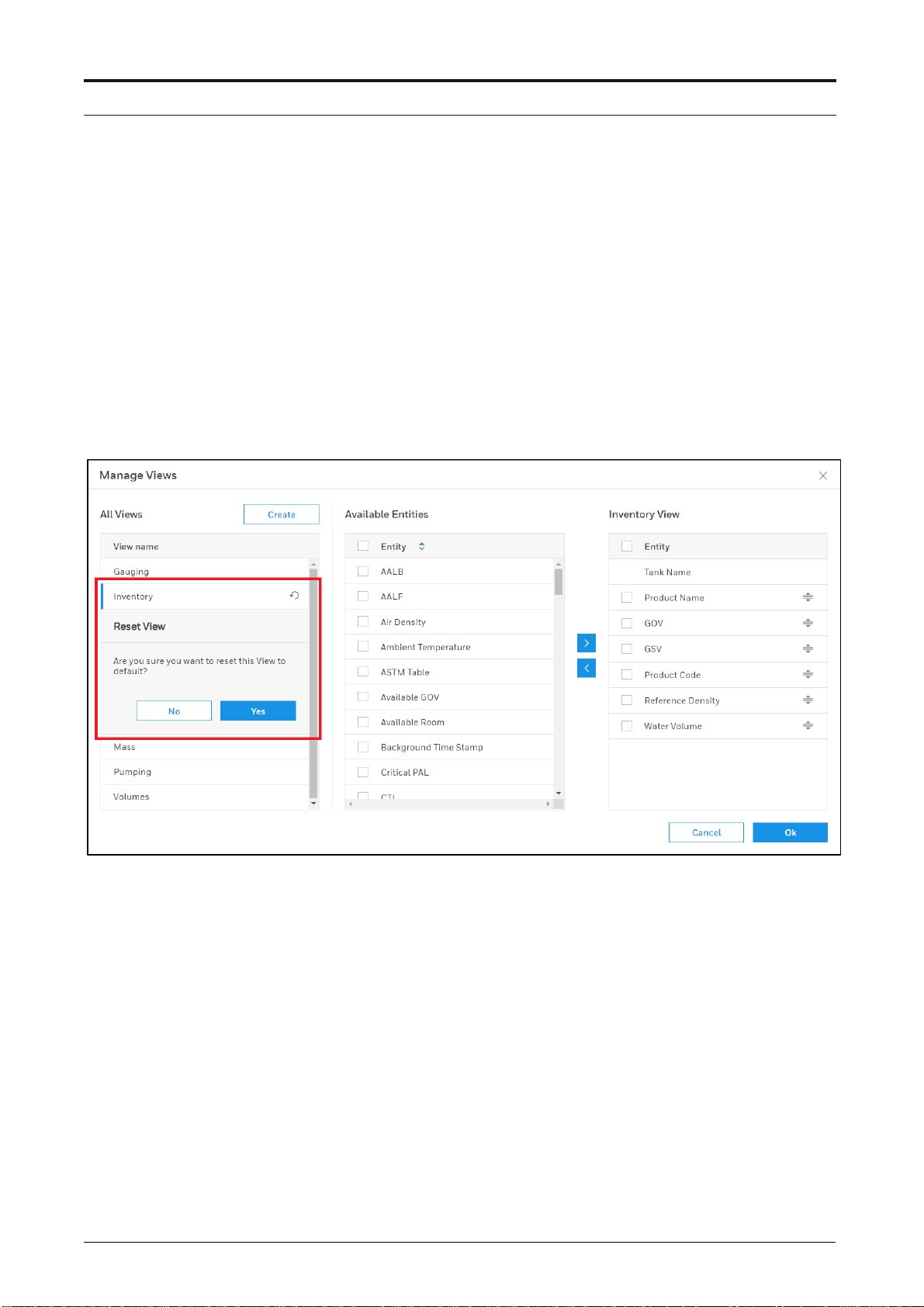

Manage Views

The Group Detail task displays tank inventory data for multiple tanks in a tabular

format. Tanks are organized in rows, while the entities are displayed in columns.

This dialog enables the user to customize the view that defines the columns to be

displayed in Group Detail. The first column (Tank name) is fixed.

A number of predefined views are available; it is also possible to create new

views.

The predefined views can be altered, but not deleted. However, they can be reset

as shown below:

Figure 4: Reset Views

Newly created views can be altered and deleted.

The Manage Views dialog can be launched from the Group Detail screen.

12 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 21

Manage Displays

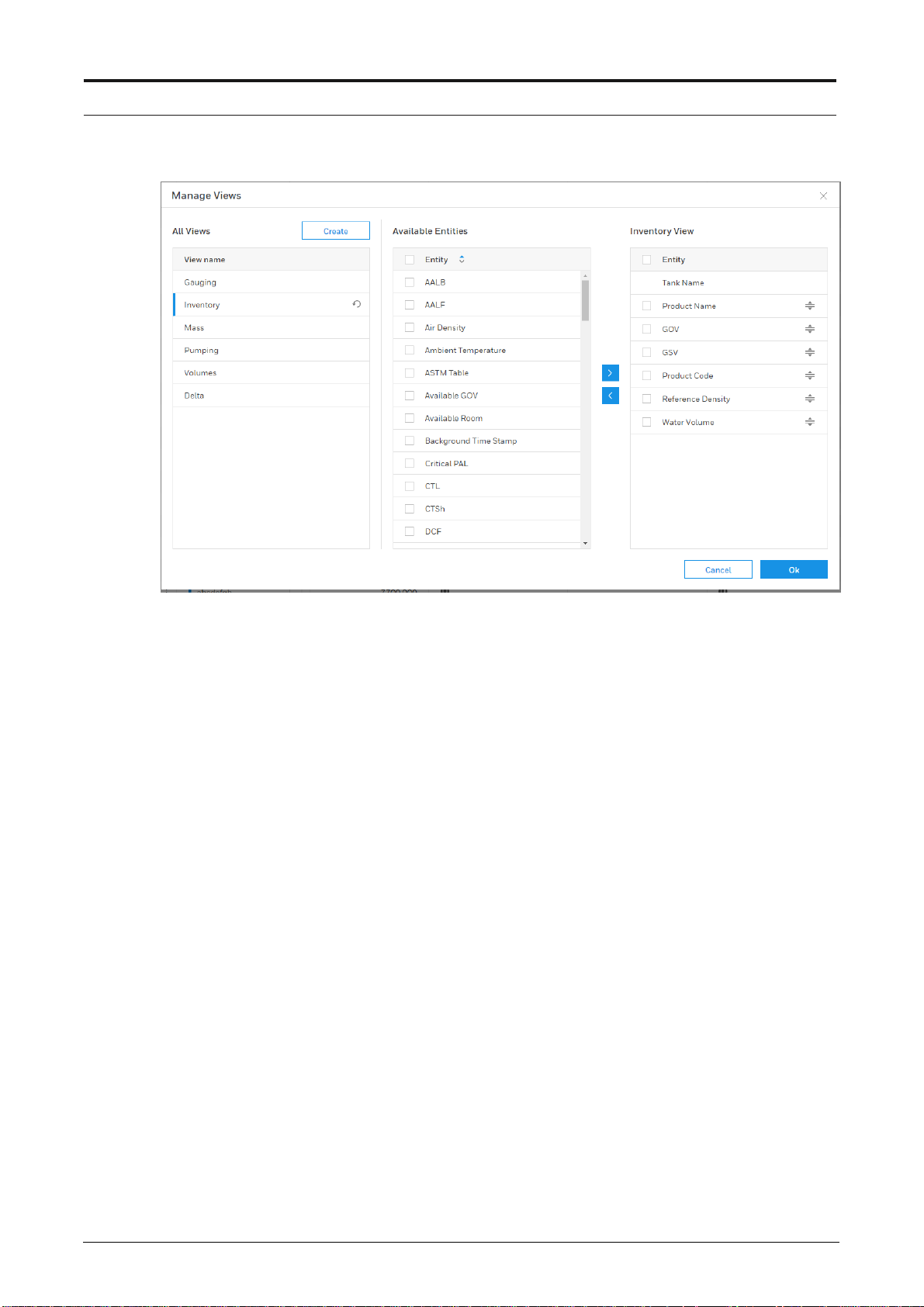

Figure 5: Manage Views

This dialog displays the following main sections:

• At the left side, all available views are shown.

• In the middle part, the available entities to be added to the view are

displayed.

• At the right side, the entities which are available in the selected view are

shown.

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 13

Page 22

Manage Displays

Creating a view

1. Log on as a user with SUPV level permissions (or higher).

2. Click the Manage Views icon from the Group Detail display.

The Manage Views dialog opens.

3. Click on Create

An edit field opens where you can enter the view name.

4. Enter the view name and click Create

The view is added to the list of available views.

5. In the middle pane of the dialog, select the entities that you want to add to

the view.

6. Click on >

The selected entities are moved from the middle pane to the righ t side of

the dialog.

7. Click OK

The window closes. The newly created view can be selected in the View

selector dropdown box on Group detail.

8. Similarly, to remove entities from a view, select the entities in the right part

of the screen and click on <

Note: the order of the entities can be changed by dragging and dropping them on

the right part of the Manage Views dialog.

14 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 23

Manage Displays

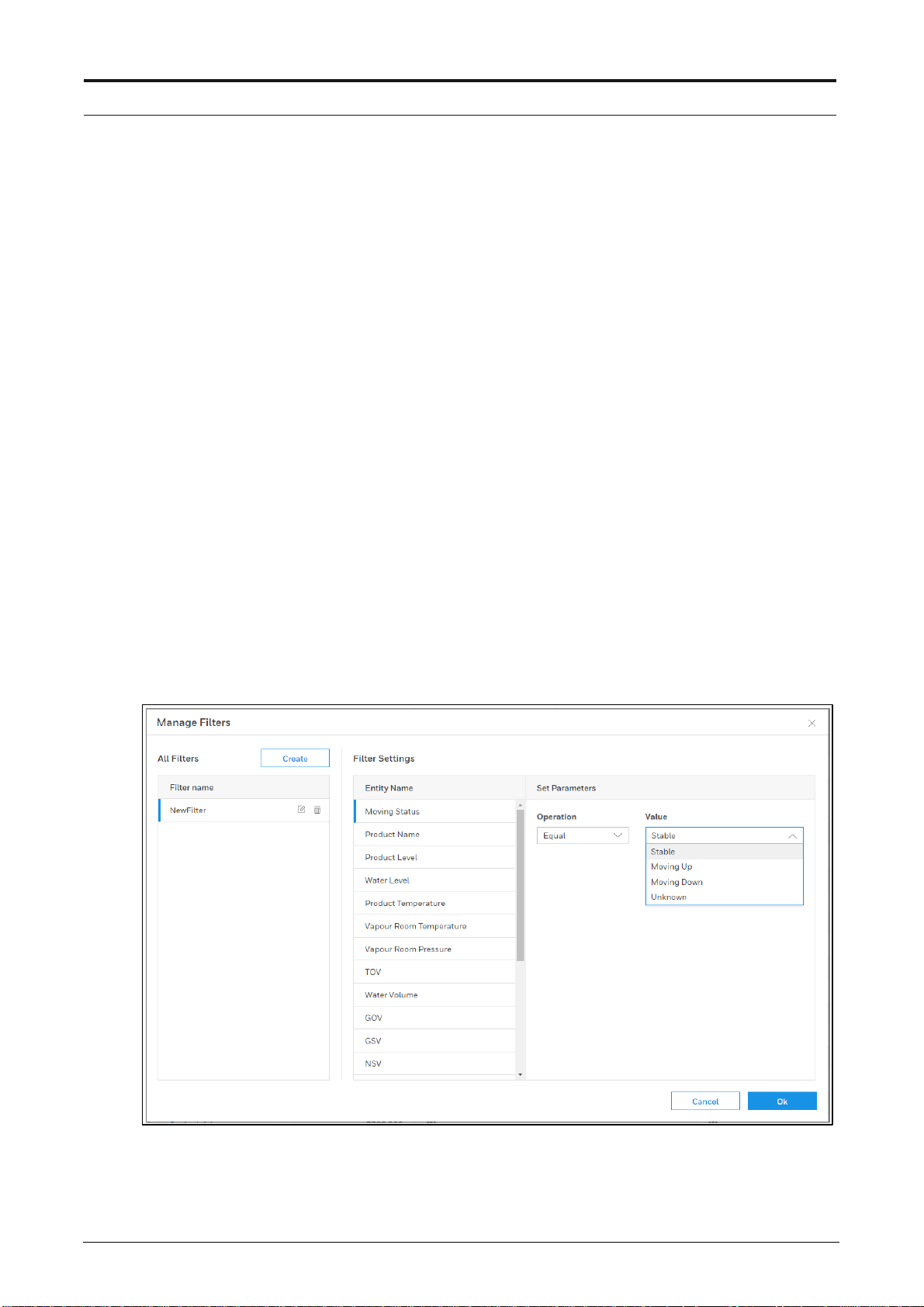

Manage Filters

This dialog offers th e possibility to define filters on tanks to be displayed in a Tank

Group.

A few examples of filters:

• Show tanks with a certain Product name.

• Show tanks with a Product temperature above a certain value.

• Show tanks with a Product level between 2 values.

The Manage Filter dialog can be launched from the Group Detail display.

Window layout

This window displays the following main sections:

• At the left side, all created filters are shown.

• In the middle part, the entities that can be used in a filter are displayed.

• At the right side, the configured parameters (Operation, Value) for the

selected filter are shown.

Figure 6: Manage Filters

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 15

Page 24

Manage Displays

Creating a filter:

1. Log on as a user with SUPV level permissions (or higher - see note below)

2. Click the Filter icon from the Group Detail display.

Then click Manage Filters.

3. Click on Create

An edit field opens where you can enter the filter name.

4. Enter the filter name and click Create

The filter is added to the list of created filters.

5. In the middle part of the dialog, select the entity that you want to be used

in the filter.

6. In the right part of the dialog, select the Operation and the Value.

7. Click OK

The window closes. The newly created filter can be selected in Group

detail by clicking on Filter, then selecting the required filter.

Notes:

When logged on as Operator, a filter can be selected to be viewed, but not

created or changed.

16 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 25

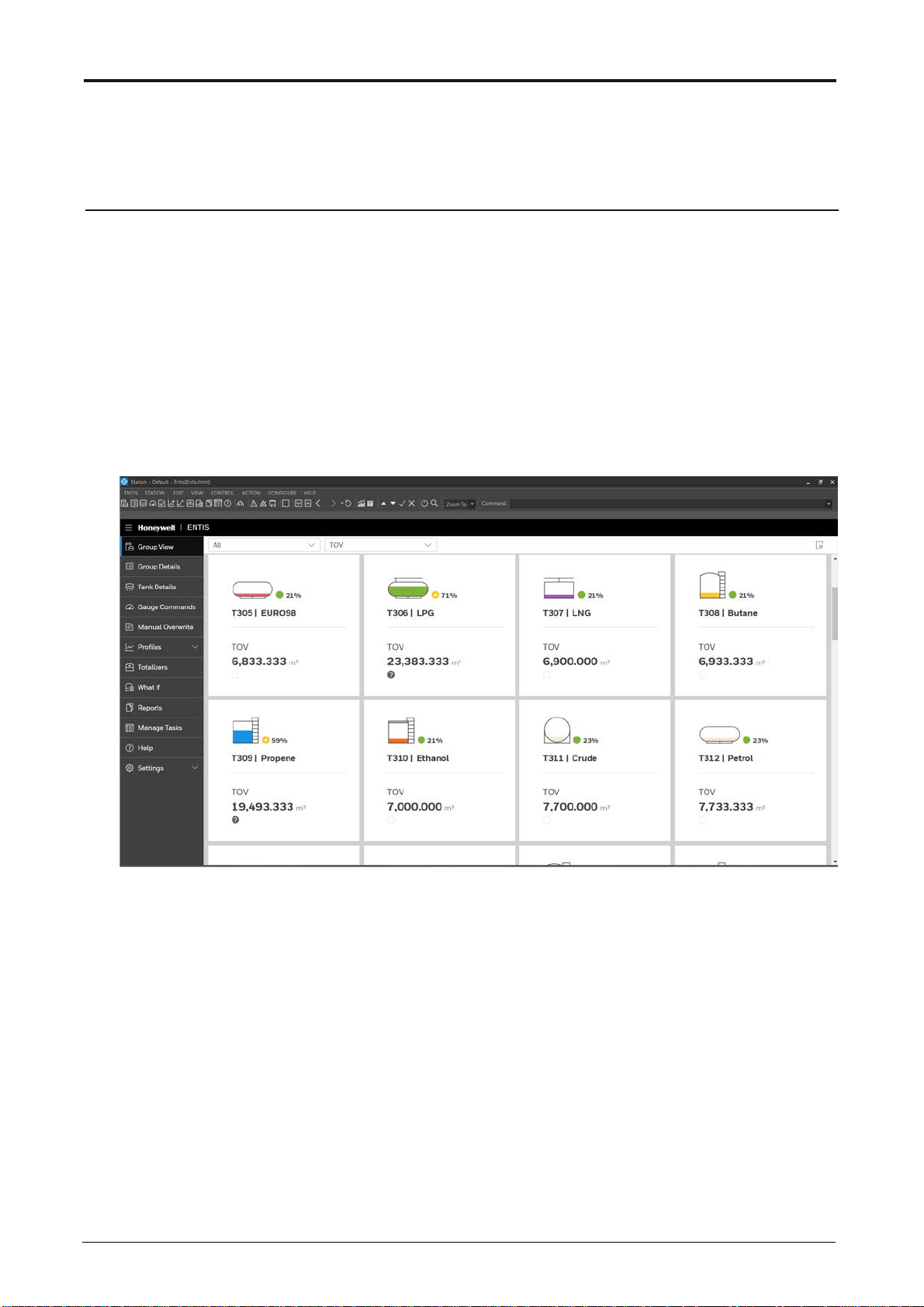

GROUP VIEW

The Group View display shows a group of Tanks with smaller images. All of the

images include a bar graph in which the height is an indication of the amount of

product in the tank, and the % level beside the tank is the product level available

in the tank. The color of the bar graph is per the product’s configured color.

The Tank icons are configurable by Tank. ( that configuration is done in the

CIU888 Service tool)

The TOV value is displayed by default, with other entity selections available from

the second selector from the left (above the tank panels).

Figure 7: Group View

How to select the Group View display

1. Group View is the default display when ENTIS is started. You can also

access the Group view display from the menu, or from the icon in the

toolbar.

2. Select the desired group from the Group selection dropdown box.

3. Select the desired entity. The default entities are: TOV, Product Level,

Product Temperature and Water Volume.

ENTIS R121.1 User’s Manual ETDOC-X615–R121.1 17

Page 26

GROUP DETAIL

The Group Detail display show tank inventory data for multiple Tanks

in a tabular format. Tanks are organized in rows, while the entities are

displayed in columns.

In addition, this display enables the user to make use of additional

functionality such as the Delta column (licensed option). Dimensions

are user-definable and displayed in the column header.

The user can create their preferred views via the Manage Views

dialog.

Display layout

The display presents Tank data in a tabular format. The data

displayed on the grid depends on the selected view. Both values and if applicable - statuses, are displayed. Clicking the mouse on the

column header will sort the selected column. Multi column sorting is

available by holding the Shift button and selecting multiple column

headers. A blue line on the column header will indicate that it is

sorted, with the blue line position indicating if the sort is ascending

(top) or descending (bottom).

A user definable number of columns, measured from the first column,

can be identified as fixed columns. Fixed columns do not scroll

horizontally. The user can select the number of rows they want to

view on a page and toggle between them via ‘Previous’ and ‘Next’

buttons.

The user can also filter the rows by using ‘Filter’ button where they

can select the column where filter should be applied and set the

parameteres of filtering accordingly.

18 ENTIS R121.1 User’s Manual ETDOC-X615– R121.1

Page 27

Group Detail

Figure 8: Group Detail

Opening the Group Detail Display

1. Click on the ‘Group Detail’ menu item, or the ‘Group Detail’ ic o n in the tool

bar

2. The ‘Group/Tank’ display will appear

3. Select a Group from the dropdown combobox

4. Tank data will appear in the table

5. ‘All’ indicates that all the tanks will be shown

6. Change the View from the the view dropdown

Column width: The current size is stored whenever the user selects

another view, or the window is closed.

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 19

Page 28

Group Detail

Delta column

The Delta column displays the difference between the actual value

and the start value. This feature enables an operator to verify tank

operations with real-time data. Delta values are available for GOV,

TGSV, Total Mass, NSV, Level, GSV and TOV.

The Delta column is only available in the Group Detail display.

The column can be enabled via the Define View dialog.

When the Delta column is available in Group Detail, a click on the

Delta column header (the horizontal ellipses) gives the following

context menu:

Figure 9: Delta Column

20 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 29

Group Detail

Selecting a Delta C olumn

Clicking on the horizontal ellipses on the delta tank entity gives the

following menu:

Start Tank When c l icked, t he delta calculation for the selected tank

(row) will be started or restarted

Stop Tank When clicked, the delta calculation for the selected tank (row)

will be stopped and cleared

Start Group When clicked, the calculation for a group of tanks is started

Stop Group When clicked, the calculation for a group of tanks is stopped

and blanked

Delta Report The delta values will be printed in form of report

Figure 10: Delta Column Group

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 21

Page 30

Group Detail

Figure 11: Delta Column Report

22 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 31

Group Detail

Critical / Operation PAL Column

This column can be used to display PAL statuses in the Group Detail

display.

A Critical PAL corresponds with Urgent priority alarms and an

Operational PAL with High and Low priority alarms.

Figure 12: Alarm Column

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 23

Page 32

Group Detail

Selecting an Alarm column from Group Detail

To view an alar m, the columns must be added through the “Manage

View” dialog in Group Detail.

1. Go to ‘Manage View’ from Group Detail

2. Select Critical PAL and Operational PAL columns from the Available

Entity list.

3. Click on the Ok button

Figure 13: Alarm Column Views

24 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 33

Group Detail

4. When the View is selected in Group detail, the selected columns

will be available in the display.

Figure 14: Group Detail Alarm Column

• Hi and HiHi alarms with Urgent priority are indicated in the Up

arrow from the Critical PAL field.

• Lo and LoLo alarms with Urgent priority are shown in the

Down arrow from Critical PAL.

• Hi and HiHi alarms with High or Low prio rity are shown in the

Up arrow from Operational PAL

• Lo and LoLo alarms with High or Low priority are shown in the

Down arrow from Operational PAL

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 25

Page 34

Group Detail

The next screenshot shows an example in Group Detail when a High

alarm is active.

Figure 15: Alarm Column HA

When the alarm is acknowledged, the tooltip is updated

Figure 16: Alarm Column HA Ack

26 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 35

Group Detail

Low alarms are indicated with the “down” arrow; in the next

screenshot an active Low alarm with Low priority and one with Urgent

priority is shown.

The number indicates the number of alarms for this type.

Figure 17: Alarm Column LA

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 27

Page 36

Group Detail

Remark Column

This column allows the user to enter additional text in the Remarks

field. The text can be entered by a left mouse click on the edit icon.

See example below. This field is only available on the Group Detail

display.

Figure 18: Remarks Column

28 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 37

Group Detail

Selecting the remark column from Group Detail

The remark columns must be added through the “Manage View” option in

Group Detail.

1. Select Manage View from Group Detail

2. Select the Remark column from the Available Entity list.

3. Click on the Ok button

4. Select the View in Group detail screen

5. Left mouse click on remark field edit icon for selected tank

6. Enter user name and save remarks

7. Remark will be available for the selected view in Group Detail

Figure 19: Remarks Views

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 29

Page 38

Group Detail

Adding a remark from group detail

1. Remark can be edited by a left mouse click on the edit icon.

2. Upon clicking, the remarks column is expanded as shown in the

screenshot below.

Figure 20: Remarks Views edit

3. The user can add their username and remarks, and click Ok.

The remark is saved as history with username, date, time and the

remark.

Figure 21: Remarks Views with history

30 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 39

TANK DETAIL

Tank Detail is a display that shows all measured and inventory data

for one particular tank.

The screen provides an excellent overview of all relevant data and is

updated continuously. It also displays the product level in %

occupancy, and second level in the case where dual guages are

connected.

To change the tank being viewed, a combo box is available to change

tank selection. This combo box shows all the tanks available in the

selected group.

Data presentation

1. Measured data is always presented as green text.

2. Calculated data, such as inventory data is presented as black text.

3. Status and Validity information is available in circular indicators.

4. Units are shown in black after the status and validity symbols.

Display layout

The tank detail window consists of two main parts:

Toolbar

The toolbar shows a ‘Tank Detail’ icon at the left-hand side. The

dropdown box allows you to choose and view another tank in the

same group. Tooltips are available for tank oriented tasks.

Graphical pane

Display of entities (measured and calculated) belonging to the

selected tank.

The time to fill is calculated from available TOV/flow TOV. The time to

empty is calculated from available room/flow TOV

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 31

Page 40

Tank Detail

Tank detail window for fixed roof tanks

This window selection is based on tanks with no corrections.

Figure 22: Tank Detail

32 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 41

Tank Detail

Tank detail window for fixed & floating roof tanks

The window selection is based on tanks with S&W and floating roof

corrections.

Figure 23: Tank Detail Floating

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 33

Page 42

Tank Detail

Tank detail window for spheres

The window selection is based on tanks with vapour room corrections

(gas volume calculations).

Figure 24: Tank Detail Sphere

34 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 43

Tank Detail

Selecting the Tank Detail display

Proceed as follows:

1. Click on the ‘Tank Detail’ option from the tool bar.

Figure 25: Tank Detail Icon

2. You can also click on the ‘Tank Details’ option available on the

left side menu.

3. The ‘Tank details’ window will appear.

4. Select a group from the tree view. The selected group will be

displayed in the tool bar

5. Individual tanks can be selected from the drop down combo

box in the tool bar, or from the ‘Group/Tank’ window.

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 35

Page 44

GAUGE COMMANDS

Modern gauges often support special commands and/or functions.

These commands can be used, for example, to ‘Block’ the displacer

at a certain level, or for testing alarm contacts remotely.

The available command and function can be dependent on the type

of gauge or the application.

The Gauge Command display for ENTIS is ‘gauge aware’. It shows

the user an icon corresponding to the gauge type, and shows which

functions are enabled for that particular gauge.

Tab layout

Figure 26: Gauge Commands

1. Select the group

2. Select the tank

3. Select one of the available command tab

4. Click on the desired function and press Apply

36 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 45

Gauge Commands

How to issue a Dipping Command

Figure 27: Dipping Command

Proceed as follows:

1. Click on the ‘Gauge Commands’ tab.

The Dipping section will be displayed by default

2. Select a group from the dropdown.

The selected group will be displayed in the tool bar

3. Individual tanks can be selected from dropdown.

4. Select the command you want to issue from the check boxes:

• Density dip

Select to execute a density dip. This command only applies to

854 type gauges with the density option. Select one of the two

radio buttons. Density can be executed in two ways:

− Downwards

− Upwards

• Water dip

Select to execute a water dip

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 37

Page 46

Radio Button

Comman Description

Gauge Commands

How to issue a Displacer Command

Figure 28: Displacer command

Two different displacer commands can be issued:

1. Go to the ‘Displacer’ panel of the ‘Gauge Commands’ tab

2. Select a group from the dropdown.

The selected group will be displayed in the tool bar

3. Individual tanks can be selected from dropdown.

4. Select the command you want to issue by means of the radio

buttons

Table 2: Displacer Commands

Test The level gauge will be set in lock test for approx. 1 minute,

followed by an unlock command

Lock Test When selecting this radio button, a data entry field will be enabled

Lock Test at Enter the Lock test value

Auto Unlock When selecting this check box, the displacer wi ll be lower ed

Verify Calibration When selecting this radio button, the dis placer wi ll be raised unt il

38 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

automatically after reaching the value enter ed in the da ta entry

field.

the CA setting in the servo gauge is reached

Page 47

Gauge Commands

How to issue a Test Gauge Alarm

Figure 29: Tank Gauge Alarm

Proceed as follows:

1. Go to the ‘Test gauge alarm’ section of the ‘Gauge Commands’ tab

2. Select a group from the dropdown.

The selected group will be displayed in the tool bar

3. Individual tanks can be selected from dropdown.

• Alarm tests: Click on one or more alarms you want to test

This command can be used to test the alarm s etting s in the r adar gauge.

The alarm settings to be tested are HiHi, Hi, Lo, LoLo in any combination

How to cancel commands

An unlock command can be sent to the level gauge in

order to cancel the command in progress.

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 39

Page 48

Gauge Commands

Running Dipping Commands

This window shows the progress of a dipping command. The

progress indicator is used to show the percentage of completion of

the issued command.

The progress of the following dipping commands can be monitored:

• Density dip

• Water dip

Tab layout

At start-up, the Tank name, dipping command and original displacer

position are shown. After start up, the actual displacer position is

displayed

Figure 30: Displacer

Title bar Displays the selected tank name and the issued

command

Displacer Position

This group box shows the displacer position:

Original - The level at start up

Actual - The actual position of the displacer

40 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 49

Gauge Commands

Running Displacer Commands

This window shows the actual displacer position during a Lock test or Verify

calibration test command. These commands can only be issued for servo

level gauges.

Tab layout

At start-up, the window shows the tank name and the displacer command

in the title bar.

The group box shows the ‘Original’ displacer position (level at start-up) and

the ‘Actual’ position. In addition to the level values the status and the

dimension are displayed.

Figure 31: Displacer

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 41

Page 50

Gauge Commands

Scheduling Gauge Command

This option is displayed at the bottom of left hand panel on the

‘Gauge Commands’ screen. This feature allows the user to send

automated commands to gauges at a given t ime.

The user can create a task and schedule gauge commands for

different intervals like daily, weekly, monthly etc., starting at a specific

time. The tasks created here are shown on ‘Manage Tasks’ screen.

Once the gauge command is scheduled, it will be executed at the

scheduled time.

Figure 32: Schedule Command Screen

42 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 51

Gauge Commands

How to schedule a gauge command

• Choose the specifications of the gauge command that needs to be

scheduled. Then click on Schedule button.

• Task Name : This is user defined field which defines name of the

task.

• Starts at : User can choose when the task execution will start.

• Repeat : If the task has to be executed only once, ‘Never’ should be

selected. If is a repeated task, ‘Always’ should be chosen.

• Select Cycle : User can choose the frequency of the task from below

available 3 options. The option will only be enabled when ‘Repeat’ is

‘Always’.

1. Interval : User can give any interval in hh:mm.After the ‘start at’ time,

this task will be executed continuously at the given interval.

2. Weekly : The user can choose the days. Every week this task will be

executed on the selected days, and the t im e provided in ‘start at’.

3. Monthly : The user can choose the dates in a month. Every month

this task will be executed on the provided dates, and the time

provided in ‘start at’.

• Never: User can opt for scheduling the gauge command only once

without repeating it.

Figure 33: Scheduling screens

ETDOC-X615– R121.1 ENTIS R121.1 User’s Manual 43

Page 52

MANUAL OVERWRITE

This display allows the user to manually overwrite tank data. The

’Manual Overwrite’ display can, for example, be used to overwrite

an invalid entity, or to enter the value of an entity that is not being

scanned or for which automatic measurement has stopped scanning

(formerly known as ‘killed’).

This display supports basically two actions:

• Stop scanning an entity (formerly known as ‘kill’)

• Resume scanning an entity (formerly known as ‘resurrect’)

Enter manual data for an entity

Display Layout

The ‘Manual Overwrite’ window consists of two main parts:

• The entity selection pane (left)

• The entity overwrite area (right)

All Entities

This panel shows a tree with all available entities.

gure 34: Manual Overwrite

44 ENTIS R121.1 User’s ETDOC-X615–R121.1Manual

Page 53

Manual Overwrite

Entity Name

This fields shows the selected entity

Stop Scan

This check box indicated whether the entity is not scanning.

Current Value

This column may contain a mix of data entry fields, combo boxes

Dimension

Shows the current dimension

Entity Pane

The entity overwrite area consists of four fields.

Table 3: Entity Fields

Marked means not scanning (or stopped). This check box is not

present by every tank entity.

and check boxes depending on the entity being displayed. The

entity value will be shown if:

- the entity status is s et to manual. (with manual data icon)

- the entity has actual dat a. (with ac tua l data icon)

If the entity has stopped scanning, it will be displayed with killed

icon and blank value

Performing a Manual Overwrite

1. Click on the ‘Manual Overwrite’ icon.

2. Click on the tree icon at the left site in the tool bar.

The ‘Group/Tank’ window will appear.

3. Select a group from the tree view.

4. Select the tank you want to overwrite.

5. Select the entity you want to overwrite from the ’All Entities’

pane

6. Click on the ‘Stop Scan’ check box of the selected entity in

the right pane means killed.The ‘Current value’ field will be

enabled.

7. Click on the ‘Current value’ field.

8. Clear the field.

9. Enter the manual value.

ETDOC-X615–R121.1 ENTIS R121.1 User’s Manual 45

Page 54

Manual Overwrite

10. Click on apply.

Figure 35: Manual Overwrite Parameter

Before you begin entering data into the currently selected entity field,

the field background will be white. After entering the value the

background changes to yellow to indicate that you have made a

change and not yet saved it.

If you want to save the entered values click on the Apply button.

The entities Dobs, Tobs and Hydro correction have a close relation. In

the entity tree they are put on one line. In the data area they are

always shown together (3 lines) but can be edited individually.

However Dobs and Tobs must be edited as a pair.

When data of an entity has been changed but not saved (Apply) and

another entity or tank is being selected then a popup windows requests

the user what is required: either cancel the changed data or apply it.

46 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 55

Manual Overwrite

The GSV calculation type combo box only shows the calculation types

that support the Product Reference Temperature that has been configured

for the selected tank. The Product Reference Temperature cannot be

overwritten manually but must be configured in the CIU 888 with ENTIS

The entities GSV Calc type and Product Code have a close relation.

When a GSV Calc type is selected that does not support the currently

selected Product Code, a pop-up message will advise other valid choices

for the Product Code. The other way around, when a Product Code is

selected that does not support the currently selected GSV calculation

type, a pop-up message will advise other valid choices for the GSV

Calculation type. If the advice is ignored, the GSV calculation type will

change to “Undefined” after applying the manual overwrite. For diagnostic

purpose, a tooltip text on the GSV Calculation type column in the Group

Detail task reveals the GSV calculation type code when an “Undefined”

combination of GSV Calculation type, Product Code and Product

Reference Temperature has been configured.

How to cancel a Manual Overwrite

1. Click on the ‘Manual Overwrite’ icon

2. Click on the tree icon at the left site in the tool bar. The ‘Group/Tank’

window will appear

3. Select a group from the tree view

4. Select the tank you want to cancel a manual overwrite

5. Select the entity from the ’All Entities’ pane

6. Click on the ‘Resume Scan’ check box of the selected entity in the right

pane. Unchecked means not scanning

ETDOC-X615–R121.1 ENTIS R121.1 User’s Manual 47

Page 56

PROFILES

The pr i mary Pr ofiles usage is to create profiles for a selected tank and to

show a graphical display of the density and/or temperature variation of the

product in a tank.

The user has a number of options to generate profiles such as:

Density profile:

Used to measure the observed density.

The 854 or 954 servo gauge is commanded to start a density measurement.

The density measurement moves the displacer through the product in the

tank, and determines the density at 10 equidistant points if a 854 gauge is

connected, and up to 50 equidistant points if a 954 gauge is connected.

Temperature profile:

VITO probe connected to Radar or servo gauges will allow user to have

temperature profiles on ENTIS, Number of temperature points configured in

VITO associated at different level’s will decide Average temperature in profile

graph

Density and temperature profile:

Determines a density and temperature profile for different product types in

the tank.

Combined profile:

Measures the water interface, and determines a density profile.

Combined profile (Incl. Temperature)

Measures the water interface and determines a density and temperature

profile.

Interface Profile

An Interface profile command starts a density measurement between two

specified levels.

The interface profile measurement moves the displacer through the product

in the tank and determines the density at 10 equidistant points if an 854

gauge is connected, and up to 50 equidistant points if the 954 gauge is

connected between the two specified levels.

48 ENTIS R121.1 User’s ETDOC-X615–R121.1Manual

Page 57

Profile

Display layout

Figure 36: Create Profile

This display has the following sections:

• At the upper part, tank data is displayed.

• In the middle part, the selection can be made for the type of profile to

be created.

• At the bottom part, a progress window is displayed for each pr ofile

currently in progress.

How to create a profile:

1. Select Profiles | Creat e Prof ile

This opens the Create Profile screen.

2. When using a user defined filename, uncheck the checkbox “Automatic

Filename Generation”. This gives you the opportunity to enter your own

filename in the edit box. By default, the checkbox is checked.

In that case the filename is:

[tankname]_yyyy-mm-ddThh-mm-ss.json

ETDOC-X615–R121.1 ENTIS R121.1 User’s Manual 49

Page 58

Profile

3. Select the required profile type (Density, Combined, Temperature,

Interface); For an Interface profile, enter the Highest and Lowest level.

4. Select advanced data Upwards or Downwards (only for Density and

Interface profile) and “Temperature profile included” (for Density,

Combined and Interface)

5. Select advanced data Upwards or Downwards (only for Density and

Interface profile) and “Temperature profile included” (for Density,

Combined and Interface)

6. Click on Start.

The profile command will be sent to the CIU888;

7. When the profile is ready, this will be indicated by a popup dialog:

Figure 37: Profile ready

50 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 59

Profile

Viewing a profi le:

1. Select Profiles | View Profiles

This opens the View Profiles screen

2. Click on Browse Profiles

3. In Filters, select whether you want to see all profiles, or only

certain types (Density, Combined, Temperature, Interface)

4. In Filters, update the date range as required

(by default, it shows the profiles from the last week)

5. From the lis t of profiles, select the profiles you want to view.

6. Click Open:

The selected profiles are displayed.

Profile screen examples

Temperature Profile

Figure 38: Temperature profile

ETDOC-X615–R121.1 ENTIS R121.1 User’s Manual 51

Page 60

Profile

Density Profile

Figure 39: Density Profile

Interface Profile

52 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 61

Profile

Figure 40: Interface Profile

Density + Temperature Profile

Figure 41: Density and Temperature profile

Density Profile (50 Density points)

Figure 42: Density profile

ETDOC-X615–R121.1 ENTIS R121.1 User’s Manual 53

Page 62

MOVEMENT

Using the Movement Screen you can calculating and set a Movement:

- From/to a selected tank, or

- Between two selected tanks.

It display the current measurement values for the selected tanks, expected

values after the movement has completed, and verifies whether the movement is

possible depending on the current tank status, available space, product type etc.

How to access the Movement screen

1. On the main application menu, select the Movement option,

2. Or, on the Group Details screen, click on the row menu (denoted by 3 dots

after the tank name) and select the Set Movement option, which will take you

to the Movement screen, where the current tank will have been selected as

the Source Tank:

54 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 63

Movement

Movement Type

Source direction

Destination direction

Receive

In

-

Load

Out

-

Transfer To

Out

In

Fill

In - Fill From

In

Out

Empty

Out

-

Empty To

Out

In

The screen contents

The screen is divided into 3 vertical sections:

- Movement,

- Source Tank,

- Destination Tank.

Source Tank and Destination Tank will be disabled if no Movement Type has

been selected.

Movement Types that can be selected are listed below along with the direction of

flow:

ETDOC-X615 – R121.1 ENTIS R121.1 User’s Manual 55

Page 64

Movement

For the movement types Receive and Load, only a Source Tank can be selected.

Measurements that can be selected are:

- GOV,

- TOV,

- TSV,

- Mass,

- Product Level.

Validations and information messages

The Calculate and Set Movement buttons will be enabled or disabled depending

on the selected parameters, entered values, current tank status, and the

calculation results.

An information or error message will be displayed at the bottom of the Movement

section to guide you through the process, such as:

Step 1: Select the Movement Parameters

Select:

- A Movement Type,

- T he Source Tank, and if applicable, also the Destination Tank.

- T he preferred Measurement,

and enter the required Amount to Move, as in the following example:

56 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 65

Movement

The right units will be displayed depending on the selected measurement and the

parameter type.

The current status of the selected tanks or tanks will be displayed, as in the

following example.

The current and target levels will be displayed for: product level, GSV and the

selected measurement.

ETDOC-X615 – R121.1 ENTIS R121.1 User’s Manual 57

Page 66

Movement

Step 2: Calculate

Click the Calculate button.

After a number of seconds, the calculated target values will be displayed in the

column under the label “Target”.

If the calculated values are valid, the Set Movement button will be enabled.

Step 3: Target Pre-alerts

Optionally, for each tank, you can enter and enable up till 4 alerts for the desired

level offsets. The corresponding setpoints will be calculated and displayed. An

alert will be triggered when each setpoint is reached.

You can also enter a Hysteresis value for the alerts for each tank, in order to

avoid repeated alerts on each setpoint due to small up and down changes in the

tank d uring the movement process.

58 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 67

Movement

Step 4: Set Movement

When you have selected all the parameters you require, you can click the Set

Movement button.

The movement will then be set on the selected tank or tanks. The movement

progress can be followed on the Group Details screen.

ETDOC-X615 – R121.1 ENTIS R121.1 User’s Manual 59

Page 68

TOTALIZER

Totalizers offer an easy way to totalize and view the contents of a group of tanks.

It totalizes the different parameters of the available tanks in a group, such as

GOV, GSV, TGSV, Total Mass, TOV and Available GOV..

Figure 43: Totalizer

Figure 44:Totalizer_All

60 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 69

How to select the Group Totalizer

Proceed as follows:

1. Click on the ‘Group Totalizer’ icon.

2. Click on the tree icon at the left site in the tool bar.

3. The ‘Group/Tank’ window will appear.

4. Select a group from the tree view. The selected group will be displayed in

5. Other groups can be selected from the combo box in the tool bar or from

Figure 45: Totalizer Icon

the tool bar.

the ‘Group/Tank’ window.

ETDOC-X615 – R121.1 ENTIS R121.1 User’s Manual 61

Page 70

WHAT IF

What if (tank calculator) .. is a predictor tool that calculates and tells us values of

other parameters, based on the custom input values of points.

1. Click on What If icon from menu toolbar

Figure 46: What If

62 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 71

What if

Tab layout

On What-If screen, choose the desired group and tank from the drop down.

Figure 47: What – If layout

ETDOC-X615 – R121.1 ENTIS R121.1 User’s Manual 63

Page 72

What If

How to use the calculator

1. Start the Tank Calculator from the toolbar of the ENTIS

2. Select a Group/Tank

3. The Tank Calculator always starts up with the actual inventory data at that

moment

4. The Start screen will pop up

5. All white fields are data entry fields and their contents can be modified.

6. The system will calculate other values and display them.

7. To restore values to real time values coming from CIU, click on Reload

Data.

Figure 48: What – If Start

64 ENTIS R121.1 User’s Manual ETDOC-X615–R121.1

Page 73

What if

Figure 49: What – If Reload

ETDOC-X615 – R121.1 ENTIS R121.1 User’s Manual 65

Page 74

REPORTS

The Reports display makes it possible to print out reports in pre-defined templates.

A user can preview and print Tank Detail and Group Detail reports from this

display. The tank data displayed in the reports consists of the last available

measured and inventory data received from the gauge. It also displays the second

level when dual gauges are connected.

Report Printing

The Report printing window consists of four main parts:

• The Browse Reports

• The type of report combo box

• The tank/group combo boxes