Page 1

Installation guide 854 ATG Page 1

Installation guide 854

Advanced Technology Gauge

July 2008

Part no. 4416.225

Rev. 6

Enraf B.V.

P.O. Box 812

2600 AV Delft

Netherlands

Tel. : +31 15 2701 100

Fax : +31 15 2701 111

E-mail : enraf-nl@honeywell.com

Website : http://www.honeywellenraf.com

Page 2

Preface

Page 2 Installation guide 854 ATG

Preface

The Honeywell Enraf 854 ATG is a servo gauge which measures the liquid level and can also be

programmed to measure two additional interface levels.

This installation guide is intended for technicians involved in the mechanical and electrical

installation of the Honeywell Enraf Series 854 ATG (Advanced Technology Gauge).

EC declaration of conformity

Refer to the EC declaration of conformity, shipped with the instrument.

Note:

All connections to the instrument must be made with shielded cables with exception of the

mains, alarm outputs and Honeywell Enraf field bus cable. The shielding must be grounded in

the cable gland on both ends of the cable.

Legal aspects

The mechanical and electrical installation shall only be carried out by trained personnel with

knowledge of the requirements for installation of explosion-proof equipment in hazardous areas.

The information in this installation guide is the copyright property of Enraf B.V., Netherlands.

Enraf B.V. disclaims any responsibility for personal injury or damage to equipment caused by:

$ Deviation from any of the prescribed procedures;

$ Execution of activities that are not prescribed;

$ Neglect of the general safety precautions for handling tools, use of electricity and

microwave radiation.

The contents, descriptions and specifications in this installation guide are subject to change without

notice. Enraf B.V. accepts no responsibility for any errors that may appear in this installation guide.

Additional information

Do not hesitate to contact Honeywell Enraf or its representative if you require additional

information.

Page 3

Safety

Installation guide 854 ATG Page 3

Safety

Safety aspects of 854 ATG

Warning

Do not use the instrument for anything else than its intended purpose.

For medium pressure versions (till 6 bar), the 854 ATG drum compartment housing is of aluminium,

and for chemical version it is of stainless steel.

For high pressure version (max. 40 bar ; max. 25 bar in acc. to PED), the 854 ATG housing is of

stainless steel.

The housing of the 854 ATG is explosion-proof:

$ II 1/2 G EEx de [ib/ia] IIB T6 acc. to KEMA 01ATEX2092 X, certified by KEMA, Netherlands

$ Class I, Division 1, Groups B, C & , D acc. to ANSI/NFPA no. 70, certified by Factory

Mutual Research USA (FM no.: 3Q2A9.AX)

Environmental conditions for the 854 ATG are:

ambient temperature : -40 to + 65 °C (-40 to +149 °F)

operating pressure : max. 6 bar for medium pressure and chemical version

max. 40 bar ; max. 25 bar in acc. to PED for high pressure version

relative humidity : 0 - 100 %

ingress protection : IP65 (NEMA 4), suitable for outdoor installation

The drum compartment, which is in contact with the tank atmosphere, is separated from electronic

compartment. A magnetic coupling transfers the drum movement (hence, displacer movement) to

electronic compartment.

Wiring for intrinsically safe options, such as temperature or pressure measurement, is fed via two

separate cable entries.

The 854 ATG covers can optionally be provided with sealing facilities on blocking devices, which

prevents unauthorized opening.

Warning

Improper installation of cable glands, conduits or stopping plugs

will invalidate the Ex approval of the 854 ATG.

Page 4

Safety

Page 4 Installation guide 854 ATG

Personal safety

The technician must have basic technical skills to be able to safely install the equipment.

When the 854 ATG is installed in a hazardous area, the technician must work in accordance with

the (local) requirements for electrical equipment in hazardous areas.

Warning

In hazardous areas it is compulsory to use personal protection and safety gear such as:

hard hat, fire-resistive overall, safety shoes, safety glasses and working gloves.

Avoid possible generation of static electricity.

Use non-sparking tools and explosion-proof testers.

Make sure no dangerous quantities of combustible gas mixtures

are present in the working area.

Never start working before the work permit has been signed by all parties.

Pay attention to the kind of product in the tank. If any danger for health,

wear a gas mask and take all necessary precautions.

Safety conventions

AWarnings@, ACautions@ and ANotes@ are used throughout this installation guide to bring special

matters to the immediate attention of the reader.

$ A Warning concerns danger to the safety of the technician or user;

$ A Caution draws the attention to an action which may damage the equipment;

$ A Note points out a statement deserving more emphasis than the general text, but not

requiring a AWarning@ or a ACaution@.

Page 5

General precautions

Installation guide 854 ATG Page 5

General precautions

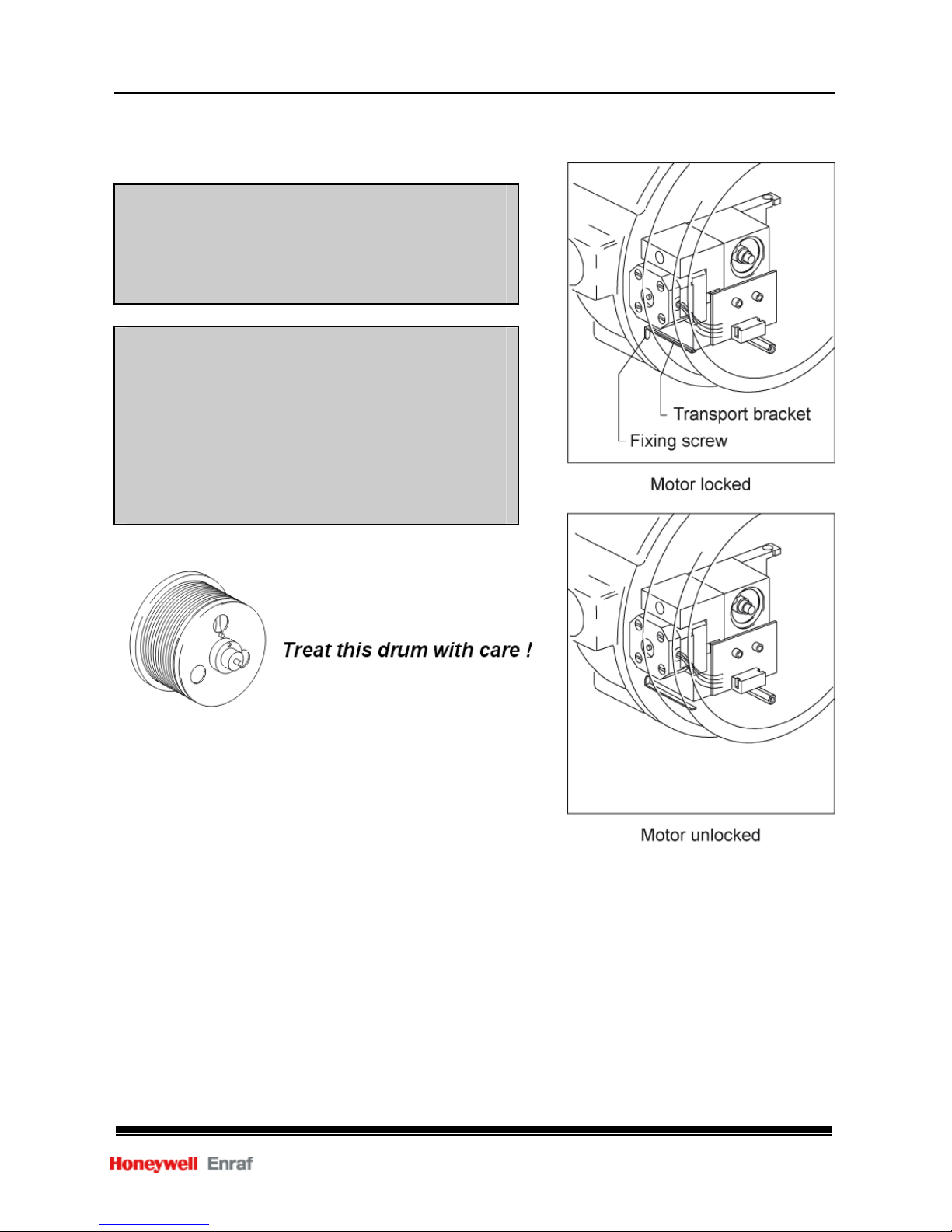

Caution

During transport of the gauge the motor block

should be locked.

This is for protection of the weighing system.

Caution

The box in which the 854 arrives also contains

the measuring drum.

This is a precision measuring device and shall only

be installed by a qualified commissioning engineer.

Accurate measurement requires an undamaged

and clean drum.

Figure 1 Motor(un)locking

Special tools

Screw driver for Hex Allen-key screws M4 (length min. 22 mm) Part No.: 2998.506

Tommy bar Part No.: 2998.026

Page 6

Mechanical installation

Page 6 Installation guide 854 ATG

Mechanical installation

Note:

The entire installation procedure shall be in accordance with national, local and company

regulations.

Preparation for transportation of the gauge

Caution

Do not transport the instrument with the motor unlocked. Refer to figure 1 for motor locking.

Drum should be transported in original protective box. Drum and displacer shall only be installed by

a qualified commissioning engineer.

Process connection

The 854 ATG can be ordered with race face or flat face flange. Select gasket that is suitable for

flange type, maximum pressure and product to be stored. Mount instrument flange horizontally.

Warning

Verify that tank or drum compartment is depressurized before opening

the tank or drum compartment cover of 854 ATG.

The 854 ATG can be adapted to various process connection flanges via adapters/calibration

chambers as specified in Appendix B. Verify that maximum working pressure of adapter/calibration

chamber complies with pressure in your tank.

Note:

When using 854 ATG on pressurized tank, it is recommended to install a suitable valve

between tank and 854 ATG to isolate the instrument from the process when required.

The valve shall have an opening large enough to feed through the displacer.

Page 7

Mechanical installation

Installation guide 854 ATG Page 7

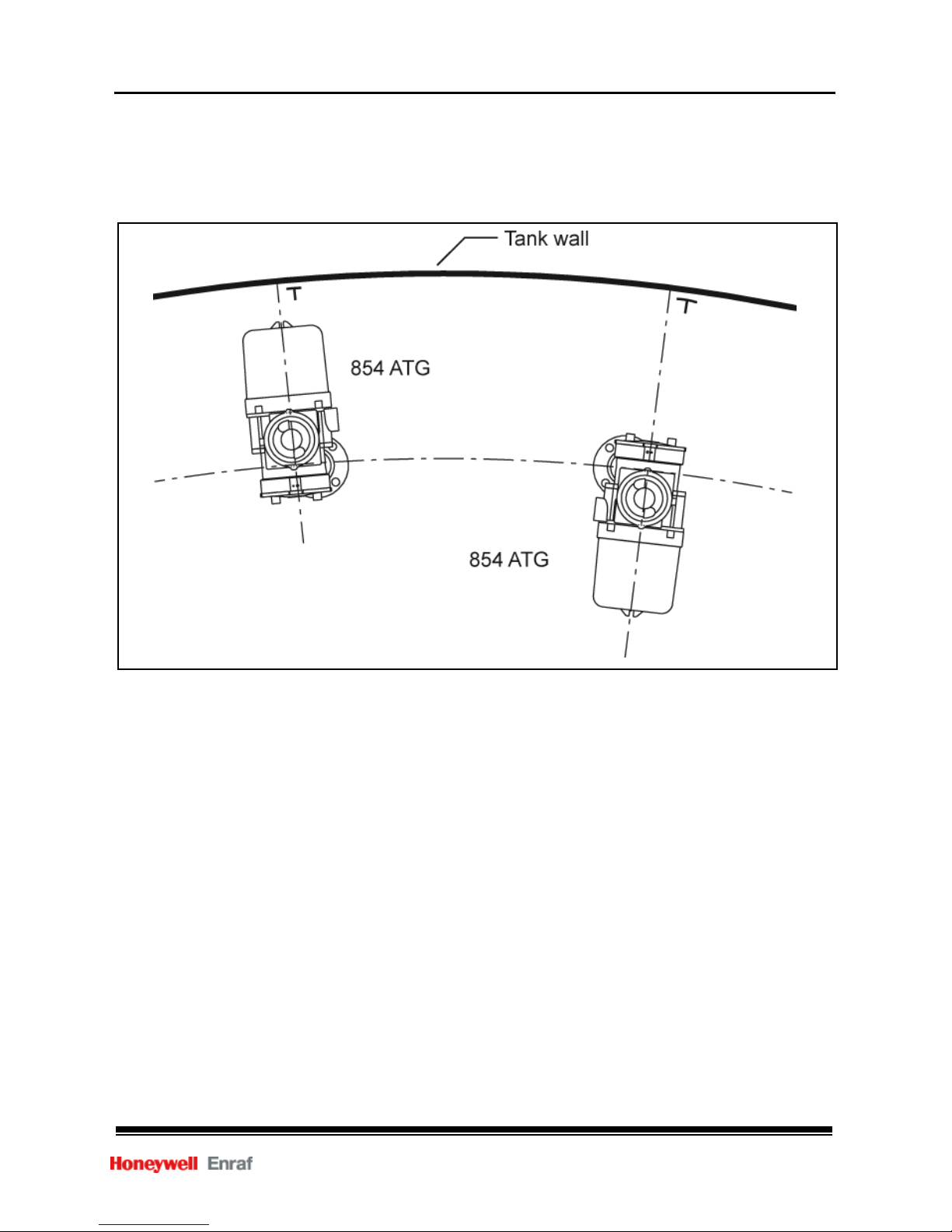

Orientation of 854 ATG gauge on tank

Mount the gauge in one of the following two ways.

Figure 2 Orientation of the gauge on a tank (top view)

On a stilling well or guide pole, the orientation of the gauge may be chosen freely.

Note:

The weight of the 854 ATG for: - medium pressure version is : 16 kg (35 lbs);

- chemical version is : 21 kg (46 lbs);

- high pressure version is : 26 kg (57 lbs).

Page 8

Mechanical installation

Page 8 Installation guide 854 ATG

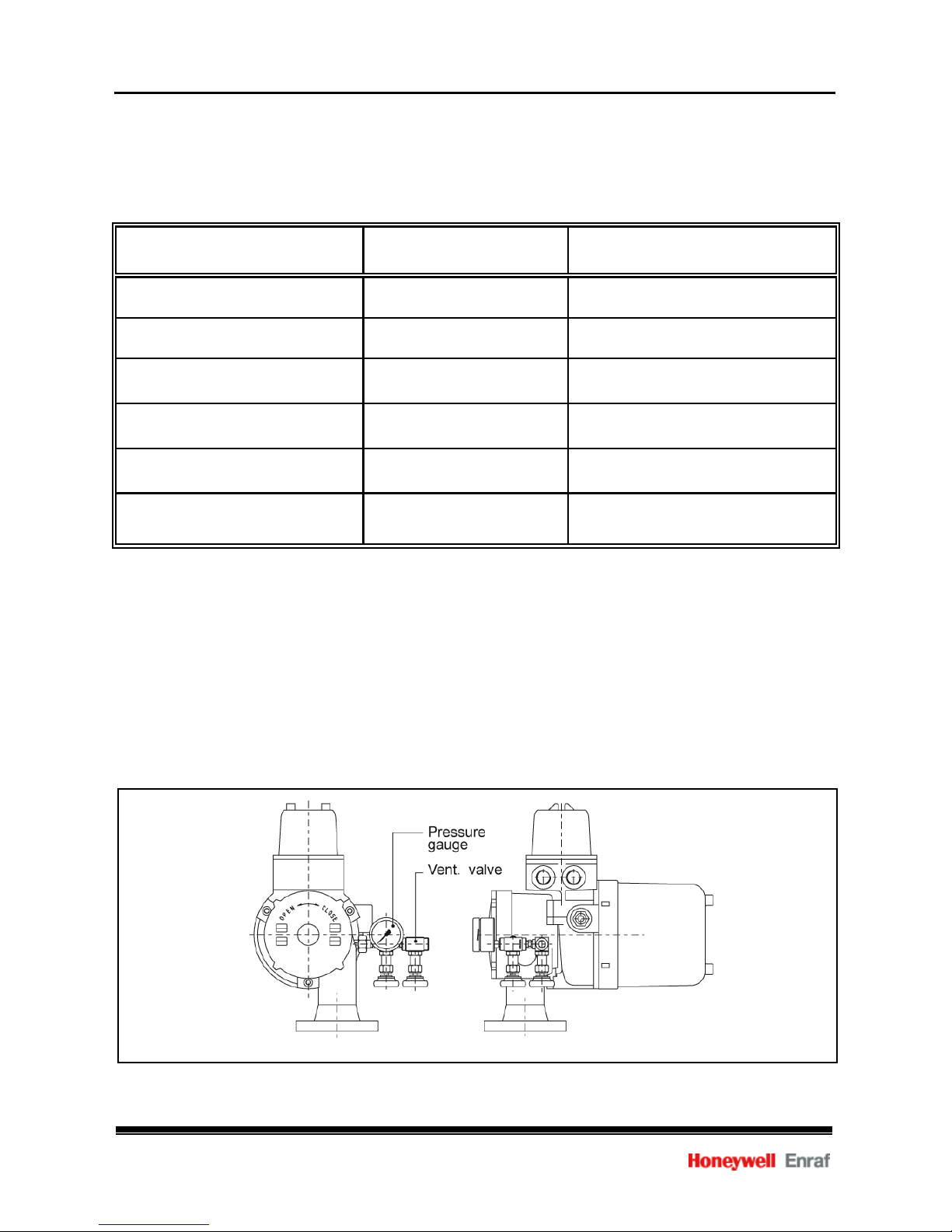

Bolts

Secure the gauge adapter by using appropriate bolts. *)

Flange type

Number of bolts

Diameter x minimum length

NW50, ND6

4

M12 x 50

NW50, ND40

4

M16 x 60

2", 150 lbs

4

5

/8" x 3" (M16 x 80)

2", 300 lbs

8

5

/8" x 3" (M16 x 80)

6", 150 lbs

8

3

/4" x 31/4" (M20 x 80)

6", 300 lbs

12

3

/4" x 4" (M20 x 100)

*) Bolt dimensions (acc. to DIN 2527, ANSI B16.5) are given in the table.

Mounting a pressure gauge set

1 Connect T-piece horizontally to drum house.

2 Check whether manometer is suitable for the maximum pressure in the tank.

3 Mount manometer and vent valve (figure 3).

4 Close vent valve.

5 Gently open valve between tank and drum compartment and check for leakage on all

connections.

Figure 3 Mounting a pressure gauge set on a 854 Servo gauge

Page 9

Mechanical installation

Installation guide 854 ATG Page 9

Grounding

Warning

For proper grounding of the 854 ATG, install a copper strip under one of

the flange bolts for each flange.

Place shark rings between flange and strip (figure 4).

Figure 4 Example of flange ground

Note:

Also in case of tanks with cathodic protection, the 854 ATG must be grounded to the tank.

Cathodic protection can be maintained by isolating the cable screen/armouring or conduit.

Page 10

Electrical installation

Page 10 Installation guide 854 ATG

Electrical installation

The entire electrical installation shall be in accordance with International Standard IEC 79-14 for

electrical equipment to be installed in hazardous areas.

Warning

Make sure that all power to the instrument is switched off before opening

the cover of the electronic and terminal compartment.

Failure to do so may cause danger to persons or damage the equipment.

All covers of the 854 ATG must be closed before switching on the power.

Figure 5 Blocking / sealing facilities

Caution

Before opening the electronic and terminal compartment cover, remove the optional

blocking devices which locks the covers: >A=: for electronic compartment cover and

terminal compartment cover; >B=: for drum compartment cover.

Caution

Do not damage the thread of the covers and instrument and keep the thread free of dirt.

After opening, grease it lightly with anti seize grease.

When closing, never tighten the covers before the threads are properly engaged.

The covers should be turned counter-clockwise until the thread Aclicks@ in place,

then turn clockwise until the covers are fully closed.

After closing the covers, do not forget to place the blocking devices.

Page 11

Electrical installation

Installation guide 854 ATG Page 11

Preparing gauge for electrical installation

Mains voltage selector

Check whether voltage selector is set correctly as

indicated on identification label of 854 ATG as well as

for the presented supply.

The voltage selector is located inside electronic

compartment (on the top of backplane).

It is marked with 'A' in figure 6.

The 854 ATG operates on a mains voltage

of 110, 130, 220 Vac (+10% to -20%) and

230 Vac ("15%).

A special 65 Vac (+10% to -20%) is available.

Power rating: 25 VA.

Frequency: 50 to 60 Hz ("10%). I

max

= 2 A.

Install an explosion-proof mains switch in the Figure 6 Voltage selector

mains supply cable to each 854 ATG.

Specify which switch you need to operate the 854 ATG.

Note:

For 240 V supply voltage, set the voltage selector to 230 V.

Supply voltage may then vary from +10% to -20%.

To change voltage setting, proceed as follows:

1) Check the local mains voltage.

2) Open electronic compartment cover.

3) If necessary, change voltage selector to applicable voltage;

$ Remove mains supply indication plate

$ Slide switch in appropriate position (refer to figure 6.)

$ Place mains supply indication plate and lock it

4) Close cover.

Caution

Changes of the mains setting shall be marked on the identification label of the 854 ATG.

Page 12

Electrical installation

Page 12 Installation guide 854 ATG

External fusing

The 854 ATG is internally fused on secondary side of transformer (fuses are located on GPS

board). Therefore, external fuses must be installed in the mains supply cable to each 854 ATG.

mains voltage fuse value (in accordance with IEC 127-2-3)

220 Vac or 230 Vac 315 mA slow

110 Vac or 130 Vac 630 mA slow

65 Vac 1 A slow

Cable glands / conduit

Cable glands:

Explosion-proof (Ex-d) or increased safe (Ex-e) cable glands must be used, depending on local

requirements. Refer to the Ex-marking on the identification label of the 854 ATG to determine

which type of cable glands is required.

Note:

Mount the glands according to the supplier=s instructions.

Conduit:

If the 854 ATG is installed in a hazardous area, threaded rigid metal conduit or threaded steel

intermediate metal conduit shall be used.

Note:

If the 854 ATG is installed in a hazardous area, stopper boxes must be applied within 18

inches (0.45 m) from the 854 ATG to seal the cabling in the conduit.

Depending on the wiring configuration, one to four :@ NPT threaded cable glands (or rigid

conduits) may be required with the 854 ATG.

Note:

Seal the unused cable inlets with an approved :@ NPT threaded stopping plug.

Warning

Improper installation of cable glands, conduit or stopping plugs will invalidate

the Ex approval of your 854 ATG.

Page 13

Electrical installation

Installation guide 854 ATG Page 13

Grounding

The 854 ATG housing should be properly grounded to the ground reference (generally the tank).

This is a safety grounding requirement. Grounding can be performed by copper strips across the

flanges (refer to section Grounding at mechanical installation), or by a ground wire.

With last mentioned method, use one of the external ground terminals of the 854 ATG.

Note:

Grounding shall be performed in accordance with local regulations.

Caution

Safety depends on proper grounding. Check the resistance of the ground connection

directly after installation. The measured ground resistance shall be below the maximum

prescribed by local grounding requirements.

Warning

When measuring the ground resistance, use a suitable explosion-proof tester.

Lay-out terminal compartment

The terminal compartment on top of the 854 ATG is divided into a non-intrinsically safe and an

intrinsically safe part. Cable entries are :@ NPT.

Figure 7 Location of 854 terminal compartment

The non-intrinsically safe cabling may only enter at the two right hand side cable entries (figure 7).

Warning

Only open the terminal compartment cover (top cover) when the power is switched off.

Page 14

Electrical installation

Page 14 Installation guide 854 ATG

Non-intrinsically safe cabling

Mains cabling : Must be suitable for the 854 ATG power rating and, moreover, approved for

the use in hazardous areas.

Honeywell

Enraf field bus : One twisted pair cable is recommended. R

max

= 200 Ω / line; C

max

= 1 µF.

Maximum length: 10 km.

Honeywell Enraf field bus lines may be interchanged. If local regulations

allow, mains and Honeywell Enraf field bus lines may share one cable. Mind

the isolation voltage of the cores in the cable; refer to the International

Standard IEC 61010-1.

Note:

If a quad cable is used and all four cores are twisted together, use two

opposite cores for Honeywell Enraf field bus lines and the two others for

mains.

Relay output : Option. The relay output contacts are potential free.

Contact rating: U

max

= 50 Vac or 75 Vdc; I

max

= 3 A non-inductive

(CSA only: 0.6 A). Mind the isolation voltage of the cores in the cable; refer

to the International Standard IEC 61010-1.

Analog output : Option. Use shielded cable. External supply voltage: 12 to 64 Vdc.

See figure 9.

Figure 8 Non-Intrinsically safe connections

Page 15

Electrical installation

Installation guide 854 ATG Page 15

When the voltage exceeds 30 Vdc,

an additional resistor is required.

The permitted operational areas are

shown in figure 9.

Operational area 1 represents the area of

operation without the need of an external

loop resistance.

Operational area 2 shows the area where

a resistance is required.

The power rating of the external resistor

depends on the value of the resistor.

We recommend 1 W / kΩ

Figure 9 Selecting the external loop resistor

Optional RS communication connections

For the cable connections of the mains and the alarm contacts, refer to previous section.

Caution

Keep the RS-232C / RS-485 lines as short as possible.

RS-232C : Cable requirements: maximum length 15 metres (50 ft); twisted and shielded.

RS-485 : Cable requirements: maximum length 1200 metres (3900 ft); twisted and shielded.

Figure 10 RS-232C / Rs-485 connections

Page 16

Electrical installation

Page 16 Installation guide 854 ATG

Intrinsically safe options

The cables for the intrinsically safe options shall only be fed through the cable entries at the side of

the intrinsically safe (blue) terminals. Blue marked cables are recommended for the intrinsically

safe options.

Caution

The intrinsically safe options described in this section are explosion-proof certified.

Make sure that the certificate of approval is available on site and act in accordance

with the instructions as given in the approval certificate.

Caution

Intrinsically safe wiring shall be separated from all other wiring.

Cable lay-outs shall be in accordance with local regulations.

Note:

The shield of the intrinsically safe cable shall not be connected inside the 854 ATG housing.

Connect the shield of the cable externally in the cable gland at both ends of the cable.

Device Cable requirements

Spot temperature element : Shielded; R

max

= 12 Ω / line.

Average temp. element : Twisted pair and shielded; R

max

= 25 Ω / line.

(combined water probe) Wiring between the 854 ATG and 762 VITO must be protected with

EMC shielded conduit. Same conditions for connection to 862 MIR.

Pressure transmitters : Twisted pair and shielded; R

max

= 25 Ω / line (only pressure

transmitters with HART7 protocol).

Pressure transmitter P1 is the bottom transmitter (measures liquid

head) and P3 is the top transmitter (measures vapour pressure).

Note:

If pressure transmitters are connected to HART input 2, it must be verified that the maximum

values for current and power of the HCU option board HART input 2 circuit are not exceeding the

maximum values of the connected pressure transmitters. Refer to Appendix C.

If the values of the HART input 2 circuit are too high, then connect the pressure transmitters to

HART input 1 and the 762 VITO Interface to HART input 2 (only possible when HART input 1 is

available!).

Page 17

Electrical installation

Installation guide 854 ATG Page 17

Device Cable requirements

977 Tank Side Indicator : Twisted pair and shielded; R

max

= 5 Ω / line, maximum cable length

50 m (160 ft).

GFC (Foundation™ Fieldbus) : Requires external supply 9 – 24 Vdc

Nominal current 11 mA

Maximum current (startup) 16.70 mA

Water bottom probe : Twisted pair and shielded; R

max

= 25 Ω / line.

(no VITO water sensor) (only with HART7 protocol).

Note:

If also pressure transmitters are connected, use a junction box for parallel connection of the

pressure transmitters and water bottom probe.

Figure 11 Intrinsically safe option connections

Page 18

Appendix

Page 18 Installation guide 854 ATG

Appendix A

Dimensions 854 ATG (medium pressure and chemical version)

Page 19

Appendix

Installation guide 854 ATG Page 19

Dimensions 854 ATG (high pressure version)

Page 20

Appendix

Page 20 Installation guide 854 ATG

Appendix B

Available adapters & calibration chambers

Page 21

Appendix

Installation guide 854 ATG Page 21

Appendix C

ATEX approval

The terminal compartment of the 854 ATG level gauge has been ATEX approved as explosionproof and as being increased safe. The type of cable glands that must used:

For protection type increased safe EEx e approved glands are to be used.

For protection type explosion proof EEx d approved glands or conduit are to be used.

Connection requirements of optional boards

The identification label on the 854 ATG indicates whether your instrument is equipped with an

optional board with intrinsically safe measuring circuits.

XPU-2 board (i.s. option), [EEx ib] IIB

Output circuit for 977 TSI:

Max. values : U = 21 V, I = 395 mA, P = 1.41 W

Max. permissible ext. inductance : 0.8 mH

Max. permissible ext. capacitance : 1.27 µF

HCU option board, [EEx ia] IIB

Spot temperature input circuit:

Max. values : U = 23.1 V, I = 221 mA, P = 0.19 W

Max. permissible ext. inductance : 3.5 mH

Max. permissible ext. capacitance : 980 nF

HART input 1 circuit (for 762 VITO Interface):

Max. values : U = 23.1 V, I = 90 mA, P = 0.52 W

Max. permissible ext. inductance : 15 mH

Max. permissible ext. capacitance : 1.02 µF

HART input 2 circuit (for HART7 pressure transmitters and/or external water probe):

Max. values : U = 23.1 V, I = 148 mA, P = 0.86 W

Max. permissible ext. inductance : 7 mH

Max. permissible ext. capacitance : 1.02 µF

GFC option board, [EEx ia] IIC

Fieldbus interface circuit

Max. values : U = 24V, I = 380 mA, P = 5.32W

Max. permissible ext. inductance : 6.5 µH

Max. permissible ext. capacitance : 1.8 nF

Page 22

Appendix

Page 22 Installation guide 854 ATG

Appendix D

Related documents

Instruction manual 854 ATG level gauge

Instruction manual 854 density option

Instruction manual SPU II Hard alarm output contacts

Installation guide 762 VITO Interface & 764, 765 or 766 VITO temperature and/or water sensor

Installation guide 977 Tank Side Indicator

Instruction manual XPU-2 option RS-232C/RS-485

Instruction manual Temperature, Water bottom and Analog output options

Instruction manual HIMS / HTG and vapour pressure (P3) measurement

Instruction manual Foundation™ Fieldbus Interface

Instruction manual 847 PET

Installation info 003 "Installation of Pressure Transmitters for HTG and HIMS"

Page 23

Notes

Installation guide 854 ATG Page 23

Page 24

Page 24 Installation guide 854 ATG

Delftechpark 39

2628 XJ Delft

Tel. :+31 15 2701 100

E-mail : enraf-nl@honeywell.com

Webiste: www.honeywellenraf.com

PO Box 812

2600 AV Delft

The Netherlands

We at Honeywell Enraf are committed to excellence.

Information in this publication is subject to change without notice

Enraf is a registered trade mark. Enraf B.V. Netherlands

Loading...

Loading...