Page 1

CAGE 99866

User Guide

For

Vibrex™ 2000,

Vibrex™ 2000 Plus

and

Enhanced Vibrex™ 2000 Plus

(Helicopter and Fixed Wing Versions)

Digital Dynamic Balancer/Analyzer

Systems

13841 Rev. A

May 07, 2015

Honeywell International, Inc

AEROSPACE – Torrance, CA USA

HONEYWELL CONFIDENTIAL: This copyrighted work and all information is the

property of Honeywell, contains trade secrets, and may not, in whole or in part,

be used, duplicated, or disclosed for any purpose without prior written permission

of Honeywell. All rights reserved.

Page 2

COPYRIGHT NOTICE

Copyright © 05/07/2015 by Honeywell International, Inc.

All Rights Reserved

Revision – May 2015

Printed in the U.S.A.

This Manual is supplied to the User under license, subject to

change without notice and/or recall by Honeywell International

Inc., at any time. The Manual at all times remains the property

of Honeywell International Inc. The information contained in

this Manual is considered confidential. No part of this Manual

is to be copied or reproduced or transmitted in any form

whatever (including orally or by electronic transmission), nor

is any information in this Manual to be disclosed in any form

whatever (including orally or by electronic transmission) to

anyone other than an authorized representative of the User's

employer who also shall agree not to disclose same, without

express prior written consent of Honeywell International, Inc.

Trademarks

Honeywell, International Inc.

2525 West 190th Street

Torrance, CA 90504

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

13841 Rev A

ii

Page 3

REV

LTR

PAGE/PARA

DESCRIPTION

DATE

-

ALL

Initial Release per

ECO-0204365

November

3, 2013

A

ALL

SEE ECO-0256422

May 07,

2015

REVISION HISTORY

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

13841 Rev A

iii

Page 4

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Contents

Quick Reference Guide ...................................................xi

1.0 Introduction ..................................................................1

1.1 About This User Guide ........................................................ 1

1.1.1 Organization .................................................................. 3

1.1.2 Notice Formats .............................................................. 3

1.1.3 Document Conventions ................................................. 4

1.1.4 Reference Documentation ............................................. 4

1.2 Product Support................................................................... 5

1.2.1 Fax Service .................................................................... 6

1.2.2 Internet Service.............................................................. 6

2.0 System Overview ..........................................................7

2.1 Vibrex Systems: Introduction ............................................. 7

2.2 Product Description ............................................................. 8

2.2.1 Vibrex 2000 System Overview...................................... 9

2.2.1.1 System Operations 9

2.2.1.2 System Benefits 10

2.2.1.3 Self-Test Feature 11

2.2.2 Vibrex 2000 Plus Enhancements ................................... 12

2.2.3 Enhanced Vibrex 2000 Plus Enhancements .................. 13

2.3 System Specifications ........................................................... 14

2.3.1 Vibrex 2000 Specifications ........................................... 14

2.3.2 Vibrex 2000 Plus Specifications.................................... 17

2.3.3 Enhanced Vibrex 2000 Plus Specifications ............ 21

3.0 Getting Started .............................................................27

13841 Rev A

iv

Page 5

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

3.1 Getting Started: Introduction ............................................. 27

3.2 Basic Features ...................................................................... 28

3.2.1 Display .......................................................................... 30

3.2.1.1 Adjusting Screen Contrast 30

3.2.1.2 Screen Operations 30

3.2.1.3 Self-Test Screen 31

3.2.2 Keypad .......................................................................... 31

3.2.2.1 Alpha-Numeric Keys 32

3.2.2.2 Dedicated Keys 33

3.2.2.3 Context Keys 34

3.2.3 Channel Configuration .................................................. 34

3.3 Printing Data ........................................................................ 36

3.3.1 Direct Serial Printing ..................................................... 36

3.3.1.1 Basic Settings 37

3.3.1.2 Connecting the Printer 37

3.3.2 Printing With a PC ........................................................ 41

3.3.2.1 Downloading Data 42

3.3.3 Reading FFT Data ......................................................... 44

3.3.4 Using the PRINT Key ................................................... 45

3.3.4.1 Global Printing 46

3.3.4.2 Printing With REVIEW and PRINT Keys 51

4.0 Installation ....................................................................53

4.1 Installation: Introduction .................................................... 53

4.2 Vibrex 2000 Basic Equipment ............................................ 54

4.2.1 V2K Propeller Balance Kits .......................................... 55

4.2.1.1 V2K Single-Engine Kits 55

4.2.1.2 V2K Twin-Engine Kits 56

4.2.2 V2K Rotor Track & Balance Kits ................................. 57

4.2.3 V2K Helicopter and Fixed Wing Kit ............................. 59

4.3 Vibrex 2000 Plus Equipment .............................................. 62

4.3.1 V2K Plus Propeller Balance Kits .................................. 62

13841 Rev A

v

Page 6

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

4.3.1.1 V2K Plus Single-Engine Kit 62

4.3.1.2 V2K Plus Twin-Engine Kit 63

4.3.2 V2K Plus Rotor Track & Balance Kit ........................... 64

4.3.3 EV2K Plus Rotor Track & Balance Kit Options ........... 66

4.3.4 V2K Plus Helicopter & Fixed Wing Kit........................ 67

4.3.5 Optional Equipment ...................................................... 69

4.3.6 Carrying Case ................................................................ 71

4.4 General Installation ................................ ............................. 71

4.4.1 Velocimeters .................................................................. 73

4.4.2 Photocell System ........................................................... 74

4.4.2.1 Retro-Reflective Target 75

4.4.2.2 General Photocell Use 76

4.4.2.3 Repair of Photocell Wiring. 77

4.4.2.4 Photocell Placement 77

4.4.2.5 Target Positioning 80

4.4.3 Magnetic Pickup ............................................................ 81

4.5 Sample Installations ............................................................. 82

4.5.1 Lycoming O/IO-320/360 ............................................... 83

4.5.2 Lycoming O/IO-540 ...................................................... 83

4.5.3 Continental O/IO-470/520/550 ...................................... 83

4.5.4 P&W R-985/2800 .......................................................... 84

4.5.5 Flat Opposed General Rules .......................................... 84

4.5.6 Radial Engine General Rules ......................................... 84

4.5.7 Turbine Engines ............................................................ 84

4.5.8 Geared Reciprocating Engines ...................................... 85

5.0 General Operation ........................................................87

5.1 Operation: Introduction ...................................................... 88

5.2 Beginning Operation ........................................................... 88

5.2.1 Powering Up .................................................................. 89

5.2.2 Main Menu Screen ........................................................ 89

5.3 Basics of Operation .............................................................. 94

13841 Rev A

vi

Page 7

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

5.4 Propeller Balancing (Generic) ............................................ 96

5.4.1 Propeller Balance Setup ................................................ 99

5.4.1.1 Entering Aircraft IDs 99

5.4.1.2 Selecting Channels 100

5.4.1.3 Entering Horsepower 101

5.4.1.4 Setting Sensitivity 104

5.4.1.5 Saving Corrected Propeller Configurations (EV2K+

only) 107

5.4.1.6 Multiple Propeller Feature 109

5.4.2 Acquiring Balance Readings ......................................... 112

5.4.2.1 Annotating the Reading 114

5.4.2.2 Balance Quality Indicator 114

5.4.3 Obtaining Balance Solutions ......................................... 117

5.4.3.1 Application Guidelines 117

5.4.3.2 Using the Propeller Protractor 118

5.4.3.3 Changing Performed Solutions 121

5.4.4 Finishing Propeller Balance .......................................... 122

5.4.4.1 If Unable To Use Weight Azimuth 123

5.4.5 Reviewing Balance Histories ........................................ 124

5.4.5.1 Reviewing Propeller Balance Measurements 126

5.4.5.2 Reviewing Other Balance Measurements 127

5.4.5.3 Reviewing Spectrum Peak Measurements 128

5.4.5.4 Reviewing Spectrum Order Analysis 129

5.4.5.5 Clearing Runs, Measurements, and Lists 129

5.5 Helicopter Rotor Track and Balancing (Generic) ............. 129

5.5.1 Main Rotor Track .......................................................... 132

5.5.1.1 Main Rotor Track (Strobex) (V2K and V2K+) 132

5.5.1.2 Main Rotor Track (Strobex) (EV2K+) 134

5.5.1.3 Main Rotor Track (FasTrak®) (EV2K+ Heli Only) 136

5.5.1.4 Saving or Removing User Track Configurations

(EV2K+ Only) 141

5.5.2 Main Rotor Balance – Paper Charts (All units) ............. 144

5.5.3 Using the Rotor Protractor............................................. 145

5.5.3.1 Counter-Clockwise Rotor Correction 151

13841 Rev A

vii

Page 8

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

5.5.3.2 Clockwise Rotor Correction 156

5.5.4 Tail Rotor Balance – Using Protractor .......................... 156

5.5.4.1 Clockwise Rotors 157

5.5.4.2 Counter-Clockwise Rotors 158

5.5.5 Tail Rotor Track ............................................................ 159

5.6 Helicopter Balance (EV2K+ Heli Only) ............................. 161

5.6.1 Helicopter Balance Initial Startup ................................. 162

5.6.2 Helicopter Balancing ..................................................... 164

5.6.2.1 Alternate Solutions 173

5.6.3 Auto-Correction............................................................. 176

5.6.4 Job Selection ................................................................. 179

5.6.5 Removing and Editing Models and Charts .................... 180

5.6.6 Helicopter Balance Run Print, Review and Clearing .... 185

5.7 Fixed Wing Balance (EV2K+ Fixed Wing only) ............... 186

5.8 Spectrum Analysis (All Vibrex 2000 units)........................ 188

5.8.1 Spectrum Analysis Setup ............................................... 190

5.8.1.1 Ranging Feature 192

5.8.1.2 Annotating Spectra 193

5.8.2 Collecting Spectral Data ................................................ 193

5.8.3 Order Analysis ............................................................... 195

5.8.4 Spectrum Viewer Feature .............................................. 196

5.8.4.1 After Taking Measurements 197

5.8.4.2 Displaying Cursor Data 199

6.0 Maintenance ..................................................................201

6.1 Maintenance: Introduction ................................................. 201

6.2 Theory of Operation ............................................................ 202

6.2.1 Digital Subsystem .......................................................... 202

6.2.2 Display Subsystem ........................................................ 203

6.2.3 Analog Subsystem ......................................................... 204

6.2.3.1 Velocity Signal 204

6.2.3.2 Azimuth Signal 204

13841 Rev A

viii

Page 9

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

6.2.4 Power Subsystem .......................................................... 205

6.2.4.1 Battery Power 205

6.2.4.2 On-Off Logic 206

6.2.4.3 Power Supplies 206

6.2.4.4 Short-circuit Protection 206

6.3 Routine Servicing ................................................................. 207

6.3.1 Batteries and Replacement ............................................ 207

6.3.1.1 Battery Types 207

6.3.1.2 Battery Usage 208

6.3.1.3 Battery Insertion Diagram 209

6.3.1.4 Removal 210

6.3.1.5 Reinstallation 210

6.3.1.6 Setting Battery Time 211

6.3.2 EPROM Replacement ................................................... 211

6.3.2.1 Determining EPROM Versions 212

6.3.2.2 Getting Started 212

6.3.2.3 Replacement Procedures 213

6.3.3 Panel Retention Screws ................................................. 215

6.3.4 Cleaning ........................................................................ 216

6.3.5 Testing ........................................................................... 216

6.3.5.1 System Testing Using Model 11 Calibrator 216

6.3.5.2 Instrument Test Procedures for the Vibrex 2000 and

Vibrex 2000 Plus 219

6.3.5.3 Approach: 219

6.3.5.4 Procedure: 220

6.3.5.5 For The Vibrex 2000 (Basic) 221

6.3.5.6 For The Vibrex 2000 Plus 222

6.3.6 Clearing Memory Contents ........................................... 224

6.3.6.1 Vibrex 2000 224

6.3.7 Complete Unit Disassembly .......................................... 224

6.3.7.1 Parts List 232

6.3.7.2 Disassembly 233

6.3.7.3 Assembly 234

6.4 Troubleshooting ................................................................... 235

13841 Rev A

ix

Page 10

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

6.4.1 Fault Logs ...................................................................... 236

6.4.1.1 Printing the Fault Log 236

6.4.1.2 Clearing the Fault Log 237

6.4.1.3 Failure Modes 237

6.4.2 Troubleshooting Guide .................................................. 238

6.4.2.1 Reference Table 238

6.4.2.2 No Vibration Reading 245

Appendix A: Photocell Taping .......................................249

Appendix B: EV2K+ Helicopters ...................................255

Appendix C: EV2K+ FasTrak Configurations ............259

Appendix D: EV2K+ Fixed Wing Aircraft ....................263

Glossary ..............................................................................263

Notes ....................................................................................270

13841 Rev A

x

Page 11

Quick Reference Guide

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Quick Reference Guide

This guide provides a quick-start reference for the Vibrex 2000

and Vibrex 2000 Plus and the Enhanced Vibrex 2000 Plus

Digital Dynamic Balancer systems. The term Vibrex unit refers

to all these systems. Throughout this document they may also be

referred to V2K, V2K+ and EV2K+ respectively.

To order this User Guide use Part Number 768-13841-X

(Latest Dash number).

Propeller Balance (Generic)

Propeller Balance, Run No. 1

Install the photocell, velocimeter(s), and reflective tape on

the propeller to be balanced.

Turn on the Vibrex unit.

Select Propeller Balance from the Main Menu

screen.

Ensure the propeller input is plugged into channel No. 1 and

A and any other propeller or velocimeter in the other

channel. Press START.

Select the engine horsepower, then press START.

Operate the propeller at the desired balance RPM. When the

RPM is steady, press START.

When the Vibrex unit has finished collecting data, press

START.

If the reading is not acceptable (greater than 0.2 IPS),

press START.

13841 Rev A

xi

Page 12

Quick Reference Guide

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Observe displayed note then press START.

Implement the solution and power off the Vibrex unit.

Propeller Balance, After Run No. 1

Turn on the Vibrex unit.

Select Propeller Balance from the Main Menu

screen.

Vibrex 2000 Plus Only - Select Continue Current

Session.

Edit the solution if it is different from the solution done

earlier then press START.

Operate the propeller at the same RPM as done in Run No.

1. When the RPM is steady, press START.

When the Vibrex unit has finished collecting data, press

START.

Continue making adjustments until the propeller yields the

desired IPS level, then press DONE from the Prop Balance

Quality screen.

Helicopter/Fixed Wing Balance

(EV2K+ only)

First Time Startup

Install the photocell, velocimeter(s), and reflective tape on

the helicopter/aircraft.

Turn on the Vibrex unit.

Select Helicopter Balance from the Main Menu

screen. (Fixed Wing Balance for fixed wing version.)

Use the ↑↓ ARROW keys to select your user

helicopter/aircraft model from the factory selections.

13841 Rev A

xii

Page 13

Quick Reference Guide

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

After First Time Startup, Balance Run No. 1

Make sure the proper model is selected at the Choose A/C

Model screen, then press START.

Select the Component, Flight Regime and Change Type to

be used for balance, then press START.

Select Measurement Sensor. The default EV2K+ balance

channel can be changed, if desired. AutoCorrection

may also be toggled to <ON >. Press START.

Operate the component at the desired balance RPM. When

the RPM is steady, press START.

When the Vibrex unit has finished collecting data, press

START.

Press START to view the solution.

Apply changes exactly as specified or use ALTERNATE

SOLUTION to view other solution options.

Press Done (Next Run/Job) if balance is acceptable,

otherwise ensure the proper solution (change) type is

selected and press START.

Implement the solution and power off the Vibrex unit.

After Balance Run No. 1

Turn on the Vibrex unit.

Select Helicopter Balance (or Fixed Wing

Balance) from the Main Menu screen.

Select the component and <Continue Job> then press

START.

Operate the helicopter/aircraft at the same RPM as done in

Run No. 1. When the RPM is steady, press START.

When the Vibrex unit has finished collecting data, press

START.

Continue making adjustments until the component yields the

desired IPS level, then press DONE from the Aircraft

Balance Quality screen.

13841 Rev A

xiii

Page 14

Quick Reference Guide

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Spectrum Analysis

Install the velocimeter in the desired location for

measurement.

Power up the Vibrex unit.

Press the SPECTRUM ANALYSIS context key.

Select the velocimeter channel and azimuth sensor channel

(if used).

Select the RPM range of interest.

Operate the aircraft at the desired condition for taking

measurements, then press START.

Press START to save.

Balance Reading

Install the velocimeters and photocell, as desired, for the

aircraft to be balanced.

Power up the Vibrex unit.

Press the TRACK & BALANCE context key from the Main

Menu screen.

Operate the aircraft in the desired condition.

Press the desired channel to take measurement input.

Press START to save.

Strobex Track

Install the Photocell (or magnetic pickup), Strobex, and

retro- reflective targets to be viewed.

Power up the Vibrex unit.

Press the TRACK & BALANCE context key from the Main

Menu screen.

Operate the aircraft in the desired condition.

Vibrex 2000 and Vibrex 2000 Plus

Press the STROBEX TRACK context key.

13841 Rev A

xiv

Page 15

Quick Reference Guide

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Enter the number of blades to be tracked and observe the

targets.

Enhanced Vibrex 2000 Plus

Press the TRACK context key.

Insure that the proper helicopter model is selected.

Press the STROBEX context key.

Enter the number of blades to be tracked (if incorrect) and

observe the targets.

FasTrak® (EV2K+ Helicopter Only)

Install the magnetic pickup, FasTrak® and mounting bracket.

Connect the magnetic pickup to MAG PU A. Connect the

FasTrak® to MAG PU B.

Power up the Vibrex unit.

Press the TRACK & BALANCE context key from the Main

Menu screen.

Operate the aircraft in the desired condition.

Press the TRACK context key.

Insure that the proper helicopter model is selected.

Press the FasTrak context key.

Press the START key twice to acquire and observe the track

readings.

Press the START key to obtain a solution.

Printing

Connect the Vibrex unit to the printer using the appropriate

serial interface cable.

Power up the Vibrex unit and select PRINT.

Select the reading or reading set wanted to print then press

START or PRINT.

13841 Rev A

xv

Page 16

Page 17

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page..

Chapter 1

1.0

INTRODUCTION

This chapter gives a general overview of this user guide

and using it with the Honeywell Vibrex 2000 (V2K),

Vibrex 2000 Plus (V2K+) and Enhanced Vibrex 2000

Plus (EV2K+) Digital Dynamic Balancer/Analyzer

systems. It also gives information on customer support

services. Chapter 1 contains the following sections:

1.1 About This User Guide .................................................. 1

1.2 Product Support ............................................................ 5

1.1 About This User Guide

This user guide explains how to install, operate, and maintain the

Vibrex 2000 and Vibrex 2000 Plus systems. The text sets out the

basic procedures required to accomplish dynamic balancing with

optimum results, using these systems.

NOTE: If the user wants to get started right away, go to the

“Quick Reference Guide” at the beginning of this user guide.

13841 Rev A

1

Page 18

Chapter 1 - Introduction

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Vibrex 2000 Release - This user guide is written for the

following Vibrex 2000 firmware release:

Version 2.73

Vibrex 2000 Plus Release - This user guide is written for the

following Vibrex 2000 Plus firmware release:

Version 2.73+

Enhanced Vibrex 2000 Plus Release - This user guide is

written for the following Enhanced Vibrex 2000 Plus firmware

release:

Version 4.03+ (Helicopter)

Version 5.00+ (Fixed Wing)

NOTE: The Enhanced Vibrex 2000 Plus software runs

only on the Vibrex 2000 Plus hardware platform. Any

references to the Vibrex 2000 Plus hardware unit

specifications also apply to the Enhanced Vibrex 2000 Plus

system.

NOTE: The user must document all aircraft maintenance

actions according to existing instructions and perform them in

accordance with the appropriate maintenance manual.

The chapters explain basic steps required to accomplish optimum

one- per-revolution smoothing of aircraft rotors and other

equipment, if applicable.

WARNING: Installation of some brackets on some aircraft

involves removing nuts and/or bolts, affecting the safety of

13841 Rev A

2

Page 19

Chapter 1 - Introduction

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

flight. Follow the aircraft maintenance manual if these

actions require additional procedures such as retorquing,

safetying, the reuse of nuts, inspections, or sign-offs.

1.1.1 Organization

This user guide has the following topical organization:

Chapter 1. Introduction - General user guide information and

overview.

Chapter 2. System Overview - Basic instructions on how to use

the Vibrex 2000 series and a general system description.

Chapter 4. Installation - Equipment list and general system

installation procedures.

Chapter 5. General Operation - Using the Vibrex 2000 to

achieve optimum dynamic balance results.

Chapter 6. Maintenance - Checking out the system, basic

repairs, and solving problems; includes a troubleshooting guide.

1.1.2 Notice Formats

In many places in this user guide, the user may see special

notices. Their headings have the following meanings:

NOTE: Here is additional useful information pertaining to

the current subject.

CAUTION: Be careful with this procedure or item because

of possible damage to equipment or loss of data.

WARNING: Exercise extreme care with this procedure or

item because of possible personal injury.

Special notices appear in the format shown here.

13841 Rev A

3

Page 20

Chapter 1 - Introduction

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

1.1.3 Document Conventions

This user guide employs the following text and format

conventions:

Text on screen is shown in bold monospaced type.

This type represents text in this guide exactly as it appears

on the Vibrex 2000 display screen.

Vibrex 2000 and Vibrex 2000 Plus key names appear in

boldface and all-caps. Dedicated keys appear in bold, like

START, but context keys appear in bold italic, like DONE.

Bold italics designate personal computer (PC) keys, for

example, Enter.

Important topics or terms are in italics. Definition lists show

the defined term first in boldface, at the left-side margin.

Unnumbered sectional subtopics have the first term at the

start of the paragraph in boldface followed by a hyphen, for

example,

Vibrex 2000 Plus - Digital Dynamic Balancer.

Titles of chapters or sections are in quotation marks, for

example, “Document Conventions,” but the section numbers

are not, for example, see Section 1.1.3 “Document

Conventions”.

1.1.4 Reference Documentation

This user guide utilizes the following reference documentation:

The Smooth Propeller (Version 2), No. 9511-2

V2K Download Software User Guide, No. 14984

V2K Plot Software User Guide, No. 14983-1

Polar Coordinate Chart, No. 8016

13841 Rev A

4

Page 21

Chapter 1 - Introduction

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Photocell System Operation and Maintenance Manual, No.

10473 (covers the Honeywell Photocell but is useful for any

type of photocell installation)

Model 135M-12 Strobex Operation and Maintenance

Manual, No. 9076

The documentation numbers given in the previous list are

Honeywell part numbers, for ordering purposes.

1.2 Product Support

In the United States the user may reach a Vibrex technical

representative from Honeywell’s Technical Operations Center by

dialing the numbers below,

Honeywell Customer Care Help Desk 24/7

+1 602 365-3099 International

+1 800 601-3099 US & Canada (Toll Free)

24/7 AOG Pricing Support (Help Desk Option 4) AOG@Honeywell.com

Quotes / Availability (Help Desk Option 1) Quotes@Honeywell.com

Technical Publication, Repair order status and capability,

Training Solutions, etc go to www.myAerospace.com

**New Direct Line** Honeywell Technical Operations Center

Help Desk 24/7

855-808-6500 US & Canada (Toll Free)

602-365-6500 International

Option 1 avionics

Option 2 mechanical

13841 Rev A

5

Page 22

Chapter 1 - Introduction

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

AeroTechSupport@Honeywell.com

If at all possible, fax a copy of a customer support report in care

of Vibrex 2000 and Vibrex 2000 Plus support before calling.

NOTE: If necessary, check with the Technical Operations

Center for an update on the latest part and software revisions.

1.2.1 Fax Service

You may send a fax detailing any questions or comments at any

time, by dialing the 24-hr number below:

602-365-1871

Address any fax to the Technical Operation Center.

1.2.2 Internet Service

If you want more information about us, Honeywell has an

Internet site at the following URL:

http:// www.MyAerospace.com

We also have an e-mail box. Make sure to send any messages to

the attention of the Technical Operations Center. Our e-mail

address is

aerotechsupport@honeywell.com or through the portal at

myAerospace.com

For more details on this or any other customer support services,

please contact Honeywell’s Technical Operations Center.

13841 Rev A

6

Page 23

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page..

Chapter 2

2.0

SYSTEM OVERVIEW

This chapter gives an explanation of the basic system

characteristics and technical specifications of the Vibrex 2000,

Vibrex 2000 Plus and Enhanced Vibrex 2000 Plus Digital

Dynamic Balancer/Analyzer systems. Chapter 2 contains the

following sections:

2.1 Vibrex Systems: Introduction ............................................... 7

2.2 Product Description ............................................................. 8

2.3 System Specifications ......................................................... 14

2.1 Vibrex Systems: Introduction

The Vibrex 2000, Vibrex 2000 Plus and Enhanced Vibrex 2000

Plus have the following general features:

13841 Rev A

7

Page 24

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

They are portable, easy-to-use digital dynamic balancers. In

addition, they can do quick, efficient vibration analysis,

allowing the user to identify additional sources of vibration.

The Vibrex 2000, Vibrex 2000 Plus and Enhanced Vibrex

2000 Plus were developed to meet the dynamic balance

needs of the aviation community.

Although primarily intended for light aircraft propeller

balance, they perform as well as the world-famous

Honeywell Model 177M and Model 8350 “ring-of-lights”

Vibrex products developed for rotary-wing applications.

The Vibrex 2000, Vibrex 2000 Plus and Enhanced Vibrex

2000 Plus are not limited to the aircraft field. Like their

predecessors, these products are usable in a wide range of

uses, including agricultural, forest product-related, marine,

and industrial applications.

2.2 Product Description

This section gives a general description of the Vibrex 2000,

Vibrex 2000 Plus and Enhanced Vibrex 2000 Plus systems,

including the differences between the two products.

NOTE: See the “Glossary” for definitions of specific Vibrex

2000, Vibrex 2000 Plus and Enhanced Vibrex 2000 Plus related terms that may not be familiar to the user.

Keep in mind that the Vibrex 2000 Plus system and Enhanced

Vibrex 200 Plus have all the capabilities of the Vibrex 2000. In

addition, it has the added features and benefits listed under

Section 2.2.2 “Vibrex 2000 Plus Enhancements and Section

2.2.3 Enhanced Vibrex 2000 Plus Enhancements”.

For more details information on both the Vibrex 2000, Vibrex

2000 Plus and Enhanced Vibrex 2000 Plus systems, as well as

13841 Rev A

8

Page 25

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

the exact differences between the three models, see Section 2.3

“System Specifications”.

2.2.1 Vibrex 2000 System Overview

The Vibrex 2000 unit is a hand-held, battery-powered vibration

analyzer. It is a vibration analysis and balancing tool that rapidly

and accurately acquires and analyzes aircraft vibration data. It

uses that data to calculate balance solutions and to analyze

aircraft vibration levels across a broad frequency range.

The Vibrex 2000 system provides accurate helicopter vibration

readings for chart calculations on main and tail rotors, shafts, and

blowers. As a spectrum analyzer, they provide the operator with

an overview of rotor and drive-train vibration. The Vibrex unit

uses cables and transducers (for example, the Honeywell Model

7310 Velocimeter, magnetic pickups, and photocells) from

previous generations of our equipment, further reducing the cost

of ownership.

2.2.1.1

System Operations

The Vibrex 2000, Vibrex 2000 Plus and Enhanced Vibrex 2000

Plus systems allow the user to do the following operations:

Propeller Balance Operations - Easy-to-understand menus let

the user initiate up to four different balancing jobs at one time.

The instrument can automatically correct for the propeller

response to weight changes, and the user can save this correction

for future balancing operations.

A “first round hit” solution means lower vibration solutions,

even on the first move. Two channels allow the user to measure

the propeller and rear of the engine during balancing. All

measurements, solutions, sensitivities, and annotation are saved

13841 Rev A

9

Page 26

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

in memory and can be reviewed on the instrument, printed out on

the optional portable thermal printer, or downloaded to a

personal computer (PC) through a standard RS-232 serial cable.

Rotor Track-and-balance Operations - The track-and-balance

menus are designed to simplify taking multiple measurements

without having to change the setup. The user can acquire and

save balance readings, in inches per second (IPS) and clock

angles.

The user can also track up to seven helicopter blades, using the

Honeywell Model 135M-12 Strobex Tracker.

Spectrum Analysis - Vibration peaks listed by frequency or

order are available up to 24,000 RPM (600,000 for V2K+). The

lists are based on 400-line fast Fourier transform (FFT)

calculations. As with all measurements, the lists can be saved,

reviewed, printed, or transferred to a PC.

The user can save the complete spectrum and view it with a

standard spreadsheet or with one of Honeywell's ground-based

software packages. Up to twelve orders and associated halforders can be listed.

2.2.1.2

System Benefits

The Vibrex 2000 systems offer the user the following benefits:

Reduced aircraft operating costs and down time

Reduced propeller and rotor vibration that translates into

increased reliability, increased mean time before failure

(MTBF) for avionics, as well as mechanical and

aerodynamic structures

Better ride comfort for pilots and passengers

13841 Rev A

10

Page 27

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Federal Aviation Association (FAA)-approved propeller

balance, when used with Honeywell’s The Smooth Propeller

manual publication

Balance jobs that are stored in memory and can be archived

on a PC

A 32-bit microprocessor for rapid-balance computations and

FFT calculations

Use of common rechargeable or disposable D-cell batteries

Honeywell's worldwide customer support

2.2.1.3

Self-Test Feature

Each time the Vibrex 2000, Vibrex 2000 Plus or the Enhanced

Vibrex 2000 Plus unit is powered up, it checks its memory and

characterizes its analog filters to compensate for aging

components, temperature drifts, and so on. The unit then reports

the total amount of time the batteries have been used since

installation.

Press the unit’s STATUS key to display checked battery and

sensor voltages, along with the date, time, and firmware version.

Using this key, you may print the fault log for easy

troubleshooting. See Section 6.4.1 “Fault Logs” for details.

Self-Test Modes - The power-up self test has the following

modes:

Comprehensive Test - Performed if the unit has been turned off

for more than 2 hours and takes approximately 20 seconds, that

is, the unit’s full built- in test (BIT). Such timing allows this test

to be done sufficiently to ensure that all the unit’s functions are

tested at reasonable intervals.

Abbreviated Test - Takes only a few seconds. The unit does this

test if it has been in use during the last 2 hours. The

comprehensive test (or BIT) is unnecessary each time the unit is

13841 Rev A

11

Page 28

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

powered up, so the unit only does an abbreviated test for shortterm power-down/power-up cycles.

2.2.2 Vibrex 2000 Plus

Enhancements

The Vibrex 2000 Plus model represents a significant

performance increase over the Vibrex 2000 (Part Number 135902 and earlier). In addition to all existing Vibrex 2000 benefits

features, and capabilities, the Vibrex 2000 Plus system offers the

following extended capabilities.

An increase in maximum spectrum frequency from 24,000

RPM to 600,000 RPM (10 kHz)

A graphic spectrum viewing mode

An extended balance frequency range from 120 RPM to

30,000 RPM

Support for running up to four propeller balance jobs in

parallel operation (can suspend one then jump out and start

another)

Four times the memory, allowing more data to be saved (1

Mb)

The ability to store balance jobs, adjustments, sensitivities,

spectra, and balance measurements in the instrument’s

memory and archive them on a PC

Storage of firmware in the instrument’s Flash memory,

facilitating software upgrades and enhancements; there is no

longer any need to open the instrument for this purpose

13841 Rev A

12

Page 29

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

2.2.3 Enhanced Vibrex 2000 Plus

Enhancements

Using the same hardware package as the Vibrex 2000 Plus, the

Enhanced Vibrex 2000 Plus model improves some of the Vibrex

2000 Plus software features as well as adding a completely new

capability to track and balance specific helicopter (version

4.xx+) and fixed-wing aircraft (version 5.xx+) models. These

features are summarized below.

Adds the ability to save and recall Propeller Balance

configurations. Auto-corrected and user-entered balance

coefficients can be renamed and saved for later use.

The FasTrak optical blade tracker is now supported in

addition to the Strobex. The EV2K+ provides the ability

to use preset helicopter FasTrak setups as well as modify

and create new FasTrak configurations.

Adds an extensive new Helicopter Balance capability

(version 4.xx+). A complete set of balance charts for 28

helicopter models and variants are included. These

function as simple “single-plane” balance charts and can

be selected for various components, flight regimes,

change types and measurements. These balance charts

are the same as provided in the advanced VXP balancer.

They can be modified and stored as new configurations.

Adds an extensive new Fixed Wing Balance capability

(version 5.xx+) similar to the EV2K+ Helicopter

13841 Rev A

13

Page 30

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

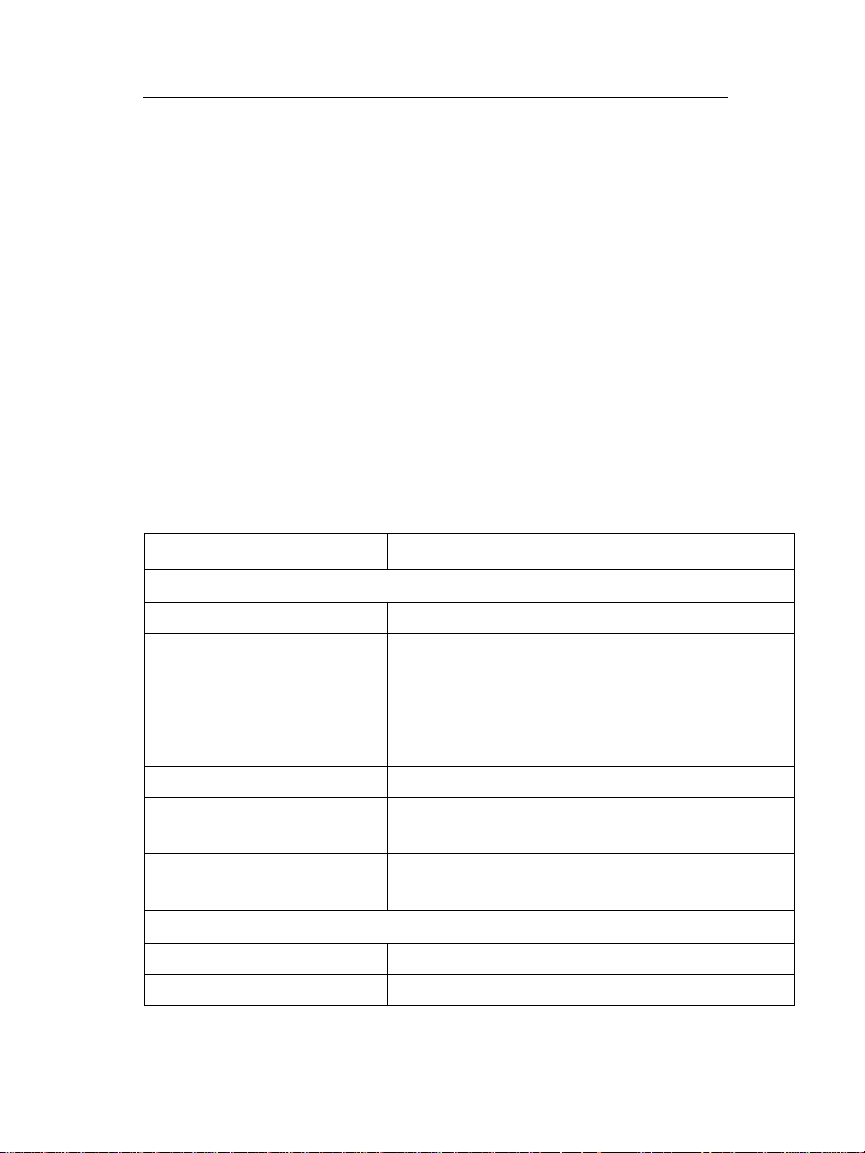

Characteristic

Specifications

Basic Specifications

Data storage capacity

1 Mb

Built-in test (BIT)

coverage

Memory check and calibration on power

up; user-initiated tests (with STATUS key)

check battery and sensor power

NOTE: Errors are logged to a

printable fault log.

Date and time stamping

Yes

Log (data) files contents and formats

Balance jobs, log book, balance, spectrum,

fault log, all in ASCII format

Compatible software

(ground based)

Honeywell V2K Download and V2K Plot

programs

Basic Performance

Frequency range

0 to 400 Hz

Accuracy

±5%, from 5 Hz to 333 Hz

capability. This version supports balance charts for over

30 specific fixed wing models.

2.3 System Specifications

The tables in this section provide complete lists of the Vibrex

2000, Vibrex 2000 Plus and Enhanced Vibrex 2000 Plus

systems’ technical specifications.

2.3.1 Vibrex 2000 Specifications

The table, starting below, lists complete technical specifications

for the Vibrex 2000 system.

13841 Rev A

14

Page 31

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Characteristic

Specifications (Continued)

Acquisition capability

2 vibration and 2 tachometer (azimuth)

Balance Measurements

Phase units

Hours and minutes

Phase resolution

2 min or 1°

Phase accuracy

±15°

Balance frequency range

240 to 10,000 RPM

Spectrum Analysis

Analysis ranges

(maximum frequencies)

1500, 3000, 6,000, and 12,000 and

24,000 RPM

Window type

Flat top

FFT resolution

400 lines

Signal Conversion (Vibration Inputs)

Channel configuration

options

Sensor type - Model 7310 Velocimeter

Coupling

Type - ac

High-pass filter

3-pole Chebyshev, -3 dB @ 3 Hz

Analog-to-digital

converter type

13-bit

Spurious free dynamic

range

> 50 dB

Input ranges

0 to 380 mV peak (20 IPS)

13841 Rev A

15

Page 32

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Characteristic

Specifications (continued)

Input sensitivity

19 mV/IPS peak

Signal Conversion (Magnetic Pickup Inputs)

Input frequency range

100 to 50,000 RPM

RPM accuracy

0.15%

Input voltage range

0.5V to 12.0V peak nominal, diode

protected

Coupling

Type - dc

Interface Specifications

Vibration transducer

2-each, Model 7310 Velocimeter

(19 mV/IPS sensitivity)

Magnetic pickup/

tachometer

2-each, pulse input, magnetic pickup or

logic type

PC or printer

1 serial, RS-232, 9600 baud

Accessory power

4-each, D-cell batteries, reverse-polarity,

circuit-protected and fused

Physical Particulars

Dimensions (including

mounting flanges)

Nominal measurements (in inches) are

• Height - 7.38

• Width - 7.25

• Depth - 1.81

Weight

3.5 lb nominal

13841 Rev A

16

Page 33

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Characteristic

Specifications (Continued)

Mating connector type

(PC to printer)

D-sub, 9-pin

Power requirement

3 to 6.4 Vdc, 250 mA

Battery life (typical)

40 hr

Case material

Aluminum alloy

Environmental Conditions

Temperature

0°C to 50°C

Electromagnetic

interference (EMI)

susceptibility and

radiated emissions

standards

Industrial Electronic Control Equipment

Class certified to

• Class Standard EN50081-2

• Standard EN50082-2

Characteristic

Specifications

Basic Specifications

Data storage capacity

1 Mb

Built-in test (BIT)

coverage

Memory check and calibration on power

up; user-initiated tests (with STATUS key)

check battery and sensor power

NOTE: Errors are logged to a

printable fault log.

2.3.2 Vibrex 2000 Plus

Specifications

The table, starting below, lists complete technical specifications

for the Vibrex 2000 Plus system.

13841 Rev A

17

Page 34

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Characteristic

Specifications (Continued)

Date and time stamping

Yes

Log (data) files contents and formats

Balance jobs, log book, balance, spectrum,

fault log, all in ASCII format

Compatible software

(ground based)

Honeywell V2K Download and V2K Plot

programs

Basic Performance

Frequency range

0 to 10,000 Hz

Accuracy

±.5dB, from 5 Hz to 500 Hz; ±1dB, from

500 Hz to 10,000 Hz

Acquisition capability

2 vibration and 2 tachometer (azimuth)

Balance Measurements

Phase units

Hours and minutes

Phase resolution

2 min or 1°

Phase accuracy

±15°

Balance frequency range

120 to 30,000 RPM

Spectrum Analysis

Analysis ranges

(maximum frequencies)

1200, 3000, 6000, 12,000, 30,000, 60,000,

120,000, 300,000 and 600,000 RPM

Window type

Flat top

FFT resolution

400 lines

Signal Conversion (Vibration Inputs)

13841 Rev A

18

Page 35

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Characteristic

Specifications (Continued)

Channel configuration

options

Sensor type - Model 7310 Velocimeter

Coupling

Type - ac

High-pass filter

3-pole Chebyshev, -3.0 dB @ 1.5 Hz

Analog-to-digital

converter type

13-bit

Spurious free dynamic

range

> 50 dB

Input ranges

0 to 380 mV peak (20 IPS)

Input sensitivity

19 mV/IPS peak

Signal Conversion (Magnetic Pickup Inputs)

Input frequency range

100 to 50,000 RPM

RPM accuracy

0.15%

Input voltage range

0.5V to 12.0V peak nominal, diode

protected

Coupling

Type - dc

Interface Specifications

Vibration transducer

2-each, Model 7310 Velocimeter

(19 mV/IPS sensitivity)

Magnetic pickup/

tachometer

2-each, pulse input, magnetic pickup or

logic type

PC or printer

1 serial, RS-232, 9600 baud

13841 Rev A

19

Page 36

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Characteristic

Specifications (Continued)

Accessory power

4-each, D-cell batteries, reverse-polarity,

circuit-protected and fused

Physical Particulars

Dimensions (including

mounting flanges)

Nominal measurements (in inches) are

• Height - 7.38

• Width - 7.25

• Depth - 1.81

Weight

3.5 lb nominal

Mating connector type

(PC to printer)

D-sub, 9-pin

Power requirement

3 to 6.4 Vdc, 250 mA

Battery life (typical)

40 hr

Case material

Aluminum alloy

Environmental Conditions

Temperature

0°C to 50°C

Electromagnetic

interference (EMI)

susceptibility and

radiated emissions

standards

Industrial Electronic Control Equipment

Class certified to

• Class Standard EN50081-2

• Standard EN50082-2

13841 Rev A

20

Page 37

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Characteristic

Specifications

Basic Specifications

Data storage capacity

1 Mb

Built-in test (BIT)

coverage

Memory check and calibration on power

up; user-initiated tests (with STATUS key)

check battery and sensor power

NOTE: Errors are logged to a

printable fault log.

Date and time stamping

Yes

Log (data) files contents and formats

Balance jobs, log book, balance, spectrum,

fault log, all in ASCII format

Compatible software

(ground based)

Honeywell V2K Download and V2K Plot

programs

Basic Performance

Frequency range

0 to 10,000 Hz

Accuracy

±.5dB, from 5 Hz to 500 Hz; ±1dB, from

500 Hz to 10,000 Hz

Acquisition capability

4 vibration and 2 tachometer (azimuth)

Balance Measurements

Phase units

Hours and minutes

Phase resolution

2 min or 1°

2.3.3 Enhanced Vibrex 2000 Plus

Specifications

The table, starting below, lists complete technical specifications

for the Enhanced Vibrex 2000 Plus system.

13841 Rev A

21

Page 38

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Characteristic

Specifications (Continued)

Phase accuracy

±15°

Balance frequency range

120 to 30,000 RPM

Spectrum Analysis

Analysis ranges

(maximum frequencies)

1200, 3000, 6000, 12,000, 30,000, 60,000,

120,000, 300,000 and 600,000 RPM

Window type

Flat top

FFT resolution

400 lines

Signal Conversion (Vibration Inputs)

Channel configuration

options

Sensor type - Model 7310 Velocimeter

Coupling

Type - ac

High-pass filter

3-pole Chebyshev, -3.0 dB @ 1.5 Hz

Analog-to-digital

converter type

13-bit

Spurious free dynamic

range

> 50 dB

Input ranges

0 to 380 mV peak (20 IPS)

Input sensitivity

19 mV/IPS peak

Signal Conversion (Magnetic Pickup Inputs)

Input frequency range

100 to 50,000 RPM

RPM accuracy

0.15%

13841 Rev A

22

Page 39

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Characteristic

Specifications (Continued)

Input voltage range

0.5V to 12.0V peak nominal, diode

protected

Coupling

Type - dc

Interface Specifications

Vibration transducer

2-each, Model 7310 Velocimeter

(19 mV/IPS sensitivity)

Magnetic pickup /

Tachometer / Fastrak

2-each, pulse input, magnetic pickup or

logic type

PC or printer

1 serial, RS-232, 9600 baud

Accessory power

4-each, D-cell batteries, reverse-polarity,

circuit-protected and fused

Physical Particulars

Dimensions (including

mounting flanges)

Nominal measurements (in inches) are

• Height - 7.38

• Width - 7.25

• Depth - 1.81

Weight

3.5 lb nominal

Mating connector type

(PC to printer)

D-sub, 9-pin

Power requirement

3 to 6.4 Vdc, 250 mA

Battery life (typical)

40 hr

Case material

Aluminum alloy

Characteristic

Specifications (Continued)

13841 Rev A

23

Page 40

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Environmental Conditions

Temperature

0°C to 50°C

Electromagnetic

interference (EMI)

susceptibility and

radiated emissions

standards

Industrial Electronic Control Equipment

Class certified to

• Class Standard EN50081-2

• Standard EN50082-2

13841 Rev A

24

Page 41

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

13841 Rev A

25

Page 42

Chapter 2 – System Overview

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

13841 Rev A

26

Page 43

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page..

Chapter 3

3.0

GETTING STARTED

This chapter explains the basic features of the Vibrex 2000 and

Vibrex 2000 Plus Digital Dynamic Balancer/Analyzer systems

and tells how to get started out in using them. Chapter 3 contains

the following sections:

3.1 Getting Started: Introduction ............................................. 27

3.2 Basic Features ................................................................... 28

3.3 Printing Data ..................................................................... 36

3.1 Getting Started: Introduction

This chapter gives a general explanation of how to get started

using the Vibrex 2000 and Vibrex 2000 Plus systems. In general,

the basic and startup features of both systems are the same.

Where there are differences between the two Vibrex units, they

are explained in detail.

Basic features of the Vibrex 2000 and Vibrex 2000 Plus include

13841 Rev A

27

Page 44

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Liquid-crystal display (LCD) with eight text lines

Keypad (16 dedicated keys and 4 context keys)

Input channels (vibration and azimuth/frequency)

Printing feature (explained in a separate section)

See Section 3.2 “Basic Features” for a diagram of the front of the

Vibrex unit.

3.2 Basic Features

This section explains basic operating features that the Vibrex

2000 and Vibrex 2000 Plus offer the user.

Diagram - The illustration below shows a picture of the Vibrex

2000 unit. Except for the logo, the Vibrex 2000 Plus is identical.

Use this diagram to locate the operating features explained in this

chapter.

13841 Rev A

28

Page 45

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

13841 Rev A

29

Page 46

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

3.2.1 Display

The Vibrex 2000 and Vibrex 2000 Plus use an LCD screen on

the front panel, for visual output. This screen subdivides into

eight lines of text.

CAUTION: In extreme temperatures, the display may turn

black (too hot), or blank (too cold). In hot climates, covering

the display from direct sunlight is generally sufficient to

prevent the screen from becoming unreadable. In cold weather

climates, it is advisable to keep the Vibrex unit in a warm

enough place (near or above freezing if possible) to ensure its

continued use.

3.2.1.1

Adjusting Screen Contrast

With the Vibrex unit powered up, use the raised buttons on the

arrowheads to the right of the display to adjust screen contrast

for easy viewing.

The display’s contrast changes with changes in temperature. As

the unit warms, the screen stabilizes at a darker setting than

viewed when powered up initially. Small corrections, using the

arrowhead buttons, restore the screen to a comfortable viewing

contrast. The user may use the contrast keys at any time.

3.2.1.2

Screen Operations

The Vibrex unit’s display has the following operational

characteristics:

13841 Rev A

30

Page 47

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Plain brackets ([ ]) display to indicate choices for alpha or

numeric (alpha-numeric) entries. The user may edit the

information between the brackets.

Generally, a cursor blinks inside the brackets, indicating the

space is ready for the appropriate type of data entry.

Angle brackets (< >) indicate that the user has

preprogrammed choices. Press the adjacent context key to

cycle through the available choices.

Up (^) or down (v) arrows on the left margin indicate there is

more information that can be displayed, than the eight lines

shown. Press the context key next to the arrowhead to see

the remaining information.

3.2.1.3

Self-Test Screen

The unit automatically performs a built-in test (BIT) every time

it powers up. Important characteristics of this test are

The self-test does not check the cables or sensors attached to

those cables.

The Self-test screen displays directly after the user powers

up the unit, telling the user that the BIT is taking place. If

there are no problems, the Main Menu screen displays after a

few seconds.

If the BIT discovers any problems, see Section 6.4

“Troubleshooting” for details on troubleshooting.

3.2.2 Keypad

The Vibrex 2000 series have a simple, easy-to use keypad on the

front panel, for entering data and doing operations.

13841 Rev A

31

Page 48

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

This keypad has the following general types of keys:

Alpha-numeric

Dedicated

Context

3.2.2.1

Alpha-Numeric Keys

Use the keys in the unit’s alpha-numeric keypad for entering

numbers, letters, and some symbols.

To enter the indicated number (numeral one in the example

below), press the desired key once. To enter a letter, press the

desired key several times until the display cycles to the desired

letter.

For example, to enter a number one in the display, press the 1

KEY one time. To enter a desired letter, using this key, do one of

the following actions:

For A, press the 1 KEY twice.

For B, press the 1 KEY three times.

For C, press the 1 KEY four times.

NOTE: In this user guide, plain BOLD CAPS appear in print

to show a dedicated key on the Vibrex unit. Italic BOLD CAPS

13841 Rev A

32

Page 49

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

indicate a context key.

Use the same actions with all the alpha-numeric keys. For

another example, the 2 KEY includes the letters D, E, and F. For

the number two, press this key once. For D, press the 2 KEY

twice, for E three times, and so on.

3.2.2.2

Dedicated Keys

The Vibrex 2000 and Vibrex 2000 Plus have several dedicated

keys that perform often-used functions. Find these keys next to

the alpha-numeric keypad.

The following list names the dedicated keys and gives their uses:

ON/OFF The power button see Section 5.2

“Beginning Operation”

START Analogous to the Enter (Return) key on a

personal computer (PC). It initiates actions

based on prompts the user sees on the

display or accepts changes and edits already

made.

GO BACK Functions like the PC Escape key or

Windows Cancel button. It returns the

screen display to the last screen shown or

returns the display to the Main Menu screen.

CAUTION: In most screens the GO BACK key undoes changes

and edits already made. Pressing this key erases data entered.

REVIEW Reviews data and solutions that were part of

a previous exercise, for example, a propeller

balance or spectrum.

13841 Rev A

33

Page 50

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

RPM A

RPM B

PRINT Offers selections of data in the memory that

the user can print. For details on the printing

feature, see Section 3.3 “Printing Data.

SPACE Acts as a multi-functional key. Use it as a

space when entering information, changing

signs for numbers, and entering slashes. The

user may also use it to return directly to the

main menu. This function is available only

on inactive screens, that is, screens with no

active revolutions per minute (RPM) or test.

3.2.2.3

Context Keys

There are four unlabeled keys to the left of the display. These are

the context keys. One or more of these keys may be active when

there is a pointer on the display next to the key on the front

panel.

These keys perform operations relevant to the screen currently

displayed, for example, data entry, channel selections, or making

other choices.

3.2.3 Channel Configuration

The table below shows the Vibrex 2000 and Vibrex 2000 Plus

units’ channel configuration choices.

13841 Rev A

34

Page 51

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Velocimeter No. 1

1A

1B

Velocimeter No. 2

2A

2B

RPM A

RPM B

Velocimeter No. 1

(902-18701-1)

1A

1B

Velocimeter No. 2

(902-18701-1)

2A

2B

Velocimeter No. 3

(902-18701-2)

3A

3B

For example, selecting configuration 1A means the Vibrex unit

is using channels No. 1 and A. The channel names shown in the

previous table represent the following values:

Numbers refer to the Velocimeter (vibration) transducer

channel(s) the Vibrex unit is using and show values in IPS.

Letters refer to the photocell or magnetic pickup (azimuth)

channel(s) being used and show values in RPM.

Choosing a Channel Entry - As many times as necessary,

press the context key next to the screen display line that contains

the angle brackets, until the desired channel entry displays.

Additional Channels on Enhanced Vibrex 2000 Plus – this

unit also allows the selection of two additional channels using

optional multi-channel adaptor cable (part number 902-18701X). The table below shows the Enhanced Vibrex 2000 Plus units’

channel configuration choices.

13841 Rev A

35

Page 52

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Velocimeter No. 4

(902-18701-2)

4A

4B

3.3 Printing Data

The Vibrex 2000 and Vibrex 2000 Plus allow the user to print

hard-copy readouts of collected data or status information. The

systems print through an RS-232 serial port on the connector

subpanel. Because of the large selection of serial printers, it is

impossible to address every setup for every printer. For details,

refer to any appropriate PC and/or printer manual that pertains to

the user’s computer system.

3.3.1 Direct Serial Printing

To connect the Vibrex unit to a Seiko Model DPU-414 printer,

connect the nine-pin DBA female cable that terminates against a

9- to 25-pin male adapter. Use an adapter that has the No. 5 pin

of the 9-pin connector switched to the No. 7 pin of the 25-pin

connector.

This switching can occur on the adapter or in the 9- to 9-pin

cable or in the 9- to 25-pin connector. This type of setup works

for most other serial printers as well.

13841 Rev A

36

Page 53

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Parameter

Setting

Baud rate

9600

Number of bits

8

Number of stop bits

1

Parity

None

Xon/Xoff

Supported

3.3.1.1

Basic Settings

See the following table for a list of the basic settings to use for

downloading data from the Vibrex 2000 or Vibrex 2000 Plus to

any printer and/or serial interface.

3.3.1.2

Connect a Seiko Model DPU-414 printer to the Vibrex 2000 or

Vibrex 2000 Plus, as follows:

1. Connect the printer cable No. 610-449 to the Vibrex unit and

2. Turn ON the printer and press the ONLINE button if the on-

3. Select the desired information to be printed in the Vibrex

Connecting the Printer

the printer.

line light- emitting diode (LED) is not illuminated.

unit and press PRINT.

NOTE: If the batteries are depleted in the DPU-414,

connect the ac wall adapter (No. 610-463 for 110 Vac or

No. 610-463A for 220 Vac) and operate the printer

normally.

13841 Rev A

37

Page 54

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Setting DIP Switches - The start-up settings and input method

can be set by the DIP switches (DIP SW). Set the printer’s DIP

switches, as follows:

1. Slide the power switch to OFF.

2. Slide the power switch to ON while pressing the ONLINE

button. Release the ONLINE button after a list of the current

settings starts printing out.

3. The printout of the current settings is followed by the

prompt:

Continue? : Push ‘On-line SW’

Write? : Push ‘Paper feed SW’

To change the DIP SW settings, push the ONLINE

button, and go

to step 4.

To leave the DIP SW settings unchanged, push the

FEED button, and go to step 6.

4. Dip SW1 is printed, prompting the input of new settings

for switch No. 1 through 8 of DIP SW-1.

NOTE: Always input either ON or OFF for every setting in

order for switch No. 1 through 8 because the DIP SW set

mode cannot be canceled once it is initiated.

• ON can be set by pushing the ONLINE button

once and OFF by pushing the FEED button

once.

• The setting is printed out after the ONLINE or

FEED button is pushed to confirm the new

setting.

5. As soon as switch No. 8 is set, the printer once again

prompts with Continue? or Write?, and stops. Repeat

step 3 for DIP SW-2 and -3.

NOTE: The on-line lamp lights when the ONLINE button is

13841 Rev A

38

Page 55

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

pressed and the off-line lamp when the FEED button is

pressed to allow confirmation of the button operation.

6. After the FEED button is pushed, the on-line and off-line

lamps alternately blink, and the new settings are written to

memory. When the printer finishes writing everything to

memory, the DIP SW setting complete message is

printed out, and the printer returns to the on-line mode.

7. As soon as switch No. 8 of DIP SW-3 is set, the printer

writes the settings to memory regardless of which button

(ONLINE or FEED) is pushed. See the following page for an

example of the settings printout.

CAUTION: Never turn off the printer while it is writing the

new settings to memory. Always wait until the DIP SW

setting complete message is printed, then turn the

power off.

13841 Rev A

39

Page 56

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Dip Switch Setting Printout Example

[DIP SW setting mode] Dip SW-1

1 (OFF) : Input = Serial

2 (ON : Printing Speed = High

3 (OFF) : Auto Loading = OFF

4 (ON) : Auto LF = ON

5 (OFF) : Setting Command = Disable

6 (OFF) : Printing

7 (ON) : Density

8 (ON) : = 100%

Dip SW-2

1 (ON) : Columns = 40

2 (ON) : User Font Back-up = ON

3 (ON) : Character Select = Normal

4 (ON) : Zero = Normal

5 (ON) : International

6 (ON) : Character

7 (ON) : Set

8 (OFF) : U.S.A.

Dip SW-3

1 (ON) : Data Length = 8 bits

2 (ON) : Parity Setting = No

3 (ON) : Parity Condition = Odd

4 (ON) : Busy Control = H/W Busy

5 (OFF) : Baud

6 (ON) : Rate

7 (ON) : Select

8 (ON) : = 9600 bps

Continue? : Push ‘On-line SW’

Write? : Push ‘Paper feed SW'

DIP SW setting complete!!

13841 Rev A

40

Page 57

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

3.3.2 Printing With a PC

This section explains how to print in a Windows 95, Windows

98, or Windows NT environment. Connect the Vibrex 2000 or

Vibrex 2000 Plus to the PC with a nine-pin serial connector,

used by most computers.

NOTE: From this point on, the text uses Windows when

referring to all three of these operating systems.

For an illustration of the general printing setup with a PC, see the

diagram below.

13841 Rev A

41

Page 58

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

3.3.2.1

Downloading Data

To print data from the Vibrex unit, using a PC, the user must

first download that data from the unit to an IBM-compatible PC

running Windows. Do this action by using the V2K Download

Software program that comes with the Vibrex kit.

NOTE: First, make sure you installed the V2K Download

Part No. 14129-1software on your PC, following the

provided instructions.

13841 Rev A

42

Page 59

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

Download Vibrex 2000 or Vibrex 2000 Plus data, using the V2K

Download Software program, as follows:

1. Connect the Vibrex unit to your PC, using the 9-pin DBA

female connector to a 9-pin DBA female connector. This is

called a straight- through cable connection (see the diagram

Section 3.3.2 Printing With a PC).

2. Run the V2K Download software in your PC.

3. Power up the Vibrex unit.

4. Click on the OPEN NEW button in the V2K Download

software.

5. Type in the name of the file you wish to contain the data,

then click on OPEN.

6. Click on CAPTURE FROM V2K.

7. At the Vibrex unit, select the data to be stored from the Print

or Review menu.

8. Press PRINT or START.

9. Downloaded data is displayed on screen. Data is now stored

in the PC for later use.

CAUTION: Attempting to download data without the V2K

Download Software program is cumbersome and may

result in lost data. Contact your Honeywell provider for

ordering information for this program, if you do not

already have it.

For more details on how to download data to a PC, see the V2K

Download Software User Guide.

The following example shows an annotated sample Vibrex unit

printout on hard copy:

13841 Rev A

43

Page 60

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

3.3.3 Reading FFT Data

One of the types of data available to print in the Vibrex 2000 or

Vibrex 2000 Plus spectral data file is called raw FFT. Fast

Fourier transform (FFT) is a method used to record vibration

spectra digitally. An FFT consists of individual bins (also called

13841 Rev A

44

Page 61

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

lines). Each bin contains a percentage of the RPM range. The

user may determine the actual RPM range contained in each bin

by dividing the spectrum range (in RPM) by the number of bins.

The Vibrex unit uses a 400-bin FFT setup. If the frequency range

selected is 0 to 24,000 RPM, each bin consists of 60 RPM worth

of vibration energy. As the RPM range goes down, the bins hold

fewer RPM, so the RPM accuracy is generally improved for the

spectrum. When the user prints raw FFT data, both the header

information containing the annotation, channels numbers, RPM

range, day/date code, and so on are recorded with the vibration

energy in each bin.

The number in each line of the FFT as printed in the Terminal or

Hyperterminal program is equal to the inches per second (IPS)

divided by 1000. For example, if the range selected was 24,000

RPM, the 9th bin (9th numerical entry after the 0, would

correspond to 540 RPM in the spectra and the 200th bin (line)

would correspond to 12,000 RPM.

The value in storing the vibration measurements as FFT data lies

in its PC versatility. The user can create plots and graphs of the

data, using the Honeywell V2K Plot Software program. For

details on how to use this program to plot FFT data, see the V2K

Plot Software User Guide.

3.3.4 Using the PRINT Key

Only data that has been stored to history and the operating Status

screen may be printed. The two methods of finding desired

information to be printed are

Global printing from the PRINT key

Printing with the REVIEW and PRINT keys

This section explains these printing modes.

13841 Rev A

45

Page 62

Chapter 3 – Getting Started

Honeywell Confidential: Use or disclosure of information on this page is subject to the restrictions on the title page.

3.3.4.1