Page 1

FC1-OI-EN h 2017-11-16

as of 2017-11-16

From Basic System version 03-22

Flow Computer

Device Series enCore FC

FC1, MC1

Manual

Operating Instructions

Page 2

Page 2 of 120

Operating Instructions

enCore FC

Disclaimer

The information contained in this document is the property of Honeywell. The following

information is to be used exclusively for the intended purpose. This document or its

contents may not be reproduced, published or made available to a third party in whole

or in part without the express permission of Elster GmbH.

All information and descriptions in this Operating Instructions have been compiled

after careful examination. Nevertheless, errors cannot be completely excluded.

Honeywell therefore does not guarantee the completeness or correctness of the

content. The manual cannot be understood as a guarantee of product properties. It

also describes properties that are only available as an option.

Honeywell is in no case liable to third parties for direct, special or consequential

damages. The information in this document is subject to change without notice.

With regard to extended product liability, the data and material properties listed may

only be regarded as guidelines and must always be checked and, if necessary,

corrected on a case-by-case basis. This is particularly true where safety aspects are

concerned.

Further support is available from your local office or representative. The address can

be found on the Internet or at Honeywell.

The passing on and reproduction of this manual or parts thereof is only permitted with

the written permission of Honeywell.

If the product described herein is improperly handled, repaired or modified by

unauthorized persons or if Honeywell spare parts other than original spare parts are

used, the warranty will be void.

This product may contain or be derived from third party material, including software.

Third party material may be subject to license terms, notices, restrictions and

obligations of the Licensor. The licenses, notices, restrictions and obligations, if any,

may be found in the materials accompanying the Product, in the documents or files

containing the material of third parties, in a file called third_party_licenses on the

media containing the Product, or at www.honeywell.com/ps/thirdpartylicenses.

Copyright © 2017 Elster GmbH, D-55252 Mainz-Kastel. All rights reserved.

Dortmund, October 2017

Page 3

enCore FC

Operating Instructions

Page 3 of 120

Contents

1 General Information 8

1.1 The enCore/enSuite Concept 8

1.2 Scope of Delivery 9

2 About these Instructions 11

2.1 Target Group Definition 11

2.2 The enCore FC Manual at a Glance 13

2.3 Text Labelling 15

2.3.1 Presentation of Safety and Risk Instructions 15

2.3.2 Paragraph Formats 16

2.3.3 Character Formats 17

2.3.4 Character Formats in Flow Charts 18

2.4 Limitation of Liability 19

2.5 Applicable Standards and Guidelines 20

3 Security considerations for your network 21

4 Safety 23

4.1 General Safety Instructions 23

4.2 Intended Use 25

4.3 Unacceptable use while Impaired 26

4.4 Operator Liability 26

5 Design and Function 28

5.1 Functional Description of enCore FC devices 28

5.1.1 Number of Streams and their Flow Directions 29

5.1.2 International Standards 29

5.2 Device Description 30

5.3 Operation Panel 31

5.3.1 Device Keys 32

5.3.2 Touch Screen 32

Page 4

Contents

Page 4 of 120

Operating Instructions

enCore FC

5.3.3 Operation and Navigation within the Display 33

5.3.4 Security Switch 36

5.3.5 LEDs 36

5.4 Interfaces (Rear Side of Device) 39

5.5 Available Process Boards 40

5.5.1 ExMFE5 Process Board 40

5.5.2 MFE7 Process Board 43

5.5.3 MSER4 Process Board 43

5.5.4 ESER4 Process Board 44

5.5.5 MFA8 Process Board 44

6 Assembly Instructions 45

6.1 Line Connection 45

6.2 Power Supply and Grounding 47

6.3 Installation and Conversion of Process Boards 48

6.3.1 Insert a Process Board in a Free Board Slot 49

6.4 Connection Diagrams 54

6.4.1 General Recommendations for Signal and Data Cable 55

6.4.2 Pt100 (EEx i) via ExMFE5 Board 57

6.4.3 Pt100 (EEx d) via MFE7 Board 58

6.4.4 Analog Measurement Transmitter (EEx i) via ExMFE5 Board 59

6.4.5 Analog Measurement Transmitter (EEx d) via MFE7 Board

(without barrier) 60

6.4.6 Analog Measurement Transmitter (EEx i) via MFE7 Board

(barrier in sink mode) 61

6.4.7 Analog Measurement Transmitter (EEx i) via MFE7 Board

(barrier in source mode) 62

6.4.8 HART Measurement Transmitter (EEx i) via ExMFE5 Board 63

6.4.9 HART Measurement Transmitter (EEx d) via MFE7 Board

(without barrier, internal Power Supply) 65

6.4.10 HART Measurement Transmitter (EEx d) via MFE7 Board

(without barrier, external Power Supply) 67

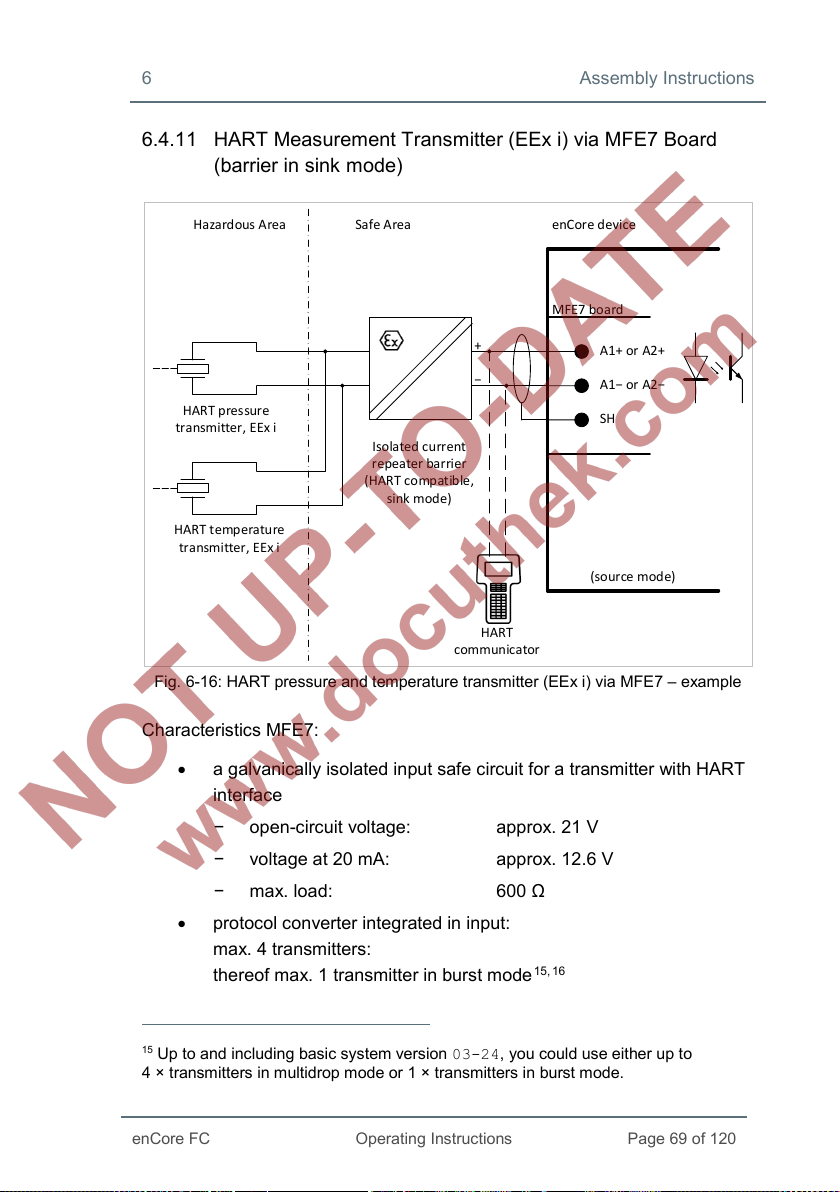

6.4.11 HART Measurement Transmitter (EEx i) via MFE7 Board

(barrier in sink mode) 69

Page 5

Contents

enCore FC

Operating Instructions

Page 5 of 120

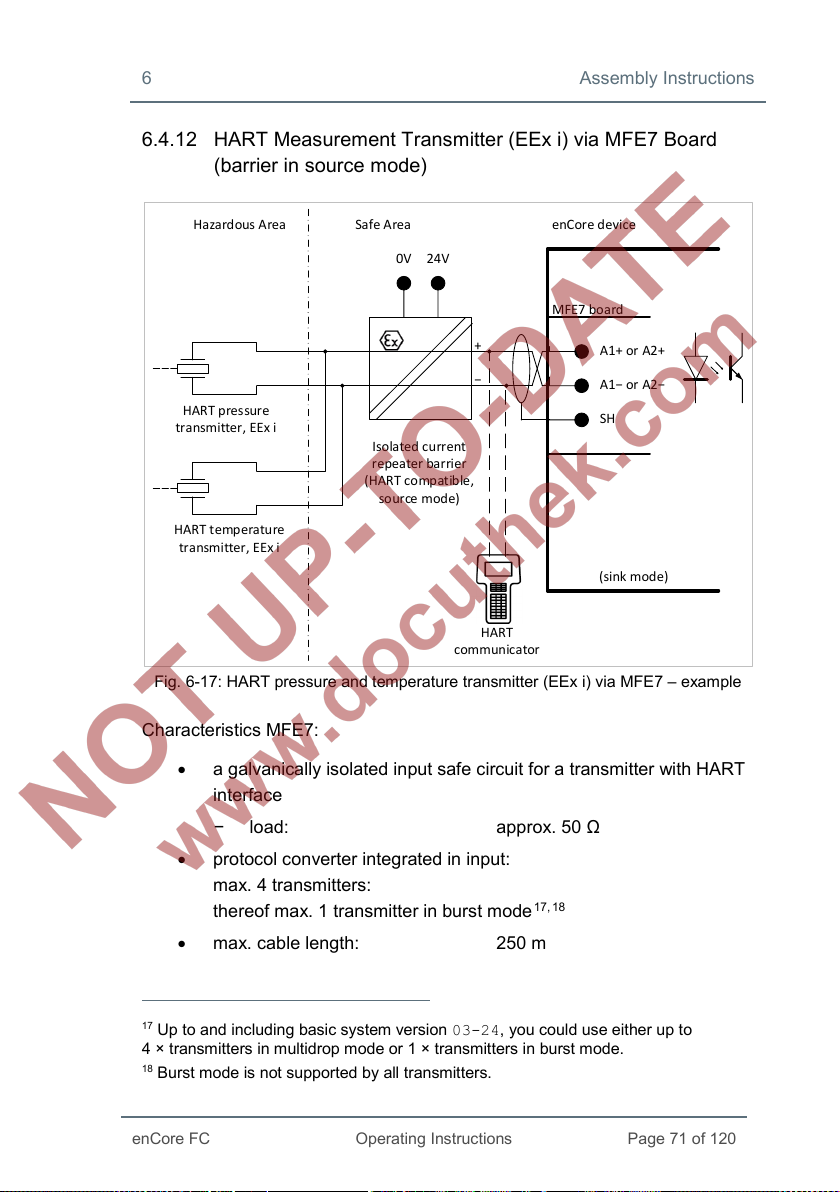

6.4.12 HART Measurement Transmitter (EEx i) via MFE7 Board

(barrier in source mode) 71

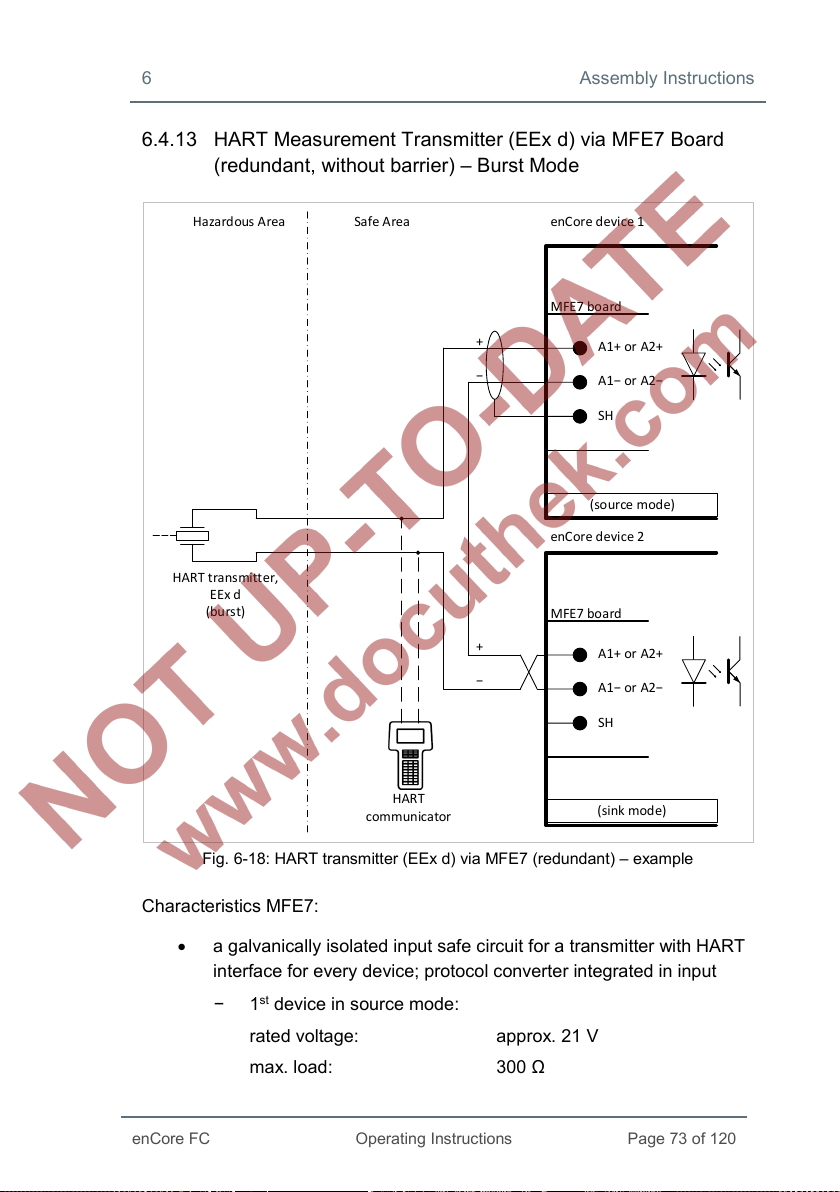

6.4.13 HART Measurement Transmitter (EEx d) via MFE7 Board

(redundant, without barrier) – Burst Mode 73

6.4.14 HART Measurement Transmitter (EEx i) via MFE7 Board

(redundant, barrier in source mode) – Burst Mode 75

6.4.15 HART Measurement Transmitter (EEx d) via MFE7 Board

(Multi-Master, without barrier) – Multidrop Mode (from Basic

System 03-25) 77

6.4.16 HART Measurement Transmitter (EEx i) via MFE7 Board

(Multi-Master, barrier in source mode) – Multidrop Mode (from

Basic System 03-25) 79

6.4.17 Gas Meter (Turbine): Encoder Index, 2 LF/HF Sensors (EEx i)

via ExMFE5 Boards 81

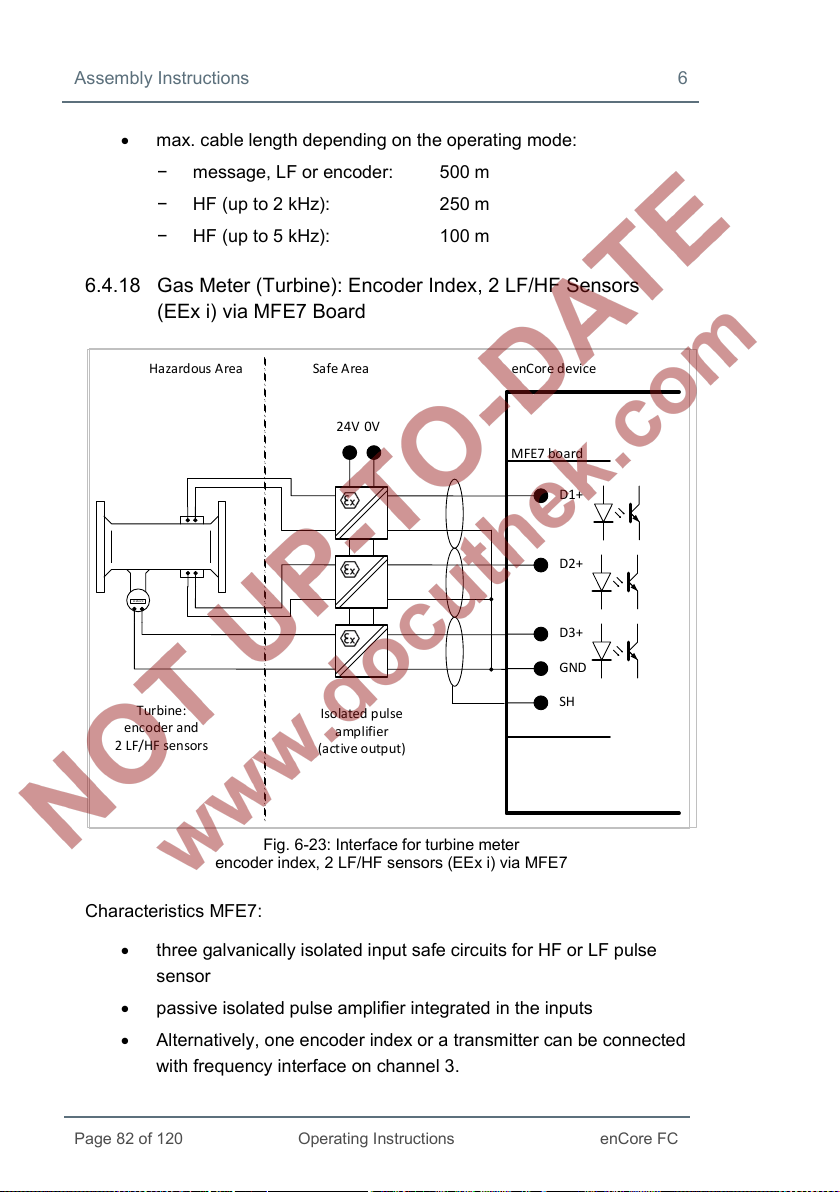

6.4.18 Gas Meter (Turbine): Encoder Index, 2 LF/HF Sensors (EEx i)

via MFE7 Board 82

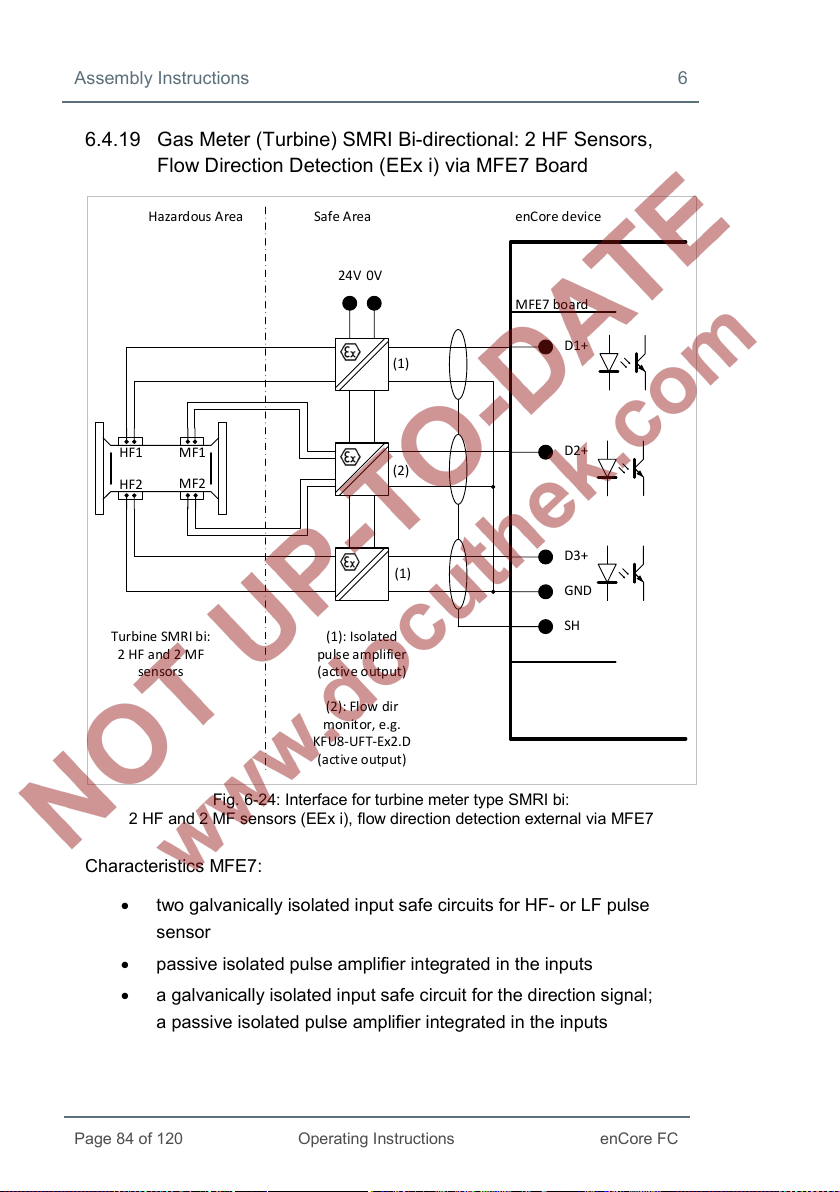

6.4.19 Gas Meter (Turbine) SMRI Bi-directional: 2 HF Sensors, Flow

Direction Detection (EEx i) via MFE7 Board 84

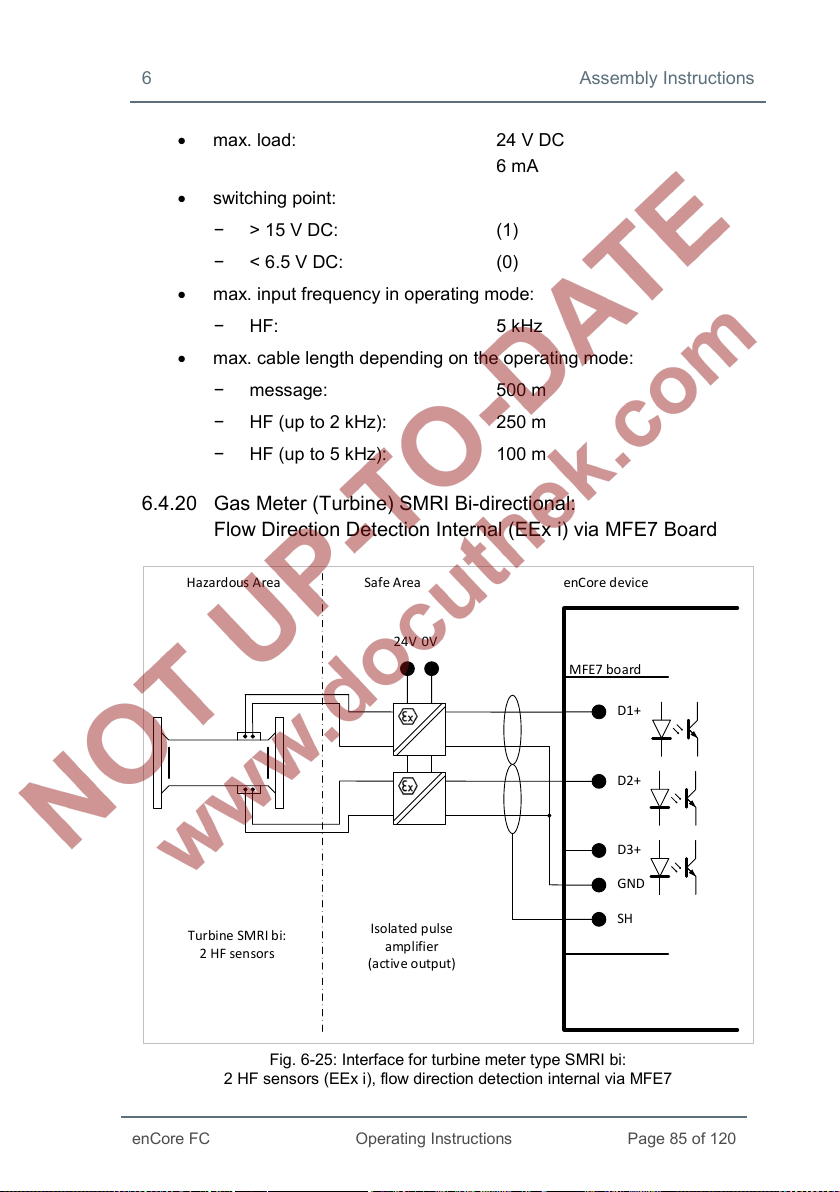

6.4.20 Gas Meter (Turbine) SMRI Bi-directional:

Flow Direction Detection Internal (EEx i) via MFE7 Board 85

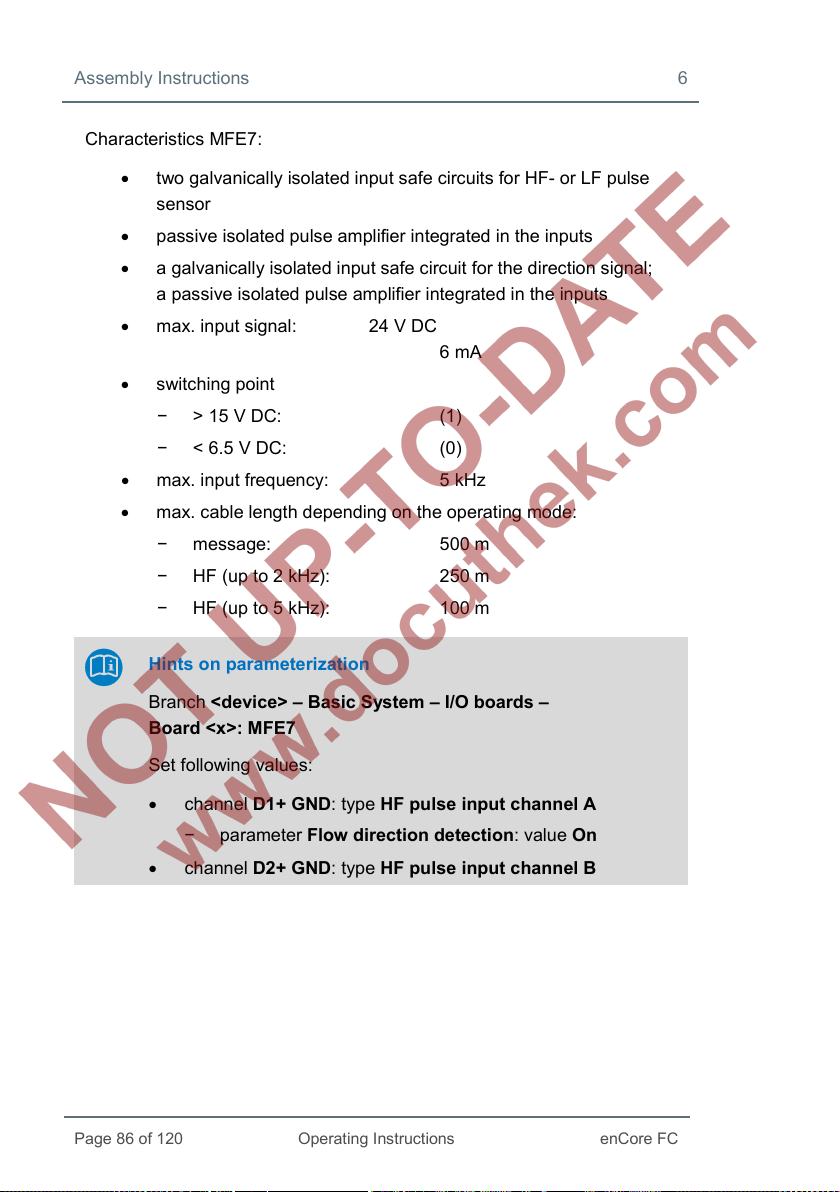

6.4.21 Q.Sonic Ultrasound Gas Meter: Serial RS485 (EEx d) via

MFE7 Board 87

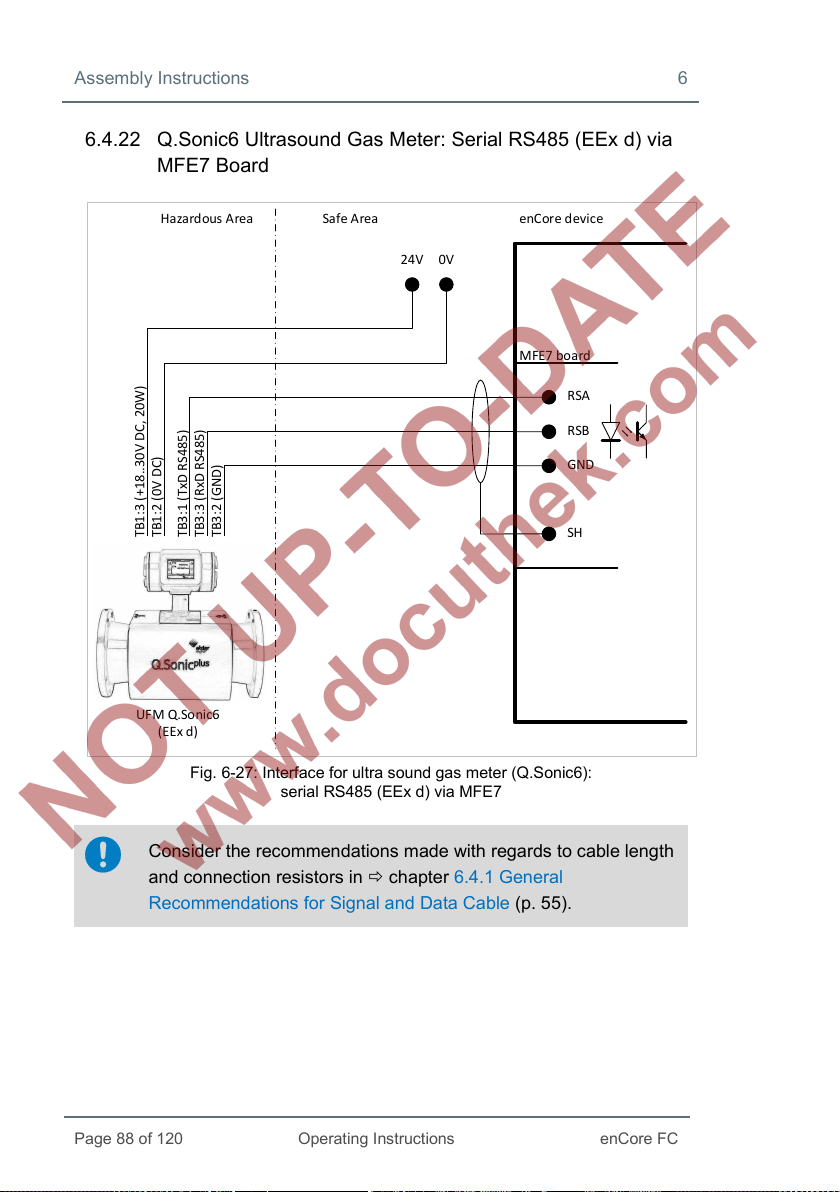

6.4.22 Q.Sonic6 Ultrasound Gas Meter: Serial RS485 (EEx d) via

MFE7 Board 88

6.4.23 FLOWSIC600 Ultrasound Gas Meter: Serial RS485 (EEx d)

via MFE7 Board 89

6.4.24 Serial Interface through COM Port (CPU or MSER4-Board) 90

6.4.25 Analog Output over MFA8 Board (0/4 ... 20 mA) 92

6.4.26 Message Output over MFA8 Board 93

6.4.27 Pulse Output over MFA8 Board 95

7 Device Configuration and Commissioning 96

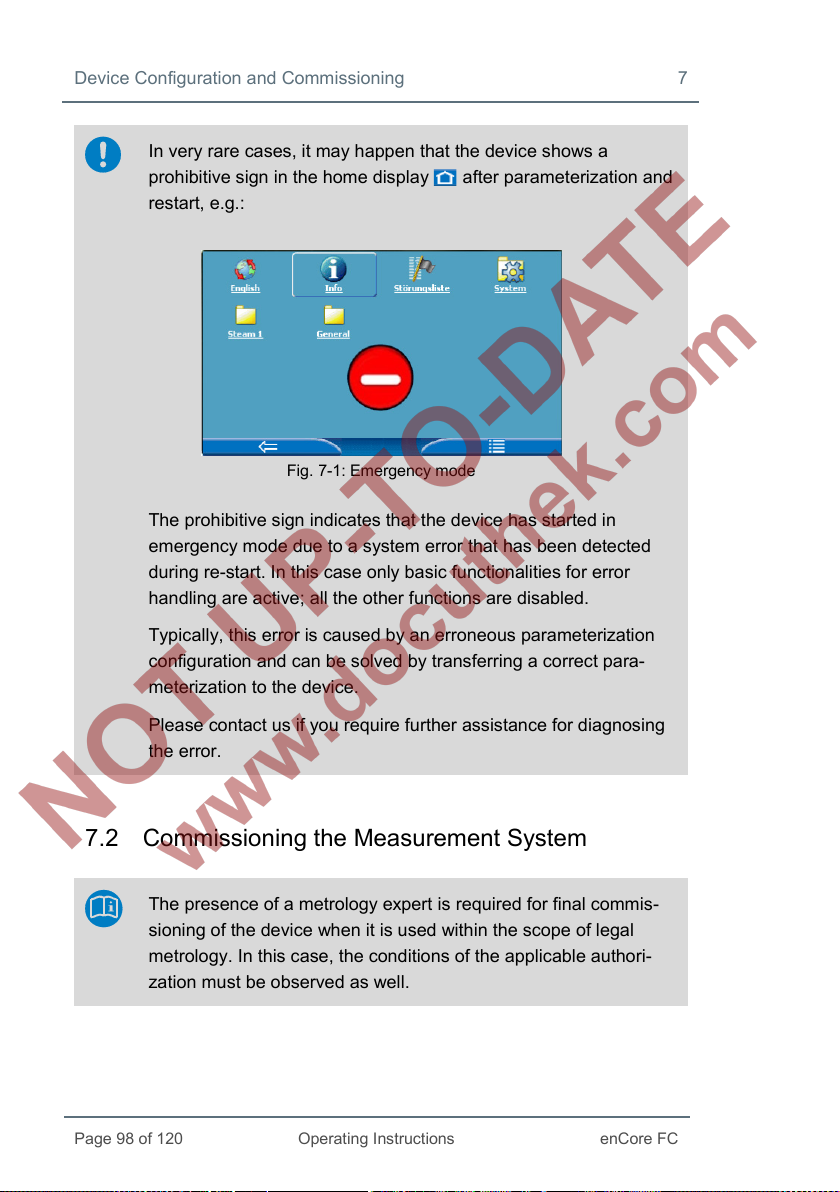

7.1 Device Configuration 97

7.2 Commissioning the Measurement System 98

7.2.1 Checking Device Settings 99

7.2.2 Checking Measurement Input Values 99

Page 6

Contents

Page 6 of 120

Operating Instructions

enCore FC

7.2.3 Checking Output Signals 99

7.2.4 Checking Digital Communication (Modbus, etc.) 99

7.2.5 Checking Measurements and Calculations 99

7.2.6 End of Commissioning (from Basic System 03-24) 99

7.2.7 Sealing (if necessary) 100

8 Maintenance 101

8.1 Battery Replacement 101

8.1.1 Changing Batteries 102

8.2 Cleaning 104

8.3 Technical Assistance Center (TAC) 105

8.4 Replacement Parts and Accessories 105

8.5 Warranty Conditions 106

9 Decommissioning/Disposal 107

9.1 Storage 107

9.2 Disposal 108

10 Technical Data 109

10.1 General Information 109

10.2 Input channels 110

10.3 Outputs 111

10.4 Interfaces for Digital Communication 112

10.5 Data Protocols 112

10.5.1 Data protocols and its TCP default port (Ethernet) 113

10.6 Housing dimensions 114

10.6.1 1/3 housing width 114

10.6.2 1/2 housing width 115

11 FAQs 116

11.1 How to report a security vulnerability to Honeywell? 116

11.2 Limitations for multidrop and burst mode up to basic system version ≤

03-24 116

Page 7

Contents

enCore FC

Operating Instructions

Page 7 of 120

12 Index 118

13 Appendix 120

Page 8

Operating Instructions

1 General Information

1.1 The enCore/enSuite Concept

enCore is the name of an Elster product platform for advanced measure-

ment devices. All enCore devices are based on the same hardware

components and software concepts. Both the hardware and software of

enCore devices have a modular design; the configuration of the process

board equipment and the arrangement of software components are variable.

On one hand, the software components consist of basic functionalities,

which are provided by the Basic System with its System Function Blocks

(abbreviated as: SFBs), and on the other hand consist of application-related

functionalities, which come with different Application Function Blocks

(abbreviated as: AFB). Owing to this modular design principle, each device

can be optimally adapted to individual requirements.

enSuite is the name of the PC software supporting all enCore devices along

with a number of other Elster devices. The enSuite software provides tools

for configuration, parameterization, diagnosis, software downloads and other

services.

Parameterization in enSuite

Please note that the changes that you make in parameterization

of enSuite become active in the device only when you activate the

action Transfer parameterization to device and after the enCore

device restarts (automatically).

volume “Configuration fo Device Software” of enCore FC

manual

Page 8 of 120

enCore FC

Page 9

1 General Information

enCore FC

Operating Instructions

Page 9 of 120

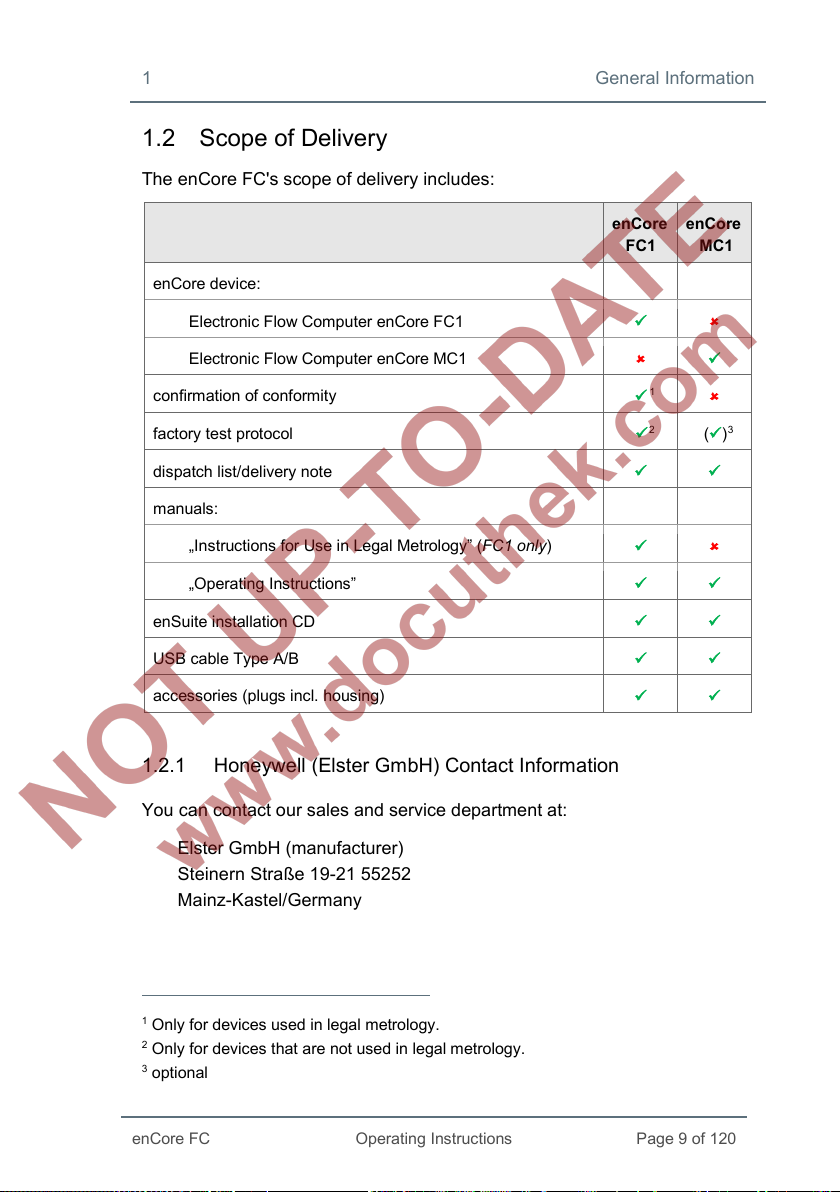

1.2 Scope of Delivery

The enCore FC's scope of delivery includes:

enCore device:

Electronic Flow Computer enCore FC1

Electronic Flow Computer enCore MC1

confirmation of conformity

factory test protocol

dispatch list/delivery note

manuals:

„Instructions for Use in Legal Metrology” (FC1 only)

„Operating Instructions”

enSuite installation CD

USB cable Type A/B

accessories (plugs incl. housing)

1.2.1 Honeywell (Elster GmbH) Contact Information

enCore

FC1

1

2

enCore

MC1

()3

You can contact our sales and service department at:

Elster GmbH (manufacturer)

Steinern Straße 19-21 55252

Mainz-Kastel/Germany

1

Only for devices used in legal metrology.

2

Only for devices that are not used in legal metrology.

3

optional

Page 10

General Information 1

Page 10 of 120

Operating Instructions

enCore FC

Phone: +49 6134 605-0

Email: info@elster.com

Website: www.elster-instromet.com

You can reach our Technical Assistance Center (TAC) at:

Phone: +49 231 937110-88

Email: ElsterSupport@Honeywell.com

Website: www.elster-instromet.com

Page 11

enCore FC

Operating Instructions

Page 11 of 120

2 About these Instructions

The present documentation are the Operating Instructions of the overall

documentation, and describe the assembly, installation, commissioning and

maintenance of the flow computer enCore FC series (called enCore FC

below).

These instructions make it possible to work with the enCore FC in a safe and

efficient manner.

Compliance with all the safety and handling instructions specified in these

Operating Instructions is a prerequisite to working with the enCore FC in a

safe manner and using it properly, and for obtaining accurate measurement

and calculation results.

In addition, compliance is also necessary with the guidelines, standards,

local accident prevention regulations and general safety regulations that

apply for the enCore FC's area of application.

The illustrations in this manual serve to depict the facts that are being

explained, and therefore may differ from the actual design of the enCore FC

depending on the configuration of the device and enSuite.

The data and material properties that are presented below are

guidelines. They must be reviewed for each individual case and

corrected if required.

2.1 Target Group Definition

The present documentation is directed to qualified electricians in the fields of

switch cabinet construction and maintenance, as well as qualified personnel

with specialized knowledge in device assembly and commissioning.

The qualifications for different areas of activity are listed below:

• trained individual

A person, who has been instructed by the plant operator in an

Page 12

About these Instructions 2

Page 12 of 120

Operating Instructions

enCore FC

informational session on the tasks assigned to him or her, and on

possible hazards in case of improper behavior.

• specialist personnel

A person who has the ability, because of his or her technical

training, knowledge and experience, as well as his or her

knowledge of the relevant regulations, to carry out the work

assigned to him or her at the enCore FC, and to recognize and

avoid possible hazards independently.

• gas specialist

A person who has the ability, because of his or her technical

training, knowledge and experience, as well as his or her know-

ledge of the relevant standards and regulations, to carry out work in

gas systems, and to recognize possible hazards independently. A

gas specialist receives training for the specific location in which he

or she works, and is acquainted with the relevant standards and

regulations.

• authorized metrology expert

A person who has the ability and is authorized, because of his or

her technical training, knowledge and experience, to carry out

legally relevant tasks in gas systems within the scope of legal

metrology. An authorized metrology expert is acquainted with the

relevant standards and legal regulations that apply in specific

countries. In the European Union the legally relevant tasks are

executed by designated notified bodies.

• qualified electrician

A person who has the ability, because of his or her technical

training, knowledge and experience, as well as his or her know-

ledge of the relevant standards and regulations, to carry out work in

electrical systems, and to recognize and avoid possible hazards

independently. A qualified electrician receives training for the

specific location in which he or she works, and is acquainted with

the relevant standards and regulations.

Page 13

2 About these Instructions

enCore FC

Operating Instructions

Page 13 of 120

2.2 The enCore FC Manual at a Glance

The manual for the enCore FC device series is modular:

For all device types that can be used in legal metrology, there is a volume

that specifically describes the legally relevant functions and characteristics.

All other volumes of the manual apply to all devices of the enCore FC series,

i.e. they are independent of the device type.

The manual consists of the following volumes:

• “Instructions for Use in Legal Metrology”, enCore FC1 only

This volume focuses on the legally relevant properties and

functions of the FC1 flow computer.

• “Operating Instructions”

This volume describes the assembly, installation, commissioning

and maintenance of all enCore FC devices.

• “Configuration of Device Software”

This volume describes parameterizing devices of the enCore series

with the software system enSuite, the software download and

further services.

• “Basic System with SFBs”

This volume describes the basic system, which provides all basic

functions of the device software. The basic system e.g. manages

the system resources, the I/O boards or the connection to other

devices via digital protocols.

• Functionality of individual Application Function Blocks

Each volume describes the parameterization, function and

operation of each AFB. These volumes always describe the full

range of functions of the respective AFBs.

Page 14

About these Instructions 2

Page 14 of 120

Operating Instructions

enCore FC

Delivery form of the individual volumes

Die Anleitung zur „Verwendung im gesetzlichen Messwesen“ und

die „Betriebsanleitung“ sind Produktbestandteile und werden in

gedruckter Form mit dem Gerät ausgeliefert.

Bewahren Sie diese Dokumente in unmittelbarer Nähe des

enCore FC zur Verwendung für das Fachpersonal der benannten

Stellen sowie für das Installations-, Bedienungs-, Wartungs- und

Reinigungspersonal jederzeit zugänglich auf.

Alle weiteren Bände des enCore FC-Handbuchs können Sie im

PDF-Format aus unserer Docuthek (www.docuthek.com)

herunterladen. Zusätzlich stehen hier die Anleitung zur „Operating

Instructions“ sowie die „Betriebsanleitung“ in digitaler Form zur

Verfügung.

Die Dokumente in der Docuthek werden regelmäßig aktualisiert.

Manuals as product components

The volume “Use in Legal Metrology” and this “Operating

Instructions” are product components and delivered in printed

form with the device. Therefore, these must always be kept in the

immediate vicinity of the enCore FC and easily accessible to the

installation, operational, maintenance and cleaning personnel.

All other volumes of the enCore FC manual can be downloaded

from our Docuthek (www.docuthek.com) in PDF format. In

addition, the instructions for "Use in Legal Metrology" as well as

the "Operating instructions" are available in digital form.

The documents in the Docuthek are regularly updated.

Page 15

2 About these Instructions

enCore FC

Operating Instructions

Page 15 of 120

2.3 Text Labelling

Texts containing different contents are labelled differently. With the help of

following characteristics, you can identify which content of the text is pro-

vided to you:

2.3.1 Presentation of Safety and Risk Instructions

Hazard Warnings

Hazard warnings indicate hazardous situations which may result in material

damage and bodily harm or even death if disregarded.

Hazard warnings are described below:

DANGER WORD!

Type of danger

Consequences in case of non-compliance

Avoiding danger

The danger word signals the hazard level:

• DANGER!

… indicates an imminently hazardous situation that leads to death

or severe injuries.

• WARNING!

… indicates a possibly hazardous situation that may lead to death

or severe injury.

• CAUTION!

… indicates a possibly hazardous situation that may lead to slight

or minor injuries.

• ATTENTION!

… indicates a possibly hazardous situation that may lead to

material damage.

Page 16

About these Instructions 2

Page 16 of 120

Operating Instructions

enCore FC

Safety Instructions

Safety instructions include notes and information which if disregarded may

lead to functions not working correctly or not working at all.

Safety instructions are described below:

Safety instruction (optional)

Safety instruction text

Tips and recommendations

Tips include notes and information that make it easier for the user to operate

the enCore FC.

Tips are described below:

Heading (optional)

Hint text

2.3.2 Paragraph Formats

► This triangle prompts you for an action.

This character will show you the immediate result of your action.

For the enCore FC symbol, the result of your operation is shown in

Example

Multi-row examples are marked by two continuous blue lines and the

keyword “Example”.

running operation of the device after you have transferred an enSuite

parameterization to the device and the device is restarted with this para-

meterization.

Page 17

2 About these Instructions

enCore FC

Operating Instructions

Page 17 of 120

2.3.3 Character Formats

Example Use

Time Service

chapter 2.3.3 Character

Formats (p. 17)

Tab Parameters

[OK]

[F1]

<Modbus AFB >

[Group 1.]Modbus

Names of the individual SFB and AFB soft-

ware elements of the enCore FC.

References to additional information are

marked with an arrow. If the arrow refers to

information within document, these referen-

ces are formated as hyperlinks in blue font.

You directly go to corresponding text pas-

sage by clicking the blue text.

Marking of graphic screen elements or

messages which you find again on the

screen. These include, for example, menu

items, marking of tabs and parameters.

Marking of buttons and keys are additionally

framed with square brackets.

Place holders are specified in angle-

brackets and represent the corresponding,

current value of your system – as in the ex-

ample the name of the Modbus AFB.

Optional information is specified in square

brackets. In the example, Group 1 is shown

only when a group has been created in your

device.

admin1

www.docuthek.com

Texts which you enter in enSuite in the

corresponding field.

links (Hyperlink)

Page 18

About these Instructions 2

Page 18 of 120

Operating Instructions

enCore FC

generated counters

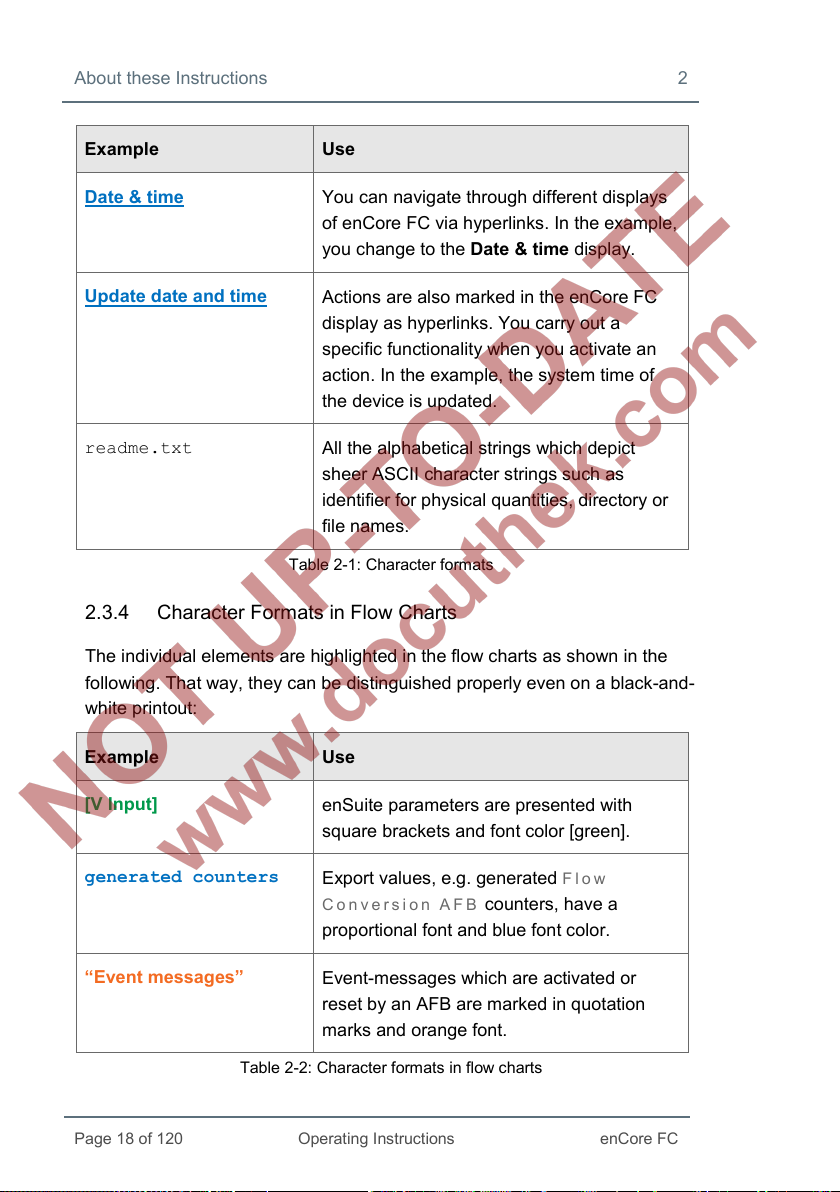

Example Use

Date & time

You can navigate through different displays

of enCore FC via hyperlinks. In the example,

you change to the Date & time display.

Update date and time

Actions are also marked in the enCore FC

display as hyperlinks. You carry out a

specific functionality when you activate an

action. In the example, the system time of

the device is updated.

readme.txt

All the alphabetical strings which depict

sheer ASCII character strings such as

identifier for physical quantities, directory or

file names.

Table 2-1: Character formats

2.3.4 Character Formats in Flow Charts

The individual elements are highlighted in the flow charts as shown in the

following. That way, they can be distinguished properly even on a black-and-

white printout:

Example Use

[V Input]

“Event messages”

enSuite parameters are presented with

square brackets and font color [green].

Export values, e.g. generated Flow

Conversion AFB

counters, have a

proportional font and blue font color.

Event-messages which are activated or

reset by an AFB are marked in quotation

marks and orange font.

Table 2-2: Character formats in flow charts

Page 19

2 About these Instructions

enCore FC

Operating Instructions

Page 19 of 120

2.4 Limitation of Liability

All specifications and instructions in these Operating Instructions were

compiled after taking into consideration the applicable standards and

regulations, the current state of the art and the knowledge and experience

we gained over the years.

The manufacturer assumes no liability for loss due to:

• non-compliance with these Operating Instructions

• unintended use

• use of the device by non-instructed personnel

• unauthorized device modifications

• technical changes

• use of non-authorized replacement parts

The actual scope of delivery may differ from the explanations and de-

scriptions included here in case of special device designs, the use of

additional order options or because of the latest technical changes.

The obligations arranged in the delivery contract apply, as do the General

Terms and Conditions, manufacturer delivery conditions and current legal

regulations that apply at the time the contract was concluded.

Read through these Operating Instructions carefully before

beginning any work to and with the enCore FC, especially before

commissioning the device!

The manufacturer assumes no liability for loss and malfunctions

that result from non-compliance with these instructions.

We reserve the right to make technical changes within the scope of im-

proving performance characteristics and continuous development of the

device.

Page 20

About these Instructions 2

Page 20 of 120

Operating Instructions

enCore FC

2.5 Applicable Standards and Guidelines

The construction, production and operation of the enCore FC is based on

the following standards and guidelines:

4

• EN 12405-1

5

Gas meter – Conversion devices – Part 1: Volume conversion

• EN 61000-6-2

Electromagnetic compatibility – Immunity for industrial environ-

ments

• EN 61000-6-3

Electromagnetic compatibility – Emission standard for residential,

commercial and light-industrial environments

• EN 60079-0

Explosive atmospheres – Equipment – General requirements

• EN 60079-11

Explosive atmospheres – Equipment protection by intrinsic safety “i”

• EN 60079-17

Explosive atmospheres – Electrical installations inspection and

maintenance

• EN 60079-25

Explosive atmospheres – Intrinsically safe systems

4

Further applicable standards and guidelines result from the specific fields of

application of the individual device.

5

Only applies to converters of the enCore FC series.

Page 21

Page 21 of 120

Operating Instructions

enCore FC

3 Security considerations for your network

enCore FC devices are used in modern accounting infrastructures and

network control technology with the task of transmitting process information

such as counters, measurements and messages to an accounting center or

control station. Such a connection represents a significant security risk and

therefore careful consideration must be given to the design.

Reporting a security issue to Honeywell

As soon as you encounter a possible security gap of a Honeywell

product, please report it directly to Honeywell.

FAQs 11.1 How to report a security vulnerability to Honeywell?

(p. 116)

Enforce a strong password policy

here are different attacks on passwords today, so you should follow the

T

best practices for managing your passwords. Here are some of the best

practices:

• Always change default passwords.

• Choose strong passwords.

Use a combination of uppercase and lowercase letters, numbers,

and special characters when assigning a password.

In addition, protection increases with the password length. A strong

password consists of at least 8 characters.

Document deviations of the best practices

If the system does not allow one of the best practices to be

followed this should be documented. For example: maybe you do

not allow the special character "=" in the password.

Page 22

Security considerations for your network 3

Page 22 of 120

Operating Instructions

enCore FC

Preventing unauthorized external access using a firewall

To reduce the risk to your network, we highly recommend to include a

firewall or some other mechanism to limit the network traffic between the

(external) central accounting center resp. control station and the (internal)

network of the gas measuring plant.

Furthermore, we recommend to allow protocols and ports only that are

actually used for data exchange with the external network, e.g. by adding

these to the white list of the firewall ( 10.5.1 Data protocols and its TCP

default port (Ethernet), p. 113).

For example:

Fig. 3-1: Router and firewall between measurement plant and control station

plus data exchange via Modbus TCP in a trusted network – example

Page 23

Operating Instructions

4 Safety

4.1 General Safety Instructions

WARNING!

Risk of explosion

A risk of explosion exists if the enCore FC device (FC1 or

MC1) is improperly assembled and connected!

• The enCore FC device must be installed outside of Ex zones

0, 1 and 2.

• Assemblies which are authorized as associated category ib

electrical equipment with intrinsically safe electrical circuits in

accordance with EN 60079-11 can be installed in the enCore

FC device, e.g. input boards with the label ExMFE5. The

enCore FC device is therefore suitable for connecting to

transmitters, pulse and signal sensors that are located in the

potentially explosive area e.g. in zone 1. A mixed connection

of intrinsically safe and non-intrinsically safe circuits is not

permitted for these assemblies.

• Only measurement transmitters and pulse sensors that follow

at least the requirements of the intrinsically safe protection

class [Ex ib Gb] II C may be connected to the ExMFE5

assembly terminals provided for that purpose.

• When using input boards of ExMFE5 type, it is not permitted

(according to the EC type examination certificate ATEX) to

include more than one ExMFE5 board (i.e. more than one

associated apparatus) into the same intrinsically safe circuit.

• All signals from the potentially explosive area (zone 0,

zone 1, zone 2) must be regulated using suitable Ex isolators

if they are connected to some other assembly group that is

not the input board ExMFE5.

enCore FC

Page 23 of 120

Page 24

Safety 4

Page 24 of 120

Operating Instructions

enCore FC

• The regulations in the relevant standards, especially

EN 60079-0, EN 60079-11, EN 60079-17 and EN 60079-25,

must be obeyed unconditionally.

Safety and warning instructions

The following safety and warning instructions must be observed

unconditionally:

• Any individual appointed to perform work on or with the

enCore FC device must read and understand these

Operating Instructions before beginning work. This also

applies if the individual concerned has already worked with

such a device or a similar one, or was instructed by the

manufacturer.

• In order to avoid risks and to ensure that the enCore FC

device performs in an optimal manner, no changes or

modifications that were not expressly authorized by the

manufacturer may be performed on the device.

• The enCore FC device must not be exposed to temperatures

below −25°C or above +60°C during storage.

• A temperature that is between −10°C and +55°C must be en-

sured while the enCore FC device is being operated.

• The power supply in enCore FC device is over a 24 V DC,

and this supply must be protected externally using a 1A time-

delay fuse.

• The grounding system is connected to the power supply

socket PE for potential equalization.

• The threshold values listed in the certificates of conformity

(e.g. EC type examination certificate ATEX) for the boards to

be connected to the device must be observed.

The threshold values that are listed in the certificate of conformity

for the applicable authorization must be observed while using the

device within the scope of legal metrology e.g. of EU type

examination certificate (MID).

Page 25

4 Safety

enCore FC

Operating Instructions

Page 25 of 120

For a description of the process boards refer to chapter 5.5

Available Process Boards (p. 40).

4.2 Intended Use

The enCore FC device is designed and constructed exclusively for its

intended use as described here.

All enCore FC devices are process computer which process information on

the externally connected measurement devices and signal sensors.

The specific intended use varies according to device type:

• enCore FC1

The FC1 is mainly used for (fiscal) gas measurement. In this case,

the main task of the device is to convert the gas volume measured

at the measurement conditions to base conditions (volume

conversion). Moreover, the corresponding thermal energy and

mass can be calculated. The measured and/or calculated data can

be recorded and monitored.

The FC1 can also carry out other functions and calculations

depending on the scope of application (e.g. volume or mass flow

conversion for liquids).

Moreover, the FC1 can also be used to measure, record and

monitor other process signals.

• enCore MC1

The MC1 is a process computer, which processes the information

from the connected external measurement devices and signal

sensors. This device type is mainly used in industrial gas measure-

ment. The main tasks of the device are monitoring and controlling

processes. The measured and/or calculated data can be recorded

and archived.

Page 26

Safety 4

Page 26 of 120

Operating Instructions

enCore FC

Compliance with all the specifications in these “Operating Instructions” also

falls under the device's intended use.

Any use of the enCore FC that goes beyond or deviates from its intended

use is considered a misuse of the device, and may lead to hazardous

situations.

Claims of any kind due to loss resulting from non-intended use of the device

are excluded.

Adhering to age and profession-specific regulations

When selecting a personnel, make sure to comply with the

specific regulations of the overall gas system that concern age

and occupation.

4.3 Unacceptable use while Impaired

Individuals whose ability to react is impaired, e.g. because of drugs, alcohol

or medication, are not permitted to operate, assemble and configure the

device. The operator is responsible for the careful selection of the personnel.

4.4 Operator Liability

The enCore FC is used in industrial applications. The operator of the device

is therefore subject to legal obligations of occupational health and safety.

In addition to the safety instructions in these Operating Instructions, current

regulations of safety, accident prevention and environmental protection must

be observed for the enCore FC area of application.

The following items especially apply:

• The operator must ensure compliance with the current regulations

of safety, accident prevention and environmental protection that

apply for the overall system in which the enCore FC is integrated.

• The operator must keep himself or herself informed of the

applicable occupational health and safety regulations, and

determine, over the course of a risk assessment, the additional

Page 27

4 Safety

enCore FC

Operating Instructions

Page 27 of 120

risks that arise from the specific working conditions when the

enCore FC is being used. The operator must include these items in

the form of Operating Instructions for the enCore FC.

• The operator must review, over the entire operational life of the

enCore FC, whether the Operating Instructions prepared by him or

her correspond to the current status of the bodies of regulations,

and adapt the instructions if necessary.

• The operator must definitively regulate and establish the respon-

sibilities for enCore FC assembly, connection, commissioning,

operation and maintenance.

• The operator must ensure that all employees who work with the

enCore FC have read and understood these Operating Instructions.

In addition, the operator must train these personnel at regular

intervals and inform them of the risks involved with the device.

• The operator of the overall system in which the enCore FC is

integrated must provide the personnel with the required protective

equipment.

In addition, the operator is responsible for ensuring the enCore FC is always

in a technically perfect state. The following therefore apply:

• The operator must ensure that the installation and maintenance

work described in these Operating Instructions are performed

properly.

• The operator must have all safety installations checked regularly to

ensure they function correctly and are complete.

Page 28

Operating Instructions

5 Design and Function

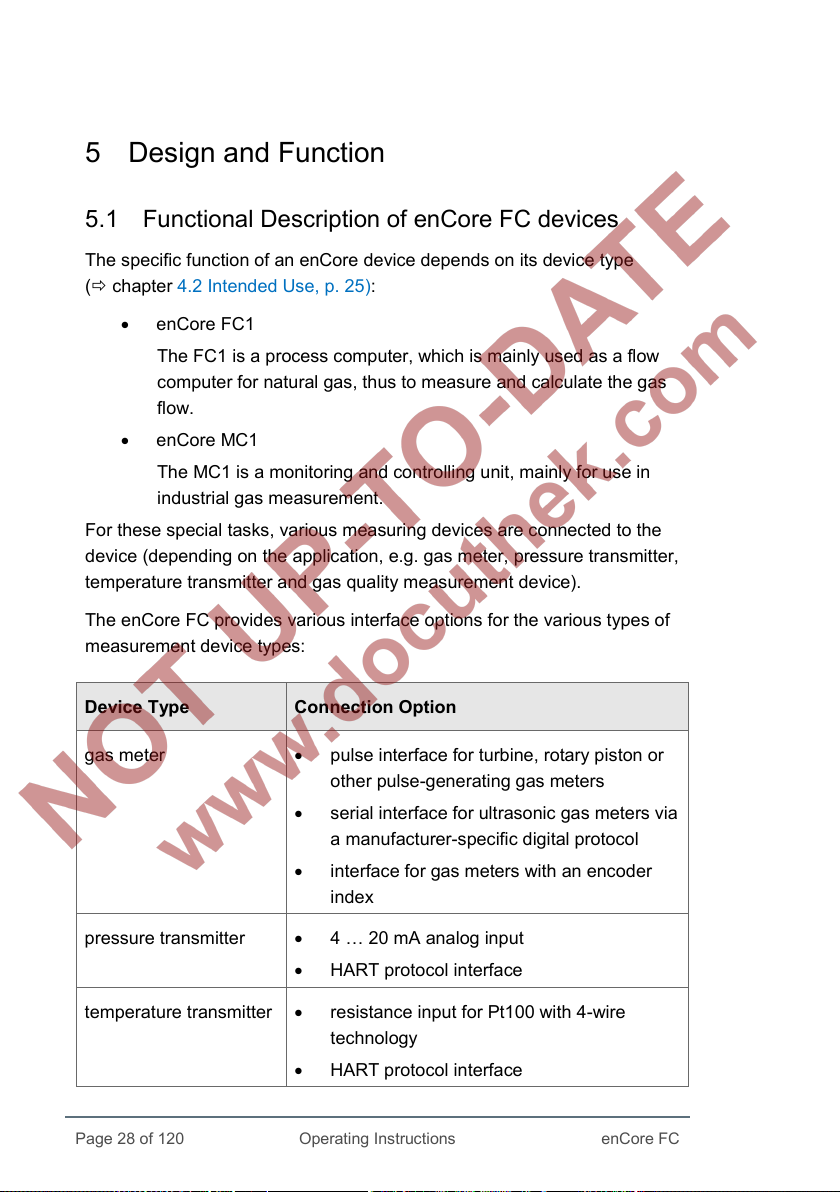

5.1 Functional Description of enCore FC devices

The specific function of an enCore device depends on its device type

( chapter 4.2 Intended Use, p. 25):

• enCore FC1

The FC1 is a process computer, which is mainly used as a flow

computer for natural gas, thus to measure and calculate the gas

flow.

• enCore MC1

The MC1 is a monitoring and controlling unit, mainly for use in

industrial gas measurement.

For these special tasks, various measuring devices are connected to the

device (depending on the application, e.g. gas meter, pressure transmitter,

temperature transmitter and gas quality measurement device).

The enCore FC provides various interface options for the various types of

measurement device types:

Device Type Connection Option

gas meter • pulse interface for turbine, rotary piston or

other pulse-generating gas meters

• serial interface for ultrasonic gas meters via

a manufacturer-specific digital protocol

• interface for gas meters with an encoder

index

pressure transmitter • 4 … 20 mA analog input

• HART protocol interface

temperature transmitter • resistance input for Pt100 with 4-wire

technology

• HART protocol interface

Page 28 of 120

enCore FC

Page 29

5 Design and Function

enCore FC

Operating Instructions

Page 29 of 120

Device Type Connection Option

gas quality

measurement devices

• serial interface

• LAN interface

Table 1: Interface options

5.1.1 Number of Streams and their Flow Directions

The number of streams and their flow directions are variable since device

hardware and software can be extended. This number depends upon the

number of board slots available, individual hardware settings and the soft-

ware configuration.

5.1.2 International Standards

Flow Computers of the enCore FC device series support the following

international standards for the calculation of the gas characteristics which

are used for flow conversion. Which standards are supported in detail varies

according to device type:

Value Selectable Calculation Standard

compressibility • AGA8-92 DC (ISO 12213-2)

• SGERG-88 (ISO 12213-3)

• AGA-NX19 mod

• AGA-NX19 mod BR.KOR.3H

• AGA-NX19 GOST

• GOST 30319.2-2015

• GOST 30319.3-2015

gas density, relative density • AGA8-92 DC (ISO 12213-2)

• ISO 6976

• GOST 30319.3-2015

heating value, Wobbe index • ISO 6976

Page 30

Design and Function 5

Page 30 of 120

Operating Instructions

enCore FC

Table 2: International standards

Depending on the field of application, the enCore FC supports other

European or international standards as well.

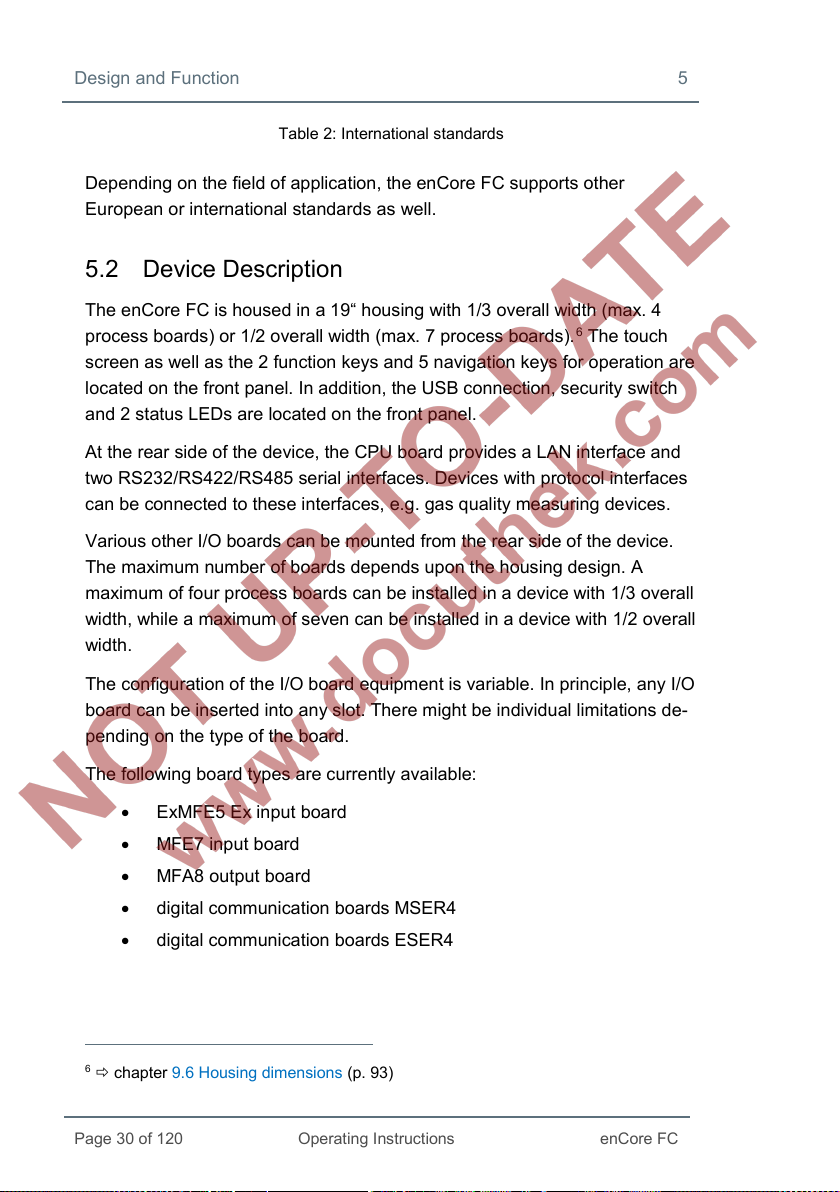

5.2 Device Description

The enCore FC is housed in a 19“ housing with 1/3 overall width (max. 4

process boards) or 1/2 overall width (max. 7 process boards).

screen as well as the 2 function keys and 5 navigation keys for operation are

located on the front panel. In addition, the USB connection, security switch

and 2 status LEDs are located on the front panel.

At the rear side of the device, the CPU board provides a LAN interface and

two RS232/RS422/RS485 serial interfaces. Devices with protocol interfaces

can be connected to these interfaces, e.g. gas quality measuring devices.

Various other I/O boards can be mounted from the rear side of the device.

The maximum number of boards depends upon the housing design. A

maximum of four process boards can be installed in a device with 1/3 overall

width, while a maximum of seven can be installed in a device with 1/2 overall

width.

6 The touch

The configuration of the I/O board equipment is variable. In principle, any I/O

board can be inserted into any slot. There might be individual limitations de-

pending on the type of the board.

The following board types are currently available:

6

chapter 9.6 Housing dimensions (p. 93)

• ExMFE5 Ex input board

• MFE7 input board

• MFA8 output board

• digital communication boards MSER4

• digital communication boards ESER4

Page 31

5 Design and Function

enCore FC

Operating Instructions

Page 31 of 120

1

2

3

4

5

6

7

5

7

2

6

1 2 4

3

For a detailed description of the process boards and possible limitations for

the board equipment refer to chapter 5.5 Available Process Boards

(p. 40).

5.3 Operation Panel

Fig. 5-1: enCore FC operation panel – example enCore FC1

navigation keys

function keys

touch screen

security switch

power-LED

status-LED

USB connection for PC connection

Page 32

Design and Function 5

Page 32 of 120

Operating Instructions

enCore FC

2

3

4

5

1

2

3

4

5

5.3.1 Device Keys

Two function keys are arranged below the touch screen. Pressing one of

these keys activates the display button positioned directly over it.

1

up

down

left

right

Fig. 5-2: Navigation keys

enter

The navigation keys (up, down, left, right, enter) are provided for navigation

purposes in device menus and displays. They provide an alternative option

to the touch screen for operating the display. An acoustic signal is given out

when a key is pressed.

5.3.2 Touch Screen

All the key functions can be executed from the touch screen. An acoustic

signal indicates that a function was activated.

Re-calibration of the touch screen

Elster calibrates the touch screen before delivery. In case a re-

calibration should be necessary, select in the home display of

the device Info – Display calibration and follow the in-

structions on the device.

You can cancel he calibration at any time with the back key

and then restart the calibration.

In case of erroneous calibration you can always use the function

and navigation keys of the device.

Page 33

5 Design and Function

enCore FC

Operating Instructions

Page 33 of 120

or AFB ...

5.3.3 Operation and Navigation within the Display

Display test

Using the display test, you can check whether the device display of the

enCore FC is working correctly.

To run the display test, …

► … switch to the home display if necessary.

► Double-click the symbol to open the Info display.

► Start the test with the action Display test.

During test mode, all pixels of the login area are alternately black and

white.

► End the test with or .

Different types of device displays

Main display is the name of the first display of an AFB or a functionality of

the basic system; it shows the most important results of this functionality.

Depending on the AFB or functionality, further information is displayed in

subordinate device displays.

The basic display is displayed immediately after the device is started. If no

operation is performed during a preset time, the device switches back to the

basic display automatically. For some device types, it is parameterizable

which display is used as basic display.

Changing the „basic display“

For most device types (e.g. devices that are intended for the use

in legal metrology), the basic display is fixed. In case that the

basic display is not fixed, you can parameterize it in enSuite for a

device parameterization in node Displays on tab Basic

display editor:

To define a display as basic display, select …

► … from the 1

st

dropdown list Basic display the desired SFB

Page 34

Design and Function 5

Page 34 of 120

Operating Instructions

enCore FC

► ... and from the 2

nd

dropdown list Basic display the display of

this SFB or AFB.

► If necessary, adjust the time (in seconds) without any

operation before ...

• ... the device switches back to the basic display in

parameter Go to basic display after <x> sec.

• ... the brightness of the screen is reduced in parameter

Duration bright display <x> sec.

• ... the screen is turned off in parameter Duration

dimmed display <x> sec.

Home is a special display and shows the software structure of the device. In

enSuite you add further entries to the home display in the parameter

branch Displays on tab Menu-editor – Home fest. Single software

modules (like e.

easily accessible (e.

g. AFBs) and further selected functionalities, which shall be

g. time or language setting), are represented with small

symbols in this display. The symbols are labelled with the name of the

corresponding functionality.

AFBs are labelled with their user-defined names, if parameterized –

otherwise the default name is displayed.

During parameterization, you can group AFBs in user-defined structures.

Each group of AFBs is displayed in a folder <Group name> in the home

display .

Navigating via touch-screen

In general

Two buttons are displayed at the bottom of the touch screen. Depending on

the context, you can use the symbols and or and .

The function of the buttons is as follows:

You switch directly to the home display.

You switch directly to the basic display.

Page 35

5 Design and Function

enCore FC

Operating Instructions

Page 35 of 120

You switch back to the calling display, i.

e. the display that was

previously opened.

The basic display can always be reached with a maximum of two steps –

either by pressing and successively, or by pressing , if this button

is displayed directly.

If the buttons are marked with the checkmark or the X symbol , a user

action has been performed previously (e.

g. setting the system time) and the

device is waiting for a confirmation by the user. User actions can be

accepted with or discarded with .

Navigation options in the „home“ display

You open a folder by touching its symbol in the display; the AFBs grouped in

that folder are shown subsequently.

After having touched the symbol of an AFB or any other selected func-

tionality, the corresponding main display is shown.

Navigation options in other displays

Most device displays show measurement results, status information or

settings.

When operating an enCore FC device, hyperlinks and actions are distin-

guished: Use hyperlinks to navigate through the device's displays and use

actions to perform a specific functionality. Both hyperlinks and actions are

presented in the display with a blue font color and underlined.

If a display contains more lines than can be presented at once, an orange

scroll bar appears at the right edge of the screen.

You can scroll the contents of the display up or down by moving your finger

vertically across the display area (vertical "wiping").

Navigation via keys

The buttons at the lower edge of the touch screen can alternatively be

activated by pressing the associated (hardware) keys located directly

underneath.

Page 36

Design and Function 5

Page 36 of 120

Operating Instructions

enCore FC

You can activate the controls located at the top of the touch screen by using

the [Up], [Down], [Left] and [Right] keys, and activate them by pressing

[Enter].Use the [Up] and [Down] keys to scroll through the contents of a

display. ( chapter 5.3.1 Device Keys, S. 32)

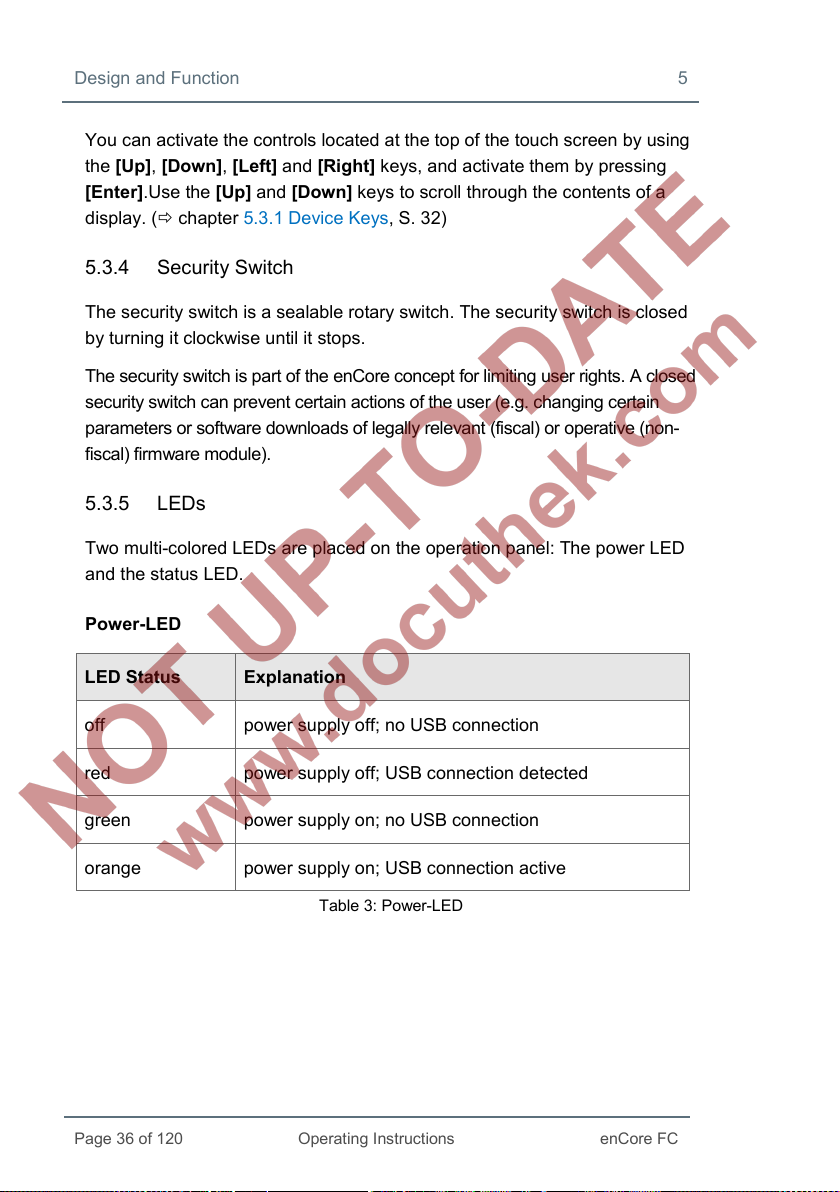

5.3.4 Security Switch

The security switch is a sealable rotary switch. The security switch is closed

by turning it clockwise until it stops.

The security switch is part of the enCore concept for limiting user rights. A closed

security switch can prevent certain actions of the user (e.g. changing certain

parameters or software downloads of legally relevant (fiscal) or operative (non-

fiscal) firmware module).

5.3.5 LEDs

Two multi-colored LEDs are placed on the operation panel: The power LED

and the status LED.

Power-LED

LED Status Explanation

off power supply off; no USB connection

red power supply off; USB connection detected

green power supply on; no USB connection

orange power supply on; USB connection active

Table 3: Power-LED

Page 37

5 Design and Function

enCore FC

Operating Instructions

Page 37 of 120

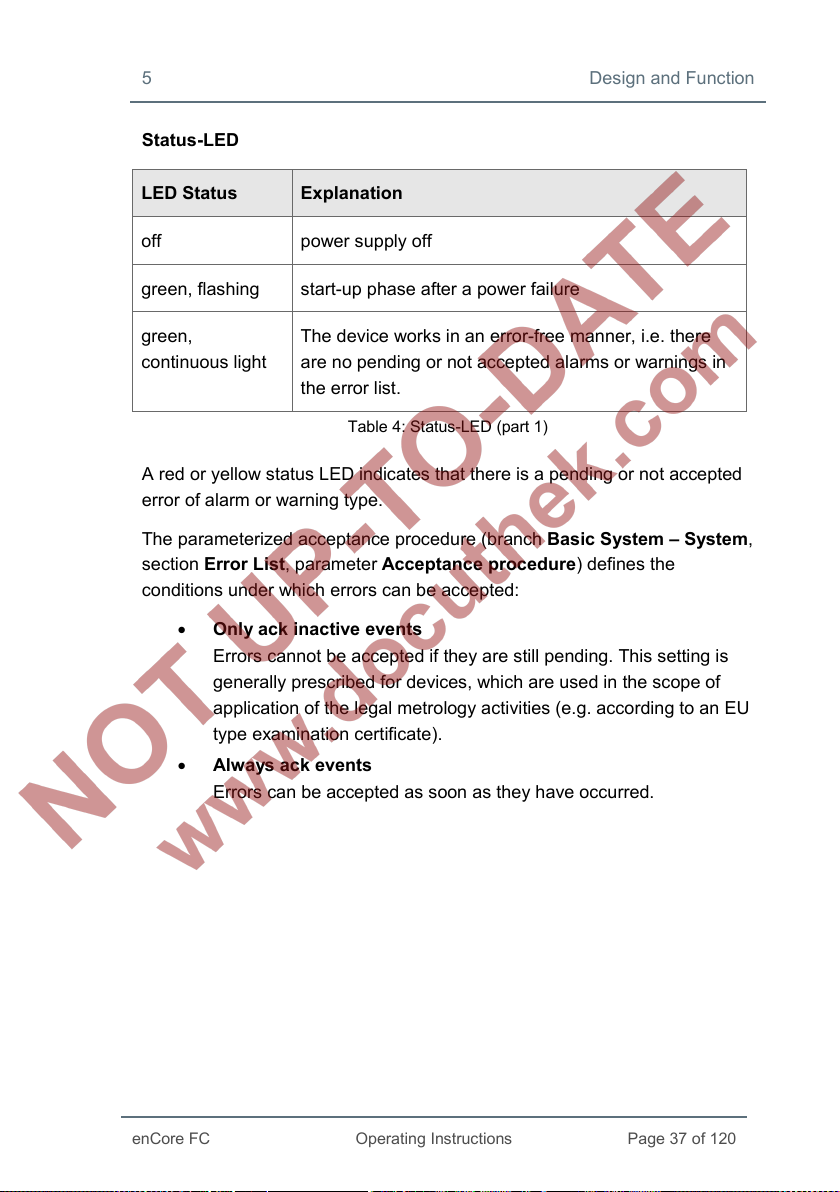

Status-LED

LED Status Explanation

off power supply off

green, flashing start-up phase after a power failure

green,

continuous light

The device works in an error-free manner, i.e. there

are no pending or not accepted alarms or warnings in

the error list.

Table 4: Status-LED (part 1)

A red or yellow status LED indicates that there is a pending or not accepted

error of alarm or warning type.

The parameterized acceptance procedure (branch Basic System – System,

section Error List, parameter Acceptance procedure) defines the

conditions under which errors can be accepted:

• Only ack inactive events

Errors cannot be accepted if they are still pending. This setting is

generally prescribed for devices, which are used in the scope of

application of the legal metrology activities (e.g. according to an EU

type examination certificate).

• Alwa ys ack events

Errors can be accepted as soon as they have occurred.

Page 38

Design and Function 5

Page 38 of 120

Operating Instructions

enCore FC

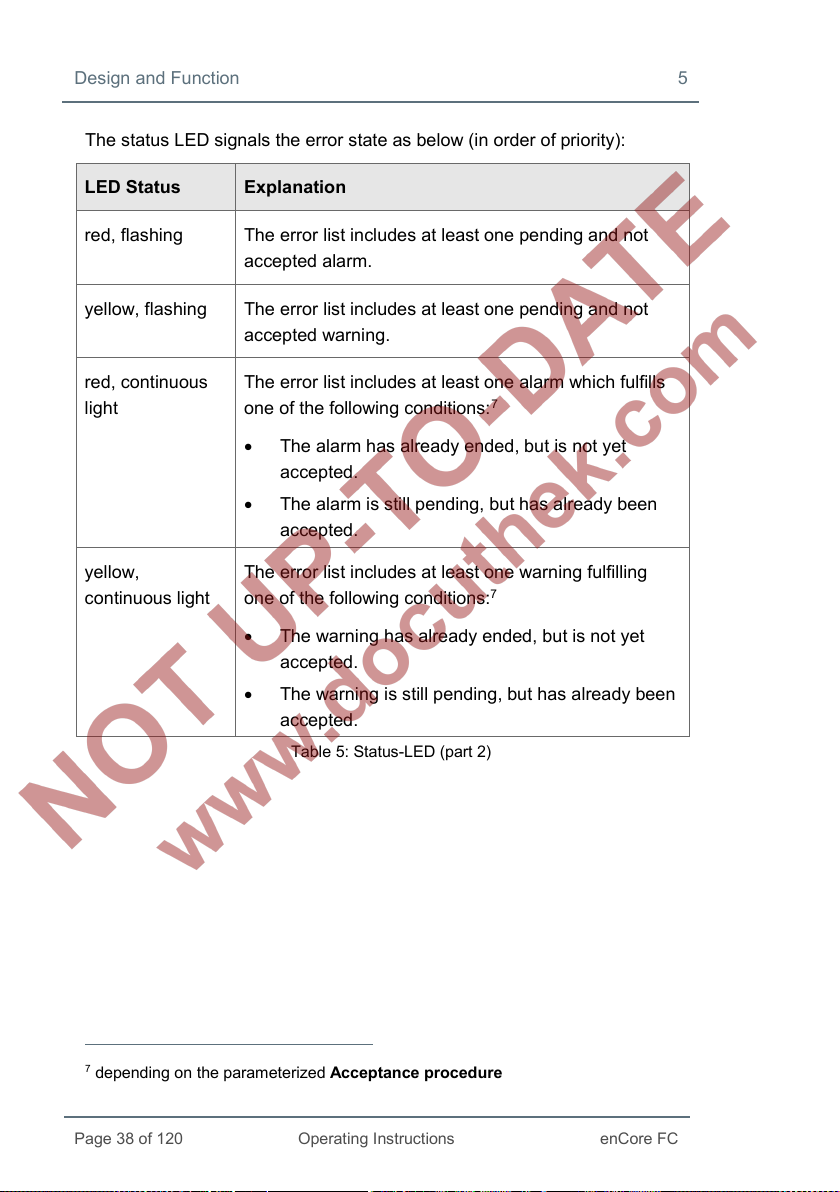

The status LED signals the error state as below (in order of priority):

LED Status Explanation

red, flashing The error list includes at least one pending and not

accepted alarm.

yellow, flashing The error list includes at least one pending and not

accepted warning.

red, continuous

light

yellow,

continuous light

The error list includes at least one alarm which fulfills

7

one of the following conditions:

• The alarm has already ended, but is not yet

accepted.

• The alarm is still pending, but has already been

accepted.

The error list includes at least one warning fulfilling

one of the following conditions:

7

• The warning has already ended, but is not yet

accepted.

• The warning is still pending, but has already been

accepted.

Table 5: Status-LED (part 2)

7

depending on the parameterized Acceptance procedure

Page 39

5 Design and Function

enCore FC

Operating Instructions

Page 39 of 120

1

2

3

4

1

2

5.4 Interfaces (Rear Side of Device)

1

Fig. 5-3: Rear of device (example 1/3 overall width)

LAN interface (Ethernet network)

serial interfaces

24 V DC power supply

optional process boards

Page 40

Design and Function 5

Page 40 of 120

Operating Instructions

enCore FC

5.5 Available Process Boards

The configuration of the I/O board assignment is variable. In principle, any

I/O board can be inserted into any slot. If there are any kind of technical

limitations – depending on the board type, they are listed in the following

chapters (descriptions individual boards):

6.3 Installation and Conversion of Process Boards (p. 48)

This chapter describes the ways you can change the I/O board

equipment.

6.4 Connection Diagrams (p. 54)

This chapter includes connection diagrams for typical applications.

5.5.1 ExMFE5 Process Board

WARNING!

Risk of explosion

A risk of explosion exists if lines are connected to the

ExMFE5 board while the device is connected to the power

supply!

The transmitter-, pulse- and signal lines are connected only to the

ExMFE5 board if the enCore FC is connected in a voltage-free

manner.

Page 41

5 Design and Function

enCore FC

Operating Instructions

Page 41 of 120

WARNING!

Risk of explosion

A risk of explosion exists if the enCore FC (FC1 or MC1) is

improperly assembled and connected!

• The enCore FC must be installed outside of Ex zones 0, 1

and 2.

• Assemblies which are authorized as associated category ib

electrical equipment with intrinsically safe electrical circuits in

accordance with EN 60079-11 can be installed in the enCore

FC, e.g. input boards with the label ExMFE5. The enCore FC

is therefore suitable for connecting to transmitters, pulse and

signal sensors that are located in the potentially explosive

area e.g. in zone 1. A mixed connection of intrinsically safe

and non-intrinsically safe circuits is not permitted for these

assemblies.

• Only measurement transmitters and pulse sensors that follow

at least the requirements of the intrinsically safe protection

class [Ex ib Gb] II C may be connected to the ExMFE5

assembly terminals provided for that purpose.

• When using input boards of ExMFE5 type, it is not permitted

(according to the EC type examination certificate ATEX) to

include more than one ExMFE5 board (i.e. more than one

associated apparatus) into the same intrinsically safe circuit.

• All signals from the potentially explosive area (zone 0,

zone 1, zone 2) must be regulated using suitable Ex isolators,

if they are connected to some other assembly group that is

not the input board ExMFE5

• The regulations in the relevant standards, especially

EN 60079-0, EN 60079-11, EN 60079-17 and EN 60079-25,

must be obeyed unconditionally.

Page 42

Design and Function 5

Page 42 of 120

Operating Instructions

enCore FC

Comply with the safety- and risk instructions of the ExMFE5

input boards!

4.1 General Safety Instructions (p. 23)

6.1 Line Connection (p. 45)

The process board ExMFE5 is an “associated electrical

equi

pment” according to EN50020, which provides five

intrinsically safe input circuits of the category [Ex ib Gb] II C:

• Three NAMUR inputs (Z1+/Z1-, Z2+/Z2-, Z3+/Z3-) for

signals, LF pulses and HF pulses.

As an alternative, the first channel is suitable for

connecting an encoder index.

• A resistance input in 4-wire technology (I+/U+/U-/I-).

• An analog current input 4 … 20mA (P+/P-), alter-

natively usable as a HART interface.

Fig. 5-4

Page 43

5 Design and Function

enCore FC

Operating Instructions

Page 43 of 120

5.5.2 MFE7 Process Board

The process board MFE7 provides seven input circuits:

• A resistance input in 4-wire technology

(RI+/RU+/RU-/RI-).

• Two analog current inputs (A1+/A1-, A2+/A2-) in

operational modes 0…20 mA or 4...20 mA, alter-

natively usable as a HART interface.

• Three pulse inputs or signal inputs (D1, D2, D3/GND)

for signals, LF pulses or HF pulses. As an alter-

native, the third channel (D3/GND) is suitable for

connecting an encoder index. As an alternative,

channels 2 and 3 (D2, D3/GND) can be used as a

frequency input

• A RS485 serial interface (RSA/RSB/GND).

Fig. 5-5

5.5.3 MSER4 Process Board

The process board MSER4 provides for four serial interfaces,

each for one protocol channel (CH1, CH2, CH3, CH4). Every

protocol channel alternatively supports RS485, RS422 or

RS232.

For a device in 1/3 overall width, a maximum of

one MSER4 board can be installed in slot 4 only.

For a device in 1/2 overall width, up to two

MSER4 boards can be installed in slots 6 and 7

only.

Fig. 5-6

Page 44

Design and Function 5

Page 44 of 120

Operating Instructions

enCore FC

5.5.4 ESER4 Process Board

The process board ESER4 provides for three serial interfaces,

each for one protocol channel (CH1, CH2, CH3). Every

protocol channel alternatively supports RS485, RS422 or

RS232. Moreover, one LAN interface (Ethernet network) is

available.

For a device in 1/3 overall width, a maximum of one

ESER4 board can be installed in slot 4 only. For a

device in 1/2 overall width, up to two ESER4 boards

can be installed in slots 6 and 7 only.

Fig. 5-7

5.5.5 MFA8 Process Board

The process board MFA8 provides eight output circuits:

• One digital message output (D1a/D1b).

• Three digital outputs (D2+/D2-, D3+/D3-, D4+/D4-)

for messages, trigger outputs or LF pulses.

• Four analog outputs (I1, I2, I3, I4/I-) 0... 20 mA or

4 … 20 mA for measurements.

Fig. 5-8

Page 45

Page 45 of 120

Operating Instructions

enCore FC

6 Assembly Instructions

The enCore FC is provided for assembly within a 19" cabinet, and is

available in either a 1/3 overall width or 1/2 overall width model. Compliance

with the device's installation depth of 170 mm (with plugs approx. 220 mm) is

necessary so the connection terminals located on the rear of the device

remain accessible.

The enCore FC must be installed in an Ex free plant room

(electrical room) outside of Ex zones 0, 1 and 2, in accordance

with protection class IP 20.

It is recommended that the enCore FC be installed in a swivel

frame.

6.1 Line Connection

WARNING!

Risk of explosion

A risk of explosion exists if lines are connected to the

ExMFE5 board while the device is connected to the power

supply!

Only connect transmitter, pulse and signal lines to the ExMFE5

board when power supply of the enCore FC is disconnected

completely.

Page 46

Assembly Instructions 6

Page 46 of 120

Operating Instructions

enCore FC

ATTENTION!

Risk of short circuit

The enCore FC device can be damaged if lines are connected

while the device is connected to the power supply.

Always make sure the enCore FC is free of voltage before making

any changes to device wiring or before connecting sensor, supply,

signal or data lines.

The transmitter, pulse, signal and data lines are connected to the enCore FC

by using plug-in screw terminals that are located in a cable housing. Fixed

screw terminals are used for the power supply connection.

Special attention must be paid to the intrinsically safe electrical circuits.

Before switching on the power supply, the operator must ensure that the

plug connections for the gas meter, pressure and temperature inputs of the

ExMFE5 input board are inserted, since this is the only way the minimum

distance of 50 mm required in the relevant guidelines can be maintained.

The relevant installation guidelines must be observed when arranging the

wiring.

The device lines must be free of tensile stress and must be provided with a

kink protection if the enCore FC is being installed in a swivel frame.

Enough length must be allocated to cables so no tensile stress occurs in

cables when the swivel frame is opened up.

It is recommended that the lines be placed on transfer terminals in a switch

cabinet, and then be connected with the enCore FC from that point.

However, these terminals must sometimes fulfill Ex regulations, and must

also be sealable if applicable, for example in order to fulfill the requirements

of an applicable approval.

Page 47

6 Assembly Instructions

enCore FC

Operating Instructions

Page 47 of 120

Hazard ous A rea Safe A rea enCore device

CPU board

24V

0V

PE

+24V DC

Fuse 1A slow

0V

6.2 Power Supply and Grounding

Fig. 6-1: Power supply

The enCore FC must be operated with a rated voltage of 24 V DC (max.

permissible range: 20.4 V to 28.8 V).

The 24 V power supply is connected via the (+) and (–) terminals at the rear

of the device, and must be protected externally using a 1A time-delay fuse.

It is recommended to operate the process computer in conjunction with an

uninterruptible power supply. Its design must comply with EN 60654-2 for

direct current; nominal voltage 24 V DC, permitted range 20.4 V DC to

28.8 V DC, switching time not exceeding 10 ms. The external power supply

must provide at least 12 W power. With a mains voltage of 100 V up to

230 V for the uninterruptible power supply, the switching time must not be

greater than a mains period (50 or 60 Hz), based on the nominal value of the

mains frequency.

The device is protected internally by means of a self-resetting over-current

protection component.

Page 48

Assembly Instructions 6

Page 48 of 120

Operating Instructions

enCore FC

The grounding system is connected to the power supply socket PE for

potential equalization.

6.3 Installation and Conversion of Process Boards

The process board configuration of the device is in correspondence with the

order at the time of delivery. Owing to the modular hardware concept it is

now possible to insert additional process boards in free board slots even

later or to change the compilation of the process boards.

For safety reasons, any modifications of the process board

configuration should be carried out only by the manufacturer's

service department or by an appropriately trained specialist

working for the plant operator.

The housing of the device must be opened in order to add or

change process boards. The presence of a metrology expert may

be required for this purpose when the device is being used within

the scope of legal metrology.

ATTENTION!

Risk of short circuit

The device may damage if it is opened in case of connected

power supply.

Always make sure the enCore FC is free of voltage before

opening the device.

Page 49

6 Assembly Instructions

enCore FC

Operating Instructions

Page 49 of 120

ATTENTION!

The integrated circuits of the process boards may be

damaged due to electrostatic discharges.

According to EN 61340-5-1, an ESD-protected workplace (ESD

pad and ESD wrist strap) must be used while working on a device

when changing the I/O board configuration.

ATTENTION!

Incorrect replacement parts and accessories are a safety

risk!

Incorrect or defective replacement parts and accessories

may detract from safety and lead to damage, malfunction, or

total device failure.

• Use only original replacement parts and accessories from the

manufacturer.

If required, please contact our support staff directly.

6.3.1 Insert a Process Board in a Free Board Slot

The method used for changing or removing process boards is similar.

► Ensure that all the required accessories are available:

• process board(s)

• suitable labelling plate(s)

• jumper(s)

Page 50

Assembly Instructions 6

Page 50 of 120

Operating Instructions

enCore FC

A

A

► If necessary, install or update to the next enSuite on the work computer

( enSuite installation guide

► Read out the enCore FC device's parameterization with enSuite.

► Disconnect the power supply.

► Remove all the external cable connections from the device.

► Remove the 4 mounting screws present on the rear of the device

8).

(Positions A).

8

The installation guide is located on the enSuite installation CD. Alternatively, you can

download the PDF from the Elster website in the software downloads section:

www.elster-instromet.com/en/software-downloads.

Fig. 6-2: Rear side of the device (example),

mounting screws are removed

Page 51

6 Assembly Instructions

enCore FC

Operating Instructions

Page 51 of 120

► Pull the board frame carefully and straight out of the housing.

Fig. 6-3: Remove the board frame

Fig. 6-4:

Removed board frame

Check the position for the additional board (number of board slot).

►

Page 52

Assembly Instructions 6

Page 52 of 120

Operating Instructions

enCore FC

(slot no.)

Set up the board number on the board

Note that the number of the board slot as well as the board

number on the board must be set; this is essential for further

functioning of the internal I/O bus communication.

► Insert the relevant jumpers in the suitable pin connector in order to

define the number on the board ( Fig. 6-5 and 6-6).

=

jumper

board position

►

Remove the cover plate of the respective slot (2 screws).

► Insert the board with the side meant for the process connection in the

1 2 3 4 5 6 7

Fig. 6-5: Pin connector with jumper positions

slot on the rear panel (blue plug for Ex boards, otherwise green plug,

Fig. 6-2).

Page 53

6 Assembly Instructions

enCore FC

Operating Instructions

Page 53 of 120

C B

C

B

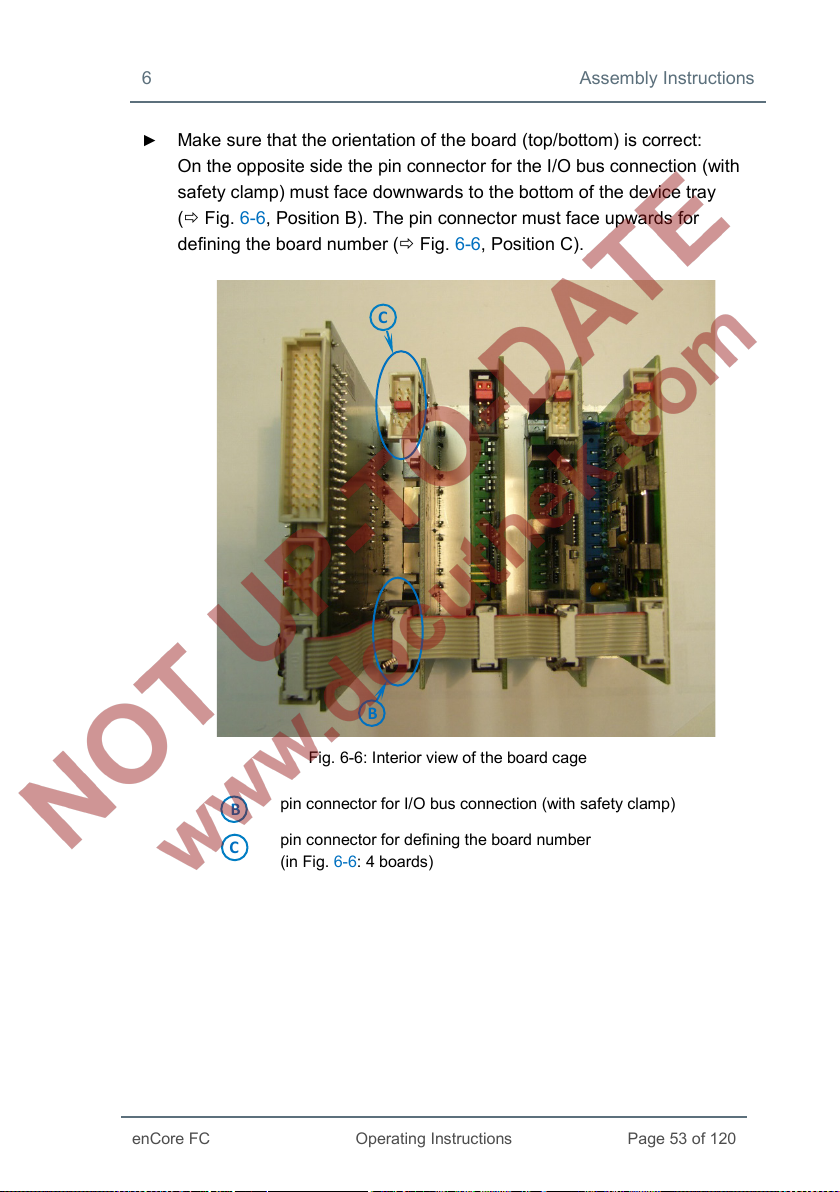

► Make sure that the orientation of the board (top/bottom) is correct:

On the opposite side the pin connector for the I/O bus connection (with

safety clamp) must face downwards to the bottom of the device tray

( Fig. 6-6, Position B). The pin connector must face upwards for

defining the board number ( Fig. 6-6, Position C).

Fig. 6-6: Interior view of the board cage

pin connector for I/O bus connection (with safety clamp)

pin connector for defining the board number

(in Fig. 6-6: 4 boards)

Page 54

Assembly Instructions 6

Page 54 of 120

Operating Instructions

enCore FC

► Position the labelling plate of the board on the rear side of the device

and screw the board firmly on to the labelling plate.

► Insert the plug for the internal I/O bus on the other side of the board.

The safety clamp closes automatically. Check whether all the other bus

plugs are still plugged in properly.

► Re-insert the board frame carefully inside the device. Press gently on

the board frame in order to re-establish a connection between CPU and

the display board.

► Close the device with the help of the 4 mounting screws

(Positions A in Fig. 6-2).

► Restore all external cable connections with enCore FC.

► Connect the power supply.

► Use the enSuite to edit the imported parameterization by taking into

consideration the new board configuration.

Add the new board to the parameterization (parameter branch Basic

System – I/O boards, section Board <x>) and adjust all settings for its

process connection.

► Transfer the edited parameterization to the device.

Details on parameterization

For details on the parameterization procedure refer to volume

“Configuration of Device Software” of the enCore FC manual.

6.4 Connection Diagrams

This section shows connection diagrams for those measurement devices that

are typically connected to an enCore FC flow computer (e.g. temperature and

pressure transmitter, gas meter and gas quality measurement devices).

Moreover, typical connection diagrams for processing devices such as station

control or remote transfer device are illustrated here.

Page 55

6 Assembly Instructions

enCore FC

Operating Instructions

Page 55 of 120

Minimum requirements

If a special setting is required for connecting a specific board or a

specific board channel with a measuring device, you get only the

minimum required settings below the respective connection

diagram.

For details on parameterization refer to the online help.

6.4.1 General Recommendations for Signal and Data Cable

Signal Connection

The following standard minimum requirements for the used type of cable are

recommended for the signal connection with external transmitters and sen-

sors as well as for the signal connection of external devices:

• signal cable with a line-to-line capacity smaller than 120 pF/m and

an inductance smaller than 0.7 µH/m

• Wire diameter greater or equal to 0.5 mm

ding to the application, stranded cable, shielded together. Screen at

just one place (preferably on enCore FC) connected with PE.

• The maximum cable length is dependent on the type of the signal;

refer to the following section for exact specifications.

2

, number of wires accor-

Data Communication Connection

The following standard minimum requirements for the used type of cable are

recommended for the data communication connection with external sensors

as well as for the data communication connection of external devices accor-

ding to RS232, RS422 or RS485:

• signal cable with a line-to-line capacity smaller than 120 pF/m and

an inductance smaller than 0.7 µH/m

• Wire diameter greater or equal to 0.25 mm

2

, number of wires accor-

ding to the application, stranded cable, shielded together. Screen at

just one place (preferably on enCore FC) connected with PE.

Page 56

Assembly Instructions 6

Page 56 of 120

Operating Instructions

enCore FC

• The maximum cable length is 30 m for RS232, and 500 m for

RS422 and RS485.

RS485

According to RS485, resistors are required for resting potential generation at

any places in case of data communication connections, for every 470 Ω

between R/TA and +U and also between R/TB and SGND. Other bus resis-

tors at every 120 Ω between R/TA and R/TB on both the physical ends of the

cable are recommended for cable length from 200 m onwards.

Ethernet

A standard type of cable is recommended for data communication connec-

tion via Ethernet according to Category 5 (Cat 5), the maximum cable length

is 100 m.

Page 57

6 Assembly Instructions

enCore FC

Operating Instructions

Page 57 of 120

Hazard ous A rea Safe Area enCore device

ExMFE 5 board

I+

U+

U−

I−

SH

Pt100, EEx i

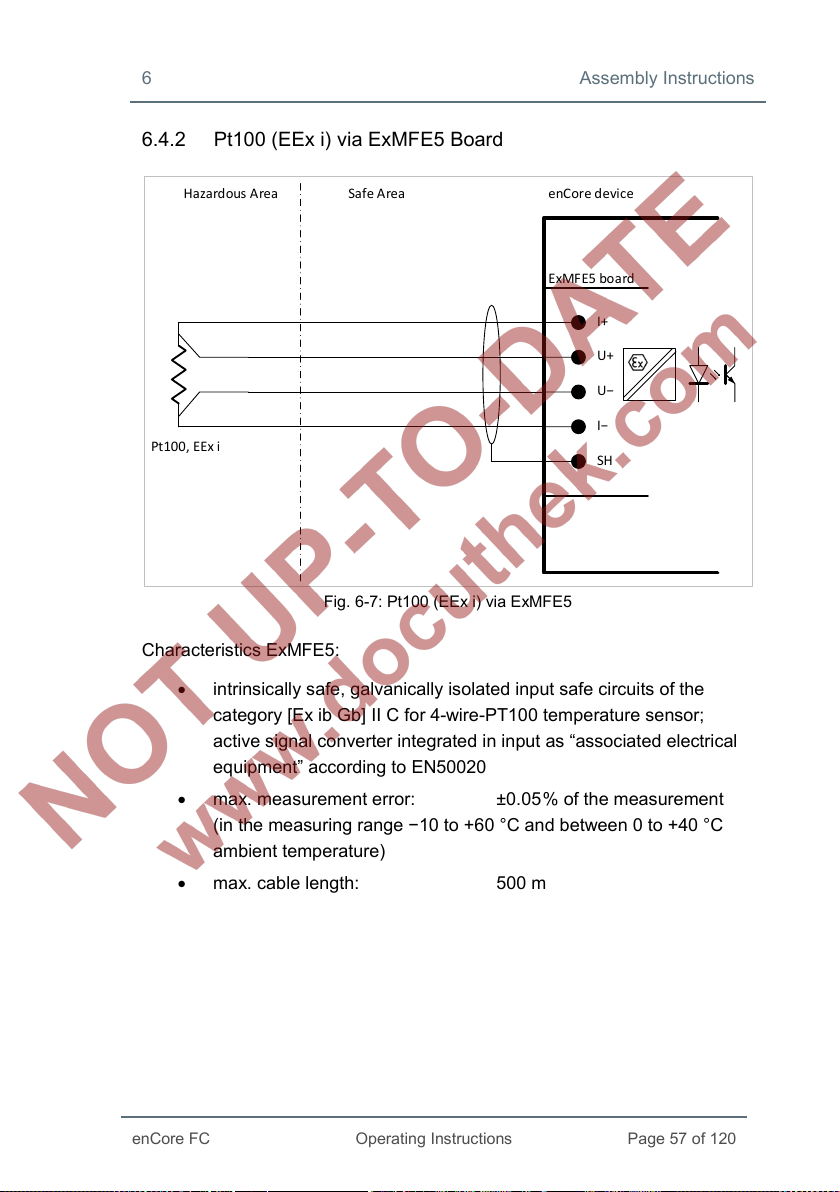

6.4.2 Pt100 (EEx i) via ExMFE5 Board

Fig. 6-7: Pt100 (EEx i) via ExMFE5

Characteristics ExMFE5:

• intrinsically safe, galvanically isolated input safe circuits of the

category [Ex ib Gb] II C for 4-wire-PT100 temperature sensor;

active signal converter integrated in input as “associated electrical

equipment” according to EN50020

• max. measurement error: ±0.05

(in the measuring range −10 to +60 °C and between 0 to +40 °C

ambient temperature)

• max. cable length: 500 m

% of the measurement

Page 58

Assembly Instructions 6

Page 58 of 120

Operating Instructions

enCore FC

Hazard ous A rea Safe Area enCore device

MFE7 bo ard

RI+

RU+

RU−

RI−

SH

Pt100, EEx d

6.4.3 Pt100 (EEx d) via MFE7 Board

Fig. 6-8: Pt100 (EEx d) via MFE7

Characteristics MFE7:

• a galvanically isolated input safe circuit for 4-wire-PT100

temperature sensor

• max. measurement error: ±0.05

(in the measuring range −40 to +120 °C and between −10 to +55 °C

ambient temperature)

• max. cable length: 500 m

% of the measurement

Page 59

6 Assembly Instructions

enCore FC

Operating Instructions

Page 59 of 120

Ha zardous Area Safe Area

enCore device

ExMFE 5 board

P+

SH

Analog pressure

transmitter

4...20 mA, EEx i

P−

6.4.4 Analog Measurement Transmitter (EEx i) via ExMFE5 Board

Fig. 6-9: analog pressure transmitter (EEx i) via ExMFE5 – example

Characteristics ExMFE5:

• intrinsically safe, galvanically isolated input safe circuits of the

category [Ex ib Gb] II C for transmitter with 4 ... 20mA interface

• active signal converter integrated of the category “associated

electrical equipment” according to EN50020 in input:

− open-curcuit voltage: approx. 18 V

− voltage at 20mA: approx. 10.6 V

− max. load: 300 Ω

• max. measurement error: ±0.05

(in the measuring range 4 to 20 mA and between 0 to +40 °C

ambient temperature)

• max. cable length: 500 m

% of the measurement

Page 60

Assembly Instructions 6

Page 60 of 120

Operating Instructions

enCore FC

Ha zardous Area Safe Area enCore device

MFE7 bo ard

A1+ or A2+

A1− or A2−

SH

Analog pressure

transmitter

4...20 mA, EEx d

(so ur ce m od e)

Hints on parameterization

Branch <device> – Basic System – I/O boards –

Board <x>: ExMFE5

Set the following value:

• channel P1+ P1−: type Current input

6.4.5 Analog Measurement Transmitter (EEx d) via MFE7 Board (without barrier)

Fig. 6-10: Analog pressure transmitter (EEx d) via MFE7 – example

Characteristics MFE7:

• a galvanically isolated input safe circuit with 4 ... 20 mA interface:

− open-circuit voltage: approx. 21 V

− voltage at 20 mA: approx. 12.6 V

− max. load: 600 Ω

• max. measurement error: ±0.05

(in the measuring range 4 ... 20 mA and between −10 to +55 °C

ambient temperature)

% of the measurement

Page 61

6 Assembly Instructions

enCore FC

Operating Instructions

Page 61 of 120

Ha zardous Area Safe Area

enCore device

MFE7 bo ard

A1+ or A2+

A1− or A2−

SH

Analog pressure

transmitter

4...20 mA, EEx i

Isola ted cu rrent

repeater barrier

(sink mode)

+

−

(so ur ce m od e)

• max. cable length: 500 m

Hints on parameterization

Branch <device> – Basic System – I/O boards –

Board <x>: MFE7

Set the following values:

• channel A1+ A1− or A2+ A2−: type Current input

• parameter Power supply: value On (source mode)

6.4.6 Analog Measurement Transmitter (EEx i) via MFE7 Board (barrier in sink mode)

Characteristics MFE7:

Fig. 6-11: Analog pressure transmitter (EEx i) via MFE7 – example

• a galvanically isolated input safe circuit with 4 ... 20 mA interface:

− open-circuit voltage: approx. 21 V

− voltage at 20mA: approx. 12.6 V

− max. load: 600 Ω

Page 62

Assembly Instructions 6

Page 62 of 120

Operating Instructions

enCore FC

Ha zardous Area Safe Area

enCore device

MFE7 bo ard

A1+ or A2+

A1− or A2−

SH

Analog pressure

transmitter

4...20 mA, EEx i

0V 24V

Isola ted cu rrent

repeater barrier

(so ur ce m od e)

+

−

(sink mode)

• max. measurement error: ±0.05 % of the measurement

(in the measuring range 4 ... 20 mA and between −10 to +55 °C

ambient temperature)

• max. cable length: 500 m

Hints on parameterization

Branch <device> – Basic System – I/O boards –

Board <x>: MFE7

Set the following values:

• channel A1+ A1− or A2+ A2−: type Current input

• parameter Power supply: value On (source mode)

6.4.7 Analog Measurement Transmitter (EEx i) via MFE7 Board (barrier in source mode)

Fig. 6-12: Analog pressure transmitter (EEx i) via MFE7 – example

Characteristics MFE7:

• a galvanically isolated input safe circuit with 4 ... 20 mA interface:

Page 63

6 Assembly Instructions

enCore FC

Operating Instructions

Page 63 of 120

Ha zardous Area Safe Area enCore device

ExMFE 5 board

P+

SH

HART pressure

transmitter, EEx i

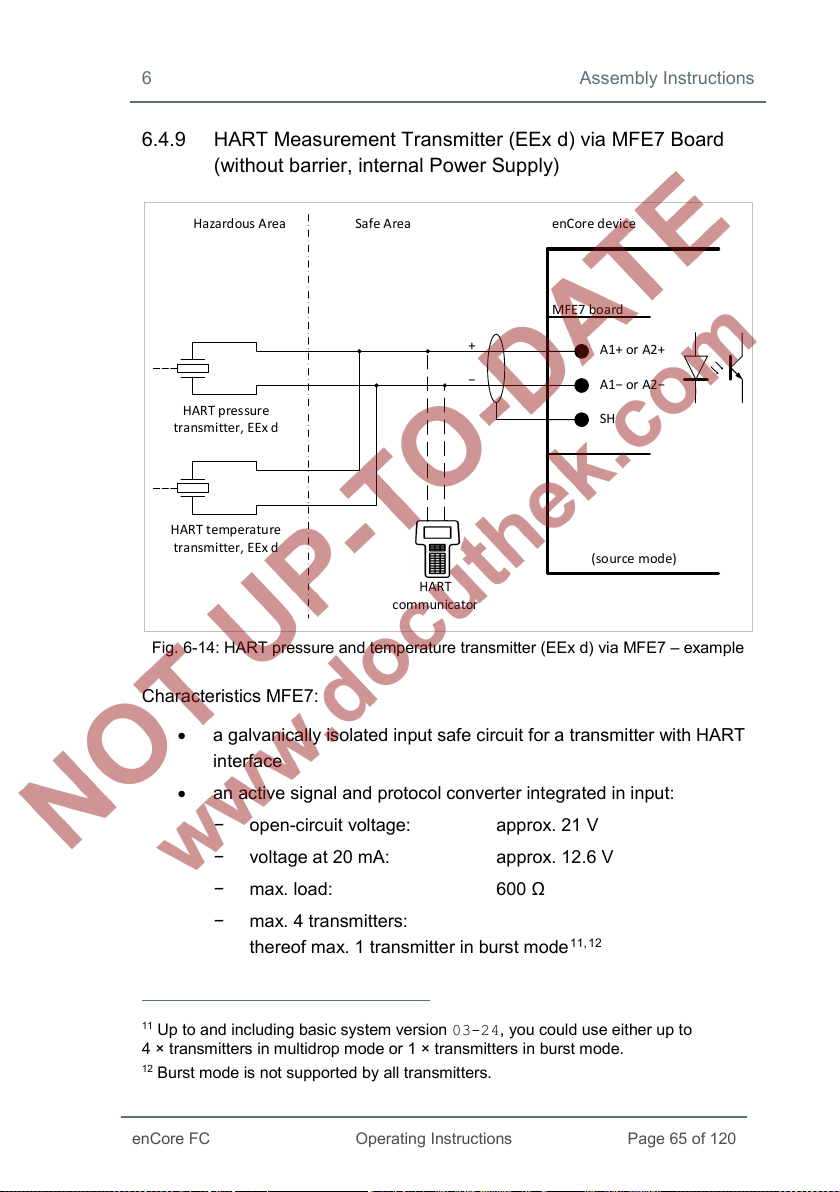

HART temperature