Page 1

GB

F

NL

I

E

1000248560-002-05

03251009

D GB

I

➔ www.docuthek.com

Safety

Safety

Please read and keep in a safe place

Operating instructions for

operators and installers

Electronic index EI

© 2017 Elster GmbH · Edition 08.17

Translation from the German

Contents

Contents

Electronic index EI .....................

Contents ..............................

Safety.................................

Checking the usage .....................

Installation ............................

Operating the electronic index ............

Navigating within the menu ..............

Service mode ..........................5

Establishing an optical communications link 8

Setting the index parameters .............8

Replacing the communication module .....8

Changing the SIM card ..................9

Changing the battery ....................9

Electrical pulse output..................0

Check test............................0

Assistance in the event of malfunction ....4

Accessories ..........................4

Spare parts ...........................4

Technical data ........................4

Logistics .............................5

Contact ..............................6

carefully before installing or operating. Following the

Please read through these instructions

installation, pass the instructions on to the operator. This unit must be installed and commissioned

in accordance with the regulations and standards

in force. These instructions can also be found at

www.docuthek.com.

Explanation of symbols

• , , , ... = Action

▷ = Instruction

Liability

We will not be held liable for damage resulting from

non-observance of the instructions and non-compliant use.

Safety instructions

Information that is relevant for safety is indicated in

the instructions as follows:

DANGER

Indicates potentially fatal situations.

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

All interventions may only be carried out by qualified

gas technicians. Electrical interventions may only be

carried out by qualified electricians.

Conversion, spare parts

All technical changes are prohibited. Only use OEM

spare parts.

Changes to edition .

The following chapters have been changed:

– Checking the usage

– Logistics

GB-1

Page 2

GB

F

NL

I

E

Checking the usage

*Current meter reading

Electronic index EI for diaphragm gas

meters BK-G...B

The electronic index EI3 indicates the volume at base

conditions. It can be used for reading out absolute

consumption values and for retrieving consumption

data for the various tariffs.

This function is only guaranteed when used within the

specified limits – see page14 (Technical data). Any

other use is considered as non-compliant.

Type code

Code Description

EI Electronic index based on EI3

.00

.05

▷

The index version is shown on the index plate,

ECM.05, GSM wireless technology

see page 2 (Type label/Index plate).

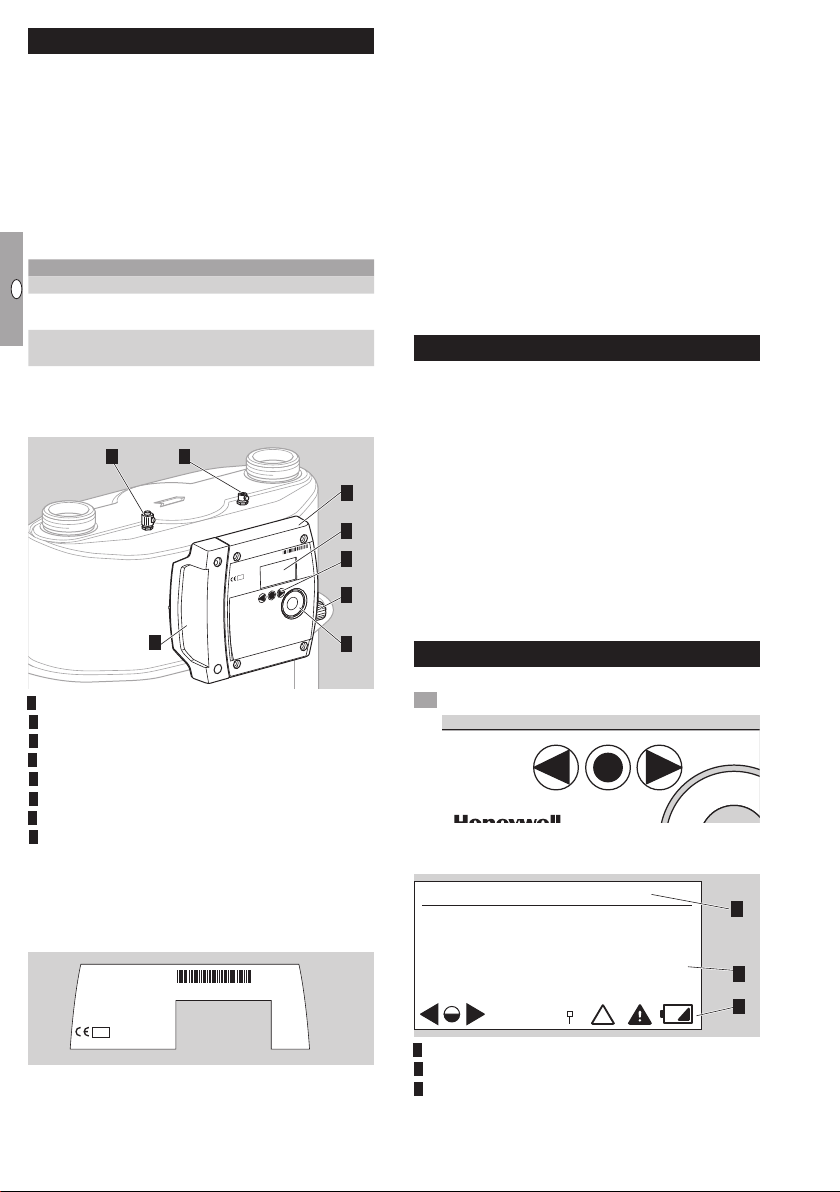

Part designations

87

5

Electronic index EI3

Display

User keys

4 Opto-adapter interface

5 Service cover

6 Pulse output

7 Pressure test point with sealing sleeve (optional)

8 Thermowell (optional)

Type label/Index plate

Please quote for all enquiries:

▷

Manufacturer’s serial number S/N (at the bottom left)

▷ Index version EI (next to the serial number)

BK-G..B

Q

max

t

m

Q

min

V

p

max

class 1,5

M ... 0102

S/N: ............

t

g

t

b

p

b

EI3. ...

V

b

12345678

Standard version

Communication module

1234 5678

BK-Gx

max

Q

min

Q

DE-07-MI002-PTB001

M07 0102

^

...

1 imp

=

Variant

1

2

3

6

4

ATEX

▷

The electronic index is suitable for use in po-

tentially explosive atmospheres. For the exact

use (zone), see ATEX sticker on the diaphragm

gas meter or see “Operating instructions for

diaphragm gas meters BK-G1.6 to BK-G25” →

http://docuthek.kromschroeder.com/doclib/

main.php?language=1&folderid=400041&by_

class=2&by_lang=-1

“Instruction Manual, Industrial Diaphragm Gas

Meters Type BK-G40 · BK-G65 · BK-G100

and Type BK-G40T · BK-G65T · BK-G100T” →

http://docuthek.kromschroeder.com/doclib/

main.php?language=1&folderid=400045&by_

class=2&by_lang=-1

Installation

Installing the gas meter

▷

For installing the gas meter in the pipework, see “Operating instructions for diaphragm gas meters BK-G1.6 to BK-G25” →

http://docuthek.kromschroeder.com/doclib/

main.php?language=1&folderid=400041&by_

class=2&by_lang=-1

“Instruction Manual, Industrial Diaphragm Gas

Meters Type BK-G40 · BK-G65 · BK-G100

and Type BK-G40T · BK-G65T · BK-G100T” →

http://docuthek.kromschroeder.com/doclib/

main.php?language=1&folderid=400045&by_

class=2&by_lang=-1

Operating the electronic index

▷ The display on the index is switched off.

• Briefly press any key.

▷ A beep sounds and the main screen appears.

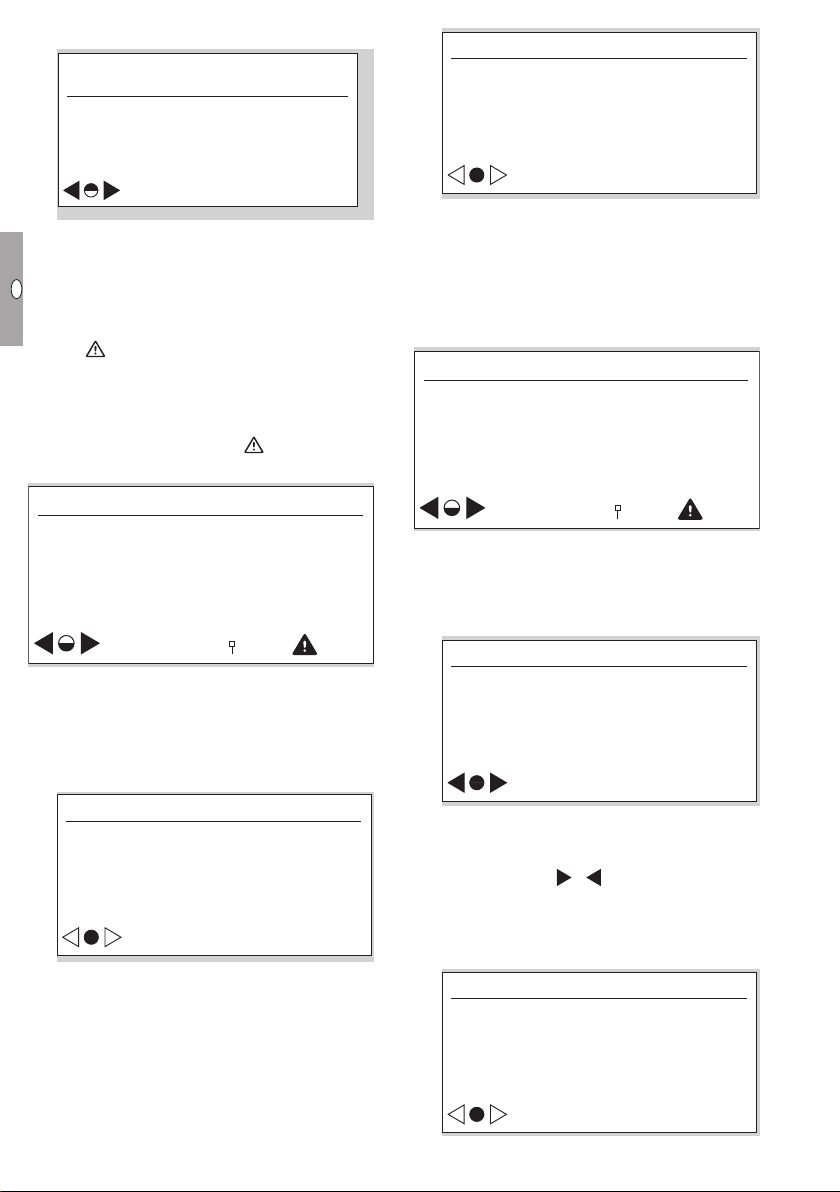

Main screen

1

3

0000004

Tariff: F01

Menu area

Information area

Status line (symbols)

.00

*

m

2

3

GB-2

Page 3

GB

F

NL

I

E

User keys, selection key and symbols

=

*

*Date and time: (UTC + X)

▷

You can navigate through the menu using the

user keys , and the selection key .

Symbol Meaning

Navigate to the left or the right on each

,

level using the user keys.

Briefly pressing the selection key selects

a sub-menu.

Holding the selection key pressed down

switches the display back to the previous

menu.

Briefly pressing the selection key selects

a sub-menu.

Holding the selection key pressed down

switches the display back to the previous

menu.

Keys inactive

, ,

RF module/communication is active

RF module/communication is inactive

RF communication – pairing successful

Invalid data

Alarm

Low index battery. This symbol is only

displayed when battery power is low.

Temperature out of operational range

T

p

Pressure out of operational range

Multiple sensor data out of operational

range

▷ In each menu, the meaning of the symbols for

the keys is described in the information area.

▷ In the main screen under “General instructions”,

all the symbols are explained.

Navigating within the menu

▷ The menu is constructed hierarchically.

▷

The “Current meter reading” main screen appears

when switching on the index.

▷

If you are in a different menu, the display will

automatically change back to the main screen

when no user key has been pressed for 30s,

and switches off after a further 30s.

▷

You can navigate from the main screen to the

various menus, such as “Date and time (UTC)”

using the user keys

, .

Menu overview

Main menu

–

Current meter reading

General instructions

–

Date and time (UTC)

Past meter readings

–

Monthly

Daily

Hourly

–

Tariff information

–

Billing information

–

Metering point identification

Current meter reading

▷

The absolute meter reading and optionally the

current tariff are indicated in the main screen.

▷ This appears when switching on the index.

▷

You can receive information about the symbols by

pressing the selection key and the user keys

, , or see page 3 (User keys, selection

key and symbols).

Date and time (UTC + X)

▷ UTC = coordinated universal time + X = offset

for conversion to local time.

▷ Information on the date and time display.

▷

The current date and time appears when the

selection key is pressed.

▷ Local time is supported.

▷ Daylight saving time can be supported.

▷

For further information, contact the meter operator.

20–04–2013

07:15:30

▷ The date is given in the format DD-MM-YYYY.

Past meter readings

▷

Consumption data dating as far back as

20 weeks can be called up.

▷ By pressing the selection key

data are displayed, which are given by month,

day or hour intervals:

M: monthly

D: daily

H: hourly

, consumption

GB-3

Page 4

GB

F

NL

I

E

▷ “hourly summary” example:

*H: 01-05-13 18:00->19:00

Billing information

Billing information (1/5)

0000000.00->0000004.00m

Vb

4.00m

Tariff: F02

▷

The timeframe is displayed with date and time

for the start and end of the period.

▷ The meter reading is displayed for the start and

end of the period in m3.

▷

The consumption for this period is indicated in m3.

▷ The tariff (e.g. F02) may be displayed.

▷ The symbol is displayed if, for example, the

tolerance between the internal time recording

and the actual time is too large. This can lead

to invalid consumption data. After the next time

synchronization, the consumption data are recorded again correctly and disappears.

Tariff information

Tari information

Tariff program &

Details

▷

This menu contains information on the current

tariff program.

▷

By briefly pressing the selection key, you can

access further information. Here, the active tariff

program is displayed, as are the date and time

of activation.

Tari information

ID :Green Spring Demo

From : 01-01-2000 06:00

▷

By briefly pressing the selection key, you can

visualize the consumption data.

Consumption results

3

3

F01: 0.00m

F02: 0.00m

F03: 0.00m

3

3

3

UES:0x0240000000000000

▷

In lines F01 to F03, the current absolute gas

consumption values of the relevant tariff register

are displayed.

▷ In the “UES” (UNI-TS 11291 event status) field,

the current diagnostic information is displayed.

▷ The data are updated hourly.

Billing information

Current &

previous billing

▷

This menu provides further information on the

gas consumption values within the periods in

the register.

▷

By briefly pressing the selection key, you can

visualize the overview of the saved billing periods.

Billing information (1/5)

ID :SPIDER NET

From :01-01-2000 06:00

To :01-01-2000 03:26

▷ At this menu level, you will find the identification

and the scope of validity (length of time) of the

relevant billing period.

▷ By pressing the

between the current billing period and the last

four billing periods.

▷

By briefly pressing the selection key, you can

visualize the relevant consumption data.

Vb : 4.00 m

F01 : 0.00m

F02 : 0.00m

F03 : 0.00m

UES :0x0240000000000000

, keys, you can change

3

3

3

3

GB-4

Page 5

GB

F

NL

I

E

▷

Test instructions

*Temperature

Vb is the absolute value of the gas meter reading.

▷

In lines F01 to F03, the absolute values of the

tariff registers are displayed.

▷ In the “UES” (UNI-TS 11291 event status) field,

the current diagnostic information is displayed.

▷ All figures are absolute values, which are saved

at the end of the relevant billing period.

▷

The data for the current billing period are up-

dated hourly.

Service mode

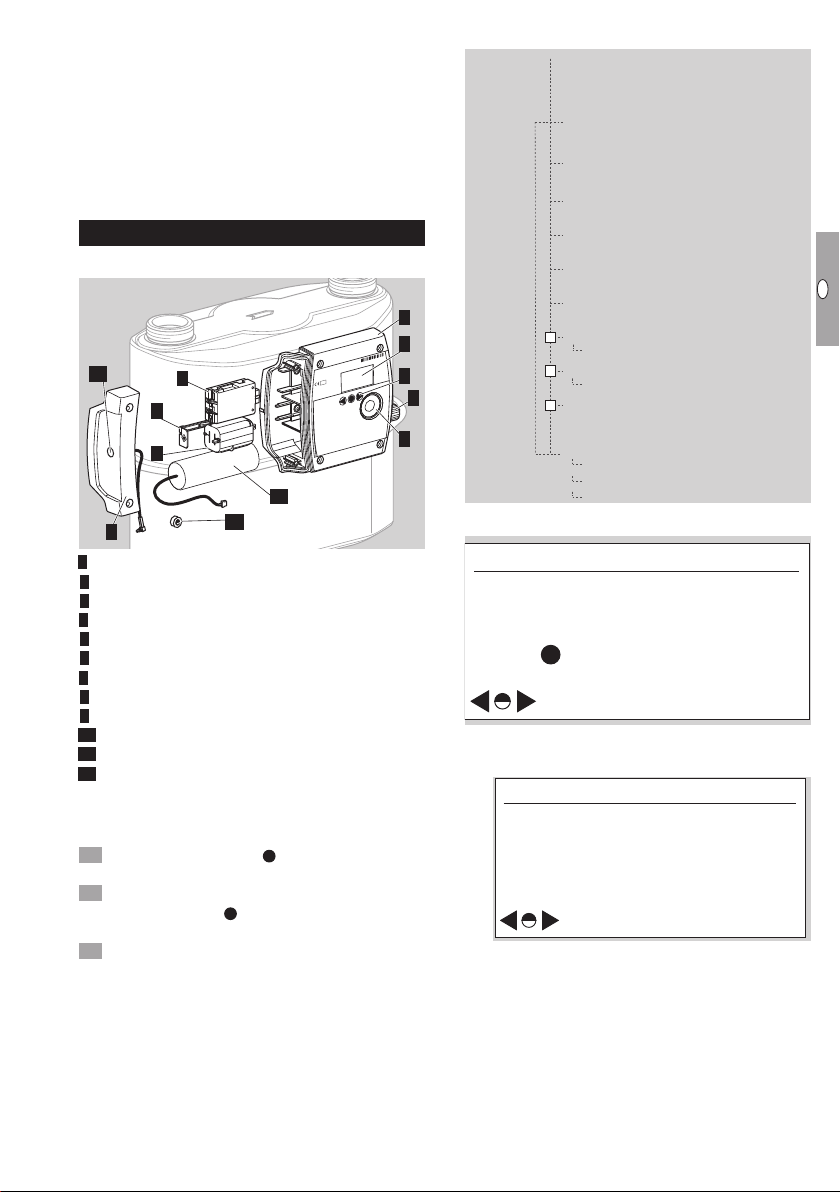

Part designations

12

9

8

5

Electronic index EI3

Display

User keys

4 Opto-adapter interface

5 Service cover

6 Pulse output

7 Communication module

8 Battery for the index

9 Protection clip

0 Battery for the communication module

Installer seal

Connection for external antenna (option)

▷ In Service mode, meter-specific operating data

can be called up.

Activating Service mode

Hold the selection key

▷ A pixel will appear in each corner of the display.

Observe one pixel: while the pixel is visible, hold

the selection key pressed down. Release the

key as soon as the pixel has disappeared.

Repeat the process, until all the pixels are off and

“Test instructions” appears in the menu area.

▷ Service mode is activated.

Service mode menu overview

Main menu

Test instructions

Temperature

Pressure

Conversion

Battery diagnosis

1

2

1234 5678

BK-Gx

max

Q

min

Q

7

DE-07-MI002-PTB001

M07 0102

3

6

4

10

11

Test instructions

Date and time

–

LCD pixel test

–

Cyclic test

–

GPRS modem status

Identification & calibration info

Meter information

Calibration factors

Firmware traceability

Automatic return to main

menu after 5 minutes of

inactivity

Hold on any screen to

return immediately

Temperature

▷ The current gas temperature is displayed.

tg 25.00°C

TC : electronic

pressed down.

tg :[-25, 55]°C

tsp :20°C

tb :15°C

– tg currently measured gas temperature

– TC: type of temperature conversion

Electronic: mathematical conversion to tb

– tg: [ ] max. allowable gas temperature range

– tsp: specified centre temperature (in accordan-

– t

in index

tg [min. value, max. value]

ce with EN 1359)

: base temperature (in accordance with

b

EN1359), see page 14 (Technical data)

GB-5

Page 6

GB

F

NL

I

E

▷ Check test for temperature measurement, see

*Pressure

Conversion

Battery diagnosis

*

*Cyclic test: Starting

page 10 (Check test).

Pressure

▷ The current pressure data will be displayed.

Date and time

▷ Information on the date and time display.

Date and time

pg 1013.25mbar

PC :electronic

pg :[800.00, 1600.00]mbar

pb :1013.25mbar

– pg actual absolute gas pressure inside the

– PC: electronic – type of pressure conversion

– pg: [ ] max. allowable gas pressure range pg [min.

– pb: base pressure (in accordance with

meter

value, max. value]

EN1359)

▷

Check test for pressure measurement, see page

13 (Pressure test).

Conversion

▷ The conversion values are displayed.

Va 0000000.00m

3

Cf 00.9455660

pg 1013.25mbar

tg 25.00°C

Vb 0000000.00m

– Va volume alarm conditions

– Cf conversion factor Cf=

(p

/ pb) x (Tb / Tg) x (Zb / Z)

g

/ Z = 1

with Z

– pg actual absolute gas pressure inside the

– tg actual gas temperature

– Vb volume at base conditions

Battery diagnosis

▷ When the battery is connected, the status “OK”

is shown in the display.

b

meter

U(battery) 3.60 V

Status : OK

3

10–01–2011

10

:02:06

▷

The operator can transfer the switchover be-

tween winter and summer time to the communication module, provided that it supports this.

▷

The date is given in the format day - month - year.

▷

The date format can differ depending on the

market.

▷ This display is only visible if access to the past

meter readings has been activated.

LCD pixel test

▷ A display test can be carried out in this menu.

Follow the displayed instructions.

▷ A test pattern is shown in the display.

Briefly press the selection key

▷ A further test pattern appears in the display.

Hold the selection key pressed down. The display

switches to the previous menu.

Cyclic test

▷ The accuracy of the meter can be checked us-

ing a cyclic test.

C 000.00000

U 000.00000

tg 25.04°C

m

m

pg 1023.25mbar

N 00000-0 t 00000.00s

Press to abandon test

– C converted volume (temperature and

pressure)

– U non-converted volume

– tg gas temperature

– pg gas pressure (absolute)

– N number of complete measuring cycles

(measuring unit revolutions)– number of

intermediate sampling points in the measu-

ring cycle (max.8)

– t total testing time in seconds

Briefly press the selection key in order to start

the measurement. A beep confirms the start of

the measurement.

▷

The display is visible for the first 5minutes. It

then disappears but lights up every minute for

10seconds.

.

3

3

GB-6

Page 7

GB

F

NL

I

E

▷ In order to end the measurement, briefly press

GPRS modem status

ON

Meter information

Identification &

calibration info

Calibration information

Q1: 0.000m3/h CF1:16384

Q2: 6.000m

3

/h CF2:16384

Q3: 12.000m

3

/h CF3:16384

Meter information

the selection key

once the full number of measuring unit revolutions has been completed.

Measurement is terminated automatically after

▷

5hours.

▷ A beep indicates that measurement has ended.

Read off the measurement results.

▷ Check test for cyclic test, see page 10 (Check

test).

GPRS modem status

▷ The communication data are displayed.

again. Measurement stops

GSM.L : 100%

StCon : GPRS attached

GSM.N : Provider

IPAdr : 192.168.12.1

P.Sta : OK

– GSM.L: GSM reception level

The reception level between 1 – 31

– StCon: Connection status

GSM attached: comms module is

GSM not attached: comms module is

– GSM.N: GSM network operator

The name of the current provider is di-

– IPAdr: IP address is displayed

– P.Sta: PIN status: OK

PIN status: Failed

▷

▷

Identification & calibration info

Meter-specific technical data are displayed in submenus by pressing the user keys , and the

selection key .

is transferred to a percentage value

between 3 and 100%.

switched on

switched off

splayed in clear text.

For symbols, see page 3 (User keys, selection key and symbols).

Depending on the GPRS reception level (see

display), the use of an internal or an external

antenna is possible. The internal antenna is the

standard. In order to use an external antenna,

the service cover has to be exchanged by one

with an SMA connector.

Meter information

Version :1.xx.xx

CRC :0x0000

Details :REL 120727

Produced :2000

Meter information:

– Software version

– CRC: software checksum

– Software details

– Year of manufacture

▷ Other screen descriptions (not illustrated):

Calibration information:

– Meter calibration parameters Q1 to Q3

(adjustment values Q1 to Q3 for three-point

calibration)

Meter characteristics:

– Cyclic meter volume

– Transitional flow rate

– EN 1359 Reg. No.: NG-4701BM0443 (example)

Ambient conditions:

– Electromagnetic

– Mechanical

Firmware traceability

▷ The events shown are saved in the non-volatile

permanent log memory.

▷

The metrology-relevant system events, e.g. firm-

ware upgrades, restarts, low voltage, etc. are

stored in the permanent log memory.

▷

The events in the permanent log have unique

numbers, e.g.:

2 –> Firmware upgrade

15 –> Restart demand

16 –> Restart

▷ Only events which are relevant for the firmware

history are listed in the “Firmware traceability”

sub-menu.

Event: 2

Time: 12:18:45

Date: 12.06.2013

Info: 0xFFFFFFFFFFFF0104

6

Menu description

Event: event that has occurred; can be as-

signed the number 2, 15 or 16

Time: time at which the event occurred

4 Date: date on which the event occurred

5 Info: additional data, as explained below

6 Navigation symbols

1

2

3

4

5

GB-7

Page 8

GB

F

NL

I

E

In the case of event , “Firmware upgrade”, the

Event: 4

Time: 12:18:45

Date: 12.06.2013

Event: 4

Time: 12:18:45

Date: 12.06.2013

meaning of the additional data is as follows:

Info: 0xFFFFFFFFFFFF0104

Additional manufacturerspecific data

Reason:

00: upgrade started;

01: upgrade completed;

02: upgrade failed/error;

03: upgrade rejected

Establishing an optical communications link

▷ In order to configure the electronic index for the

respective application, the optical communications link must be activated.

Position the opto-adapter head on the interface

provided.

The user ID (HEX coded; here 0x04) means:

First position (1

information for the communication port:

0: unknown;

8: GSM modem;

9: opto-port.

Second position (2

a unique user ID 0 to F, e.g. 6 =>

manufacturer; further information is to be

requested from the meter owner.

In the case of event 5 “Restart demand” and

event 6 “Restart”, the meaning of the additional data is as explained below:

▷

The HEX values must always be itemized in pairs

(1byte).

▷ The HEX values of the firmware version are dis-

played “LSB first” coded.

▷ LSB first:least significant byte first.

▷ MSB first:most significant byte first.

Info: 0xXXXX 7DFE 1D150104

Additional manufacturerspecific data

Checksum (CRC), e.g.:

0x7DFE (MSB first coded)

Version information, e.g.:

0x1D1501 (display: LSB first)

=> 0x01151D (HEX, MSB first coded)

=> 01.21.29 (DEC, MSB first coded)

The user ID (HEX coded; here 0x04) means:

First position (1

information for the communication port:

0: unknown;

8: GSM modem;

9: opto-port.

Second position (2

a unique user ID 0 to F, e.g. 6 =>

manufacturer; further information is to be

requested from the meter owner.

st

nibble/here 0) contains the

nd

nibble/here 4) contains

st

nibble/here 0) contains the

nd

nibble/here 4) contains

Press any user key.

▷ Optical communication is enabled for 1 minute.

▷

If the optical communications link is not used

during this time, the interface will be deactivated.

Initiate communication.

▷ The procedure depends on your user software.

Setting the index parameters

▷

The index parameters can be adjusted using the

user equipment. Please contact manufacturer.

Replacing the communication module

WARNING

Risk of explosion in explosion-hazard areas!

– As a general rule, maintenance and repair work

should be avoided in explosive atmospheres.

– Check that the electrical system complies with

the special electrical explosion protection requirements.

– When working on electrical equipment in an

explosion-hazard area, only design-approved

electrical operating equipment may be used.

– Use original spare parts supplied by Elster

GmbH, see page 14 (Spare parts).

▷ When changing the SIM card together with the

communication module or just exchanging the

SIM card, the optical communications link has

to be established, see page 8 (Establishing

an optical communications link).

▷

For safe handling in an explosion-hazard area,

the order of the following steps has to be ensured.

GB-8

Page 9

GB

F

NL

I

E

Replacing the communication module

▷ TORX screw driver size T20 required.

31 2

4

7

5

8

6

9

0 Replace the service cover on the electronic index.

Push in a new screw locking cap, see page 14

(Spare parts). The body carrying out this task

should apply its own adhesive seal for sealing

the service cover.

Changing the SIM card

Establish the optical communications link, see

page 8 (Establishing an optical communications link).

Follow steps 1 to 6 of “Replacing the commu-

nication module”, see section above.

▷

The SIM card slot can be found on the underside

of the module.

Briefly press the SIM card to remove it from the

holder.

4 Insert the new SIM card in the same position

and lock it by pressing briefly.

5 To reinstall the communication module, follow

steps 7 to 11 of “Replacing the communication

module”, see section above.

▷ The new SIM card requires a new PIN number.

6 Enter the new PIN number via the optical in-

terface. The procedure depends on your user

software.

WARNING

Risk of losing data!

– Before changing the SIM card, ensure that the

GSM connection is not active!

Changing the battery

WARNING

Risk of explosion in explosion-hazard areas!

– As a general rule, maintenance and repair work

should be avoided in explosive atmospheres.

– Check that the electrical system complies with

the special electrical explosion protection re-

quirements.

– When working on electrical equipment in an

explosion-hazard area, only design-approved

electrical operating equipment may be used.

– Use original spare parts supplied by Elster

GmbH, see page 14 (Spare parts).

▷

The battery is available as a spare part, see

page14 (Spare parts).

▷ Prepare the index for changing the batteries.

▷ TORX screw driver size T20 required.

31 2

Battery for the communication module

▷ The battery can only be replaced when no data

communication is taking place (check for the RF

module symbol in the display). Otherwise, data

communication will be cut off.

Replace the battery as shown in the following steps:

5

7

8

0 Reprogram the battery parameters via the optical

interface.

▷ The procedure depends on your user software.

Replace the service cover on the electronic index.

Push in a new screw locking cap, see page 14

(Spare parts). The body carrying out this task

should apply its own adhesive seal for sealing

the service cover.

64

9

GB-9

Page 10

GB

F

NL

I

E

Electrical pulse output

WARNING

Risk of explosion in explosion-hazard areas!

– As a general rule, maintenance and repair work

should be avoided in explosive atmospheres.

– Check that the electrical system complies with

the special electrical explosion protection requirements.

– When working on electrical equipment in an

explosion-hazard area, only design-approved

electrical operating equipment may be used.

– This pulse output is not suitable for metrolo-

gical testing purposes, but for monitoring the

consumption.

▷ The generated pulses correspond to the values

shown in the technical data, see page 14

(Technical data).

▷

When gas consumption is higher than the output

can transmit its pulses, the pulses are buffered

and will be transmitted afterwards when con-

sumption is low.

Pin assignment:

Pin 1, 2, 4, 6: not connected

Pin 3: output +

Pin 5: output -

3

452

6

1

▷ To connect the pulse output, use a socket type

IEC 60130-9.

Check test

Directive 2014/32/EU (MID) prescribes that it must

be possible to check the meter.

▷

The requirements and test methods must comply

with national laws and regulations.

▷

The following tests describe the check tests

which are carried out by accredited testing

agencies.

▷

Always conduct a pressure and temperature

correction in accordance with established pro-

cedures (unit under test against master meter).

▷

Measurement accuracy class, see page 14

(Technical data).

▷

The unit under test must be acclimatized and

installed on the test rig.

▷

Maintain the climatic conditions constant dur-

ing the entire test duration. Otherwise, the test

results will be inaccurate.

▷ Immediately before commencing the test, pass

the quantity of test air, which corresponds to at

least 50times the cyclic volume of the unit under

test, through the meter at a flow rate of Q

(maximum flow rate of a gas meter).

max

▷

To conduct the tests, the thermowell and the

pressure test point (if available) can be used as

a reference for the temperature and pressure

measured by the index.

Cyclic test

The manual test is described below.

Legend

Δt

= total master meter testing time in s

N

ΔtP = testing time of the unit under test in s

Q

= maximum flow rate of a gas meter

max

Q

= minimum flow rate of a gas meter

min

QN = flow on master meter in m³/h based on

the displayed volume V

Q

= actual flow rate on master meter in m³/h

act,N

QP = flow determined on unit under test based

N

on VP in m³/h

VN = displayed volume on master meter in m³

V

= actual volume having flowed through the

act,N

master meter in m³

VP = displayed volume on unit under test in m³

Value after C or U in display, depending

on device configuration and test method.

See test procedure below for further

details.

FN = error of the master meter in %

FP = error of the unit under test in %

pN = absolute pressure on the master meter in

mbar

pP = absolute pressure on the unit under test in

mbar

TN = absolute temperature on the master meter

in K

TP = absolute temperature on the unit under

test in K

tb = base temperature in °C

Vb = converted volume with reference to tb and

p

pb = base pressure in mbar

b

Cyclic test at a constant flow rate

▷ The test rig is in pre-trial operation.

▷ Maintain the flow rate constant.

Test load and minimum test volumes for the test with

index readout:

Type

BK-G6 10 6 6 60 300

BK-G10 16 6 6 60 300

BK-G16 25 6 6 60 300

BK-G25 40 12 12 120 600

BK-G40 65 18 18 180 900

▷

Q

The minimum test volumes are recommended

max

in

m3/h

Cyclic

volume

in dm

Test volume in dm3 at

Q

0.2 Q

min

3

guide values. The measurement uncertainty of

the complete system (test rig plus unit under

test) must not exceed 1/3 of the maximum permissible error (MPE). The testing time must be

at least 10 s.

GB-10

maxQmax

Page 11

GB

F

NL

I

E

▷

In the test procedure described below, it is guaranteed that the unit under test always performs

full measuring unit rotations.

Master meter test procedure

Q

N

∆t

N

61

the master meter have already been taken into

account here:

FP = 100% x (((QP x pP x TN) / (Q

TP)) - 1)

act,N

x pN x

The following applies:

= (273.15 + {tg}) K

T

P

p

= {pg} mbar

P

in step 7 is determined from the non-con-

If Q

P

verted volume VP, the following applies:

TP = (273.15 + {tg}) K

where tg = relevant gas temperature on the unit

under test in °C (display)

▷ The curly brackets mean “numerical value of”.

▷

On a nozzle test rig with a known flow rate,

steps and 6 can be omitted.

▷

∆t

P

2 3 4 5

The error calculation is based on PTB Testing

Instructions, Volume 29: “Messgeräte für Gas –

Gaszähler” (Measuring instruments for gas – gas

meters), Edition 2003.

Set the test flow rate.

Start measuring the reference timeΔtN at mark-

er1.

Immediately afterwards, briefly press the selec-

tion key on the index to start the cyclic test

on the unit under test– marker2. The index will

thus be “armed” for measurement.

▷

As soon as one of the significant sensor posi-

tions has been detected, the unit changes to

measuring mode– marker3. A beep confirms

Cyclic test with a given volume

Test load and minimum test volumes for the test with

index readout:

Q

Cyclic

Type

BK-G6 10 6 180 360 360

BK-G10 16 6 180 360 360

BK-G16 25 6 180 360 360

BK-G25 40 12 360 720 720

BK-G40 65 18 540 1080 1080

max

in

m3/h

volume

in dm

Test volume in dm3 at

Q

min

3

0.2 Q

maxQmax

the start of the measurement.

▷

Once the required minimum testing time has

Master meter test procedure

been reached, the measurement can be terminated– marker4.

4 Briefly press the selection key in order to end

V

N

the measurement.

▷

Measurement on the unit under test stops automatically once the full number of measuring

unit revolutions has been completed– marker5.

8

10

▷ A beep acknowledges the end of the measure-

ment.

▷

Measurement is terminated automatically after

5 hours.

5 Stop the test on the master meter– marker6.

97

11

▷ The measurements are then available.

6 Read off the flow rate on the master meter or

calculate if necessary:

a) taking into account the inherent error of the

master meter:

Q

b) If the inherent error of the master meter has

= VN x 3600 s/h / ((1+FN/100) x ΔtN)

act,N

already been taken into account in the dis-

played volume (VN = V

Q

7 Calculate the flow rate on the unit under test:

8 The accuracy is checked by comparing the flow

= V

act,N

QP = VP/Δt

x 3600 s/h / Δt

act,N

P

act,N

):

N

rates. The pressure and temperature values of

the unit under test corrected with reference to

To activate the cyclic test on the unit under test,

briefly press the selection key on the index–

marker7. The index will thus be “armed” for

measurement.

Start the test on the master meter– marker8.

▷

As soon as one of the significant sensor positions has been detected, the unit changes to

measuring mode– marker9.

Test is ended– marker10.

4 Read off the test results on the unit under test.

▷

The measured values are updated with each 1/8

revolution of the measuring unit.

GB-11

Page 12

GB

F

NL

I

E

5 Compare the measurement results with the mas

ter meter and determine the measuring deviation

on the unit under test:

a) taking into account the inherent error of the

master meter:

FP = 100% x (((VP x (1+FN/100) x pP x TN) /

(V

x pN x TP)) - 1)

b) If the inherent error of the master meter has

N

already been taken into account in the displa-

yed volume (VN = V

FP = 100% x (((VP x pP x TN) / (V

T

)) - 1)

▷ The following applies:

T

pP = {pg} mbar

P

= (273.15 + {tg}) K

P

), the following applies:

act,N

act,N

x pN x

If the non-converted volume VP is taken for VP:

T

= (273.15 + {tg}) K

P

where t

= relevant gas temperature on the unit

g

under test in °C (display)

▷ The curly brackets mean “numerical value of”.

6 Stop execution of the cyclic test– marker 11.

Briefly press the selection key twice in order

to stop the measurement.

A beep confirms interruption of the measurement.

▷

▷

Measurement is terminated automatically after

5 hours.

▷

The error calculation is based on PTB Testing

Instructions, Volume 29: “Messgeräte für Gas –

Gaszähler” (Measuring instruments for gas – gas

meters), Edition 2003.

Pulse test (optical interface)

Test load and minimum test volumes for the test with

index readout:

Q

Cyclic

Type

BK-G6 10 6 180 360 360

BK-G10 16 6 180 360 360

BK-G16 25 6 180 360 360

BK-G25 40 12 360 720 720

BK-G40 65 18 540 1080 1080

▷ Pulse value V

▷ This test can only be carried out when the opti-

max

in

m3/h

volume

in dm

Imp

Test volume in dm3 at

Q

0.2 Q

min

3

maxQmax

, see page 14 (Technical data).

cal communications link has been established.

The procedure depends on your user software.

Establish the optical communications link, see

page 8 (Establishing an optical communications link).

Interrupt communication to the installed commu-

nication modules before starting the test so that

the measurement accuracy will not be adversely

affected.

-

Pulse test at a constant flow rate (optical

interface)

Master meter test procedure

Q

N

∆t

N

12

∆t

P

13 14

Set the test flow rate.

4 Start measuring the reference time ΔtN at mark-

er12.

▷ Marker12 indicates the release of the test flow

rate on the master meter.

5 Immediately afterwards, start the pulse test on

the unit under test– marker13.

▷ Then the unit under test generates the volume

pulses on the optical interface each time the

lowest-order decimal place on the meter display

is incremented– marker14. The test begins.

6 As soon as the required minimum test volume

has been reached on the unit under test, the

time measurement on the unit under test can

be stopped– marker15.

7 End the pulse test using any command– mark-

er16.

▷

Measurement is terminated automatically after

90minutes.

8 Shut off the gas flow to the master meter–

marker17.

9 Determine the volume on the unit under test VP:

VP = N x V

N = number of pulses during Δt

V

= pulse value V

Imp

nical data)

Imp

, see page 14 (Tech-

Imp

0 Calculate the flow rate on the unit under test:

QP = VP/Δt

Read off the flow rate on the master meter or

P

calculate if necessary:

a) taking into account the inherent error of the

master meter:

Q

b) If the inherent error of the master meter has

= VN x 3600 s/h / ((1+FN/100) x ΔtN)

act,N

already been taken into account in the displayed volume (VN = V

Q

act,N

= V

act,N

x 3600 s/h / Δt

act,N

):

17

15 16

P

N

GB-12

Page 13

GB

F

NL

I

E

The accuracy is checked by comparing the flow

rates. The pressure and temperature values of

the unit under test corrected with reference to

the master meter have already been taken into

account here:

FP = 100% x (((QP x pP x TN) / (Q

TP)) - 1)

act,N

x pN x

The following applies:

= (273.15 + {tg}) K

T

P

pP = {pg} mbar

▷ The curly brackets mean “numerical value of”.

▷

On a nozzle test rig with a known flow rate,

steps 4 and can be omitted.

▷

The error calculation is based on PTB Testing

Instructions, Volume 29: “Messgeräte für Gas –

Gaszähler” (Measuring instruments for gas – gas

meters), Edition 2003.

RTC test

▷

The climatic conditions must be maintained con-

stant at 22± 5°C during the entire test duration.

Temperature changes in 24hours ≤2K.

▷

Ensure that conditions remain sufficiently stable

during the measurement.

▷ The accuracy of the time count can be verified

with this test.

Acclimatize the unit under test and place next

to the time reference unit.

If necessary, activate the time display on both

units.

Ensure synchronous reading by taking a photo.

4 Observe a min. testing time of 72hours.

5 Repeat steps and .

6 The clock deviation of the unit under test must

not exceed the maximum admissible deviation. Maximum admissible deviation= 5ppm in

24hours.

Temperature test

▷ The accuracy of the temperature measurement

can be verified with this test.

▷ The temperature test can only be carried out in

Service mode.

CAUTION

To avoid damage to the meter:

– Comply with ambient temperature, see

page 14 (Technical data). Deviations from

the permitted ambient temperature will be recorded in the error memory.

▷ Temperature measurement accuracy, see page

14 (Technical data).

Install the diaphragm gas meter in a climatic

5 Select an ambient temperature as a reference

value and bring the climatic chamber to this temperature.

▷

To ensure there is also a uniform temperature

in the meter, we recommend starting the meter

air/gas flow during the temperature adjustment

phase.

▷

Ensure that temperature distribution remains

uniform and stable during the temperature

measurement.

6 Compare the measured value to the temperature

reference value.

If required, several reference values can be

▷

checked. In this case, repeat the test as of

point 5 .

Pressure test

▷

The accuracy of the pressure measurement can

be verified with this test.

▷

The pressure test can only be carried out in

Service mode.

CAUTION

To avoid damage to the meter:

– Comply with the maximum allowable operating

pressure, see page 15 (Technical data). Deviations from the permitted operating pressure will

be recorded in the error memory.

▷

Pressure measurement accuracy, see page

14 (Technical data).

▷

Keep the meter a sufficient time under stable

conditions to ensure acclimatization.

▷

Ensure stable conditions (temperature and pressure) during testing.

Close off the meter outlet connector so that it

is leak-tight, preferably with a valve to permit

venting.

Install a closed system with pressure pump and

reference pressure gauge at the inlet.

Slowly increase the pressure with the pressure

pump to the desired pressure.

4 Activate Service mode, see page 5 (Service

mode).

5 Change to the “Pressure” menu.

▷

The current pressure inside the meter housing

is displayed as absolute pressure.

6 Apply at least 5 minutes waiting time to ensure

pressure stabilization.

7 Compare the measured pressure value to the

pressure reference value.

8 Slowly open the outlet using the valve to prevent

meter damage.

chamber.

Activate Service mode– see page 5 (Service

mode).

Change to the “Cyclic test” menu.

▷ The current gas temperature is displayed.

4 Close the climatic chamber.

GB-13

Page 14

GB

F

NL

I

E

Assistance in the event of malfunction

? Fault

! Cause

• Remedy

Possible faults and suggested solutions

? The

! If the symbol appears next to a measured

• After the next time synchronization, the data are

? When pressing the user keys, the display

! Energy-saving mode is active. Due to excessive

• Leave the index unused for an extended period,

? When pressing the user keys, the display

! The index is defective.

• Contact the manufacturer.

symbol is displayed.

value, this means that the value is invalid.

recorded again correctly and disappears.

remains switched off. A beep can nevertheless be heard.

use of the index, the average energy consumption has been exceeded.

e.g. 24hours. After this, the user interface will

once again be available.

remains switched off and no beep can be

heard.

72910265, “Retrofit kit external antenna EI3 / 5m”

composed of:

– service cover -cpl. EA EI3 (32320088)

– PT screw K40x16 (03017232)

– GSM antenna L=5m (04271002)

Spare parts

Only the following spare parts are approved:

Communication module

Use only original Elster communication modules.

Elster Part No.:

72910267, “spare parts kit communication mod-

uleEI3” composed of:

– communication module GSM EI3 (32320046)

– PT screw K40x16 (03017232)

– screw locking cap EI (32447510)

Battery for the communication module

Use only original Elster batteries.

Elster Part No.:

72910266, “spare parts kit batterypack C.M. GSM

EI3” composed of:

– batterypack comm.module GSM EI3 (32447571)

– PT screw K40x16 (03017232)

– screw locking cap EI (32447510)

Screw locking cap

? The

symbol is displayed.

! Low index battery. This symbol is only displayed

when index battery power is low.

• Replace the index battery.

? Display light is off.

! Low index battery voltage.

• Replace the index battery.

! Display light is defective.

• Contact the manufacturer.

▷

In the case of faults which are not described here,

contact the manufacturer immediately.

Accessories

External antenna

Only the following antennas are approved as external

antennas.

Elster Part Nos.:

72910264, “Retrofit kit external antenna EI3 / 2.5m”

composed of:

– service cover -cpl. EA EI3 (32320088)

– PT screw K40x16 (03017232)

– GSM antenna L=2.5m (04271001)

Part No.: 32447510.

Technical data

RoHS compliant

Application with diaphragm gas meters BK..B

Enclosure: IP 65.

Maximum allowable operating pressure p

overpressure): see index plate,

base gas pressure pb: see index plate,

operating pressure range (absolute) pg:

800 to 1600mbar.

Life of battery for index: approx. 15 years.

Life of battery for communication module:

approx. 5 years.

Ambient temperature of index: -25 to +55°C (for

entire meter, see index plate).

Accuracy of the clock: 0.4 s/day at 20°C on the

day of manufacture.

Temperature measurement accuracy on the day of

manufacture:

± 0.2°C in the range from -10 to +55°C.

± 0.25°C in the range from -25 to -10°C.

Pressure measurement accuracy: ± 5 mbar on the

day of manufacture.

GB-14

max

(as

Page 15

GB

F

NL

I

E

Pulse value V

face:

Gas meter

BK-G6 3 1

BK-G10 – BK-G40 2 10

for pulse tests via optical inter-

Imp

Decimal

place

value V

in display

Pulse

in dm

Imp

3

The electrical interfaces feature the following

parameters:

Pulse output:

– U

= 26.6 V

i

= 250 mA

– I

i

– Pi = 414 mW

– C

= 0.012 µF

i

= 0 mH

– L

i

Communication module: GSM RF technology.

Data logger for past meter readings:

up to 20 weeks in hourly intervals.

Optical interface: pursuant to EN 62056-21,

Mode(E), Annex B.2.

Pulse output

Type of switch: open collector transistor, normally

closed.

For switching voltage and current, see section

“ATEX explosion protection” below.

Resolution: 1 pulse per 10 litres of base volume.

Maximum pulse frequency: 4 Hz.

For further technical data on diaphragm gas

meters BK, see:

“Operating instructions for diaphragm gas meters

BK-G1.6 to BK-G25” → http://docuthek.kromschroeder.com/doclib/main.php?language=1&folderi

d=400041&by_class=2&by_lang=-1

“Instruction Manual, Industrial Diaphragm Gas

Meters

Type BK-G40 · BK-G65 · BK-G100 and Type BK-

G40T · BK-G65T · BK-G100T” →

http://docuthek.

kromschroeder.com/doclib/main.php?language=1

&folderid=400045&by_class=2&by_lang=-1

Minimum pulse duration: 125 ms.

Logistics

For further technical data on diaphragm gas meters

BK, see:

“Operating instructions for diaphragm gas meters

BK-G1.6 to BK-G25” →

http://docuthek.kromschroeder.com/doclib/main.ph

p?language=1&folderid=400041&by_class=2&by_

lang=-1

“Instruction Manual, Industrial Diaphragm Gas Meters

Type BK-G40 · BK-G65 · BK-G100 and Type BK-G40T

· BK-G65T · BK-G100T” →

http://docuthek.kromschroeder.com/doclib/main.ph

p?language=1&folderid=400045&by_class=2&by_

lang=-1

ATEX explosion protection

The index EI3 is certified as an ATEX subassembly

and is marked as follows:

II 2 G Ex ib IIA T4 Gb

= Specific explosion protection mark

II = Equipment group for “non-mining”

2G = Equipment category 2 (zone 1) for gas

EX = Symbol for electrical equipment

built according to European standards

ib = Type of ignition protection:

i = intrinsically safe

b = suitable for use in zone 1

IIA = Explosion group for gases

T4 = Temperature class: maximum allowable

surface temperature: 135°C

Gb = Equipment protection level (zone 1)

The batteries and communication modules are

certified as parts of the electronic index. Use only

spare parts from Elster. For suitable batteries and

communication modules, see page 14 (Spare

parts).

Transport

Diaphragm gas meters are always to be transported

in the upright position. On receipt of the product,

check that the delivery is complete, see page 2

(Part designations). Report any transport damage

immediately.

Storage

Diaphragm gas meters are always to be stored in

the upright position and in a dry place. Ambient temperature: see page 14 (Technical data).

Disposal

Meters with electronic components:

Components, particularly batteries, are to be disposed of separately.

On request, old units may be returned carriage paid

to the manufacturer, see page 16 (Contact), in

accordance with the relevant waste legislation requirements.

GB-15

Page 16

GB

F

NL

I

E

Contact

Contact

United Kingdom

Elster Metering Limited

Paton Drive

Tollgate Business Park

Beaconside

Stafford, ST16 3EF

Tel. +44 1785 275200

Fax +44 1785 275305

jeavons.info@gb.elster.com

www.elstermetering.co.uk

Germany

Elster GmbH

Strotheweg 1

49504 Lotte

Tel. +49 541 1214-0

Fax +49 541 1214-370

info@elster-instromet.com

www.elster-instromet.com

Ireland

Active Energy Control Ltd.

Unit 4, Clare Marts

Quin Road

Ennis, Co. Clare

Tel. +353 65 6840600

Fax +353 65 6840610

info@aec.ie

www.aec.ie

GB-16

in the interests of progress.

We reserve the right to make technical modifications

Loading...

Loading...