Page 1

GB

F

NL

I

SK

1000106001-002-06

03250952

D GB

I

➔ www.docuthek.com

Safety

Safety

Please read and keep in a safe place

Operating instructions for

operators and installers

Electronic index EI

© 2017 Elster GmbH · Edition 08.17

alpha

Translation from the German

Contents

Contents

Electronic index EI .....................

Contents ..............................

Safety.................................

Checking the usage .....................

Installation ............................

Operating the electronic index ............

Navigating within the menu ..............

Service mode ..........................5

Establishing an optical communications link 7

Changing the battery ....................7

Setting the index parameters .............8

Releasing the valve .....................8

Retrofitting/replacing the communication

module ...............................9

Check test.............................9

Assistance in the event of malfunction ....4

Spare parts ...........................4

Technical data ........................5

Logistics .............................5

Contact ..............................6

carefully before installing or operating. Following the

Please read through these instructions

installation, pass the instructions on to the operator. This unit must be installed and commissioned

in accordance with the regulations in force. These

instructions can also be found at www.docuthek.com.

Explanation of symbols

• , , , ... = Action

▷ = Instruction

Liability

We will not be held liable for damage resulting

from non-observance of the instructions and noncompliant use.

Safety instructions

Information that is relevant for safety is indicated in

the instructions as follows:

DANGER

Indicates potentially fatal situations.

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

All interventions may only be carried out by qualified

gas technicians. Electrical interventions may only be

carried out by qualified electricians.

Conversion, spare parts

All technical changes are prohibited. Only use OEM

spare parts.

Changes to edition .

The following chapters have been changed:

– Checking the usage

– Logistics

GB-1

Page 2

GB

F

NL

I

SK

Checking the usage

*

Current meter reading

OFF

Electronic index EI.00, EI.05, EI.06,

EI. for diaphragm gas meters BK-G...E,

BK-G...ET or BK-G...ETe

Electronic index for reading out absolute meter readings and for retrieving consumption data, current

tariffs, messages and the valve position.

This function is only guaranteed when used within the

specified limits – see page 15 (Technical data). Any

other use is considered as non-compliant.

Type code

Code Description

EI Electronic index based on EI2

.00

.05

.06

.

Zigbee with valve Vs

Zigbee with valve Ve

Zigbee, valve Vs, top reading

Zigbee, valve Ve, top reading

Communication module

.00

.0

.0

▷

The index version is shown on the index plate,

ECM.10 (Zigbee SMETS 1)

ECM.02 (Zigbee)

see page 2 (Type label/Index plate).

When retrofitting or replacing the communication

▷

module, it may be the case that the last two characters in the type code are no longer applicable.

Part designations

Variant

None

ATEX

▷

The electronic index is suitable for use in potentially

explosive atmospheres. For the exact use (zone),

see ATEX sticker on the diaphragm gas meter or

see the operating instructions for diaphragm gas

meters BK-G1.6 to BK-G25 → http://docuthek.

kromschroeder.com/doclib/main.php?language

=1&folderid=400041&by_class=2&by_lang=-1.

Installation

Installing the gas meter

▷

For installing the gas meter in the pipework, refer

to the operating instructions for diaphragm gas

meters BK-G1.6 to BK-G25 → http://docuthek.

kromschroeder.com/doclib/main.php?language=1

&folderid=400041&by_class=2&by_lang=-1.

Gas meter with integrated valve

▷ If the integrated shut-off valve in the gas meter

is closed, it must be released, see page 8

(Releasing the valve).

Operating the electronic index

▷ The display on the index is switched off.

• Briefly press any key.

123 45678

BK-Gx

DE-07-MI002-PTB001

max

Q

min

Q

M07 0102

002545632734

5

6

Electronic index EI2

Display

User keys

4 Opto-adapter interface

5 Service cap

6 Installation seal/screw locking cap

Type label/Index plate

Please quote for all enquiries:

▷

Manufacturer’s serial number S/N (at the bottom left)

▷ Index version EI (next to the serial number)

V

p

S/N: ............ EI2. ...

BK-G..E..

Q

max

Q

min

max

M ... 0102

12345678

class 1,5

t

m

t

g

class 1,5

Valve Ve

1

2

3

▷ A beep sounds and the main screen appears.

▷

An internal buzzer gives audible feedback, e.g. a

short beep indicates a valve is open and a long

beep indicates a valve is closed. A short beep

sounds each time a key is pressed or if the unit

automatically changes back to the main screen.

▷

4

This function can be switched off, see page 8

(Setting the index parameters).

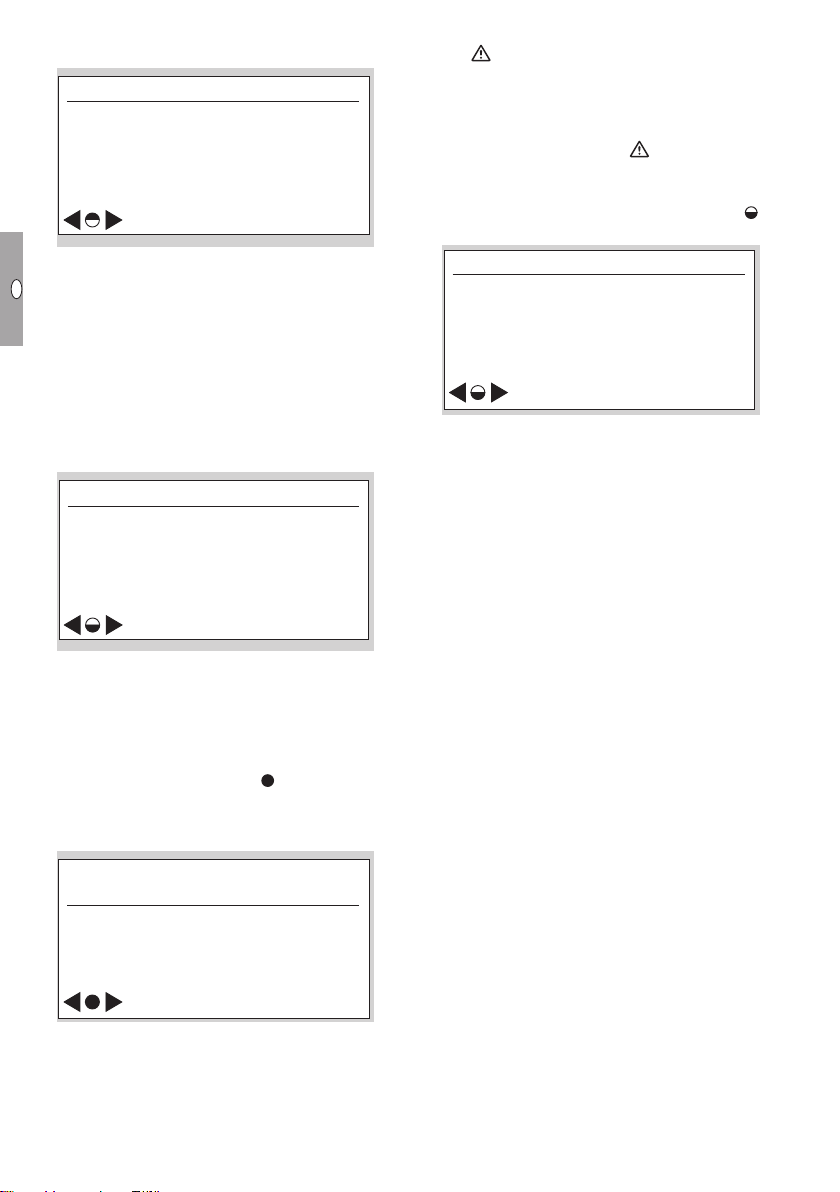

Main screen

1

3

00000.

ON

004

m

2

3

Menu area

Information area

Status line (symbols)

▷

The ON/

symbols are only displayed when

a valve is integrated in the gas meter.

GB-2

Page 3

GB

F

NL

I

SK

OFF

ON

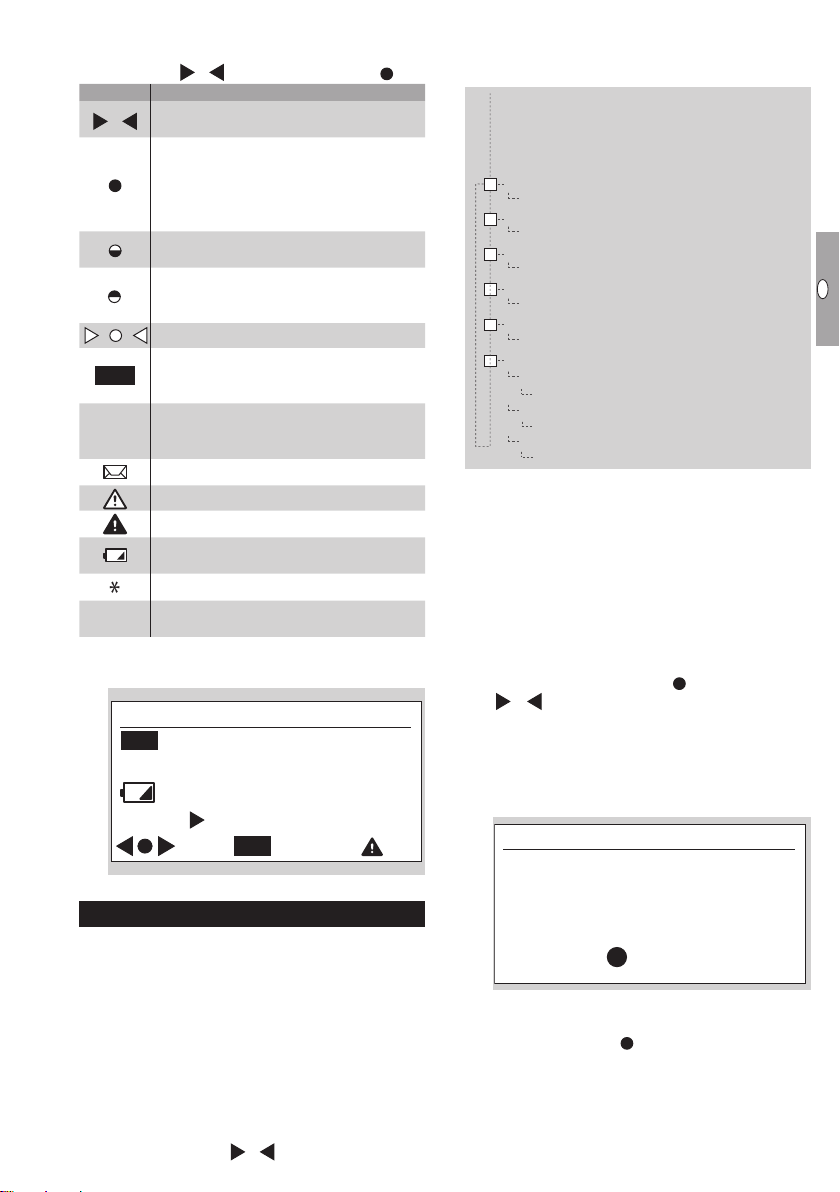

User keys, selection key and symbols

▷

You can navigate through the menu using the

user keys , and the selection key .

Symbol Meaning

▷

Navigate to the left or the right on each

,

level using the user keys.

Briefly pressing the selection key selects

a sub-menu.

Holding the selection key pressed down

switches the display back to the previous menu.

Briefly pressing the selection key selects

a sub-menu.

Holding the selection key pressed down

switches the display back to the previous menu.

Keys inactive

, ,

Valve/gas flow closed. This symbol is only

displayed when a valve is integrated in

the gas meter.

Valve/gas flow released. This symbol is

only displayed when a valve is integrated

in the gas meter.

New messages

Invalid data

Error message

Low battery. This symbol is only dis-

played when battery power is low.

Marking for metrology-relevant data

Substitute for undisplayable character

□

in sentence

In the “Icon definitions” menu, the most important

symbols are described briefly.

Icon denitions

OFF

Valve closed

Valve open

ON

Low battery

Press for more ...

OFF

Navigating within the menu

▷ The menu is constructed hierarchically.

▷

Depending on the configuration, some menus

may be missing.

▷

The “Current meter reading” main screen appears

when switching on the index.

▷

If you are in a different menu, the display will

automatically change back to the main screen

when no user key has been pressed for 30s,

and switches off after a further 30s.

You can navigate from the main screen to the

▷

various menus, such as “Meter information” using the user keys

, .

Menu overview

The display can differ depending on the parameteriza-

tion or communication module.

Main menu

–

Optional contents from communication module

–

Current meter reading

Icon definitions

–

Valve release procedure

–

Date and time

–

Historic meter readings

–

Meter information

Meter identification

Calibration information

Temperature conversion (optional)

Optional contents from communication

module

▷

For further information, refer to the operating

instructions for communication modules type

ECM (for electronic index).

Current meter reading

▷

The absolute meter reading and optionally the

current tariff are indicated in the main screen.

▷ This appears when switching on the index.

▷

You can receive information about the symbols by

pressing the selection key and the user keys

, , or see page 3 (User keys, selection

key and symbols).

Valve release procedure

▷ If the valve was released while the display was

switched off, the release note will appear the

next time the index is switched on.

Valve open safety check

CHECK IF

APPLIANCES OFF

HOLD FOR GAS

▷ The note remains active until the valve has been

released, see page8 (Releasing the valve).

▷

If the selection key is not pressed, the display

will switch back to the main screen after 30s.

GB-3

Page 4

GB

F

NL

I

SK

Date and time

*

Date and time

*

4 hour summary: Sat

▷ Information on the date and time display.

10–01–2011

10

:02:06

▷

The operator can transfer the switchover be-

tween winter and summer time to the communication module, provided that it supports this.

▷

The date is given in the format day - month - year.

▷

The date format can differ depending on the

market.

▷

This display is only visible if access to the historic

meter readings has been activated.

Historic meter readings

▷

Consumption data dating as far back as

60weeks can be called up.

Interval data

Historic

meter readings

ON

▷

The historic meter readings can be viewed as an

option. Depending on the parameterization, ac-

cess to the historic meter readings can either be

– fully activated or

– protected by entering a password or

– deactivated.

▷ By pressing the selection key , consumption

data are displayed, which are given by month,

week or day, or 4-hour or ½-hour intervals.

“4 hour summary” example:

Electronic index with communication module:

▷ The

Meter information

▷

symbol is displayed if, for example, the

tolerance between the internal time recording

and the actual time is too large. This can lead

to invalid consumption data. After the next time

synchronization, the consumption data are recorded again correctly and disappears.

Meter-specific technical data are displayed in

sub-menus by pressing the selection key

several times.

Meter information

Identification &

calibration info

ON

Meter identification:

– No.: (Owner’s meter number)

– EN 1359 Reg. No.: NG-4701BM0443 (exam-

ple)

– Firmware version

– CRC (checksum)

– Details (firmware details)

▷

For further information, see page 15 (Techni-

cal data).

Calibration information:

– Meter calibration parameters Q1 to Q3 (adjust-

ment values Q1 to Q3 for three-point calibration)

– Cyclic meter volume

Temperature conversion (optional):

– Type of conversion (mechanical or electronic)

– Base temperature tb (in accordance with

EN1359)

– Specified centre temperature tsp (in accordance

with EN1359)

01-02-2011 04:00 → 08:00

00000.351 → 00000.353m

0.002 m

▷

The timeframe is displayed with date and time

for the start and end of the period.

▷ The meter reading is displayed for the start and

end of the period in m

The consumption for this period is indicated in m3.

▷

▷ The tariff band may be displayed.

3

.

3

3

GB-4

Page 5

GB

F

NL

I

SK

Service mode

Test instructions

*

Part designations

Service mode menu overview

8

1234 5678

BK-Gx

DE-07-MI002-PTB001

max

Q

min

Q

M07 0102

002545632734

5

1

2

3

4

7

6

Electronic index EI2

Display

User keys

4 Opto-adapter interface

5 Service cover

6 Installation seal/screw locking cap

7 Battery

8 Communication module (optional)

▷ In Service mode, meter-specific operating data

can be called up.

Activating Service mode

Hold the selection key

pressed down.

▷ A pixel will appear in each corner of the display.

Observe one pixel: while the pixel is visible, hold

the selection key pressed down. Release the

key as soon as the pixel has disappeared.

Repeat the process, until all the pixels are off and

“Test instructions” appears in the menu area.

▷ Service mode is activated.

Main menu

Test instructions

Temperature (optional)

Battery diagnosis

Date & time

–

LCD pixel test

–

Cyclic test

–

UMI peripherals

UMI-1

UMI-2

UMI-3

–

Optional contents from communication module

–

Meter information

Test instructions

Automatic return to main

menu after 5 minutes of

inactivity

Hold on any screen to

return immediately

ON

Temperature (optional)

▷

This menu is available if temperature conversion

has been activated.

Temperature

tg 25.04°C

TC : electronic

tg : [-10, 40]°C

tsp : 20°C

tb : 0°C

OFF

– tg currently measured gas temperature t

– TC: type of temperature conversion

Electronic: mathematical conversion to tb

in index

Mechanical: mechanical conversion to t

in measuring unit

GB-5

g

b

Page 6

GB

F

NL

I

SK

– tg: [ ] max. allowable gas temperature range

OFF

Battery diagnosis

U(hlc) : 3.60 V

U(min) : 3.00 V

Status : OK

OFF

OFF

Battery diagnosis

U(hlc) : 3.60 V

U(min) : 3.00 V

Status : OK

Battery diagnosis

U(hlc) : 3.60 V

U(min) : 3.00 V

Status : Change required

Battery diagnosis

U(hlc) : 3.60 V

U(min) : 3.00 V

Status : Test in progress

Time : 05:00 h:m

*

Date and time

*

Cyclic test: Starting

– tsp: specified centre temperature tsp (in ac-

– tb: base temperature t

▷

▷

Battery diagnosis

▷ When the battery is connected, the status “OK”

t

[min. value, max. value]

g

cordance with EN 1359)

EN 1359), see page 15 (Technical data)

Check test for temperature test, see page 9

(Check test).

The measured value is updated once per minute.

is shown in the display.

(in accordance with

b

Battery diagnosis

U(hlc) : 3.60 V

U(min) : 3.00 V

Status : OK

OFF

– The U(hlc) value indicates the current voltage

measured on the battery or HLC.

– The U(min) value signals the minimum voltage

measured on the battery or HLC.

▷ If battery power is low, the display changes to

the status “Change required”. The battery must

be changed within a short time.

Battery diagnosis

U(hlc) : 3.60 V

U(min) : 3.00 V

Status : Change required

▷

Having disconnected the battery, the display

switches to the status “Removed”.

Battery diagnosis

U(hlc) : 3.60 V

U(min) : 3.00 V

Status : Removed

OFF

OFF

Date and time

▷ Information on the date and time display.

10–01–2011

10

:02:06

▷

The operator can transfer the switchover be-

tween winter and summer time to the communication module, provided that it supports this.

▷

The date is given in the format day - month - year.

▷

The date format can differ depending on the

market.

▷

This display is only visible if access to the historic

meter readings has been activated.

LCD pixel test

▷ A display test can be carried out in this menu.

Follow the displayed instructions.

▷ A test pattern is shown in the display.

Briefly press the selection key

▷ A further test pattern appears in the display.

Hold the selection key pressed down. The display

switches to the previous menu.

Cyclic test

▷ The accuracy of the meter can be checked us-

ing a cyclic test.

C 00.000000

U 00.000000

m

m

tg 25.04°C

N 00000-0 t 00000-0 s

Press to abandon test

– C = converted volume (temperature only)

for BK-G...E: no function (C = U)

for BK-G...ET: C = V

for BK-G...ETe: C = Vb, conversion to tb (see

page 15 (Technical data))

– U = non-converted volume V

for BK-G...ET: U = converted volume V

▷

The conversion takes place in the measuring unit.

– tg = measured gas temperature in °C

– N = number of complete measuring cycles

(measuring unit revolutions) – number of intermediate sampling points in the measuring cycle

(max. 8)

– t = total testing time in seconds

▷ for BK-G...ETe, the following applies:

The relationship between Vb and VP is as follows:

Vb = VP x Tb / T

GB-6

, conversion to tb = 15°C

b15

g

.

3

3

P

b15

Page 7

GB

F

NL

I

SK

where Tb = (273.15 + {tb}) K

ON

Meter information

Identification &

calibration info

Calibration information

Q1: 0.000m3/h CF1:16384

Q2: 6.000m

3

/h CF2:16384

Q3: 12.000m

3

/h CF3:16384

5

m

m

T

= (273.15 + {tg}) K

g

tb is specified in the technical data, see page

15 (Technical data).

▷ The curly brackets mean “numerical value of”.

For detailed information on the check test op-

▷

erating sequence, see page 9 (Check test).

UMI peripherals

▷

The status of the available interfaces for optional

communication modules is displayed.

Meter information

▷

Meter-specific technical data are displayed in

sub-menus by pressing the selection key and

the user keys , .

Meter information

Version :x.xx.xx

CRC :0x0000

Details :REL YYMMDD

Year of man. :YYYY

Meter information:

– Software version

– CRC: software checksum

– Software details

– Year of manufacture

▷ Other screen descriptions (not illustrated):

Calibration information:

– Meter calibration parameters Q1 to Q3 (adjust-

ment values Q1 to Q3 for three-point calibration)

Meter characteristics:

– Cyclic meter volume

– Transitional flow rate Q

– EN 1359 Reg. No.: NG-4701BM0443 (example)

Ambient conditions:

– Electromagnetic

– Mechanical

Establishing an optical communications link

▷ Depending on customer requirements, the opti-

cal interface can be locked.

▷ In order to configure the electronic index for the

respective application, the optical communications link must be activated.

Position the opto-adapter head on the interface

provided.

1234 5678

Press any user key.

▷ Optical communication is enabled for 1minute.

▷

If the optical communications link is not used

during this time, the interface will be deactivated.

Initiate communication.

▷ The procedure depends on your user software.

▷

For further information, refer to the operating

instructions for communication modules type

ECM (for electronic index).

Changing the battery

WARNING

Risk of explosion in explosion-hazard areas!

– As a general rule, maintenance and repair work

should be avoided in explosive atmospheres.

– Check that the electrical system complies with

the special electrical explosion protection requirements.

– When working on electrical equipment in an

explosion-hazard area, only design-approved

electrical operating equipment may be used.

– Use original spare parts supplied by Elster

GmbH, see page 14 (Spare parts).

▷ The battery is available as a spare part.

Prepare the index for changing the battery.

▷

The battery can only be replaced when the optical

communications link has been established, see

page 7 (Establishing an optical communica-

t

GB-7

tions link). Otherwise, data can be lost.

Start the battery change procedure.

▷ The procedure depends on your user software.

▷

Important! The battery may only be removed

once a release message has been issued by

the index. Otherwise, an integrated valve will be

closed and/or an error message will be transferred via the communication module.

▷ The index confirms disconnection of the battery

with a sound sequence.

Replace the battery as quickly as possible.

Q

Q

00254

▷

The index confirms connection of the battery

max

Q

min

Q

M07 0102

002545632734

with a sound sequence.

▷

The main screen appears when any key is

pressed.

▷ Optical communication is enabled for 1minute.

If the optical communications link is not used

during this time, the interface will be deactivated.

Page 8

GB

F

NL

I

SK

4 Reprogram the battery parameters.

ON

Valve open safety check

CHECK IF

APPLIANCES OFF

HOLD FOR GAS

Gas ow check complete

Gas flow check

successful

ON

OFF

Valve open safety check

CHECK IF

APPLIANCES OFF

HOLD FOR GAS

Opening valve

Please wait

Gas ow check complete

Gas flow check

successful

Gas flow check

failed

Gas ow check complete

▷ The procedure depends on your user software.

Electronic index without communication module:

▷ After the battery has been replaced, check the

time and update it if necessary. Note the global

UTC format.

5 Replace the service cover.

6 Push in a new screw locking cap, see page 14

(Spare parts). The body carrying out this task

should apply its own seal.

▷ After a short time, the unit switches to initializa-

tion mode.

Opening valve

Please wait

Setting the index parameters

The following index parameters can be adjusted using

the user software:

– properties of the historic values screen,

– time display,

– audible feedback when a key is pressed,

– parameters for valve release procedure.

Releasing the valve

▷

If a valve is integrated in the diaphragm gas

meter BK, this must be released/opened for

commissioning.

CAUTION

To avoid damage:

– Ensure the customer’s consumers are closed.

▷ The valve can only be released when the optical

communications link has been established or via

a communication module.

▷ Unless otherwise agreed, the valve is open on

delivery as standard.

▷ Once the valve has been released via the com-

munication module, this must be confirmed at

the meter on site by the consumer or another

person if applicable.

Establish the optical communications link, see

page 7 (Establishing an optical communications link).

Release the valve. The procedure depends on

your user software.

Valve open safety check

▷

After successful initialization, the gas flow check

is started. The test duration is shown in the display.

Gas ow check in progress

Max time:

Min time

▷

Once the release criteria have been checked,

the results are shown in the display.

Gas ow check complete

Gas flow check

successful

ON

00:29:56

:

00:06:08

CHECK IF

APPLIANCES OFF

HOLD FOR GAS

▷ The test procedure may differ from the descrip-

tion.

▷ Press the selection key and hold down.

GB-8

Page 9

GB

F

NL

I

SK

Retrofitting/replacing the

31 2

G

2

31 2

3

4

5

communication module

WARNING

Risk of explosion in explosion-hazard areas!

– As a general rule, maintenance and repair work

should be avoided in explosive atmospheres.

– Check that the electrical system complies with

the special electrical explosion protection re-

Replacing the communication module

Establish the optical communications link, see

page 7 (Establishing an optical communications link).

Deactivate the respective communication mod-

ule.

BK-

DE-07-MI00

max

Q

min

Q

M07 0102

002545632734

quirements.

– When working on electrical equipment in an

explosion-hazard area, only design-approved

electrical operating equipment may be used.

6

– The communication module may only be pulled

out if it has first been deactivated.

– When installing a communication module, en-

sure that the communication interface has been

deactivated.

– Further information can be found in the operat-

ing instructions for communication modules

type ECM (for electronic index).

– Use original spare parts supplied by Elster

GmbH, see page 14 (Spare parts).

▷

The communication module is available as a

spare part.

▷ The communication module can only be retrofit-

ted or replaced when the optical communications link has been established.

▷

The procedure differs depending on whether

the communication module is to be retrofitted

or replaced. See “Retrofitting the communication module” or “Replacing the communication

module”.

Retrofitting the communication module

▷

Check the status of the interface and deactivate

if necessary.

7 The communication module and index must be

paired.

▷ The procedure depends on your user software.

▷ Set the parameters of the communication mod-

ule according to the instructions or the servicing

steps provided by the relevant operator.

8 Replace the service cover.

9 Push in a new screw locking cap, see page 14

(Spare parts). The body carrying out this task

should apply its own seal.

Check test

Directive 2014/32/EU (MID) prescribes that it must

be possible to check the meter.

▷

The requirements and test methods must comply

with national laws and regulations.

▷

The following tests describe the check tests

which are carried out by accredited testing

agencies.

▷

Always conduct a pressure and temperature

correction in accordance with established procedures (unit under test against master meter).

▷

Measurement accuracy class, see page 15

(Technical data).

4 Establish the optical communications link, see

page 7 (Establishing an optical communications link).

▷ The intended interface for the optional commu-

nication module is UMI-1.

5 The communication module and index must be

paired.

▷ The procedure depends on your user software.

▷ Set the parameters of the communication mod-

ule according to the instructions or the servicing

steps provided by the relevant operator.

6 Replace the service cover.

7 Push in a new screw locking cap, see page 14

should apply its own seal.

(Spare parts). The body carrying out this task

▷

The unit under test must be acclimatized and

installed on the test rig.

▷

Maintain the climatic conditions constant during the entire test duration. Otherwise, the test

results will be inaccurate.

▷

Immediately before the beginning of the test, the

quantity of test air, which corresponds to at least

50x the cyclic volume of the meter to be tested,

is fed through the meter at a flow rate of Q

(maximum flow rate of a gas meter).

▷

During an active cyclic test, the display disappears after 5 minutes but lights up every minute for 10 seconds. This function is available for

max. 5 hours.

max

GB-9

Page 10

GB

F

NL

I

SK

▷

To conduct the tests, the thermowell and the

pressure test point (if available) can be used as

a reference for the temperature and pressure

measured by the meter.

Cyclic test

The cyclic test is designed for checking the meter

with a master meter. The recorded volume of the

unit under test during the testing period can be read

off directly from the index once the test has been

completed and can be compared with the master

meter. Testing at a constant flow rate thus ensures

the lowest possible level of measurement uncertainty

for the unit under test.

Legend

ΔtN = total master meter testing time in s

ΔtP = testing time of the unit under test in s

Q

= maximum flow rate of a gas meter

max

Q

= minimum flow rate of a gas meter

min

QN = flow on master meter in m³/h based on

the displayed volume V

Q

= actual flow rate on master meter in m³/h

act,N

QP = flow determined on unit under test based

N

on VP in m³/h

VN = displayed volume on master meter in m³

V

= actual volume having flowed through the

act,N

master meter in m³

VP = displayed volume on unit under test in m³

Value after C or U in display, depending

on device configuration and test method.

See test procedure below for further

details.

FN = error of the master meter in %

FP = error of the unit under test in %

pN = absolute pressure on the master meter in

mbar

pP = absolute pressure on the unit under test in

mbar

TN = absolute temperature on the master meter

in K

TP = absolute temperature on the unit under

test in K

tb = base temperature in °C

V

= converted volume with reference to

b15

Vb = converted volume with reference to t

There are two different options for carrying out the

tb=15°C

b

cyclic test:

Option : cyclic test at a constant flow rate

▷ The test rig is in pre-trial operation, i.e. start of

measurement on the unit under test will be delayed.

▷ Maintain the flow rate constant.

Test load and minimum test volumes for the test with

index readout:

Type

BK-G1.6 2.5 1.2 1.2 12 60

BK-G2.5 4.0 1.2 1.2 12 60

BK-G4 6.0 1.2 1.2 12 60

BK-G2.5 4.0 2 2 20 100

BK-G4 6.0 2 2 20 100

BK-G6 10 2 2 20 100

BK-G6 10 4 4 40 200

BK-G6 10 6 6 60 300

BK-G10 16 6 6 60 300

BK-G16 25 6 6 60 300

BK-G25 40 12 12 120 600

▷

Q

The minimum test volumes are recommended

max

in

m3/h

Cyclic

volume

in dm

Test volume in dm3 at

Q

0.2 Q

min

3

maxQmax

guide values. The measurement uncertainty of

the complete system (test rig plus unit under test)

must not exceed 1/3 of the maximum permissible error (MPE).

▷

The testing time must be at least 10s due to

the system design.

▷

In the test procedure described below, it is guaranteed that the unit under test always performs

full measuring unit rotations.

Master meter test procedure

Q

N

∆t

N

61

∆t

P

2 3 4 5

Set the test flow rate.

Start measuring the reference timeΔtN at mark-

er1.

Immediately afterwards, briefly press the selec-

tion key on the index to start the cyclic test

on the unit under test– marker2. The index will

thus be “armed” for measurement.

▷

As soon as one of the significant sensor positions has been detected, the unit changes to

measuring mode– marker3. A beep confirms

the start of the measurement.

GB-10

Page 11

GB

F

NL

I

SK

▷

Once the required minimum testing time has

been reached, the measurement can be terminated– marker4.

4 Briefly press the selection key in order to end

the measurement.

Measurement on the unit under test stops au-

▷

tomatically once the full number of measuring

unit revolutions has been completed– marker5.

▷ A beep acknowledges the end of the measure-

ment.

▷

Measurement is terminated automatically after

5 hours.

5 Stop the test on the master meter– marker6.

▷ The measurements are then available.

6 Read off the flow rate on the master meter or

Option : cyclic test with a given volume

Test load and minimum test volumes for the test with

index readout:

Cyclic

Q

max

Type

BK-G1.6 2.5 1.2 36 72 72

BK-G2.5 4.0 1.2 36 72 72

BK-G4 6.0 1.2 36 72 72

BK-G2.5 4.0 2 60 120 120

BK-G4 6.0 2 60 120 120

BK-G6 10 2 60 120 120

BK-G6 10 4 120 240 240

BK-G6 10 6 180 360 360

BK-G10 16 6 180 360 360

BK-G16 25 6 180 360 360

BK-G25 40 12 360 720 720

volume

in

3

/h

in dm

m

Test volume in dm3 at

Q

min

3

0.2 Q

maxQmax

calculate if necessary:

a) taking into account the inherent error of the

Master meter test procedure

master meter:

Q

b) If the inherent error of the master meter has

= VN x 3600 s/h / ((1+FN/100) x ΔtN)

act,N

V

N

already been taken into account in the dis-

played volume (VN = V

= V

Q

act,N

7 Calculate the flow rate on the unit under test:

x 3600 s/h / Δt

act,N

act,N

):

N

8

10

QP = VP/ΔtP

for BK-G...ET, the following applies: VP = V

8 The accuracy is checked by comparing the flow

rates. The pressure and temperature values of

the unit under test corrected with reference to

b15

97

11

the master meter have already been taken into

account here:

FP = 100% x (((QP x pP x TN) / (Q

The following applies:

x pN x TP)) - 1)

act,N

pP = relevant absolute pressure on the unit under

test

The following also applies:

for BK-G...E: T

where t

under test in °C (display)

= (273.15 + {tg}) K

P

= relevant gas temperature on the unit

g

for BK-G...ET: TP = (273.15 + {tb}) K

where tb = 15°C (see page 15 (Technical data)):

T

= 288.15 K

P

for BK-G...ETe:

in step 7 is determined from the converted

If Q

P

volume Vb, the following applies:

TP = (273.15 + {tb}) K (tb see page 15 (Techni-

cal data))

in step 7 is determined from the non-con-

If Q

P

verted volume VP, the following applies:

TP = (273.15 + {tg}) K

where tg = relevant gas temperature on the unit

under test in °C (display)

▷ The curly brackets mean “numerical value of”.

▷

On a nozzle test rig with a known flow rate,

steps and 6 can be omitted.

▷

The error calculation is based on PTB Testing

Instructions, Volume 29: “Messgeräte für Gas –

meters), Edition 2003.

Gaszähler” (Measuring instruments for gas – gas

To activate the cyclic test on the unit under test,

briefly press the selection key on the index–

marker7. The index will thus be “armed” for

measurement.

Start the test on the master meter– marker8.

▷

As soon as one of the significant sensor positions has been detected, the unit changes to

measuring mode– marker9.

Test is ended– marker10.

4 Read off the test results on the unit under test.

▷

The measured values are updated with each 1/8

revolution of the measuring unit.

5 Compare the measurement results with the mas

ter meter and determine the measuring deviation

on the unit under test:

a) taking into account the inherent error of the

master meter:

FP = 100% x (((VP x (1+FN/100) x pP x TN) /

(VN x pN x TP)) - 1)

b) If the inherent error of the master meter has al-

ready been taken into account in the displayed

volume (VN = V

FP = 100% x (((VP x pP x TN) / (V

TP)) - 1)

▷

The following applies: pP = relevant absolute

), the following applies:

act,N

act,N

x pN x

pressure on the unit under test

-

GB-11

Page 12

GB

F

NL

I

SK

▷ The following also applies:

for BK-G…E: T

where t

g

under test in °C (display)

= (273.15 + {tg}) K

P

= relevant gas temperature on the unit

for BK-G...ET: TP = (273.15 + {tb}) K

where tb = 15°C (see page 15 (Technical data)):

T

= 288.15 K

P

for BK-G…ETe:

If the converted volume V

TP = (273.15 + {tb}) K (tb see page 15 (Techni-

is taken for VP:

b

cal data))

If the non-converted volume V

= (273.15 + {tg}) K

T

P

where tg = relevant gas temperature on the unit

is taken for VP:

P

under test in °C (display)

▷ The curly brackets mean “numerical value of”.

6 Stop execution of the cyclic test– marker 11.

Briefly press the selection key twice in order

to stop the measurement.

▷

A beep confirms interruption of the measurement.

▷

Measurement is terminated automatically after

5 hours.

The error calculation is based on PTB Testing

▷

Instructions, Volume 29: “Messgeräte für Gas –

Gaszähler” (Measuring instruments for gas – gas

meters), Edition 2003.

Pulse test

The pulse test is designed for checking the meter with

a master meter. The recorded volume is provided by

pulses which are emitted via the optical interface.

Test load and minimum test volumes for the test with

index readout:

Q

Cyclic

Type

BK-G1.6 2.5 1.2 36 72 72

BK-G2.5 4.0 1.2 36 72 72

BK-G4 6.0 1.2 36 72 72

BK-G2.5 4.0 2 60 120 120

BK-G4 6.0 2 60 120 120

BK-G6 10 2 60 120 120

BK-G6 10 4 120 240 240

BK-G6 10 6 180 360 360

BK-G10 16 6 180 360 360

BK-G16 25 6 180 360 360

BK-G25 40 12 360 720 720

▷ Pulse value V

▷ This test can only be carried out when the opti-

max

in

m3/h

volume

in dm

Imp

Test volume in dm3 at

Q

0.2 Q

min

3

maxQmax

, see page 15 (Technical data).

cal communications link has been established.

The procedure depends on your user software.

Establish the optical communications link, see

page7 (Establishing an optical communications link).

Interrupt communication to the installed commu-

nication modules before starting the test so that

the measurement accuracy will not be adversely

affected.

As of step 3, continue as described in one of the two

following sections.

Pulse test at a constant flow rate (optical

interface)

Master meter test procedure

Q

N

∆t

N

12

∆t

P

13 14

17

15 16

Set the test flow rate.

4 Start measuring the reference time ∆tN at mark-

er12.

▷ Marker12 indicates the release of the test flow

rate on the master meter.

5 Immediately afterwards, start the pulse test on

the unit under test– marker13.

▷ Then the unit under test generates the volume

pulses on the optical interface each time the

lowest-order decimal place on the meter display

is incremented– marker14. The test begins.

6 As soon as the required minimum test volume

has been reached on the unit under test, the

time measurement on the unit under test can

be stopped– marker15.

7 End the pulse test using any command– mark-

er16.

▷

Measurement is terminated automatically after

90minutes.

8 Shut off the gas flow to the master meter–

marker17.

9 Determine the volume on the unit under test VP:

VP = N x V

N = number of pulses during Δt

V

= pulse value V

Imp

Imp

cal data)

, see page 15 (Techni-

Imp

P

0 Calculate the flow rate on the unit under test:

QP = VP/Δt

Read off the flow rate on the master meter or

P

calculate if necessary:

a) taking into account the inherent error of the

master meter:

Q

b) If the inherent error of the master meter has

= VN x 3600 s/h / ((1+FN/100) x ΔtN)

act,N

already been taken into account in the dis-

played volume (VN = V

Q

act,N

= V

x 3600 s/h / Δt

act,N

act,N

):

N

GB-12

Page 13

GB

F

NL

I

SK

The accuracy is checked by comparing the flow

rates. The pressure and temperature values of

the unit under test corrected with reference to

the master meter have already been taken into

account here:

FP = 100% x (((QP x pP x TN) / (Q

TP)) - 1)

act,N

x pN x

The following applies:

pP = relevant absolute pressure on the unit under test

The following also applies:

for BK-G...E: TP = (273.15 + {tg}) K

where t

= relevant gas temperature on the unit

g

under test in °C (display)

for BK-G...ET and BK-G...ETe:

TP = (273.15 + {tb}) K (tb see page 15 (Techni-

cal data))

▷ The curly brackets mean “numerical value of”.

▷

On a nozzle test rig with a known flow rate,

step 4 can be omitted.

▷

The error calculation is based on PTB Testing

Instructions, Volume 29: “Messgeräte für Gas –

Gaszähler” (Measuring instruments for gas – gas

meters), Edition 2003.

Recommission the previously switched off com-

munication modules.

Pulse test with a given volume

Master meter test procedure

V

N

19

18 21

20

Start the pulse test on the unit under test–

marker18.

4 Start the test on the master meter– marker19.

5 Record the pulses from the unit under test.

▷

The unit under test generates the volume pulses

on the optical interface each time the lowest-

order decimal place on the index display is in-

cremented.

6 The test volume is achieved and the test ends–

marker20.

7 End the pulse test on the unit under test using

any command– marker21.

▷

Measurement is terminated automatically after

90minutes.

8 Determine the volume on the unit under test VP:

V

= N x V

P

N = number of pulses

V

= pulse value in m³

Imp

9 Read off the volume on the unit under test.

Imp

The inherent error of the master meter is to be

taken into account if applicable:

V

0 Determine the measuring deviation on the unit

= VN / (1 + FN/100)

act,N

under test:

FP = 100% x (((VP x pP x TN) / (V

▷

The pressure and temperature values of the unit

x pN x TP)) - 1)

act,N

under test corrected with reference to the master

meter have already been taken into account here.

The following applies:

pP = relevant absolute pressure on the unit under

test

The following also applies:

for BK-G…E: T

where tg = relevant gas temperature on the unit

= (273.15 + {tg}) K

P

under test in °C (display)

for BK-G…ET and BK-G…ETe:

TP = (273.15 + {tb}) K (tb see page15 (Techni-

cal data))

▷ The curly brackets mean “numerical value of”.

▷

The error calculation is based on PTB Testing

Instructions, Volume 29: “Messgeräte für Gas –

Gaszähler” (Measuring instruments for gas – gas

meters), Edition 2003.

Recommission the previously switched off com-

munication modules.)

RTC test

▷

The climatic conditions must be maintained con-

stant at 22± 5°C during the entire test duration.

Temperature changes in 24hours ≤2K.

▷

Ensure that conditions remain sufficiently stable

during the measurement.

▷ The accuracy of the time count can be verified

with this test.

Acclimatize the unit under test and place next

to the time reference unit.

If necessary, activate the time display on both

units.

Ensure synchronous reading by taking a photo.

4 Observe a min. testing time of 24hours.

5 Repeat steps and .

6 The clock deviation of the unit under test must

not exceed the maximum admissible deviation.

Maximum admissible deviation= 100ppm in

24hours.

GB-13

Page 14

GB

F

NL

I

SK

Temperature test

▷

A temperature test is required on diaphragm gas

meters with temperature conversionBK..Te only.

▷ The accuracy of the temperature measurement

can be verified with this test.

▷ The temperature test can only be carried out in

Service mode.

CAUTION

To avoid damage to the unit:

– Comply with ambient temperature, see

page 15 (Technical data). Deviations from

the permitted ambient temperature will be recorded in the error memory.

▷

Temperature measurement accuracy, see

page15 (Technical data).

Install the diaphragm gas meter in a climatic

chamber.

Activate Service mode– see page 5 (Service

mode).

Change to the “Temperature” menu.

▷ The current gas temperature is displayed.

4 Close the climatic chamber.

5 Select an ambient temperature as a reference

value and bring the climatic chamber to this temperature.

▷

To ensure there is also a uniform temperature

in the meter, we recommend starting the meter

air/gas flow during the temperature adjustment

phase.

▷

Ensure that temperature distribution remains

uniform and stable during the temperature

measurement.

6 Compare the measured value to the temperature

reference value.

▷

If required, several reference values can be

checked. In this case, repeat the test as of

point 5 .

• Leave the index unused for an extended period,

e.g. 24hours. After this, the user interface will

once again be available.

? When pressing the user keys, the display

remains switched off and no beep can be

heard.

! The index is defective.

• Contact the manufacturer.

? The

symbol is displayed.

! Low battery. This symbol is only displayed when

battery power is low.

• Replace the battery.

▷

In the case of faults which are not described here,

contact the manufacturer immediately.

Spare parts

Battery

For meters without communication module:

Elster Part No.: 32906520.

For meters with communication module:

Elster Part No.: 72910321.

Communication module

Use ATEX compliant communication modules only.

A safety sticker with the following code must be

attached to the communication module:

II 3G Ex ic IIA Gc (-25°C ≤ Ta ≤ +55°C).

Electrical connection parameters, see page 15

(Technical data).

Screw locking cap

Assistance in the event of malfunction

? Fault

! Cause

• Remedy

Possible faults and suggested solutions

? The

! If the symbol appears next to a measured

• After the next data synchronization, the data are

? When pressing the user keys, the backlight-

! Energy-saving mode is active. Due to excessive

symbol is displayed.

value, this means that the value is invalid.

recorded again correctly and disappears.

ing and/or display remain switched off. A

beep can nevertheless be heard.

use of the index, the average energy consumption has been exceeded.

Elster Part No.: 32447510.

GB-14

Page 15

GB

F

NL

I

SK

Technical data

Application with diaphragm gas meters BK..E

RoHS compliant

Enclosure: IP 54.

Battery life: approx. 10years.

Maximum allowable ambient temperature range: see

type label/index plate.

Data logger for historic meter readings:

up to 60weeks in 30-minute intervals.

Optical interface: pursuant to EN62056-21, Mode(E),

AnnexB.2.

Accuracy of the clock: 0.4 s/day at 20°C on the day

of manufacture.

Diaphragm gas meter BK..ETe with temperature

conversion:

Temperature measurement accuracy: ± 1°C on the

day of manufacture.

The base temperature tb is specified on the index

plate.

Pulse output of optical interface

Pulse value V

Gas meter

BK-G 1.6 – BK-G 6 3 1

BK-G 10 – BK-G 25 2 10

Pulse duration: 90 ms

For further technical data on diaphragm gas meters

BK– see the operating instructions for diaphragm

gas meters BK-G1.6 to BK-G25 → http://docuthek.

kromschroeder.com/doclib/main.php?language=1&

folderid=400041&by_class=2&by_lang=-1.

Imp

:

Decimal

place

in display

Pulse

value V

in dm

Imp

3

Logistics

Transport

Diaphragm gas meters are always to be transported

in the upright position. On receipt of the product,

check that the delivery is complete, see page 2

(Part designations). Report any transport damage

immediately.

Storage

Diaphragm gas meters are always to be stored in

the upright position and in a dry place. Ambient temperature: see page 15 (Technical data).

Disposal

Meters with electronic components:

Components, particularly batteries, are to be disposed of separately.

On request, old units may be returned carriage paid

to the manufacturer, see page 16 (Contact), in

accordance with the relevant waste legislation requirements.

ATEX explosion protection

Battery

Only use approved batteries from Elster.

The “Battery pack cpl. EI2” is certified as part of the

electronic index.

Communication modules

Please contact the manufacturer for details on suitable communication modules. Information on the

ATEX suitability can be found in the operating instructions of the respective communication module.

The UMI interface features the following parameters:

– UO = 3.9 V peak, 3.6 V nominal,

– IO = 7.5 A peak, 506 mA nominal,

– PO = 1.55 W,

– CO = 12 µF,

– LO = 50 nH.

For more data on explosion protection of diaphragm

gas meters BK– see the operating instructions for

diaphragm gas meters BK-G1.6 to BK-G25 → http://

uage=1&folderid=400041&by_class=2&by_lang=-1.

docuthek.kromschroeder.com/doclib/main.php?lang

GB-15

Page 16

GB

F

NL

I

SK

Contact

Contact

United Kingdom

Elster Metering Limited

Paton Drive

Tollgate Business Park

Beaconside

Stafford, ST16 3EF

Tel. +44 1785 275200

Fax +44 1785 275305

jeavons.info@gb.elster.com

www.elstermetering.co.uk

Germany

Elster GmbH

Strotheweg 1

49504 Lotte

Tel. +49 541 1214-0

Fax +49 541 1214-370

info@elster-instromet.com

www.elster-instromet.com

Ireland

Active Energy Control Ltd.

Unit 4, Clare Marts

Quin Road

Ennis, Co. Clare

Tel. +353 65 6840600

Fax +353 65 6840610

info@aec.ie

www.aec.ie

GB-16

in the interests of progress.

We reserve the right to make technical modifications

Loading...

Loading...