Page 1

Honeywell Electronics

Enhanced Ground Proximity Warning

Flight History Data

J

s

Jus

System (EGPWS):

im Mulkin

EGPWS Sr. Systems Engineer

Honeywell Aerospace

August 27, 2012

Page 2

EGPWS Flight History Data

EGPWS Flight History Data was designed to:

p p

pp g

•

- Provide detailed data on EGPWS alerts

to improve terrain database

to evaluate the performance of EGPWS algorithms in real-world operation

• maximize CFIT protection

• minimize nuisance alarms

• EGPWS Flight History Data can:

- Hel

Where FDRs do not exist on the aircraft or fail to function

But, it wasn’t designed for accident investigation purposes

2

rovide data to investigate Incidents / Accidents

• EGPWS does not add much beyond what FDR provides

File Number

Page 3

EGPWS Flight History Data - Limitations

EGPWS Flight History Data:

•

- Does NOT record Date & Time

EGPWS system time (hours:minutes:seconds) powered

Flight Leg (Leg 1 is most recent flight)

- Is NOT environmentally protected or crashworthy

The EGPWS can be damaged beyond the ability to provide any data

- Does NOT provide a rapid data rate

1 sample per second

- Does NOT record data from all sources

Typically only records source being used

This may not be the source being used by the pilot in command

3

File Number

Page 4

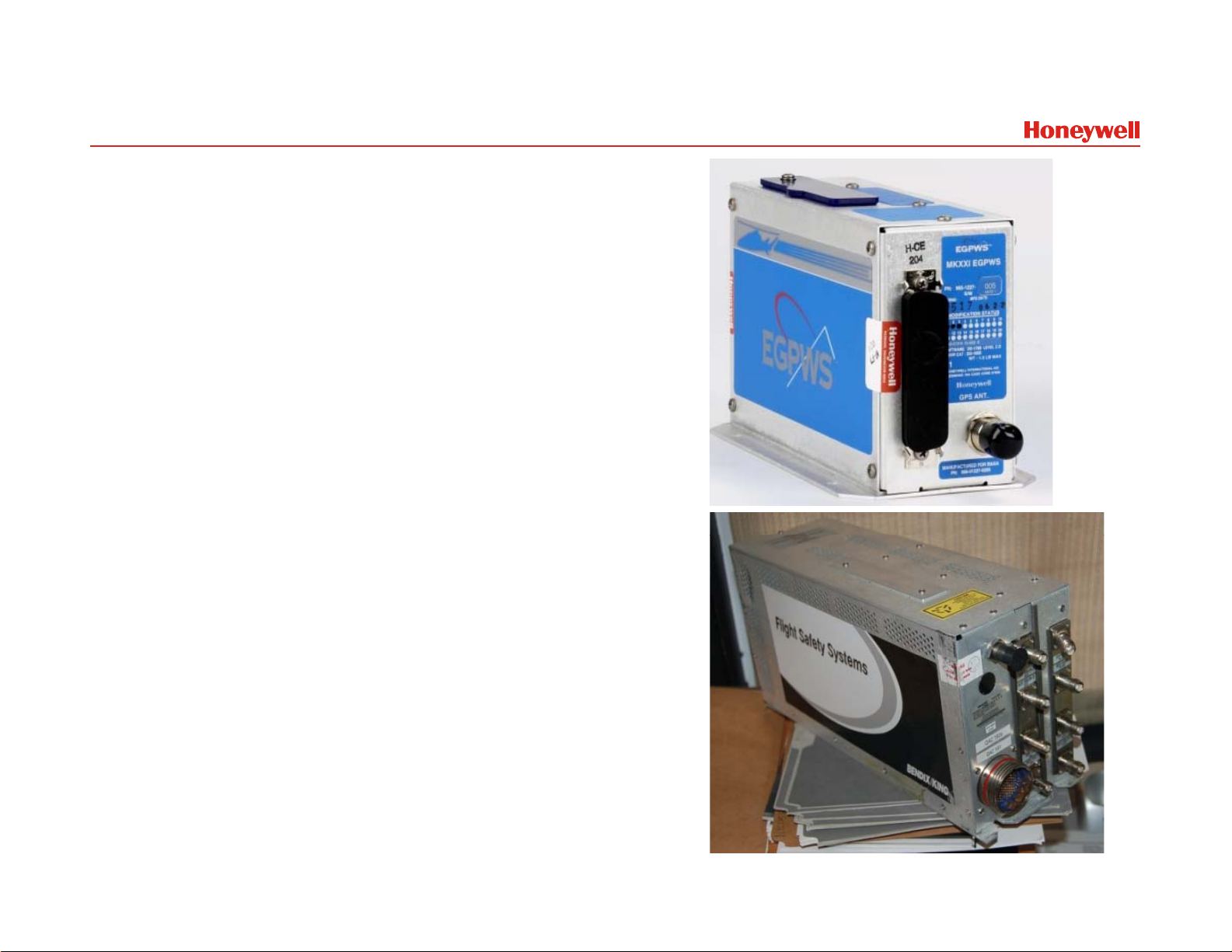

EGPWS Units – Class A TAWS

MK V & MK VII

p

p

•

- 2 MCU (2.5”W x 8”H x 13”D)

- Found in

All Boeing

Most Airbus

Large and Medium business jets

• MK VI & MK VIII & MK XXII

- (3”W x 6”H x 10”D)

- Found in

Medium and Small business jets

Turboprops

IFR Helico

4

ters

File Number

Page 5

EGPWS Units – Class B TAWS

Found in

VFR Helicopters

KMH820 & KMH920

F

• KGP560 & KGP860 & MK XXI

- (2”W x 4”H x 6”D)

-

Small business jets

Turboprops

•

- 4 MCU (4”W x 7”H x 13”D)

- Earlier units are black

-

ound in

Small business jets

Turboprops

5

File Number

Page 6

EGPWS Flight History Data (Warning/Caution)

g

gp

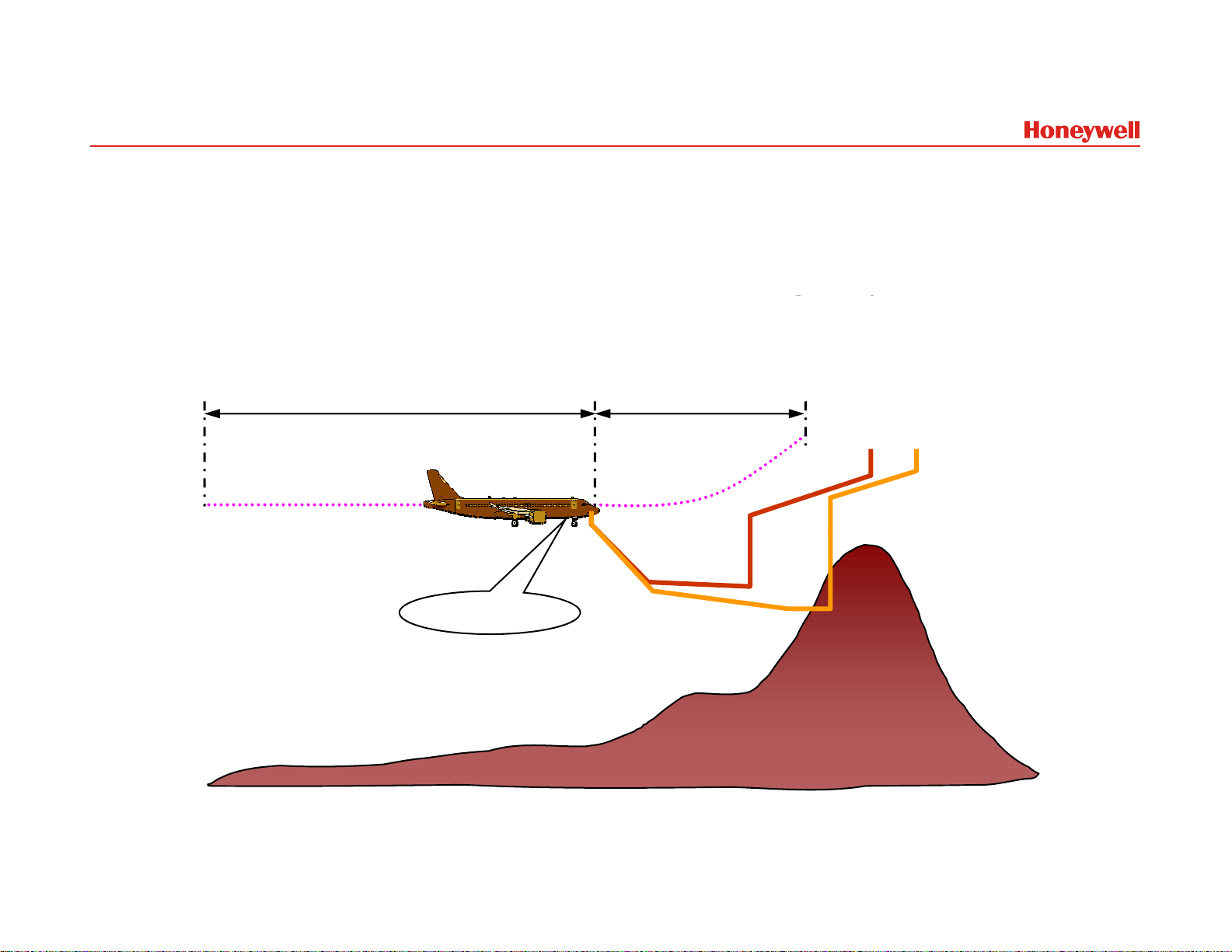

• EGPWS records data 20 seconds before and 10

seconds after every EGPWS alert/warning

Used to determine a cause of the alert/warnin

20 Seconds 10 Seconds

Caution Terrain

and pilot reaction

6

File Number

Page 7

EGPWS Flight History Parameters

Alert Type

Terrain Database Elevation

Engine Torque Data #1

Positi

Glidesl

• List of parameters recorded in EGPWS Warning Flight

History Data

System Operating Time GPS Satellites Visible

Corrected A l t i t ude GPS Satellit es Tracked

Lati tude Pit ch Angle

Longit ude Roll Angle

on Source

Positi on Uncertai nt y( HFOM ) Localizer Deviati on

Ai r speed Display Range #1

True Air spe ed Displ a y Range #2

Gr ound Spee d Terr ain Display Enabl ed # 1

Mi ni m um O per at i ng Speed Terrai n Displ ay Enabl ed #2

Barome t r ic Altitude ( Uncor r e ct ed) Landing Gear Down

Geom e t r ic Altitude Landing Flaps Sel ec t ed

Geom e t r i c A lti tude VFOM Terr ai n Awareness & TCF Inhibit

GPS Alt itude Audio Inhibit

GPS VFOM Body AOA

Radio A ltitude Longit udinal Accel er a t i on

Alti tude Rate Normal A cce l er a t ion

Magneti c Track Inert i al Vert ical A ccel er at i on

True Tr ac k Filter ed She ar /Total Shear

True Heading Stati c A i r Temperat ure

ope Deviation

Engine Torque Dat a #2

Engine Torque Dat a #3

Tacti cal ( Low A l t i t ude) Sel ect

Helicopter EGPWS Only

7

File Number

Page 8

EGPWS Flight History Data

Does not record what is not input

•

- For example, no radio altitude on KGP or KMH Class B units

• Data that is invalid is noted as such

- For example, glideslope deviation when not ILS tuned

• Data is recorded even when manually inhibited by pilot

• Data can be exported to Excel spreadsheet (.xls file)

- Excel format facilitates graphing of data

• Data can be superimposed over maps/chart (KML)

8

File Number

Page 9

Flight History Retrieval Process

Data can be downloaded via PCMCIA or CF card

Decoding of encrypted information is done by Hone

ell

If unit is damaged:

Honeywell can accept data directly from chip reader

• Flight History information is stored in the EGPWS in a

specific area of the non-volatile memory

•

- Card must be programmed with special instruction file

- Process similar to terrain database upload, requires < 5 minutes

- Cards available upon request from Honeywell Engineering

- Data is encrypted

•

using proprietary tools, tools are not distributed

•

- Circuit boards can be placed in donor units or fixtures

- Memory chips can be removed and data retrieved via chip reader

Occasionally memory chips are damaged and unreadable

9

yw

File Number

Page 10

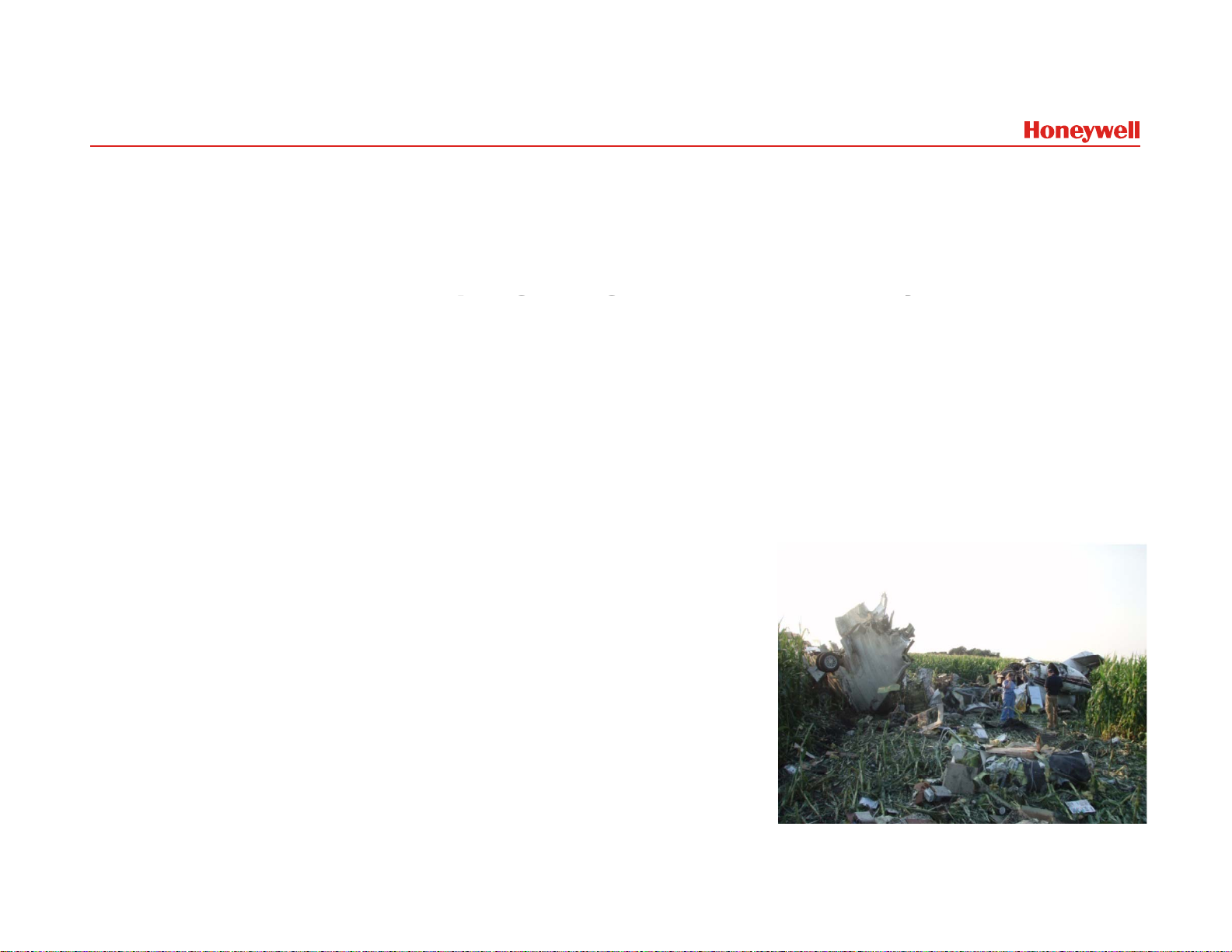

Hawker 800 crash at Owatonna MN

p

pg g

y

Flight History download performed at Honeywell

Speed increase on runway

• NTSB AAR-11/01, 31 July 2008, – 8 Fatal

- CVR, no FDR and none required

- Crashed while attem

ting late go-around on runway 30

• EGPWS issued Bank Angle alert

- Aircraft rolled 90 degrees after becoming airborne off rwy end

•

- Unit functional post-accident

- Memory contained 22 seconds of data

20 before Bank Angle alert

2 after Bank Angle alert (then loss of power)

• Data used to confirm:

- Flaps down before landing

- Flaps retracted after landing

-

- 8 knot tailwind

10

File Number

Page 11

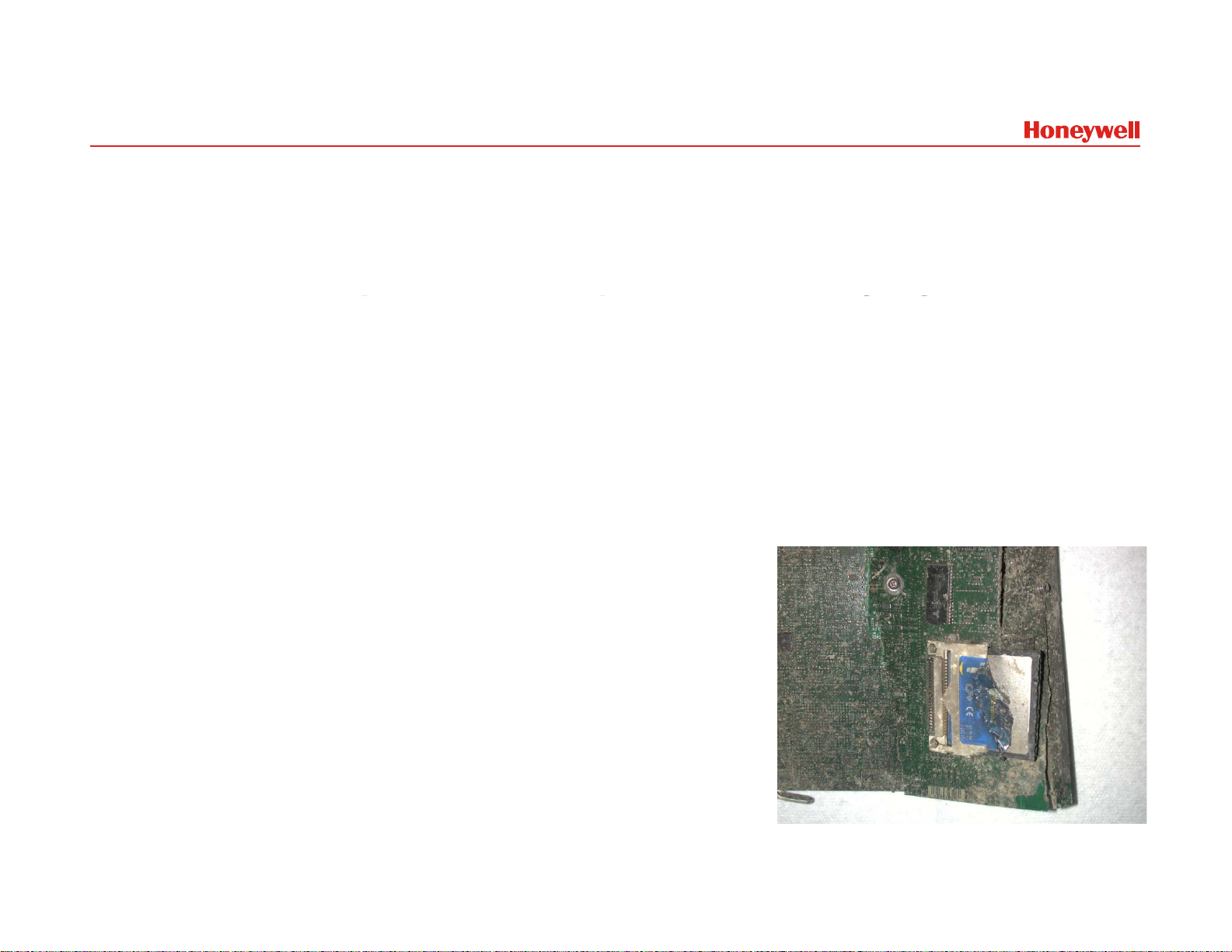

Cessna 560 crash at Pueblo, CO

p

pp

yg

EGPWS destroyed in impact, fire

• NTSB AAR-07/02, 16 February 2005 – 8 fatal

- CVR, no FDR and none required

- Pueblo was a

lanned fuel stop on cross-country flight

- Crashed 4 mi short of airport in freezing rain

• EGPWS issued Bank Angle alert

-

- Circuit cards returned to Honeywell for possible analysis

• 1 of 2 Flight History data chips broken, data irretrievable

- Manual process used on surviving chip

- 30 seconds of partial data set recovered

Altitude, descent rate

Pitch, roll

Ground speed, ground track angle

- Data correlated to radar data

11

File Number

Page 12

Honeywell Electronics

g

gg

Non-Volatile Memory (NVM):

An Increasin

Air Safety Investigator

Honeywell Aerospace

August 27, 2012

Aide in Investigations

Jay Eller

12

File Number

Page 13

Agenda

What can we learn from data obtained from NVM?

and

cations and precautions exist

at co p cat o s a d p ecaut o s e st

What Data

What is the manufacturer’s intended use of NVM data?

is

Available

Airframes

What types of equipment What types of airframes

have NVM data? have NVM data?

Equipment

Handling

What compli

when handling equipment with NVM?

13

13

of

Equipment

Containing

NVM

File Number

Page 14

Intended Uses of NVM in Electronics

Maint

/T

ki

i

y

Could be specific to an altitude, temperature, or other

-

Capturing detailed data when a particular event has occurred

•

enance

rac

ng

- Logging of failures which require maintenance at next interval.

- Logging of exceedances or failures which may require

mmediate attention.

- Tracking of fleet such as EMS and Fire Fighting.

• Trend analysis

- Engine performance over a period of time.

- Aircraft performance over a period of time.

-

operational condition.

• Trouble Shooting

- Event could be pilot initiated (press of a button) or a

predetermined scenario.

All Could be Beneficial in Accident Investigation

14

14

.

File Number

Page 15

Various Levels of Data Available

Fidelity Dat

•

Medium Fidelity Data:

W

bili

•

High Fidelity Data:

•

Good indication of immediate behaviors and performance just

•Low

a:

• Slow sample rates (greater than 1 sample per minute)

• Minimal data precision (ie: Latitude, Longitude, altitude, etc)

• Would show long term trending with little inability to show

immediate behaviors/signatures.

• Medium sample rates from 1/sec to 1/minute

• Moderate data precision.

•

ould show medium range trending with minimal a

show immediate behaviors/signatures

ty to

• High frequency rate of data capture (1Hz or faster)

• High data precision.

prior to the accident.

15

15

File Number

Page 16

Example of Low Fidelity Data

16

16

Data points are on 4

minute increments.

File Number

Page 17

Example of Medium Fidelity Data

)

p)

T urn made but unable to determine

accuracy during the turn. (1 minute

data points

17

17

File Number

Page 18

Example of High Fidelity Data (1Hz Rate)

18

18

File Number

Page 19

Example of High Fidelity Data (1Hz Rate)

taxi!

Notice location

precision as

witnessed during

19

19

File Number

Page 20

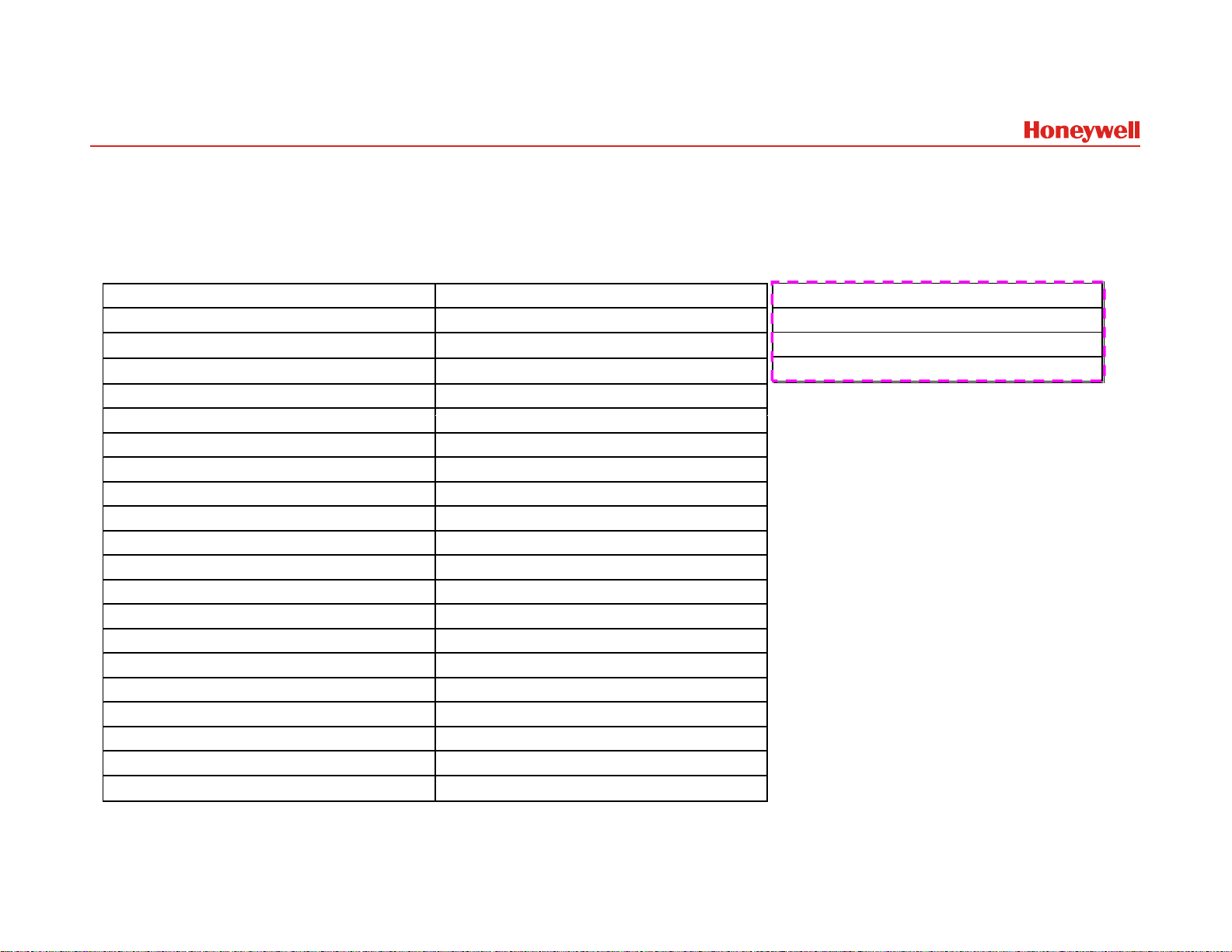

Types of Equipment and Data Fidelity

a

a

w

(

)

Sky

t

()

Transport)

a

Servo

EVXP

HUMS

l

ard

ight

Str

For

Connect

FDR

a Retriev

se of Da

Somewhat

reasing E

Inc

Highly

20

20

Involved

Radios

Involved

Smart

EPIC

Maintenance

System

Increasing Fidelity of Data

EGPWS

Gen Av

EGPWS

(Air

APEX

ACMS

Engine

Controls

HighMediumLow

ACMS = Aircraft Condition Monitoring System

HUMS = Health and Usage Monitoring System

File Number

Page 21

Aircraft With Primus APEX

Twin Otter 400

High, Medium, and Low Fidelity Data

Pilatus PC-12 NG

21

21

Viking Air

File Number

Page 22

Aircraft With HUMS

Fidelit

Health and Usage

S

Sikorsky S76C++

High, Medium, and Low

y Data

HUM

22

22

=

Monitoring System

Agusta A109E

File Number

Page 23

Aircraft with Primus EPIC (Medium and Low Fidelity)

Dassault F7X

Dassault F2000EX/LX

Cessna 680 Sovereign

Dassault F900EX/DX/LX

Gulfstream 450

Embraer 170/190

Gulfstream 650

Gulfstream 550

Hawker 4000

23

23

Agusta A W139

File Number

Page 24

Examples of Aircraft With Sky Connect

24

24

EMS Helo Fleet

Medium and Low Fidelity Data

Fire and Rescue

Note: Aircraft models shown may not represent actual models containing Sky Connect

Charter Fleet

Agriculture Fleet

File Number

Page 25

P

reservation

& R

ecovery of

Non-Volatile Memory (NVM) Evidence

25

25

File Number

Page 26

General Precautions

ssume that the electronic component is subject to electrostatic

Assume that the electronic component is subject to electrostatic

•

Before cutting wires to components, insure component does not

Ship it as is to the component supplier or investigation lab.

If th

ith

y, ,

team will focus on prior to going on

-

scene

• A

discharge (ESD) damage.

- Do not attempt to handle any electronic components using leather

gloves.

have holdup RAM requiring power to maintain.

• If the component is dry, keep it dry.

-

“

”

- Do not attempt to scrub, brush, or otherwise mechanically remove

dirt and debris from electronic components.

• If the component is wet, keep it wet.

-

the same as a water-soaked board from a water crash site. Flush it

with water and ship it in water.

e electronic component is wet w

mud or other material, treat it

• Do not use any chemicals, such as bleach, to clean the

component.

- This is critical for components with biohazard contamination.

• Attempt to identify the types of electronics that the investigation

.

- Establish a priority listing for non-volatile memory

Be prepared to handle electronic devices prior to arriving at the accident site.

26

26

File Number

Page 27

If an accident has occurred in fresh or salt water…

-

Never try to transfer a component to another medium (such as air)

• Recovered electronic components should be placed in a

container filled with 2 MOhm de-ionized water.

- Bottled drinking water is acceptable, provided the water has been

produced using a reverse osmosis (RO) process, as opposed to

bottled spring water.

- Do not use tap water, distilled water or medical grade 10 MOhm

water.

• If de-ionized or RO water is not available at the accident site,

clean and ship the component in the water it was found in – salt

or fresh.

.

- Never remove components from water and allow to "air dry“, or

attempt to use uncontrolled heating devices to dry the components.

Use de-ionized or RO water, NOT tap or distilled water

27

27

File Number

Page 28

General Packing and Shipping Guidelines

p

ppy

-

Do not use Styrofoam peanuts or other similar packing materials

• Use hard plastic shipping containers when possible – avoid

Styrofoam.

• Wra

electronic components with a layer of electrostatic safe

material, such as “pink poly” (named for its color) or other ESD

approved product.

• Use packing materials that will not react with the contents or

deteriorate while packed. ESD-safe bubble wrap, or empty

plastic containers inserted between the shipped items and the

sides of the container, is appropriate.

“

”

• Ship wet accident site components in a manner that preserves

the integrity of the water-filled packing container.

.

Use a hard plastic container and ESD safe packing materials.

28

28

File Number

Page 29

In Closing…

g

g

options installed

• Monitoring Systems and NVM Data – What it is… and is not.

- It is a tool for investigators to use

- It is not a fli

• Plus's and Minus’s

Large volume of available data Not crashworthy

High G-load tolerant plastic NVM Not fire tolerant

Fire tolerant ceramic NVM Not G-load tolerant

Easy to read data format (Excel) Only downloadable by OEM

• Limited Availability

ht data recorder

- Aircraft equipped with Apex or EPIC.

- Helicopters equipped with HUMS functionality.

- Installations with Sky Connect.

- Installation can vary from S/N to S/N on same platform depending on

29

29

.

File Number

Page 30

Honeywell Digital Engine Controls

Incident Recorder

M

id

Applicability to Accident Investigation

Jim Allen

anager of Acc

Honeywell Aerospace

August 27, 2012

ent Investigation

Page 31

Agenda

Applications

Use of Engine Control Data in Accident Investigation

• Introduction

•

•

• Post Accident Precautions

• Honeywell Support in Investigations

• Questions

31

File Number

Page 32

Turbofan Engine Digital Control System

g

g

g

Operational Information

• Honeywell Turbofan Engines utilize Digital Control

with Engine Condition Trend Monitoring (ECTM)

- Two

Generation One, Digital Electronic Engine Controls (DEEC)

Generation Two, Full Authority Digital Electronic Control (FADEC)

enerations of controls

• TFE731-2/3/4/5 (New Production and Retrofit of older units)

• TFE731-20/40/50/60 (All from Production)

• HTF7000 series

• ECTM data is divided into three broad catagories.

- Engine Statistics

- Engine Maintenance/Troubleshooting

-

• In addition, both generations have Incident

Recorders incorporated.

32

File Number

Page 33

Examples of Data available via ECTM

Performance Trending

•

Engine Troubleshooting & Maintenance

Event Data

Auto capture of in

flight events

Engine Speed & Thrust Reverser Cycles

Flight Chronology

• Engine Statistics

- Engine & Computer Information – Model, Part, and Serial Number

-

- Life Cycle Data – Engine Times, Cycle Counting, Landings, etc.

- Engine & Computer Data – Engine Exceedances, Computer

Faults

-

–

• Operational Information

-

- Interturbine Temperature Trends and Cycles

-

- Power Lever Angle (PLA) Usage Profile

-

33

File Number

Page 34

TFE731 DEEC – Generation One (Gen 1)

(Retrofit)

(Prod

)

34

TFE731-2/3/4/5 N1 DEEC

- Fuselage mounted -

TFE731-20/40/50/60 DEEC

uction

- Engine mounted*-

TFE731-50 DEEC in Hawker 900XP is fuselage mounted

File Number

Page 35

Gen 1 Incident Recorder Design Parameters

•

Design Features

last 1 1/2 hours of engine operation

() (g)

i.e

The N1 speed was between 75 and 80% maximum speed

g

g

- Records nine engine and aircraft parameters.

- Records basic engine and aircraft information for approximately the

.

- Begins recording when the start initiates.

- Stops recording after engine shutdown or 5 minutes after Weight on

Wheels (WOW) is true (On ground).

• Data is collected in “Buckets” to indicate parameter range

-

.

- This allowed data to fit into available memory.

- Medium to High Fidelity data.

• Data Resolution

- Data is collected at increasing intervals from the end of the data

stream startin

at one second intervals.

- This allowed for the most recent data to have the highest fidelity

while maximizing the data stream available for download.

35

.

File Number

Page 36

HTF7000 Family – Generation Two (Gen 2)

36

HTF7000 FADEC

(Engine mounted, 2 units per engine)

File Number

Page 37

Gen 2 Incident Recorder Design Parameters

•

Design Features

minutes of operation

I.E

N1 speed was 75.7% of maximum speed; Altitude was 21,316

g

- Records 36 engine and aircraft parameters.

- Records enhanced engine and aircraft information for the last 60

.

- Begins recording when the start initiates.

- Stops recording after engine shutdown or 5 minutes after WOW is

true (On ground).

• Data is collected as discrete values.

-

.,

feet.

- Aircraft Latitude and Longitude are stored parameters.

• Data Resolution

- Data is collected at increasing intervals from the end of the data

stream starting at 100 millisecond intervals.

37

File Number

Page 38

TFE731 Applications – Gen 1 Civil DEEC (Retrofit)

Lockheed Jetstar / Jetstar

IAI Westwind 1124

Gulfstream G100

Cessna Citation III/VI/VII Raytheon Hawker HS1-731;

Dassault Falcon 10/100 Dassault Falcon 50 / 50-

(Astra 1 125)

Dassault Falcon 20-

5/200

North American

Rockwell Sabreliner 65

/1124A

125-400-731/600-731/700/800/800XP

Dassault Falcon 900

4

II

Learjet M35 / M35A / M36 Learjet M31 Learjet M55

38

File Number

Page 39

TFE731 Applications – Gen 1 Military DEEC (Retrofit &

Production)

AIDC A T -3 “Tzu Chiang”

CASA 101AA / BB / CC “Aviojet”

39

FMA IA 63 “Pampa”

Hongdu (Nanchang) Aviation Industry Corporation

K8 “Karakorum”

(Production)

File Number

Page 40

TFE731 Applications – Gen 1 Civil DEEC (Production)

X

Hawker 900XP

Dassault Falcon 50E

Gulfstream 100

(Astra SPX)

Learjet M40

Dassault Falcon 900EX / 900DX

Gulfstream G150

Learjet M45

40

File Number

Page 41

HTF7000 Family Turbofan Applications – Gen 2 Civil

gg

FADEC (Production)

Bombardier Challenger CL 300Bombardier Challenger CL 300

41

Gulfstream 280Gulfstream 280

Embraer Legacy 450 and 500Embraer Legacy 450 and 500

File Number

Page 42

Use of Incident Recorder Data in Accident

gp

have an FDR

impact or loss of power to the DEEC or FADEC)

Investigation

• These are NOT Flight Data Recorders but,

- The data can be very helpful in backing up FDR and CVR

data.

- Can be especially helpful if FDR data is not recoverable,

wasn’t working, or the aircraft wasn’t equipped with one.

• Units are not hardened and designed for impact and

fire protection like an FDR or CVR.

• Units are installed on some aircraft not required to

.

• Does not record Date & Time.

- Data is presented based on time from the end of the data (i.e.

42

File Number

Page 43

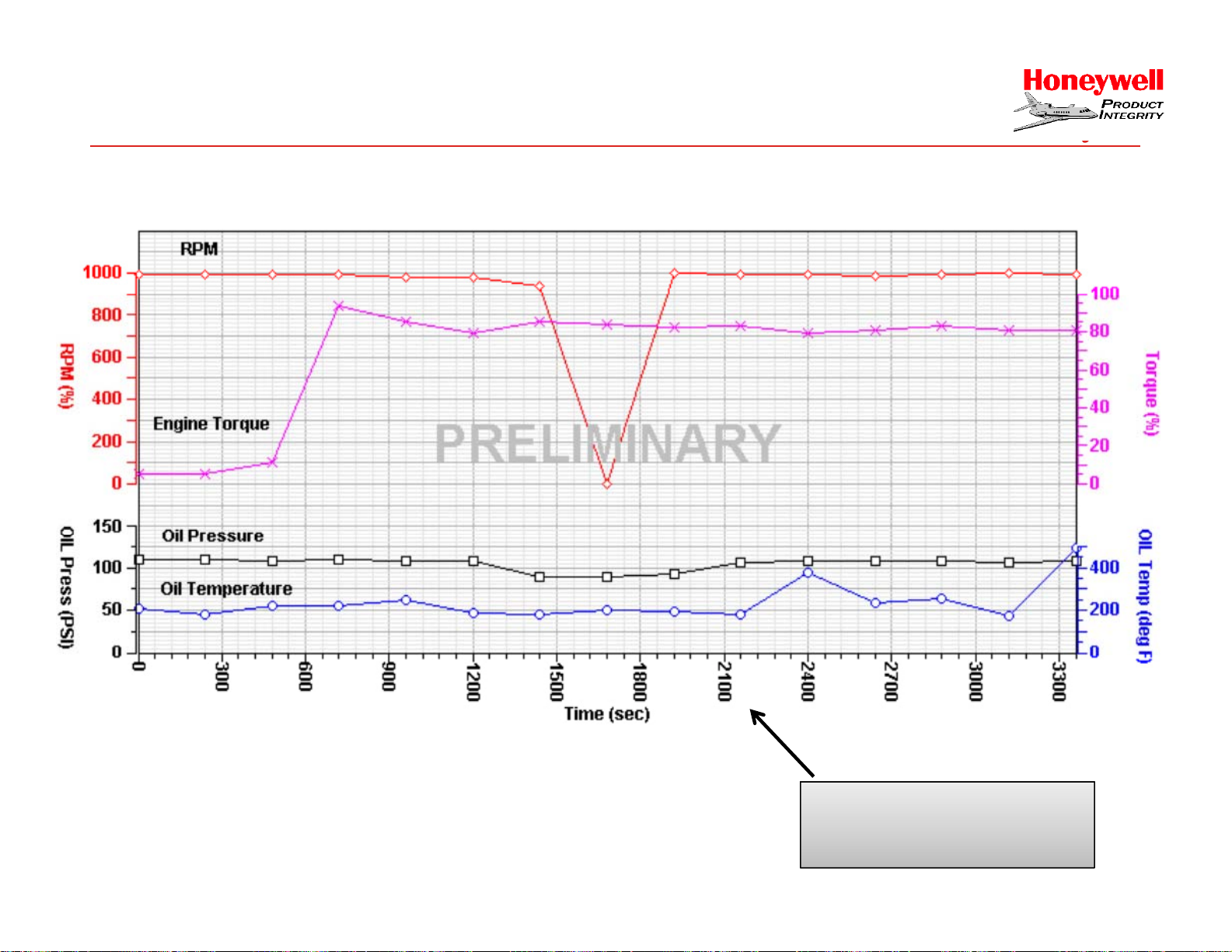

Generation 1 DEEC Plotted Data

43

File Number

Page 44

Generation 1 DEEC Plotted Data

44

File Number

Page 45

Generation 2 FADEC Plotted Data

45

File Number

Page 46

Post Accident Precautions

•

If the DEEC or FADEC appears intact:

operator and field service personnel

•

If units are damaged, collect parts potentially from

Foll

di

Do Not Att

t to

the DEEC

- Do not attempt to power up the units.

- Do not attempt to download the data with process used by

.

This process automatically erases the data from the units as part of the

download.

the units and return.

- Especially loose integrated circuit chips.

•

ow General Precautions previously

Electrostatic precautions

• No leather gloves when handling.

If wet, keep wet, if dry, keep dry.

No chemicals for cleaning.

Use appropriate shipping procedures.

emp

power up

FADEC after an accident has occurred

46

scussed.

or

File Number

Page 47

Post Accident Precautions (continued)

If possible, don t allow any electronic debris to

circuit card

Att

t to id

tify the t

that the

• Use care when cutting wires and removing harness

•

’

freeze.

• Do not flex or straighten a bent, broken or damaged

.

• Avoid exposure to magnetic fields such as large

motors, large magnets or shipboard radar.

emp

investigation will focus on prior to going to the accident site.

47

en

ypes of electronics

File Number

Page 48

Honeywell Support for Downloading and Analysis

•

Honeywell is best equipped to handle and download

H

to damage from impact and fire, etc.

Experienced in analysis of the downloaded data with tools

pp

pp p y

the data from our engine DEEC’s and FADEC’s after

an accident or incident.

-

ave appropriate equipment and trained personnel to

properly analyze and prepare units for downloading.

- Access to Engineering expertise to deal with challenges due

- Experienced in dealing with chip level recovery and use of

slave units for downloading.

-

prepared for quick analysis

• Units shi

ed separately or with accident/incident

engines will be bonded, unopened until appropriate

party members are in attendance.

48

File Number

Page 49

Example of Challenging Download

•

Engine mounted TFE731 DEEC was severely heat

p

then installed in a

and impact damaged during the accident sequence.

• Incident Recorder chip

was cleaned, removed,

and copied.

• The chip copy was

slave unit and

successfully

downloaded.

49

File Number

Page 50

Accident Contact Information

•

For assistance with any Honeywell Aerospace

ager o

ccident

estigatio

aageo ccdet estgato

Phoenix, Arizona 85234

products involved in an Accident or Incident,

Contact:

Jim Allen

Man

Honeywell Product Integrity

1944 E Sky Harbor Circle

Phone 602-365-5672

24 hour Accident Hot Line, 1-602-365-2423

f A

Inv

n

50

File Number

Page 51

Questions?

51

File Number

Loading...

Loading...