Page 1

EC-P2

Gas Sensor

Instruction and

Maintenance Manual

Rev G

11511 West 83rd Terrace email sales@manningsystems.com

Lenexa, Kansas 66214 www.gasalarm.com

1.800.444.9935 or 913.894.1185

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 1

fax 913.894.1296 18272 ECP2 04/2005 REVG

Page 2

Contents Serial number:

Section Title Page

1 System Description 3

2 Operation 5

3 Maintenance 7

4 Programming and Advanced Features 9

5 Appendices 13

6 Limited Warranty 15

Introduction

This manual has been prepared to help in the use of the Manning Systems EC-P2 portable gas

detector.

This manual must be carefully followed by all individuals who have or will have the

responsibility for using or servicing the sensor.

Warranties made by Manning Systems, Inc.

with respect to this equipment will be voided if the equipment is not used and serviced in

accordance with the instructions in this manual. If in doubt about a procedure, please contact

Manning Systems, Inc. before proceeding.

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 2

Page 3

1 System Description

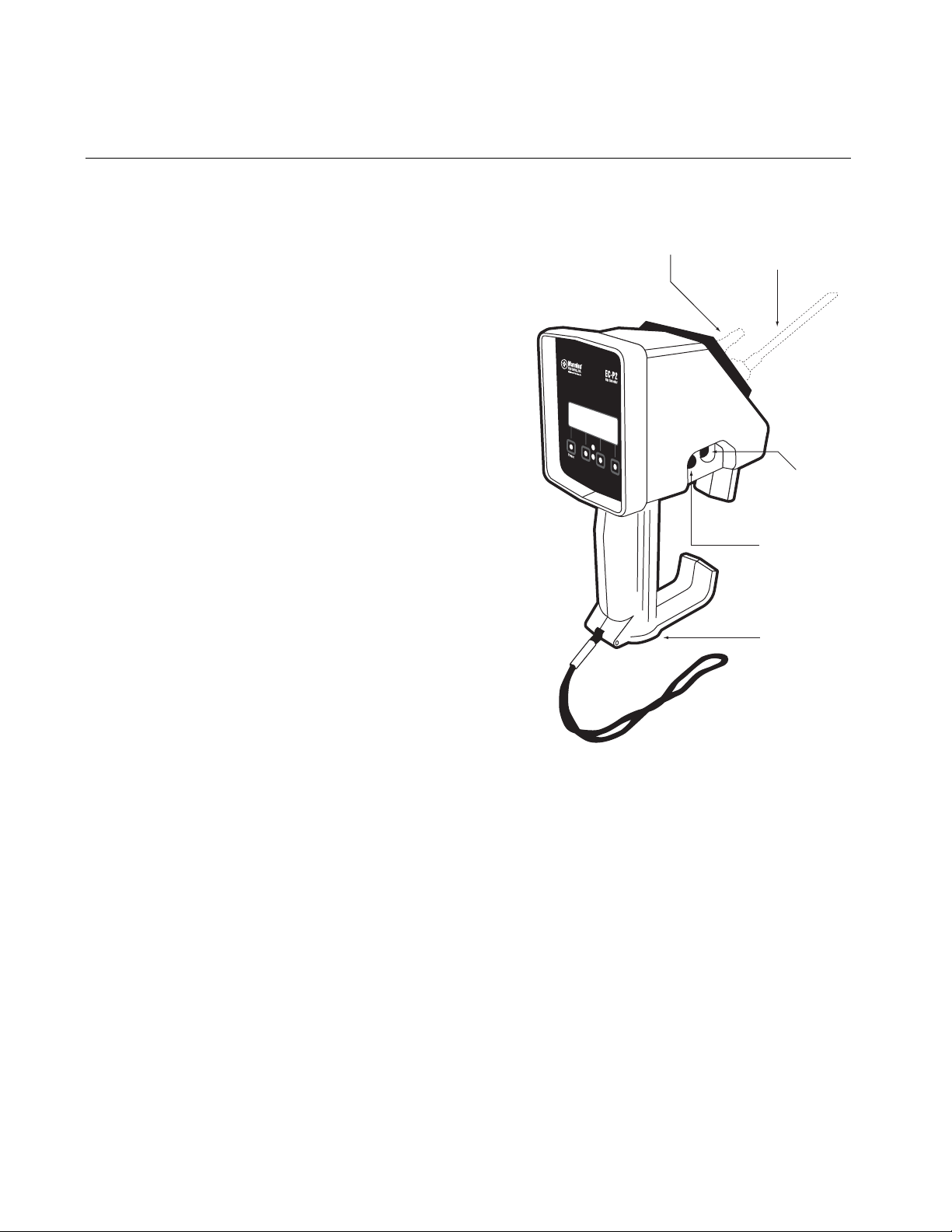

The EC-P2 is a portable, battery operated instrument for

the measurement of gas concentrations in ambient air.

The EC-P2 can be converted from one target gas to

another by simply plugging in a different SMART-CELL

for the desired target gas (takes about 30 seconds). This

allows one instrument to detect a number of different

gases.

All calibration and alarm setpoint data is stored on the

individual SMART-CELL so reconfiguration is not

necessary when changing target gases. Extra SMARTCELLs should be kept on the optional sensor keeper

when not in use to keep them “warmed up” and ready

for immediate use.

The EC-P2 utilizes two different batteries to insure that

you’ll never be without power when you need it. The

primary power source is a “C” size alkaline battery

housed in the handle. It will run the unit approximately

48 hours. When this battery is removed or dead, the unit

will switch to its standby power source, an internal

rechargeable NiCad battery, which will run the unit

approximately six hours. When not in use, the unit

should be plugged into the charger to keep this standby

battery charged. If desired, the unit can be run

continuously when plugged into the charger.

Figure 1: Basic Parts of the EC-P2 Sensor

Outlet Tube

Sampling Wand

Assembly

Data Logger Port

Standby Battery

Recharge Receptacle

Primary Battery

The EC-P2 also has advanced capabilities such as data

logging to an Excel spreadsheet, 0 to 1.0 Volt DC analog

output capability, and a sampling mode for taking a

single reading in a controlled, repeatable manner.

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 3

Page 4

1 System Description continued

System Specifications

Primary Power: Alkaline C cell battery, 48 hours

operation.

60 seconds indicates that either the Alkaline C cell

battery is low or the internal rechargeable NiCad

battery is low.

Standby Power: Internal rechargeable NiCad

battery, 6 hours operation.

single beep every 60 seconds indicates that either

the Alkaline C cell battery is low or the internal

rechargeable NiCad battery is low.

Charger: 120 VAC plug-in charger for internal

standby battery

Display: Backlit LCD

Pump: Miniature internal diaphragm type,

flowrate 0.5 SCFH

Alarms: Two concentration alarms, zero drift

caution, Low flow and Low battery alarms. Alarms

displayed on LCD and indicated by audible beeper.

Standard Accessories: Storage case, 10" extension

wand, battery charger, filter material, datalogging

software, RS-232 output cable (DB9 connector)

Note: An audible alarm single beep every

Note: An audible alarm

Repeatability: ± 1% full scale

Operating Ambient Temperature Range: 0

Storage Temperature: Recommend storing on the

o

to +120o F

charger in an air conditioned office

Weight: 3 lbs. (shipping weight), 1.8 lbs. (detector only)

Dimensions: Approx 3.5" x 5" x 8.5"

Outputs: RS-232 output of stored gas values. Analog

output 0 to 1.0 VDC (requires optional analog output

cable)

Memory: 12,000 data points, storage interval between

points programmable at 1, 5, 10, or 15 minutes. Typical

capacity: 8 days at 1 minute storage interval

Optional Accessories: Analog output cable. Sensor

Keeper for storage of additional SMART-CELLs

Sensor Type: Target gas selective electrochemical

SMART-CELL

Accuracy: Sensor dependant but generally ± 5% of

reading

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 4

Page 5

2 Operation

MENU SMPL

PPM

NH

3

OFF

0

P

A

BATTERY IN USE

P = Primary (“C” cell)

S = Standby (Internal NiCad)

Flashing indicates low battery

CURRENT GAS CONCENTRATION

(Blinking indicates sensor over range)

TARGET GAS

SMART-CELL dependent

ADVANCED FEATURES ONLY

Do not push for normal operation

ALARM INDICATION CODE

Blank = No alarm condition present

C = Caution—Cell has excessive zero downdrift

W = Warning—Gas concentration has exceeded warning level

A = Alarm—Gas concentration has exceeded alarm level

P = Pump trouble

Lg = Data logging in progress

Battery Light

A Operating the Sensor

The EC-P2 is shipped ready for use. To power up the

instrument, push the PWR button. The power up

sequence displays first the self check, the sensor full

scale value, the downscale caution level, warning

concentration setpoint, alarm concentration setpoint,

output ranges, software version, then the normal

operating screen.

The unit will then display the instantaneous gas

concentration and is ready for use.

The normal operating screen displays the information as

shown in Figure 2.

The EC-P2 is designed to avoid accidental shut-off of the

To turn the unit off, the PWR button must be

power.

held down for approximately three seconds.

Release

the button after the “Power Down” message appears.

B Changing the Target Gas

using SMART-CELL

Technology

4) Replace the manifold and hand tighten the thumbscrews.

5) Verify proper flow through the sampling wand using the

flowmeter provided.

Extra SMART-CELLS should be kept on the optional

sensor keeper when not in use to keep them “warmed

up” and ready for immediate use. The sensor keeper is

powered by an Alkaline “C” size battery which should be

replaced every 6 months.

For a variety of target gases, see page 13 for a list of

available SMART-CELLs. Contact Manning Systems if

the desired target gas is not listed, as new cells may be

available.

Figure 2: Normal Operating Screen of the EC-P2 Sensor

The EC-P2 can easily be changed to sense another target

gas by installing the SMART-CELL for the desired target

gas. Each SMART-CELL contains all the calibration and

alarm setpoint information on its internal memory chip,

so recalibration or reprogramming is not necessary

when changing the EC-P2 from one gas to another. This

procedure can be performed with the unit powered on

or off (see Figure 3).

1) Unscrew the two stainless steel thumbscrews and remove

2)

To remove the existing SMART-CELL, grip the sides of the

3)

Install the desired SMART-CELL by gently inserting it into

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 5

the black inlet / outlet manifold lid from the back of the

unit.

cell and pull it straight out.

the socket. Notice that the SMART-CELL is keyed so it

cannot be inserted incorrectly.

Page 6

2 Operation continued

C Response Test

Prior to use, the unit should first be tested for proper

response. With the detector operating, the unit should

be exposed to a sample of the target gas. The display

should show an increasing concentration. If not, do not

use it for field measurements.

D Sample Inlet Port

The EC-P2 is provided with a quick disconnect flexible

extension wand. It will work with or without the wand.

When using the extension wand, the internal walls must

be kept dry. Water on the walls of the tubing can

potentially absorb the target gas. To dry, allow the unit

to pump dry, ambient air for 15 minutes.

E Response/Recovery Time

Under normal conditions, the instrument will reach 90%

of final value within two minutes. This is dependent on

concentration and temperature.

Recovery time for the sensor depends on duration and

concentration of exposure. Short exposures of concentrations at the lower end of the target gas range result

in rapid recovery. Long exposures to levels above the

middle of the target gas range or short exposures to

levels exceeding the target gas range can extend recovery

times to hours. Repeated exposures above the target gas

range will reduce cell life and should be avoided.

F Interference Gases

The EC-P2 is generally quite specific to the target gas,

but depending on the target gas, other gases may cause

a reading. See Appendix B for a listing of potential

interference gases for the various SMART-CELLs.

G Alarm Functions

The EC-P2 provides both visible and audible gas concentration alarms and system alarms. An alarm condition

will be displayed on the normal operating screen as

described on page 5. In addition to the alarm indication

code in the left side of the screen, an alarm message

will flash intermittently on the screen, the audible beeper

will sound and the ACK button will appear. Pushing the

ACK button will silence the beeper and stop the display

flashing. The Alarm Indication Code will remain on the

left side of the screen until the alarm condition clears.

Alarm setpoints are stored on the individual SMARTCELL and can be changed by the user as described in

Section 4.

Note: An audible alarm single beep every 60 seconds

indicates that either the Alkaline C cell battery is low or

the internal rechargeable NiCad battery is low.

H Display Resolution

The EC-P2 displays gas concentration with a resolution

that depends upon the range of the unit. Full scale ranges

of 0-4.00 or below will provide resolution of 0.01. Ranges

from 0-5.0 up to 0-49.9 will provide resolution of 0.1.

Full scale ranges above 50 will have a resolution of 1.

Figure 3: Manifold Assembly of the EC-P2 Sensor

Sampling

wand

Inlet fitting

Outlet tube

barb fitting

TEST UNIT PRIOR TO USE

OUTLET

INLET

CAUTION

DO NOT BLOCK INLET

OR OUTLIET PORTS

Manifold lid

Thumbscrews

(loosen to remove

manifold lid)

Sensor

(SMART-CELL)

Sensor

alignment

groove

Sensor

alignment

pin

Filter Material

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 6

Page 7

3 Maintenance

A Periodic Maintenance

It is essential that the test and calibration schedule be

adhered to. Manning Systems recommends the following

maintenance schedule:

• Response test prior to each use. Expose sensor to

a sample of the target gas to verify proper sensor

response and alarm functions.

• Calibration should be performed with certified

calibration gas every six months, and all tests

must be logged.

• Check filter material every six months. Replace if

dirty or moist.

• If the optional sensor keeper is used for extra

SMART-CELLs, change the sensor keeper battery

once every 6 months. Use only alkaline “C” size

batteries.

B Sensor Life

The electrochemical SMART CELL is extremely reliable,

but the following can cause the cell chemicals to

become depleted:

• A period of time

C Calibration

Calibration is recommended every six months in normal

use. Each SMART-CELL stores its calibration and alarm

setpoint information on its own memory chip. When the

SMART-CELL is plugged into the EC-P2, this information

is used by the EC-P2. The SMART-CELL can be field

calibrated by the user or returned to Manning Systems

for factory calibration.

The calibration procedure requires the use of a bypass

tee to allow the gas to be drawn into the flow cell

without creating variable pressure or dilution problems.

Calibration gas cannot be fed into the flow cell under

pressure.

When applying calibration gas use the bypass tee as

shown in figure 4 on page 8. The flowrate of calibration

gas should be high enough that at least 0.5 SCFH is

flowing out of the calibration tee. This can be measured

with the supplied flowmeter and insures that air is not

being drawn into the unit and diluting the calibration

gas.

The unit may be zeroed without spanning it; however,

never span the unit without first zeroing it.

The following procedure will calibrate the SMART-CELL.

• Exposure to high temperatures

• Exposure to high concentrations of the target gas

• Exposure to high moisture

When the cell becomes depleted, the unit will give no

indication of failure other than that the sensor will not

respond. For this reason it is absolutely essential that

these units be exercised with a gas sample on a regular

basis.

Typical sensor life under normal use is two years or

more. When the SMART-CELL will no longer calibrate

properly, simply purchase a new SMART-CELL and

replace.

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 7

To Enter ZERO / SPAN Mode

1) Push power button to turn unit on. Wait for power up

sequence to finish (30 seconds).

2) Push and hold the unnamed button (second from left) first,

then Push and hold the Menu button. Hold both buttons

until the screen goes blank (2 seconds). Release both

buttons and the unit is now in Programming Mode.

3) Push the SENS button and the unit is now in the zero/span

mode.

Page 8

3 Maintenance continued

Zero Calibration

4) Be sure the unit is in clean air or apply zero air for two

minutes.

5)

Push ZERO button.

6)

Push SAVE button to save the new zero calibration.

Span Calibration

7) Push SPAN button.

8) Apply span gas for two minutes.

9) Push INC button (increase) or DEC button (decrease) until

the display matches the span gas concentration.

10) Push SAVE button to store new span calibration.

To Exit ZERO / SPAN Mode

11) Push DONE button twice slowly to get back into normal

operation mode.

D Troubleshooting

The detector does not start: Check to see that a fresh

battery is installed. Both the primary and standby

batteries must be discharged for this problem to occur.

Plug the charger into the EC-P2 to charge the standby

battery. Wait 10 minutes and retry.

The detector does not respond to the target gas: Verify

the proper flow rate using the supplied flowmeter.

Perform calibration. If sensor won’t calibrate, the

SMART-CELL may be depleted. Contact Manning

Systems for a replacement SMART-CELL.

Pump alarm: This will occur if the pump motor stops

or if an internal pressure sensor detects blockage of the

inlet. Check that the internal filter is not clogged or wet

and that the inlet tube is clear.

External flowmeter indicates no flow: Verify that pump

is running. Check that the manifold screws are tight and

the extension wand connection is tight.

Unit does not respond when keys are pressed: Press

and hold all four buttons for five seconds. This will reset

the EC-P2. Turn the unit back on by pressing the PWR

button.

High reading won’t clear: When the sensor is exposed

to very high gas concentrations, it takes a relatively long

time for the sensor to clear. Leave the unit running in a

clean environment for a few hours to clear the sensor. If

it doesn’t clear after six hours, the sensor may have

been damaged. Contact Manning Systems for a

replacement SMART-CELL.

Unit is in alarm with gas reading of 0 ppm: Check the

alarm setpoints and alarm functions as described on

page 9. Verify that alarm is not programmed as a

downscale alarm, and that the setpoint is above zero.

Figure 4: Calibration of the EC-P2 Sensor

using a Bypass Tee

Vent through

flowmeter

Bypass tee

LPM AIR

1.0

.8

.6

.4

.2

Calibration gas

flowmeter

TEST UNIT PRIOR TO USE

OUTLET

INLET

DO NOT BLOCK INLET

OR OUTLIET PORTS

CAUTION

Calibration gas bottle

(use only Certified

Calibration Gas)

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 8

Page 9

4 Programming and Advanced Features

A Alarm Setpoints and

Functions

The EC-P2 has three adjustable alarm setpoints. These

setpoints are stored on each SMART-CELL. The Caution

setpoint is to warn of excessive negative zero drift. The

WARNING and ALARM setpoints are to warn of

potentially dangerous target gas concentrations. The

following procedure will change the WARNING setpoint.

To Enter CAUT / WARN / ALRM Mode

1) Push power button to turn unit on. Wait for power up

sequence to finish (30 seconds).

2) Push and hold the unnamed button first, then Push and

hold the Menu button. Hold both buttons until the screen

goes blank (two seconds). Release both buttons and the

unit is now in Programming Mode.

3) Push the ALRM button and the unit is now in the

CAUT / WARN / ALRM mode.

Warning Setpoint

4) Push WARN button.

5) Push S.P. button (setpoint).

6) Push INC button (increase) or DEC button (decrease)

until the display matches the desired warning setpoint.

Notice the minus sign above the arrow if the setpoint is

below zero.

7) Push SAVE button to store new warning setpoint.

8) Push DONE button to return to Alarms mode.

The function of each alarm can be selected to alarm on

increasing gas concentration (UP arrow), alarm on

decreasing gas concentration (DOWN arrow), or be

disabled (off). The following procedure will set the

Warning function to alarm on decreasing concentration

(Useful for Oxygen Depletion warning).

To Enter CAUT / WARN / ALRM Mode

1) Push power button to turn unit on. Wait for power up

sequence to finish (30 seconds).

2) Push and hold the unnamed button first, then Push and

hold the Menu button. Hold both buttons until the screen

goes blank (two seconds). Release both buttons and the

unit is now in Programming Mode.

3) Push the ALRMS button and the unit is now in the

CAUT / WARN / ALRM mode.

Warning Function

4) Push WARN button.

5) Push FUNC (function) button.

6) Push SELECT button while viewing the arrow in the lower

left hand corner of the screen to toggle through the

following three possibilities:

• UP arrow – Warn on increasing concentration

(gas goes higher than setpoint).

• DOWN arrow – Warn on decreasing concentration

(gas goes lower than setpoint).

• Blank – warning function turned OFF.

7) Push SAVE button when the DOWN arrow is displayed to

store new warning function.

To Exit CAUT / WARN / ALRM Mode

9) Push DONE button twice slowly to get back into normal

operation mode.

The Caution and Alarm setpoints are programmed in the

same manner, except for step four above in which you

would push either the CAUT or ALRM button.

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 9

8) Push DONE button to return to Alarms mode.

To Exit CAUT / WARN / ALRM Mode

9) Push DONE button two times slowly to get back into

normal operation mode.

The Caution and Alarm functions are programmed in the

same manner, except for step four above in which you

would push either the CAUT or ALRM button.

Page 10

4 Programming and Advanced Features continued

B Display Variables

The EC-P2 has two adjustable display variables. These

variables control signal conditioning of the LCD display.

Variables are stored on each SMART-CELL. The AVG

(Average) variable determines the number of one

second samples to average to calculate the displayed

value. The lower the averaging value, the faster the

display will change and the more “wiggle” will be

displayed. The BLANK (zero blanking) variable controls

the lowest reading that will be displayed. This is to

eliminate the misleading display of signals within the

zero noise of the sensor. The following procedure will

change the AVG variable.

To Enter AVG / BLANK Mode

1) Push power button to turn unit on. Wait for power up

sequence to finish (30 seconds).

2) Push and hold the unnamed button first, then Push and

hold the Menu button. Hold both buttons until the screen

goes blank (two seconds). Release both buttons and the

unit is now in Programming Mode.

3) Push the MORE button.

4) Push the DISP (display) button and the unit is now in the

AVG / BLANK mode.

AVG Variable

5) Push AVG button.

6) Push INC button (increase) or DEC button (decrease) until

the display matches the desired value.

7) Push SAVE button to store new AVG variable.

To Exit AVG / BLANK Mode

8) Push DONE button twice slowly to get back into normal

operation mode.

The Blanking variable is programmed in the same

manner, except for step five above in which you would

push the BLANK button.

C Sample Mode

The Sample Mode feature allows the user to take a

measurement using a predefined repeatable method to

eliminate user “interpretation” of a gas concentration

that is changing. This is similar to a digital scale, for

example, so the exact same reading will be taken

regardless of who is taking it.

The measuring sequence used in Sample Mode is as

follows:

• Draw a

time to allow unit to stabilize to the existing gas

concentration.

Measure the gas concentration and average it for

•

a user programmed measuring time.

•

Clear the gas concentration to below a user

programmed recovery value before allowing

another cycle to start. (Unit should be moved to

fresh air during the clear time.)

Sample for a user programmed sampling

Taking a sample:

To take a sample, locate the detector at the desired

sample location, and push the SMPL (sample) button on

the normal operation screen. The unit will countdown

the Sample time, followed by the Measure time, at the

end of which the average value will be displayed.

Note the displayed sample value. Pushing the CLEAR

button will return the unit to the normal operation

screen once the gas concentration is below the

predefined recovery value. The unit is now ready to take

another sample if desired.

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 10

Page 11

4 Programming and Advanced Features continued

Programming sample mode variables:

The sample mode variables are Sample, Measure and

Clear as described above. The following procedure will

change the Sample variable.

To Enter SAMP / MEAS / CLEAR Mode

1) Push power button to turn unit on. Wait for power up

sequence to finish (30 seconds).

2) Push and hold the unnamed button (second from left) first,

then Push and hold the Menu button. Hold both buttons

until the screen goes blank (two seconds). Release both

buttons and the unit is now in Programming Mode.

3) Push the MORE button.

4) Push the SMPL (sample) button and the unit is now in the

SAMP / MEAS / CLEAR mode.

SAMP Variable

5) Push SAMP (sample) button.

6) Push INC button (increase) or DEC button (decrease) until

the display matches the desired value. The display is in

minutes and seconds.

7) Push SAVE button to store new SAMP variable.

To Exit SAMP / MEAS / CLEAR Mode

8) Push DONE button twice slowly to get back into normal

operation mode.

The Measure and Clear variables are programmed in the

same manner, except for step five above in which you

would push the MEAS or CLEAR button.

D Data Logging

The EC-P2 can log periodic gas concentration readings

to be downloaded to a file which can be read by

Microsoft Excel or other popular spreadsheet applications. The EC-P2 will store instantaneous gas values

every one, five, 10, or 15 minutes. Multiple sessions can

be logged and then downloaded as separate files.

EC-P2 software installation:

The EC-P2 is supplied with a CD containing the “Manning

Systems EC-P2” program. It will run on Windows 95,

Windows 98, or Windows 2000. To install the program,

place the disk in your CD drive. The CD should

automatically begin the installation process. Follow the

prompts as they appear on your screen. Accepting the

default directory locations is recommended for most

installations. If the CD does not automatically start, click

on “My Computer” and then your CD drive. Double-click

on the file named “Setup.exe.”

Prior to your first datalogging session it is recommended

that you connect the EC-P2 to your computer with the

data logging program running. The computer can then

set the time in the EC-P2 to match its own clock.

Data logging with the EC-P2:

To Start the Data Logging Session

1) Push power button to turn unit on. Wait for power up

sequence to finish (30 seconds).

2) Push the MENU button.

3) Push the LOG button and the unit is now in the

CLEAR / INT / START mode.

4) If the CLEAR button is available, that means there is data

currently stored in the unit. If desired, you can erase the

data already in the unit by pushing the CLEAR button.

(If you don’t push CLEAR, each data logging session can

be downloaded as a separate file).

5) Push INT button (interval) to cycle through the choices for

how often to log a data point. Stop when the desired

interval is displayed. Notice how much time can be

covered with the remaining free memory.

6) Push and hold the START button until the screen goes

blank (two seconds) to begin a new data logging session.

The unit will now display the gas concentration. The Lg

symbol in the left side of the display indicates that the unit

is logging data. If you watch this symbol carefully, you will

see it change to an “s” each time a data point is stored.

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 11

Page 12

4 Programming and Advanced Features continued

To Stop the Data Logging Session

7) Push the MENU button.

8) Push the LOG button.

9) Push and hold the STOP button until the screen changes

to CLEAR / INT / START / MODE (two seconds).

10) Push the DONE button to get back into normal operation

mode.

Working with the “EC-P2” program:

The “EC-P2” program downloads the logging files from

the EC-P2. It does not display the data. The files it

downloads can be opened by or imported into Excel,

Lotus 123 or other programs for graphing and analysis.

Turn on the EC-P2 and connect it to your PC using the

RS-232 cable supplied. From Windows START menu,

select “PROGRAMS,” then “Manning Systems EC-P2,”

and then “EC-P2”. As soon as you start the “EC-P2”

program, your computer will try to establish a

connection to the EC-P2. If the EC-P2 is currently

logging data, the “EC-P2” program will automatically

stop the logging function.

The program contains two tabs, one marked “Download”

and one marked “Configure”. Review the settings on the

“Configure” tab, making changes as necessary.

From the “Download” tab, review the Link Status block

in the lower right hand corner. It should indicate

“Link OK”. Link Trouble can be caused by selection of

the wrong Com port in the Configure Tab, improperly

connecting the RS-232 cable, or not turning on the

EC-P2.

E Analog Output

The EC-P2 has a 0 to 1.0 volt DC analog output

capability when used with the optional analog output

cable. With the analog output cable plugged into the

communication port of the EC-P2, the user can measure

the voltage between the two wires and correlate it to

gas concentration. The voltage output will be linear

between zero and the full scale range of the SMARTCELL as programmed below. Each SMART-CELL has a

wide range of choices of full scale values.

The full scale range as programmed below only affects

the analog output and the data logging full-scale output.

The display will always cover the entire operating range

of the SMART-CELL. Changing the range can affect the

display resolution for some SMART-CELLs.

Changing the full scale range on EC-P2:

To Enter RANGE Mode

1) Push power button to turn unit on. Wait for power up

sequence to finish (30 seconds).

2) Push and hold the unnamed button (second from left) first,

then Push and hold the Menu button. Hold both buttons

until the screen goes blank (two seconds). Release both

buttons and the unit is now in Programming Mode.

3) Push the MORE button.

4) Push the DISP (display) button.

5) Push the MORE button and the unit is now in the RANGE

mode.

Adjusting the RANGE

When you are ready to transfer data from the EC-P2 to

your PC, click on “get data” and the files will be

downloaded to your computer. Note the file names in

the destination window so you can locate the files.

These files can now be opened with Excel (use .csv

filename), Lotus 123, or other user supplied programs.

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 12

6) Push RANGE button.

7) Push INC button (increase) or DEC button (decrease) until

the display matches the desired full scale range.

8) Push SAVE button to store new full scale range.

To Exit RANGE Mode

9) Push DONE button twice slowly to get back into normal

operation mode.

Page 13

5 Appendices

APPENDIX A: SMART-CELLs Available

GAS RANGE PART NUMBER

Alcohol 0-500 ppm EC-P2-SMART-CELL-OH-0/500ppm

Ammonia 0-500 ppm EC-P2-SMART-CELL-NH

Ammonia 0-2000 ppm EC-P2-SMART-CELL-NH

Bromine 0-5 ppm EC-P2-SMART-CELL-Br

-0/500ppm

3

-0/2000ppm

3

-0/5ppm

2

Carbon Monoxide 0-1000 ppm EC-P2-SMART-CELL-CO-0/1000ppm

Chlorine 0-5 ppm EC-P2-SMART-CELL-Cl

Chlorine 0-200 ppm EC-P2-SMART-CELL-Cl

Chlorine Dioxide 0-5 ppm EC-P2-SMART-CELL-ClO

Flourine 0-5 ppm EC-P2-SMART-CELL-Fl

-0/5ppm

2

-0/200ppm

2

-0/5ppm

2

-0/5ppm

2

Formaldehyde 0-200 ppm EC-P2-SMART-CELL-HCHO-0/200ppm

Hydrogen 0-2000 ppm EC-P2-SMART-CELL-H

-0/2000ppm

2

Hydrogen Chloride 0-200ppm EC-P2-SMART-CELL-HCl-0/200ppm

Hydrogen Peroxide 0-200 ppm EC-P2-SMART-CELL-H

Hydrogen Sulfide 0-200 ppm EC-P2-SMART-CELL-H

-0/200ppm

2O2

S-0/200ppm

2

Nitric Oxide 0-500 ppm EC-P2-SMART-CELL-NO-0/500ppm

Nitrogen Dioxide 0-200 ppm EC-P2-SMART-CELL-NO

Oxygen 0-25% EC-P2-SMART-CELL-O

-0/200ppm

2

-0/25%

2

Ozone 0-5 ppm EC-P2-SMART-CELL-O

Ozone 0-100 ppm EC-P2-SMART-CELL-O

Sulfur Dioxide 0-500 ppm EC-P2-SMART-CELL-SO

-0/5ppm

3

-0/100ppm

3

-0/500ppm

2

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 13

Page 14

5 Appendices continued

APPENDIX B: SMART-CELL Cross-Sensitivity Table (Interference Gases)

SENSOR AND TARGET GAS

Br2 Cl2 ClO2 O3 NH3 CO H2 O2 NO H2S NO2 SO2 HCHO OH Fl2 HCl H2O

Bromine ----- 1.0 1.0 0.7 -0.1 None None None None None 0.5 -0.1 None None 1.0 None None

I

Chlorine 1.0 ----- 1.0 0.7 -0.1 None None None None None 0.5 -0.1 None None 1.0 None None

N

Chlorine dioxide 1.0 1.0 ----- 0.7 -0.1 None None None None None 0.5 -0.1 None None 1.0 None None

T

Ozone 1.5 1.5 1.5 ----- -0.1 None None None None None 0.65 -0.1 None None 1.5 None None

Ammonia None None None None ----- None None None None None None None None None None None None

E

Carbon monoxide None None None None 0.05 ----- 0.1 None None 0.002 0.001 None 0.5 0.5 None 0.005 0.005

R

Hydrogen None None None None 0.02 0.1 ----- None 0.001 0.001 0.001 0.005 0.05 0.05 None 0.01 0.01

F

Oxygen None None None None None None None ----- None None None None None None None None None

E

Nitrogen oxide None None None None None 0.1 None None ----- 0.4 0.001 0.04 0.8 0.8 None 1.5 1.5

R

Hydrogen sulfide -0.1 -0.1 -0.1 -0.07 0.3 None None None None ----- -2.5 None 2 2 -0.1 3 4

Nitrogen dioxide 0.2 0.2 0.2 0.15 None None None None None 0.1 ----- -0.08 0.1 0.1 0.2 0.2 0.2

E

Sulfur dioxide -0.01 -0.01 -0.01 -0.01 None None None None None 0.1 -1 ----- 0.4 0.4 -0.01 0.5 1

N

Formaldehyde None None None None 0.03 0.1 0.1 None 0.05 0.01 None 0.02 ----- 1.2 None None 0.1

C

Alcohol None None None None 0.03 0.1 0.1 None 0.05 0.01 None 0.02 None ----- None None 0.1

E

Flourine 1.0 1.0 1.0 0.7 -0.1 None None None None None 0.5 -0.1 None None ----- None None

Hydrochloric acid None None None None None None None None None None -0.3 None 0.2 0.2 None ----- 0.1

Hydrogen peroxide None None None None 0.03 0.1 0.1 None 0.05 0.01 None 0.02 None None None None -----

G

Hydrogen cyanide -0.08 -0.08 -0.08 -0.05 None 0.1 None None None None -0.07 0.15 0.1 0.1 -0.08 0.01 0.1

A

Hydroflouric acid None None None None None None None None None None None None None None None None None

S

Hydride None None None None 0.5 None None None 1 0.5 -2 2 2 2 None 1.5 2

E

Silica hydride None None None None 0.5 None None None 1 0.5 -2 2 2 2 None 1.5 2

Carbon dioxide None None None None None None None None None None None None None None None None None

S

Methane None None None None None None None None None None None None None None None None None

Carbosulfonic acid -0.04 -0.04 -0.04 -0.03 None None None None None 0.3 -0.8 None 1 1 -0.04 1 1.3

Ethylene None None None None None 0.1 0.1 None None None None None 1 1 None None None

Ethyl alcohol None None None None 0.01 None None None 0.001 0.005 0.001 0.05 2 2 None 0.01 0.02

2

Notes: 1) None means there is no interference.

2) A number indicates that when exposed to the interference gas, the sensor will react the specified amount for a given concentration.

For example, on the first line of the table above, if the NO

This interference is in addition to the target gas present. For example, if an NH

the same time, the reading will be 0.9 ppm (1ppm NH

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 14

sensor is exposed to 1 ppm Bromine (Br2), the sensor will read 0.5 ppm.

2

sensor is exposed to 1 ppm NH3 and 1 ppm Br2 at

3

+ -0.1 ppm Br2 = 0.9 ppm reading).

3

Page 15

6 Limited Warranty

1. Limited Warranty

Manning Systems, Inc. (“Manning”) warrants to

the original purchaser and/or ultimate customer

(“Purchaser”) of Manning’s Products (“Product”)

that if any part thereof proves to be defective in

material or workmanship within eighteen (18)

months of the date of shipment by Manning or

twelve (12) months from the date of first use by

the purchaser, whichever comes first, such

defective part will be repaired or replaced, free of

charge, at Manning’s discretion if shipped prepaid

to Manning at 11511 W. 83rd Terrace, Lenexa,

Kansas 66214, in a package equal to or in the

original container. The Product will be returned

freight prepaid and repaired or replaced if it is

determined by Manning that the part failed due to

defective materials or workmanship. The repair

or replacement of any such defective part shall be

Manning’s sole and exclusive responsibility and

liability under this limited warranty.

2. Exclusions

A. If gas sensors are part of the Product, the gas

sensor is covered by a twelve (12) month

limited warranty of the manufacturer.

B. If gas sensors are covered by this limited

warranty, the gas sensor is subject to

inspection by Manning for extended exposure

to excessive gas concentrations if a claim by

the Purchaser is made under this limited

warranty. Should such inspection indicate that

the gas sensor has been expended rather than

failed prematurely, this limited warranty shall

not apply to the Product.

C. This limited warranty does not cover

consumable items, such as batteries, or items

subject to wear or periodic replacement,

including lamps, fuses, valves, vanes, sensor

elements, cartridges, or filter elements.

3. Warranty Limitation and Exclusion

Manning will have no further obligation under this

limited warranty. All warranty obligations of

Manning are extinguishable if the Product has

been subject to abuse, misuse, negligence, or

accident or if the Purchaser fails to perform any

of the duties set forth in this limited warranty or

if the Product has not been operated in

accordance with instructions, or if the Product

serial number has been removed or altered.

4. Disclaimer of Unstated Warranties

THE WARRANTY PRINTED ABOVE IS THE ONLY

WARRANTY APPLICABLE TO THIS PURCHASE.

ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO,

THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE ARE HEREBY DISCLAIMED.

5. Limitation of Liability

IT IS UNDERSTOOD AND AGREED THAT

MANNING’S LIABILITY, WHETHER IN

CONTRACT, IN TORT, UNDER ANY WARRANTY,

IN NEGLIGENCE OR OTHERWISE SHALL NOT

EXCEED THE AMOUNT OF THE PURCHASE

PRICE PAID BY THE PURCHASER FOR THE

PRODUCT AND UNDER NO CIRCUMSTANCES

SHALL MANNING BE LIABLE FOR SPECIAL,

INDIRECT, OR CONSEQUENTIAL DAMAGES.

THE PRICE STATED FOR THE PRODUCT IS A

CONSIDERATION LIMITING MANNING’S

LIABILITY. NO ACTION, REGARDLESS OF

FORM, ARISING OUT OF THE TRANSACTIONS

UNDER THIS WARRANTY MAY BE BROUGHT BY

THE PURCHASER MORE THAN ONE YEAR

AFTER THE CAUSE OF ACTION HAS

OCCURRED.

Manning EC-P2 Sensor 18272 ECP2 04/2005 REVG Copyright © 2005 Manning Systems, Inc. All Rights Reserved. 15

Loading...

Loading...