Page 1

7 Edition 10 .17

Technical Information · GB

• For direct and indirect heating

• Economical, energy-saving operation by

virtue of internal air preheating up to 650°C

• Uniform distribution of temperature by

means of a high burner impulse

• 7 sizes from 25 to 500 kW

• Highly efficient with a ceramic burled tube recuperator or a cast

steel ribbed tube recuperator.

Self-recuperative burner ECOMAX for gas

Page 2

ECOMAX · Edition 10.17 2

▼

= To be continued

Contents

Self-recuperative burner ECOMA X for gas ..........1

Contents ............................................2

1 Application ........................................4

1.1 Direct heating ......................................4

1.2 Indirect heating ....................................4

1.3 Application examples ..............................5

1.4 ECOMAX for direct heating systems...............6

1.4.1 Flow rate control.......................................6

1.4.2 Air/gas ratio control....................................7

1.4.3 No pneumatic air/gas ratio control system ...........8

1.5 ECOMAX® for indirect heating systems ...........9

1.5.1 No pneumatic air/gas ratio control system .........10

1.5.2 Air/gas ratio control .................................10

2 Certification ......................................11

3 Structure .........................................12

3.1 Burner body .......................................12

3.2 Recuperator.......................................13

3.3 Air guide tube .....................................14

3.4 Gas insert .........................................15

3.5 Version overview ..................................16

4 Function ..........................................17

5 Selection ........................................ 19

5.1 Burner type .......................................19

5.2 Burner size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.3 Burner length .................................... 20

5.4 Burner head .......................................21

5.4.1 Use....................................................21

5.4.2 Gas type ..............................................21

5.5 Type of heating ...................................22

5.6 Connection for additional furnace cooling .......23

5.7 Electrode made of Kanthal APM..................23

5.8 Selection table ...................................24

5.8.1 ECOMAX..C.......................................... 24

5.8.2 ECOMAX..M .........................................24

5.8.3 ECOMAX..P.......................................... 25

5.8.4 ECOMAX..F..........................................25

5.8.5 Type code............................................26

5.9 Selection table for flue gas eductor EJEK ........27

5.9.1 Type code............................................28

5.10 Selection table for flue gas connector FLUP....29

5.10.1 Type code ..........................................30

6 Project planning information for direct heating ..31

6.1 Heating system design ...........................31

6.2 Flue gas guide tube FGT set ......................32

6.3 Flue gas eductor EJEK............................33

6.4 Furnace flue gas system..........................34

6.5 Installation........................................35

6.5.1 Installation position ................................ 35

6.5.2 Tangential or angled burner installation ............35

6.5.3 Clearances .......................................36

6.5.4 Furnace temperature measurement.................37

6.5.5 Heat guard ...........................................37

6.6 Flame control .....................................38

6.7 Burner control units and ignition transformers ..39

6.7.1 Burner control unit configurations ..................40

6.8 Gas connection ..................................41

6.8.1 Selecting components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

6.8.2 Gas pressure .........................................41

6.8.3 Operation with LPG .................................42

6.9 Air connection ....................................43

6.9.1 Selecting components ..............................43

6.9.2 Air pressure ..........................................43

6.10 Air flow monitoring ............................. 44

6.11 Purge air and cooling air........................ 44

6.12 Condition on delivery............................45

6.13 Cooling with ECOMAX ..........................45

6.14 Emissions ...................................... 46

Page 3

ECOMAX · Edition 10.17 3

▼

= To be continued

6.15 Build up of noise................................ 46

6.16 Process boundary conditions . . . . . . . . . . . . . . . . . . . 47

6.17 Resistance of SiSiC ..............................47

7 Project planning information for indirect heating 48

7.1 Heating system design........................... 48

7.2 Radiant tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

7.3 Flue gas channelling ............................. 50

7.4 Furnace flue gas system ..........................51

7.5 Installation ........................................52

7.5.1 Heat guard ...........................................52

7.6 Flame control......................................53

7.7 Burner control units and ignition transformers ...54

7.7.1 Burner control unit configurations...................55

7.8 Gas connection ...................................56

7.8.1 Selecting components...............................56

7.8.2 Gas pressure .........................................56

7.8.3 Operation with LPG ...................................57

7.9 Air connection .....................................58

7.9.1 Selecting components...............................58

7.9.2 Air pressure ..........................................58

7.10 Air flow monitoring ...............................59

7.11 Purge air and cooling air .........................59

7.12 Condition on delivery ........................... 60

7.13 Increased furnace cooling with ECOMA X..K.... 60

7.14 Build up of noise .................................61

7.15 Emissions ........................................61

8 Accessories.......................................62

8.1 Air connection set.................................62

8.2 Air flow detector set...............................62

8.3 VAH connection set ...............................63

8.4 UV adapter set ....................................63

8.5 Purge air/cooling air nozzles......................63

8.6 Flue gas guide tube FGT Set..D ...................64

8.7 Flue gas eductor EJEK............................65

8.8 Flue gas connector FLUP.........................65

8.9 Ceramic radiant tube SERC..................... 66

8.10 Segmented flame tube SICAFLEX ............. 66

8.11 Cruciform spacer ................................67

8.12 Flue gas guide tube FGT SET ECO..SERC......67

8.13 Piping........................................... 68

8.13.1 Direct heating......................................68

8.13.2 Indirect heating ....................................69

9 Technical data ................................... 70

9.1 Dimensions .......................................71

9.1.1 ECOMAX..C for direct heating........................71

9.1.2 ECOMAX..M for direct heating......................72

9.1.3 ECOMAX..F for direct heating.......................73

9.1.4 ECOMAX..C for indirect heating .................... 74

9.1.5 ECOMA X..M for indirect heating ....................75

9.1.6 ECOMAX..F for indirect heating.....................76

10 Maintenance ....................................77

Feedback ...........................................78

Contact.............................................78

Page 4

ECOMAX · Edition 10.17 4

ECOMAX..M

ECOMAX..C

Application

1 Application

Self-recuperative burners ECOMAX are used for heating

on either direct or indirect furnace systems in ON/OFF

intermittent mode. The hot flue gases are fed through

the ceramic or metallic heat exchanger, which is integrat-

ed in the burner, heating the additional supply of cold

combustion air flowing in the opposite direction. The

maximum achievable air preheat temperature amounts

to approx. 650°C, depending on the application.

1.1 Direct heating

In conjunction with an eductor EJEK to extract the flue

gases, the burner ECOMAX is used to save energy in a

direct heating system without long hot air pipes requir-

ing insulation.

Applications include heat treatment furnaces in the

iron and steel industry and in the non-ferrous metal

industr y.

1.2 Indirect heating

Self-recuperative burners ECOMAX are used in conjunction with metallic or ceramic radiant tubes and

ceramic segmented flame tubes SICAFLEX for indirect

heating. Indirect heating equipment is used whenever

the combustion gases are to be separated from the

product, e.g. in heat treatment furnaces with inert gas

atmospheres in the steel industry or when heat-treating

aluminium.

Page 5

ECOMAX · Edition 10.17 5

Application

Roller hearth furnace Bogie hearth furnace Batch furnace

1.3 Application examples

Page 6

ECOMAX · Edition 10.17 6

ApplicationApplication > ECOMAX for direct heating systems

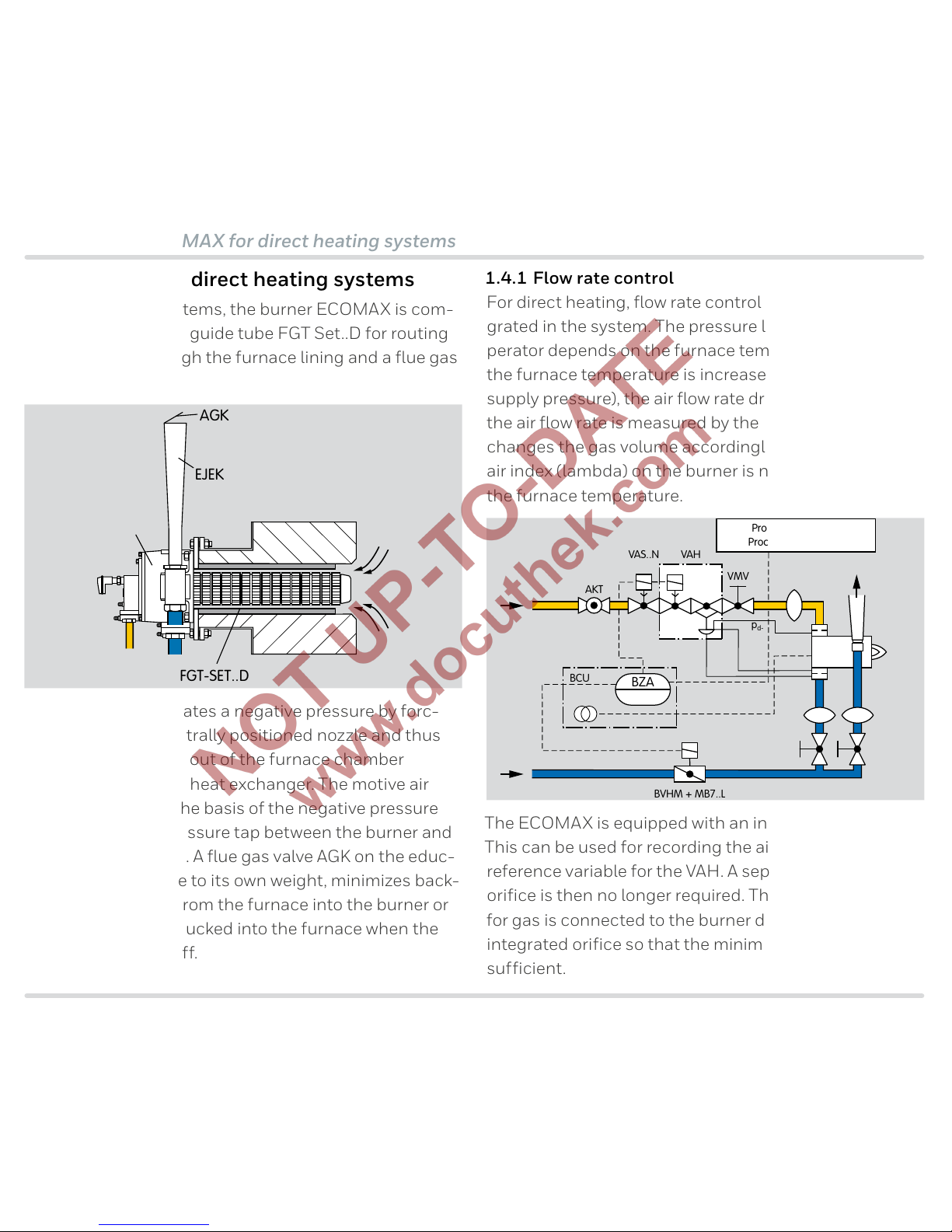

1.4 ECOMAX for direct heating systems

In direct heating systems, the burner ECOMAX is com-

bined with a flue gas guide tube FGT Set..D for routing

the flue gases through the furnace lining and a flue gas

eductor EJEK.

AGK

ECOMAX

FGT-SET..D

EJEK

Eductor EJEK generates a negative pressure by forc-

ing air through a centrally positioned nozzle and thus

draws the flue gases out of the furnace chamber

through the burner’s heat exchanger. The motive air

flow is adjusted on the basis of the negative pressure

measured on the pressure tap between the burner and

the motive air nozzle. A flue gas valve AGK on the educ-

tor, which closes due to its own weight, minimizes back-

flow of hot flue gas from the furnace into the burner or

infiltrated air being sucked into the furnace when the

burner is switched off.

1.4.1 Flow rate control

For direct heating, flow rate control should be integrated in the system. The pressure loss in the recuperator depends on the furnace temperature. When

the furnace temperature is increased (at a constant air

supply pressure), the air flow rate drops. This change in

the air flow rate is measured by the orifice and the VAH

changes the gas volume accordingly to ensure that the

air index (lambda) on the burner is not dependent on

the furnace temperature.

BVHM + MB7..L

VMV EKO

LEH

ECOMAX

VAH

BCU

BZA

Prozess-Steuerung/

Process Control (PCC)

AKT

p

sa-

p

sa

p

d-

VAS..N

The ECOMAX is equipped with an integrated air orifice.

This can be used for recording the air flow rate as a

reference variable for the VAH. A separate upstream air

orifice is then no longer required. The impulse line pdfor gas is connected to the burner downstream of the

integrated orifice so that the minimum gas pressure is

sufficient.

Page 7

ECOMAX · Edition 10.17 7

Application

1.4.2 Air/gas ratio control

If the system does not include flow rate control, tem-

perature-dependent pressure losses in the burner are

not compensated for. The air index lambda drops with

increasing furnace temperature (increasing air preheat-

ing). Therefore, in a cold furnace, an increased lambda

value is to be set to ensure sufficient excess air, even

when the furnace temperature is at its maximum. A fur-

nace at 1100°C with λ = 1.1 (approx. 2% O2) requires a

burner setting of approx. 4% O2, for example, when the

furnace is cold.

BVHM + MB7..L

VMV

ECOMAX

VAS..N

BCU

BZA

Prozess-Steuerung/

Process Control (PCC)

AKT

VAG

Page 8

ECOMAX · Edition 10.17 8

ApplicationApplication

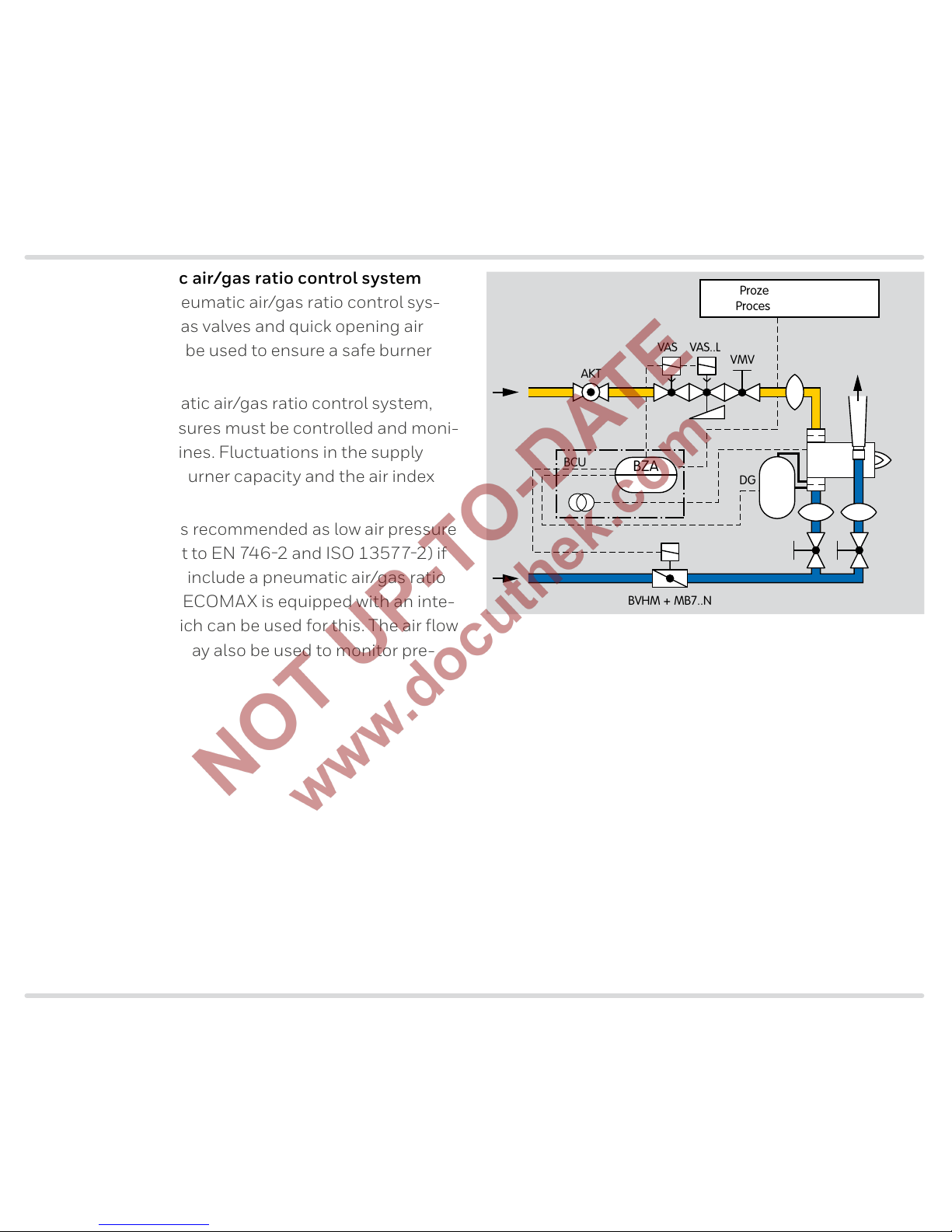

1.4.3 No pneumatic air/gas ratio control system

When there is no pneumatic air/gas ratio control sys-

tem, slow opening gas valves and quick opening air

control valves are to be used to ensure a safe burner

start.

If there is no pneumatic air/gas ratio control system,

the gas and air pressures must be controlled and moni-

tored in the supply lines. Fluctuations in the supply

pressure affect the burner capacity and the air index

(lambda).

Air flow monitoring is recommended as low air pressure

protection (pursuant to EN 7462 and ISO 135772) if

the system does not include a pneumatic air/gas ratio

control system. The ECOMAX is equipped with an inte-

grated air orifice which can be used for this. The air flow

monitoring system may also be used to monitor pre-

purge.

BVHM + MB7..N

VMV EKO

LEH

ECOMAX

VAS VAS..L

BCU

BZA

Prozess-Steuerung/

Process Control (PCC)

PDZ

DG

AKT

Page 9

ECOMAX · Edition 10.17 9

Application

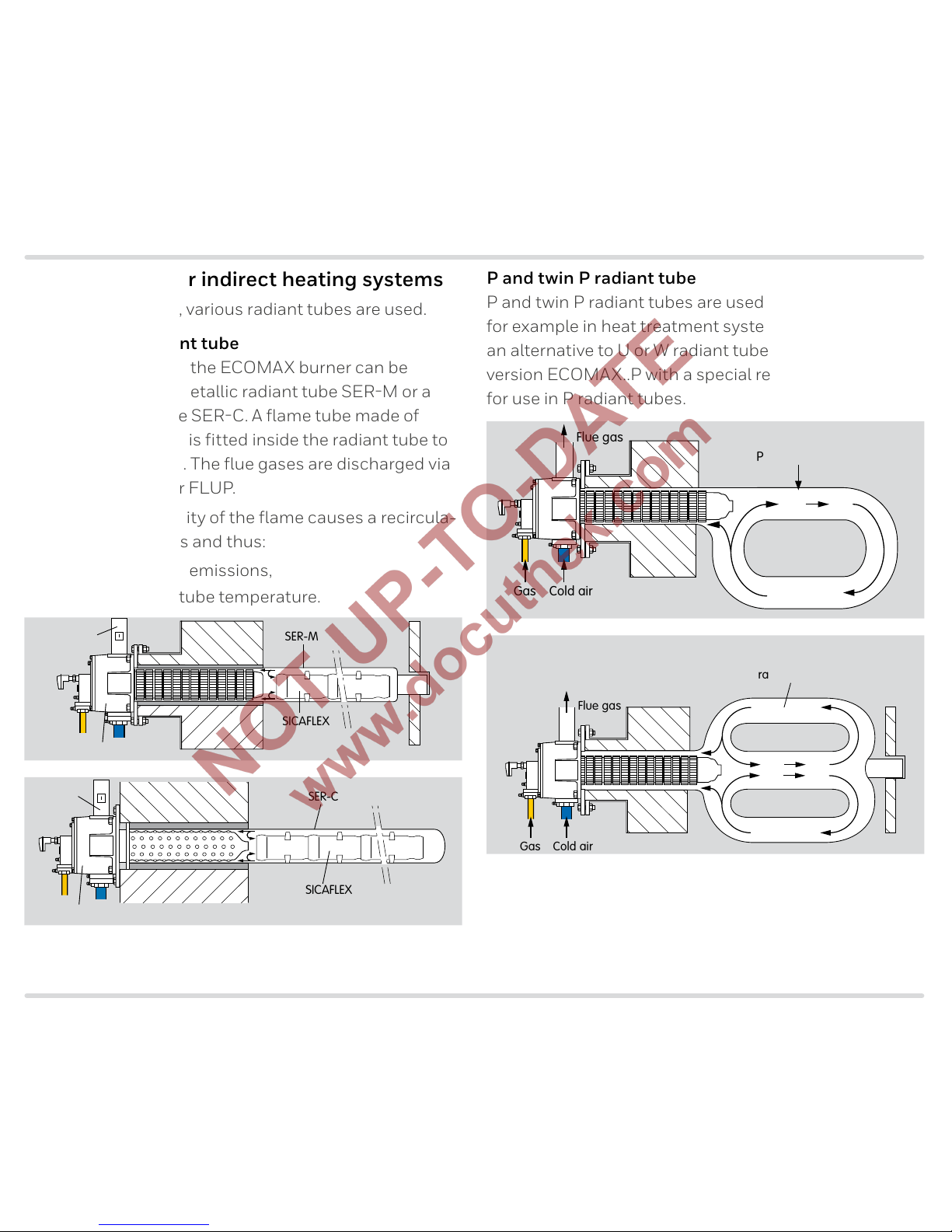

1.5 ECOMAX® for indirect heating systems

For indirect heating, various radiant tubes are used.

Single ended radiant tube

Indirect heating with the ECOMAX burner can be

carried out using a metallic radiant tube SERM or a

ceramic radiant tube SERC. A flame tube made of

SICAFLEX elements is fitted inside the radiant tube to

guide the flue gases. The flue gases are discharged via

a flue gas connector FLUP.

The high outlet velocity of the flame causes a recircula-

tion of the flue gases and thus:

– a reduction in NO

X

emissions,

– a uniform radiant tube temperature.

SER-M

FLUP

ECOMAX..M

SICAFLEX

SER-C

SICAFLEX

FLUP

ECOMAX..C

P and twin P radiant tube

P and twin P radiant tubes are used in some processes,

for example in heat treatment systems for steel strip as

an alternative to U or W radiant tubes. The new burner

version ECOMAX..P with a special recuperator head is

for use in P radiant tubes.

Gas Cold air

P radiant tube

Flue gas

Gas Cold air

Twin P

radiant tube

Flue gas

Page 10

ECOMAX · Edition 10.17 10

Application

1.5.1 No pneumatic air/gas ratio control system

For indirect heating, slow opening gas valves and quick

opening air control valves are to be used to ensure a

safe burner start.

If there is no pneumatic air/gas ratio control system,

the gas and air pressures must be controlled and moni-

tored in the supply lines. Fluctuations in the supply

pressure affect the burner capacity and the air index

(lambda).

A system which includes air flow monitoring is recom-

mended to monitor pre-purge and as low air pressure

protection (pursuant to EN 7462 and ISO 135772).

The ECOMAX is equipped with an integrated air orifice

which can be used for this.

VR..N

VMV

ECOMAX

VG VG..L

BCU

BZA

Prozess-Steuerung/

Process Control (PCC)

PDZ

DG

AKT

1.5.2 Air/gas ratio control

The pneumatic air/gas ratio control system ensures

that changes in the air pressure in the air supply line are

compensated for by controlling the gas pressure at the

burner accordingly.

VR..N

VMV VG..L

ECOMAX

BCU

BZA

Prozess-Steuerung/

Process Control (PCC)

PDZ

DG

AKT

VAG

A system which includes air flow monitoring is also

recommended to monitor pre-purge (pursuant to

EN 7462 and ISO 135772) even if there is a pneumatic

air/gas ratio control system.

Page 11

ECOMAX · Edition 10.17 11

Certification

2 Certification

Certificates – see w ww.docuthek.com.

Machinery Directive

The product ECOMAX is a partly completed machine

pursuant to Article 2g of Directive 2006/42/EC and

complies with the essential health and safety require-

ments in accordance with Annex I, as stated in the Dec-

laration of Incorporation.

Eurasian Customs Union

The product ECOMAX meets the technical specifica-

tions of the Eurasian Customs Union.

Page 12

ECOMAX · Edition 10.17 12

Structure

3 Structure

The burner ECOMAX is composed of four modules:

burner body, recuperator, air guide tube and gas insert.

The modular design facilitates adapting the burners to

the respective application or integrating them into an

existing furnace system. Maintenance and repair times

are reduced, and existing furnace installations can eas-

ily be converted.

3.1 Burner body

The burner body is made of cast aluminium, which

means it has a low weight. The housing has a double-

wall design. The combustion air is fed into the burner

via the outer annular void. This cools the burner body

and reduces emissions. A shaped part made of vacu-

um-formed ceramic fibres (RCF) is fitted in the housing

as internal insulation on the flue gas side.

From construction stage B, the ECOMAX is equipped

with two pressure taps on the air connection, which allow the differential pressure to be measured across the

orifice so that the burner can be adjusted.

Page 13

ECOMAX · Edition 10.17 13

StructureStructure

3.2 Recuperator

The burner ECOMAX is available in three versions:

– ECOMAX..C with ceramic burled tube recuperator

– ECOMAX..M and ECOMAX..P with cast steel ribbed

tube recuperator

– ECOMAX..F with metallic flat tube recuperator

Ceramic burled tube recuperator

The surface of the ceramic recuperator, which is made

of SiSiC for high thermal stress, is burled in order to

achieve high efficiency.

Cast steel ribbed tube recuperator

The ribs on the cast steel ribbed recuperator offer a

large surface area, allowing it to achieve high efficiency

even at low temperatures.

The burner version ECOMAX..P with a special recu-

perator head is available for use in P radiant tubes. The

geometry is tailored to this application to improve gas

recirculation and therefore the temperature uniformity

of the radiant tube.

Flat tube recuperator

The flat tube recuperator has a smooth surface. It is a

cost-effective alternative at a lower efficiency level.

Page 14

ECOMAX · Edition 10.17 14

Structure

3.3 Air guide tube

ECOMA X..C

Burners ECOMAX..C are equipped with a ceramic air

guide tube that for sizes 0 to 3 also serves as the com-

bustion chamber.

ECOMA X..M, ECOMAX..F and ECOMAX..P

Air guide tube for ECOMAX..M and ECOMAX..F

Burners ECOMAX..M and ECOMAX..F are equipped

with an air guide tube made of heat-resistant steel.

Page 15

ECOMAX · Edition 10.17 15

Structure

3.4 Gas insert

The gas insert consists of the gas connection flange,

the torch with burner head and the spark electrode

(also serves as monitoring electrode). A measuring

orifice, which is integrated in the gas insert, allows for

simple measurement of the gas flow rate. The orifice is

designed depending on the gas types (see 5.4.2).

To ensure accurate measurements of the pressure

differential on the integrated orifice, flow to the ori-

fice must not be disturbed. For this reason, burners

ECOMAX are equipped as standard with a special pipe

nipple to serve as inlet section on the gas connection.

Gas insert without combustion chamber for ECOMAX..C

(sizes 0 to 3)

Gas insert with combustion chamber for ECOMAX..M

(sizes 1 to 3)

Gas insert with combustion chamber for ECOMAX

(sizes 4 to 5)

Page 16

ECOMAX · Edition 10.17 16

ECOMAX..C 0 – 3

ECOMAX..C 4 – 5

ECOMAX..M 1 – 3

ECOMAX..M 4 – 5

Structure

3.5 Version overview

Burner Size Gas insert Air guide tube

ECOMAX..C

0– 3 With mixing funnel

Ceramic,

with integrated

combustion chamber

4– 5

With swirl plate and

ceramic combustion

chamber

Ceramic

ECOMAX..M

ECOMAX..P

ECOMAX..F

1– 3

With mixing funnel

and ceramic

combustion chamber

Metallic

4– 6

With swirl plate and

ceramic combustion

chamber

Metallic

Page 17

ECOMAX · Edition 10.17 17

Function

4 Function

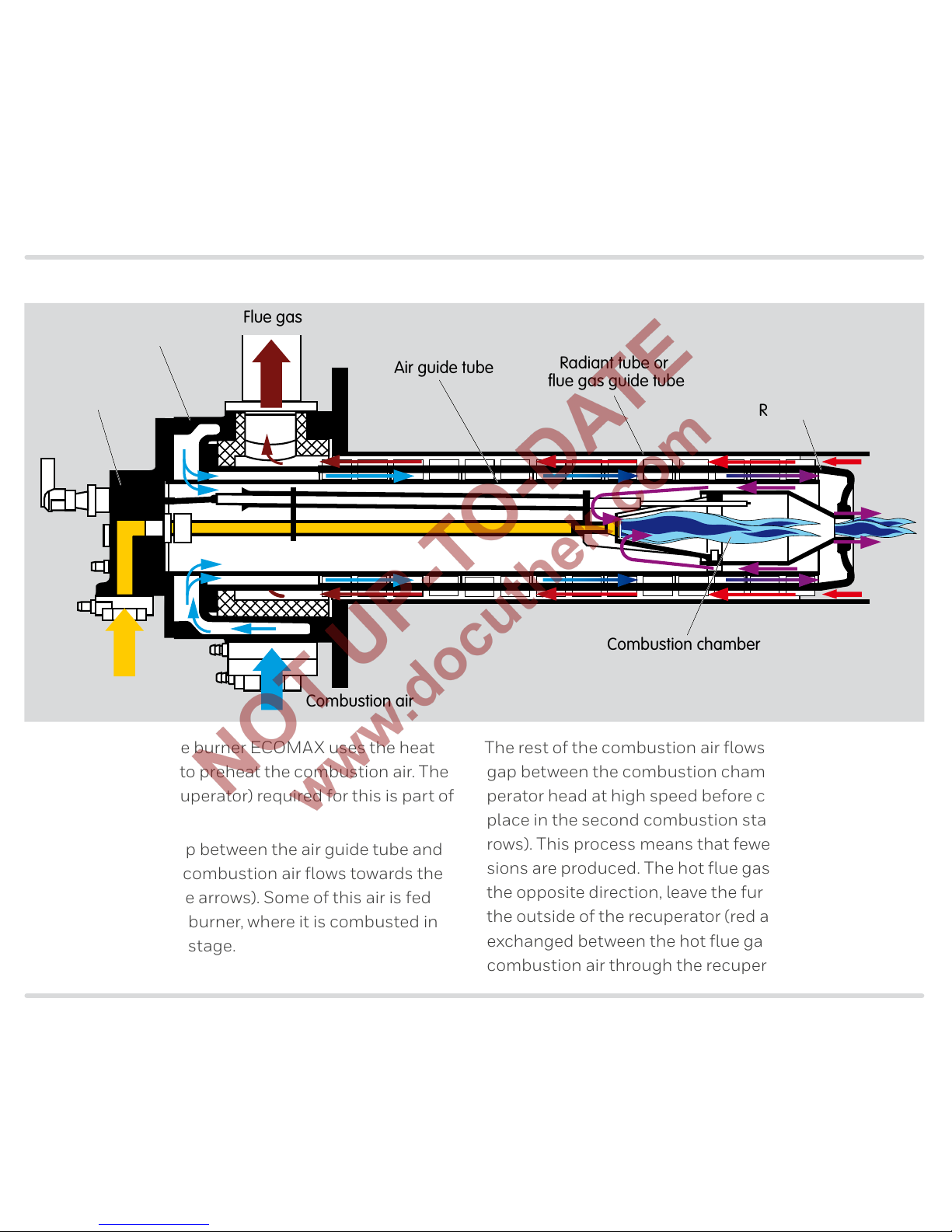

Recuperator

Combustion chamber

Air guide tube

Radiant tube or

flue gas guide tube

Flue gas

Combustion gas

Combustion air

Housing

Gas insert

The self-recuperative burner ECOMAX uses the heat

from the flue gases to preheat the combustion air. The

heat exchanger (recuperator) required for this is part of

the burner.

After entering the gap between the air guide tube and

the recuperator, the combustion air flows towards the

tip of the burner (blue arrows). Some of this air is fed

into the inside of the burner, where it is combusted in

the first combustion stage.

The rest of the combustion air flows out through the

gap between the combustion chamber and the recuperator head at high speed before combustion takes

place in the second combustion stage here (violet arrows). This process means that fewer pollutant emissions are produced. The hot flue gases, flowing in

the opposite direction, leave the furnace chamber on

the outside of the recuperator (red arrows). Heat is

exchanged between the hot flue gases and the cold

combustion air through the recuperator wall.

Page 18

ECOMAX · Edition 10.17 18

Function

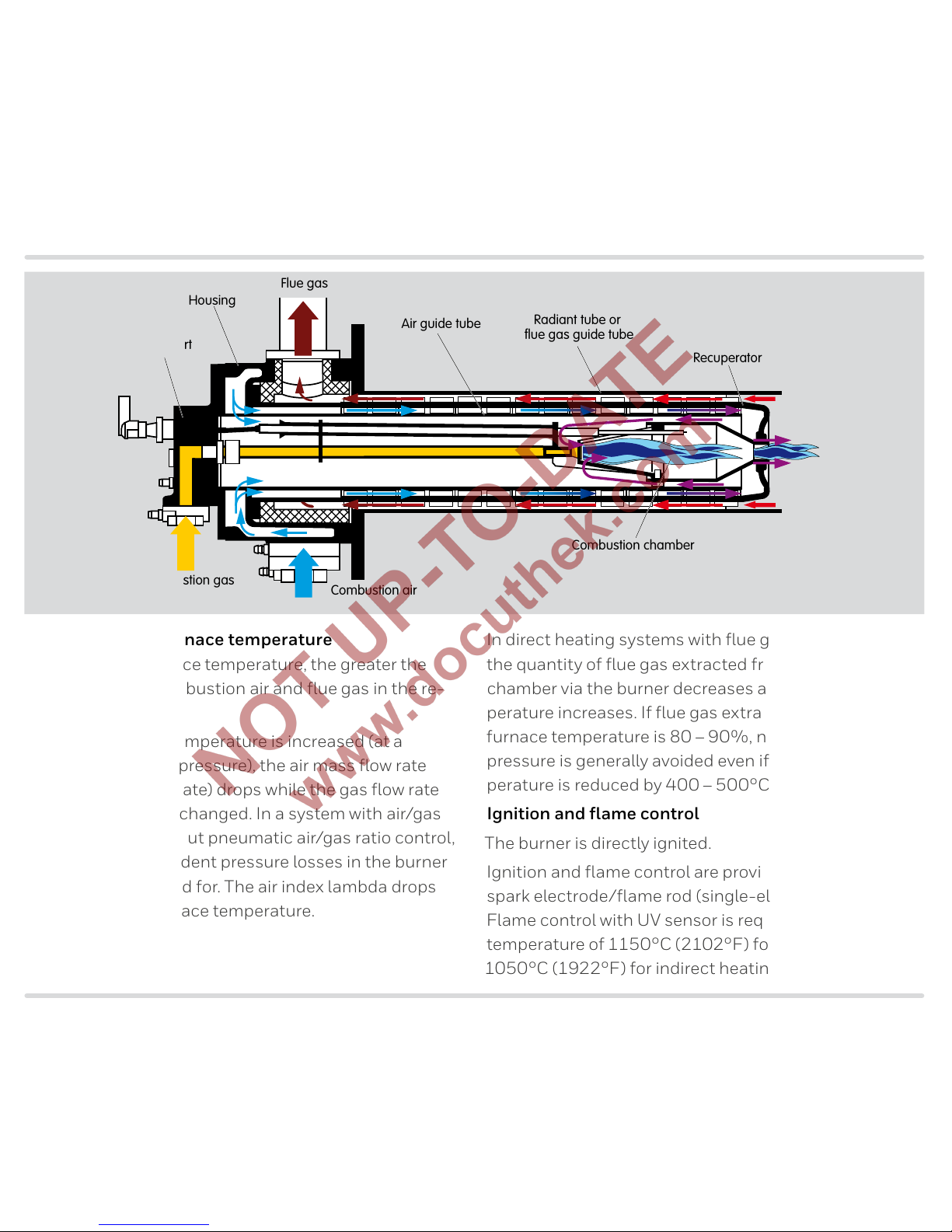

Influence of the furnace temperature

The higher the furnace temperature, the greater the

pressure loss in combustion air and flue gas in the re-

cuperator.

When the furnace temperature is increased (at a

constant air supply pressure), the air mass flow rate

(= standard air flow rate) drops while the gas flow rate

remains virtually unchanged. In a system with air/gas

ratio control or without pneumatic air/gas ratio control,

temperature-dependent pressure losses in the burner

are not compensated for. The air index lambda drops

with increasing furnace temperature.

In direct heating systems with flue gas eductor EJEK,

the quantity of flue gas extracted from the furnace

chamber via the burner decreases as the furnace temperature increases. If flue gas extraction at maximum

furnace temperature is 80–90%, negative furnace

pressure is generally avoided even if the furnace temperature is reduced by 400–500°C.

Ignition and flame control

The burner is directly ignited.

Ignition and flame control are provided by a combined

spark electrode/flame rod (single-electrode operation).

Flame control with UV sensor is required if a furnace

temperature of 1150°C (2102°F) for direct heating or

1050°C (1922°F) for indirect heating is exceeded.

Recuperator

Combustion chamber

Air guide tube

Radiant tube or

flue gas guide tube

Flue gas

Combustion gas

Combustion air

Housing

Gas insert

Page 19

ECOMAX · Edition 10.17 19

Selection

5 Selection

5.1 Burner type

Selection is dependent on the type of heating and

the furnace temperature. Details on selection, see

page 31 (Heating system design) for direct heat-

ing or page 48 (Heating system design) for indirect

heating.

Burner Max. flue gas temperature at recuperator inlet

[°C] [°F]

ECOMAX..C 1250 2282

ECOMAX..M

ECOMAX..P

1150 2102

ECOMAX..F 1050 1922

5.2 Burner size

Burner

Size

Capacity

1)

Recuperator

kW

2)

103 BTU/h

3)

C M P F

ECOMA X 0 25 95

– – –

ECOMA X 1 36 136

–

ECOMA X 2 60 227

ECOMA X 3 100 378

ECOMA X 4 180 681

ECOMA X 5 250 945

–

ECOMA X 6 500 1890 –

– –

= available

1)

For operation with natural gas. For operation with coke oven gas,

the capacity is approx. 80%, for operation with LCV gas, approx.

65%.

2)

Capacities in kW refer to the lower calorific value Hu.

3)

Capacities in BTU/h refer to the upper calorific value Ho.

When using the burner in geodetic ranges over 500 m

above MSL, the possible capacity is reduced due to

a decrease in the density of gas and air. Guide value:

reduction of 5% per 1000 m above MSL, more details

on request.

Page 20

ECOMAX · Edition 10.17 20

SelectionSelection

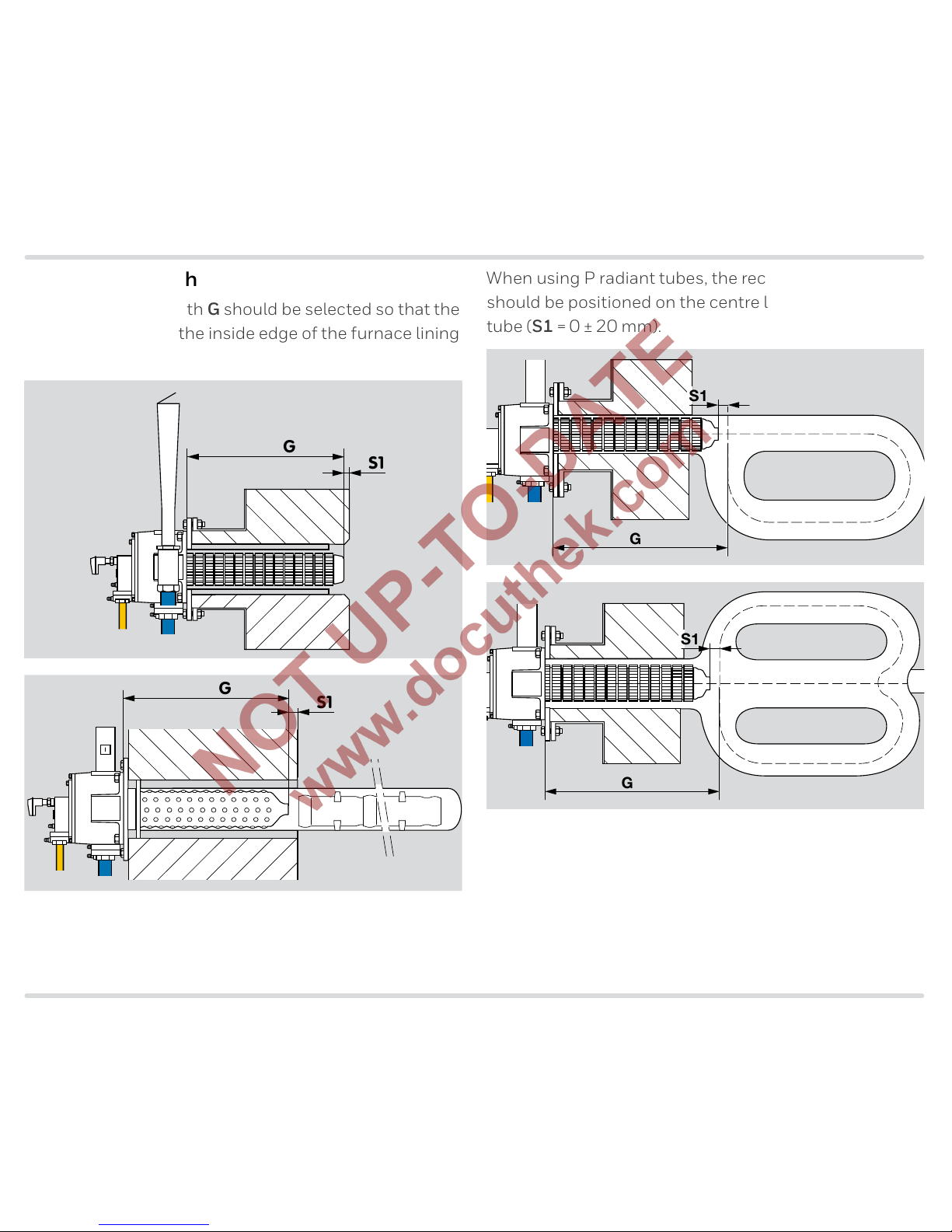

5.3 Burner length

The recuperator length G should be selected so that the

burner is flush with the inside edge of the furnace lining

(S1 = 0 ± 20 mm).

S1

G

S1

G

When using P radiant tubes, the recuperator head

should be positioned on the centre line of the radiant

tube (S1 = 0 ± 20 mm).

S1

G

S1

G

Page 21

ECOMAX · Edition 10.17 21

SelectionSelection

5.4 Burner head

5.4.1 Use

The burner ECOMAX can be equipped with 2 different

burner heads. Stage combustion is standard. For some

burner variants, a menox version is also possible, which

allows for switchover to menox® low NOX mode with

flameless combustion when the furnace temperature

exceeds 850°C in a direct heating system.

Use Burner head code letter

Standard flame mode S

menox

®

low NOX mode

1)

M

1)

menox® low NOX mode on request.

5.4.2 Gas type

Gas type Code letter Calorific value range

Density ρ

kWh/m

3

(n)

2)

BTU/scf

3)

kg/m3(n) lb/scf

Natural gas L and H quality B 8– 12 810– 1215 0.7– 0.9 0.041– 0.053

Propane, propane/butane, butane G 25– 35 2560– 3474 2.0– 2.7 0.118– 0.159

Coke oven gas, town gas D 4– 5 421– 503 0.4– 0.6 0.024– 0.035

Low calorific value gas L 1.7

1)

–3 161– 290 0.9– 1.15 0.053– 0.068

1)

Calorific value range < 1.7 on request.

2)

Calorific value ranges in kWh/m3 refer to the

lower calorific value Hu.

3)

Calorific value ranges in BTU/SCF refer to the

upper calorific value Ho.

Page 22

ECOMAX · Edition 10.17 22

Selection

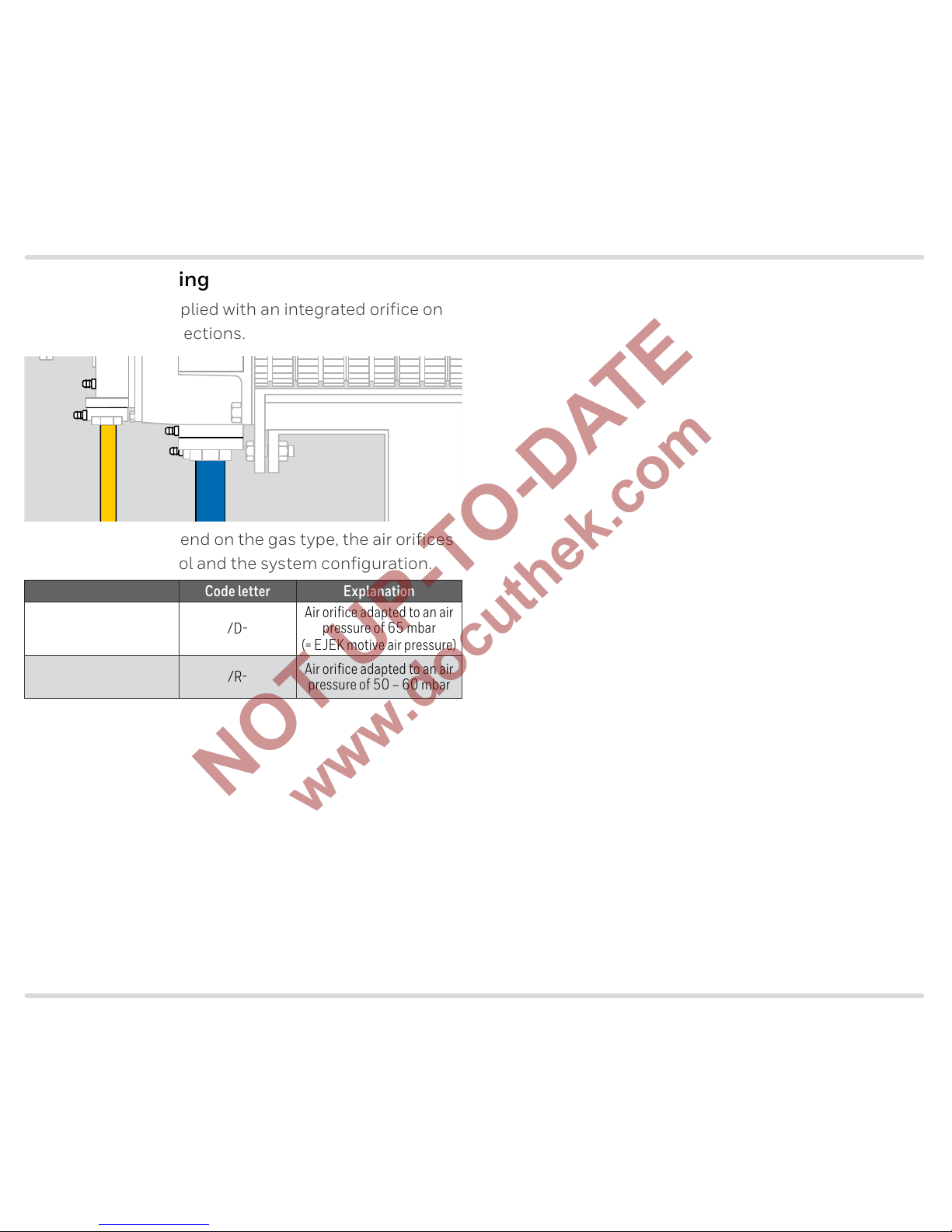

5.5 Type of heating

The ECOMAX is supplied with an integrated orifice on

the gas and air connections.

The gas orifices depend on the gas type, the air orifices

on the type of control and the system configuration.

Type of heating Code letter Explanation

Direct heating with

eductor

/D

Air orifice adapted to an air

pressure of 65 mbar

(= EJEK motive air pressure)

Indirect heating without

an eductor

/R

Air orifice adapted to an air

pressure of 50 – 60 mbar

Page 23

ECOMAX · Edition 10.17 23

Selection

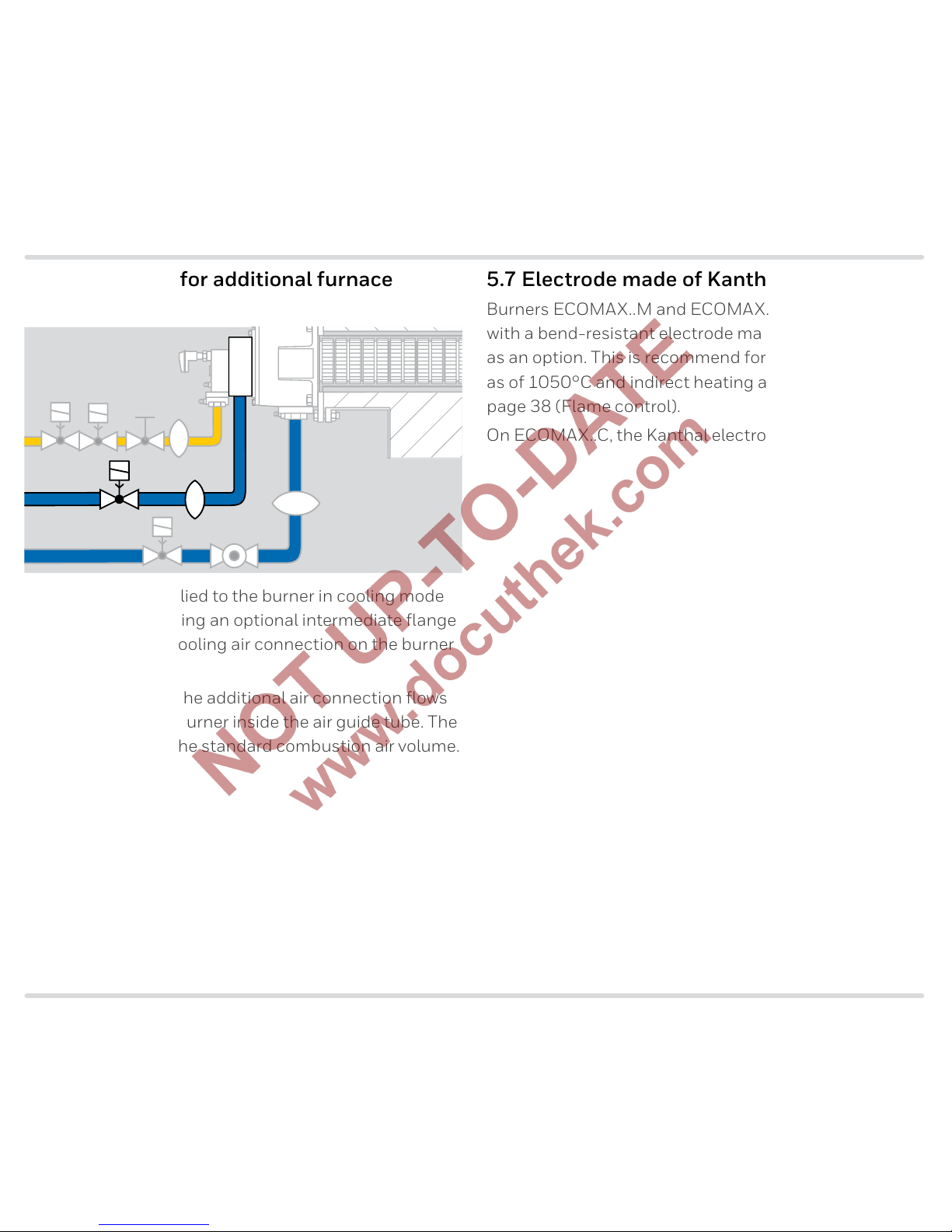

5.6 Connection for additional furnace

cooling

The air volume supplied to the burner in cooling mode

can be increased using an optional intermediate flange

with an additional cooling air connection on the burner

ECOMAX.

The air supplied via the additional air connection flows

in the centre of the burner inside the air guide tube. The

air volume is twice the standard combustion air volume.

5.7 Electrode made of Kanthal APM

Burners ECOMAX..M and ECOMAX..P can be equipped

with a bend-resistant electrode made of Kanthal APM

as an option. This is recommend for direct heating

as of 1050°C and indirect heating as of 950°C, see

page 38 (Flame control).

On ECOMA X..C, the Kanthal electrode is standard.

Page 24

ECOMAX · Edition 10.17 24

Selection

5.8 Selection table

5.8.1 ECOMAX..C

395 475 545 556 593 613 617 636 641 681 689 S B D G L1)/D /R (1–99) A–E – K T

ECOMA X 0C

● ● ● ● ● ● ● ● ● ● ● ●

ECOMA X 1C

● ● ● ● ● ● ● ● ● ● ● ●

ECOMAX 2C

● ● ● ● ● ● ●

● ● ● ●

ECOMA X 3C

● ● ● ● ● ● ●

● ● ● ●

ECOMA X 4C

● ● ● ● ●

● ● ● ●

ECOMAX 5C

● ● ● ● ●

● ● ● ●

1)

On request.

ECOMA X..C is supplied with Kanthal electrodes as standard.

●

= standard, = available

Order example

ECOMA X 1C545SB/R(31)B

5.8.2 ECOMA X..M

545 595 645 695 S M B D G L1)/D /R (1–99) A–E – K A T

ECOMAX 1M

● ● ● ● ● ● ● ● ● ● ● ●

ECOMAX 2M

● ● ● ● ● ● ● ●

● ● ● ●

ECOMA X 3M

● ● ● ● ●

● ● ●

● ● ● ●

ECOMAX 4M

● ● ● ● ●

● ● ●

● ● ● ●

ECOMAX 5M

● ● ●

● ● ●

● ● ● ●

ECOMA X 6M

●

● ● ● ●

● ● ● ●

1)

On request.

●

= standard, = available

Order example

ECOMA X 3M545SB/D(34)B

Page 25

ECOMAX · Edition 10.17 25

Selection

5.8.3 ECOMAX..P

645 695 S B D G L

1)

/R (1–99) A–E – K T

ECOMAX 2P

● ● ●

●

● ● ●

ECOMA X 3P

● ● ●

●

● ● ●

ECOMAX 4P

● ● ●

●

● ● ●

1)

On request.

●

= standard, = available

Order example

ECOMA X 3P695SB/R(34)B

5.8.4 ECOMAX..F

545 595 645 695 S B D G L

1)

/D /R (1–99) A–E – K T

ECOMAX 1F

●

● ●

● ● ● ● ●

ECOMAX 2F

●

● ●

●

● ● ● ●

ECOMA X 3F

●

● ●

●

● ● ● ●

ECOMAX 4F

●

● ●

●

● ● ● ●

ECOMAX 5F

●

● ●

●

● ● ● ●

1)

On request.

●

= standard, = available

Order example

ECOMA X 3F545SB/D(34)B

Page 26

ECOMAX · Edition 10.17 26

Selection

5.8.5 Type code

Code Description

ECOMAX Self-recuperative burner for gas

0– 6 Burner size

C

M

P

F

Ceramic burled tube recuperator made of SiSiC

Cast steel ribbed tube recuperator

Cast steel ribbed tube recuperator for P radiant tube

Flat tube recuperator, metallic

E Special recuperator version

395– 695 Recuperator length in mm

S

M

1)

Standard fl ame

menox® low NOX operation

B

D

G

L

1)

Gas type2):

natural gas

coke oven gas

LPG

LCV gas

/D

/R

/V

/E

/nnn/N

For direct heating with eductor

For radiant tube heating without eductor

For radiant tube heating with VAH

Burner with customized orifi ces

Burner construction stage X for nnn kW

Burner without orifi ces

(1–99) Burner head identifi er

X, A, B, … Construction stage

– The following features differ from the standard version:

K

Additional cooling air connection for increased furnace

cooling

A Electrode made of Kanthal APM

T NPT connections

S SICAFLEX spacer

W Air connection without intermediate fl ange

Z Special version

1)

On request.

2)

Other t ypes of gas on request.

Page 27

ECOMAX · Edition 10.17 27

Selection

5.9 Selection table for flue gas eductor EJEK

Axis spacing Kxxx* Height Tzzz* H V 3* * 9** F.. R.. AGK HT*** A B S

EJEK 0 - K269

- M625

● ● ● ●

EJEK 1 - K269

- M625

● ●

● ● ●

EJEK 2 - K285

- M540

● ●

● ● ● ●

EJEK 3 - K292

- M620

● ● ● ●

EJEK 4 - K345

- M920

● ● ● ●

EJEK 5 - K345

- M1165

● ● ● ●

EJEK 6 - K530

- M1618

● ● ● ●

* Special dimensions on request.

* Only relevant for special dimension Tzzz.

*** HT version for ECOMAX..C.

●

= standard, = available

Order example

EJEK 4K345M920AGKHTAS

Page 28

ECOMAX · Edition 10.17 28

Selection

5.9.1 Type code

Code Description

EJEK Flue gas eductor

0– 6 Size for ECOMAX 1 – 6

Kxxx Axis spacing K in mm

Myyy Height M in mm

Tzzz* Distance T in mm

H

V

Burner installation position:

horizontal

vertical

3

9

Installation on the burner**:

right-hand side

left-hand side

F5 to F15

R5 to R15

Eductor angle in °:

pointing towards furnace

pointing away from furnace

AGK With fl ue gas valve

HT*** High temperature version

A

B

Construction stage

S Standard dimension

* If “none”, this letter is omitted.

** Only required for special dimension Tzzz.

*** HT version for ECOMA X..C.

MKM

KT

M

Page 29

ECOMAX · Edition 10.17 29

Selection

5.10 Selection table for flue gas connector FLUP

32 50 65 100 D F Kxxx Installation height Myyy* Tzzz* H** V** 0** 3** 9** C A HT B S

FLUP 0

● ●

-M230

●

● ●

FLUP 1–2

● ●

-M331

●

●

FLUP 3

● ●

-M353

●

●

FLUP 4–5

● ●

-M399

●

●

* Special dimensions on request.

** Only relevant for special dimensions K xxx and/or Tzzz.

●

= standard, = available

Order example

FLUP 365DM3530S

Page 30

ECOMAX · Edition 10.17 30

Selection

5.10.1 Type code

Code Description

FLUP Flue gas connector

0

1/2

3

4/5

For ECOMAX 0–5

32 to 100 Nominal size

D

F

Pipe connector

Flange to ISO 7005

Kxxx Axis spacing K in mm

Myyy Installation height M in mm

Tzzz* Distance T in mm

H

V

Burner installation position:

horizontal

vertical

0

3

9

Installation on the burner**:

top

right-hand side

left-hand side

C

A

Measuring port with sealing clip

Threaded pressure tap with cap

HT High temperature version

A

B

Construction stage

S Standard dimension

* If “none”, this letter is omitted.

** Only required for special dimension Tzzz.

DN

K

M

M

DN

T

DN

M

Page 31

ECOMAX · Edition 10.17 31

Project planning information for direct heating

6 Project planning information for direct heating

6.1 Heating system design

Selection of the burner type is dependent on the fur-

nace temperature.

Burner

Recommended

range of use

Max. flue gas temperature at

recuperator inlet

[°C] [°F] [°C] [°F]

ECOMAX..C up to 1250 up to 2282 1250 2282

ECOMAX..M up to 1100 up to 2012 1150 2102

ECOMAX..F up to 1000 up to 1832 1050 1922

Burners ECOMAX..M (sizes 1 to 5) and ECOMAX..F can

be used for furnace temperatures up to the max. appli-

cation temperature if it is ensured that the burner head

cannot overheat, e.g. due to burners positioned oppo-

site the ECOMAX or non representative temperature

measurements, see also page 37 (Furnace tempera-

ture measurement).

Selection of the burner size is dependent on the net

heat output. From this, the required burner capacity is

calculated using the firing efficiency value.

Net heat output [kW]

= Burner capacity [kW]

Firing efficiency η

400 500 600 700 800 900 1000 1100

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

1

1200

1300

1400

F

M

C

Firing efficiency η

Flue gas temperature on recuperator inlet [°C]

Cold air burner

Details on heating system design on request.

Page 32

ECOMAX · Edition 10.17 32

Project planning information for direct heating

6.2 Flue gas guide tube FGT set

The furnace flue gases are routed by the flue gas guide

tube through the furnace lining via the recuperator. The

FGT set must be ordered separately and is not included

in the burner delivery, see page 64 (Flue gas guide

tube FGT Set..D).

The flange thickness P1 of the flue gas guide tube is

15 mm. Plan the length of the furnace extension M1 so

that the front edge of the recuperator is flush with the

inside edge of the furnace lining (S1 = 0 ± 20 mm).

∅A

G

P1

S1

FGT-Set

Burner FGT OD A in mm

ECOMA X 0C 142

ECOMA X 1C 180

ECOMAX 2C 200

ECOMA X 3C 236

ECOMA X 4C 300

ECOMAX 5C 336

Force must not be applied to the flue gas guide tube by

the furnace lining.

When installing the FGT, the tube must be wrapped in

a ceramic fibre blanket so as to ensure that no hot furnace atmosphere may reach the furnace wall or furnace

extension. The installation opening in the furnace wall

must thus be larger than the FGT outside diameter A,

leaving an annular gap corresponding to the size of the

fibre blanket, e.g. 25 mm.

S1

∅A

P1

G

M1

FGT-Set

Burner FGT OD A in mm

ECOMAX 1M/ECOMAX 1F 133

ECOMAX 2M/ECOMAX 2F 156

ECOMA X 3M/ECOMA X 3F 193

ECOMAX 4M/ECOMAX 4F 254

ECOMAX 5M/ECOMAX 5F 287

ECOMA X 6M/ECOMA X 6F 390

Page 33

ECOMAX · Edition 10.17 33

Project planning information for direct heating

6.3 Flue gas eductor EJEK

Flue gas eductor EJEK is available in 2 versions. The

standard version EJEK is used in conjunction with

ECOMAX..M and ECOMAX..F. The high temperature

version EJEK..HT is intended for use in conjunction

with ECOMAX..C.

The eductors serve to extract the flue gas via the burner

ECOMAX and cannot be used for furnace pressure con-

trol. We recommend discharging 10 to 20% of the flue

gases via an additional flue gas opening on the furnace

fitted with a furnace pressure control system.

With 80 to 90% flue gas extraction at max. furnace

temperature, a positive furnace pressure can generally

be maintained even at low furnace temperatures. In the

case of heavily leaking furnaces, flue gas extraction

must be reduced, where necessary, to avoid pulling in

cold air due to negative pressure in the furnace cham-

ber.

p

FG

p

atm

p

FG

0

p

FG

The motive air is set at the eductor by measuring the negative

flue gas pressure pFG between the burner and eductor.

If the furnace temperature is too high, damage can occur to burners which are switched off due to the flow of

hot flue gases over them.

For direct heating, eductors EJEK..AGK with mechanical flue gas valve (AGK) are recommended so as to

avoid gas creepage while the burner is switched off.

Page 34

ECOMAX · Edition 10.17 34

Project planning information for direct heating

6.4 Furnace flue gas system

A flue gas system must be fitted on the furnace as a

means of guiding the flue gas to the chimney. In the

flue gas system there should be a low negative pressure

thanks to the draught of the chimney or an exhaust fan.

The flue gas system on the furnace should be fitted

flush with the eductor (± 10 mm). The diameter of the

flue gas pipe on the furnace should be twice the educ-

tor diameter P. If the diameter is too small, even with

the EJEK..AGK with flue gas valve there is the danger of

hot flue gases creeping through the burner when it is

switched off.

The branch lines from the furnace flue gas manifold to

the individual burners should be designed such that

condensate cannot seep upstream into the burner.

∅P

∅2P

0 mm (±10 mm)

∅1,5P

∅P

∅2P

0 mm

(±10 mm)

∅ P [mm]

ECOMA X 0 EJEK 0(B) 43

ECOMA X 1 EJEK 1 43

ECOMA X 2 EJEK 2(A) 83

ECOMA X 3 EJEK 3(A) 98

ECOMA X 4 EJEK 4(A) 128

ECOMA X 5 EJEK 5(A) 153

ECOMA X 6 EJEK 6(A) 215

Page 35

ECOMAX · Edition 10.17 35

Project planning information for direct heating

6.5 Installation

6.5.1 Installation position

15°

0°

90°

The burner ECOMAX can be installed in any position

between 0° (horizontal) and 90° (vertical from top to

bottom). The ECOMAX may be oriented upwards at an

angle of max. 15° from the horizontal.

Eductor EJEK installation position:

vertical, max. angle 10°.

If the burner is installed at an angle of more than 10°

from the vertical or horizontal, a special version of flue

gas eductor EJEK is required. This is available on re-

quest.

6.5.2 Tangential or angled burner installation

If the burner is installed tangentially or at an angle, an

opening should be provided in the furnace lining to

ensure unobstructed flue gas extraction. The choice of

furnace lining in this area should take account of the

burner’s very high outlet velocity. In addition, reflection

from the furnace wall to the burner must be considered.

B

1,5 x B

Page 36

ECOMAX · Edition 10.17 36

Project planning information for direct heating

6.5.3 Clearances

Y

X

X

X

2

X

X

RZ

Allow for adequate clearance from the charge and the

interior furnace wall so as to ensure complete combus-

tion and avoid local overheating. Due to the high air

preheat temperature of the ECOMAX, the flame tem-

perature is also higher than usual.

Z

2

Z

X

The minimum lateral clearance between two burners

or between a burner and the furnace side wall is de-

termined by the geometric dimensions of the burners

including the eductor.

In addition, it must be noted that burners facing each

other can cause overheating of the recuperator heads.

Flame mode

Burner

Reaction zone RZ (mm)

Clearance (mm)

X Z

ECOMA X 0 500 130 270

ECOMA X 1 700 155 270

ECOMA X 2 900 200 285

ECOMA X 3 1200 250 300

ECOMA X 4 1600 340 350

ECOMA X 5 1800 400 400

ECOMA X 6 2200 570 570

For menox® low NOX mode, a sufficiently large reaction

zone (RZ) and undisturbed recirculation of the flue gas

into the reaction zone are required. Operation in very

small combustion chambers leads to an increase in

NOX emissions.

menox

®

low NOX mode

Burner

Reaction zone RZ (mm)

Clearance (mm)

X Y Z

ECOMA X 3M 2100 300 320 300

ECOMAX 4M 2800 360 400 360

ECOMAX 5M 3300 400 480 400

Page 37

ECOMAX · Edition 10.17 37

Project planning information for direct heating

6.5.4 Furnace temperature measurement

Measurement of the furnace temperature must be

representative for the flue gas temperature in the ex-

traction zone on the burner. If measurement is not rep-

resentative, this will involve a risk of overheating of the

recuperator head.

6.5.5 Heat guard

During operation, the burner body and eductor or flue

gas connector can reach surface temperatures of

over 80°C. Do not insulate the burner, eductor and flue

gas connector to prevent material overheating.

We recommend that warning signs and a contact guard

be fitted, for example made of perforated sheet metal.

Page 38

ECOMAX · Edition 10.17 38

Project planning information for direct heating

6.6 Flame control

Burners ECOMAX are equipped with a combined spark

electrode/flame rod. For direct heating, ionization con-

trol is possible up to a temperature of 1150°C (single-

electrode operation). In this respect, it must be noted

that the burner control unit BCU must feature at least

firmware version FW 16xx, see page 39 (Burner con-

trol units and ignition transformers).

Flame control with UV sensor is only necessary if fur-

nace temperatures of 1050°C for direct heating or

1150 °C for indirect heating are exceeded.

We also recommend using bend-resistant Kanthal

electrodes for ignition on ECOMA X..M as of a furnace

temperature of more than 1050°C. These are fitted as

standard on ECOMAX..C.

We recommend the UV sensor UVS 10D1 with integrated purge air connection (Order No. 84315202) for

UV control.

For ECOMA X 0, the UV sensor UVS 10L1 (Order

No. 84315203) with lens is required for UV control. For

burners ECOMAX 1 –6 with a burner length of more

than 545 mm, the UV sensor UVD 10L1 with lens is

also required for UV control.

An adapter set is required for connection to the UVS 10,

see page 63 (UV adapter set).

Page 39

ECOMAX · Edition 10.17 39

Project planning information for direct heating

6.7 Burner control units and ignition

transformers

ECOMAX burners with burner control unit BCU

ECOMAX burners are designed for On/Off control.

We recommend burner control unit BCU 460..L or

BCU 465..L. In order to be able to carry out ionization

control up to 1150°C, the burner control unit must be

equipped with firmware FW 16xx or higher.

For burners ECOMAX..K with additional cooling air

connection, we recommend using burner control unit

BCU..C with additional circuit board for signal distribution.

For ignition, the ECOMAX burners require an ignition

transformer with 7.5 kV high voltage and an output current of 20 mA. An appropriate ignition transformer is

already integrated in burner control units BCU 460..8

and BCU 465..8.

For further information on burner control units and ignition transformers, see www.docuthek.com, Technical

Information BCU 460, 465.

Page 40

ECOMAX · Edition 10.17 40

Project planning information for direct heating

6.7. 1 Burner control unit configurations

Description Configuration D1 Configuration D2 Configuration D3 Configuration D4

Flame control Ionization UVS 10 Ionization U VS 10

Pneumatic air/gas ratio control VAH/ VAG VAH/VAG None/VAH/VAG None/VAH/VAG

Air flow monitoring – –

Differential pressure switch PDZ Differential pressure switch PDZ

Hardware BCU 460..L BCU 460..L BCU 465 BCU 465

Ignition transformer 8 = TZI 7,520/33 8 = TZI 7,520/33 8 = TZI 7,520/33 8 = TZI 7,520/33

Rewiring for electrode operation 1 electrode 2 electrodes 1 electrode 2 electrodes

Description Parameter Configuration D1 Configuration D2 Configuration D3 Configuration D4

Switch-off threshold of the flame amplifier 04

4 μA 4 μA 4 μA 4 μA

Air flow monitoring during purging 06 N /A N/A 1 1

Air flow monitoring during operation 07 N/A N/A 1 1

Delayed air flow monitoring 08 N/A N /A 1 1

Safety time during operation t

SB

for V1 and V2 14 1 1 1 1

Minimum burner on time t

B

20 8 8 8 8

Minimum burner pause time t

BP

21 4 4 4 4

Safety time on start-up t

SA

22 3 3 3 3

Air valve control 30 1 1 1 1

Air valve can be activated externally on start-up 31 1 1 1 1

Low fire over-run time t

KN

after a controlled shut-down 36 N/A N/A 0 0

Pre-ventilation time t

VL

before start-up 37 N/A N/A 0 0

Post-ventilation time t

NL

after a controlled shut-down 38 N /A N/A 0 0

Pre-ventilation time after safety shut-down 39 N/A N/A 0 0

Pre-ventilation for restart/start-up attempts 40 N/A N/A 0 0

Pre-ventilation after reset 41 N/A N/A 0 0

BCU for direct heating Configuration D1 Configuration D2 Configuration D3 Configuration D4

230 V 88613276 88614259 88614263 88614267

230 V, Profibus 88611901 88613865 88614264 88614268

230 V, HT operation 88614257 88614260 88614265 88614269

230 V, HT operation, Profibus 88611887 88611883 8 861426 6 88614270

Page 41

ECOMAX · Edition 10.17 41

Project planning information for direct heating

6.8 Gas connection

6.8.1 Selecting components

To ensure a safe burner start, use a pneumatic air/gas

ratio controller together with a slow opening air valve. If

there is no pneumatic air/gas ratio control system, use

a slow opening gas valve and a quick opening air valve.

The following gas valves are recommended for natural

gas:

Burner Flow rate control

Air/gas ratio

control

No pneumatic air/

gas ratio control

system

ECOMA X 0

VAS 115..N +

VAH 115..B +

VMV 115

VAS 115..N +

VAG 115..B +

VMV 115

VG 15..N +

VG 15..L +

VMV 115

ECOMA X 1

VAS 115..N +

VAH 115..B +

VMV 115

VAS 115..N +

VAG 115..B +

VMV 115

VG 15..N +

VG 15..L +

VMV 115

ECOMA X 2

VAS 115..N +

VAH 115..B +

VMV 115

VAS 115..N +

VAG 115..B +

VMV 115

VG 15..N +

VG 15..L +

VMV 115

ECOMA X 3

VAS 115..N +

VAH 115..B +

VMV 115

VAS 115..N +

VAG 115..B +

VMV 115

VG 15..N +

VG 15..L +

VMV 115

ECOMA X 4

VAS 120..N +

VAH 120..A +

VMV 120

VAS 120..N +

VAG 120..B +

VMV 120

VAS 120..N +

VAS 120..L +

VMV 120

ECOMA X 5

VAS 125..N +

VAH 125..A +

VMV 125

VAS 125..N +

VAG 125..B +

VMV 125

VAS 125..N +

VAS 125..L +

VMV 125

ECOMAX 6*

VAS 240..N +

VAH 240..A +

VMV 240

VAS 240..N +

VAG 240 +

VMV 240

VAS 240..N +

VAS 240..L +

VMV 240

* As of 360 kW, ignition with a start rate of < 33% is required

(pursuant to EN 746-2 and ISO 13577-2); a pneumatic ratio

control system and a BVH with IC 40 must be used for this.

A bellows unit EKO should be provided between the

burner and controls to prevent external force being applied to the burner.

A connection set with 6 x 1 compression fittings

is available to connect the VAH control line, see

page 63 (VAH connection set). The set is installed on

the burner before delivery.

6.8.2 Gas pressure

The required gas pressure depends on the burner size,

the gas type and the system configuration.

Gas supply line pressure*

Gas pressure

upstream of

burner

Natural gas H

Natural gas L,

LPG

Flow rate control 50 –65 mbar 100 mbar 120 mbar

Air/gas ratio

control**

50 –65 mbar 100 mbar 120 mbar

No pneumatic air/

gas ratio control

system

50 –65 mbar 80 mbar 100 mbar

* If a stainless steel flexible tube ES is used instead of the

stainless steel bellows unit EKO, the higher pressure loss must

be taken into account.

** Gas pressure in the supply line min. 10 – 20 mbar greater than

the air pressure in the supply line.

Page 42

ECOMAX · Edition 10.17 42

Project planning information for direct heating

6.8.3 Operation with LPG

GEH

For operation with LPG, it is essential to cool the gas

lance via a central air lance in order to prevent the LPG

from cracking in the gas lance and soot formation dur-

ing combustion.

GEH

The central air volume is approx. 3 to 5% of the com-

bustion air volume and must also flow while the burner

is switched off.

Open the adjuster in the central air lance fully. On the

ECOMAX 1, the adjuster must be restricted to 45° or 50%

.

If high temperature operation without flame control

using ionization or a UV sensor is intended for LPG, air

flow monitoring using an ECO air flow detector set must

be provided to prevent backflow of the central air into

the gas line or of gas into the air line in the event of the

flue gas route being blocked.

Page 43

ECOMAX · Edition 10.17 43

Project planning information for direct heating

6.9 Air connection

6.9.1 Selecting components

In the case of a pneumatic air/gas ratio control system,

slow opening air valves or butterfly valves with solenoid ac-

tuator are required. If the system does not include a pneu-

matic air/gas ratio control system, quick opening air valves

or butterfly valves with solenoid actuator are to be used.

The following air control valves are recommended for air:

Burner

Flow rate control or

air/gas ratio control

No pneumatic air/gas

ratio control system

ECOMA X 0 VR 40..L VR 40..N

ECOMA X 1 VR 50..L VR 50..N

ECOMA X 2 VR 65..L VR 65..N

ECOMA X 3 BVHM 65 + MB 7..L BVHM 65 + MB 7..N

ECOMA X 4 BVHM 80 + MB 7..L BVHM 80 + MB 7..N

ECOMA X 5 BVHM 80 + MB 7..L BVHM 80 + MB 7..N

ECOMAX 6* BVHM 100 + MB 7..L BVHM 100 + MB 7..N

* As of 360 kW, ignition with a start rate of < 33% is required

(pursuant to EN 746-2 and ISO 13577-2); a pneumatic ratio

control system and a BVH with IC 40 must be used for this.

VR LEH

LEH

ECOMAX 0

ECOMAX

1

ECOMAX 2

MB

7

+

BVHM

LEH

LEH

ECOMAX 3

…

ECOMAX 6

6.9.2 Air pressure

The motive air setting for eductor EJEK is critical when

designing the air supply. The required pressure depends

on the burner capacity, the flue gas extraction via the

burner and the furnace temperature:

Motive air pressure

upstream of

eductor*

Air supply

line pressure*

ECOMA X 0 and 1 at a furnace

temperature of 1000°C

approx. 100 mbar approx. 115 mbar

ECOMA X 2C – 5C

with EJEK ..HTA (construction

stage A) at a furnace

temperature of 1250°C

approx. 65 mbar approx. 80 mbar

ECOMA X 2M – 6M

with EJEK ..A (construction

stage A) at a furnace

temperature of 1100°C

approx. 65 mbar approx. 80 mbar

* The air pressures apply for burner ratings at the specified

furnace temperatures and 80% flue gas extraction.

Flow rate curves are available in the Docuthek for EJEK

construction stage A to allow precise dimensioning.

To ensure accurate measurements of the pressure dif-

ferential on the integrated orifice, flow to the orifice

must not be disturbed. We recommend using the connection set for air, which guarantees correct measurement at the measuring orifice, see page 62 (Air connection set). The attachment of a coupling, a bellows

unit or a pipe bend directly upstream of the orifice can

cause turbulence in the gas flow resulting in the burner

being incorrectly adjusted.

Page 44

ECOMAX · Edition 10.17 44

Project planning information for direct heating

6.10 Air flow monitoring

A system which includes air flow monitoring is recom-

mended to monitor pre-purge and as low air pressure

protection (pursuant to EN 7462 and ISO 135772) if

there is no pneumatic air/gas ratio control system. This

is implemented using a differential pressure switch at

the air connection together with a burner control unit

BCU 465. An air flow monitoring set is available for this

purpose as an accessory, see page 62 (Air flow de-

tector set).

6.11 Purge air and cooling air

Purge air must be connected to the burner ECOMA X in

order to ensure safe ignition and monitoring. Otherwise,

wet flue gas will enter the burner in the case of direct

heating, due to the furnace pressure.

The required purge air volume is approx. 0.5 to 1.0%

of the air volume for rated capacity, or a minimum of

1 m

3

(n)

/h.

The purge air is connected to the gas connection flange

next to the electrode, or in the case of UV control to

the purge air connection of the UV sensor. The purge

air is tapped upstream of the air control valve so that

the purge air continues to flow even if the burner is

switched off.

In order to limit the volume of purge air, special nozzles

can be used which are adjusted to the required air supply pressure for the ECOMAX – see page 63 (Purge

air/cooling air nozzles).

Burner

Nozzle for electrode

purge

Purge air nozzle on

UV sensor

ECOMA X 0

Nozzle electrode ECO 0

Rp 1/4 D = 2.5 /E

Nozzle UV ECO 03

Rp 1/4 D = 2.5 /B

ECOMA X 1–3

Nozzle electrode ECO 13

Rp 1/4 D = 2.5 /E

Nozzle UV ECO 03

Rp 1/4 D = 2.5 /B

ECOMA X 4–6

Nozzle electrode ECO 46

Rp 1/4 D = 4.0 /E

Nozzle UV ECO 46

Rp 1/4 D = 4.0 /B

At very high furnace temperatures, we recommend

cooling the burner head by selecting a larger nozzle or a

supply line with a diameter of 8 mm without a nozzle.

Page 45

ECOMAX · Edition 10.17 45

Project planning information for direct heating

6.12 Condition on delivery

The position of the gas, air and flue gas connections

can be customized depending on how the burner is to

be installed on the furnace. The connection positions

are coded using the numbers 0, 3, 6 and 9.

Code Connection position

0 Top

3 Right-hand side

6 Bottom

9 Left-hand side

The codes relating to the positions of the connections

are specified in the following order: flue gas – air – gas.

Provided that there are no specifications, the burners

are supplied as follows:

ECOMAX../D for direct heating with connector posi-

tion 366, i.e. flue gas connection for eductor installa-

tion on the right-hand side and gas and air connections

at the bottom.

0

3

6

9

The FGT Set..D for direct heating is installed on the

burner at the factory, provided that it is ordered at the

same time as the burner. This also applies to all add-on

components with the marking /E, such as the air flow

detector set, UV adapter set, purge air nozzle, inlet section for gas and air, see page 62 (Accessories).

6.13 Cooling with ECOMAX

Extraction of the flue gases via the burner and thus the

preheating of the combustion air can be switched off to

ensure controlled cooling of the furnace. Install separate valves for combustion air and motive air instead

of an air valve for this. In this case, a separate flue gas

route must be opened on the furnace, via which the

cooling air can be discharged from the furnace.

Page 46

ECOMAX · Edition 10.17 46

Project planning information for direct heating

6.14 Emissions

CO and NOX values depend on the furnace tempera-

ture, air preheat temperature, burner type and burner

settings (NOX values on request).

If operated with LPG, NO

X

values are approx. 25%

higher.

600 700 800 900 1000 1100 1200 1300

0

100

200

300

400

500

600

ECOMAX..C

ECOMAX..M

Flue gas temperature at recuperator inlet [°C]

NO

x

[mg/m

3

ref. 5 % O

2

]

NOX values in the diagram apply to natural gas.

6.15 Build up of noise

The sound level of a naked flame may be significantly

more than 90 dB(A) due to the high flame velocity. In

the case of fitted burners, the sound level of the single

burner which can be measured outside the furnace is

usually between 75 and 82 dB(A).

In a furnace system, the value which can be measured

depends on the capacity, excess air volume, flue gas

extraction and flue gas temperature of the single burners as well as the burner arrangement and ambient

influences.

Page 47

ECOMAX · Edition 10.17 47

Project planning information for direct heating

6.16 Process boundary conditions

In direct heating systems, the flue gases are routed

out of the furnace chamber via the burner. Impurities

from the process can affect burner operation. Deposits

of dust or components from the material to be heated

which turn to gas (e.g. molybdenum) can accumulate

on the recuperator. This means that the volume of flue

gas routed via the recuperator falls and thus the burner

is less efficient. Furthermore, this can also lead to in-

creased furnace pressure and damage to the furnace

and burner. In this case, increased maintenance and

shorter cleaning intervals are required.

Other impurities, such as alkalis formed during the

heating of cast parts or from cooling and washing liq-

uids, can cause chemical attacks on the material. This

reduces the service life of the recuperator and the flue

gas guide tube. We therefore advise against use in forg-

ing and heating furnaces, in which raw materials are

heated. We also advise against use in aluminium smelt-

ing furnaces due to the dusty furnace atmosphere, the

danger of liquid metal spillings and possible chemical

attacks.

Avoid sub-stoichiometric burner operation. A reducing

atmosphere can lead to damage to the burner insula-

tion on the flue gas side, the metallic recuperator and

flue gas guide tube, and the vacuum-formed parts of

the flue gas guide tube for ECOMAX..C.

6.17 Resistance of SiSiC

The ceramic recuperator of the ECOMAX..C consists of

reaction-bound silicon carbide (SiSiC), infiltrated with

metallic silicon. During the manufacturing process, a

protective layer made of SiO2 is formed on the surface,

which ensures good chemical resistance.

When installing the burners, it must be ensured that

the protective layer on the ceramic surface is not damaged.

The burners should be adjusted so that an excess air

value of 1 – 5% O

2

in the flue gas is maintained in order

to preserve the protective layer. In the case of substoichiometric burner operation (concentration of CO

> 1000 ppm), white deposits can build up on the SiSiC

over a long period of time. This reduces the service life

of the ceramic material.

Impurities such as fluorine, chlorine and alkali compounds (e.g. with sodium or potassium) in the furnace

atmosphere also lead to chemical attack and shorten

the service life of the ceramic recuperator. We therefore

advise against use in forging and heating furnaces, in

which raw materials are heated. We also advise against

use in aluminium smelting furnaces.

Page 48

ECOMAX · Edition 10.17 48

Project planning information for indirect heating

7 Project planning information for indirect heating

7.1 Heating system design

When designing a radiant tube heating system, it must

be ensured that the energy can be transferred to the

furnace chamber via the surface of the radiant tube

to avoid exceeding the maximum permissible flue gas

temperature at the recuperator inlet of the burner.

It must also be ensured that the permitted material

temperature of the radiant tube and, in the case of sin-

gle ended radiant tubes, of the flame tube used is not

exceeded.

Burner Max. flue gas temperature at recuperator inlet

[°C] [°F]

ECOMAX..C 1250 2282

ECOMAX..M/ECOMAX..P 1150 2102

ECOMAX..F 1050 1922

The possible radiation output in the furnace depends

on the furnace temperature and the surface of the radi-

ant tube as well as the material that the radiant tube

and burner are made of.

The burner capacity also depends on how efficient the

burner is.

The heat exchange must be determined to ensure safe

design of a radiant tube heating system. To this end,

please consult a member of the sales team.

700 800 900 1000 1100 1200

0

60

40

20

50

30

10

90

70

80

100

0

60

40

20

50

30

10

90

70

80

100

1300

Furnace temperature [°C]

Max. radiation output in kW/m²

SER-C with ECOMAX..C

SER-M with ECOMAX..M

Spec. burner capacity in kW/m²

Depending on the system configuration, it may be necessary to reduce the power input on the basis of the

furnace temperature, e.g. by reducing the duty cycle.

In this case, the combustion time should not exceed

2 minutes to avoid thermal overload of the radiant tube

and burner.

100 %

Power input

Furnace temperature

Page 49

ECOMAX · Edition 10.17 49

Project planning information for indirect heating

7. 2 Radiant tubes

For ECOMA X..C

Burners ECOMAX..C are intended for use with ceramic

radiant tubes SERC.

See Technical Information SERC.

Standard combinations:

Radiant tube Burner Segmented flame tube

SERC 100/088 ECOMA X 0C SICAFLEX 100/088/084

SE RC 142 /128 EC OMAX 1C SICAFLE X 142/127/123

SE RC 162/14 8 ECOMA X 2C SI CA FLEX 162 /147/143

SERC 202/188 ECOMAX 3C SICAFLE X 202/186/182

In special cases, a ceramic burner ECOMAX..C can be

installed in a metallic radiant tube. Here, external forces

on the ceramic burner due to the radiant tube being de-

formed must be excluded, however.

For ECOMAX..M

Metallic radiant tubes are available in a variety of dimensions in either centrifugal casting or in welded

form. The efficiency of the burner ECOMAX..M is determined by the inside diameter d

i

of the radiant tubes in

the vicinity of the burner. The following dimensions are

recommended:

Burner

Min.

radiant tube inside

diameter d

i

[mm]

Radiant tube inside

diameter d

i

as of which a

flue gas guide tube FGT

set is recommended

[mm]

ECOMAX 1M 128 140

ECOMAX 2M 147 164

ECOMA X 3M 185 202

ECOMAX 4M 248 266

ECOMAX 5M 280 298

If the inside diameter of the radiant tube is considerably

larger than that of the burner, a flue gas guide tube FGT

set should also be used.

Depending on the geometry, additional adapter flanges

may be required for radiant tubes.

Page 50

ECOMAX · Edition 10.17 50

Project planning information for indirect heating

7.3 Flue gas channelling

A flue gas connector FLUP, which is to be ordered sepa-

rately, is available as standard to channel flue gas in

an indirect heating system. In special cases, an educ-

tor EJEK can also be installed to channel flue gas. This

also must be ordered separately.

Flue gas connector FLUP

SER-C

SICAFLEX

FLUP

ECOMAX..C

Flue gas connector FLUP serves to discharge the flue

gases into the furnace flue gas system and features an

opening which is closed by a clip to connect flue gas

analysis equipment.

Eductor EJEK

SER-M

EJEK

SICAFLEX

In indirect heating systems with metal radiant tubes,

eductor EJEK can generate a negative pressure in the

radiant tube. This prevents the inert gas atmosphere in

the furnace being contaminated by flue gases from the

burner in the event of leakage from the single ended

radiant tube.

Page 51

ECOMAX · Edition 10.17 51

Project planning information for indirect heating

7.4 Furnace flue gas system

A flue gas system must be fitted on the furnace as a

means of guiding the flue gas to the chimney. In the

flue gas system there should be a low negative pressure

thanks to the draught of the chimney or an exhaust fan.

The branch lines from the furnace flue gas manifold to

the individual burners should be designed such that

condensate cannot seep upstream into the burner.

The branch lines to the burner should stop 10 mm away

from the flue gas connector FLUP, or be fitted flush

with the eductor EJEK.

For indirect heating with flue gas monitoring kit DW and

BCU 465, excessive negative pressure in the flue gas

system or an excessively narrow flue gas pipe diameter

on the furnace can cause problems with setting the

switching point of the pressure switch.

∅Q

∅

1,5Q

10 mm ±5

∅1,5Q

∅

2Q*

∅2Q*

∅Q

10 mm ±5

∅

P

∅1,5P

0 mm

(±10 mm)

* With flue gas monitoring kit DW; without flue gas monitoring

kit DW: 1.5Q to 2Q.

FLUP dia. Q EJEK dia. P

ECOMA X 0 DN 32 43

ECOMA X 1 DN 50 43

ECOMA X 2 DN 50 83

ECOMA X 3 DN 65 98

ECOMA X 4 DN 100 128

ECOMA X 5 DN 100 153

In a closed flue gas system, a pressure regulator is to

be fitted. The gas and air flow rates depend on the total

pressure differential between the supply lines and the

flue gas system. If the pressure in the flue gas system

fluctuates, the burner capacity changes. In a system

without air/gas ratio control, the lambda may also

change.

Page 52

ECOMAX · Edition 10.17 52

Project planning information for indirect heating

7.5 Installation

Installation of burners with FLUP in the horizontal posi-

tion, in the vertical position with the firing end pointing

downwards or at an angle with the firing end pointing

downwards.

Allow for adequate clearance between the radiant tubes

and the furnace wall to avoid local overheating, see

Technical Information SERC.

Ensure that there is a recirculation gap D1 between burn-

er and flame tube, e.g. SICAFLEX, (30 mm for ECOMAX

0–3 or 50 mm for ECOMAX 4–5). The deflector gap V1

should equal 0.5 to 1.5 times the radiant tube diameter X.

X

SICAFLEX

SER

D1 (ECOMAX 0–3 = 30 mm)

(ECOMAX 4–5 = 50 mm)

V1 = 0.7 × max. 1.5 × X for SER-C

0.5 × max. 1.5 × X

for SER-M

7.5.1 Heat guard

During operation, the burner body and flue gas con-

nector or eductor can reach surface temperatures of

over 80°C. Do not insulate the burner, flue gas connec-

tor and eductor to prevent material overheating.

We recommend that warning signs and a contact guard

be fitted, for example made of perforated sheet metal.

Page 53

ECOMAX · Edition 10.17 53

Project planning information for indirect heating

7.6 Flame control

Burners ECOMAX are equipped with a combined

spark electrode/flame rod. For indirect heating,

ionization control is possible up to a furnace tempera-

ture of approx. 1050°C (single-electrode operation).

In this respect, it must be noted that the burner con-

trol unit BCU must feature at least firmware version

FW 16xx, see page 54 (Burner control units and igni-

tion transformers).

Flame control with UV sensor is required if a furnace

temperature of 1050°C for indirect heating is ex-

ceeded. We recommend using bend-resistant Kanthal

electrodes for ignition on ECOMA X..M as of a furnace

temperature of more than 950°C. These are fitted as

standard on ECOMAX..C.

We recommend the UV sensor UVS 10D1 with integrated purge air connection (Order No. 84315202) for

UV control.

For ECOMA X 0, the UV sensor UVS 10L1 (Order

No. 84315203) with lens is required for UV control. For

burners ECOMAX 1 –6 with a burner length of more

than 545 mm, the UV sensor UVD 10L1 with lens is

also required for UV control.

An adapter set is required for connection to the UVS 10,

see page 63 (UV adapter set).

Page 54

ECOMAX · Edition 10.17 54

Project planning information for indirect heating

7.7 Burner control units and ignition

transformers

ECOMAX burners are designed for On/Off control.

We recommend burner control units BCU 465. In order

to be able to carry out ionization control up to 1050°C,

the burner control units must be equipped with firm-

ware FW 16xx or higher.

Pre-ventilation should be performed after every safety

shut-down in order to purge the radiant tube (param-

eters 39 and 40 of the BCU 465).

For burners ECOMAX..K with additional cooling air

connection, we recommend using burner control unit

BCU..C with additional circuit board for signal distribu-

tion.

For ignition, the ECOMAX burners require an ignition

transformer with 7.5 kV high voltage and an output cur-

rent of 20 mA. An appropriate ignition transformer is

already integrated in burner control units BCU 460..8

and BCU 465..8.

For further information on burner control units and ig-

nition transformers, see www.docuthek.com, Technical

Information BCU 460, 465.

Page 55

ECOMAX · Edition 10.17 55

Project planning information for indirect heating

7.7. 1 Burner control unit configurations

Description Configuration R1 Configuration R2

Recuperator Metallic Ceramic

Flame control Ionization UV S 10

Pneumatic air/gas ratio control None/VAG None/VAG

Air flow monitoring Differential pressure switch PDZ Differential pressure switch PDZ

Hardware BCU 465..L BCU 465..L

Ignition transformer 8 = TZI 7,520/33 8 = TZI 7,520/33

Rewiring for electrode operation 1 electrode 2 electrodes

Description Parameter Configuration R1 Configuration R2

Switch-off threshold of the flame amplifier 04

4 μA 4 μA

Air flow monitoring during purging 06 1 1

Air flow monitoring during operation 07 1 1

Delayed air flow monitoring 08 1 1

Safety time during operation t

SB

for V1 and V2 14 1 1

Minimum burner on time t

B

20 8 8

Minimum burner pause time t

BP

21 4 4

Safety time on start-up t

SA

22 3 3

Air valve control 30 1 1

Air valve can be activated externally on start-up 31 1 1

Low fire over-run time t

KN

after a controlled shut-down 36 0 0

Pre-ventilation time t

VL

before start-up 37 0 0

Post-ventilation time t

NL

after a controlled shut-down 38 0 0

Pre-ventilation time after safety shut-down 39 7 7

Pre-ventilation for restart/start-up attempts 40 1 1

Pre-ventilation after reset 41 1 1

BCU for indirect heating Configuration R1 Configuration R2

230 V 88 614271 88614275

230 V, Profibus 88614272 88614276

230 V, HT operation 88614273 88614277

230 V, HT operation, Profibus 88 614274 88614278

Page 56

ECOMAX · Edition 10.17 56

Project planning information for indirect heating

7.8 Gas connection

7.8.1 Selecting components

For indirect heating, slow opening gas valves and quick

opening air control valves are to be used to ensure a

safe burner start.

The following gas valves are recommended for natural

gas:

Burner

No pneumatic air/gas

ratio control system

Air/gas ratio control

ECOMA X 0

VG 15..N +

VG 15..L +

VMV 115

VAG 115..B +

VG 15..L +

VMV 115

ECOMA X 1

VG 15..N +

VG 15..L +

VMV 115

VAG 115..B +

VG 15..L +

VMV 115

ECOMA X 2

VG 15..N +

VG 15..L +

VMV 115

VAG 115..B +

VG 15..L +

VMV 115

ECOMA X 3

VG 15..N +

VG 15..L +

VMV 115

VAG 115..B +

VG 15..L +

VMV 115

ECOMA X 4

VAS 120..N +

VAS 120..L +

VMV 120

VAG 120..B +

VAS 120..L +

VMV 120

ECOMA X 5

VAS 125..N +

VAS 125..L +

VMV 125

VAG 125..A +

VAS 125..L +

VMV 125

A bellows unit EKO should be provided between the

burner and controls to prevent external force being ap-

plied to the burner.

7.8.2 Gas pressure

The required gas pressure depends on the burner size,