Page 1

Industrial Air Vent

The Honeywell Braukmann EA79 Industrial

AirVentpurges air from highpressure mains and

equipment in hot or cold closed water systems.

Honeywell Braukmann

EA79

ff

Includes built-in shutoff valve for servicing with

out system shutdown.

Removable float/valve assembly for easy servicing.

includes safety drain connection and vent cap with

leakage guard.

Brass shell construction.

Internal parts made of corrosion-resistant and

chemical-resistant materials for use with water

systems containing glycol, mineral oils, or petro

leum-based oils.

For use with water systems up 250° F [120° C].

3/4 in. NPT male pipe thread with 1/2 in. NPT

female pipe thread connections.

Maintains quiet and efficient operation.

CONTENTS

Sp ecificalions. i. i.

Ordering ihfprtnMan

Installation

Operation

Service

Troubleshopting.:. ,.

...................

.2

..2

.3

..4

..4

,.5

C.H. ■ 10-92 ” © Honeywell Inc. 1992 ■ Form Nundrer 62-3034

Page 2

E/^

SPECiFICATIONS • ORDERINgInFORMATÌON

Specifications

MATERIALS OF CONSTRUCTION:

Body: Brass.

Cover ring: Brass.

Float, valve lever and cover: Engineered thermoplastics.

Seal disc and rings: Synthetic rubbers.

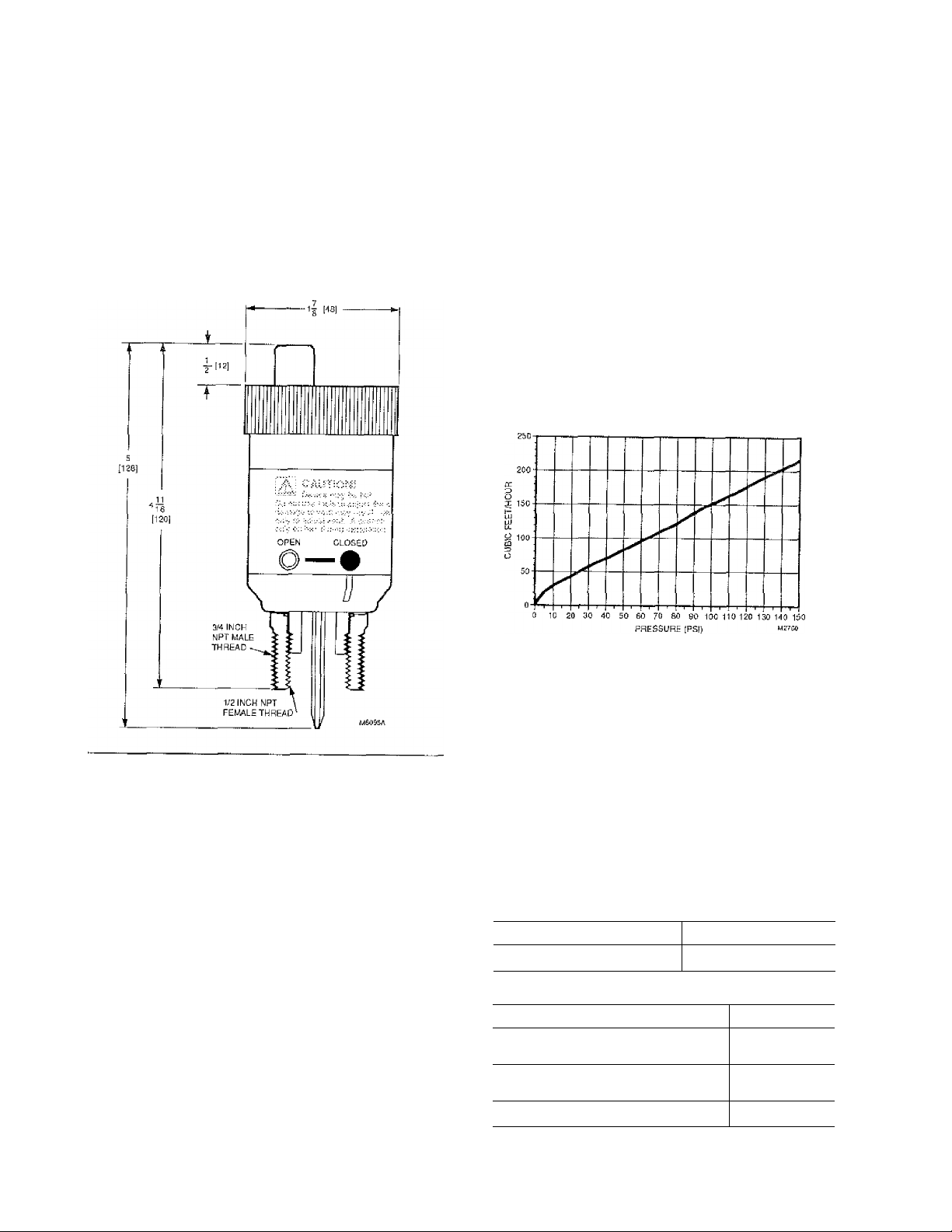

Fig. 1—EA79 dimensions in in. [mm].

OPERATING RATINGS:

Maximum Pressure; 150 psi

Maximum Temperature; 250° F [120° C]

SAFETY RATINGS:

Maximum Pressure: 450 psi

Maximum Temperature: 250° F [120° C]

CONNECTIONS: 3/4 in. NPT male pipe thread with 1/2 in.

NPT female pipe thread.

DIMENSIONS: Refer to Fig. 1.

CAPACITTES: Refer to Fig. 2.

Fig. 2—EA79 flow capacities, with leakage guard

cap.

NOTE: Capacity indicated is for device with leakage guard

cap correctly installed and operational. Additional capac

ity may be obtained by removing the leakage guard cap

and installing a connection between the vent discharge

and drain using Q122A1001 Safe Waste Connector.

Ordering Information

When purchasing replacemenr and modernization products, specify Ore complete model number.

1. If you have additional questions, need further information,

or want to comment on our products or services, call;

l-SOO-345-6770, ext. 7188.

Or write;

Honeywell Customer Assistance Center

Honeywell Plaza, MN27-2164, P.O. Box 524

Minneapolis, Minnesota 55440-0524

2. To place an order, contact:

Honeywell Braulanann Customer Service

1985 Douglas Drive North

Minneapolis, Minnesota 55422-3992

(612)542-7106 (Eastern US)

(612) 542-7103 (Western US)

3. Or fax your order to 1-800-356-0149.

INDUSTRIAL AIR VENT:

Description

Industrial automatic air vent

ACCESSORIES:

Description

Cover assembly—includes replacement

0 ring, cover and float assembly.

Safe waste connector for connecting

top vent to 1/4 in. O.D. tube.

Red vent cap with leakage guard.

Model Number

EA79A1004

Part Number

P79B1003

Q122A1001

^204992

Page 3

_________

INSTALLATION

Installation

EA79

WHEN INSTALLING THIS PRODUCT...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for your

application,

3. Installer must be a trained, experienced service

technician,

4. After installation is complete, check out product

operation as provided in tliese instructions.

f\ CAUTION

Do not use tools to adjust the EA79 or damage

to vent may result, Use hands only to adjust

vent. A wrench may be used only on hex during

installation.

LOCATION

Install the EA79 on the positive side of tlie circulator

pump at the point where air will accumulate. This is usually

the high point of the supply or the retum main in the system

as shown in Fig, 3.

INSTALLATION

1. Fit EA79 vent in piping at a location as specified in

the Location section,

2. Turn EA79 until vent fits tightly on piping. Use a

wrench to securely tighten hex.

3. If safety drain connection is desired, inslali a pipe

between vent discharge and drain using Q122A1001 Safe

Waste Connector.

4. Make sure that the red vent cap is securely tight, and

that the valve is in the closed position by turning vent body

clockwise. See Fig. 4. U,se hands only to avoid damaging

the vent.

5. With the valve in the closed position, flush the system

as required to remove dirt, debris and contaminants.

6. Fill the system with the appropriate solution.

7. Operate the EA79 by turning the air vent body coun

terclockwise to the open position. Use hands only, .see Fig. 4.

8. Make sure the red vent cap is tightened all Ihe way

to the slop position for proper leakage guard operation.

Use hands only to tighten.

Fig. 4—Turn vent body counterclockwise to

open or clockwise to close.

Fig. 3—Install EA79 at high point in system.

BETWEEN VALVE DISCHARGE AND DRAIN

INSTALL EA79 AT HIGH POINT IN SYSTEM,

62-3034

Page 4

£A79

__________________

OPERATION ® SERVICE

Operation

The EA79 operates as Ibllows:

Opening the air vent (Lurning valve body counterclock

wise) exposes tiie EA79 to the system. Water and air may

enter the vent chamber. The float will fall through any air in

the cliambcr. This opens the vent scat.

The red ven t cap aliows air to pass through the open vent.

As the air is released through tlie vent cap, water replaces

!\ CAUTION

The EA79 may be hot due to system temperature

extremes. Use caution when adjusting vent to pre

vent bunting hands.

The EA79 may become accumulated with dirt in the seat

area of the float assembly, which may cause itie vent to

malfunction. Periodic cleaning is recommended to prevent

the vent from malfunctioning.

NOTE: The EA79 may be serviced without depressurizing

or draining the system.

tiieairin the vent chamber and the floatrises. This closes the

vent seal. When additional air enters the vent chamber, the

operation repeats.

If the vent seat remains open, water will rise through the

vent and cause the swelling disks inside the red cap to close

off the vent. Closing the air vent (turning valve body clock

wise) isolates theEA79 from the system, allowing service.

Service

9. Make sure the red vent cap is tightened all the way

to the Slop position for proper leakage guard operation.

Use hands only to tighten.

Fig. 5—EA79 construction.

■ OUTER RIWG

To clean the seat area, proceed as follows:

1. Turn the vent body clockwise to the closed position,

isolating the vent from the system. See Fig. 4.

2. Remove the float assembly by unscrewing the outer

ring at the top of Lhe body and lifting up the black cover

assembly. See Fig. 5.

3. Carefully clean the scat area of any din or debris.

i\ CAUTION

Do not bend spring on float assembly or damage to

the vent may result.

4. Carefully clean any dirt or debris from inside the

vent chamber.

5. Replace the float assembly, making sure that the O

ring is seated properly (see Fig. 5).

6. Replace black cover assembly on air vent body.

7. Using hands only, replace outer ring, turning until

hand tight.

8. Operate the E A79 by turning the air ventbody counter

clockwise to the open position. Use hands only. See Fig. 4,

Page 5

!\ CAUTION

The EA79 may be hoi due to system temperature

extremes. Use caution when adjusting vent to pre

vent burning hands.

_______________

TROUBLESHOOTING

Troubleshooting

EA79

Problem

The EA79 is not venting air or

there is too much air in the system.

Water is leaking from the EA79.

Action

1. Check the red vent cap; make sure the vent passage is open (disks are

not swelled).

2. Check that th.e valve is in the open position.

3. Make sure that the float is attached to the vent lever as shown in Fig. 5.

1. Make sure the red vent cap is tightened all the way to the stop position.

2. Adj ust the valve to the closed position by turn ing the vent body clockwise.

3. Clean the vent as described in the Service section.

4. If internal parts appear damaged or deteriorated, replace cover assembly

(part no. P79B1003).

62-3034

Page 6

Honeywell Braukmann

Honeywell Braukmann

Honeywell Inc.

1985 Douglas Drive North

Golden Valley, Miimesota 55422

Printed in U.S.A.

Helping You Coftlrol Your World

Loading...

Loading...