Page 1

Air Temperature Sensors

APPLICATION

The C7046 series of Air Temperature Sensors function as

primary and/or secondary sensors in electronic control

systems.

C7046A,B,C,D

PRODUCT DATA

FEATURES

• C7046A,C Sensors have probe lengths of 8 in.

(203 mm) and nominal sensor resistance of 3000 ohms

at 77°F (25°C).

• C7046B Sensor has probe length of 6 in. (152 mm) and

nominal sensor resistance of 22,800 ohms at 77°F (25°C).

• C7046D Sensor has probe length of 8 in. (203 mm) and

nominal sensor resistance of 1097 ohms at 77°F (25°C).

• Carbon type, negative temperature coefficient

(NTC) thermistor sensing element in the C7046A,B,C

and platinum thin film, positive temperature coefficient

(PTC) element in C7046D precisely measures

temperature changes.

• No settings or calibration required.

• Solid state components not affected by dust or dirt.

• Fast reacting.

• Rugged stainless steel insertion probe.

• Mounts on duct or plenum surface with mounting

flange or in a 2 in. by 4 in. (51 by 102 mm) junction box.

• C7046B can be used as a replacement for C7100B

Averaging Temperature Sensor where duct or plenum

cross section is less than 13 in. (330 mm).

® U.S. Registered Trademark

© 2004 Honeywell International Inc.

All Rights Reserved

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 3

Wiring ............................................................................... 4

Operation and Checkout .................................................. 5

60-2350—8

Page 2

C7046A,B,C,D AIR TEMPERATURE SENSORS

)

D

)

02

(25)

)

)

)

)

)

)8 (

)

GASKET

R

)

USH

)

C

BUS

G

SPECIFICATIONS

IMPORTANT

Specifications given in this publication do not include

normal manufacturing tolerances. Therefore, this unit

may not exactly match the listed specifications. Also,

this product is tested and calibrated under closely

controlled conditions and some minor differences in

performance can be expected if those conditions are

changed.

Models:

C7046A Air Temperature Sensor: Intended for use as a

discharge sensor with the W973 Single Zone Logic Panel.

C7046B Air Temperature Sensor: Intended for use as a zone

discharge, hot deck, cold deck, mixed air and/or return air

sensor in the W7080 Multizone Control System.

C7046C Air Temperature Sensor: Intended for use as a

discharge sensor in rooftop applications.

C7046D Air Temperature Sensor: Intended for use as a

discharge air sensor in the Excel 500 Control System.

Dimensions: See Fig. 1.

Mounting: Integral mounting flange requiring two No. 8 screws.

Sensing Element:

C7046A,B,C: Carbon type, thermistor-resistor element.

C7046D: Platinum thin film element.

Maximum Ambient Temperature: 250°F (121°C).

Operating Temperature Range: 40 to 150°F (4 to 66°C).

Wiring Connections: 6 in. (152 mm) leadwires.

Performance Characteristics:

Reaction Time Constant with Air Approach Velocity of

500 ft/min (2 m/sec):

C7046A: 100 seconds.

C7046B: 165 seconds.

C7046C: 60 seconds.

C7046D: 130 seconds.

Resistance/Temperature (NTC):

C7046A,C:

Nominal Resistance: 3000 ohms at 77°F (25°C)

Nominal Sensitivity: 70 ohms per degree F (124 ohms

per degree C) at midrange.

C7046B:

Nominal Resistance: 22,800 ohms at 77°F (25°C).

Nominal Sensitivity: 675 ohms per degree F (1290 ohms

per degree C) at midrange.

C7046D:

Nominal Resistance: 1097 ohms at 77°F (25°C).

Nominal Sensitivity: 2.1 ohms per degree F (3.9 ohms

per degree C).

2 (51

1-1/2 (38

5/16 (9) DIAMETE

(BUSHING

3/4 (19

203

PLASTI

HIN

LOCKING P

1/4 (6

NUTS (2

IAMETER (2 HOLES

1 (25

6 (152

1/16 (2

NEOPRENE

Fig. 1. C7046A,B,C,D Air Temperature

Sensor dimensions in in. (mm).

M224

NOTE: Sensor probe diameter is 1/4 in. (6 mm).

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

60-2350—8 2

Page 3

INSTALLATION

SENSO

OBE

GE

)

S

(

)

O

E

SYSTEM

COMPO

S

CO

W

O

W

S

(

)

03

SENSO

E

SYS

UM

GE

S

Y

CONDU

OX

CO

OR

CONDUIT

E

(

)

SYS

COMPO

S

CO

S

(

)

P

)

C7046A,B,C,D AIR TEMPERATURE SENSORS

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

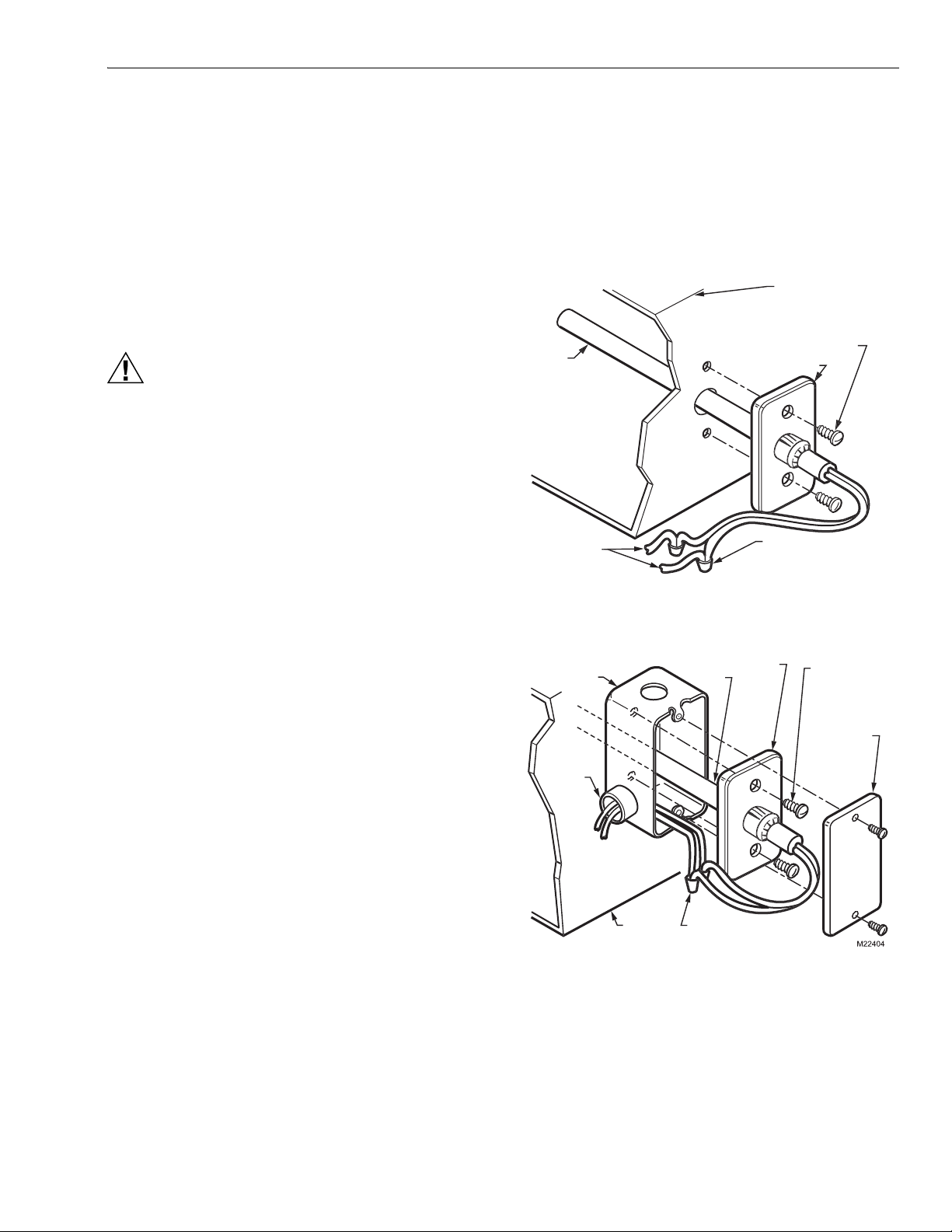

The sensor assembly (see Fig. 1) consists of an aluminum

sensor probe (element housed internally) with attached flange

that can be mounted on a flat duct or plenum surface, or in

a 2 in. by 4 in. (51 by 102 mm) junction box using two No. 8

screws. Connections to the sensor are made through two 6 in.

(152 mm) leadwires.

Location

The sensor should be located in the air duct or plenum where

it will sample an average air temperature. Avoid locations

where air stratification can cause sensing errors.

Mounting

3. Using the flange as a template, mark and drill two holes

in the junction box and the duct or plenum surface for

No. 8 mounting screws.

4. Insert sensor probe through both the junction box

knockout and the 3/8 in. (9.5 mm) hole drilled in the duct

or plenum and fasten the junction box and sensor to the

duct or plenum surface.

SYSTEM DUCT

OR PLENUM

NO. 8 (4mm

MOUNTING SCREW

R

PR

T

APPROPRIAT

NENT

M224

NOT PROVIDED

FLAN

NNECT SENSOR

IRES WITH TW

IRENUT CONNECTOR

NOT PROVIDED

Fig. 2. Mounting C7046 Air Temperature

Sensor on a flat duct or plenum surface.

TANDARD UTILIT

IT B

PROB

FLAN

R

NO. 8 (4mm)

MOUNTING

SCREWS (NOT

ROVIDED

Mounting on a Flat Duct or Plenum Surface (Fig. 2)

1. Cut a 3/8 in. (9.5 mm) hole in the duct or plenum

surface at the desired location.

2. Insert sensor probe into the duct or plenum until the

flange rests against the duct or plenum wall.

3. If necessary, use the flange as a template to mark

and drill two holes for No. 8 mounting screws.

4. Fasten the sensor to the duct or plenum surface

with two No. 8 sheet metal screws (not provided).

Mounting in a Junction Box (Fig. 3)

1. Cut a 3/8 in. (9.5 mm) hole in the duct or plenum

surface at the desired location.

2. Remove the center rear knockout from the junction box

and insert the sensing probe through the knockout with

the flange flat against the outlet box.

NNECT

LOCKNUT

TO APPROPRIATE

TEM

NENT

TEM

DUCT OR

PLEN

NNECT SENSOR WIRE

WITH TWO WIRENUT

CONNECTORS

Fig. 3. Mounting C7046 Air Temperature

Sensor in a junction box.

FACEPLAT

OPTIONAL

NOT PROVIDED

3 60-2350—8

Page 4

C7046A,B,C,D AIR TEMPERATURE SENSORS

Wiring

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

CAUTION

Erratic System Operation Hazard.

Failure to follow proper wiring practices can

introduce disruptive electrical interference (noise).

Keep wiring at least one foot away from large inductive

loads such as motors line starters, lighting ballasts,

and large power distribution panels.

Shielded cable is required in installations where these

guidelines cannot be met.

Ground shield only to grounded controller case.

IMPORTANT

1. All wiring must agree with applicable codes,

ordinances and regulations.

2. Do not mount sensor in incorrect environment.

3. Wire according to the applicable controller

instructions.

4. Erratic temperature readings from a sensor can be

caused by improper wiring practices. These must

be avoided to assure proper operation:

•Avoid poor wiring connections.

•Avoid intermittent or missing building earth ground.

•Do not mount sensor in incorrect environment.

W7081

LIMIT CONTROLLER

ECONOMIZER/MIXED AIR LOW LIMIT–A5

COLD DECK LOW LIMIT–A6

HOT DECK HIGH LIMIT–A7

12C7100B AVERAGING

TEMPERATURE SENSOR

MAY BE SUBSTITUTED IF

SPACE PERMITS.

REMOTE RETURN AIR SENSOR

USED WITH T7080B ONLY.

3456

21

21

3456

21

3456

(OR C7100B)

AIR SENSOR

50

55

60 NO JUMPER

45

55

55 NO JUMPER

90

110

130 NO JUMPER

24 Vdc

78

–+

+24 VDC

C7046B

REMOTE

RETURN

(IF USED)

2

T7080A,B

7

6

5

4

1

2

3

8

C7046B

(OR C7100B)

MIXED AIR

SENSOR

C7046B

(OR C7100B)

COLD DECK

SENSOR

C7046B

(OR C7100B)

HOT DECK

SENSOR

C7046B

(OR C7100B)

ZONE (N)

DISCHARGE

SENSOR

M17966

Connect low voltage wiring from the sensor to the appropriate

system component terminals using solderless connectors.

See Fig. 3.

NOTES:

1. For connections to the W973 Single Zone Logic

Panel, see Fig. 4.

2. For connections to the W7080 Multizone System,

see Fig. 5.

3. For connections to the Excel 500 Control System,

see Fig. 6.

4. For additional wiring information, refer to the

appropriate specification.

W973 LOGIC PANEL

SENSOR STAT 24 VAC ECONO

C7046A

1

POWER SUPPLY. PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

C +20 H N

TT134251TRTRWBY

1

L1

L2

(HOT)

M17965

R

Fig. 4. Connecting C7046A Air Temperature

Sensor to a W973 Single Zone Logic Panel.

Fig. 5. Connecting C7046B Air Temperature Sensor

for mixed air, cold deck and hot deck sensing, zone

discharge and optional remote return air sensing

in W7080 Multizone System.

C7046D XF521A/XF526

1

1

2

2

AI 1

AI 2

AI 3

AI 4

AI 5

AI 6

AI 7

AI 8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

M2825

Fig. 6. Connecting C7046D Air Temperature

Sensor to Excel 500 Control System.

60-2350—8 4

Page 5

OPERATION AND CHECKOUT

C7046A,B,C,D AIR TEMPERATURE SENSORS

Operation

The C7046A,B,C Air Temperature Sensors consist of a

thermistor sensing element mounted in a tubular probe. They

are applied at various locations throughout single zone and

multizone duct systems. The negative temperature coefficient

(NTC) characteristic of the thermistor element causes its

resistance to decrease as the sampled air temperature

increases. This resistance shift is balanced with other system

sensor signals by appropriate system logic panels to stabilize

system control.

The C7046D Air Temperature Sensor consists of a platinum

thin film sensor element mounted in a tubular probe. It can be

applied at various locations throughout single zone and

multizone duct systems. The positive temperature coefficient

(PTC) characteristics of the platinum thin film element causes

its resistance to increase as the sampled air temperature

increases. This resistance shift is balanced with other system

sensor signals by the Excel 500 Control System.

Checkout

Allow the C7046 Air Temperature Sensor to soak in the air

moving through the duct or plenum for a minimum of five

minutes before taking a resistance measurement.

1. Disconnect the sensor leadwires from the associated

system components.

2. Connect an ohmmeter across the leadwires.

3. Assure nominal resistance measurements are in

accordance with the resistance/temperature curves

shown in Figs. 7, 8 and 9.

4. Reconnect sensor leadwires to associated system

components.

5. Check operation of the complete control system.

120000

100000

80000

60000

40000

20000

0

RESISTANCE (OHMS)

20

30

-7 50 60

50 70 90

40

0 10 20 30 40

5 15 25

TEMPERATURE (DEGREES)

22,800 OHMS AT

77 F (25 C)

60 80 100

35

120

110

45 55

130

140

M17973

Fig. 8. C7046B Sensor resistance vs. temperature.

RESISTANCE

(OHMS)

1159

1141

1126

1111

1096

1081

1066

1051

60 65 70 75 80 85 90 95 100 105

55

1097 OHMS AT

77 F [25 C]

F

C

F

17000

16000

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

RESISTANCE (OHMS)

5000

4000

3000

2000

1000

605040 70

0-10

5

TEMPERATURE (DEGREES)

2010

15

3,000 OHMS

AT 77 F (25 C)

8010 20 30 90 100

30 35

25-5

F

C

M17969

Fig. 7. C7046A,C Sensor resistance vs. temperature.

13 15

20

25

TEMPERATURE (DEGREES)

30 35 38 41

M2826

Fig. 9. C7046D Sensor resistance vs. temperature.

C

5 60-2350—8

Page 6

60-2350—8 6

Page 7

7 60-2350—8

Page 8

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or modification to,

the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability, cost, or damages,

including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

Scarborough, Ontario

M1V 4Z9

60-2350—8 B.B. Rev. 7-04 www.honeywell.com

Loading...

Loading...