Page 1

C7027A, C7035, C7044A, C7927A

Minipeeper® Ultraviolet Flame Detectors

C7027A

C7044A

APPLICATION

The C7027A, C7035A, C7044A and C7927A Minipeeper®

Ultraviolet Flame Detectors detect the ultraviolet radiation

emitted by combustion flames. The flame detectors are used

with Honeywell flame safeguard controls to provide flame

supervision for gas, oil, or combination gas-oil burners.

FEATURES

• C7027A, C7035A, and C7044A Flame Detectors are

used with R7249A, R7290A, R7749B and R7849A,B

Amplifiers and the appropriate Honeywell controls.

C7035A

C7927A

PRODUCT DATA

• C7044A may also be used with the following 50 Hz

Honeywell combustion controls/amplifiers:

— R4341/R7323

— R4343/R7323

— R4344/R7323

• C7027A has an integral collar threaded (internal

1/2-14 NPSM) for mounting on a one-half-inch sight

pipe.

• C7035A has an integral collar threaded (internal

1-11-1/2 NPSM) for mounting on a one-inch sight pipe.

• C7035A housing meets Underwriters Laboratories Inc.

requirements for rain tightness and complies with

NEMA enclosure standards, types 4 and 4X.

• C7044A mounts with a two screw bracket. The UV

sensor tube is enclosed in a stainless steel housing.

• C7044A has the capability of side or end viewing in

flame monitoring applications.

• Because of their compact size, the C7027A and

C7044A are particularly suitable for blast tube

mounting.

• Properly installed, the C7027A and C7035A are

pressure rated for 5 psi.

• C7035A ultraviolet radiation sensor tube is field

replaceable.

• Two C7027A, C7035A or C7044A Flame Detectors can

be wired in parallel for difficult flame sighting

installations.

• C7927A is used with only the R7851B Flame Amplifier

and the appropriate Honeywell controls.

• C7927A has an integral collar threaded (internal

1/2-14 NPSM) for mounting on a one-half inch sight

pipe.

® U.S. Registered Trademark

Copyright © 2000 Honeywell • All Rights Reserved

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 4

Wiring (All Models—Fig. 10) ............................................. 8

Adjustments and Checkout .............................................. 9

Troubleshooting ................................................................ 12

Maintenance ..................................................................... 12

60- 2026- 10

Page 2

MINIPEEPER® ULTRAVIOLET FLAME DETECTORS

SPECIFICATIONS

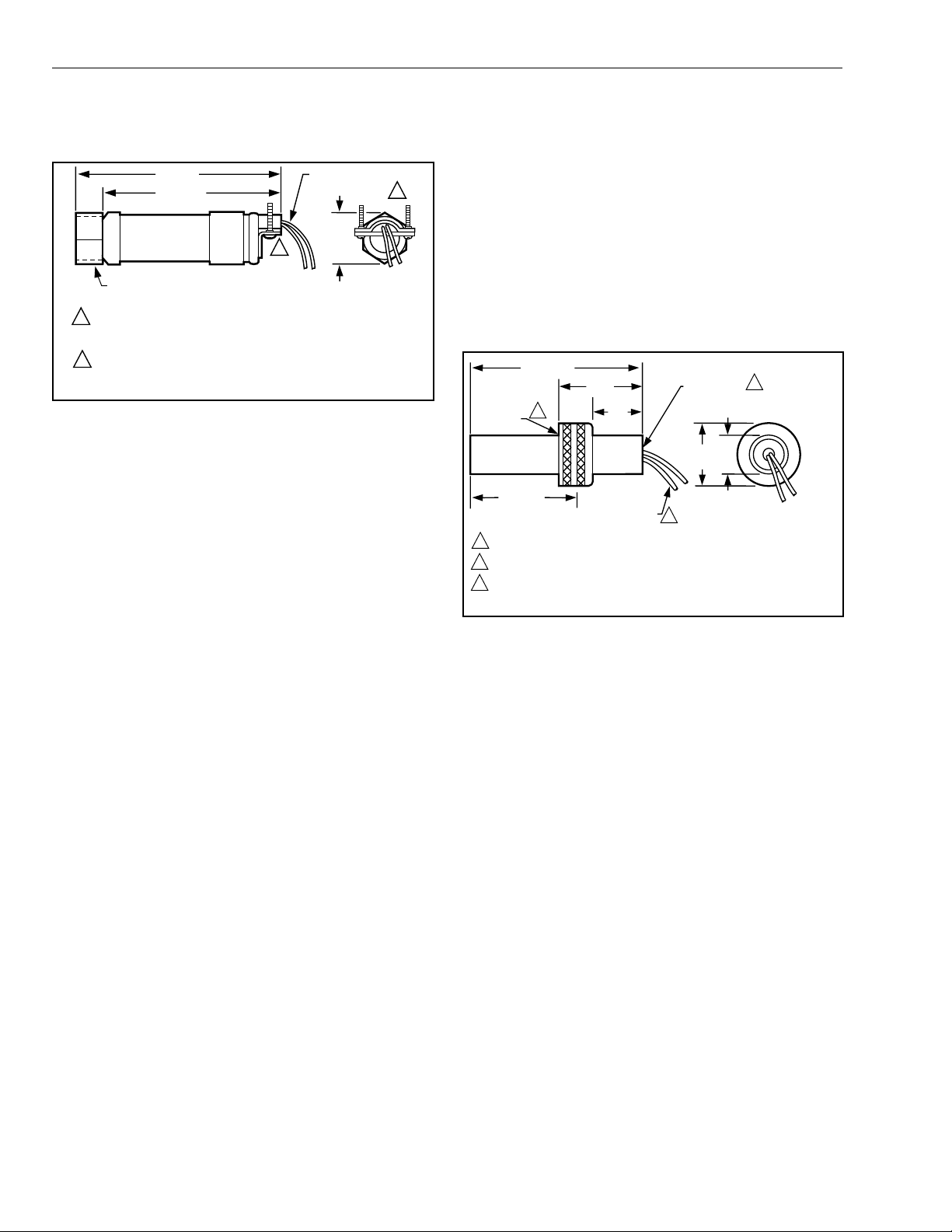

4 (102)

3-1/2 (89)

COLLAR WITH 1/2-14 NPSM

INTERNAL THREADS

1

C7027A1064 HAS 24 FOOT (7.32 METER) LEADWIRES.

C7027A1114 HAS 44 IN. (1.118 M) LEADWIRES WITH

22 IN. (558 MM) FLEXIBLE CONDUIT.

MODELS AVAILABLE WITH SPUD CONNECTOR (1/2-14 NPSM INTERNAL

2

THREADS) INSTEAD OF CLAMP TYPE CONNECTOR.

C7027

Fig. 1. Installation dimensions of C7027A in in. (mm).

C7027A Minipeeper® Ultraviolet Flame Detector:

Ambient Operating Temperature Ratings:

(-18°C to 102°C), or -40°F to 215°F [-40°C to +102°C),

depending on model.

Maximum Pressure Rating:

Mounting:

Collar with 1/2-14 NPSM internal threads for

mounting on a 1/2 in. sight pipe.

Wiring Connections:

NEC Class 1 leadwires, rated for 221°F (105°C).

(C7027A1064 has 24 ft [7.32 m] leadwires.) Rear of

detector has a clamp type connector for 1/2 in. flexible

metallic conduit. (Models are available with 1/2 in.

internally threaded spud connector instead of the

clamp). C7027A1114 has 44 in. (1.118 m) leadwires and

22 in. (558 mm) flexible conduit.

5 psi (34.5 kPa).

Two 6 ft [1.83 m], color-coded,

6 FOOT (1.83 METER)

LEADWIRES (2)

2

1-1/16

(27)

0°F to 215°F

1

M1943D

Dimensions:

Replacement Part:

See Fig. 1.

129685 Flange Gasket.

NOTE: The ultraviolet radiation sensing tube is not field

replaceable.

Accessory:

136733 Heat Block, laminated plastic, insulating the flame

detector from sight pipe tempera tures up to 266°F (130 °C),

1/2-14 NPSM external threads on one end and 1/2-14

NPSM internal threads on the other end (see Fig. 8).

Included with C7027A1080.

390427B Bushing, for mounting to 3/8 in. sight pipe. Included

with C7027A1080.

4-1/8 (105)

31/32

(25)

2

M1945C

COLLAR WITH

1–11-1/2 NPSM

INTERNAL

THREADS

INSERTION DEPTH

1

2

3

1

2-5/8 (67)

DIN APPROVED C7035A1064 HAS 1-11 BSP.P1 INTERNAL MOUNTING THREADS.

DIN APPROVED C7035A1064 HAS 1/2-14 BSP-F INTERNAL MOUNTING THREADS.

C7035A1056 HAS 12 FOOT (3.66 METER) LEADWIRES.

2 (51)

1-3/16

(30)

6 FOOT

[1.83 METER]

LEADWIRES (2)

C7035

1/2-14 NPSM

INTERNAL THREADS

1-1/2

(38)

3

Fig. 2. Installation dimensions of C7035A in in. (mm).

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1.

Your local Home and Building Control Sales Office (check white pages of your phone directory).

2.

Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (800) 328-5111

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

60-2026—10 2

Page 3

MINIPEEPER® ULTRAVIOLET FLAME DETECTORS

C7035A Minipeeper® Ultraviolet Flame Detector:

Flame Detection:

Ambient Operating Temperature Ratings:

(-18°C to +121°C), or -40°F to 250°F (-40°C to +121°C),

depending on model.

Maximum Pressure Rating:

Mounting:

mounting on a 1 in. sight pipe. (The DIN approved

C7035A1064 has 1-11 BSP.P1 threads.)

Wiring Connections:

Class 1 leadwires rated for 302°F (150°C). One model is

available with 12 ft. (3.66 m) leadwires. Rear of detector

has 1/2-14 NPSM internal threads for connecting to a

conduit. The DIN-approved C7035A1064 has 1/2-14

BSP-F threads.

C7035A1056 has 12 ft (3.66 m) leadwires.

C7035A1080 leadwire is rated for 600°F (204°C).

End viewing.

0°F to 250°F

5 psi (34.5 kPa).

Collar with 1-11-1/2 NPSM internal threads for

Two 6 ft. [1.83 m], color-coded NEC

6 FOOT [1.83 METER]

LEADWIRES (2)

Dimensions:

See Fig. 2.

Replacement Parts:

129808 Flange Gasket.

129464M Ultraviolet Sensing Tube, 0°F to 250°F (-18°C to

+121°C).

129464N Ultraviolet Sens in g Tube, -40°F to +250°F (-40°C to

121°C).

C7027A AND C7035A:

Approvals:

Underwriters Laboratories Inc. listed: File No. MP268.

Canadian Standards Association certified: Master Report LR

95329-1.

Factory Mutual approved.

Industrial Risk Insurers acceptable.

DIN approved models: C7027A1056, C7035A1049,

C7035A1064.

Accessory:

118367A Swivel Mount; provides adjustable

positioning of the C7027A or C7035A.

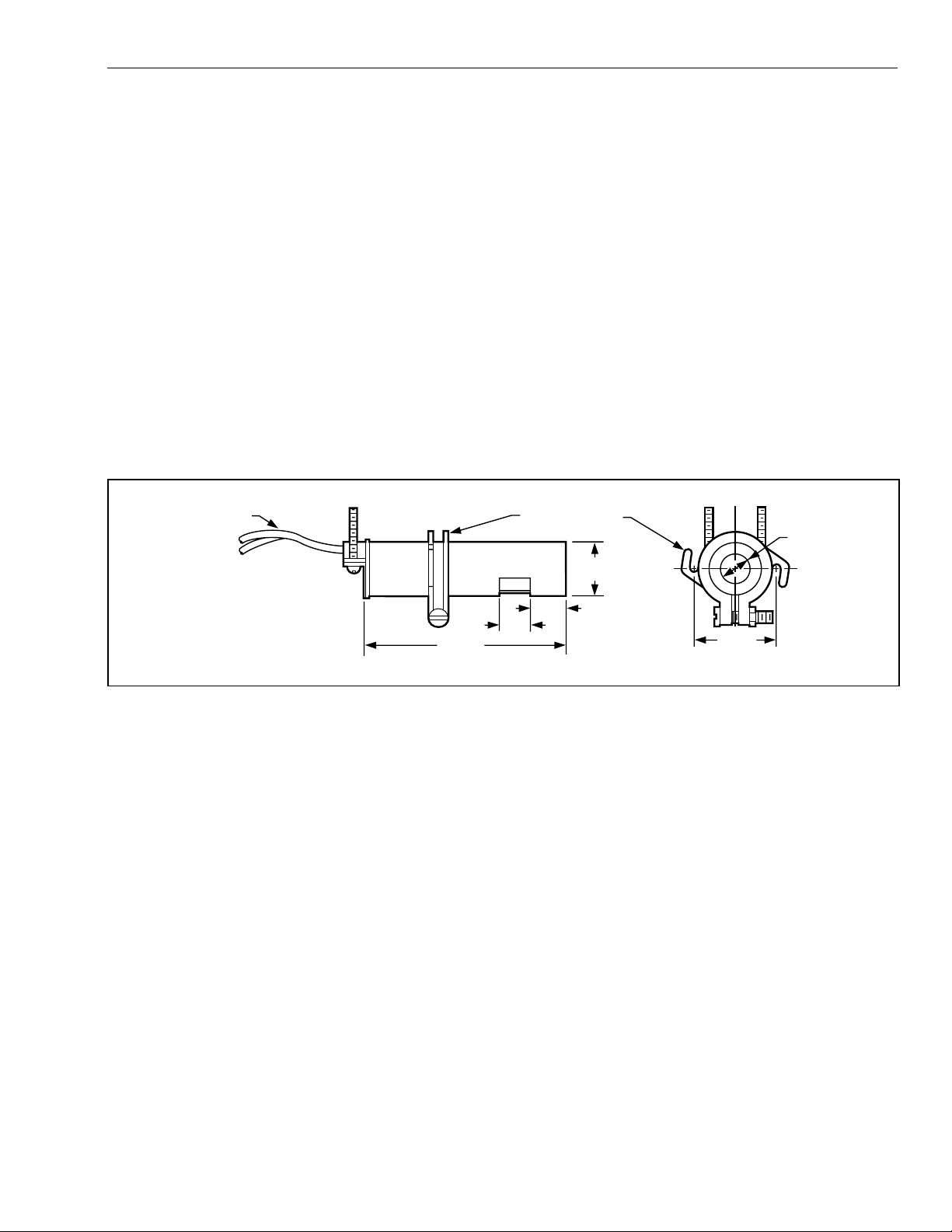

MOUNTING BRACKET

3/8

(10)

7/8

(22)

3-5/8 (92)

Fig. 3. Installation dimensions of C7044A in in. (mm).

C7044A Minipeeper® Ultraviolet Flame Detector:

Flame Detection:

side or end viewing. Side viewing is 1/8 as sensitive as end

viewing.

Mounting:

secured by two 8-32 RHIS (European M-4) screws (not

included).

Wiring Connections:

Class 1 leadwires. Rear of detector has a clamp type

connector for 1/2 in. flexible metallic conduit.

Dimensions:

Housing has two openings to permit either

Bracket (included in 4074BVK Bag Assembly),

Two 6 ft. (1.83 m) color-coded NEC

See Fig. 3.

9/16

(14)

1/2

(13)

C7044

1-27/64

(36)

M1944B

C7927A Minipeeper® Ultraviolet Flame Detector:

Ambient Operating Temperature Ratings:

C7927A1016 (U.S. Version): -40°F to +200°F (-40°C to

+93°C).

C7927A1008 (European Version): -4°F to +140°F

(-20°C to +60°C).

Storage Temperature Rating:

(-28°C to +49°C).

Maximum Pressure Rating:

Mounting:

Collar with 1/2-14 NPSM internal threads for

mounting on a 1/2 in. (13mm) sight pipe.

Wiring Connections:

Two four-foot (1.2 meter) color-coded

NEC Class 1 leadwi res . Rear of detector has a cla mp -type

connector for 1/2 in. (13mm) flexible metal conduit.

Dimensions:

See Fig. 4 and 5.

Approvals:

Underwriters Laboratories Inc. (UL): Pending.

Factory Mutual (FM): Pending.

IAS: Pending.

-20°F to +120°F

5 psi 34.5 kPa).

3 60-2026—10

Page 4

MINIPEEPER® ULTRAVIOLET FLAME DETECTORS

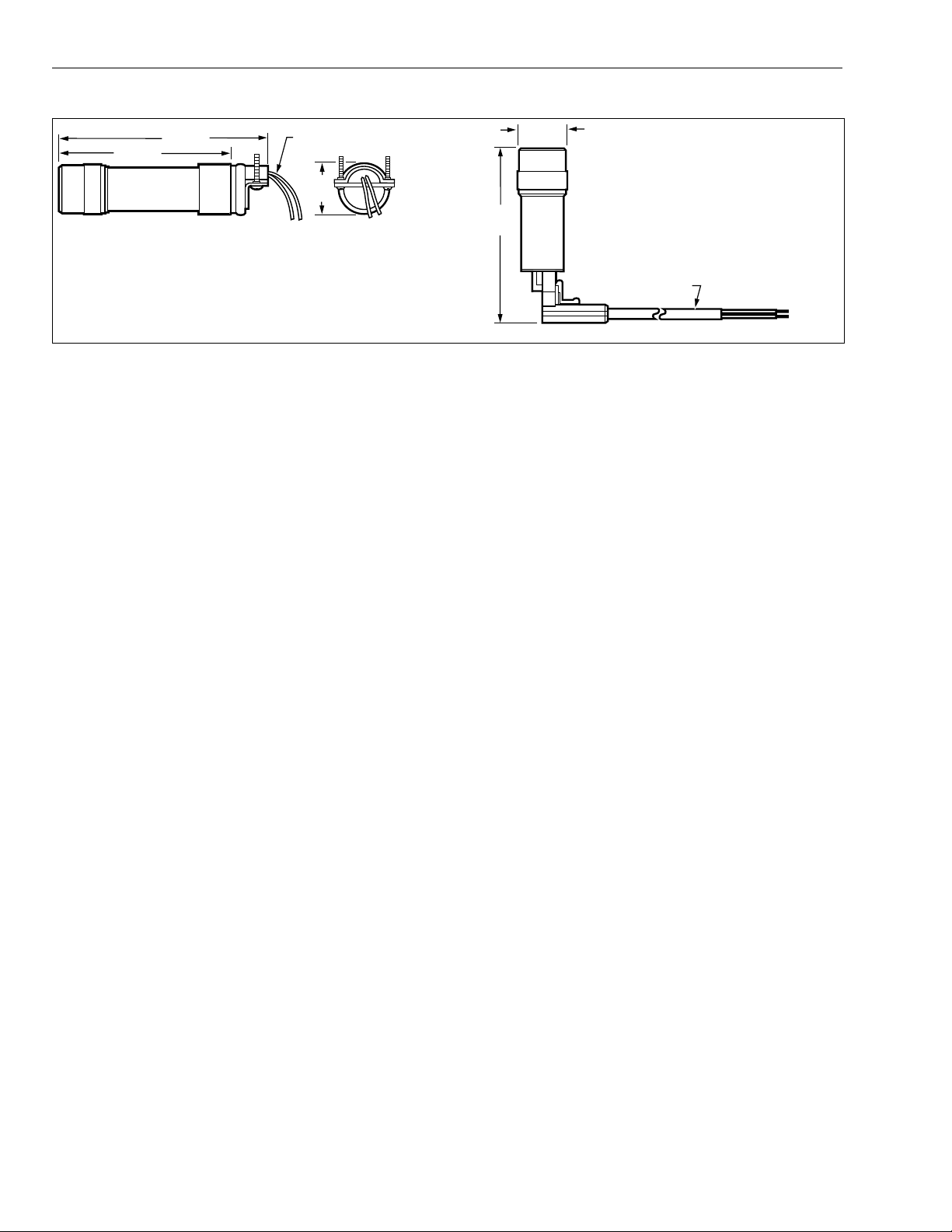

3-11/16

(94)

1 (25)

6-1/2 FT. (1.98M)

C7927A1008

3-1/4 (82)

C7927A1016

3-3/4 (95)

4 FOOT (1.2 METER)

LEADWIRES (2)

1

(25)

M17783

Fig. 4. Installation dimensions of C7927A1016 (U.S.A. version) and C7927A1008 (European version) in in. (mm).

INSTALLATION

IMPORTANT

Ultraviolet radiation sensing tubes have a life

expectancy of 40,000 ho urs of co ntinuo us use within

When Installing This Product...

1.

Read these instructio ns c aref ull y. Failure to follow them

could damage the product or cause a hazardous

condition.

2.

Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3.

Installer must be a trained, experienced, flame

safeguard co ntrol technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

Disconnect power supply before beginning installation to

prevent electrical shock and equipment damage. All wiring

must comply with applicable electrical codes, ordinances and

regulations. Use NEC Class 1 wiring.

the flame detector's specified ambient temperature

and voltage ratings. Wearout of an ultraviolet

radiation sensing tube results in failure of the UV

sensor to properly discriminate between flame

conditions.

The C7027A, C7035A and C 7044A F lame De tectors

should only be used on burners that cycle on/off

periodically or, in the absence of cycling, are

periodically checked for proper operation.

Recommended industry standards for the frequency

of sensor checks, either through cycling (employing

safe-start check methods) or periodic maintenance,

vary between once every ten seconds and once

every week, depending on the standard used and

the application needs.

M17784

60-2026—10 4

Consult the equipment manufacturer or the

governing standard for recommendations about

frequency of checks.

Controls incorporating safe-start checks, and

sensors and controls employing constant check

means are available from Honeywell. See your

Honeywell representative for specific information.

Page 5

WARNING

Explosion Hazard and Electrical Shock Hazard.

Can cause serious injury, death or property

damage.

1. The C7027A, C7035A , C7044A and C7927 Flame

Detectors must be used with Honeywell flame

safeguard controls (primaries, programmers,

multiburner systems, and burner management

systems). Using with controls not manufactured by

Honeywell could result in unsafe conditions.

2. Disconnect power supply before beginning

installation to prev en t el ec tric al shock or equipment

damage, more than one disconnect may be

involved.

3. Read the installation instructions before starting the

installation.

4. All wiring must be NEC Class 1 (line voltage).

5. The flame detector must be positioned so that it

sights the flame and does not respond to the UV

radiation emitted by sparks generated by a spark

ignitor . The Q624A Solid-State Ignite r may be useful

in difficult installations.

MINIPEEPER® ULTRAVIOLET FLAME DETECTORS

Other Radiation Sources Sensed By The UV Detector

Examples of radiation sources (other than flame) that could

actuate the detection system are:

1.

Ultraviolet Sources:

a. Hot refractory above 2800°F (1371°C).

b. Spark.

c. ignition transformers.

d. welding arcs.

e. lightning.

f. Gas lasers.

g. Sun lamps.

h. Germicidal lamps.

2.

Gamma Ray and X-ray Sources:

a. Diffraction analyzers.

b. Electron microscopes.

c. Radiographic X-ray machines.

d. High voltage vacuum switches.

e. High voltage condensers.

f. Radioscotopes.

Except under unusual circumstances, none of these sources

except hot refractory an d igni tion s park wou ld be p resent in or

near the combustion chamber.

Basic Requirements For Ultraviolet Detector Installations

All flames emit ultraviolet radiation, invisible to the human eye

but detected by the UV sensi ng tube. Th ere are tw o importan t

factors in UV detector install ati on:

The detector must have a line-of-sight view of the flame.

The detector must not be exposed to other sources of

ultraviolet radiation, the most common being ignition spark.

Other sources are listed in the next section.

Because it is necessary for the detector to actually see the

flame, it is desirable to locate the detector as close to the

flame as physical arrangement and temperature restrictions

permit.

Sighting requiremen ts for different types of flame supervision

are:

1.

Pilot flame only—Sighting must be along the axi s of th e

pilot flame. The smallest pilot flame that can be sighted

must be capable of igniting the main burner (see Pilot

Turndown Test, page 9).

2.

Main flame only—Sighting must be at the most stable

part of the flame for all firing rates.

3.

Pilot and main flame—Sighting must be at the junction

of both flames.

The detector may respond to hot refractory above 2800°F

(1371°C) if the refractory surface represents a significant

percentage of the field of view of the detector. If the

temperature of the hot refractory causes the flame relay

(in the flame safeguard cont rol ) to pul l in, re-pos iti on the si ght

pipe so the detector views a cooler area of the refractory.

Ignition spark is a source of ultrav iolet radiation. When

installing the C7027A, C7035A, C7044A or C7927 Flame

Detector , m ak e sure i t does not respond to ig nit ion s park (s ee

Ultraviolet Response Test, page 9.) If the installation is such

that response to the ignition sparks cannot be avoided, the

Q624A Solid-State Ignition Transformer may eliminate the

ignition spark response. The Q624A, when properly installed,

prevents C7027A, C7035A, C7044A and C7927 ignition

spark response by alternately activating the spark generator

and the UV sensing tube.

5 60-2026—10

Page 6

MINIPEEPER® ULTRAVIOLET FLAME DETECTORS

Mounting a C7027A, C7927 or C7035A

Locate the Sight Pipe

The location of the sight pipe is the most critical part of the

installation. A black iron pipe is recommended. Do not use a

stainless steel or galv an ize d pi pe because its internal surface

blackens with use as deposits from the combustion chamber

settle on it. Initial ly, its shiny internal surface reflect s ultraviolet

radiation, which could result in a satisfactory flame signal,

even though the pipe may be improperly located. As it

blackens, less ultraviolet radiation is reflected and the flame

signal may become marginal.

Under optimum sighting conditions, the C7027A , C7927 and

C7035A Flame Detectors can detect most common gas and

oil combustion flames at a distance of six feet. The critical

factors in determining the flam e-d ete ctor distance separation

are the optimized flame signal (current or voltage) and the

flame detector temperature. Other factors may be influential

and are associat ed wi th the specific insta lla tion. For minimum

flame signals, see Table 1 and for ambient operating

temperatures, refer to Specifications, page 2.

Use 1/2 in. pipe for a C7027 or C7927, and 1 in. pipe for a

C7035. Since no two situations are likely to be the same,

length and sighting angle of the pipe must be determined at

the time and place of installation. Generally, it is desirable to

have the sight pipe tilting downward to prevent soot or dirt

buildup.

Mounting The Sight Pipe (Fig. 6)

Thread one end of the pipe to fit the mounting collar on the

detector. Cut the pipe to the desired length (as short as

practicable), and at an angl e s o it fi ts fl us h with the w al l of the

combustion chamber. Tack-weld the pipe to the wall in a trial

position. Do not permanently weld the sight pipe in place until

after completing the Adjustments and Checkout beginning on

page 7.

NOTE: If you use a swivel mount (part no. 118367A) and

you are positive about the location and sighting

angle, you can permanently weld the pipe.

TEMPORARY

TACK WELD

FLARED HOLE

BLACK IRON

SIGHT PIPE

REFRACTORY

M3019A

Fig. 5. Mounting sight pipe.

BOILER

PLATE

If a C7027A or C7927A is to be used for a blast tube

installation, its location should be determined by the burner

manufacturer; contact the manufacturer before making any

modifications to the installation.

In locations wh ere water is usually sp ray ed on the body of th e

detector , use a C7 035A. Interna l threads in its base permi t the

use of waterproof flexible conduit for this type of application.

Prepare Hole In Wall Of Combustion Chamber

Cut a hole of the proper diameter for the sight pipe in the wall

of the combustion chamber at the selected location. Flare the

hole to leave room for sm all adjus tments of the s ighting an gle.

The taper of the hole should be about 1 in. for every 3 in.

(25 mm for every 76 mm) of wall thickness.

Sight Pipe Ventilation

It may be necessary to ventilate the sight pipe to cool the

flame detector or to clear the sight pipe of UV radiation

absorbing substances suc h as sm ok e, ex c ess ive m ois ture or,

in some instances, unburne d fuel .

For a negative pressure combustion chamber, drilling a few

holes in the sect ion of t he sight pipe outs ide of the co mbustion

chamber will allow air at atmosphe ric pressure to flow through

the sight pipe into the chamber. A perforated pipe nipple

between the sight p ipe and the detec tor can a lso be u sed (see

Fig. 7).

For a positive pressure combustion ch amber, connect a

supply of pressurized air from the burner blower through the

sight pipe into the chamber. The supply air pressure must be

greater than the chamber pressure.

60-2026—10 6

Page 7

Swivel Mount

WARNING

M3021

C7027A (OR C7035A)

FLANGE

GASKET

BLACK IRON

SIGHT PIPE

COMBUSTION

CHAMBER

WALL

ADD PIPE TEE,

PERFORATED

NIPPLE, OR OTHER

SUITABLE DEVICE

FOR VENTILATION,

IF REQUIRED.

To facilitate proper sighting of the flame, a swivel mount (part

no. 118367A) is available. The swivel mount will require a 3/4

to 1/2 in. reducer and a 1/2 in. close nipple to mount a

C7027A, or a 1 in. pipe at least 2-1/2 in. [63.5 mm] long to

mount a C7035A. For mounting details, refer to form 60-0361

for the 118367A Swivel Mount.

Mount The Detector (Fig. 7)

Mount the detector onto the sight pipe, pipe tee, nipple, or

other fitting. Make sure the flange gaske t is in place i nside the

mounting collar on the dete ctor , and then screw the collar ont o

the sight pipe or fitting.

MINIPEEPER® ULTRAVIOLET FLAME DETECTORS

NOTE: If a win dow is ins tal led between the UV detect or a nd

the flame, it must be fabricated from quartz or fused

silica. Ordinary glass filters out ultraviolet radiation.

Using a Heat Block With a C7027 (Fig. 8)

If the temperature of the si ght pipe will be come high eno ugh to

cause the C7027A to overheat (above 215°F (102°C) up to

266°F (130°C), screw a 136733 Heat Block (orde r separ ately)

onto the sight pipe before mounting the detector.

C7027A DETECTOR

4 [102]

1

[27]

1/2-14 NPSM

INTERNAL

THREADS

HIGH TEMPERATURES (ABOVE 215° F [102° C])

DO NOT USE FOR TEMPERATURES ABOVE 266° F [130°C]

136733 HEAT BLOCK

5

1 [41]

8

9

[14]

16

1

16

1/2-14 NPSM

EXTERNAL

THREADS

Fig. 6. Mounting a C7027A or C7927A on a

combustion chamber (viewed from above).

C7035A mounting is similar.

5

[16]

8

1

[32]

1/2-14 NPSM

INTERNAL

THREADS

1/2-INCH SIGHT PIPE

1

4

M1942

Fig. 7. Mounting dimensions of 136733 Heat Block in in. (mm).

Mounting a C7044A On a Blast Tube (Fig. 9)

The C7044 is designed to be mounted on the blast tube of a

burner . The exact lo cation shou ld be determined b y the burner

manufacturer. Contact the manufacturer before making any

modifications to the installation.

Explosion Hazard.

Can cause serious injury or property damage.

The C7044 will allow air leakage through its housing.

Do not locate the C7044 in an atmosphere of fuel

vapors under positive pressure. The C7027 or C7035

should be used if internal pressure sealoff is required.

7 60-2026—10

Page 8

MINIPEEPER® ULTRAVIOLET FLAME DETECTORS

8-32 RHIS

(EUROPEAN M-4)

SCREW (2)

MOUNTING

BRACKET

C7044A

DETECTOR

29/32 IN. (23.0 mm)

MOUNTING HOLE

IN BLAST TUBE

CLAMP

SCREW

WIRING (ALL MODELS—FIG. 10)

CAUTION

Equipment Damage Hazard.

Can cause improper operation.

The blue (tan with blue tracer with C7035A1080)

leadwire must be connected to the F terminal of the

flame safeguard control subbase or terminal strip and

the white (tan leadwi re without blue tracer w ith

C7035A1080) to the G terminal (see Fig. 10). Failure

to observe the circuit polarity by reversing the

leadwires (even momentarily) may cause the flame

detector to improperly supervise the combustion

flame.

1.

Disconnect power sup ply befo re beginni ng instal lation to

prevent electrical shock and equipment damage. All

wiring must comply with applicable electrical codes,

ordinances, and regulations. Use NEC Class 1 wiring.

2.

If the leadwires are not long en ough t o reach the term inal

strip or wiring subbase, make the required splices in a

junction box.

3.

If splicing is neces sary, use moisture-resistant wire

suitable for at least 167°F [75°C] if the detector is used

with a flame safeguard prim ary control, or at lea st 194°F

[90°C] if used wit h a flame safeguard programming

control.

4.

For high temperature insta llations, use Honeywell

Specification no. R1298020 or equivalent for the F

leadwire. (This wire is rated up to 400°F [204°C] for

continuous duty. It is tested for operation up to 600V

and breakdown up to 7500V.) For the other leadwires,

use moisture-resistant wire selected for a temperature

rating above the maximum operating temperature.

1-27/64 IN.

(36.1 mm)

M3020

Fig. 8. Mounting C7044A Detector on blast tube.

The C7044 is mounted in a 29/32 in. (23.0 mm) hole in the

blast tube. The mounting bracket is fastened to the blast tube

with 2 screws on 1-27/64 in. (36.1 mm) centers.

The mounting bracket is designed so that the detector can be

removed from the blast tube for cleaning and then replaced

without disturbing the sighting angle. Loosen the 2 screws

holding the bracket to the blast tube, but do not loosen the

clamp screw on the bracket. Twist both the bracket and

detector to remove them.

IMPORTANT:

Do not run the flame detector wiring in the same

conduit with high voltage ignition transformer wires.

60-2026—10 8

Page 9

MINIPEEPER® ULTRAVIOLET FLAME DETECTORS

Connecting Detectors In Parallel

For a flame that is difficult to sight, using two flame detectors

connected in parallel will reduce the occurrence of nuisance

shutdowns. If only one of the parallel detectors loses the

flame signal, the other will continue to indicate the presence

of the flame and keep the burner in operation.

When the flame detectors are connected in parallel, the low

level background signals are additive. Therefore, no more

than two C7027A, C7927A, C7035A, or C7044A Flame

Detectors should be paralleled. Furthermore, the background

signal increases as temperature decreases. Because of this,

the minimum ambient operating temperature must be

increased when the C7027A, C7927A, C7035A or C7044A

Flame Detectors are paralleled.

When using detectors rated for a minimum of 0°F (-18°C),

limit the minimum ambient temperature at the detectors to

32°F (0°C). When using detectors rated for a minimum of

-40°F (-40°C), limit the minimum ambient temperature at the

detectors to -10°F (-23°C).

Connect the blue leadw ires of both det ectors to the F termi nal

of the wiring subbase or terminal strip, and the white

leadwires of both detectors to the G terminal, as shown in

Fig. 10.

Earth Ground

The detector and the flame safeguard control must be

connected to earth ground. A convenient method of

accomplishing this is to connect the detector to the flame

safeguard control with a flexible conduit, or ensure a good

ground connection at the mounting bracket.

WIRING SUBBASE

OR

TERMINAL STRIP

M3018

UV DETECTOR

UV DETECTOR

OPTIONAL

SECOND

DETECTOR

BLUE

WHITE

BLUE

WHITE

F

G

ADJUSTMENTS AND CHECKOUT

Before welding the C7027A, C7927A or C7035A sight pipe

in its final location, or before tightening the C7044A clamp

screw, c ompl ete bot h the ad ju stmen ts and check out tes ts tha t

follow and any required by the burner manufactu r er.

Uv Sensor Tube Test

NOTE: For initial burner lightoff, consult the burner

manufacturer instructions or the instru cti ons for

the flame safeguard control.

During the initial burner lightoff, make sure the flame

safeguard control starts (i.e., the load relay, usually 1K,

pulls in). If it does not start, visually check the sensing tube in

the C7027A, C7035A, or C7044A flame detector. If the tube

continues to glow when no flame is present, replace the

sensing tube (C7035A), or replace the detector (C7027A or

C7044A).

Adjust Detector Sighting Position

With the flame detector installed and burners running, adjust

the position of the flame detector for optimum flame signal.

The flame signal will be read in microamps or voltage (Vdc)

depending on the Honeywell flame safeguard combustion

control used.

Most existing Honeyw ell fl ame sa feguar d contro ls inc orpora te

a flame current jack on the flame amplifier or on the control

itself. The flame signal c an be m easured with a v olt-ohmm eter

such as the Honeywell W136A. To measure the flame current

(signal), use a cable connector (pa rt number 19614 6, included

with the W136A) in conjunction with the meter. With the

W136A (or equivalent) positioned at the zero to 25

microampere scale, make connecti on s fr om the m eter pro bes

to the two ends of the cable connector plug (red to red, black

to black). Make these connections before inserting the plug

end of the connector plug into the flame jack of the control or

control amplifier (see Fig. 11). Read the flame signal in

microamperes directly from the W 136A meter. Refer to

Table 1 for the minimum acceptable flame currents.

Fig. 9. Wiring C7027A, C7927A, C7035A, and

C7044A flame detectors in parallel.

9 60-2026—10

Page 10

MINIPEEPER® ULTRAVIOLET FLAME DETECTORS

W136A VOLTOHMMETER

RED (+)

METER

LEAD

W136A SELECTOR

SWITCH

196146 METER

CONNECTOR

PLUG

PLUG

FLAME SIGNAL

METER JACK

PLUG-IN FLAME

SIGNAL AMPLIFIER

RED CONNECTOR

BLACK CONNECTORBLACK (–) METER LEAD

M6532A

Fig. 10. Measuring microamp flame signal.

Measure the flame signal voltage as illustrated in Figs. 12

and 13. Be careful to connect the positive meter lead to the

positive (+) amplifier jack and the negative meter lead to the

negative (-) amplifier jack (BCS 7700) or the (-Com) jack for

a 7800 SERIES control. If the BCS 7700 and Series 7800

controls have the optional Keyboard Display Module, a zero

to five Vdc reading will be displayed on the module.

Move the flame detector and sight pipe (if not permanently

attached to the burner/boiler) to view the flame from various

positions. Allow a few seconds for the meter reading to

stabilize. A maximum steady microamp or voltage reading is

desirable. The flame signal must be above the minimum

acceptable level for the flame safeguard control and

associated amplifier as indicated in Table 1.

Measure the flame signal for the pilot alone, the main burner

flame alone, and both together (unless monitoring pilot only

when using an intermittent pilot or supervising the main flame

only when using direct spark ignition). Also, measure the

flame signal at low and high firing rates and while modulating

(if applicable).

The R7749B and R7849A,B Amplifiers used with the

Honeywell BCS 7700 and 7800 SERIES controls,

respectively, have a dc voltage flame signal output.

For the R7749B Amplifie r, a volt-ohmmeter with a zero to 5 or

10 Vdc scale and a mi nimum s ensitivi ty of 20, 000 volts /ohm is

suggested.

For the R7849A,B Amplifiers used with the 7800 SERIES

controls, a volt-oh mmeter wi th a z ero to 5 or 10 Vdc scale and

a minimum sensitivity of one megohm/volt is recommended,

(see Fig. 12).

POSITIVE (+)

NEGATIVE (-)

METER LEAD

METER LEAD

ONE

MEGOHM/VOLT

METER

M7382

Fig. 11. Measuring flame signal voltage

of 7800 SERIES controls.

With the flame detector in its final position, all flame signals

must be steady with a current/voltage value as indicated in

Table 1. If the minimum signal cannot be obtained or is

unstable, refer to Troubleshooting, page 10.

Pilot Turndown Test

If the detector is used to prove a pilot flame before the main

fuel valve can be opened, perform a Pilot Turndown Test.

Follow the procedures in both the Instructions for the

appropriate flame safeguard control, and in the burner

manufacturer's instructions.

RESET

BUTTON

BCS 7700 CHASSIS MODULE FOOTMOUNT

Fig. 12. Measuring the BCS 7700 flame signal voltage.

PROGRAM

MODULE

METER

PROBES

FLAME

AMPLIFER

20,000

VOLTOHMMETER

M7860

60-2026—10 10

Page 11

Table 1. Flame Signal.

Honeywell Flame

Flame

Detector

C7027A,

C7035A,

C7044A

C7927A R7851B 7800 SERIES ——1.25 5.0

Plug-in

Amplifier

R7249A BC7000 + PM720 3.5 7.5 ——

R7749B

(AMPLICHECK™)

R7249A R4075C,D,E 3.5 7.5 ——

R7290A R4795A,D 1.5 2.25 ——

None R7023C 1.5 2.25 ——

NONE R7795A,C,E,G 1.5 2.25 ——

R7849A or

R7849B

(AMPLICHECK™)

None RA890G 1.5 2.25 ——

Safeguard

Control

BCS7700A ——2.2 4.98

R4138C,D 3.5 7.5 ——

R4140G,L,M 3.5 7.5 ——

7800 SERIES ——1.25 5.0

Minimum Acceptable

Steady Current

(microamps)

Maximum Current

Expected

(microamps)

Minimum

Acceptable

Voltage (Vdc)

Maximum

Voltage

(Vdc)

Ignition Spark Response Test

Test to be sure that ignition spark is not actuating the flame

relay (usu ally 2K) in the flame safeguard cont rol.

1.

Close the pilot and main burner manual fuel shutoff

valves.

2.

Connect the appropriate meter to the flame safeguard

control amplifier. Start the burner and run through the

ignition period. Ignition spark should occur, but the

flame relay must no t pull in. The flame signa l shou ld not

be more than 0.25 microamp.

3.

If the flame relay does pull in, repo s ition the flame

detector to increase the distance between the flame

detector and the ignition spark. If the flame detector is

not in the line of sight of the ignition spark but appears

to respond to the spark, it may be responding to

reflected spark generated UV radiation. If so, relocate

the flame detector so it does not receive the reflected

UV radiation. It may be necessary to construct a barrier

to block the UV radiation generated by the spark from

the flame detector view.

4.

Continue making the adjustments until the flame signal

due to ignition spark is less than 0.25 microamp or

1.25 Vdc.

5.

The use of the Q624 or Q652 solid-state ignition

transformer may also provid e a me tho d to el im ina t e th e

C7027A, C7035A, or C7044A flame detector response

to UV radiation generated by ignition spark. The Q624

and Q652 prevents flame detector response to ignition

spark by providing alternating periods of spark

generation and UV sensor activation. If ignition spark is

detected, try reversing the leads on the Q624 or Q652.

Response to Other Ultraviolet Sources

Some sources of artificial light produce small amounts of

ultraviolet radiation. Under certain conditions, an ultraviolet

detector will respond to them as if it is sensing a flame.

Do not use an artificial light source to check the response

of an ultraviolet detector. To check for proper flame detector

operation, test for flame failure response under all operating

conditions.

Weld The Sight Pipe (o r Tighten the C7044A Clamp Screw)

When the flame signal is acceptable after all adjustments are

made, remove the fla me detect or and weld th e sight pip e in its

final position. If you are using a swivel mount, the pipe may

already be welded. Then reinstall the flame detector.

NOTE: If using a C7044A Detector with no sight pipe,

do not remove the detector; tighten the clamp

screw securely.

Final Checkout

Before putting the burner into service, check out the

installation using the procedures in the Checkout section of

the Instructions for the appropriate flame safeguard control.

After completing the che ckou t, run the burner through at leas t

one complete cycle to verify correct operation.

11 60-2026—10

Page 12

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

TROUBLESHOOTING

WARNING

Electrical Shock Hazard.

Can cause serious injury or death.

Be extremely careful while troubleshooting the

detector; line voltage is present on some of the

terminals when power is on.

Open the master switch to disconnect power before

removing or installing the detector.

5.

Clean the inside of the sight pi pe (if one is use d) be fore

reinstalling the detector.

6.

If the flame signal continues to be too low, replace the

plug-in amplifier (if the control has one).

7.

If you still cannot obtain a proper flame signal, replace

flame detector (C7027A, C7044A) or UV radiation

sensing tube (C7035A).

IMPORTANT:

At the completion of troubleshooting, be sure to

perform the Adjustments and Chec kout beg inning on

page 8.

Inadequate Flame Signal

If a satisfactory flame signal cannot be obtained while

adjusting the sighting position of the detector, perform the

procedures indicated in steps 1 through 7. If other difficulties

are encountered in the sy stem, r efer to T ro ubles hootin g in the

Instructions for the appropriate Honeywell flame safeguard

control.

1.

Check for proper line voltage. Make sure the master

switch is closed, connections are correct, and power

supply is the correct voltage and frequency.

2.

Check the detector wiring for defects, including:

a. incorre ct connection s.

b. wiring type or size of wire.

c. deteriorated wire.

d. open circuits.

e. short circuits.

f. leakage paths caused by moisture, soot, or dirt.

3.

With the burner running, check the temperature at the

detector. When it exceeds 215°F (102°C) for a C7027,

C7927 or C7044, or 250°F (121°C) for a C7035:

a. use a heat block (part no. 136733) if using a

C7027A Flame Detector.

b. add the additional insul ation be twee n the wall of th e

combustion chamber and the detector.

c. add a shield or screen to reflect radiated heat away

from the detector, or

d. add cooling (refer to Sight Pipe Ventilation, page 6).

4.

Remove the detecto r and clean the viewing w indow with

a soft, clean cloth.

MAINTENANCE

Periodic Maintenance

1.

Clean the viewin g wind ow a nd s igh t p ipe (i f u se d) wh en

necessary. Remove the detector and use a soft, clean

cloth to remove accumulated contaminants from the

UV radiation sensor tube glass envelope.

2.

Ultraviolet sensing tubes have a life expectancy of

40,000 hours of continuous use within the ambient

temperature and voltage ratings. Replace the sensing

tube in the C7035, or replace the C7027, C7927 or

C7044 Detector, at appropriate intervals.

3.

Keep the flame detection system adjusted for the

smoothest, most reliabl e operation as recommen ded by

the burner manufacturer.

Cleaning the C7044A Detector

When necessary, clean the C7044 Flame Detector by using

the following procedure:

1.

Loosen the two screws holding the C7044 mounting

bracket to the blast tube. To remove, twist the bracket

and detector. Do not loosen the clamp screw that holds

the mounting bracket to the detect or.

2.

Clean the viewing window with a soft, clean cloth.

3.

Insert the detector into the mounting hole, and to realign

it, twist against the mounting screws. Tighten the two

mounting screws.

Home and Building Control Home and Building Control

Honeywell Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

60-2026—10 G.R. Rev. 12-00 www.honeywell.com

M1V 4Z9

Loading...

Loading...