Page 1

220738A Adapter Bracket

CAUTION

INSTALLATION INSTRUCTIONS

APPLICATION

The 220738A Adapter Bracket can be used with all

Modutrol IV motors. The adapter bracket raises the shaft

height of the Modutrol IV motors to match that of older

Honeywell Modutrol motors (e.g., M934, M975, M944,

M945 type). This is required on all valve linkage

applications, Q607 Auxiliary Switch applications, and on

some damper linkage applications (either to provide

clearance for the crank arm to rotate through the

downward position, or to allow the damper linkage to

reach the shaft).

INSTALLATION

The adapter bracket raises the shaft height of the motors

by 0.75 inch to match that of older Honeywell Modutrol

motors (e.g., M934, M975, M944, M945 type).

When Installing This Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service tech-

nician.

4. After installation is complete, check product out.

Location

You may mount the motor in any position as long as the

shaft remains horizontal. Install the Modutrol motor in any

location except where acid fumes or other deteriorating

vapors might attack the metal parts, or in atmospheres of

escaping gas or explosive vapors. Allow enough clearance

for installing accessories and servicing the motor when

selecting a location. The wiring box provides NEMA 3

weather protection (shown in Figs. 1 and 2).

Damper Linkages

Use of the 220738A Adapter Bracket packed with the

Modutrol IV motors is optional for many damper

applications. In applications requiring the crank arm to

rotate through the bottom plane of the actuator, the

adapter bracket or the new crank arm, which is shorter

than the original crank arm, must be used. If the bracket is

not used in a replacement application, the damper linkage

will have to be adjusted to the new shaft location.

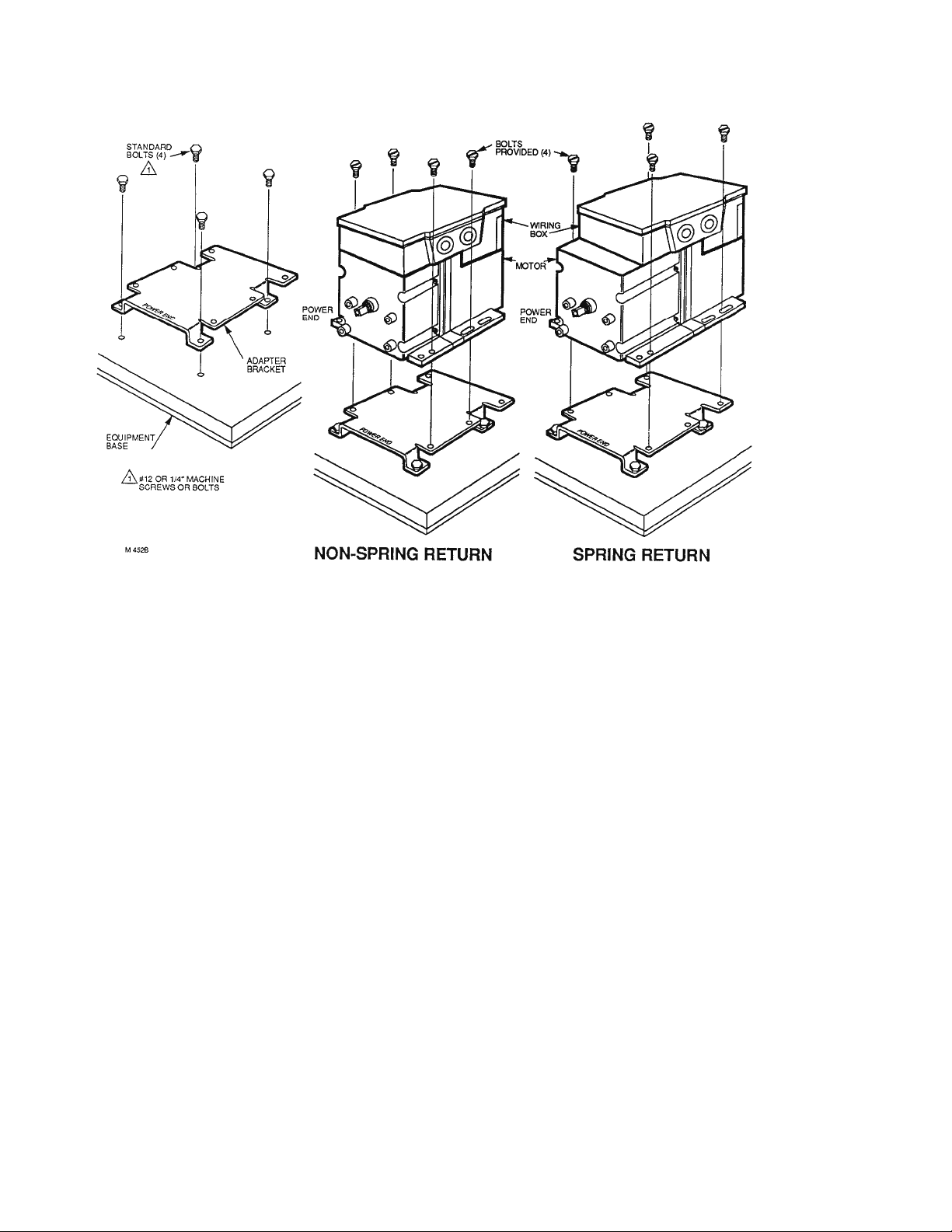

For damper linkage applications: First mount the bracket

to the equipment with existing or standard bolts. Then

mount the motor to the bracket using the bolts provided

(see Fig. 1).

Notice the difference between the configuration for

mounting of the spring return motor versus the nonspring

return motor to the adapter bracket as shown in Fig. 1.

Valve Linkages

The 220738A Adapter Bracket must be used with the

0100, 0601, 0618 linkages in all valve applications.

1. Disconnect the power supply before beginning

2. Never turn the motor shaft by hand or with a

3. Always conduct a thorough checkout when

installation to prevent electrical shock and

equipment damage.

wrench. This will damage the motor.

installation is complete.

For valve linkage applications: The bracket should first

be mounted to the valve linkage. Hand tighten screws only

until motor is secured to bracket. The bracket then

provides a convenient base on which the motor can be

positioned. After the motor shaft is aligned to the valve

linkage, it can then be attached to the bracket with the

four bolts provided (see Fig. 2).

Notice the difference between the configuration for

mounting of the spring return motor versus the nonspring

return motor to the bracket as shown in Fig. 2.

63-2216-02

Page 2

220738A ADAPTER BRACKET

Fig. 1. Damper Application. First mount adapter bracket to equipment, then mount motor to bracket using bolts

provided.

CHECKOUT

For detailed instructions on the assembly of specific

linkages, refer to the instruction sheet packed with each

linkage. In general, however, check the following points of

operation when installing a motor and linkage:

1. Linkages for valves and louver type dampers should

be adjusted so that the damper or valve moves

through only the maximum required distance when

the motor moves through its full stroke.

2. With modulating control, maximum damper opening

should be no more than 60°. Little additional airflow

is provided beyond this point.

3. The motor must be stopped at the end of its stroke

by the limit switch and must not be stalled by the

damper or valve. The motor will be damaged if it is

not permitted to complete its full stroke.

4. Do not exceed the motor ratings in any installation.

5. Do not turn motor shaft manually or with a wrench.

This will damage the motor.

63-2216—02 2

Page 3

220738A ADAPTER BRACKET

Fig. 2. Valve Linkage Application. First mount adapter bracket to the linkage, then mount motor to bracket using

bolts provided.

3 63-2216—02

Page 4

220738A ADAPTER BRACKET

Honeywell Building Technologies

In the U.S.:

Honeywell

715 Peachtree Street NE

Atlanta, GA 30308

customer.honeywell.com

buildingcontrols.honeywell.com

® U.S. Registered Trademark

©2021 Honeywell International Inc.

63-2216—02 M.S. Rev. 01-21

Printed in United States

Loading...

Loading...