Page 1

Internal Auxiliary Switches

220736A,B Internal Auxiliary Switch kits can

be installed in TRADELINE models of Modutrol

IV Motors to control auxiliary equipment as a

function of motor shaft position.

220736A,B

■ The 220736A includes one Spdt Micro Switch V3

precision switch.

■ The 220736B includes two Spdt Micro Switch V3

precision switches.

■ Either kit can be installed in any Tradeline

Modutrol IV Motor.

■ Kits provide switch mounting bracket for easy

installation internal to motor.

■ The auxiliary switches are actuated by adjustable

cams inside the motor. These cams can be set to

actuate the switches at any angle within the stroke

of the motor. Only Modutrol IV TRADELINE

models are equipped with the cam assemblies for

actuating field-addable auxiliary switches. Switch

adjustment procedures are the same as that for

switches that come factory installed in Modutrol

IV Motor models.

■ Switch differentials of 1° or 10° can be selected.

■ Leadwires color coded to ease correct wiring of

auxiliary equipment.

CONTENTS

Specifications ................................................2

Ordering Information.................................... 2

Installation .................................................... 2

Setting and Adjustments ................................6

Checkout......................................................11

S.M. • Rev. 8-91 • ©Honeywell Inc. 1991 • Form Number 63-2228—2

Page 2

220736A,B

SPECIFICATIONS • INSTALLATION • ORDERING INFORMATION

Specifications

MODELS: 220736A,B Internal Auxiliary Switches for

TRADELINE Modutrol IV Motors. Switches are actuated by cams in the motor. The cams can be set to

operate the switches at any point in the motor stroke.

220736A—Includes one Spdt Micro Switch V3

snap acting switch, mounted on left side and

operated by outer cam.

220736B—Includes two Spdt Micro Switch V3

snap acting switches.

SWITCH DIFFERENTIAL (difference between switch

make and break points): Approximately 1 or 10 degrees, determined by cam setting.

CAUTION

!

Disconnect power supply before beginning installation to prevent electrical shock or equipment damage.

NOTE: The wire colors of the 220736A,B auxiliary

switches are different from those of factory installed

auxiliary switches. See Tables 1-3 and Fig. 2.

1. When replacing a Modutrol motor determine origi-

MOUNTING: Switches factory-installed on bracket

designed for mounting inside motor.

WIRING: Color-coded, 15 in. [381 mm] leadwires.

ELECTRICAL RATINGS:

One Contact

Full Load 7.2 3.6

Locked Rotor 43.2 21.6

a

40 VA pilot duty, 120/240 Vac on opposite contact.

a

120 V 240 V

Installation

nal motor model number and refer to Tables 1-3.

2. From the appropriate table, determine switch

leadwire color coding and configuration (N.O. and N.C.

contacts).

3. For wiring convenience, make note of the difference

between the replaced motor and field addable switch color

coding.

4. Disconnect and remove the motor to be replaced.

5. Remove the cover from the wiring box of the

TRADELINE Modutrol IV motor.

6. Check motor for proper stroke setting. Adjust stroke

as needed. Refer to motor specification sheet.

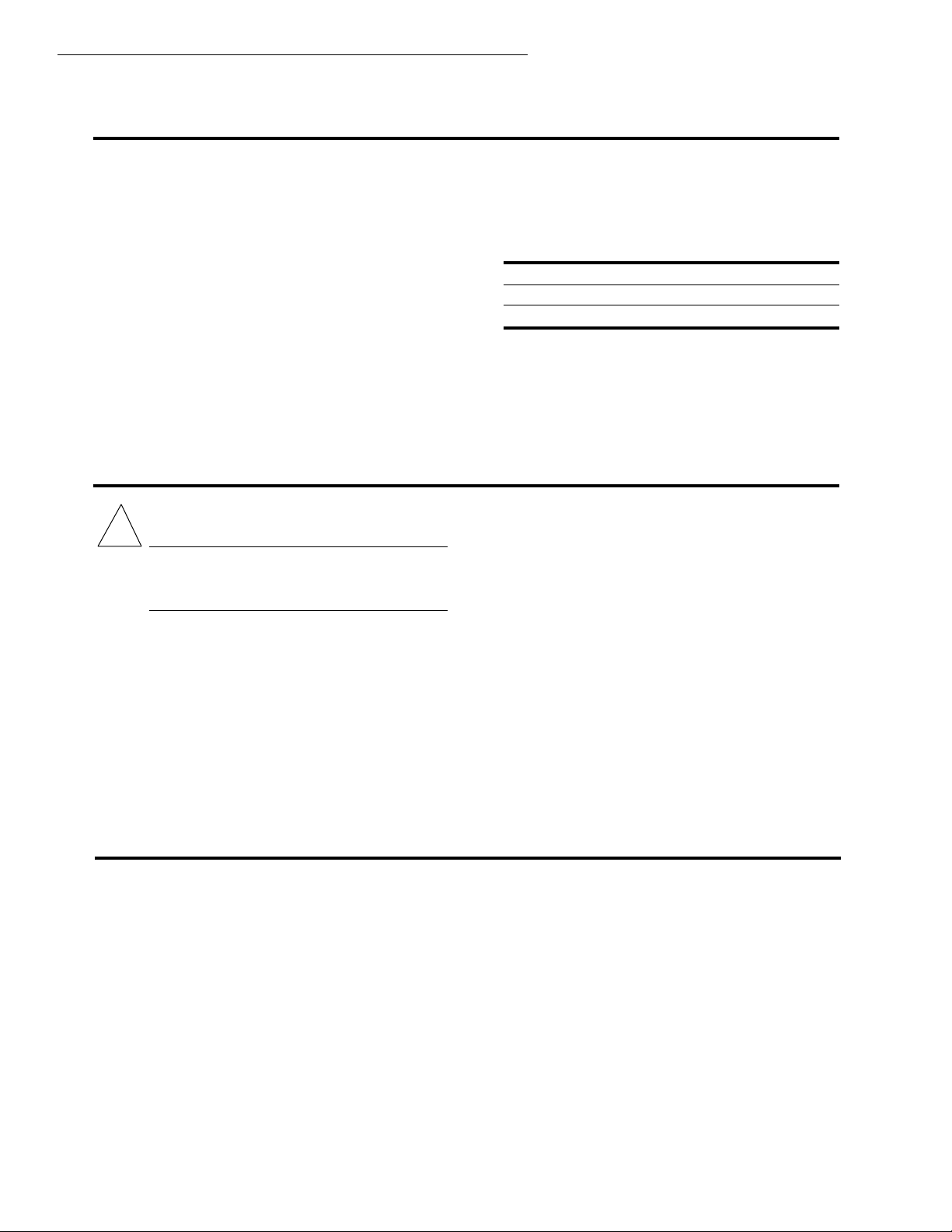

7. Position the switch assembly above the motor as

shown in Fig. 1.

Ordering Information

When purchasing replacement and modernization products from your TRADELINE wholesaler or your distributor, refer to the

TRADELINE catalog or price sheets for complete ordering number, or specify—

1. Order number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Residential and Building Controls Division Sales Office. (Check white pages of your phone di-

rectory.)

2. Residential and Building Controls Division Customer Satisfaction

Honeywell Inc. 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 542-7500

In Canada—Honeywell Limited/Honeywell Limitee, 740 Ellesmere Drive, Scarborough, Ontario M1P 2V9. International Sales and

Service Offices in all principal cities of the world.

International Sales Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan,

Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

2

Page 3

8. Lower the switch assembly into place and tighten

the two mounting screws, making sure the switch followers are properly aligned with the inner and outer cams in

the motor. The 220736A includes only the switch for the

outer cam.

9. Run all switch leadwires through slots to line voltage section (at auxiliary end of motor), where connections

to auxiliary equipment should be made with solderless

connectors.

Fig. 1—Position of auxiliary switch(es) in motor.

CAUTION

!

The auxiliary switches in the Series 91 low and

medium torque TRADELINE Modutrol IV Motors operate opposite to those in the Modutrol

motors listed in Tables 1 and 2, page 4. When

wiring the switches, connect the new switches to

the controlled equipment as shown in the appropriate table.

220736A,B

INSTALLATION

VOLTAGE BARRIER

TRANSFORMER

(CAN BE FIELD - ADDED)

MODUTROL IV WIRING BOX

OUTER CAM

SLOTS (ROUTING SWITCH LEADWIRES

TO LINE VOLTAGE SECTION)

LINE VOLTAGE SECTION

INNER CAM

INTERNAL

AUXILIARY

SWITCH KIT

POWER

END

M 455D

RIGHT

SWITCH

FOLLOWER

LEFT

SWITCH

FOLLOWER

3 63-2228—2

Page 4

220736A,B

INSTALLATION

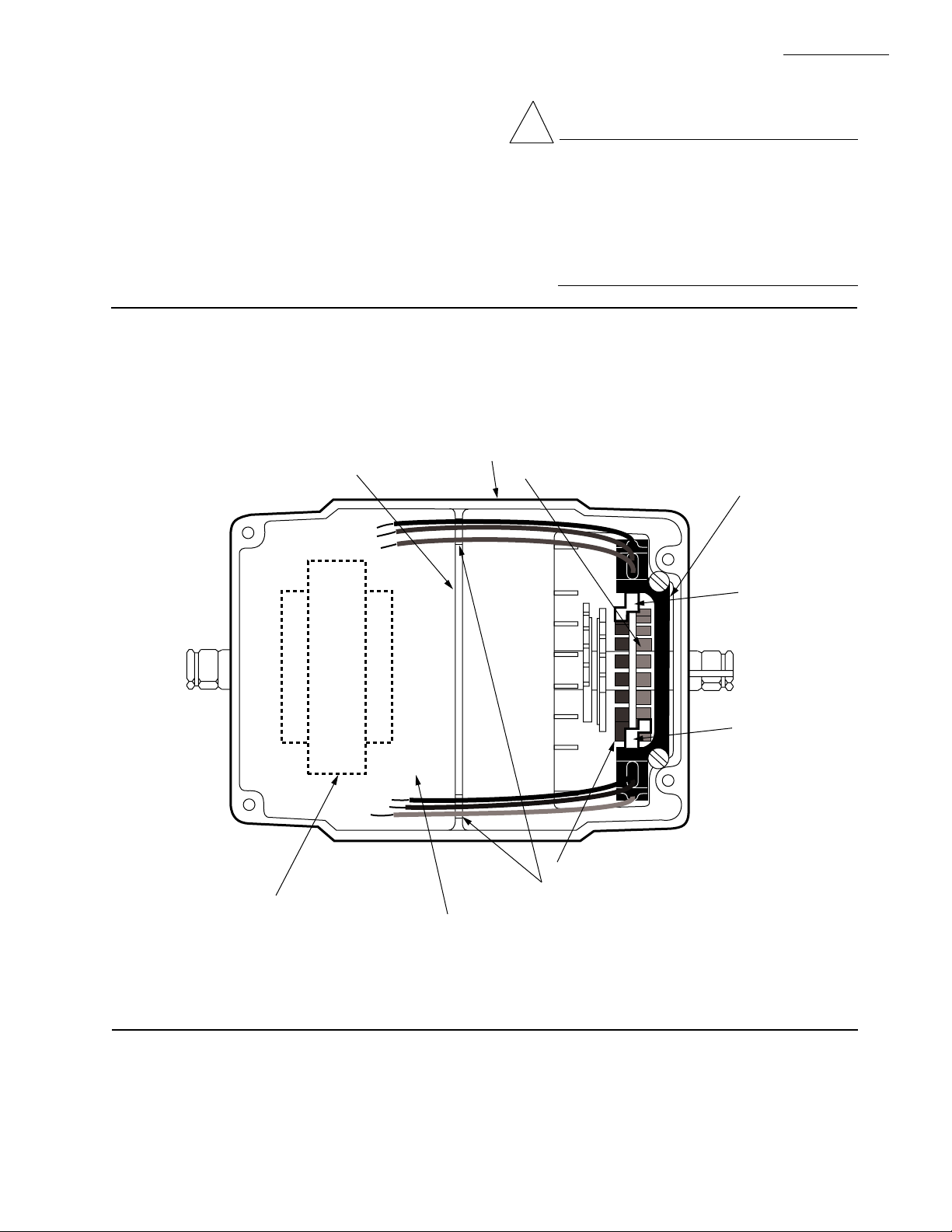

TABLE 1—AUXILIARY SWITCH LEADWIRE COLORS FOR LOW AND MEDIUM TORQUE SERIES 91 MOTORS WITH

ONE AUXILIARY SWITCH.

Replace with

Factory-Installed Auxiliary Switch Leadwire Color

a,b

220736A,B

Leadwire

Left

Auxiliary

Switch

N.O. Yellow W/Yellow Orange

N.C. Blue W/Blue Purple

Com. Red W/Red Red

Right

Auxiliary

Switch

N.O. B/Yellow B/Yellow B/Orange

N.C. B/Blue B/Yellow B/Purple

Com. B/Red B/Red B/Red B/Red

Motor M9171B1012 M734D1053 M7161B M9171B1004 M9172W M9164D1009

M9171B1020 M9164B M7164B M9174B1001 M9175W M9174D1007

M9174B1019 M934A1565 M734J1072 M9174B1043 M975B1021 M9175D1014

M9174B1027 M934A1433 M934D1000 M975B1039 Motors with

M9174B1035 220736A,B

M934D1026 Auxiliary

M934D1059 Switch Kit

a

Wiring should be NEC Class 1 unless power supply meets Class 2 requirements. Tape unused leads. Make certain the current draw

of the external circuit is less than contact rating of switch.

b

W/color= white wire with colored tracer.

B/color=black wire with colored tracer.

color = solid color wire.

TABLE 2—AUXILIARY SWITCH LEADWIRE COLORS FOR LOW AND MEDIUM TORQUE SERIES 91 MOTORS WITH

TWO AUXILIARY SWITCHES.

Replace with

Factory-Installed Auxiliary Switch Leadwire Color

a,b

220736A,B

Leadwire

Left

Auxiliary

Switch

N.O. Yellow W/Blue W/Yellow W/Yellow Orange

N.C. Blue W/Blue Purple

Com. Red W/Red W/Red W/Red Red

Right

Auxiliary

Switch

N.O. B/Blue B/Yellow B/Yellow B/Orange

N.C. B/Yellow B/Yellow B/Blue B/Purple

Com. B/Red B/Red B/Red B/Red B/Red

Motor M9171C M9174C1009 M9161C M9175Y M9164D1009

M9174C1017 M9174C1033 M9164C M975B1047 M9174D1007

M9174C1025 M934D1018 M9172C M975B1062 M9175D1014

M9174C1041 M934A1243 Motors with

M934D1034 M934A1250 220736A,B

M934D1042 M934A1268 Auxiliary

M934A1276 Switch Kit

M934A1292

M934A1318

M965B1030

a

Wiring should be NEC Class 1 unless power supply meets Class 2 requirements. Tape unused leads. Make certain the current draw

of the external circuit is less than contact rating of switch.

b

W/color= white wire with colored tracer.

B/color=black wire with colored tracer.

color = solid color wire.

4

Page 5

220736A,B

INSTALLATION

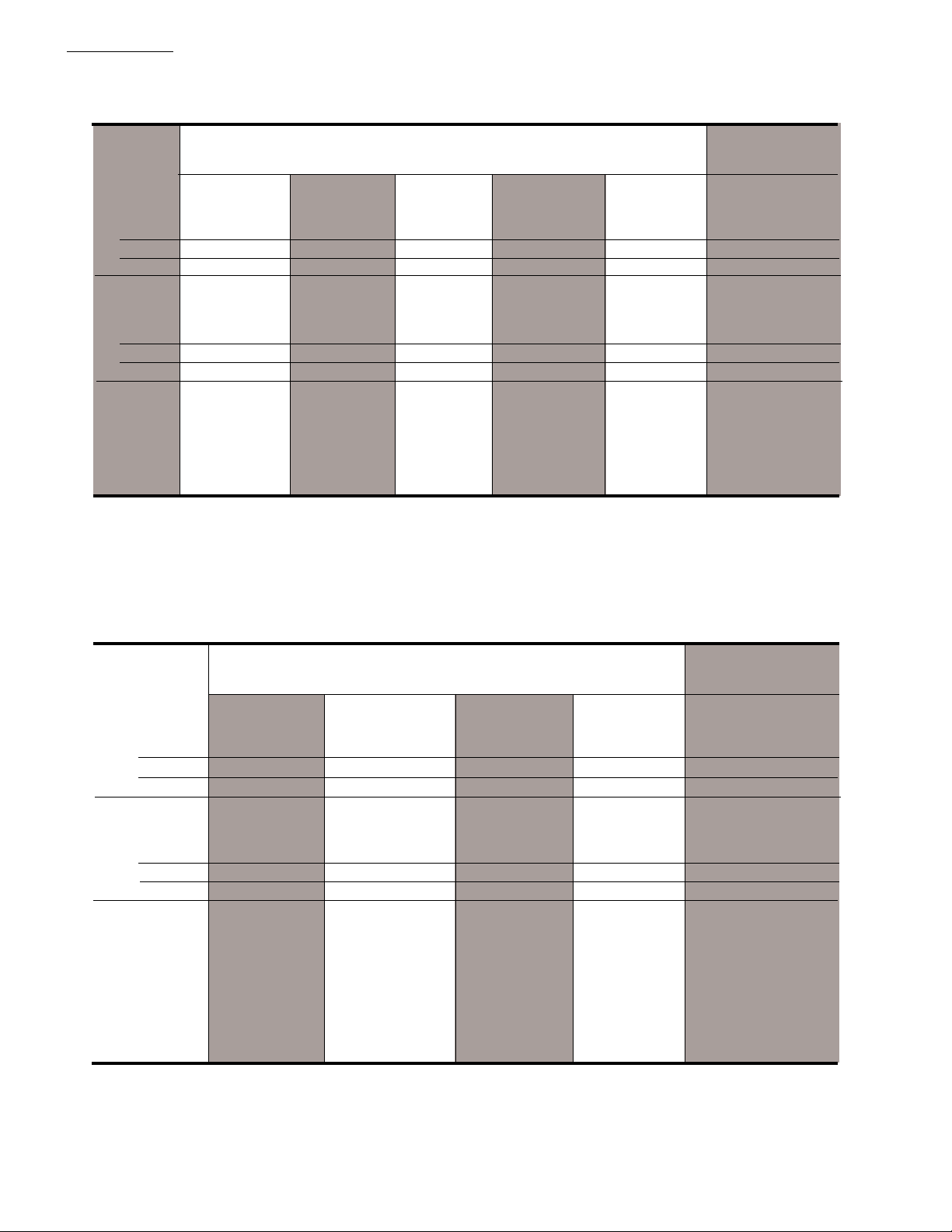

TABLE 3—AUXILIARY SWITCH LEADWIRE COLORS FOR ALL MOTOR SERIES EXCEPT LOW AND

MEDIUM TORQUE SERIES 91 (See Tables 1 and 2 ).

Replace with

220736A,B

Leadwire

Factory-Installed Auxiliary Switch Leadwire Color

a,b

Left N.O. Blue Blue W/Yellow Purple

Auxiliary N.C. Yellow Yellow W/Blue Orange

Switch Com. Red Red W/Red Red

Right N.O. B/Blue B/Yellow B/Purple

Auxiliary N.C. B/Yellow B/Orange

Switch Com. B/Red B/Red B/Red

Motor M445A M4182B M644D M6181F M9182W M8175B M6184D1035

M644E M4185B M744T M6182F M865B M6194D1017

M644L M4185E M744Y M6184F M6284D1000

M845A M4186H M745T M6194F M6285A1005

M845E M4186L M745Y M6281F M6285A1013

M941C M6161B M941D M6284C M6294D1008

M944B M6184B M944D M6284F M8185D1006

M944C M6191B M944E M6285C M9184D1013

M944G M6194B M944S M7281C M9184D1021

M944H M6194E M945C M7281Q M9185D1004

M954C M6282B M945D M7284C M9194D1003

M955C M6282E M954B M7284Q Motors with

M955E M6284B M954D M7285C 220736A,B

M6285B M955F M7285Q Auxiliary

M6294B M9181C Switch Kit

M8182B M9182C

M8185B M9184C

M9181B M9184F

M9184B M9185C

M9184E M9481F

M9185B M9484F

M9185E

M9194E

M9481E

M9484E

a

Wiring should be NEC Class 1 unless power supply meets Class 2 requirements. Tape unused leads. Make certain the

current draw of the external circuit is less than contact rating of switch.

b

W/color = white wire with colored tracer.

B/color = black wire with colored tracer.

color = solid color wire.

WIRING

Disconnect all power supplies to de-energize auxiliary

switch before servicing.

All wiring must comply with local codes and ordi-

nances. Do not exceed switch ratings of auxiliary switches.

Fig. 2—Auxiliary Switch Wiring Diagram.

LEFT SWITCH

(OUTER CAM)

PURPLE

RED

ORANGE

2

Wiring should be NEC Class 1 unless power supply meets

1

Class 2 requirements. Tape unused leads. Make certain

the current draw of the external circuit is less than contact

rating of switch.

2

Switch leads on 220736A single-switch kit same as left

switch above.

Colors are tracers on black background.

3

1

RIGHT SWITCH

(INNER CAM)

1

PURPLE/BLACK

RED/BLACK

ORANGE/BLACK

3

M418C

5 63-2228—2

Page 6

220736A,B

SETTINGS AND ADJUSTMENTS

AUXILIARY SWITCHES

The auxiliary switches are spdt switches that are actu-

ated by adjustable cams. The cams are factory mounted on

the motor shaft at the power end of the motor. The settings

of the cams determine the point in motor shaft rotation at

which the auxiliary equipment will be switched on or off.

These cams can be set to actuate the switches at any angle

within the stroke of the motor. All TRADELINE motors

include auxiliary switch cams which permit installation of

this auxiliary switch kit (220736A, 220736B).

NOTE: When the slow-rise portion of the cam is used, the

switching differential is approximately 10° of rotation.

When the fast-rise portion of the cam is used, the switch

differential is approximately 1° of rotation. Do not use

the fast rise portion of the cam if fast cycling of

auxiliary equipment is undesirable.

AUXILIARY SWITCH ADJUSTMENT

PROCEDURE

WARNING

!

FIRE OR EXPLOSION HAZARD

CAN CAUSE SEVERE INJURY OR DEATH

When auxiliary switches control combustion

equipment, incorrect wiring of the switches can

allow the burner to come on at high fire. Check

auxiliary switch wiring and cam adjustment before turning on the system. Watch the controlled

equipment through one complete cycle. Shut the

system down immediately if switches do not

correctly sequence the equipment .

Setting and Adjustments

CAUTION

!

1. Live circuits are exposed during auxiliary

switch adjustment procedure. Always turn off

power before adjusting switch cams.

2. Do not turn motor shaft by hand or with

wrench as damage to the motor can result.

NOTE:The following instructions are for normally closed

motors (motor shaft rotates clockwise, as viewed from

the power end of the motor, on an increase in signal).

Exact adjustment procedures vary for different

TRADELINE motor models. Find your model on the

following list. Then proceed to the correct section for that

model.

Motor Model Section

M8185 A

M9164, M9174, M9175 B

M9184, M9185, M9194 C

M6284, M6294 D

M6285 E

M6184, M6194 F

Additional instructions may also be found in the Auxiliary Switch Adjustment section in the specification sheet

included with the Modutrol IV Motor.

Review Table 4 and Fig. 3 before adjusting cams. Table

4 applies to both the left and right switches.

TABLE 4—AUXILIARY SWITCH POSITION WITH MOTOR SHAFT ROTATED TO EITHER SIDE OF

AUXILIARY SWITCH OPERATING POINT, AS VIEWED FROM POWER END.

Auxiliary Switch Contact Positions

N.O. Contact

(Red and Purple Leads) (Red and Orange Leads)

Shaft Shaft Shaft Shaft

Rotated Rotated Rotated Rotated

ccw of cw of ccw of cw of

Switch Switch Switch Switch

Motor Cam Switch Operating Operating Operating Operating

Type Arrangement Differential Point Point Point Point

TRADELINE, Red inner 1° Closed Open Open Closed

low and cam, blue

medium outer cam 10° Open Closed Closed Open

torque, series 91

All other Blue inner 1° Open Closed Closed Open

TRADELINE cam, red

motors outer cam 10° Closed Open Open Closed

a

cw = clockwise

ccw = counterclockwise

6

a

N.C. Contact

a

Page 7

220736A,B

SETTINGS AND ADJUSTMENTS

To turn the cams, insert small screwdriver (1/8" or

3 mm blade) through wiring box into slot on cam and move

the screwdriver at the top. Refer to Fig. 3. Each division on

the cam represents 15° of motor rotation.

A) Two position motors (M8185):

1. Turn off power and remove cover of wiring box.

2. Determine amount of shaft rotation, in degrees,

desired before switch is energized.

3. Note the position of the cam slots and, with screw-

driver, rotate the cam to the desired position for switch

Fig.. 3—Auxiliary switch adjustment.

M9164D1009, M9174D1007 AND M9175D1014

MOVE SCREWDRIVER AT TOP ONLY TO ADJUST CAM.

1/8 IN. STRAIGHT-BLADE

SCREWDRIVER

SLOW RISE

PORTION

(APPROX.

10° DIFF.)

INNER

AUXILIARY

CAM

(RED)

SWITCH

FOLLOWER

RIGHT/INNER

AUXILIARY

SWITCH

FAST RISE

PORTION

(APPROX.

1° DIFF.)

action. Each division on the cam represents 15° of motor

rotation. Therefore, if 60° of motor rotation is desired

before switch operates, rotate the cam 4 divisions from the

reference point.

4. Connect auxiliary equipment to auxiliary switch

leads. See Wiring section.

5. Turn on power and check for proper switch differential and switching of auxiliary equipment by driving the

motor through full stroke (in both directions). If necessary

repeat steps 3 and 5 until correct switching action is

obtained.

6. Replace cover of wiring box.

ALL OTHER TRADELINE MOTORS

MOVE SCREWDRIVER AT TOP ONLY TO ADJUST CAM.

1/8 IN. STRAIGHT-BLADE

SCREWDRIVER

SLOW RISE

PORTION

(APPROX.

10° DIFF.)

INNER

AUXILIARY

CAM

(BLUE)

SWITCH

FOLLOWER

RIGHT/INNER

AUXILIARY

SWITCH

FAST RISE

PORTION

(APPROX.

1° DIFF.)

LEFT/OUTER

AUXILIARY

SWITCH

FAST RISE

PORTION

(APPROX.

1° DIFF.)

SWITCH

FOLLOWER

MOTOR

OPEN

ONE

DIVISION

(15°)

OUTER

AUXILIARY

CAM

(BLUE)

POWER END

SLOW RISE

PORTION

(APPROX.

10° DIFF.)

MOTOR

CLOSE

NOTE: Cams shown separately to provide better view of inner cam.

LEFT/OUTER

AUXILIARY

SWITCH

SWITCH

FOLLOWER

FAST RISE

PORTION

(APPROX.

1° DIFF.)

MOTOR

OPEN

NOTE: Cams shown separately to provide better view of inner cam.

ONE

DIVISION

(15°)

OUTER

AUXILIARY

CAM

(RED)

POWER END

MOTOR

CLOSE

SLOW RISE

PORTION

(APPROX.

10° DIFF.)

M 875

7 63-2228—2

Page 8

220736A,B

SETTINGS AND ADJUSTMENTS

Fig. 4—Auxiliary switch adjustment for low and

medium torque, Series 91 motors.

2

L2

1

L1

(HOT)

Q209/S963 135-OHM

POTENTIOMETER

W

B

R

T1 T2

LEFT/OUTER

AUXILIARY

SWITCH

1

Power supply. Provide disconnect means and

overload protection as required.

2

Transformer may be external or internal.

3

Cam arrangement varies as shown in table.

MOTOR MODEL

M9164D1009, M9164D1007,

M9175D1014

ALL OTHER TRADELINE

MOTORS

BW

INNER AUXILIARY CAM

OUTER AUXILIARY CAM

INNER CAM

Red

Blue

R

STROKE ADJUST

CAM (BROWN)

RIGHT/INNER

AUXILIARY

SWITCH

3

3

OUTER CAM

Blue

Red

M 851

B) Low and Medium Torque, Series 91 Modulating

(Proportional) Motors (M9164, M9174, M9175):

1. Turn off power and remove cover of wiring box.

2. Disconnect controller from motor.

3. Connect 135 ohm potentiometer to terminals R,W,

and B as shown in Fig. 4. Restore power.

4. Adjust potentiometer to drive motor to the position

where auxiliary equipment is to be switched.

5. For switch differential of 1°, check continuity of

auxiliary switch N.O. (Red to Purple) contacts and, with

screwdriver, rotate cam as follows:

a. If contacts are open, rotate cam counterclockwise

until N.O. (Red to Purple) contacts close.

b. If contacts are closed, rotate cam clockwise until

N.O. (Red to Purple) contacts open.

6. For switch differential of 10°, the cams must be

rotated with screwdriver approximately 180° prior to

setting switching action. Refer to Fig. 3. Check continuity

of the N.O. (Red to Purple) contacts and, with screwdriver,

rotate cam as follows:

a. If contacts are open, rotate cam clockwise until

N.O. (Red to Purple) contacts close.

b. If contacts are closed, rotate cam counterclock-

wise until N.O. (Red to Purple) contacts open.

Fig. 5—Auxiliary switch adjustment for high

and extra high torque Series 91 motors.

2

L2

1

L1

(HOT)

Q209/S963 135-OHM

POTENTIOMETER

W

B

R

T1 T2

LEFT/OUTER

AUXILIARY

SWITCH

1

2

POWER END

OF MOTOR

Power supply. Provide disconnect means and

overload protection as required.

Transformer may be external or internal.

BW

INNER AUXILIARY CAM (BLUE)

OUTER AUXILIARY CAM (RED)

R

STROKE ADJUST

CAMS (YELLOW)

RIGHT/INNER

AUXILIARY

SWITCH

M 852

7. Check for proper switch differential and switching

of auxiliary equipment by driving the motor through full

stroke (in both directions) using the potentiometer. If

necessary repeat steps 5 and 7 for 1° differential, or 6 and

7 for 10° differential until correct switching action is

obtained.

8. Turn off power and disconnect potentiometer.

9. Connect auxiliary equipment to auxiliary switch

leads. See Wiring section.

10. Reconnect controller and power supply to motor.

11. Replace cover of wiring box. Turn on power.

C) High and Extra High Torque, Series 91 Modulating (Proportional) Motors (M9184, M9185, M9194):

1. Turn off power and remove cover of wiring box.

2. Disconnect controller from motor.

3. Connect 135 ohm potentiometer to terminals R,W,

and B as shown in Fig. 5. Restore power.

4. Adjust potentiometer to drive motor to the position

where auxiliary equipment is to be switched.

5. For switch differential of 1°, check continuity of

auxiliary switch N.O. (Red to Purple) contacts and, with

screwdriver, rotate cam as follows:

a. If contacts are open, rotate cam clockwise until

N.O. (Red to Purple) contacts close.

b. If contacts are closed, rotate cam counterclock-

wise until N.O. (Red to Purple) contacts open.

6. For switch differential of 10°, the cams must be

rotated with screwdriver approximately 180° prior to

setting switching action. Refer to Fig. 3. Check continuity

of the N.O. (Red to Purple) contacts and, with screwdriver,

rotate cam as follows:

8

Page 9

Fig. 6—Auxiliary switch adjustment for M6284,

M6294 motors

24 Vac

1

32TYG1

4R

STROKE ADJUST

CAMS (YELLOW)

RIGHT

AUXILIARY

SWITCH

LEFT

AUXILIARY

SWITCH

1 Connect 24Vac to terminals 2 and 3 to drive motor open.

Connect 24Vac to terminals 3 and 1 to drive motor closed.

POWER END

OF MOTOR

INNER AUXILIARY CAM (BLUE)

OUTER AUXILIARY CAM (RED)

M 853

a. If contacts are open, rotate cam counterclock-

wise until N.O. (Red to Purple) contacts close.

b. If contacts are closed, rotate cam clockwise until

N.O. (Red to Purple) contacts open.

7. Check for proper switch differential and switching of auxiliary equipment by driving the motor through

full stroke (in both directions) using the potentiometer. If

necessary repeat steps 5 and 7 for 1° differential, or 6 and

7 for 10° differential until correct switching action is

obtained.

8. Turn off power and disconnect potentiometer.

9. Connect auxiliary equipment to auxiliary switch

leads. See Wiring section.

10. Reconnect controller and power supply to motor.

11. Replace cover of wiring box. Turn on power.

D) Series 62 Floating Control with Feedback

Non-Spring Return Motors (M6284, M6294):

1. Turn off power and remove cover of wiring box.

2. Disconnect controller from motor.

3. Connect 24 Vac power through switches or directly

to quick-connect terminals to drive motor to position

where auxiliary equipment is to be switched. Refer to

Fig. 6. Turn on power. Connecting power to terminals

2 and 3 will drive motor in the open direction, connecting

power to terminals 3 and 1 will drive the motor in the

closed direction. To stop the motor at desired position,

remove power from motor. Motor will remain at this

position until power is restored.

4. For switch differential of 1°, check continuity of

auxiliary switch N.O. (Red to Purple) contacts and, with

screwdriver, rotate cam as follows:

a. If contacts are open, rotate cam clockwise until

N.O. (Red to Purple) contacts close.

b. If contacts are closed, rotate cam counterclock-

wise until N.O. (Red to Purple) contacts open.

220736A,B

SETTINGS AND ADJUSTMENTS

5. For switch differential of 10°, the cams must be

rotated with screwdriver approximately 180° prior to

setting the switching action. Refer to Fig. 3. Check

continuity of the N.O. (Red to Purple) contacts and rotate

cams as follows:

a. If contacts are open, rotate cam counterclock-

wise until N.O. (Red to Purple) contacts close.

b. If contacts are closed, rotate cam clockwise until

N.O. (Red to Purple) contacts open.

6. Check for proper switch differential and switching

of auxiliary equipment by driving the motor through full

stroke (in both directions). If necessary repeat steps

4 and 6 for 1° differential, or 5 and 6 for 10° differential

until correct switching action is obtained.

7. Disconnect power from switches or quick-connect

terminals.

8. Connect auxiliary equipment to auxiliary switch

leads. See Wiring section.

9. Reconnect controller and power supply to motor.

10. Replace cover of wiring box.

Fig. 7—Auxiliary switch adjustment for M6285

motors.

2

L2

1

L1

(HOT)

3

34 T2

LEFT/OUTER

AUXILIARY

SWITCH

1

Power supply. Provide disconnect means and

overload protection as required.

2

Transformer may be external or internal mount.

3

Connect terminal 4 to terminal 2 to drive motor open.

Connect terminal 4 to terminal 1 to drive motor closed.

1

POWER END

OF MOTOR

G

Y

STROKE ADJUST

CAM (BROWN)

RIGHT/INNER

AUXILIARY

SWITCH

INNER AUXILIARY CAM (BLUE)

OUTER AUXILIARY CAM (RED)

M 854

E) Series 62 Floating Control with Feedback Spring

Return Motors (M6285):

1. Turn off power and remove cover of wiring box.

2. Disconnect controller from motor.

3. Connect 24 Vac power and switches to drive motor

to position where auxiliary equipment is to be switched.

Refer to Fig. 7. Turn on power. Jumpering terminals

4 and 2 will drive motor in the open direction, jumpering

terminals 4 and 1 will drive the motor in the closed

direction. To stop the motor at desired position, disconnect jumpers. Motor will remain at this position until

connection is restored. Removing power at this point will

cause motor to spring return to closed position.

9 63-2228—2

Page 10

220736A,B

SETTINGS AND ADJUSTMENTS

4. For switch differential of 1°, check continuity of

auxiliary switch N.O. (Red to Purple) contacts and, with

screwdriver, rotate cam as follows:

a. If contacts are open, rotate cam clockwise until

N.O. (Red to Purple) contacts close.

b. If contacts are closed, rotate cam counterclock-

wise until N.O. (Red to Purple) contacts open.

5. For switch differential of 10°, the cams must be

rotated with screwdriver approximately 180° prior to

setting the switching action. Refer to Fig. 3. Check

continuity of the N.O. (Red to Purple) contacts and, with

screwdriver, rotate cam as follows:

a. If contacts are open, rotate cam counterclock-

wise until N.O. (Red to Purple) contacts close.

b. If contacts are closed, rotate cam clockwise until

N.O. (Red to Purple) contacts open.

6. Check for proper switch differential and switching

of auxiliary equipment by driving the motor through full

stroke (in both directions). If necessary, repeat steps

4 and 6 for 1° differential, or 5 and 6 for 10° differential

until correct switching action is obtained.

7. Disconnect power from switches or quick-connect

terminals.

8. Connect auxiliary equipment to auxiliary switch

leads. See Wiring section.

9. Reconnect controller and power supply to motor.

10. Replace cover of wiring box.

Fig. 8—Auxiliary switch adjustment for M6184,

M6194 motors.

2

L2

1

L1

(HOT)

3

RBW

T1 T2

STROKE ADJUST

CAMS (YELLOW)

RIGHT/INNER

AUXILIARY

SWITCH

LEFT/OUTER

LEFT/OUTER

AUXILIARY

AUXILIARY

SWITCH

SWITCH

1

2

3

POWER END

OF MOTOR

Power supply. Provide disconnect means and

overload protection as required.

Transformer may be external or internal mounted.

Connect R-B to drive motor open. Connect R-W

to drive motor closed.

INNER AUXILIARY CAM (BLUE)

OUTER AUXILIARY CAM (RED)

M 492B

F) Series 61 Floating Control Non-Spring Return

Motors (M6184, M6194):

1. Turn off power and remove cover of wiring box.

2. Disconnect controller from motor.

3. Connect 24 Vac power and switches to drive motor

to position where auxiliary equipment is to be switched.

Refer to Fig. 8. Turn on power. Jumpering terminals R and

B will drive motor in the open direction, jumpering

terminals R and W will drive the motor in the closed

direction. To stop the motor at desired position,

disconnect jumpers. Motor will remain at this position

until connection is restored.

4. For switch differential of 1°, check continuity of

auxiliary switch N.O. (Red to Purple) contacts and rotate

cams as follows:

a. If contacts are open, rotate cam clockwise until

N.O. (Red to Purple) contacts close.

b. If contacts are closed, rotate cam counterclock-

wise until N.O. (Red to Purple) contacts open.

5. For switch differential of 10°, the cams must be

rotated approximately 180° prior to setting the switching

action. Refer to Fig. 3. Check continuity of the N.O.

(Red to Purple) contacts and rotate cams as follows:

a. If contacts are open, rotate cam counterclock-

wise until N.O. (Red to Purple) contacts close.

b. If contacts are closed, rotate cam clockwise until

N.O. (Red to Purple) contacts open.

6. Check for proper switch differential and switching

of auxiliary equipment by driving the motor through full

stroke (in both directions). If necessary repeat steps

4 and 6 for 1° differential, or 5 and 6 for 10° differential

until correct switching action is obtained.

7. Disconnect 24 V power and switches.

8. Connect auxiliary equipment to auxiliary switch

leads. See Wiring section.

9. Reconnect controller and power supply to motor.

10. Replace cover of wiring box.

10

Page 11

220736A,B

CHECKOUT

Checkout

WARNING

!

FIRE OR EXPLOSION HAZARD

CAN CAUSE SEVERE INJURY OR DEATH

When auxiliary switches control combustion

equipment, incorrect wiring of the switches can

allow the burner to come on at high fire. Check

auxiliary switch wiring and cam adjustment before turning on the system. Watch the controlled

equipment through one complete cycle. Shut the

system down immediately if switches do not

correctly sequence the equipment.

Use the controller to run the motor fully open and then

fully closed. Make sure that the auxiliary equipment starts

and stops at the desired points in motor rotation. When

checkout is complete, return the controller to the desired

setting.

11 63-2228—2

Page 12

220736A,B

SETTINGS AND ADJUSTMENTS

Residential and Residential and Helping You Control Your World

Building Controls Division Building Controls Division

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, Minnesota 55422 Scarborough, Ontario

M1P 2V9

QUALITY IS KEY

Loading...

Loading...