Page 1

Herculine 11280S

Smart Actuator

61-86-03-13

9/01

Page 1 of 14

Overview

Honeywell’s HercuLine 11280S Smart

actuators incorporate all of the high

quality and reliable features of the

traditional HercuLine

the added benefits of a microprocessorbased Enhanced Electronics Unit (EEU).

These additional benefits provide:

•

Faster set-up and commissioning

•

Network capability

•

Health parameter monitoring for

proactive maintenance planning.

HercuLine 11280S Smart actuators

enable operation at maximum process

efficiency, minimal downtime, and

access to all actuator parameters for

real-time business decisions.

Honeywell’s 11280S actuators are

industrial rated and engineered for very

precise positioning of dampers and

valves. The HercuLine 11280S

performs especially well in extremely

demanding environments requiring

continuous duty, high reliability, and low

maintenance. Typical applications are

ID/FD fan dampers, furnace pressure

dampers, coal mill dampers, burner tilts

and more.

actuators plus

Actuator Operation

Microprocessor-based electronics

continually monitor the performance,

health, and position of the actuator for

repeatable positioning and response to

demand signal.

A double reduction worm gear set

combines with a variable speed motor

controller (inverter) that is continuous

duty rated for accurate and repeatable

positioning of final control elements.

The worm gear set combination also

functions as a brake, capable of holding

greater than two times the output torque

in a back-driving condition.

Figure 1 Herculine 11280S Smart Actuator

Control options are available to

interface with a modulating 4-20 mA

input signal and 4-20 mA customer

feedback or remote setpoint through

Modbus. Internal balance, customer

feedback and patented slidewire

emulation is provided by a noncontacting position sensor.

Features

Performance

• Accurate Positioning –

Motor/gear train provides accurate

positioning with almost

instantaneous start/stop

characteristics.

• Non-Contact Position Sensing –

Non-contacting sensing lowers

maintenance costs and improves

performance.

• Duty Cycle – Continuous duty

rated motor.

Specification

• Full Travel Speed – Full stroke

travel speeds as fast as 10

seconds.

• Torque – High torque capability in

small package (425 – 5,500 lb-ft).

• High Accuracy – Typically 0.25 %

of 90° span.

• High Repeatability - Typically

0.2 % of 90° span.

• Characterization – Linear, square

root or programmable userconfigured 21-point

characterization allows tailoring of

control for specific applications.

• Input Filter Setting – Four

programmable combinations of

input filter settings are provided to

accommodate various customers

needs. The combinations are

none, spike, low pass, or spike +

low pass filter.

• Deadband – Deadband is

programmable between 0.2 % to

5 % of 90° span.

Sensing and Control, 11 West Spring Street, Freeport, Illinois 61032

Printed in U.S.A. © Copyright 2000—Honeywell

Page 2

61-86-03-13

Page 2

Features (continued) Health Monitoring

Operation

• Control Signals – 0/4 to 20 mA,

0/1 to 5 Vdc, 0 to 10 Vdc, Digital

remote setpoint (RS485 Modbus

RTU protocol).

• Output Signals – 0/4 to 20 mA,

0/1 to 5 Vdc and slidewire

emulation.

• Manual Operation – All 11280S

series actuators are supplied with a

manual handwheel to operate the

actuator when power is not

available.

• Auto-Manual – electric handswitch

with auxiliary contacts indicating an

"Out-of-Auto" position is available

for local electric control.

• RS485/Modbus RTU

Communication – Simple and

easy to use Modbus RTU

communication is standard with all

11280S actuators allowing

seamless networking of Honeywell

control products.

• Auxiliary Outputs – Two types of

auxiliary outputs can be specified,

SPDT switches or

electromechanical relay outputs.

Relay outputs can be programmed

to output alarm conditions, provide

control of other equipment, or

indicate status.

• Alarm Functions – Alarms may be

assigned to relay outputs or may be

accessed through Modbus. Alarms

can be triggered from stall,

temperature limits, motor cycle

count, out of automatic mode,

digital input, position, input failure,

position sensor failure, power up

failure, and more.

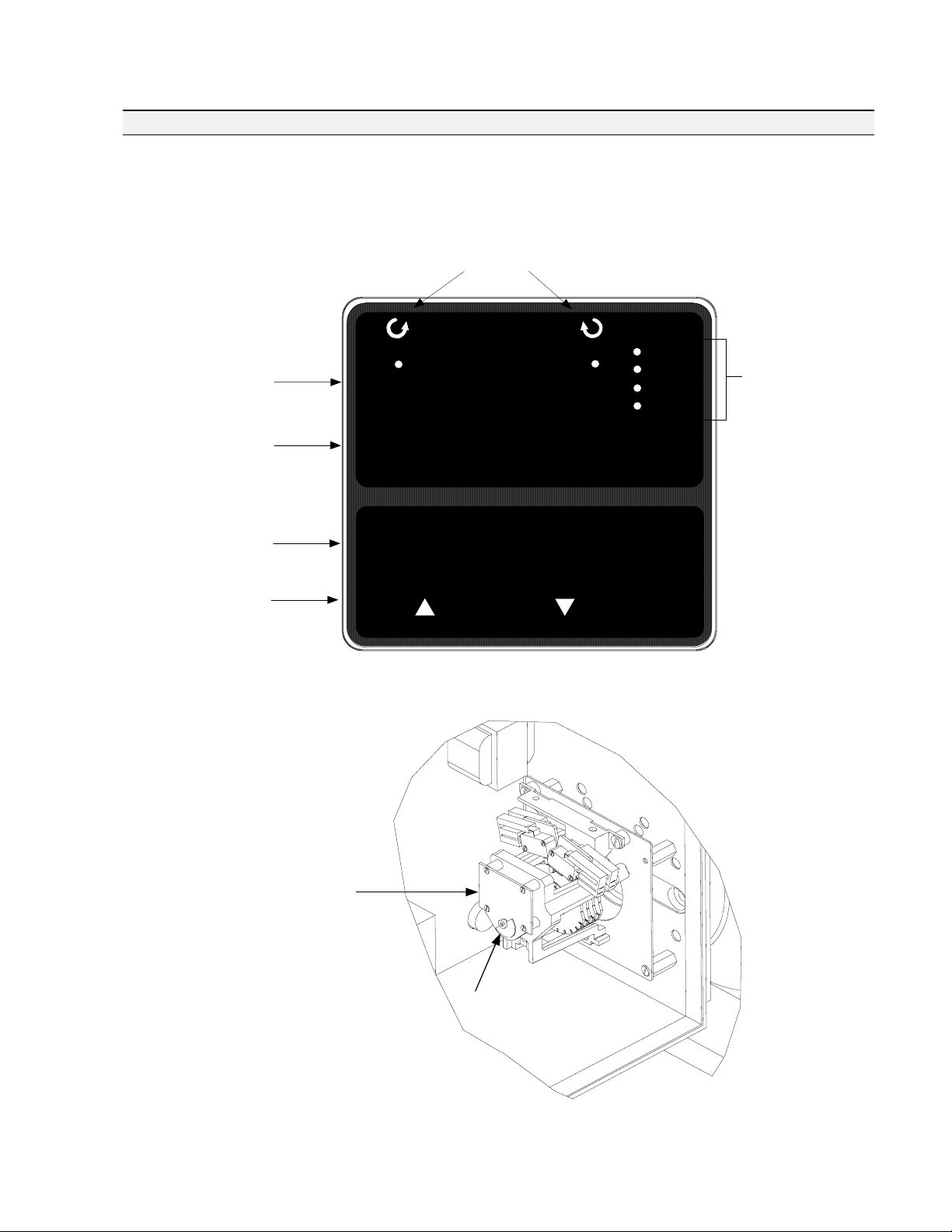

• Local HMI Configuration – An

integral keypad and high intensity

display is available for non-intrusive

local configuration of the actuator

(Figure 2).

• Configuration Security –

Password protection is provided,

allowing users to lock out some, all,

or no groups of setup parameters to

prevent tampering.

• Factory Calibration – Factory

calibration is stored in non-volatile

memory and can be restored via

the local HMI at any time.

• Direction of Rotation – Direction

of rotation on increasing input

signal is programmable.

• Split Range Operation – Split

range is programmable and

infinitely adjustable.

• Digital Input Override – A digital

input is provided and is

programmable to provide override

of all other input signals as an

emergency override of control. The

digital input can be programmed to

drive the actuator open, closed,

remain in-place, or to a userspecified position on contact

closure.

• Failsafe – When input signal

exceeds high or low range limits

(or input signal failure), the

actuator can be programmed to

drive open, closed, remain inplace, or drive to a user-specified

position.

Construction

• Enclosure – Rugged, industrial

grade enclosure.

• Low Maintenance – Simple-

proven design means high

reliability/low maintenance.

• Output Shaft Hardware – All

11280S series actuators are

supplied with an adjustable radius

crank arm. Optional linkage kits

are available.

• Limit Switches – Two end-of-

travel electric limit switches are

supplied as standard equipment

with all 11280S series actuators.

• Warranty – Exceptional warranty.

A standard feature on all 11280S

actuators accumulates information

about actuator operation. This

information then can be used to

evaluate and determine predicted or

scheduled maintenance periods. The

parameters that are monitored include:

accumulated stall time, thermal

operating rating of the actuator

exceeded, number of motor starts in a

region of motor travel, total travel and

current actuator travel.

Non-Contact

Position Sensing

Honeywell 11280S series actuators

implement a variable inductance, noncontact position sensor mounted directly

to the actuator output shaft providing

precision position sensing from 0 to 90

degrees, (Figure 3). This technology

eliminates maintenance items such as

wipers, bearings, as well as static

friction, hysteresis and electrical noise

over a wide range of demanding

environmental conditions.

Slidewire Emulation

The Slidewire Emulation Circuit (SEC)

emulates the proportional voltage

output of a typical slidewire through a

high impedance circuit. The voltage

output is proportional to the supply

voltage and shaft position. A noncontact position sensor is used to

determine shaft position in place of the

slidewire.

Page 3

61-86-03-13

Page 3

Local Display and Keypad

Configuration and set-up is through the local HMI, consisting of a display and keypad interface (Figure 2). A high intensity

10-character LED display and simple pushbuttons provide quick access for actuator set up and status information. If relay

outputs are specified, all configuration can be done through either the local HMI interface. If mechanical switches are

specified, then the user must manually set the auxiliary output.

Control Arm Rotation

CCW CW

Upper Display

(Four Characters)

Lower Display

(Six Characters)

Indicators

STALLED

ALARM

MANUAL

AUTO

LED Status

Indicators

Pushbuttons to

Access Actuator

Set Up, Status and

Calibration

Parameters.

Non-Contact Sensor

Sensing PWA

FUNCTIONSET UP

MAN/AUTO

DISPLAY

Figure 2 Local HMI (Display and Keypad)

Non-Contact Sensor Spoiler

Figure 3 Non-Contact Sensor Assembly

Page 4

61-86-03-13

Page 4

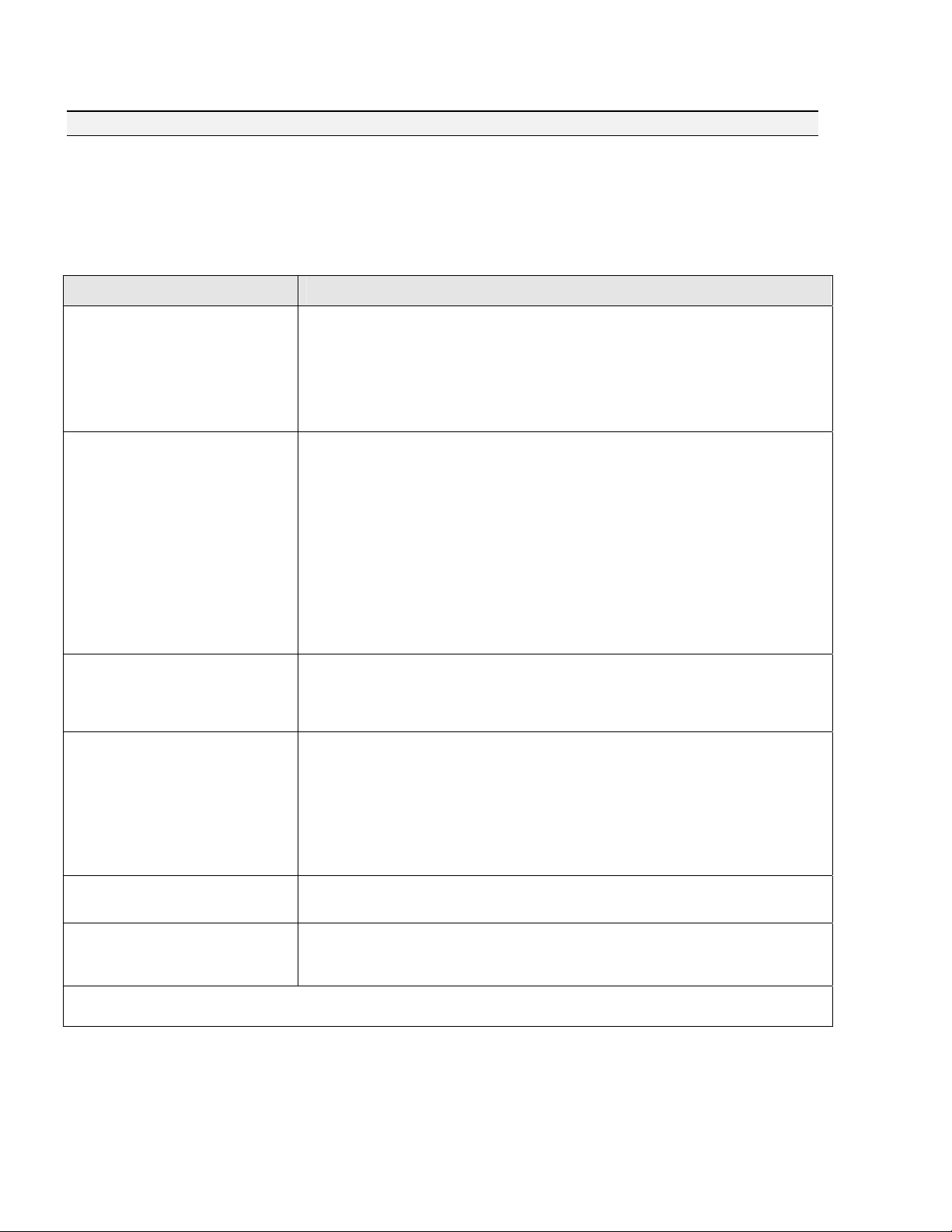

Set Up/Configuration Parameters

Configuration parameters are logically grouped and accessed using the local HMI. Actuator calibration is also

accomplished through a simple procedure using the keypad. By pressing the SETUP button on the HMI, you can step

through the set up groups that contain all of the configuration parameters. The table below summarizes the configuration

parameters available within the various set up groups. Full details of all configuration parameters are found in the 11280S

Series Smart Actuator Installation, Operation and Maintenance Manual, document number 61-86-25-09.

Set Up Group Configuration Parameter Selections/Settings

SET INPUT Selects various

parameters that define actuator

operation.

SET RELAY When the actuator

is equipped with optional relays,

this set up group allows you to set

relay action for various actuator

operating conditions. Contact

closure can be wired to external

annunciators or alarm points to

indicate conditions for any of the

Relay Types.

SET CUROUT Selects the

current (or voltage) output range

of the actuator.

SET COMM Actuator can be

defined as a master or slave

device on a Modbus RTU RS-485

loop. Operating setpoint can be

transmitted to the actuator and

operating status can be read

when connected to supervisory

control systems.

SET DIGINP Selects digital

input action upon contact closure.

SET DISPLA Selects desired

decimal places and engineering

units for local display.

CAL INPUT, MTR, CURENT If needed, calibration of the actuator input, motor position and actuator output can be

performed using the local keypad and display.

IN TYP – Input Actuation Type

INP HI – Input High Range Value

INP LO – Input Low Range Value

FILTYP – Input Filter Type

LPFILT – Low Pass Filter Time Constant

Direct – Actuator Rotation

RTYPnn – Relay Type

Input Range

Position Range

Deviation

Upper or Lower Limit Travel

Temperature High or Low

Motor Starts

Motor Stalled

Manual Mode

Power Up Test Failure

Input Signal Failure

Position Sensor Signal Failure

Digital Input Closure

CUROUT - Output Signal Range

4 – 20 mA, 0 – 20 mA,

1 – 5V, 0 – 5V,

SW E (Slidewire Emulation)

COMM – Communications Parameters

ADDRES – Device Address

BAUD – Baud Rate

XmtDLY – Response Delay

DBLBYT – Floating Point Data Format

DIGINP – Digital Input State

Endpos – End Position Value

DECMAL – Decimal Point Location

EUNITS – Units Display

UNITS – Display Units

Dband – Input Deadband

FsTYP – Failsafe Type

FsVAL – Failsafe Value

CHAR – Input Characterization

LDCAL – Restore Calibration Type

RnnE – Relay Count Multiplier

RnnVAL – Relay Value

Rnn HL – Relay High/Low

RLYnHY – Relay Hysteresis

Continued on next page ⇒

Page 5

Set Up Group Configuration Parameter Selections/Settings

61-86-03-13

Page 5

SET LOCK Enables lock

out or access to selected

set up group parameters

and calibration values.

READ STATUS

Displays failsafe condition

and the results of various

diagnostics performed

during power up.

SET DRVINF Allows

access to actuator device

information.

SET MAINT Allows

access to parameters that

monitor operating

conditions.

Physical

LOCKID – Set Security Password

LOCK – Lock Out

FAILSF – Failsafe

RAMTST – RAM Test Diagnostic

SEETST – Serial EEPROM Test

Diagnostic

VERSON – Firmware Version

SPEED – Stroke Speed

POWER – Power Input Voltage and Line

Frequency

TAG – Tag Name

TEMP – Actuator Temperature

TEMPHI – High Temperature Limit

TEMPLO – Low Temperature Limit

ACST – Accumulated Motor Stall Time

STARTS – Accumulated Motor Starts

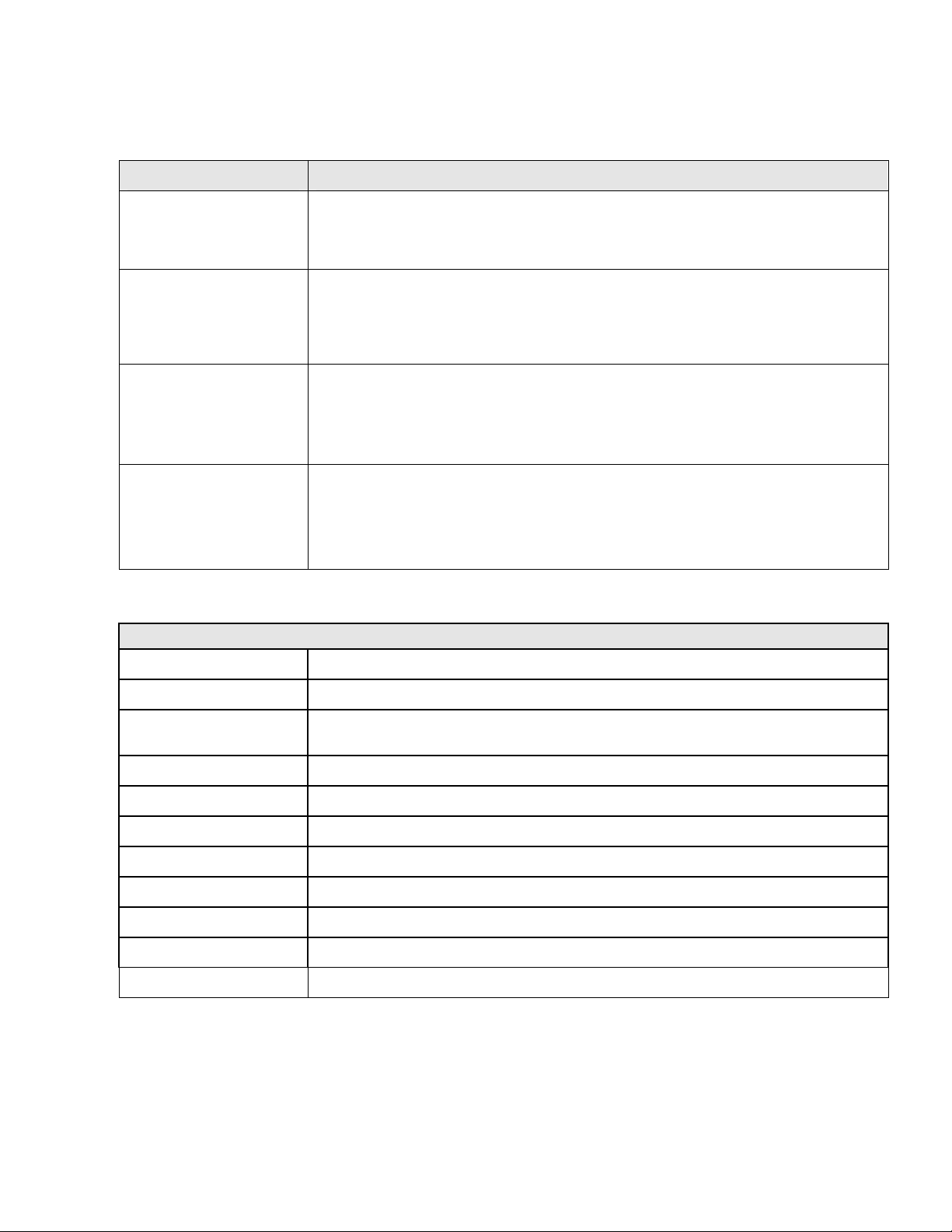

Specifications – General

CFGTST – Configuration Test Diagnostic

CALTST – Calibration Test Diagnostic

MFGDAT – Manufacturing Date

LREP – Date of Last Repair

LCAL – Date of Last Field Calibration

REPTYP – Repair Type

RLnCNTS – Relay Cycle Counts

REGNn – Accumulated Motor Starts

(Regions of Travel)

TOTDEG – Total Degrees of Motor Travel

MANRST – Reset Maintenance Statistics

Enclosure

Gear Train

Operating Temperature

Storage Temperature

Relative Humidity

Crank Arm

Rotation

Direction of Rotation

Manual Handwheel

Lubrication

Weight

Precision-machined ductile iron with corrosion resistant paint

Precision-machined double reduction worm gear

-30 °C to +65 °C (-20 °F to +150 °F)

except Model 11287S which has a range of: -20 °C to +65 °C (-4 °F to +150 °F)

-40 °C to +93 °C (-40°F to +200 °F)

0-99% R.H. noncondensing, over the full operating temperature range.

Adjustable radii (8” to 14”) crank arm is standard

Factory set to 90 degrees, for 0% to 100% travel

Field programmable via local display and keypad

Provides a means of positioning the actuator in the event of a power failure or set-up

Mobil Synthetic bearing and gear lubricant SHC 634 (ISO 460) or equivalent

300 lb to 600 lb (136 kg to 272 kg)—See Table below for more information.

Specifications continued on next page ⇒

Page 6

61-86-03-13

Page 6

Physical

Specifications – General, Continued

Model #

11284S 425

11285S 840

11286S 1500

11288S 2500

11289S 4000

11287S 5500

Torque

lb-ft (N_M)

(576)

(1139)

(2033)

(3389)

(5423)

(7457)

Electrical

Mains Supply

Motor

Output

Shaft Size

2"

(51 mm)

2"

(51 mm)

2"

(51 mm)

2-1/2"

(64 mm)

2-1/2"

(64 mm)

2-1/2"

(64 mm)

115/220 Vac, single phase 50/60 Hz up to 1500 lb-ft

208/200 – 240/380 – 480/575 Vac, three phase 50/60 Hz

Inverter rated, continuous duty, C face mounting

Shaft Key

Size

1/2"

(13 mm)

1/2"

(13 mm)

1/2"

(13 mm)

5/8"

(16 mm)

5/8"

(16 mm)

5/8"

(16 mm)

Output

Shaft

Length

5"

(127 mm)

5"

(127 mm)

5"

(127 mm)

6"

(152 mm)

6"

(152 mm)

6"

(152 mm)

Maximum

Overhang

Load

3700 lb.

(1678 kg)

3700 lb.

(1678 kg)

3700 lb.

(1678 kg)

7500 lb.

(3402 kg)

7500 lb.

(3402 kg)

7500 lb.

(3402 kg)

Handwheel

Diameter

18"

(457 mm)

18"

(457 mm)

18"

(457 mm)

18"

(457 mm)

18"

(457 mm)

18"

(457 mm)

Approx.

Maximum

Weight

300 lb.

(136 kg)

300 lb.

(136 kg)

300 lb.

(136 kg)

550 lb.

(251 kg)

600 lb.

(272 kg)

600 lb.

(272 kg)

Motor Current Motor Size Full Load Amps (FLA)

(Horsepower) @ 230 Vac @ 460 Vac

Loss of Power

Local Auto - Manual

Switch

Limit Switches

Auxiliary

Switches/Relays

Installation Category

(Overvoltage Category)

Pollution Degree

½

¾

1

1 ½

2

3

Stays in place

Allows local manual and automatic operation of the actuator

Standard - Two SPDT end-of-travel limits rated 10 A at 125 Vac, 5 A at 250 Vac.

Optional – Up to 2 additional SPDT switches (or 4 relay outputs, programmable)

Category II: Energy-consuming equipment supplied from the fixed installation. Local level

appliances, and industrial control equipment. (EN 61010-1)

Pollution degree 2: Normally non-conductive pollution with occasional conductivity caused by

condensation. (ref. IEC 664-1)

1.6

2.2

2.6

4.4

5.6

7.8

0.8

1.1

1.3

2.2

2.8

3.9

Page 7

61-86-03-13

Specifications – Actuator

Electrical

Input Signals Analog: 0/4 to 20 mA (With supplied 250 ohm shunt resistor for current range)

0/1 to 5 Vdc

0 to 10 Vdc

Digital: Remote Setpoint via Modbus RTU (RS485)

Page 7

Input Impedance

Input Characterization

Sensitivity

Hysteresis

Deadband

Repeatability

Voltage/ Supply Stability

Temperature Coefficient

Zero Suppression

Input Filters

Solid State Motor Control

Input

0/4 to 20 mA

0/1 to 5 Vdc

Provides characterization of the input signal.

Selections are: Linear, Square Root or Custom.

0.2 % to 5 % of 90° span, proportional to deadband

Less than 0.4 % of full scale

0.2 % to 5 % of 90° span, adjustable. Shipped at 0.5%

0.2 % of 90° span

0.25 % of span with +10/-15 % voltage change

Less than ± 0.030 % of span per degree C for 0 °C to 50 °C

Less than ± 0.05 % of span per degree C for

90% of span

Selectable spike and low pass filters

CW/CCW open collectors (opto-isolators) for use as discrete control inputs to the inverter

for motor operation.

Input Impedance

250 ohms

10 K ohms

-30 °C to 65 °C

Failsafe operation

Feedback signals/Output

Slidewire Emulation

Isolation

Load Requirement (4-20)

Programmable Functions

If input signal exceeds configured input range. Selectable and adjustable.

0 to 20 mA, 4 to 20 mA

0 to 5 Vdc, 1 to 5 Vdc with 250 ohm resistor; (0 to 16 Vdc with 800 ohm resistor)

Provides output voltage ratiometric to shaft position and potentiometric to supply voltage

(1 to 20 Vdc) without a slidewire. Emulates a 100 ohm to 1000 ohm slidewire. 10 mA

output maximum.

Input signal, output signal and power are isolated from each other.

Current Out — 0 to 1000 ohms

Selectable and configurable operating parameters:

• Input range

• Input filtering

• Input characterization

• Security

• Digital Input action

• Deadband

• Failsafe on loss of

input signal

• Failsafe on loss of

position sensor

• Direction of rotation

• Relay closure

action

• Communication

parameters

• Split range

operation

• Output range

• Alarms

Page 8

61-86-03-13

Page 8

Pipe Linkage Kit

Pipe linkage kits are available from Honeywell and can be used for linkage lengths from 24 to 240 inches (61 to 610 cm). The

kits include the mechanical pipe couplings, load rod end (left-hand thread), connecting rods and locking nuts. See Figure 4.

The actuator rod end (right-hand thread), nut and bolt are supplied with the actuator. The customer must supply a piece of

schedule 40 pipe 2 ½” * (both ends with right-hand NP threads) and a nut and bolt to connect the rod end to the load. Pipe

linkage kits can be ordered with the Actuator using Table VIII of the Model Selection Guide.

Linkage Minimum = 24in. (61 cm)

Linkage Maximum = 240in. (610 cm)

+

Pipe Length *

*Pipe length = Overall linkage length minus (-) 20 inches (51 cm).

Figure 4 Pipe Linkage Kit

Actuator Crank Arm

The 11280S Series Actuator comes standard with an 8” to

14” adjustable radius crank arm. The crank arm uses a

standard right-hand thread 1” rod end to compliment the

pipe linkage kit.

The crank arm for the 11284S, 11285S and 11286S has a

2” shaft hole, while the crank arm from the 11287S, 11288S

and 11289S has a 2 ½” shaft hole.

This rod end

supplied on Actuator

with crank arm

+

Recommended Bolt Torque

The table below lists the type of bolts to be used and the

recommended torque for each bolt.

Bolt Type Torque

Clamp bolts 220 lb.-ft

Rod End Bolt 220 lb.-ft

Jam nuts 100 lb.-ft

Figure 5 11280S Crank Arm

Page 9

61-86-03-13

External Transformers

120 Vac (Single Phase)

For customer applications requiring 120/240 Vac single phase operation, a step-up transformer is mounted in a separate

enclosure (Model Selection Guide Table I, option 1). Figure 6 shows the installation for the transformer enclosure.

575 Vac (3 Phase)

For customer applications requiring 575/460 Vac 3 phase operation, a step-down transformer is mounted in a separate

enclosure (Model Selection Guide Table I, option 6). Figure 6 shows the installation for the transformer enclosure.

14.0

(355.6 mm)

Ground

Stud

Page 9

120/240 Vac

Single Phase

Transformer

575/460 Vac

Three Phase

Transformer

10.0

(254 mm)

16.0

(406.4 mm)

Figure 6 Installation Drawing for External Transformer

Enclosure

Page 10

61-86-03-13

_-_

_

_

_ _IV_

_

_

_

_

_

Page 10

Model Selection Guide Reference 62-86-16-19

Instructions

Select the desired key number. The arrow to the right marks the selection available.

Make the desired selections from Tables I thru VIII using the column below the arrow.

A dot ( ) denotes unrestricted availability.

Key Number I II VI VII VIII IX

_ _ _ _ _ _ _

-

KEY NUMBER - Electronics

Output Torque

(lb. - ft.) (N - M)

425 (575)

850 (1150)

III

----_-

_

V

_

(Note 1)

(Note 1)

- -_

_ _ _ _

Selection Availability

011284S

011285S

1500 (2025) 011286S

2500 (3400) 011288S

4000 (5425) 011289S

5500 (7450) 011287S

TABLE I - POWER SUPPLY

Single Phase 120 Vac, 50/ 60 Hz

240 Vac, 60 Hz / 200 Vac, 50 Hz a

Three Phase 200 - 240 Vac, 60 Hz

380 - 480 Vac, 50-/60 Hz

575 Vac, 60 Hz

1

2

4

5

6

a

TABLE II - STROKE SPEED

Stroke Speed @ 60 Hz 10 sec/90 degrees

30 sec/90 degrees

60 sec/90 degrees

1

2

3

TABLE III - MOTOR ORIENTATION

Motor Right-hand floor configuration, H.W. Shaft Horizontal

Orientation Left-hand floor configuration, H.W. Shaft Horizontal

(See specification 61-86-03-13 for diagrams)

01

03

TABLE IV - ANALOG INPUT/OUTPUT SIGNALS

Input 4-20 mA, 0-20mA (1-5 Vdc, 0-5 Vdc, 1-10 Vdc, 0-10Vdc) 0 _ _

Output No Analog Position Output _ 00

4-20 mA, 0-20mA (1-5 Vdc, 0-5 Vdc, 1-10 Vdc, 0-10Vdc) _ 20

Slidewire Emulation

(Note 2)

_ 40

Page 11

61-86-03-13

S

Page 11

Model Selection Guide, continued

01128_ _

4S

5S

6S

8S

TABLE V - SWITCH AND RELAY OUTPUT

Auxiliary Switches None

and 2 Aux. SPDT Switches

2 Aux. + 2 Programmable Relay Outputs

2 Programmable Relay Outputs

4 Programmable Relay Outputs

Auto/Manual Switch None

One Auto/Manual Switch with Out-of-Auto Contact

TABLE VI - CONFIGURATION INTERFACE

Remote None 0

Local Integrally mounted local display/keypad interface 1

(2 mech end-of-travel limits standard) Selection 9S 7S

00 _

20 _

22 _

02 _

04 _

_ _0

_ _1

TABLE VII - COMMUNICATIONS/PROTOCOL

Modbus RTU RS485 RS-485 Modbus compliant - standard with EEU 0

Additional Communications Future 1

TABLE VIII - OPTIONS

Crank Arm Adjustable 8" to 14" Radii - Standard 0_ _ _ _ _

None 1_ _ _ _ _

Linkage Kit None _0_ _ _ _

Up to 20 ft. length - customer supplies schedule 40 pipe _1_ _ _ _

Future Option None _ _0_ _ _

Future Option None _ _ _0_ _

Tagging None _ _ _ _0_

Linen (Note 3) _ _ _ _1_

Stainless Steel (Note 3) _ _ _ _2_

Future Option None _ _ _ _ _0

TABLE IX - FACTORY OPTIONS

Motor Orientation None 00

RESTRICTIONS

Restriction Available Only With Not Available With

Letter Table Selection Table Selection

a

I 11284S, 11285S, 11286S I 11287S, 11288S, 11289S

Note 1: Requires (2) adapters PN 51204694-501 for retrofit of existing Leeds & Northrup 011284 and 011285 actuators.

Note 2: Slidewire emulation is a solid state circuit providing a ratiometric voltage output proportional to shaft position.

Note 3: Customer must supply tagging information: Up to 3 lines (22 characters for each line)

Page 12

61-86-03-13

Page 12

Figure 7 Mounting and Outline Dimensions for 11284S, 11285S, 11286S, 11288S, and 11289S

Weather-Proofed Motor Actuators -

Right Hand Floor Mounting, Handwheel Shaft Horizontal (D-MTG-616-200)

Page 13

61-86-03-13

Page 13

Figure 8 Mounting and Outline Dimensions for 11284S, 11285S, 11286S, 11288S, and 11289S

Weather-Proofed Motor Actuators -

Left Hand Floor Mounting, Handwheel Shaft Horizontal (D-MTG-616-210)

Page 14

61-86-03-13

Tlf: 67150 250 Faks: 67 150 251

Mail: post@instrumentteam.no

Web: www.instrumentteam.no

Page 14

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship.

Contact your local sales office for warranty information. If warranted goods are returned to Honeywell during

the period of coverage, Honeywell will repair or replace without charge those items it finds defective. The

foregoing is Buyer's sole remedy and is in lieu of all other warranties, expressed or implied, including

those of merchantability and fitness for a particular purpose. Specifications may change without

notice. The information we supply is believed to be accurate and reliable as of this printing. However, we

assume no responsibility for its use. © Honeywell 2004.

While we provide application assistance personally, through our literature and the Honeywell web site, it is

up to the customer to determine the suitability of the product in the application.

Distributor :

Sensing and Control

Honeywell

11 West Spring Street

Freeport, IL 61032

2-86-03-13 9/01 Printed in USA www.honeywell.com/imc 6

Loading...

Loading...