Page 1

the filter and hvac store

Page 2

Page 3

Page 4

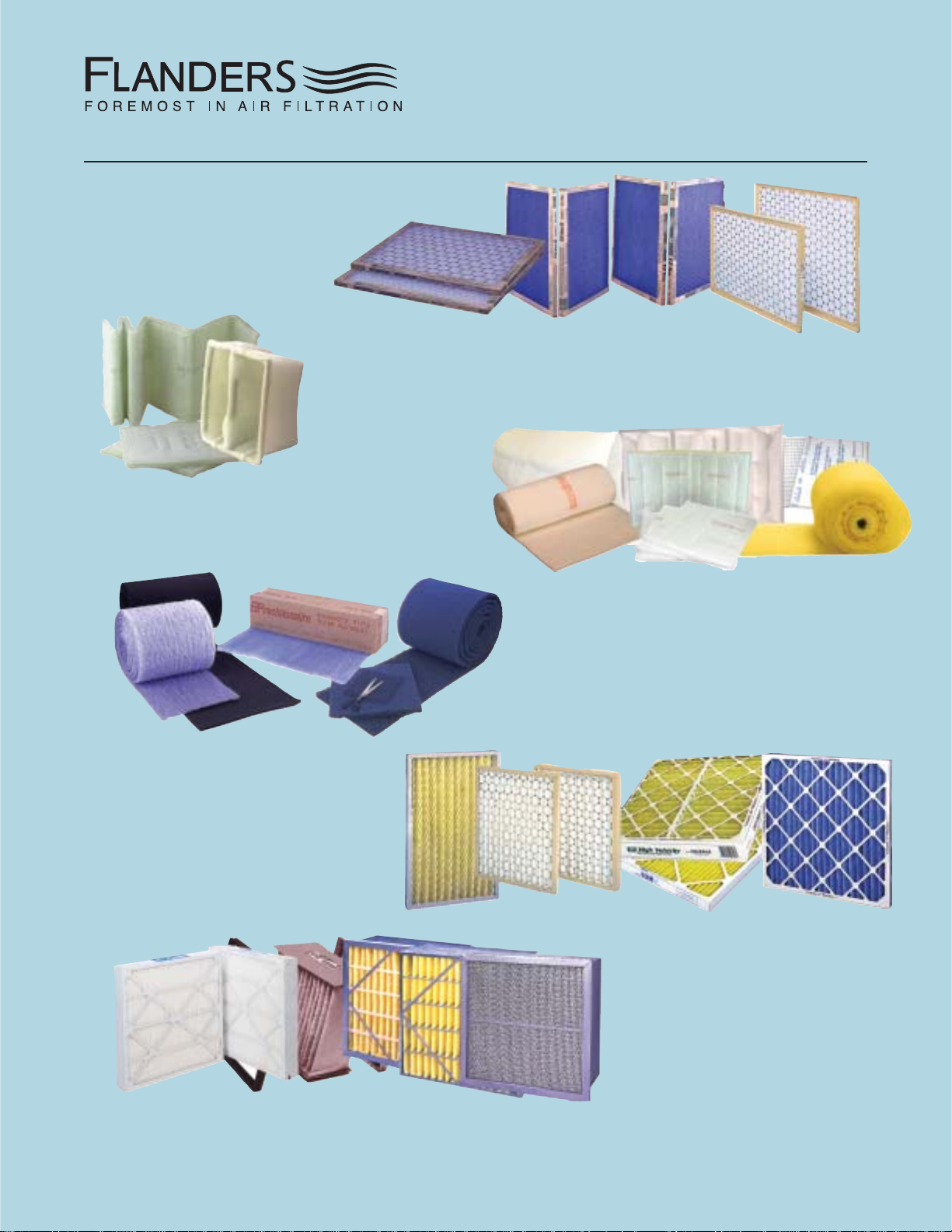

Disposable Air Filters

The widest selection of disposable

panels you will find anywhere. Spun

glass and synthetic media...all standard sizes and almost any

“special” size.

Polyester Panels, Links, Sleeves

High grade polyester synthetic fiber media in a variety of styles,

heat sealed onto heavy wire frames.

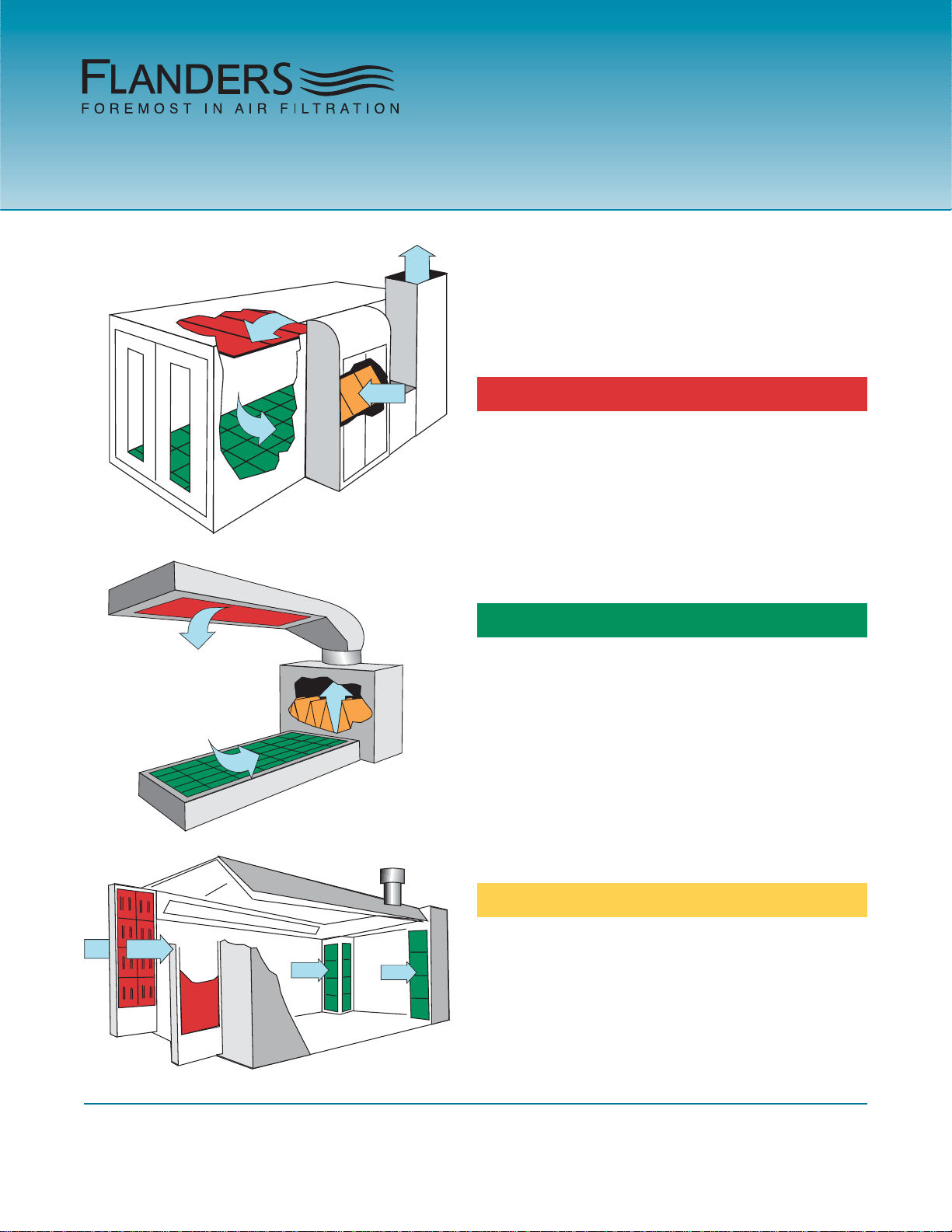

Paint Booth Products

A complete line of

aftermarket filter products for all

styles of paintbooth...downdraft,

cross-draft and work station.

Air Filter Media & Auto Rolls

Cut-to-fit hammock and service roll media in

a variety of styles, plus bulk rolls of spun

glass and synthetic media. Auto rolls in the

media style of your choice, wound on the

core style of your choice. Hundreds of models.

Pleated Air Filters

One of the largest inventories of

pleated panel filters you will find

anywhere. Five styles are offered

in just about any size you will

ever need.

Medium & High

Efficiency Rigid Type

Air Filters

A wide variety of styles, sizes

and efficiencies.

the filter and hvac store

Page 5

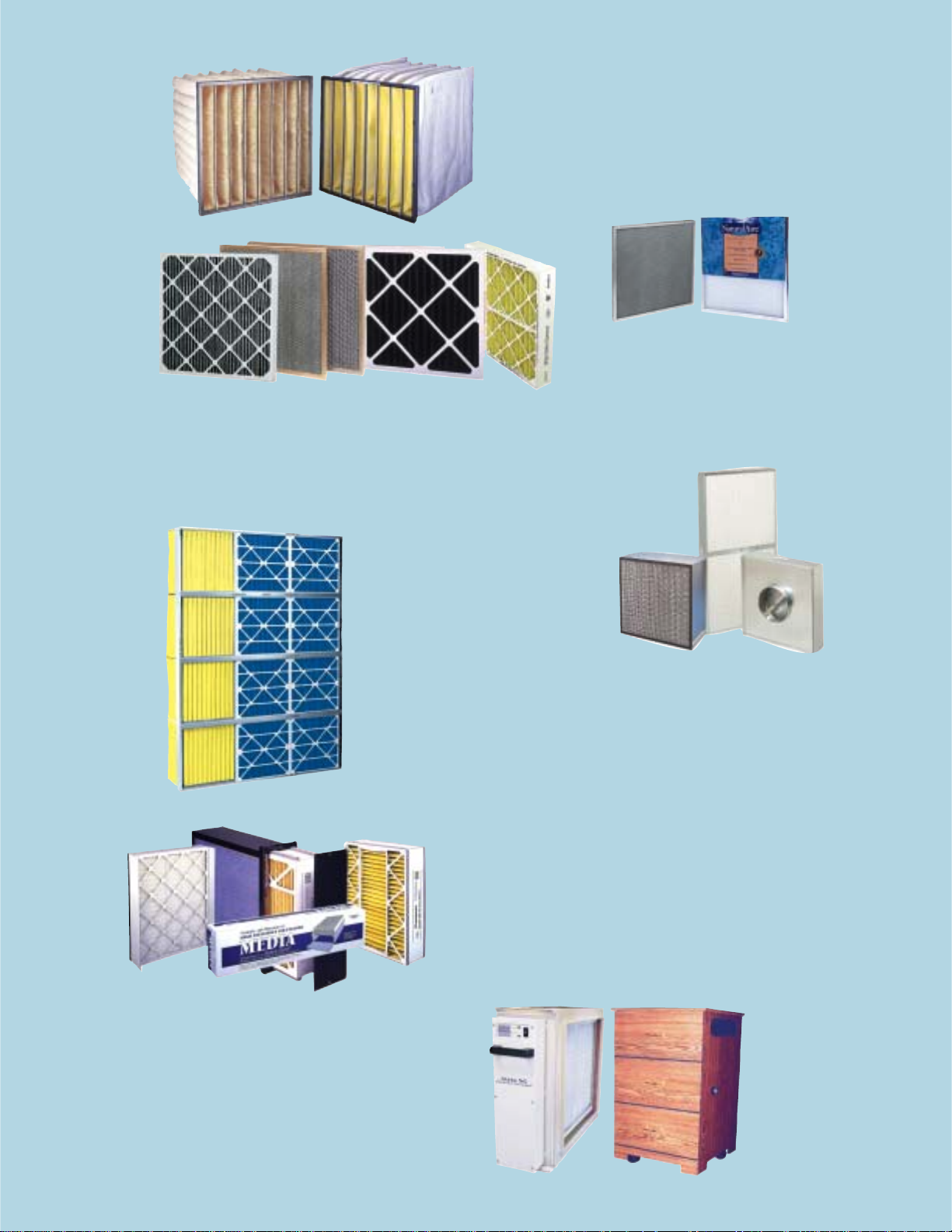

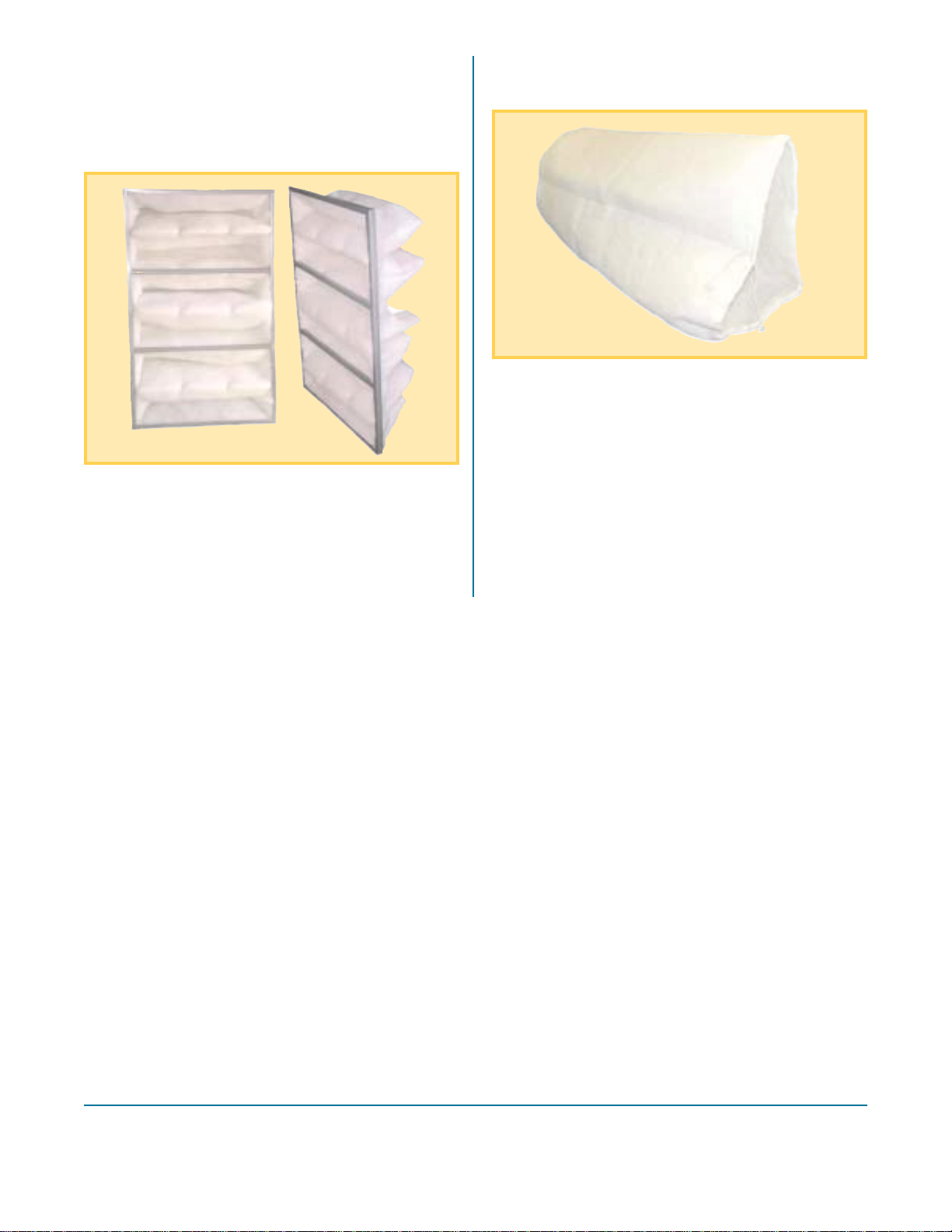

Medium & High Efficiency Extended

Surface T ype Filters

Huge line of “bag” filters in all of the most popular

sizes and efficiencies, plus our new XDH bag which

holds up to twice as much dust as ordinary bags.

Metal Washable Filters

Rugged metal filters for a variety

of applications. Top quality

materials and workmanship.

Gas Phase and Odor Control

Pleated panel filters that have been treated with special

odor adsorbing/neutralizing materials, as well as 50% &

75% fill granular carbon filters.

Residential/Light Commercial Air

Cleaners & Filters

Fast, easy and profitable air filtration upgrades...made

by one of the world’s leaders in critical air filtration.

Equal or superior filter media replacements for competing systems...and typically easier to install.

Electronic Air Cleaners

Near-HEPA quality air purification for the

whole house or just a room.

HEPA Filter

For genuine HEPA grade filtration with mini-

mum efficiency of 99.97% on

0.30 micrometer size particles.

Several types, including high

capacity, high temp, high velocity,

minipleat panels, terminal modules and fan powered modules.

Framing Systems and Holding Frames

Media holding frames, filter holding frames, modular filter framing systems and hard ceiling adaptor

framesfor Terminal Modules

the filter and hvac store

Page 6

Disposable Air Filters: Page

HD Industrial Grade Heavy Duty Box Frame, Spun Glass or Synthetic Media . . . . . . . . . . . . . . . . .8

EZ Flow and EZ Flow II Continuous Filament Spun Glass, Box Frame . . . . . . . . . . . . . . . . . . . . . . .10

Pinch Frame Framed Polyester Media with Metal on One Side . . . . . . . . . . . . . . . . . . . . . .12

Polyester Panels,Links,Sleeves and Cube Filters:

Prelock Heat Sealed Polyester Support Frame Products . . . . . . . . . . . . . . . . . . . . . .14

Paint Booth Products

Paint Booth Filtration Supported Panels, Cubes, Diffusion Media and Paint Arrestors . . . . . . . . . . .16

FP319A Two-stage and Three-stage Paint Systems` . . . . . . . . . . . . . . . . . . . . . . . . . .24

Air Filter Media and Auto Rolls:

Cut-to-Fit Hammock, Permaire and Service Rolls and Pads . . . . . . . . . . . . . . . . . . . . .26

Bulk Media Fiberglass and Synthetic Media, Rolls and Pads . . . . . . . . . . . . . . . . . . . . . .28

Auto Roll Media Treated Polyester, Scrim Back, Skin Back, Fiberglass . . . . . . . . . . . . . . . . . .30

Pleated Air Filters

Pre Pleat 40 V Wedge Pleat, Carrier Board Frame, 25-30% Efficient . . . . . . . . . . . . . . . . .32

Pre Pleat HV High Velocity/Gas Turbine Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Pre Pleat 62R Electrostatically Charged Fibers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Pre Pleat 62RM11 MERV 11 Electrosttically Charged Fibers . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Pre Pleat Class 1 UL Class 1 Fire Rated Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Pre Pleat HT High Temperature Pleated Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

E35 Metal Support Grids, 25-30% Efficient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Medium and High Efficiency Rigid Type Filters:

Superflow V Extended Surface Minipleat Aor Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Rigid-Air Extended Surface Lofted Media Box Type Filters . . . . . . . . . . . . . . . . . . . . . .59

PrecisionCell Extended Media Separator Type Rigid Filters . . . . . . . . . . . . . . . . . . . . . . . .53

PrecisionCell II Extended Surface Minipleat Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

EA Cartridge Replacement Filter Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Medium and High Efficiency Extended Surface Type Filters:

Precision Pak Extended Surface Bag Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Precision Pak XDH High Capacity Extra Dust Holding Bag Filters . . . . . . . . . . . . . . . . . . . . . . . .71

Metal Washable Filters

MS/MSG Moisture/Oil Mist Separators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

KKM Industrial Grade Aluminum or Galvanized Filters . . . . . . . . . . . . . . . . . . . . . .78

6

Replacement Air Filter

Catalog

Table of Contents

the filter and hvac store

Page 7

7

HEPA and 95DOP Filters

Alpha 95 95% DOP Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Alpha Cell HEPA Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Alpha 2000 High Capacity HEPA Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Alpha HT High Temperature HEPA Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Superflow 2K High Velocity HEPA Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Alpha Panel Minipleat HEPA/ULPA Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Pureflo Terminal HEPA/ULPA Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Pureflo-FPM Fan Powered Terminal Filter Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Gas Phase and Odor Control:

FCP Carbon Pleat Fine Mesh Carbon, Outperforms Carbon Slurry . . . . . . . . . . . . . . . . . . . . . .101

PH Odor Control Pleated Filter Treated with Sodium Bicarbonate . . . . . . . . . . . . . . . . . . . . . .103

Model C 50% and 75% Fill Granular Carbon Filters . . . . . . . . . . . . . . . . . . . . . . . . . .105

Framing Systems and Holding Frames:

Type 9 Filter Holding Frames and Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Uni-Frame Media Holding Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

K-Trac Modular Filter Framing Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Perma Frame Hard Ceiling Adaptor Frames For Terminal Modules . . . . . . . . . . . . . . . . . . .126

Residential/Light Commercial Air Cleaners and Filters:

Air Cleaner Refills Space Gard®, Air Bear® and Honeywell® Air Cleaners . . . . . . . . . . . . . . . . .128

Model 500AB Air Cleaner Housings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Electronic Air Cleaners

Airia 350 High Capacity In-Room Air Cleaner In Handsome Cabinet . . . . . . . . . . . . . .132

Aria 1000 and 2000 In-Duct Electrostatic Air Cleaners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

Replacement Air Filter

Catalog

Table of Contents

Model Numbers:

Within each section in the page heading or in the

body, you will see model number abbreviations

to help you find these products in the separate

Flanders price book. These will typically appear

as a family code followed by “xxx’s” which indicate dimensions or other identifying characteristic of specific products.

HD Industrial Grade

Heavy Duty Disposable Panel Filters

General

Flanders HD Industrial Grade filters are designed

for use in any application where disposable panel

filters are recommended. They can be relied upon

for superior performance since they are specifically

designed for heavy workloads. A wide range of

standard face sizes is available, plus nearly any

“special” size.

Construction

Flanders HD Industrial Grade filters are designed

with a one-piece moisture-resistant chipboard

frame enclosing media. Standard frames are nominal 1” thick (3/4” actual) and nominal 2” thick (1-5/8”

actual).

The fiberglass media filter consists of continuousfilament fibers bonded together with thermo-setting

Important Features

• One-piece moisture-resistant chipboard

frame prevents broken corners

• Support grilles on both sides for exceptional strength

• Media and grilles continuously glued to

the inside perimeter of the frame for rigidity

Spun Glass Media - Model 10255.xxxxxx

Synthetic Media - Model 11255.xxxxxx

resin. The synthetic media filter consists of 100%

high bulk polyester fibers that are thermo bonded

with a fire retardant resin.

Support grilles of perforated corrosion-resistant

steel or expanded metal are provided on both sides

of the filter. The media pads and support grilles are

continuously glued to the inside perimeter of the

frame, resulting in exceptional strength and rigidity.

This design virtually eliminates the possibility of

media sag within the frame.

Physical Data

Frame: One-piece moisture-resistant chipboard

Media:: Fiberglass or Synthetic

Support Grille: Perforated corrosion-resistant steel orexpanded wire on both sides of the filter

Sealant: Hot-melt resin

Synthetic

the filter and hvac store

Page 8

8

HD Industrial Grade

Heavy Duty Disposable Panel Filters

Spun Glass Media - Model 10255.xxxxxx

Synthetic Media - Model 11255.xxxxxx

Grille Sizes - Model 10355.xxxxx

General

Flanders HD Industrial Grade filters are designed

for use in any application where disposable panel

filters are recommended. They can be relied upon

for superior performance since they are specifically

designed for heavy workloads. A wide range of

standard face sizes is available, plus nearly any

“special” size.

Construction

Flanders HD Industrial Grade filters are designed

with a one-piece moisture-resistant chipboard

frame enclosing media. Standard frames are nominal 1” thick (3/4” actual) and nominal 2” thick (1-5/8”

actual).

The fiberglass media filter consists of continuousfilament fibers bonded together with thermo-setting

resin. The synthetic media filter consists of 100%

high bulk polyester fibers that are thermo bonded

with a fire retardant resin.

Support grilles of perforated corrosion-resistant

steel or expanded metal are provided on both sides

of the filter. The media pads and support grilles are

continuously glued to the inside perimeter of the

frame, resulting in exceptional strength and rigidity.

This design virtually eliminates the possibility of

media sag within the frame.

Physical Data

Frame: One-piece moisture-resistant chipboard

Media:: Fiberglass or Synthetic

Support Grille: Perforated corrosion-resistant steel orex-

panded wire on both sides of the filter

Sealant: Hot-melt resin

Spun Glass

Important Features

• One-piece moisture-resistant chipboard

frame prevents broken corners

• Support grilles on both sides for exceptional strength

• Media and grilles continuously glued to

the inside perimeter of the frame for rigidity

• Filters are UL 900 Class 2 listed

• 1/2”, 1”, 2” depths

• Special sizes available upon request

Synthetic

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 9

9

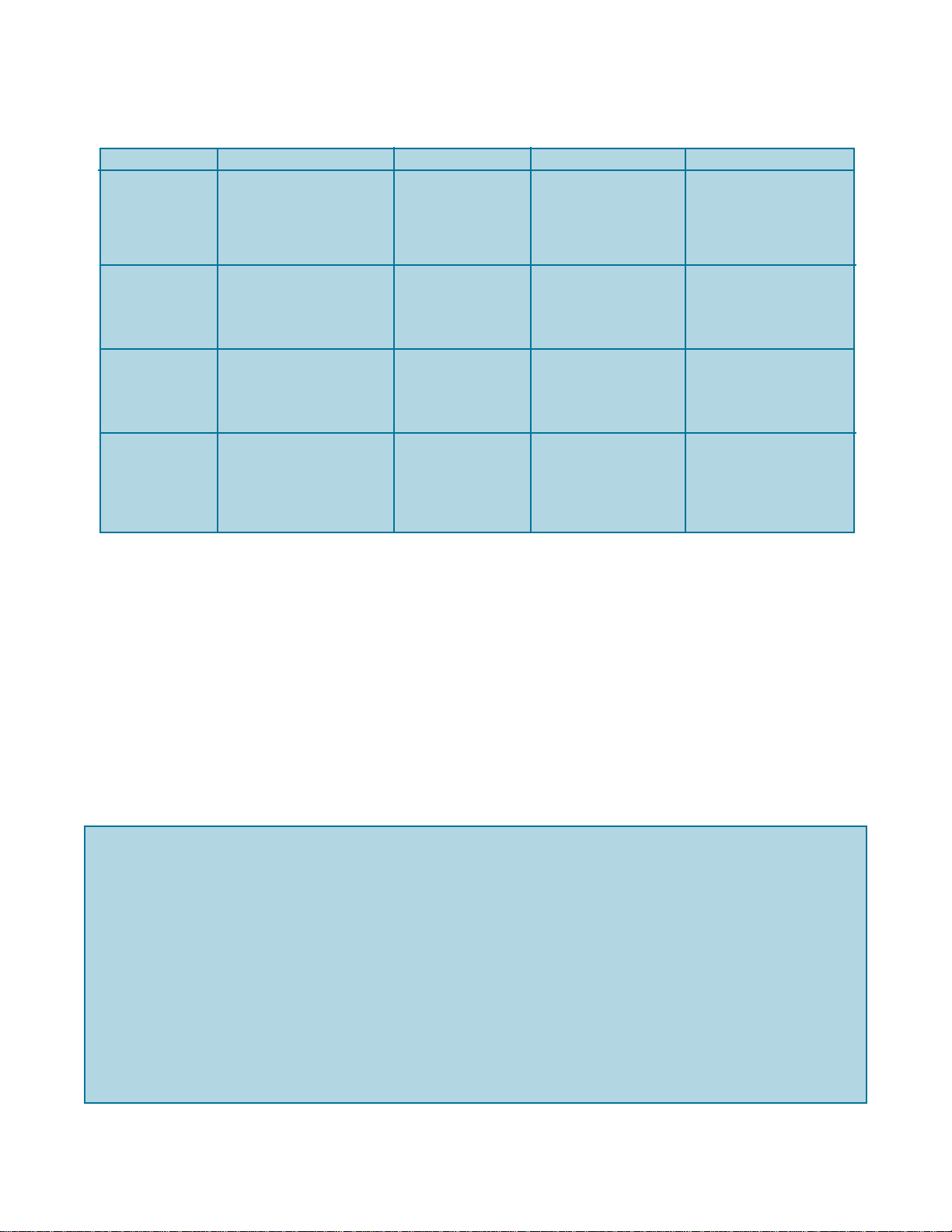

Standard Sizes Performance Data - HD Industrial Grade

Typical initial (clean) pressure drop at nominal cfm is 0.07 in. w.g.for 1 in. filters and 0.10 in.w.g.for 2 in. filters. Recommended final

resistance is 0.50 in. w.g., but the system design may dictate a lower change out point.

1.0 General

1.1Disposable filters shall be Model HD Industrial

Grade filters as manufactured by Flanders.

1.2 Filters shall be UL 900 Class 2 listed.

2.0 Filter Construction

2.1 Filters shall be constructed of fiberglass or synthetic media (as specified) enclosed in a onepiece chipboard frame.

2.2 Perforated corrosion-resistant steel or expanded

metal support grilles shall be furnished on both

entry and exit sides of the filter.

2.3 Media and grilles shall be continuously glued to

the inside perimeter of the frame.

3.0 Performance

3.1 The manufacturer shall guarantee performance

as stated in its literature within tolerances as outlined in Section 7.4 of ARI Standard 850.

Guide Specifications

Nominal Size (in.) Actual Size H x W x D (in) cfm @ 300 fpm Standard Carton Qty. Weight per Carton (lbs.)

10x10x1 9-7/8 x 9-7/8 x 3/4 208 12 3.3

10x20x1 9-7/8 x 19-7/8 x 3/4 417 12 5.2

10x24x1 9-7/8 x 23-7/8 x 3/4 500 12 6.1

10x25x1 9-7/8 x 24-7/8 x 3/4 521 12 6.5

10x30x1 9-7/8 x 29-7/8 x 3/4 625 12 7.0

12x12x1 11 -7/8 x 11 -7/8 x 3/4 300 12 4.0

12x20x1 11 -7/8 x 19-7/8 x 3/4 500 12 5.8

12x24x1 11 -7/8 x 23-7/8 x 3/4 600 12 6.7

12x25x1 11 -7/8 x 24-7/8 x 3/4 625 12 7.5

12x30x1 11 -7/8 x 29-7/8 x 3/4 749 12 8.0

14x14x1 13-7/8 x 13-7/8 x 3/4 408 12 5.2

14x20x1 13-7/8 x 19-7/8 x 3/4 583 12 6.2

14x24x1 13-7/8 x 23-7/8 x 3/4 700 12 7.3

14x25x1 13-7/8 x 24-7/8 x 3/4 729 12 7.7

14x30x1 13-7/8 x 29-7/8 x 3/4 875 12 10.5

15x20x1 14-7/8 x 19-7/8 x 3/4 625 12 6.7

15x25x1 14-7/8 x 24-7/8 x 3/4 781 12 6.8

16x16x1 15-7/8 x 15-7/8 x 3/4 533 12 6.3

16x20x1 15-3/4 x 19-1/2 x 3/4 667 12 6.9

16x24x1 15-7/8 x 23-7/8 x 3/4 800 12 8.5

16x25x1 15-3/4 x 24-5/8 x 3/4 833 12 8.3

18x20x1 17-7/8 x 19-7/8 x 3/4 750 12 8.0

18x24x1 17-7/8 x 23-7/8 x 3/4 900 12 9.0

18x25x1 17-7/8 x 24-7/8 x 3/4 938 12 9.6

19x27x1 18-7/8 x 26-7/8 x 3/4 1069 12 11.8

20x20x1 19-5/8 x 19-5/8 x 3/4 833 12 7.9

20x24x1 19-7/8 x 23-7/8 x 3/4 1000 12 9.5

20x25x1 19-5/8 x 24-5/8 x 3/4 1042 12 9.5

20x30x1 19-7/8 x 29-7/8 x 3/4 1250 12 12.5

22x22x1 21-7/8 x 21-7/8 x 3/4 1008 12 9.5

24x24x1 23-7/8 x 23-7/8 x 3/4 1200 12 11.3

24x30x1 23-7/8 x 29-7/8 x 3/4 1500 12 14.3

25x25x1 24-7/8 x 24-7/8 x 3/4 1302 12 13.5

10x10x2 9-7/8 x 9-7/8 x 1-5/8 208 12 3.9

10x20x2 9-7/8 x 19-7/8 x 1-5/8 417 12 6.6

12x24x2 11-1/2 x 23-1/2 x 1-5/8 600 12 8.0

14x20x2 13-7/8 x 19-7/8 x 1-5/8 584 12 9.1

14x25x2 13-7/8 x 24-7/8 x 1-5/8 730 12 10.5

15x20x2 14-7/8 x 19-7/8 x 1-5/8 625 12 9.6

16x20x2 15-3/4 x 19-1/2 x 1-5/8 667 12 9.6

16x24x2 15-3/4 x 23-1/2 x 1-5/8 800 12 11.6

16x25x2 15-3/4 x 24-1/2 x 1-5/8 834 12 11.6

18x24x2 17-7/8 x 23-7/8 x 1-5/8 900 12 12.8

20x20x2 19-1/2 x 19-1/2 x 1-5/8 834 12 11.9

20x24x2 19-1/2 x 23-1/2 x 1-5/8 1000 12 14.2

20x25x2 19-1/2 x 24-1/2 x 1-5/8 1042 12 14.0

24x24x2 23-1/2 x 23-1/2 x 1-5/8 1200 12 16.0

25x25x2 24-7/8 x 24-7/8 x 1-5/8 1302 12 17.2

the filter and hvac store

Page 10

10

EZ Flow and EZ Flow II

Disposable Panel Air Filters

EZ Flow - Model 10155.xxxxxx

EZFlow II - Model 10055.xxxxxx

General

EZ Flow and EZ Flow II disposable filters are

designed for protection of furnace and central air

units in residential and light commercial applications. Construction of both models is identical

except for the media retainer. The EZ Flow features

a metal media retainer on the downstream side

while the EZ Flow II has no media retainer. Instead,

the media itself is adhered directly to the frame for

non-metallic applications.

Construction

The frame is made from heavy chipboard in a onepiece design that eliminates corner separation.

The filtering media is continuous filament spun

glass. A resinous bonding agent provides rigidity

and resistance to media compression.

MEDIA SUPPORT of the EZ Flow is provided by

one metal retainer on the downstream side, either

punched metal plate or expanded metal, depending

on face size. The EZ Flow II is made to function

without a retainer, by adhering the frame directly to

the media which has a light skin to make it selfretaining.

SEALING is accomplished with a resilient hot-melt

adhesive running the full perimeter of the frame on

both upstream and downstream sides.

UL MARKING appears on the filter frame. These filters have been tested by Underwriters Laboratories

Inc. and are classified as UL 900 Class 2 for flammability.

Important Features

• One-piece frame

•UL900 Class 2

• UPC marked

• No media retainer on EZ Flow II

• Metal media retainer on EZ Flow

• 1/2”, 1” and 2” depths

• All standard sizes plus special sizes

EZ Flow II

No Metal

EZ Flow

Metal on Downstream Side

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 11

Nominal Size (inch) Actual Size H x W x D (in) cfm @ 300 fpm Standard Carton Qty. Weight per Carton (lbs.)

10x10x1 9-7/8 x 9-7/8 x 3/4 208 12 3.3

10x20x1 9-7/8 x 19-7/8 x 3/4 417 12 5.6

10x24x1 9-7/8 x 23-7/8 x 3/4 500 12 6.1

10x25x1 9-7/8 x 24-7/8 x 3/4 521 12 6.5

10x30x1 9-7/8 x 29-7/8 x 3/4 625 12 5.8

12x12x1 11 -7/8 x 11 -7/8 x 3/4 300 12 4.0

12x20x1 11 -7/8 x 19-7/8 x 3/4 500 12 5.8

12x24x1 11 -7/8 x 23-7/8 x 3/4 600 12 6.7

12x25x1 11 -7/8 x 24-7/8 x 3/4 625 12 7.5

12x30x1 11 -7/8 x 29-7/8 x 3/4 749 12 7.8

14x14x1 13-7/8 x 13-7/8 x 3/4 408 12 5.2

14x20x1 13-7/8 x 19-7/8 x 3/4 583 12 6.2

14x24x1 13-7/8 x 23-7/8 x 3/4 700 12 7.3

14x25x1 13-7/8 x 24-7/8 x 3/4 729 12 7.7

14x30x1 13-7/8 x 29-7/8 x 3/4 875 12 10.5

15x25x1 14-7/8 x 24-7/8 x 3/4 781 12 6.8

15x20x1 14-7/8 x 19-7/8 x 3/4 625 12 6.7

15x30x1 14-7/8 x 30-1/2 x 3/4 957 12 9.8

16x16x1 15-7/8 x 15-7/8 x 3/4 533 12 6.0

16x20x1 15-3/4 x 19-1/2 x 3/4 667 12 6.9

16x22x1 15-7/8 x 22-1/8 x 3/4 742 12 8.3

16x24x1 15-7/8 x 23-7/8 x 3/4 800 12 8.5

16x25x1 15-3/4 x 24-5/8 x 3/4 833 12 8.3

18x20x1 17-7/8 x 19-7/8 x 3/4 750 12 8.0

18x24x1 17-7/8 x 23-7/8 x 3/4 900 12 9.0

18x25x1 17-7/8 x 24-7/8 x 3/4 938 12 9.6

19x27x1 18-7/8 x 26-7/8 x 3/4 1069 12 11.8

20x20x1 19-5/8 x 19-5/8 x 3/4 833 12 7.9

20x22x1 19-7/8 x 22-1/8 x 3/4 938 12 9.3

20x24x1 19-7/8 x 23-7/8 x 3/4 1000 12 9.5

20x25x1 19-5/8 x 24-5/8 x 3/4 1042 12 9.5

20x30x1 19-7/8 x 29-7/8 x 3/4 1250 12 12.5

22x22x1 21-7/8 x 21-7/8 x 3/4 1008 12 9.5

24x24x1 23-7/8 x 23-7/8 x 3/4 1200 12 11.3

24x30x1 23-7/8 x 29-7/8 x 3/4 1 500 12 14.3

25x25x1 24-7/8 x 24-7/8 x 3/4 1302 12 13.5

10x10x2 9-7/8 x 9-7/8 x 1-5/8 208 12 3.9

10x20x2 9-7/8 x 19-7/8 x 1-5/8 417 12 6.6

12x24x2 11-1/2 x 23-1/2 x 1-5/8 600 12 8.0

14x20x2 13-7/8 x 19-7/8 x 1-5/8 584 12 9.1

14x25x2 13-7/8 x 24-7/8 x 1-5/8 730 12 10.5

15x20x2 14-7/8 x 19-7/8 x 1-5/8 625 12 9.6

16x20x2 15-3/4 x 19-1/2 x 1-5/8 667 12 9.6

16x24x2 15-3/4 x 23-1/2 x 1-5/8 800 12 11.6

16x25x2 15-3/4 x 24-1/2 x 1-5/8 834 12 11.6

18x24x2 17-7/8 x 23-7/8 x 1-5/8 900 12 12.8

20x20x2 19-1/2 x 19-1/2 x 1-5/8 834 12 11.9

20x24x2 19-1/2 x 23-1/2 x 1-5/8 1000 12 14.2

20x25x2 19-1/2 x 24-1/2 x 1-5/8 1042 12 14.0

24x24x2 23-1/2 x 23-1/2 x 1-5/8 1200 12 16.0

11

Notes:

1. Contact your local representative or the factory for additional standard sizes. Special

sizes are also available.

2. Manufacturing tolerances are +0”, -1/8” on height and width.

3. Nominal cfm is calculated at 300 fpm gross face velocity.

4. Typical initial (clean) pressure drop at nominal cfm is 0.07” w.g. for 1” filters and 0.10”

w.g. for 2” filters.

5. Recommended final resistance is 0.50” w.g., but the system design may dictate a lower

changeout point.

Standard Sizes Performance Data - EZ Flow and EZ Flow II

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 12

12

Pinch Frame

Disposable Panel Air Filters

Model 11655.xxxxxx

General

The Flanders Pinch Frame disposable air filter provides the user with a product of high quality and

strength.

Originally designed for light commercial and industrial applications, the Flanders Pinch Frame filter is

an excellent choice for use in residential furnace

systems.

The filter is produced on state-of-the-art production

line machinery. The result is a filter of consistently

high quality at a competitive price.

Construction

This disposable heating and air conditioning filter

has a one-piece chipboard frame. This feature eliminates the problems associated with a four-piece

frame, such as broken corners and exposed metal

edges.

The Pinch Frame filter utilizes a heat seal to bond

the frame to the filter media and metal support grid.

This process permits the use of a single metal grid

on the air exit side only, thus maximizing filter face

area and extending service life.

The media is made of 100% nonwoven polyester

synthetic fibers chemically bonded with a fire retardant resin. Because of the synthetic nature of the

fiber, the media is extremely resistant to moisture

and other environmental extremes.

Physical Data

Frame: One-piece chipboard

Media: Dry resinated polyester

Support Grid: Perforated metal on air-exit side

Sealant: Hot-melt resin

Nominal Thickness: 1”

Flammability: UL 900 Class 2

Important Features

• One-piece chipboard frame prevents broken corners and exposed metal.

• Heat-sealed frame provides unusual strength

and serviceability.

•Ametal grid on the air-exit side assures more

open face area and longer service life.

• Resinated polyester media provides resistance

to moisture.

• Filters are UL 900 Class 2 listed.

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 13

13

Nominal Size (inch) Actual Size H x W x D (inches) cfm @ 300 fpm Standard Carton Qty. Weight per Carton (lbs.)

10x20x1 9-7/8 x 19-7/8 x 7/8 420 12 4.0

10x24x1 9-7/8 x 23-7/8 x 7/8 500 12 5.0

10x30x1 9-7/8 x 29-7/8 x 7/8 620 12 5.5

12x20x1 11 -7/8 x 19-7/8 x 7/8 500 12 4.5

12x24x1 11 -7/8 x 23-7/8 x 7/8 600 12 5.0

12x25x1 11 -7/8 x 24-7/8 x 7/8 620 12 5.0

12x27x1 11-7/8 x 26-7/8 x 7/8 670 12 6.0

12x30x1 11 -7/8 x 29-7/8 x 7/8 750 12 6.0

14x20x1 13-7/8 x 19-7/8 x 7/8 580 12 4.5

14x24x1 13-7/8 x 23-7/8 x 7/8 700 12 5.5

14x25x1 13-7/8 x 24-5/8 x 7/8 730 12 5.5

14x30x1 13-7/8 x 29-7/8 x 7/8 870 12 6.5

15x20x1 14-7/8 x 19-5/8 x 7/8 620 12 5.0

15x30x1 14-7/8 x 29-7/8 x 7/8 940 12 6.0

16x20x1 15-5/8 x 19 5/8 x 7/8 670 12 5.5

16x25x1 15-5/8 x 24-5/8 x 7/8 830 12 6.5

16x30x1 15-7/8 x 29-7/8 x 7/8 1000 12 7.5

18x25x1 17-7/8 x 24-7/8 x 7/8 940 12 6.0

20x20x1 19-5/8 x 19-5/8 x 7/8 830 12 6.0

20x24x1 19-7/8 x 23-5/8 x 7/8 980 12 6.5

20x25x1 19-5/8 x 24-5/8 x 7/8 1040 12 7.0

20x30x1 19-7/8 x 29-7/8 x 7/8 1250 12 8.5

24x24x1 23-1/2 x 23-1/2 x 7/8 1200 12 8.0

25x25x1 24-7/8 x 24-7/8 x 7/8 1300 12 8.5

Standard Sizes Performance Data - Pinch Frame

Notes:

1. Manufacturing tolerances are +0”, -1/8”

2. All sizes are packed 12 per carton

1.0 General

1.1 Disposable filters shall be Pinch Frame filters as

manufactured by Flanders..

1.2 Filters shall be UL 900 Class 2 listed.

2.0 Filter Construction

2.1 Filters shall be constructed ofresinated polyester

media and a metal air-exit grid heat sealed

together in a one-piece chipboard frame.

3.0 Performance

3.1 The average arrestance of 70% shallbe as determined by the ASHRAE Standard 52.1 test

method.

3.2 The manufacturer shall guarantee performance

as stated in its literature within tolerances as

outlined in Section 7.4 of ARI Standard 850.

Guide Specifications

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 14

Rugged, Heat-sealed,Construction

Flanders Ring Panel and

Cube filters are made by

heat sealing layers of synthetic filtering media

together over an interior,

corrosion-resistant steel

support frame. An overcut

of media outside the sealforms a built-in gasket

(selvage) between the

wire support frame and

holding frame, which secures the filter and prevents

air bypass. This special feature allows these filters

to be installed without the use of retainer fasteners

Link Panels

Flanders Ring Panel filters can be ordered as standard single panels or as link panels. Alink panel is

made by heat sealing individual Ring Panel filter

panels end to end to achieve desired dimensions.

Sleeve Panels

Sleeve Panels are nearly identical to the stan-

dard Ring Panel. The only major difference in

construction with the Sleeve Panel is that one

end is left unsealed. Therefore, the interior support frame can be removed and used over and

over again, with just the soiled media thrown

away. This is more economical and makes disposal easier.

Cubes

Cubes are internally supported filters similar to the

Polyester Panel. The exception is greater surface

area for contamination capture. Unitary , 2-pocket or

3-pocket construction is available throughout our

entire product offering. Cubes are available with

13/16” thick headers for side access installations or

other systems where a header is required.

A Moisture-resistant Alternative

Because these filters are made with only metal and

synthetic materials, they are an excellent alternative to paper-frame filters in high moisture areas

because they are naturally moisture-resistant and

will not deteriorate or warp in wet or humid conditions.

14

Ring Panels, Links, Sleeves

and Cubes

Important Features

• Heat sealed construction

• Tackified, progressive density

media

• 2, 3 and 4-ply combinations

• 100% moisture resistant

• 9 gage galvanized wire frame

• Merv 6-10 available

•UL900 Class 2

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 15

15

Series ST55-Polyester Panel

Models ST55R-xxxx Ring Panel and ST55L-xxxx Link

Two-ply 1” nominal media construction using a 1/2” nominal white polyester on the upstream, followed by a 1/2” nominal green super tackified

polyester downstream.

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

Link Panels are heat-

sealed together.

Use link panels for easy

installation in filter

tracks and eliminate air

bypass!

Link panels make installation

easy. Just unfold the filter

and slide it into the track as

one continuous, long filter.

When time to replace it, the

whole filter comes out easily

in one piece. Plus, the sealing between links and the

generous selvedge eliminates air bypass.

Goes in as one

piece. Comes out

as one piece.

Overcut gaskets

against air

bypass.

Moisture

resistant

materials

Series 425T-Polyester Panel or Cubes

Models 425RT-xxxx Ring Panels and 425LT-xxxx Links

CUBx425T-xxxxxx Cube

Four-ply 1-3/4”” nominal media construction, using a 1-1/2” nominal

white/green/white tridensity, multidenier polyester upstream,with internal

tackification followed by a 1/4” dense white polyester downstream.

Series 325T-Polyester Panel or Cubes

Models 325RT-xxxx Ring Panels and 325LT-xxxx Links

CUBx325T-xxxxxx Cube

Three-ply 1-3/4”” nominal media construction, using a 1-1/2” nominal

white/green dual density, multidenier polyester upstream, with internal

tackification followed by a 1/4” dense white polyester downstream.

Series 225T-Polyester Panel or Cubes

Models 225RT-xxxx Ring Panel, 225LT-xxxx Link,

CUBx225T-xxxxxx Cube

Two-ply 1” nominal media construction, using a 3/4” nominal white polyester on the up-stream, with internal tackification followed by a 1/4”

dense white polyester downstream.

the filter and hvac store

Page 16

16

Paintbooth Filtration

Downdraft

Flanders offers a wide variety of filtration products for

downdraft and crossdraft paintbooths and prep stations. For the most part, fitlration products required for

all of these fall into three general categories which are

color coded to the drawings at left which indicate their

placement in each type of booth.

Air Intake filters are as important to a great paint job

as the booth itself. The intake filters are the primary

defense against foreign particles landing on the painting surface. Any particle larger than 10 microns can

cause a defect on a paint job. Intake filters are typically either panels or pads. Intake filters in a downdraft booth and prepstations are above the painting

surface. In crossdraft booths, they are typically in the

door.

Exhaust filters play an important role in maintaining

proper air flow balance, increasing cleanliness of

exhaust stacks, reducing maintenance of the exhaust

system and in controlling V.O.C. emissions. The purpose of exhaust filters is to capture overspray particles and remove them from the airstream as air is

removed or recirculated back into the booth.

Crossdraft and semi-downdraft booths use media

pads which are placed on grids in the rear wall or

lower portion of the side walls in filter housings.

Downdraft booths use a long pad that is placed into a

pit below the painting surface.

A prefilter is designed to filter out large particles

before the air reaches the intake filter. This prolongs

the life of the intake filter, increases airflow in your

booth and reduces maintenance costs on the intake

stack and mechanical parts. The prefilter is typically

found only in heated booths. Crossdraft booths will

very rarely have a prefilter. In downdraft and semidowndraft booths, the prefilter is located somewhere

along the duct-work bringing air into the booth.

Intake Filters

Prefilters

Exhaust/Paint Arrestor Filters

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

Prep Station

Crossdraft

the filter and hvac store

Page 17

17

SA600-G10 Diffusion Media for Air Intake

Models SA600-xxx

For downdrafts and prep stations. This filter provides the highest level of protection against paint

damaging particles available today. In addition to

its leading reputation in filtering ability, the SA600G10 is able to withstand high temperature applications, up to 140 degrees Celcius! This filter does

not discolor or break down in the heated booth

environment. Other leading media using traditional

tackifiers and PVC resins, produce a heavy discoloration and the media expands reducing the filtering ability.

Flanders’ re-engineered media and manufacturing

process has virtually eliminated these flaws. Using

ecologically sound materials, and eliminating PVC

resins, the media discoloration and media expansion have been minimized. The SA600-G10 is a 1”

diffusion media, and carries the prestigious G10

mark. G10 is a European standard for test performance, and only qualified media can claim this

mark of distinction. It has a high dust holding

capacity for long life, and stops all particles of paint

damaging size from entering a paintbooth when

installed properly.

This product has a normal service life of 10 to 18

months, depending on outside air quality and

usage. The filter is available in bulk rolls or cut

pads for your convenience. Cut pads are cut in our

facility to your booth requirements.

SAR-1 Pad for Air Intake

Models SAR1M-xxxxx

For use as an intake blanket on crossdraft booths.

The SAR-1 media, made in Switzerland, has a 1/2“

loft, and is optimally designed for efficiency and

dust holding capacity. For crossdraft booths, the

SAR-1 pad, sometimes referred to as a blanket, is

tucked into the doors of the booth. There is usually only one large pad on each door. Oversized

SAR-1 media pads can be easily trimmed.

The SAR-1 media is a premium choice for crossdraft requirements. The tackifier and heavily callendered exit side allow for excellent particle retention. The SAR-1 is a premium choice for crossdraft

filtration.

SAR-1 Panels for Air Intake

Model SAR1Pxx-xxxx

For use in crossdraft and some downdraft

booths.The SAR-1 P ANEL, made in Switzerland, is

a premium choice for panel filtration. The SAR-1

PANEL is made from two media pads. A metal

support is dielectrically heat sealed in between the

two media layers providing support and rigidity.

The first media layer is designed to catch large particles entering the booth. The second media layer

is designed to catch the smaller particles. 100% of

the fibers in the second layer are tackified to retain

trapped particles. The combination of small fiber

size and a callendered exit provide unsurpassed

R-1 filtration.

The metal support is made from 9 gauge galvanized steel, which will not rust. The support is

formed into a rectangular shape and contains two

crossbars for added stability.

When choosing the correct size, measure the metal

support. The metal support will be 3/8” under the

listed size. For instance, a 20x20 panel’s ring will

measure 19-5/8 x 19-5/8. Crossdraft booths will

have a series of housings that look like square or

rectangular holes in the booth doors. Panel filters

have extra media overlapping the metal support

which act as gasketing when placing the panel filter

inside the housing and create a tight seal to prevent

any air bypass around the filter.

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 18

18

Series ST55 Panel for Air Intake

Models ST55R-xxxx and ST55L-xxxx-xx

The SERIES ST55 P ANEL, made in the USA, is an

economical choice for crossdraft booths. The

SERIES ST55 is made from two media pads. A

metal support is dielectrically heat sealed in

between the two media layers, providing support

and rigidity.

The first media layer is designed to catch large particles entering the booth. The second media layer

is designed to catch the smaller particles. The

downstream side of the second layer is treated with

a sticky non-migrating tackifier which holds trapped

particles inside the filter. The metal support is

made from 9 gauge galvanized steel, which will not

rust. The support is formed into a rectangular

shape and contains two crossbars for added stability.

When choosing the correct size, measure the metal

support. The metal support will be 3/8” under the

listed size. For instance, a 20x20 panel’s ring will

measure 19-5/8 x 19-5/8.

Series 332 Paint Arrestor

Models 332PA-xxxx

Fiberglass with polyester for use as a paint arrestor

in all types of booth. Series 332 is our highest quality fiberglass media available. Made with 18 grams

of fiberglass per square foot, and a polyester exit

layer, the Series 332 is more efficient and holds

more paint than almost any other fiberglass products.

Series 332 comes in 200 ft. rolls and in pads for

crossdraft and semi-downdraft booths. Series 332

is made from air-laid fiberglass forming a 2.5”

thickness and a thin polyester layer bonded to the

exit side for added efficiency.

Series 332 fibers are ideal for paint capture due to

their loose weave. The paint particles collide with

the fiberglass fibers and are removed from the

airstream, and the fine particulate is removed by

the polyester exit layer.

A grid is needed to hold the pad which is standard

in most booths, or are available through Flanders

customer service.

If your downdraft booth uses a pit, measure the

width of the pit to find the appropriate roll, or check

our booth guide. To change the media, simply,

unwind the roll to the proper length, and cut a pad.

FP3-Paint Arrestor

FP3PA-xxxx

FP3 media is an excellent choice for exhaust media

in any booth. Use of this media will keep the booth

exhaust system cleaner when converting from

fiberglass, however some older booths do not work

well with the resistance levels.

FP3 media combines three distinct layers of polyester fibers forming a funnel effect. The first layer

captures large particles. The second and third layers catch the finer particles.

By utilizing an open weave on the first layer, particles do not cause the filter to quickly clog up allowing large amounts of paint to be captured without

substantial increases in air pressure.

The pad sizes listed below are typical in crossdraft

and semi-downdraft booths. If converting from

Styrobaffle or Styrofoam, grids will be needed to

hold the pads in place. If your downdraft booth

uses a pit, measure the width of the pit to find the

appropriate roll, or check our booth guide.

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 19

19

Series 331Y PA

Models 331Y-xxx

22 gram Fiberglass Paint Arrestor for use in all

booth types. Series 331Y is a high quality fiberglass

media. Made with 22 grams of fiberglass per

square foot, the Series 331Y is more efficient and

holds more paint than many other fiberglass products. It comes in 200 ft. rolls and is also available in

pads for crossdraft and semi-downdraft booths.

Series 331Y is made from air-laid fiberglass forming a 2.5” thickness. The exit side has a skin backing for added efficiency.

Series 331Y fibers are ideal for paint capture due to

their loose weave. The paint particles collide with

the fiberglass fibers and are removed from the

airstream.

If your downdraft booth uses a pit, measure the

width of the pit to find the appropriate roll, or check

our booth guide. To change the media, simply,

unwind the roll to the proper length, and cut a pad.

Series 330G PA

Models 330G-xxx

15 gram Fiberglass Paint Arrestor for all booth

types. Series 330G is our economy grade fiberglass media. Made with 15 grams of fiberglass per

square foot, the Series 330G holds more paint than

other economy fiberglass media due to its skin exit

side.

Series 330G comes in 100 ft. rolls compared to

many of our competitors 200-300 ft. rolls. The fiberglass is also available in pads for crossdraft and

semi-downdraft booths.

Series 330G is made from air-laid fiberglass forming a 2.5” thickness. The exit side has a skin backing for added efficiency.

Series 330G fibers are ideal for paint capture due to

their loose weave. The paint particles collide with

the fiberglass fibers and are removed from the

airstream.

If your downdraft booth uses a pit, measure the

width of the pit to find the appropriate roll, or check

our booth guide. To change the media, simply,

unwind the roll to the proper length, and cut a pad.

Series 225T Cube

Models CUBx225Txxxxxx

2-Ply Self Supportive Cube Filter for use as a paint

arrestor. 225T Cube filters are a single pocket

trapezoid cube filter. A 1” dual denier polyester

media is sewn into shape. The filter is then

attached to a 9 gauge wire for support when

installed in the filter housing.

Due to their unique design, cube filters have a larger surface area than conventional pads. The

increase in surface area allows the filter to hold

more contaminants thereby increasing the life of

the filter.

325Tand 425T-Cubes

Models CUBx325Txxxxxx and CUBx425Txxxx

Three and Four Stage Cube Filters for use as a

paint arrestor. Two products make up our premium

exhaust cube product line. They are the Series

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 20

20

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

325T, which is 98% efficient, and the Series 425T

which is 99% efficient. The exhaust cube filters

have a larger surface area than a conventional flat

pad. This increase in surface area reduces the

restriction to airflow, and increases the paint holding capacity of the filter. This means better airflow

and longer life.

The Series 325T is made from a polyester media

supported by a 9 gauge wire frame. The dual

denier media is used as an initial barrier, and a

tightly woven thin media is used as a final particle

barrier. This filter captures an average of 98% of

overspray in weight.

The Series 425T has an added layer of media

applied to the downstream side of the filter.

Although the construction is the same as the Series

325T, the added layer of single denier polyester

fibers gives the Series 425T a 99% efficiency rating.

PS125-Bag

Models 125BAG-xxxxxx

Scrim-Back Polyester Media Bags for use as a secondary paint arrestor in selected booths.

Each bag is hand sewn and attached to a 9 gauge

galvanized support frame, and includes a 1” header for easy placement in side access housings.

Special bags may require a wire support basket, no

header or frame, or loops at the end of each pocket for support.

The media is a 1” single denier polyester fiber with

a scrim backing. This media has little effect on the

airflow, and has a high dust holding capacity. The

unique pocket design increases the surface area of

the media. This increase in surface area will

increase the life of the filter, and reduce the pressure drop.

If the exhaust bag is the same size as a booth’s

intake bags, it is common to rotate the intake bags

to the exhaust bags to reduce costs. Bag measurements are nominal in size. If a bag is 15.5” x

24.5” x 19.5”, the listed size is 16” x 25” x 20”.

Please note this difference when measuring your

exhaust bags.

Andrea and PS125 Exhaust Filters

Models ANDREA and 125PAD-xxxx

The Andrea filter is a paper paint arrestor with a

unique design. Kraft paper is pleated into an accordion-like form with holes punched in the paper at

consistent intervals. A second layer of paper is

attached to the back with different hole placements.

When air passes through the filter, it hits the wall of

the second kraft paper layer and is diverted through

the second hole. This air turbulence and laws of

motion cause the paint to collect on the paper and

cleaned air to pass through the filter.

The PS125 Water Wash Pads are designed specifically for use in select Spraybake brand booths.

Certain models of Spraybake use a water wash

system as a secondary exhaust. This water wash

system requires special pads to be used to filter out

particulate in the system. The fiber has a reinforced

scrim backing on the downstream side to prevent

fiber breakoff or migration. The water wash pads

are also available in custom sizes.

*Our filters are not affiliated with SPRAYBAKE®. Use of the

registered SPRAYBAKE® name is for comparative purposes

only.

Series 225-Panel

Models 225RT-xxxx and 225LT-xxxxx-xx

2-ply Panel and Link Filter for use as a prefilter in

downdraft booths. The 2 ply panel filters are constructed using two layers of poly-synthetic fibers.

These layers are designed to capture large particles in the first layer and smaller particles throughout the second layer.

A9 gauge wire frame with two cross pieces is

dielectrically heat sealed inside the filter for sup

the filter and hvac store

Page 21

21

port. The media overlaps the support, which provides a gasketing effect reducing air bypass around

the filter.

A tackifier is applied in between the last two layers

to stabilize any migrating particles and prevent the

discharge of particles from the filter. The graduated media design produces a superior dust holding

capacity that will outlast most filters on the market.

Panel filters are 100% moisture resistant and will

not warp or deteriorate in wet or humid conditions.

By utilizing one continuous panel in a filter track,

and its selvedged edge, a panel filter eliminates air

bypass so common among cardboard framed filters.

When measuring the correct filter for your booth,

first measure the entire filter track. This measurement should have a track height of 14-25” and a

length of 14-100”. The height of the 2 Ply Panel is

listed as a nominal size. For instance, if a filter ring

measures 15.5” x 19.5”, then the correct size is 16”

x 20”. There are hundreds of standard sizes available. Custom sizes are also available.

Model 40 Standard Capacity Pleat

Models 80055.xxxxxx

For use as a prefilter in downdraft booths. Model 40

Pleats are designed to operate in almost every type

of installation. Available in 1”, 2” and 4“ nominal

thicknesses, these filters have an average atmospheric dust spot efficiency range of 25-30% per

ASHRAE Standard 52.1 test methods. Model 40

Pleats offer greater efficiency and service life than

disposable filters, pad and frame systems, or metal

washable filters. The overall design of this product

makes these filters the accepted choice in applications requiring high performance and extended

service.

Filter frames are constructed from two pieces of

die-cut, moisture-resistant carrier board.

Components”telescope” into one another and provide double-wall construction and a precision fit.

The frame includes diagonal and horizontal support

members bonded to the media on the air entering

and leaving sides for unsurpassed frame strength,

locking corners and positive media-to-frame seal

reduces the possibility of air bypass.

The filter is made from fully synthetic, high-loft and

reinforced media. It is continuously laminated to an

expanded metal grid on the air leaving side to provide pleat stability throughout the life of the filters

and prevent media flutter while in operation. The

unique v wedge allows for total media usage and

provides maximum air flow.

HD Poly-T/A

Models 11255.xxxxxx

These are heavy duty synthetic filters for use as

prefilters in downdraft booths.HD Industrial Grade

filters are designed for use in any application where

disposable panel filters are recommended. They

can be relied upon for superior performance since

they are specifically designed for heavy work-loads.

Both standard and special sizes are available.HD

Industrial Grade filters are designed with a onepiece moisture-resistant chipboard frame enclosing

progressive-density media. Standard frames are

nominal 1” thick (3/4” actual) and nominal 2“ thick

(1-5/8“ actual).

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

Model 40 Pleated

Series 225 Panel

the filter and hvac store

Page 22

22

The filter media consists of 100% high bulk polyester fibers that are thermo-bonded with a fire retardant res” Support grilles of expanded metal are

provided on both sides of the filter. The media pads

and support grilles are continuously glued to the

inside perimeter of the frame, resulting in exceptional strength and rigidity. This design virtually

eliminates the possibility of media sag within the

frame.

Polyester Bulk Media Rolls and Pads

Models 1Txx for 1” and 2Txx for 2”

For use as a prefilter in downdraft booths. Polyester

pads and rolls are made of a dual layer polyester

media with a dry tackifier. The filter is cut into various pad sizes from the roll and placed into a metal

holding frame (See Uniframe on page 79). The

1DT media is a 1“ thick filter, and the 2DT media is

a 2” thick filter. The media can be ordered in precut pads or bulk rolls, and can easily be trimmed

with scissors.

KKM Washable

Models 51255.xxxxx

Washable permanent filter for use as a prefilter in

downdraft booths. The KKM permanent filter is a

heavy duty, washable, aluminum media, all metal

filter.

The KKM offers large filtering area, high dust holding capacity, uniform loading and low resistance to

airflow. It is recommended that the filter media be

coated with dust adhesive for optimum perform-

ance.

The standard offering of KKM filters includes six of

the most popular face sizes in 1” and 2” depths.

Special face sizes and 1/2” depth filters are also

available. For ease of installation, all filters are

undercut slightly on length, width and depth.

Precision Pak

Models PAPxxxSxxxx

High efficiency bag filter for use as a prefilter in

downdraft booths and prep stations.

The Precision Pak ASHRAE bag use a fully synthetic media that provides an efficiency rating of 4555%. The pockets are hand sewn or ultrasonically

sealed and fastened to an all aluminum frame.

They are designed for specific booths and prep stations that can accommodate their special size and

performance properties. UL 900 Class 2 Listed.

Precision Pak bags have a large amount of media

surface area. This decreases the pressure drop

and increases the capacity. These bags hold substantial amounts of dirt removed from the airstream.

Use of these bags will ensure a clean environment

throughout the intake stack and prolonged life of

the ceiling diffusion media.

Bag filters are sized nominally in their length and

width. If the booth track measures 19.5” x 19.5”,

then the correct bag listed is 20” x 20”. Bag filters

also have a special depth. The depth describes the

length of the pockets. This is an exact size and is

usually an even number. There are many other

sizes available, and custom sizes can be made to

order. There are also other efficiencies ranging

from 45% through 95%. For additional sizes, UL

Ratings or efficiencies, please contact customer

service.

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 23

23

PS125-Bag

Models125BAG-xxxxxx

Scrim-Back polyester media bags as prefilter.

PS125 Bags are made from a single denier polyester media that contains a scrim backing for extra

rigidity . The PS125 Bags each contain a metal wire

support and a 1” channel frame for easy placement.

Prefilter bags have an ever-changing and diverse

selection of types and sizes. Call customer service

at any time to help with your selection.

PS125-Cube, PS125-Sock

Models125SOCK-xxxx

PSeries 225T Cubes are also used as an exhaust

filter in several applications. The Spraybake Sock

filter is made from a 1” single denier polyester

media. The filter has a draw string sewn at the top,

and a support loop at the bottom corner. The filter

fastens to the ductwork by the drawstring. After

fastening the support loop, the filter remains open

and stable.

*Our filters are not affiliated with SPRAYBAKE®. Use of the

registered SPRAYBAKE® name is for comparative purposes

only.

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 24

24

FP319A

Two-stage and Three-stage Paint Systems

Paintbooth Filtration

Pads: FP319AxxxxPAD, Ring Panels: FP319A2020PRK,

Cubes: FP319Axxxx ,Bags: FP319Axxxxxxxx

FP319A Chromate Recovery System

The Flanders FP319A-Chromate Recovery System

is offered in both two-stage and three-stage configurations for aerospace overspray painting environments.

The FP319A complies with EPA (Environmental

Protection Agency) Test Method 319 as it applies to

the National Emissions Standards for Hazardous

Air Pollutants (NESHAP). Reference 63 Fed. Reg.

59 (March 27, 1998) and 40 C.F.R. 9, 63.

The EPA Test Method 319 is a testing protocol in

which potassium chloride and oleic acid are substituted for chromate paint. These chemical substances attempt to simulate dry and wet overspray

characteristics of the chromate paint. This testing

protocol verifies that an air filtration system (two or

three-stage) has met minimum efficiency requirements, under laboratory conditions, utilizing potassium chloride and oleic acid.

The Flanders FP319Atwo and three-stage systems

have been qualified by independent laboratory on

specific chromate paints. These tests are performed in controlled environments to simulate the

“real world” painting environment.

Two-Stage

The two-stage version of the Flanders system utilizes a proprietary synthetic media pad in combination with a proprietary synthetic media bag type filter. The two-stage system performed as shown

below in testing.

1 Dexter (A) 454-5 + (B) X-395 fuel tank coating mixyellow - With a conventional air gun operating at 45

psi, with spray feed rate of 105 gr/min @ 120 fpm.:

Initial pressure drop was .18” w.g. running to final

pressure drop at .72” w.g., average removal efficiency was measured at 99.78% efficiency, with

279 grams holding capacity on the first stage and

2600 grams holding capacity on the second stage.

2. Deft 44GN72 green water-reducible coating (A) base

+ (B) activator - With a conventional air gun operat-

ing at 45 psi, with spray feed rate of 110 gr/min @

120 fpm.: Initial pressure drop was .10” w.g.

Running to final pressure drop at .74” w.g., average

removal efficiency was measured at 98.91% efficiency, with 469 grams holding capacity on the first

stage and 6327 grams holding capacity on the second stage.

Three-stage

*National Emissions Standards for Hazardous

Air Pollutant minimums, as defined in Test

Method 319 protocol.

Two-stage

Two-Stage Test Method 319 Data NESHAP*

KCL 2.14 - 2.85 m 84.4% >10%

4.25 - 5.55 m 94.6% >50%

7.66 - 9.46 m 97.3% >90%

OLEIC 1.88 - 2.83 m 85.6% >10%

3.69 - 4.71 m 94.4% >50%

5.11 - 6.29 m 97.1% >90%

Three-Stage Test Method 319 Data NESHAP*

KCL 0.59 - 0.73 m 97.3% >75%

0.87 - 1.16 m 98.8% >85%

2.14 - 2.85 m 99.6% >95%

OLEIC 0.37 - 0.47 m 89.2% >65%

0.94 - 1.41 m 96.8% >80%

1.88 - 2.83 m 99.0% >95%

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 25

25

1

2

3

Avg

1

2

3

Avg

1

2

3

Avg

3. Courtaulds yellow fuel tank coating (A)

513X390 base + (B) 910X624 activator - With

a conventional air gun operating at 45 psi,

with spray feed rate of 105 gr/min @ 120

fpm, initial pressure drop was .23” w.g.

Running to final pressure drop at .82” w.g.,

average removal efficiency was measured

at 99.35% efficiency, with 284 grams holding capacity on the first stage and 1366

grams holding capacity on the second

stage.

Three-Stage

The three-stage version of this system utilizes the same filters as the two-stage, plus

a proprietary internally supported Polyester

Panel filter and a proprietary pocketed cube

filter.

The three-stage system performed as

shown below in testing.

1. Dexter (A) 454-5 + (B) X-395 fuel tank coating mix-yellow - With a conventional air gun

operating at 45 psi, with spray feed rate of

105 gr/min @ 120 fpm, Initial pressure drop

was .15” w.g. Running to final pressure drop

at .70” w.g., average removal ef ficiency was

measured at 99.97% efficiency, with 470

grams dust holding capacity on the first

stage, 981 grams holding capacity on the

second stage and 1140 grams holding

capacity on the third stage.

2. Deft 44GN72 green water-reducible coating

(A) base + (B) activator - With a convention-

al air gun operating at 45 psi, with spray

feed rate of 104 gr/min @ 120 fpm: Initial

pressure drop was .15” w.g.Running to final

pressure drop at .70” w.g., average removal

efficiency was measured at 99.97% efficiency, with 470 grams dust holding capacity on the first stage, 981 grams holding

capacity on the second stage and 1140

grams holding capacity on the third stage.

3. Courtaulds yellow fuel tank coating (A)

513X390 base + (B) 910X624 activator - With

a conventional air gun operating at 45 psi,

with spray feed rate of 93 gr/min @ 120

fpm: Initial pressure drop was .15” w.g.

Running to final pressure drop at .79” w.g.,

average removal efficiency was measured

at 99.91% efficiency, with 570 grams dust

holding capacity on the first stage, 821

grams holding capacity on the second

stage and 354 grams holding capacity on

the third stage.

Filter ID:

FP319A (three-stage)

Descriptions:

6 Pocket synthetic, yel-

low 15” deep

Test Type:

Fractional Efficiency

Velocity:

120 fpm

Test Aerosol:

KCI, neutralized

Filter ID:

FP319A (three-stage)

Descriptions:

6 Pocket synthetic, yel-

low 15” deep

Test Type:

Fractional Efficiency

Velocity:

120 fpm

Test Aerosol:

Oleic Acid, neutralized

Filter ID:

FP319A (two-stage)

Descriptions:

Poly Panel, 6-Pkt. bag

Test Type:

Fractional Efficiency

Velocity:

120 fpm

Test Aerosol:

KCI, neutralized

Filter ID:

FP319A (two-stage)

Descriptions:

Poly Panel, 6-Pkt. bag

Test Type:

Fractional Efficiency

Velocity:

120 fpm

Test Aerosol:

Oleic Acid, neutralized

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 26

26

Service Rolls

Flanders Service Rolls air filtration media are manufactured in selected widths, prepared in roll

lengths that make manageable roll sizes. In most

cases, a single cut across the roll will produce a

ready-to-install filter pad.

The following media are offered as service rolls:

Spun Glass:

(Models SGxxxxKK) This is a rigid, nominal

3/8” thick, dry spun glass. It is typically used to

make rigid pads for use in room unit air conditioners. It is designed for use without a frame. Since it

is untreated, it will not harm the plastic frequently

used in the construction of room units.

Foam: (Models FRxxxxx) A rugged polyurethane foam

that is designed for use in room unit air conditioners

and in pad-holding frames. It is washable and will

withstand repeated cleaning with mild soap and

water. Foam service rolls are available in 1/4”, 1/2”,

1” and 2” media thicknesses. They are washable for

repeat use.

Aluminum: (Models EAxx) The aluminum service roll is

an expanded aluminum mesh of the type used in

room unit air conditioners. It is a nominal 1/4” thick

dry filter media that requires the addition of a dust

adhesive for effective filtration.

Kwik Kuts

(Models KKxxx)

These are 15”x24” pads of filter media that can be

easily cut to fit any window or wall mounted room

air conditioner. They are offered in the same spun

glass, foam and aluminum media described above.

Also offered are 1/2” Permaire (see column at

right) and plastic-backed foam.

Hammock Rolls and Pads

Models HRxxxx

Flanders hammock rolls are available in nominal 1”

spun glass, 2” spun glass, and 1” polyester synthetic fiber media. Performance data on all

Flanders hammock media is available upon

request.

Cut-to-Fit

Kwik Kuts, Hammock, Permaire and

Service Rolls and Pads

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 27

Typically, these are for Lennox type furnaces.

(Lennox is a brand name. It is used here for system

identification only.) Hammock rolls are 20 foot rolls

of media cut in various widths. In most cases, a single cut across the roll will produce a ready-to-use

filter pad. Flanders hammock rolls are packaged in

a handy carton that can be used as a dispenser.

Media used in all Flanders hammock rolls are UL

Class 2 fire rated. The 1” spun glass is also available in pre-cut hammock pads, individually packaged in plastic

Permaire Rolls and Pads

Models HHxxxx

Permaire is a unique type of air filtration media that

has evolved from a natural organic fiber media to a

new completely synthetic, self-supporting and completely washable media. It has all the benefits of

organic media but has a longer service life, better

structural integrity as well as being completely odor

free. It is made of synthetic fibers and coated with a

special resin, then baked together at a high temperature. The result of this process is a tough and

springy, thoroughly bonded, nearly rigid air filtration

media.

Describing Permaire as merely an air filtration

medium is telling only half of the story. Due to its

natural rigidity, a pad of Permaire cut to the proper

dimensions is actually a complete filter ready to

install. It is totally self supporting. With nothing

more than Permaire and a hefty pair of scissors or

a razor knife, you can replace almost any size 1/2”,

1” or 2” framed panel filter.

Permaire filters are passive electrostatic type products. Air running over the maze of fibers creates an

electrostatic charge to catch and hold airborne contaminants. Dust particles may become charged naturally, and if so, they are held by strong electrostatic forces to the oppositely charged fiber with which

they come into contact. The smaller a particle or

fiber, the relatively stronger the electrostatic

charges will be attained. Dirt loads throughout the

filter’s depth and therefore it will hold a lot more

dust than other filters before requiring changing or

cleaning.

Permaire is an ideal product for filter service professionals. With a roll of Permaire on your truck,

you can replace almost any size panel filter. It’s a

perfect answer to “odd” size filters. A10x32”special”

is as close as a pair of scissors...and the same low

cost as a 16x20 standard that you cut from the

same roll.

27

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

Cut-to-Fit

Kwik Kuts, Hammock, Permaire and

Service Rolls and Pads

the filter and hvac store

Page 28

28

Wide selection of media types

Flanders offers a wide range of top quality air filtration media available in bulk rolls and pads.

Considering the unique characteristics of each

offering, the user can get maximum value for filter

dollar spent with relation to the intended use.

Bulk media rolls are offered in selected slit widths

with roll lengths determined by manufacturing

processes. Pre-cut pads, as the name implies, are

pads of filtration media cut to standard filter face

sizes or to your desired custom sizes.

Spun glass is a rugged industry standard, known

for low resistance while providing excellent

arrestance and high dust holding capacity . They are

designed to trap dirt throughout their thickness. A

resinous bonding agent in the media increases

rigidity and resistance to compression so the filter

will not collapse in the airstream. Flashpoint is 325

degrees Fahrenheit on the treated adhesive.

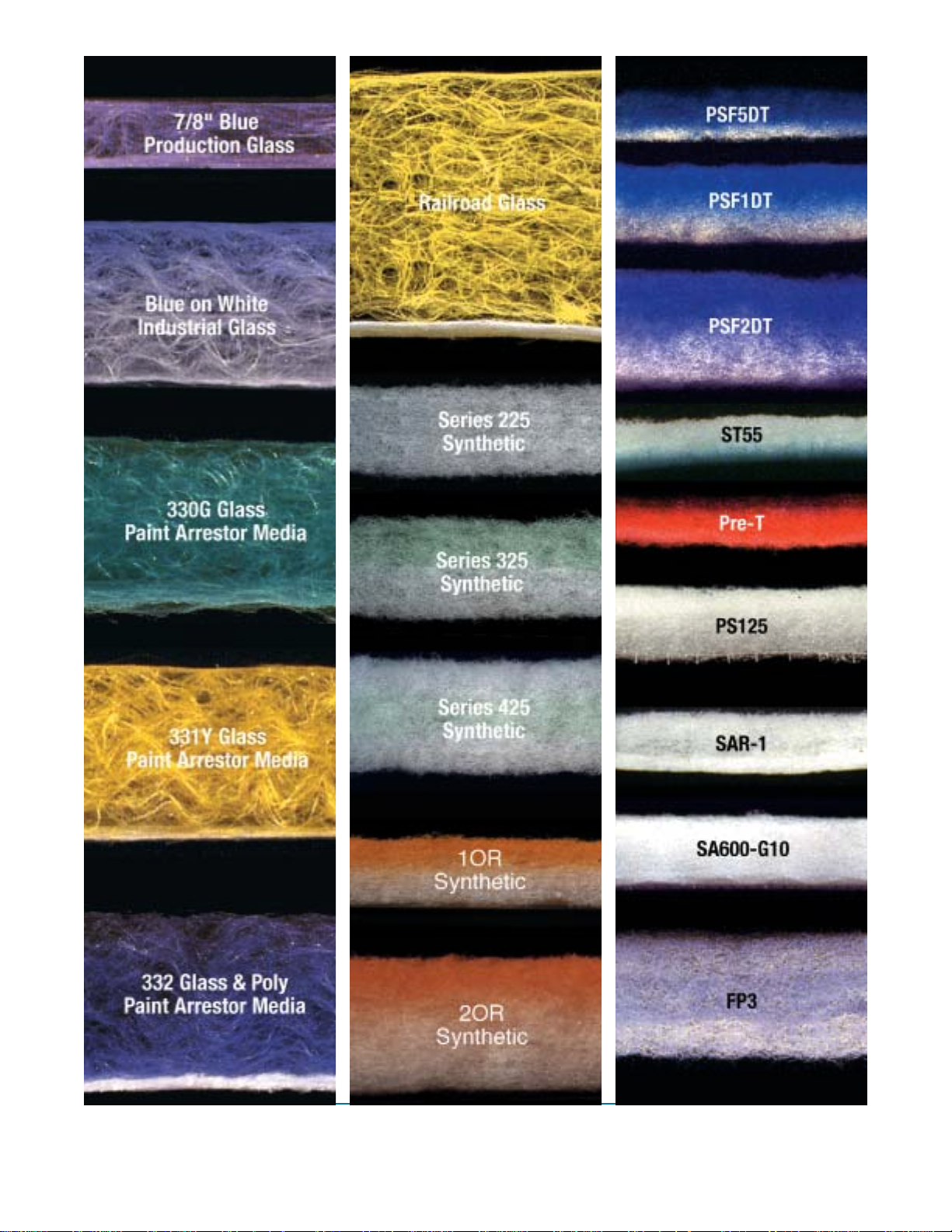

Spun Glass

7/8”Blue Production Glass (Models GMxx) Nominal 7/8”

adhesive-treated spun glass. For residential or light

industrial and commercial air filtration. Commonly

used for 1” depth disposable panel air filter production and for pad and frame systems.

Blue on White Industrial Glass (Models Gxxx) Nominal 1”

and 2” adhesive treated spun glass. For industrial

and commercial air filtration with fairly heavy dirt

loads. Commonly used for pad and frame systems

and hammock rolls. Tinted blue on the air entering

side.

Series 330G PA Green Paint Arrestor Glass (Models 330Gxxx) Model 330 Green glass is a 2.5” economical

dry spun glass media for prep station and paint

spraybooth applications.

Series 331Y PA Yellow Paint Arrestor Glass (Models 331Yxxx) Model 331 is a heavy duty version of dry spun

glass for prep station and paint spraybooth applications.

4”“Railroad” Glass Nominal 4 “ spun glass for air filtration in railroad diesel engines. Manufactured

according to customer specifications.

3/8” A/C Media (Models ACxx) Nominal 3/8 “ untreated

(no adhesive) blue on white spun glass. Makes rigid

pads for use in room air conditioning units.

Polyester Synthetic Fiber

Polyester Synthetic Fiber (PSF) media is extremely

resilient and will withstand direct moisture. In many

cases, a psf media is the ideal alternative to spun

glass. It makes an excellent prefilter for high efficiency filters and offers a high arrestance and dust

holding capacity.

PSF 5DT, 1DT, 2DT (Models 5Txx, 1Txx and 2Txx) Dry,

untreated psf media in nominal 1/2 “, 1 “ and 2 “

thickness for a wide range of filtration applications.

White and blue with blue on the air exit side.

ST55 (Models PRELK55Gxx) Nominal 1/2 “ tackified psf.

Light green and white with green on the air exit

side.

Pre-T (Models PTxx) Pre-T is an extremely rugged psf

designed for repeated cleaning by washing or vacuuming. Dry, untreated. Nominal 1/2 “ thickness

only . Red and purple with purple on the air exit side.

PS125 (Models PS125-xx) Nominal 1 “ untreated psf

which is reinforced with a scrim backing on the

downstream side.

SAR-1 (Models SAR1M-xxxxx) Nominal 1/2” or use as

an intake blanket on crossdraft spraybooths.

SA600-G10 (Models SA600-xxx) Nominal 1” diffusion

media for downdraft spraybooths.

PSF Series 225, 325, 425 (Models ENTRY225T-xx,

ENTRY325T-xx, ENTRY425T-xx) Series 225 is nominal 1

“ dual denier tackified media; 325 is nominal 1-1/2 “

three denier tackified and 425 is nominal 1-1/2 “

four denier tackified.

Bulk Media and Pads

Cut -To-Fit Room Air Conditioner,

Furnace and Central Air Filters

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 29

29

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 30

30

Auto Rolls

Automatic Roll Filter Replacement

Flanders automatic roll replacements are furnished wound

on spools or cores, ready for installation without modification or adaptors. A core selection guide is printed on the

back of this sheet. Six-foot-long kraft paper leaders and

trailers are secured to the ends of every roll. Each roll contains 65 linear feet of filtering media in selected widths.

Rolls are wrapped in heavy plastic and packed in cartons

for shipment. The following media types are available:

Scrim-back spun glass

(Models AESx, BLCSxx,CBSx, FSx, CRSx,CSx, AMSx,TSxx, LRSx)

A nominal 2” thickness progressive density spun glass

treated with dust-catching adhesive. The roll is backed on

the downstream side with a scrim mesh. Density of the

scrim is approximately 3 squares per square inch.

Skin-back spun glass

ModelsAEx, BLCx,CBx, Fxx, CRx,Cx, AMx,Tx, LRxx)

A nominal 2” thickness progressive density spun glass

treated with dust-catching adhesive. The roll is backed on

the downstream side with a spun glass “skin”.

Economy spun glass

(Models AEECx, BLECxx, CBECx, FECx, CRECx, CECxx,AMECx, TECx,

LRECx)

A nominal 2” thickness spun glass with a very light spun

glass skin on the downstream side which is reinforced with

a scrim mesh. Density of the scrim is approximately 1

square per square inch. Media weight is about two-thirds

that of the standard scrim-back glass.

Polyester

(Models AEPx,BLCPxx, CBPx,FPx, CRPUx,CPUxx,AMPx,TPx, LRPxx)

A nominal 1/2” thickness dry, non-woven polyester synthetic fiber medium, reinforced on the downstream side

with a scrim backing. Scrim density is approximately 3

grids per square inch.

Treated Polyester

(Models AEPTx, BLCPTxx, CBTx, FPTx, CRPTx, CPTxx, AMPTx, TPTx,

LRPTx,LAPTxx)

Same medium as the polyester described above, but treated with a dust-catching adhesive.

L- Designed to fit commercial

“FulFlo” and Mine Safety

Appliance machines. Core consists of 3” ID fiberboard tube with

drive pin 2-1/2” from one end.

F - Designed to fit Farr “Roll

Kleen”. Core consists of 2-1/8” ID

fiberboard tube. No drive pin,

discs or cups.

AM - Designed to fit Airmaze “RollA-Maze”. Core consists of 1-7/8”

ID fiberboard tube with metal cup

recessed 5/8” each end. Arectangular slot, 1-1/2 x 3/4”, is stamped

in each cup.

T- Designed to fit T rane Company

“Roll Filter”. Core consists of 27/16” ID fiberboard tube with

metal cup in each end, recessed

1-1/2” A1-1/2” square is stamped

in each cup.

CR - Designed to fit Carrier series

31NA and 31NC. Core is 27/167”

BLC - Designed to fit BLC

Industries. Consists of a 1-1/2”

metal pipe with 2 drive pins that

are 1-3/8” from core end, and with

11” end plates.

AE - Designed to fit American Air

Filter “Roll-O-Matic”. Core consists of 3/4” ID metal pipe with

metal end plates approximately

11” diameter attached on each

end.

CB - Designed to fit Cambridge

“Autoroll”. Core consists of 3/4”

metal pipe, no end plates unless

specified on order.

C - Designed to fit Continental

“Conomanual” or “Conomatic”.

Core consists of 3” ID fiberboard

tube with a drive pin 2-1/2” from

one end.

the filter and hvac store

Page 31

31

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 32

32

Important Features

• Media maximizing v-pleat design

• Expanded metal grid prevents media

flutter while in operation

• Diagonal and horizontal support members provide frame strength

• Filter media pack is sealed to eliminate air

bypass

• Average ASHRAE efficiency is 25-30%

• Average arrestance is 90%-92%

Pre Pleat 40

Extended Surface Pleated Filters

Economy Capacity: 84355.xxxxxx Standard capacity:80055.xxxxxx

High Capacity: 80255.xxxxxx

General

Flanders Pre Pleat 40 extended surface pleated filters are designed to operate in most every type of

installation. Available in 1”, 2”, and 4” nominal

thickness, these filters have an average atmospheric dust spot efficiency range of 25-30% per

ASHRAE Standard 52.1 test methods. Pre Pleat

40 filters offer greater efficiency and service life

than disposable filters, pad and frame systems, or

metal washable filters. The overall design of this

product makes these filters the accepted choice in

applications requiring high performance and

extended service.

These filters are suitable for variable air volume

systems. Operating face velocity ranges are from

0 to 500 fpm for 1” and 2” filters, and from 0 to 625

fpm for 4” filters. Standard and High Capacity

designs are offered.

Pre Pleat 40 filters are UL900 Class 2 listed but are

available with UL Class 1 listing.

Versatility

Most heating, air conditioning, or ventilating systems can be upgraded with the use of Pre Pleat 40

filters in place of existing flat panel types.

The inherent strength of the filter allows for easy

changeout as it will not collapse, warp, or bend in

normal service.

Pre Pleat 40 filters are available in a wide range of

sizes and will fit most commercial and industrial

installations with little or no system modification.

Fasteners are available to adapt the filter to existing filter banks.

Installation Considerations

Pre Pleat 40 pleated filters are suitable as primary

filters and can be installed in Type 9 Holding

Frames, K-Trac Framing Modules, Surepleat Side

Access Housings and similar existing hardware.

They may be used as prefilters for Precision Pak,

PrecisionCell and Rigid-Air filters in these framing

systems and in Sureseal Side Access Housings.

Physical Data

Media: High-loft, non-woven cotton/synthetic blend

Media Support: Diamond-shaped expanded metal

Pleat Design: V Pleat

Frame: Moisture-resistant carrier board

Flanders - Foremost in Air Filtration

Corporate Headquarters, St. Petersburg, FL

the filter and hvac store

Page 33

33

Expanded

Principles of Operation

Flanders’ v-pleat design insures that the greatest media area is exposed to the air flow to promote uniform

dust loading. Competitive filters cannot maintain this rigid shape and tend to flatten out, using only a portion of the media. This v-pleat design creates an air exit area (B) equal to the air entering area (A), which

minimizes end losses and reduces pressure drop.

Radial wedge pleats have unequal air exit (D) and air entering (C) areas, which cause higher resistance and

uneven use of media.

Construction

Filter frames are constructed from two

pieces of die-cut, moisture-resistant

carrier board. Components “telescope” into one another and provide

double-wall construction and a precision fit. The frame includes diagonal

and horizontal support members

bonded to the media on the air entering and leaving sides for unsurpassed

frame strength. Locking corners and

positive media-to-frame seal reduces

the possibility of air bypass.

The filter media is a high-loft, reinforced, non-woven cotton/synthetic

blend. It is continuously laminated to

an expanded metal grid on the air