Page 1

Immersion Wells and Compression Fittings

IMMERSION WELL

112632AA

IMMERSION WELL

107324A

ELEMENT

HOLDER

104484A

COMPRESSION FITTING

121371B

FOR TEMPERATURE CONTROLLERS

PRODUCT DATA

FEATURES

• Immersion wells and compression fittings are

available to fit a 1/2-14 or 3/4-14 NPT tapping with

a range of insulation depths.

• Immersion wells and compression fittings are

available in a variety of lengths and diameters.

• Immersion wells and compression fittings are

available in a variety of materials, to suit the

application. Materials include: brass, copper,

stainless steel, mild steel or Monel.

• Element holders support the capillary and bulb

or an averaging element in duct applications.

• Bulb shields protect the sensing bulb from sun

and weather with the bulb installed outdoors.

• Accessories, including mounting clips, heatconductive compound, waste nuts, a pipe strap

and a well adapter, are available for mounting

sensing bulbs in various applications.

• Immersion wells allow heat transfer while

protecting the sensing bulb from contact with the

APPLICATION

Immersion wells, compression fittings and element holders

are used with Aquastat® Temperature Controllers to hold the

temperature sensing bulb in the controlled medium.

Immersion wells and compression fittings also prevent

leakage of the controlled medium.

controlled medium.

• Immersion wells permit removal of the sensing

bulb for testing or replacement without draining

the system.

• Compression fittings seal the boiler and allow

bulb insertion directly into the controlled

medium.

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

General Information .......................................................... 7

Installation ........................................................................ 8

Checkout .......................................................................... 13

Cross Reference .............................................................. 13

68-0040-04

Page 2

IMMERSION WELLS AND COMPRESSION FITTINGS

SPECIFICATIONS

Models:

Immersion Wells: Allow heat transfer while protecting sensing

bulb from controlled medium and seal off tapping to permit

bulb removal without draining the boiler. Available in

copper, stainless steel, mild steel and Monel. See Table 1

for copper. See Table 2 for stainless steel, mild steel and

Monel.

Compression Fittings: Allow bulb insertion directly into the

controlled medium with boiler draining. Can also be used to

provide positive seal in duct applications. Available in brass

and stainless steel. See Table 3.

Element Holders: Support bulb and capillary or averaging

element in a duct. See Table 4.

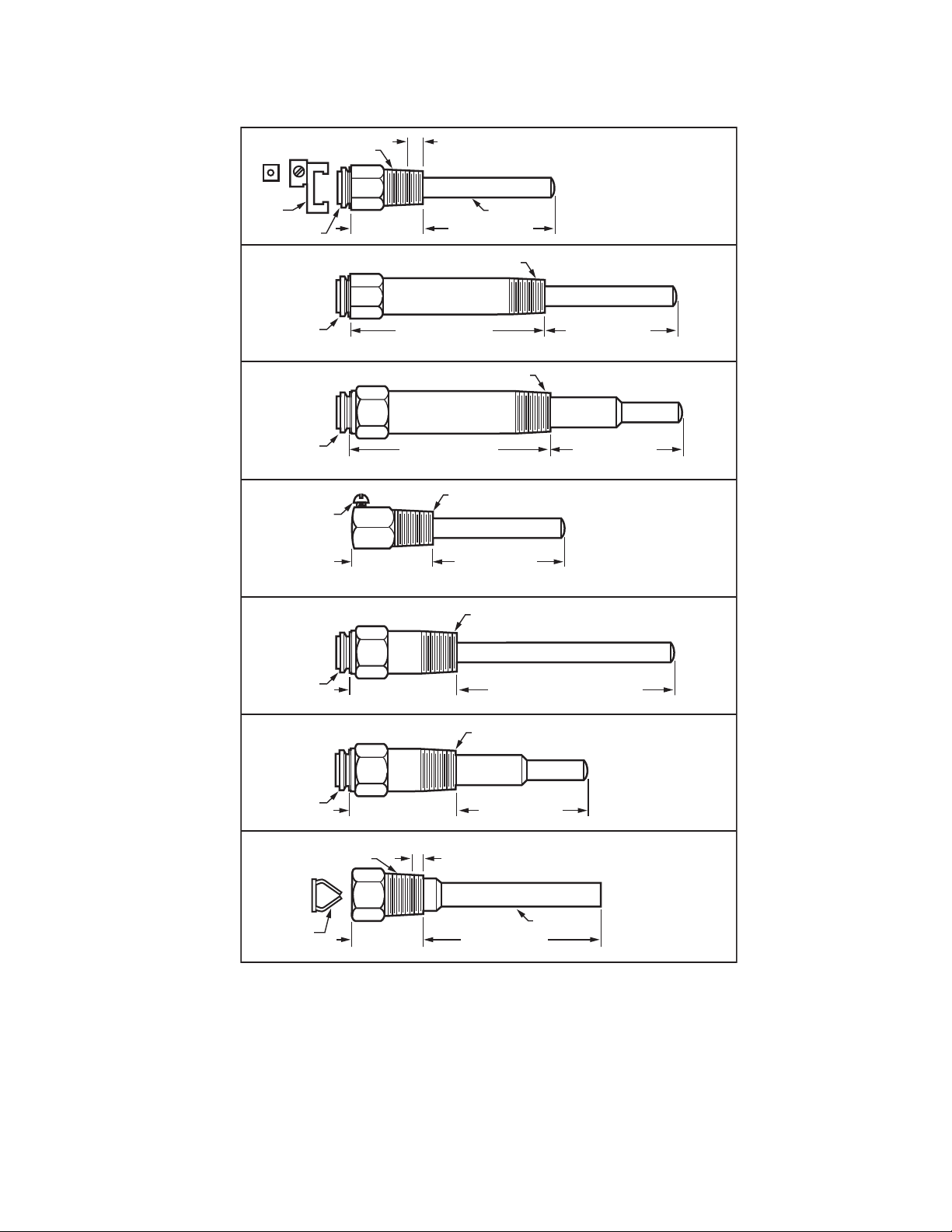

Dimensions:

See Tables 1, 2, 3 and 4, and Fig. 1 and 2.

Temperature Ratings:

IMPORTANT

Do not exceed the maximum temperature rating of

the controller element.

Wells:

Copper: 300°F (149°C) maximum.

Other Materials: Maximum temperature rating limits of the

controller sensing bulb and capillary.

Capillary Compression Fittings: 250°F (121°C) maximum.

Element Holders:

311266D Bulb Holder: -40°F to +100°F (-40°C to +38°C).

Other Element Holders: Maximum temperature rating limits

of the controller sensing bulb and capillary.

Maximum Pressure Ratings:

Copper Wells: 255 psi (1758 kPa) at 300°F (149°C).

Other Wells: 1500 psi (10,342 kPa) at 700°F (371°C).

Capillary Compression Fittings:

Water: 50 psi (345 kPa)

Air: 15 psi (103 kPa).

Accessories:

See Tables 5 and 6.

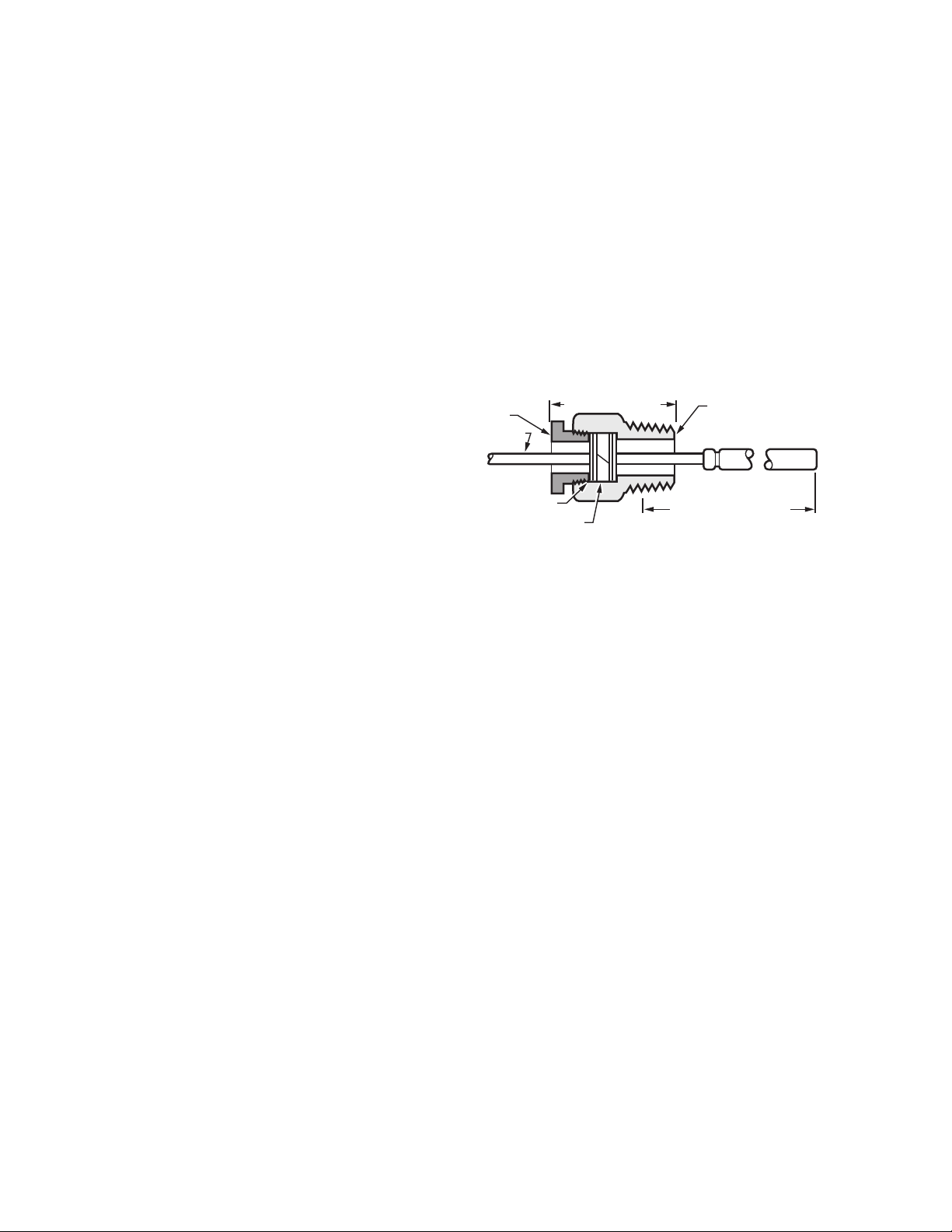

PACKING

NUT

TUBING

SLOTTED

BRASS

WASHERS (4)

COMPOSITION DISK

INSULATION DEPTH

FITTING FOR 1/2

OR 3/4-14 NPT

TAPPED HOLE

MINIMUM

INSERTION LENGTH

APPROXIMATELY 4-3/4 IN.

M17260

Fig. 1. Capillary compression fitting

dimensions and components.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Toronto, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0040—04 2

Page 3

IMMERSION WELLS AND COMPRESSION FITTINGS

WELL SPUD. FITS 1/2 OR

3/4-14 NPT TAPPED HOLE

MOUNTING

CLAMP

MOUNTING

FLANGE

MOUNTING

FLANGE

MOUNTING

FLANGE

SET SCREW

1/8-1/2 in. OF THREADS MAY

EXTEND INTO CONTROLLED MEDIUM

WELL SHELL.

INSULATION

DEPTH

FITS 1/2 OR 3/4-14 NPT TAPPED HOLE

INSULATION DEPTH

FITS 1/2 OR 3/4-14 NPT TAPPED HOLE

INSULATION DEPTH

INSULATION

DEPTH

INSERTION/MAX

BULB LENGTH

FITS 1/2 OR 3/4-14 NPT

TAPPED HOLE

INSERTION/MAX

BULB LENGTH

(LESS MOUNTING CLAMP)

NOTE: 123870F HAS DUAL

DIAMETER WELL SHELL.

INSERTION/MAX

BULB LENGTH

DUAL DIAMETER WELL

INSERTION/MAX

BULB LENGTH

121371A-S

123869A-123872A

122555A,B

122555E

123732AA

FITS 1/2 OR 3/4-14 NPT TAPPED HOLE

MOUNTING

FLANGE

MOUNTING

FLANGE

FITS 1/2 OR

3/4-14 NPT

TAPPED HOLE

SPRING

CLIP

INSULATION DEPTH

INSULATION DEPTH

INSULATION

DEPTH

1/8-1/2 in. OF THREADS MAY

EXTEND INTO CONTROLLED MEDIUM

INSERTION/MAX BULB LENGTH

FITS 1/2 OR 3/4-14 NPT

TAPPED HOLE

INSERTION/MAX

BULB LENGTH

WELL SHELL

INSERTION/MAX

BULB LENGTH

Fig. 2. Immersion well dimensions and components.

138134B

DUAL DIAMETER WELL

112620AA-112639AE

138134E

M17259A

3 68-0040—04

Page 4

IMMERSION WELLS AND COMPRESSION FITTINGS

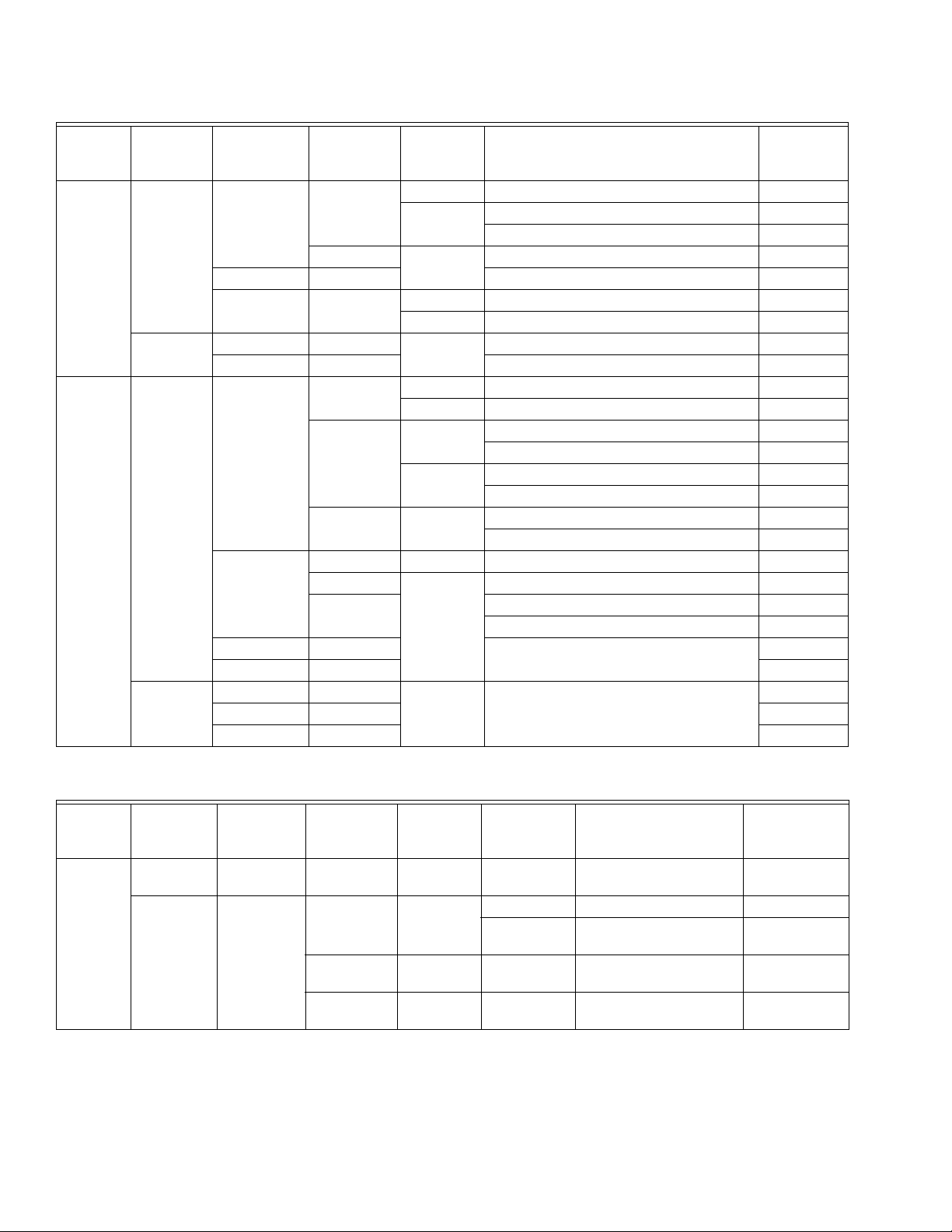

Table 1. Copper Immersion Wells.

Spud in

in. x 14

NPT

1/2 3/8 3 1-1/2 5/64 121371 Mounting Clamp 121371A

3/4 3/8 3 1-1/2 5/64 121371 Mounting Clamp 121371B

Shell ID/

Bulb

Diameter

1/2 4-1/4 1-1/2 1/8 112721 Spring Clip 112622AA

3/8 + 5/8 3 2-1/4 Plastic sleeve on well tube 138134E

1/2 4-1/4 1-1/2 1/8 112721 Spring Clip 112630AA

Insertion/

Max Bulb

Length

3-1/2 1-1/2 121371 Mounting Clamp 121371P

3-3/4 1-1/2 1/8 112721 Spring Clip 112620AA

4-1/4 4-1/2 112721 Spring Clip 112626AA

3-1/2 1-1/2 5/64 121371 Mounting Clamp 121371Q

8-1/4 1-1/2 112630AB

Insulation

Depth

3 5/64 121371 Mounting Clamp 121371L

3 5/64 121371 Mounting Clamp 121371M

4-1/2 — — 122555D

2-1/4 — — 138134B

4-1/2 Plastic sleeve on well tube 122555B

4-1/2 122555E

4 112634AA

Capillary

Diameter

— — 123869A

Spud setscrew for armored capillary, plug 123732AA

— Plastic sleeve on well tube 123869B

— — 123870A

121371 Mounting Clamp, plastic sleeve 123171N

— — 123871A

Plastic sleeve on well tube 123871B

Plastic sleeve on well tube 122555A

— 122555C

Includes

Part

Number

Table 2. Stainless Steel, Mild Steel, and Monel Immersion Wells.

Spud in

in. x 14

NPT

1/2 3/8 3 1-1/2 5/64 Stainless

68-0040—04 4

Shell ID/

Bulb

Diameter

1/2 4-1/4 1 1/8 Mild steel 112721 Spring Clip 112623AA

Insertion/

Max Bulb

Length

Insulation

Depth

4 1/8 Stainless

1 1/8 Stainless

Capillary

Diameter

Material Includes Part Number

steel

Stainless

steel

steel

steel

121371 Mounting Clamp 121371E

112721 Spring Clip 112624AA

112721 Spring Clip 112628AA

112721 Spring Clip 112632AA

Page 5

IMMERSION WELLS AND COMPRESSION FITTINGS

107324A

M17275A

131524A

M17276A

M17277A

311266D

314439

M17271

Table 3. Capillary Compression Fittings.

Material Spud Maximum Bulb Diameter Insulation Depth Capillary Diameter Part Number

Brass 1/2-14 NPT 1/2 in. 1-5/16 in. 5/64 in. 104484A

1/8 in. 7617M

1-1/2 in. 5/64 in. 104484C

2 in. 5/64 in. 7617ABY

3/4-14 NPT 1-5/8 in. 5/64 in. 104484B

11/16 in. 1-1/2 in. 1/8 in. 7617P

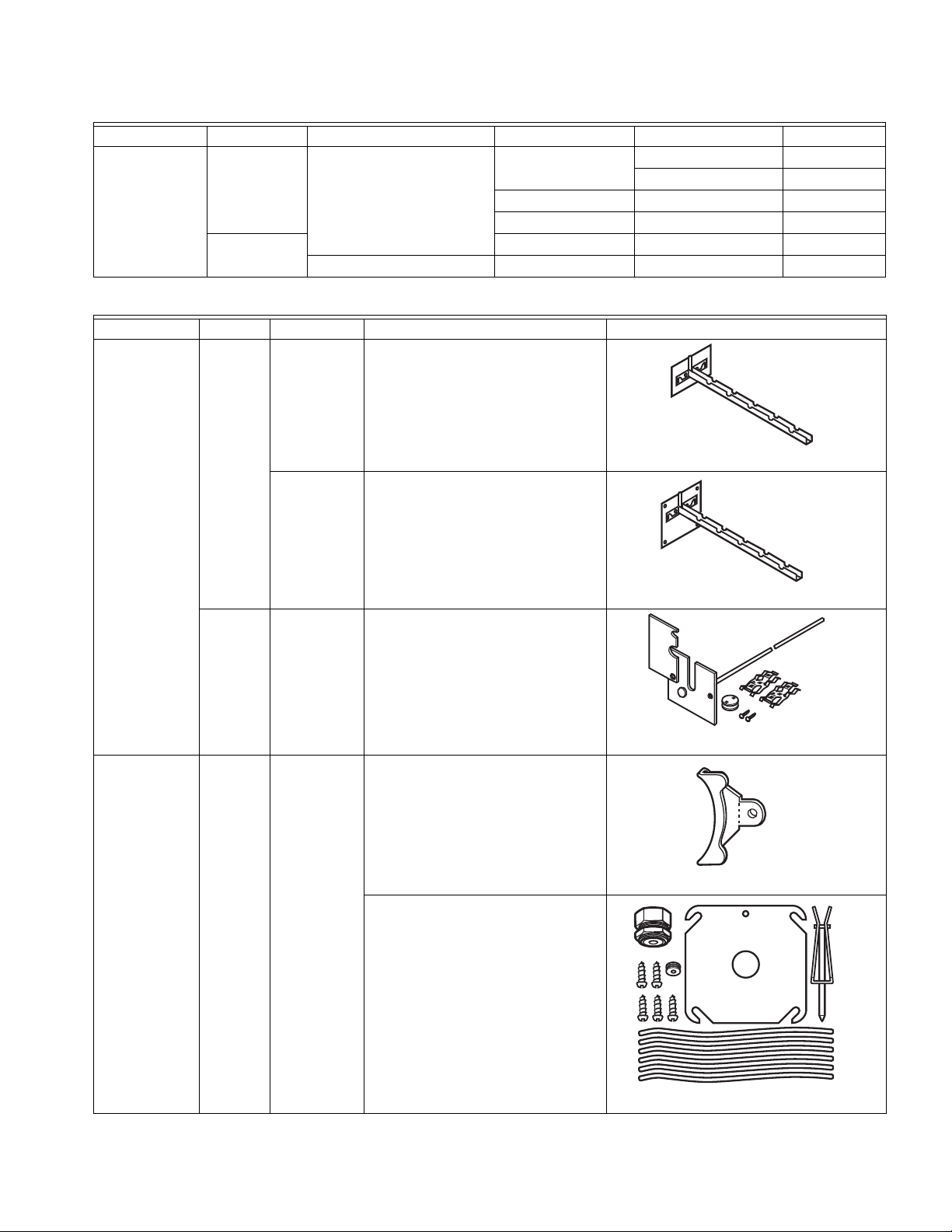

Table 4. Element Holders for Duct-Mount Applications .

Application Length Plate Size Description Part Number

Bulb holders 8-5/8 in. 2-3/4 in.

x 1-3/4 in.

Supports capillary and bulb in duct;

mounting screws not included.

2-3/4 in x 3 in.

Averaging

element holders

14 in. 3-1/4 in x

3-1/4 in.

Holds 1 or 2 elements in 0°F to

100°F air; grommet holds one

5/64 in. and one 1/8 in. diameter

capillary; helps reduce airflow through

opening in duct.

— — Mounting clip; use with grommet;

mounting screws not included; one

required per clip.

Use with 1/2 in. EMT thinwall conduit

where duct access is limited. Kit

includes 4 in. (101 mm) cover plate,

1/2 in. EMT compression fitting, 3/16

in. (5 mm) rubber grommet, clamp

assembly, wire ties and mounting

screws.

7640HX

M17279

5 68-0040—04

Page 6

IMMERSION WELLS AND COMPRESSION FITTINGS

M17274

121371AA

M17288

32002656-001

M17280

104488

M17281

107408

M17282

120650

M17283

124904

Table 5. Immersion Well Accessories .

Description Application

Mounting clamp Holds capillary in place on

123869A-123872A;

122554A,B; 12255A,B,D,E;

and 138134B-F Immersion

Wells.

Spring clip

Size in in.

(except where noted) Part Number

1/2 or 3/4 in. well spud; 5/64

capillary

Holds capillary in place on

1122620AA-112639AB

Immersion Wells.

Heat-conductive compound Improves heat conduction in

well applications where bulb

does not fit tightly.

1/2 in well spud; 5/64 capillary

1/2 in. well spud; 1/8 capillary.

3/4 in. well spud; 1/8 capillary.

4 oz. (118 ml)

Single application tube (1/2 oz)

112721

112720

Well Adapter Adapts well with setscrew on

68-0040—04 6

spud; for use with direct

insertion bulb or 121371AA

Mounting Clamp.

Page 7

IMMERSION WELLS AND COMPRESSION FITTINGS

M17284

107323A

M17285

34886A

M17286

105900

Table 6. Accessories for Duct-Mount Applications

Description Application Size Part Number

Bulb shield assembly Shields bulb from weather;

less mounting screws and

split plug.

6 in. (152 mm) long; holds 3/8

in. and 1/2 bulbs.

Shields bulb from weather;

includes mounting screws

and 33578 Split Plug.

Pipe Strap Fastens bulb to outside of

pipe.

7 in. (118 mm) long, clip holds

3/8 in. bulb.

4-1/2 in. (114 mm) long; used

with up to 3/4 in. OD pipe.

GENERAL INFORMATION

Immersion Wells

An immersion well consists of a metal tube, called the well

shell, closed on one end. A well spud externally threaded to fit

standard boiler tappings is welded or brazed on the open end.

See Fig. 1. The well is inserted into the tank and the

temperature sensing bulb is inserted into the well. The sensing

bulb never touches the controlled medium. Because the well

conducts heat rapidly, the bulb responds quickly and

accurately to temperature changes in the controlled medium.

An immersion well protects the temperature sensing bulb from

mechanical damage or damage due to chemical interaction

with the controlled medium. Also, a well permits removal of the

sensing bulb for testing or control replacement without draining

the system. The threaded fitting of the well spud provides a

tighter seal than a packing nut applied to the capillary.

Material Selection

The immersion well material must conduct heat readily and

resist corrosive and electrolytic action (especially in brine

solutions and when the well is a different material than the

container). The material must also resist fluid contamination

from chemical reaction with the well and withstand high

temperatures. Most Honeywell immersion wells are copper

because of its high conductivity. Stainless steel, mild steel and

Monel wells are also available for applications requiring higher

maximum temperature and pressure ratings or greater

corrosion resistance. Some copper wells are available with a

plastic sleeve over the tube to reduce electrolytic and corrosive

activity.

Well Sizing

Major factors in selecting well size are:

—

size of the boiler tapping.

—bulb diameter.

—insulation depth.

—insertion length.

Immersion wells are available to fit standard 1/2-14 NPT and 3/

4-14 NPT tappings. Sensing bulbs are 3/8, 1/2 or 11/16 in. in

diameter with well shells designed to fit these diameters. The

bulb should fit tightly in the shell. If the bulb fits loosely, fill the

space between the shell and bulb with heat-conductive

compound to ensure maximum heat transfer. Many Honeywell

temperature controllers ship with heat-conductive compound;

available in 4-oz cans and 1/2-oz single-application tubes. See

Table 4.

he nominal length of the spud, including the full length of the

threads and the hex, defines the insulation depth. Depending

on the characteristics of the tapping, 1/8 to 1/2 in. of the

7 68-0040—04

Page 8

IMMERSION WELLS AND COMPRESSION FITTINGS

WARNING

M17261

BACK

OF

CASE

WELL

CLAMP

SCREW

WELL

ADAPTER

IMMERSION

WELL CLAMP

SENSING BULB

SETSCREW

WELL

SPUD

BOILER

WALL

WELL

SHELL

threaded end of the spud can extend into the controlled

medium. Consider this additional length when determining how

far the well extends into the controlled medium.

The length of the well shell starting at the end of the spud

defines the insertion length. This is the active part of the well

where the fastest heat transfer occurs. The bulb should be the

same length as the well shell; however, the well shell can be

longer, but not shorter, than the length of the bulb. Longer

shells require inserting the bulb until the end touches the well

bottom. Shorter shells do not expose the full length of the bulb

to the temperature of the controlled medium, inhibiting proper

temperature controller operation.

Securing Bulb in Well

REMOTE BULB APPLICATIONS

Securing the capillary at the spud with a spring clip or a

mounting clamp holds the sensing bulb securely in place. See

Fig. 1. Use the spring-loaded clip on well spuds with no

mounting flange. Slip it over the capillary and snap it in place in

the end of the spud. The mounting requires sizing to fit both the

spud and the capillary diameter. The mounting clamp requires

wells with a mounting flange at the spud end. The jaws adjust

to fit both 1/2 and 3/4 in. spuds, and it holds a 5/64 in. capillary.

Wells are available with and without the matching spring clip or

mounting clamp. This mounting hardware is also available

separately.

A few wells have a setscrew in the spud. These wells are

designed for use on controllers with an armored capillary that

has a brass plug at the sensing bulb end; for example,

R8182H,J.

DIRECT INSERTION APPLICATIONS

Most Honeywell direct insertion controllers include provision for

clamping the controller case on the immersion well spud. This

requires a well spud with a mounting flange at the end. If the

well spud has a setscrew, but no mounting flange, a 124904

Well Adapter can provide the necessary flange. See Fig. 3.

The well adapter is shipped with several Honeywell

TRADELINE® direct-insertion controllers.

Capillary compression fittings are used to replace an

immersion well when the sensing bulb of a remote bulb

controller requires direct insertion into the controlled medium.

The fitting seals around the capillary. However, compression

fittings cannot seal off against as much pressure as immersion

wells. Capillary compression fittings can be used in duct

applications to minimize air leakage from the duct; a waste nut

is recommended to provide a secure mounting.

Material Selection

Capillary compression fittings are available in brass and

stainless steel. In hydronic applications, brass fittings with

copper sensing bulbs are used and stainless steel is used with

all other fittings to minimize electrolytic action.

Sizing

Capillary compression fittings must fit the tapping and the

capillary diameter. Because the spud must slip over the bulb

during installation, 11/16 in. bulbs require 3/4 in. spuds.

Element Holders

Bulb holders are used to support a remote bulb and capillary in

a duct, but are not suitable for hydronic applications. A bulb

holder must be selected according to the length needed to

support the bulb in the main airstream and the need for

plugging the opening in the duct wall.

For best response, string averaging elements evenly back and

forth across the duct. The element is held in place with either

perforated pipe strap or 314439 Mounting Clips. If access to

the duct is limited, use the 7640HX Duct Mounting Kit. Always

use a grommet to protect the element from abrasion where it

enters the duct.

NOTE: To minimize heat loss through the fitting, use a waste

nut and compression fitting.

INSTALLATION

Capillary Compression Fittings

A capillary compression fitting includes a spud, several

aligning washers, a neoprene packing ring and a packing nut.

The spud is internally threaded to hold the packing material

and the packing nut and externally threaded to fit standard

boiler tappings. The washers and packing ring are sized to fit a

particular capillary diameter.

68-0040—04 8

Fig. 3. Mounting direct insertion controller

case on well spud.

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation as provided in these instructions.

Severe Scalding Hazard.

Contact with hot liquid can cause severe injury or

death.

Drain system before beginning well or compression

fitting installation.

Page 9

WARNING

Electrical Shock Hazard or Equipment Damage

APPLY A MODERATE AMOUNT

OF PIPE COMPOUND (LEAVE

TWO END THREADS BARE).

M17262

M8777

WELL

BULB

SPUD

MOUNTING

CLAMP

A

DRAW

NUT

TUBING

B

MOUNTING CLAMP

SCREWDRIVER

SPREAD JAWS

TO FIT OVER

RIDGE ON

WELL SPUD

JAWS

Hazard.

Can cause sever injury, death or short equipment

circuitry.

Disconnect all power supplies before installation.

Most equipment manufacturers provide a tapping for

temperature controller sensing element insertion. The tapping

should be located to measure average system temperature.

IMPORTANT

Always install the sensing element away from hot or

cold water inlets, steam coils, and locations where the

well pressure rating will be exceeded.

1. Turn off the power.

2. If the system is filled, drain it to a point below the boiler

tapping or sensing element location.

3. If no tapping is provided, prepare one, properly threaded,

at the desired location.

Immersion Well Mounting

Instructions for mounting the well in the tapping and using the

capillary mounting clamp or spring clip in remote bulb

applications follow. Consult the appropriate Aquastat®

Controller instructions for mounting the controller on the well in

direct insertion applications. Direct insertion applications

usually require using wells with a mounting flange on the spud.

IMMERSION WELLS AND COMPRESSION FITTINGS

1. Fill the well with compound.

2. Coat the bulb generously before inserting it into the well.

3. Move the bulb up and down inside the well to ensure

even distribution of compound.

Securing Bulb with Mounting Clamp

Use the 121371 Mounting Clamp only on wells with a mounting

flange on the spud end.

1. Loosen the draw nut and spread the jaws of the clamp

with a screwdriver. See Fig. 5.

2. Slide the clamp jaws over the spud mounting flange

(point A in Fig. 5).

3. Adjust the tubing to fit through the mounting clamp

groove (point B in Fig. 5).

IMPORTANT

When tightening the draw nut, be careful not to

damage the capillary.

4. Tighten the draw nut so that the retainer clamp attaches

firmly to the well spud and holds the tubing securely in

place.

1. Coat threads with a moderate amount of pipe dope, leaving two end threads bare. See Fig. 4.

NOTE: Teflon™ tape can also be used.

2. Screw the immersion well into the tapping and tighten

securely.

Fig. 4. Proper application of pipe dope.

Insert Sensing Bulb in Well

For good temperature response, the immersion well must fit

the sensing element or bulb tightly and rest against the bottom

of the well.

NOTE: If necessary, bend the tubing to hold the bulb against

the bottom of the well.

IMPORTANT

Any bends made in the piping must be gradual to prevent breaks in the tubing and subsequent loss of fill.

For faster heat transfer, use heat-conductive compound to fill

the space between the bulb and the well. A tube of

heat-conductive compound ships with Honeywell

TRADELINE® Aquastat Controllers. The compound is also

available as an accessory. See Table 5. Use the following

procedure when installing the compound:

9 68-0040—04

Fig. 5. Fastening bulb in well using mounting clamp.

Securing Bulb with Spring Clip

The spring clip can be used with any well with the appropriately

size spud. Wells without a mounting flange on the spud require

a spring clip.

NOTE: The spring clip does not hold the capillary as securely

as does the mounting clamp. See Table 5 for spring

clip part numbers.

1. Slide the clip over the capillary with the prongs facing the

well.

2. Push the clip as far as possible into the spud. See Fig. 6.

NOTE: Make sure the bulb remains bottomed in the well.

Page 10

IMMERSION WELLS AND COMPRESSION FITTINGS

M17263

BULB

INSERTION LENGTH

APPROX. 3-3/8 IN.

TUBING SPRING CLIP

FITTING (INCLUDING WELL)

M17264

1/2 in. (13 mm) PIPE THREAD FOR 1/2 in. (13 mm) CAPSULES

3/4 in. (19 mm) PIPE THREAD FOR 11/16 in. (17 mm) CAPSULES

COMPOSITION DISK

(SLOTTED)

SPUD

CAPILLARY TUBING

SLOTTED WASHERS

ASSEMBLED IN PAIRS

THUS-

PACKING NUT

M17258

PINCH TOP EDGES OF

HOLDER TOGETHER

AT EACH SEGMENT

CAPILLARY

TUBING

SENSING

BULB

BE SURE EXTENSION TUBE IS

UNDER BULB HOLDER, AS SHOWN

M7217

M17265

CAPILLARY

TUBING

SCREW

HOLES IN

WALL OF

PLENUM

INDOOR

BULB

COMBUSTION CHAMBER

KEEP BULB WELL ABOVE COMBUSTION CHAMBER

Element Holders

Use element holders to mount air temperature sensors in a

duct. Locate the sensing element where air at representative

temperatures can circulate around it. In a plenum application,

locate the element far enough from the combustion chamber to

avoid the effect of direct radiation.

Fig. 6. Mounting spring clip into well spud.

Securing Bulb in Wells with Setscrew

Wells with a spud setscrew are designed for use with

controllers that have armored capillary with a brass collar at

the bulb end of the armor. The setscrew tightens against the

brass collar. See Fig. 7. These wells can be adapted for use

with 5/64 in. capillary by adding the 124904 Well Adapter and

the 121371 Mounting Clamp Assembly. See Fig. 3.

Fig. 7. Mounting armored capillary in well with setscrew.

Capillary Compression Fittings

1. Coat external spud threads with a moderate amount of

pipe dope, leaving two end threads bare. See Fig. 4.

NOTE: Teflon tape can also be used.

2. Screw the spud into the tapping and tighten securely.

3. Place the packing nut on the tubing.

4. Slide the bulb completely through the fitting.

5. Place the composition disk and the four slotted brass

washers on the tubing in the order shown in Fig. 8.

6. Turn the brass washers so that the slots are 180 degrees

apart and the small tabs are in the mating slots.

7. Slide the seal assembly into the fitting. Make sure the

sensing bulb extends the desired distance into the

controlled medium. See Fig. 2.

8. Tighten the packing nut.

Bulb Holders

1. Cut a hole large enough to admit the bulb and holder in

the duct or plenum at the mounting location.

2. Drill holes for the bulb holder mounting screws.

3. Mount the bulb and capillary on the holder. See Fig. 9

through 11.

107324A and 131524A Bulb Holders

Use these bulb holders to mount one bulb in a duct or plenum.

See Fig. 9 and 10. If necessary, shorten holders by using pliers

to flex the channel at one of the notches until it separates.

311266D Bulb Holder

Use this bulb holder to mount one or two bulbs in a duct where

temperatures do not exceed 100°F (38°C). The removable

plug in the mounting plate allows insertion of a thermometer to

check duct air temperature. See Fig. 11 for installation details.

Fig. 9. Installing capillary in 107324A

and 131524A Bulb Holders.

Fig. 8. Capillary compression fitting assembly.

68-0040—04 10

Fig. 10. Mounting bulb holder in furnace plenum.

Page 11

IMMERSION WELLS AND COMPRESSION FITTINGS

14 (356)

3-1/4

(83)

1-3/8

(35)

1-5/8

(41)

3-1/4

(83)

2-3/4

(70)

2-1/4 x 2-1/4 (57 x 57) APPROXIMATE

HOLE IN DUCT FOR INSTALLATION

ADJUSTABLE

SPRING

CLIPS (2)

THERMOMETER

BULB

ACCESS

HOLE

RUBBER GROMET

NO. 8 SHEET METAL

MOUNTING SCREWS (2)

CONTROLLER BULB

M7355

CAPILLARY

COMPRESSION

FITTING

CAPILLARY

TUBING

DUCT

WALL

WASTE

NUT

BULB

(CAPSULE)

M17266

DUCT

WALL

WIRE FASTENINGS

CAPILLARY

TUBING

GROMMET

ELEMENT

M17269

DUCT

WALL

CAPILLARY

TUBING

GROMMET

AVERAGING

ELEMENT

USE NO. 10

SHEETMETAL

SCREWS

314439

CLIP

BEND HERE

IF NECESSARY

M17289

DUCT

WALL

4 in.

COVER

PLATE

CAPILLARY

GROMMET

AVERAGING

ELEMENT

M17270

CONDUIT

COMPRESSION

FITTING

WIRE TIES

1/2 in. EMT CONDUIT

(OBTAIN LOCALLY)

Fig. 11. Mounting sensing bulb and

311266D Bulb Holder in duct.

NOTE: Dimensions shown in in. (mm).

Duct Mounting with Capillary Compression Fitting

In some duct-mount application, it is desirable to use a

compression fitting to reduce air leakage at the sensing

element location. For these applications, first mount a waste

nut on the duct to ensure secure mounting. See Fig. 12. See

Table 6 for part numbers.

NOTE: Do not use this mounting method for liquid

applications.

Fig. 13. Mounting averaging element with

perforated strap iron.

Fig. 14. Mounting averaging element with

314439 Mounting Clips.

Fig. 12. Mounting sensing bulb in duct using waste nut

and compression fitting.

Averaging Element Holders

The averaging element must be supported so it is distributed

evenly across the entire height and width of the duct. It can be

fastened to perforated strap iron (see Fig. 13) or mounted with

314439 Mounting Clips (see Fig. 14). This type of mounting

requires threading the element through a grommet inserted in

a hole in the duct wall.

For ducts with limited access, the 7640HX Averaging Element

Mounting Kit allows mounting the element through a single

hole in the side of the duct. This kit requires a length of 1/2 in.

EMT conduit. See Fig. 15.

Fig. 15. Mounting averaging element with 7640HX

Averaging Element Mounting Kit.

11 68-0040—04

Page 12

IMMERSION WELLS AND COMPRESSION FITTINGS

CAUTION

M17272A

OUTDOOR

SENSING

BULB

EXTENSION

TUBE

BULB SHIELD

CAPILLARY

TUBING

3/4 IN. (19 mm)

HOLE IN WALL

PLUG HOLE WITH

ACCEPTABLE MATERIAL

Bulb Shields

A bulb mounted outdoors requires protection of a bulb shield.

1. Expose the bulb to representative air temperature but

not direct sunlight.

2. Mount it high enough so:

a. Accumulated snow, leaves or other debris can-

not obstruct air circulation around it.

b. Children cannot reach it.

c. Avoid vents from the building.

3. Drill a 3/4 in. (19 mm) hole in the outside wall.

4. Bring the sensing bulb through the hole.

5. Mount the bulb in the bulb shield. See Fig. 16.

6. If the seal-off tube extends outside the shield, bend it

under the shield.

7. Hold the shield over the mounting location and form a

small-radius bend in the tubing.

8. Place the split plug (provided with 34886A; or order

107323A Split Plug separately) around the tubing and

move the bulb and shield into mounting position as a single unit.

9. Push the split plug into the hole until it is wedged

securely in place.

10. Fasten the shield on the wall with screws (provided with

34886A).

11. If the tubing is properly shaped and the split plug

installed as directed, the shield covers the split plug and

conceals the hole in the wall.

Mount the bulb on the pipe as follows:

Significant Calibration Shift Hazard.

Overtightening clamps distorts bulb calibration.

Do not overtighten hose clamps.

1. Secure the bulb to the pipe with a 105900 Pipe Strap or

metal hose clamps. See Fig. 17 and 18.

2. If necessary, cover the bulb and pipe with foam rubber

insulation that extends at least 6 in. (152 mm) beyond

both ends of the bulb. See Fig. 19.

IMPORTANT

Do not allow the duct tape to come into contact with

the pipe.

3. Secure foam rubber with duct tape.

T-CLAMP

CAPILLARY

TUBING

BULB

Strap-On Mounting

Occasionally, applications require the sensing bulb to be

strapped to the outside of a pipe. For these applications, use

either the 105900 Pipe Strap or metal hose clamps. The pipe

strap fits pipe up to 3/4 in. OD.

External mounting of the sensor produces a slight offset in the

temperature control point. Typically, the control temperature

increases as much as 5°F (2.8°C) with a bare sensor strapped

to the discharge pipe. Applying insulation around the sensor

and pipe decreases the offset. Insulation must be used if large

fluctuations in ambient temperature occur near the pipe.

Fig. 16. Mounting bulb in bulb shield.

SUPPLY WATER PIPE

M8836

Fig. 17. Mounting bulb to pipe with pipe strap.

NOTE: When using a pipe strap, the maximum pipe OD is 3/4

in.

CAPILLARY TUBE

M17267

METAL HOSE CLAMPS

Fig. 18. Mounting bulb to pipe with metal hose clamps.

CAPILLARY

TUBE

DUCT

TAP E

FOAM RUBBER WRAP (EXTEND

6 in. (152 mm) BEYOND ENDS OF BULB)

PIPE

M17268

Fig. 19. Covering bulb and pipe with foam rubber

insulation.

68-0040—04 12

Page 13

IMMERSION WELLS AND COMPRESSION FITTINGS

CHECKOUT

When installation is complete, check it as follows:

1. Visually inspect the fittings in hydronic applications for

leakage.

2. If necessary, tighten these fittings.

3. Ensure excess capillary is coiled beneath the controller

case.

4. Ensure proper operation by observing the system

through one complete cycle.

CROSS REFERENCE

Some series 121371 Wells are also available without the

mounting clamp. These pairs are listed together in Table 1 and

in Table 7for your convenience. The cross reference in Table 8

lists wells and fittings no longer available and suggests

functional replacements.

Table 7. Wells With and Without Mounting Clamp.

121371 Part Number (With

Clamp)

121371A 123869A

121371B 123870A

121371M 123871A

121371N 123871B

121371P None

121371Q

121371L 123872A

Part Number

(Less Clamp)

13 68-0040—04

Page 14

IMMERSION WELLS AND COMPRESSION FITTINGS

Table 8. Cross Reference .

Old Part

Number

Description

121371G Immersion well. Brass, 1/2-14 NPT, 1-1/2 in.

Replacement Part Number Notes

None

insulation, 6-1/2 in. insertion, includes

121371 mounting clamp.

121371N Immersion well. Copper, 3/4-14 NPT, 3 in.

123871B No mounting

insulation, 3 in. insertion, includes plastic

sleeve, 121371 mounting clamp.

122555C Immersion well. Copper, 3/4-14 NPT, 4-1/2 in.

122555B 4-1/2 in. insulation

insulation, 5 in. insertion.

122555F Immersion well. Copper, 3/4-14 NPT, 4-1/2 in.

None

insulation, 5 in. insertion, includes plastic

sleeve, dual diameter bulb.

122555G Immersion well. Copper, 3/4-14 NPT, 4-1/2 in.

None

insulation, 5 in. insertion, dual diameter bulb.

123870E Immersion well. Copper, 3/4-14 NPT, 1-1/2 in.

138134E 2-1/4 in. insulation.

insulation, 3 in. insertion, includes plastic

sleeve, dual diameter capsule.

123871D Immersion well. Copper, 3/4-14 NPT, 3 in.

138134E

insulation, 3 in. insertion, includes plastic

sleeve, dual diameter well.

123871E Immersion well. Copper, 3/4-14 NPT, 3 in.

138134C

insulation, 3 in. insertion, dual bulb.

123872A Immersion well. Copper, 1/2-14 NPT, 3 in.

121371L Includes mounting

insulation, 3 in. insertion.

104486B Bulb compression fitting. Brass, 1/2-14 NPT. 104484A Capillary Compression

Fitting or 1/2-14 NPT well with

correct insertion length and

diameter.

138134C 2-1/2 in. insulation 138134E

138134D 2-1/2 in. insulation 123871A

—

clamp.

plastic sleeve

—

—

clamp.

—

3-1/4 insulation

68-0040—04 14

Page 15

IMMERSION WELLS AND COMPRESSION FITTINGS

15 68-0040—04

Page 16

IMMERSION WELLS AND COMPRESSION FITTINGS

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2008 Honeywell International Inc.

68-0040—04 M.S. Rev. 07-08

Loading...

Loading...