Page 1

Global Leader in Integrated Room Automation Systems

MODEVA Technical Reference Manual

Disclaimer

This document contains information that is the proprietary and confidential property of INNCOM

International Inc. By acceptance hereof, each recipient agrees to use the information contained

herein only for the purpose anticipated by INNCOM, and not to disclose to others, copy or reproduce,

any part hereof without the written consent of INNCOM. The recipient agrees to return this document

to INNCOM immediately upon request.

Content

1 MODEVA Product Overview ........................................................................................ 2

2 MODEVA System Block Diagram ................................................................................. 2

3 Touch User Interface ................................................................................................ 3

4 MODEVA Logic Board ................................................................................................ 4

4.1 RF capability ........................................................................................................... 5

4.2 S5-bus ................................................................................................................... 5

4.3 IR Tx and Rx ........................................................................................................... 5

5 Load Assembly ........................................................................................................ 5

5.1 Categories of Load Assembly Load Switching ................................................................ 5

5.2 Load Assembly Dimming ........................................................................................... 6

5.3 Air-Gap Switch ........................................................................................................ 7

5.4 Overload Protection .................................................................................................. 7

5.5 Load Assembly Parallel Power Supplies ........................................................................ 8

6 MODEVA System Technical Specification ...................................................................... 8

6.1 MODEVA/Load Assembly Current Consumption Characteristics ...................................... 10

7 Load Specifications ................................................................................................. 10

7.1 Single gang installation ........................................................................................... 10

7.2 Multigang Installation ............................................................................................. 11

8 Multigang Installation Derating Chart ........................................................................ 11

8.1 Actuator Ratings .................................................................................................... 11

9 Standard Wiring ..................................................................................................... 12

10 MODEVA User Interface Assembly Ordering Information .............................................. 13

11 MODEVA Load Assembly Ordering Information ........................................................... 15

11.1 Load Assembly Ordering Information ........................................................................ 15

12 Document Information and Revision History ............................................................... 16

Page 2

M O D E V A R e f e r e n c e M a n u a l P a g e 2 o f 16

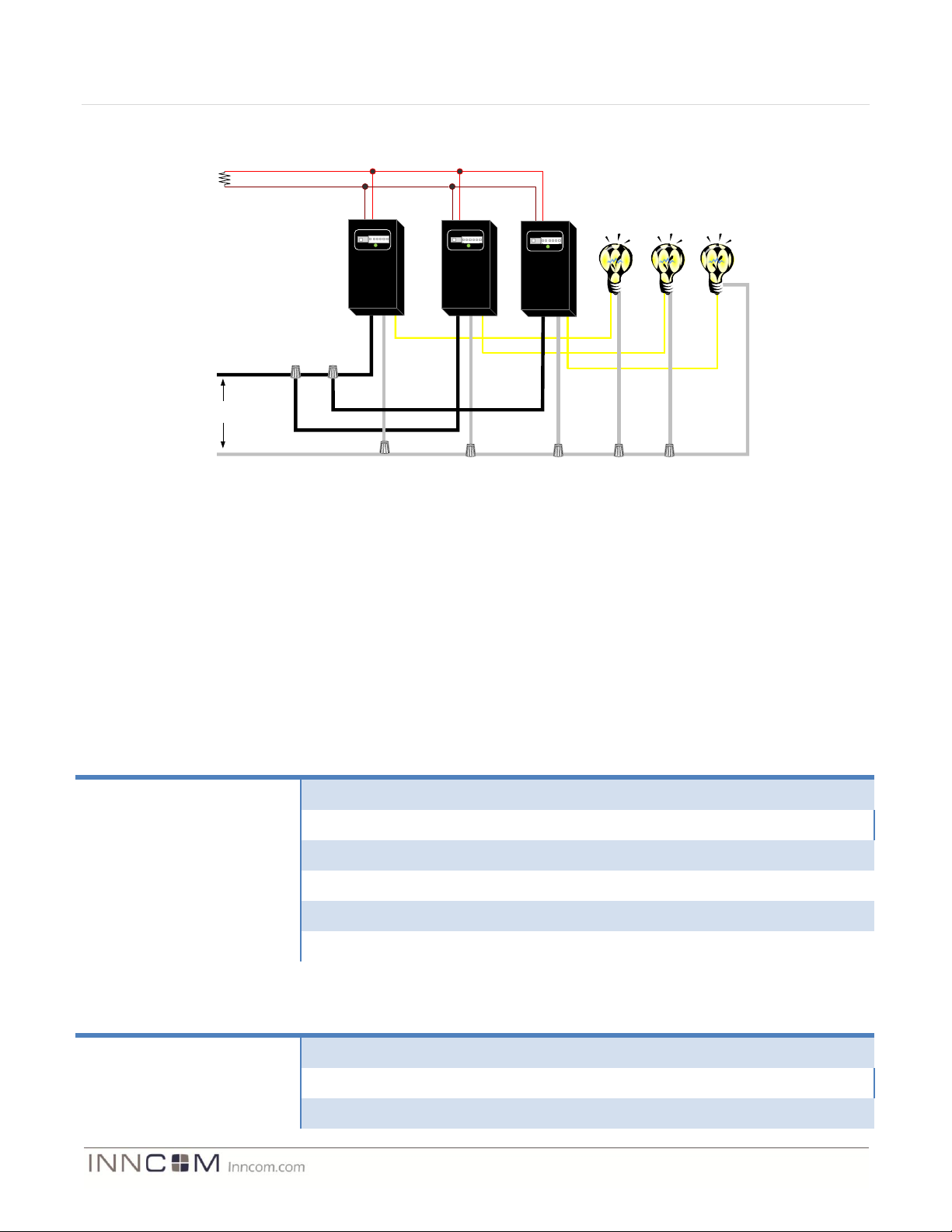

Figure 1 MODEVA Triple Gang System

1 MODEVA Product Overview

The MODEVA™ system, an elegantly

designed, easy to use lighting, drapes, and

amenities control system, provides an

unrivaled guestroom management

experience. The MODEVA system allows

guest control of multiple loads from many

locations. MODEVA (comprising a logic

board and user interface), in combination

with the Load Assembly infrastructure (see

below), consists of user interfaces, low

voltage interfaces, wired and wireless

communications, dimmers, and switches

designed to operate within INNCOM’s

Integrated Room Automation System

(IRAS). The MODEVA system brings all

guestroom control features into a sleekly

designed unit housed in either a capacitive

glass or a more traditional keypad user

interface.

The MODEVA system was designed by the engineers at INNCOM International Inc., who pioneered Energy

Management Systems in the hotel industry long before “green” was a marketing concept. INNCOM is again

blazing a trail for enhanced guestroom controls with the MODEVA and Load Assembly system.

The MODEVA system brings an unmatched level of design flexibility by utilizing a “system in a box” approach.

Mixing a variety of individual components and actuators, the MODEVA system provides endless guestroom

control features and options that interoperate seamlessly with INNCOM’s e4 Smart Digital Thermostat for an

unparalleled energy management and lighting control platform. With the fully configurable user interface and

logic board, which allows the hotelier and the INNCOM design team to create a unique look and feel while

customizing functionality, the MODEVA system can meet nearly any design requirement conceived for the hotel

guestroom.

MODEVA itself contains all of the hardware components (including logic operations, radio communications, and

user interface functionality) necessary to operate as a low voltage controls interface within a thin (8mm thick)

assembly that rests outside of the wall box cavity. This brings an incredible advantage to MODEVA by allowing it

to be decoupled safely from the line power switching and dimming performed by the system’s Load Assembly

actuators. Since the MODEVA user interface is 12VDC powered and equipped with wired S5-bus

communications and a 2.4 GHz RF radio, it can be used as a standalone, low voltage controls interface for load

center style applications. This also frees the MODEVA from the mechanical confines of gang box dimensions.

Coupled with Load Assembly WBI actuators, the MODEVA becomes a complete load controlling system in the

gang box that can perform every function conceived for guestroom controls.

2 MODEVA System Block Diagram

The MODEVAI system comprises 3 segments: the mounting frame / touch user interface, the logic board, and the

Load Assembly components (mounting brackets and actuators). The exploded diagram below illustrates the high

level functionality of each of the 3 segments.

Page 3

M O D E V A R e f e r e n c e M a n u a l P a g e 3 o f 16

Service LED

and Switch

IR Rx

CPU

WBI Gang 1

WBI Gang 2

WBI Gang 3

Touch PCB

Interface 3

Touch PCB

Interface 1

Radio

Circuit

IR Tx

Touch PCB

Interface 2

GND

S5bus

12VDC

GS2 Interface 1

GS2 Interface 2

GS2 Interface 3

Speaker / Piezo

Touch Interface 1

Touch Interface 2

Touch Interface 3

Slider

Slider

Slider

LED Array

LED Array

LED Array

GS2 Logic Board

WBI Mounting Bracket and Actuators

Service LED

and Switch

Service LED

and Switch

GND

S5bus

12VDC

GND

S5bus

12VDC

12VDC Power

supply

Touch Interface

Figure 2 MODEVA System Block Diagram

Note the modular concepts that contribute to the flexibility in the MODEVA system. For instance, the triple gang

assembly uses three touch user interfaces with the same layout and mechanical dimensions but configured in four

different ways (refer to Figure 2 above and Figure 3 below). On the back end, the system’s three actuators can be

used as dimmers or as simple load switchers and can be arranged in any configuration that the application

requires. In between lies the logic board containing all logic and communications control required for nearly any

IRAS application.

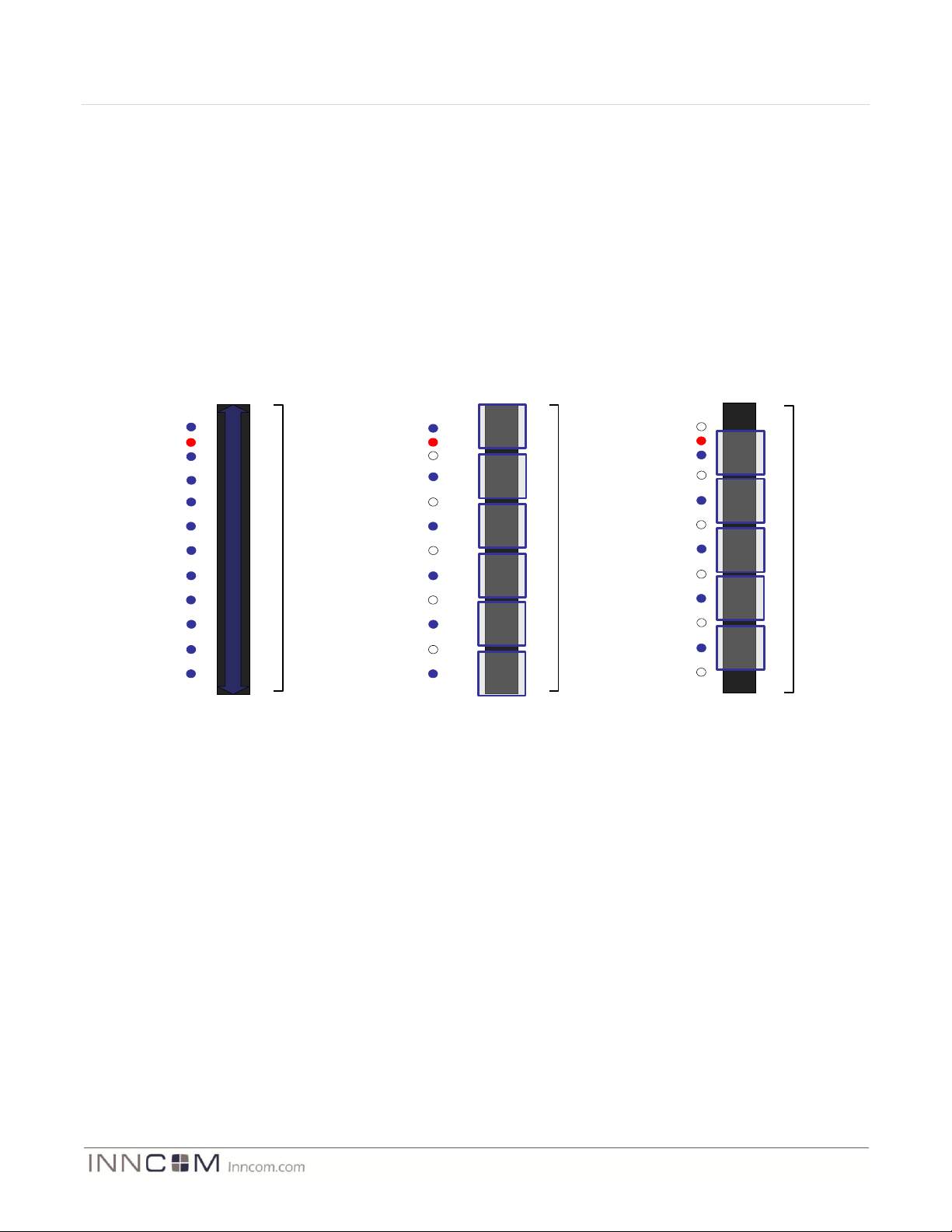

3 Touch User Interface

The MODEVA touch user interface contains the touch sensors and indicator LEDs for system input and output. The

touch user interface can be fabricated with a specific geometry and sensor layout to accommodate multiple

applications (while also easing assembly and production) by designing only one touch user interface dimension that

is used for single gang, double gang, and triple gang assemblies.

MODEVA incorporates a capacitive controller capable of detecting touch on up to 6 sensors or one single slider

per touch user interface. The sensors sense fields through any dielectric material such as glass or plastic up to

10mm thick. Each sensor can be tuned to a unique sensitivity level. INNCOM plans to provide a single touch user

interface layout at the product launch based on a single slider that can be configured in one of the four following

ways:

Basic Slider

0–255 levels of control operated by the slide of a finger across the glass in the up or down direction. This

slider array makes use of all 11 LEDs with the exception of the Red LED. This layout is optimal for slide

dimming a dimmable lighting load or as a drape control.

Five segmented slider layout

This layout segments the slider into five evenly distributed discrete sensor locations in software using a

unified hardware layout. In Figure 3 below, the five-segment layout makes use of the corresponding Blue

LEDs. In the five segment configuration, the LEDs change from array functionality to indicator

functionality. This layout is optimal where five or fewer functions (such as lighting control, amenities

such as Do Not Disturb and Make Up Room, and general purpose functionality) are required.

Six segmented slider layout

This layout segments the slider into six evenly distributed discrete sensor locations in software using a

unified hardware layout. In Figure 3, the six-sensor layout makes use of the corresponding Blue LEDs. In

the six-sensor configuration, the LEDs change from array functionality to indicator functionality. This

Page 4

M O D E V A R e f e r e n c e M a n u a l P a g e 4 o f 16

Input 5

Input 4

Input 3

Input 2

Input 1

Out 1

Out 2

Out 3

Out 4

Out 5

Out 6

Out 7

Out 8

Out 9

Out 10

Out 11

Out 12

Segmented Matrix

Discrete Input Range – 6

Key Configuration

0

255

Slider LED Array

Out 1

Out 2

Out 3

Out 4

Out 5

Out 6

Out 7

Out 8

Out 9

Out 10

Out 11

Out 12

Slider LED Array

Slider Matrix

Slider Array

0

255

Slider LED Array

Input 3

Input 1

Input 2

Input 4

Input 5

Input 6

Out 1

Out 2

Out 3

Out 4

Out 5

Out 6

Out 7

Out 8

Out 9

Out 10

Out 11

Out 12

Segmented Matrix

Discrete Input Range - 5

Key configuration

0

255

Figure 3 Slider Layout Configurations

layout is optimal where six or fewer functions (such as lighting control, amenities such as Do Not Disturb

and Make Up Room and general purpose functionality) are required. The Red LED is reserved for Do Not

Disturb functionality.

Proximity sensor layout

Optionally, a sensor on MODEVA can operate as a proximity sensor by increasing the proximity

sensitivity. This would be ideal for an application where the MODEVA assembly is backlighting text or

LED arrays located close to the nightstand or bed (see Backlighting below). When the unit is not in use,

the backlight LEDs can be dimmed to a very low level so as not to disrupt the guest’s sleep. When a hand

is waved in front of MODEVA, the unit would detect the motion and resume the backlight of the panel to

the normal bright levels or could even activate a nightlight.

Nightlight

MODEVA inputs and LEDs can be arranged to function as a nightlight/bath light by parsing the slider

into discrete inputs through software. Bright white LEDs and suppression of backlighting combine to

produce variable levels of illumination.

Backlighting

MODEVA touch user interface and front cover housings use LEDs and a housing material designed to

diffuse the backlight to an evenly illuminated glow. This can provide a subtle backlight feature to the

user interface that can illuminate text icons and other input information.

4 MODEVA Logic Board

The MODEVA logic board contains a 32-bit, 16Mhz microprocessor for all logic operations, system coordination, S5bus circuit, 2.4Ghz RF radio circuit, IR Tx, and Rx components for close proximity detection; it interfaces towards

the touch user interface and Load Assembly actuators. This is the brains and control center for the MODEVA system

designed to support nearly any application in the guestroom environment. The logic board is available in single,

double, and triple gang geometry. All features are available in each design; only the number of Load Assembly and

touch user interface interconnects changes based on the mechanical requirements. Because the MODEVA contains

Page 5

M O D E V A R e f e r e n c e M a n u a l P a g e 5 o f 16

Figure 4 Load Assembly Frame

all logic communications and interfacing capability, it can be used as a low-voltage remote control interface for load

center style applications.

4.1 RF capability

MODEVA shares the electrical design of the 0dB 2.4GHz 802.15.4 INNCOM TXR radio module by embedding the

radio components in the logic board. This sub-circuit has been specifically tuned for optimal performance for the

guestroom environment. Typically, the RF transceiver can expect to reach up to a 70ft radius in an indoor, urban

environment. MODEVA communicates on the standard INNCOM RF protocol, a proprietary encrypted protocol

that runs over the 802.15.4 platform stack. This is a shared protocol that is used by all other RF capable INNCOM

products. The protocol’s encryption method provides protection for the P5 frame being sent into the RF spectrum

and makes it very difficult to interpret the data and reuse it maliciously.

Note: RF performance can be degraded by pre existing environmental factors.

4.2 S5-bus

The logic board incorporates the most modern S5-bus circuit design, to support up to 15 S5-bus devices in a single

guestroom network segment.

4.3 IR Tx and Rx

MODEVA uses a low power IR transmitter and receiver to provide two functions: IR communications for TV and

A/V system control and proximity detection. This circuit is not to be confused with IR5 and cannot be used as a

wireless IR5 transceiver for IRAS and guestroom network purposes.

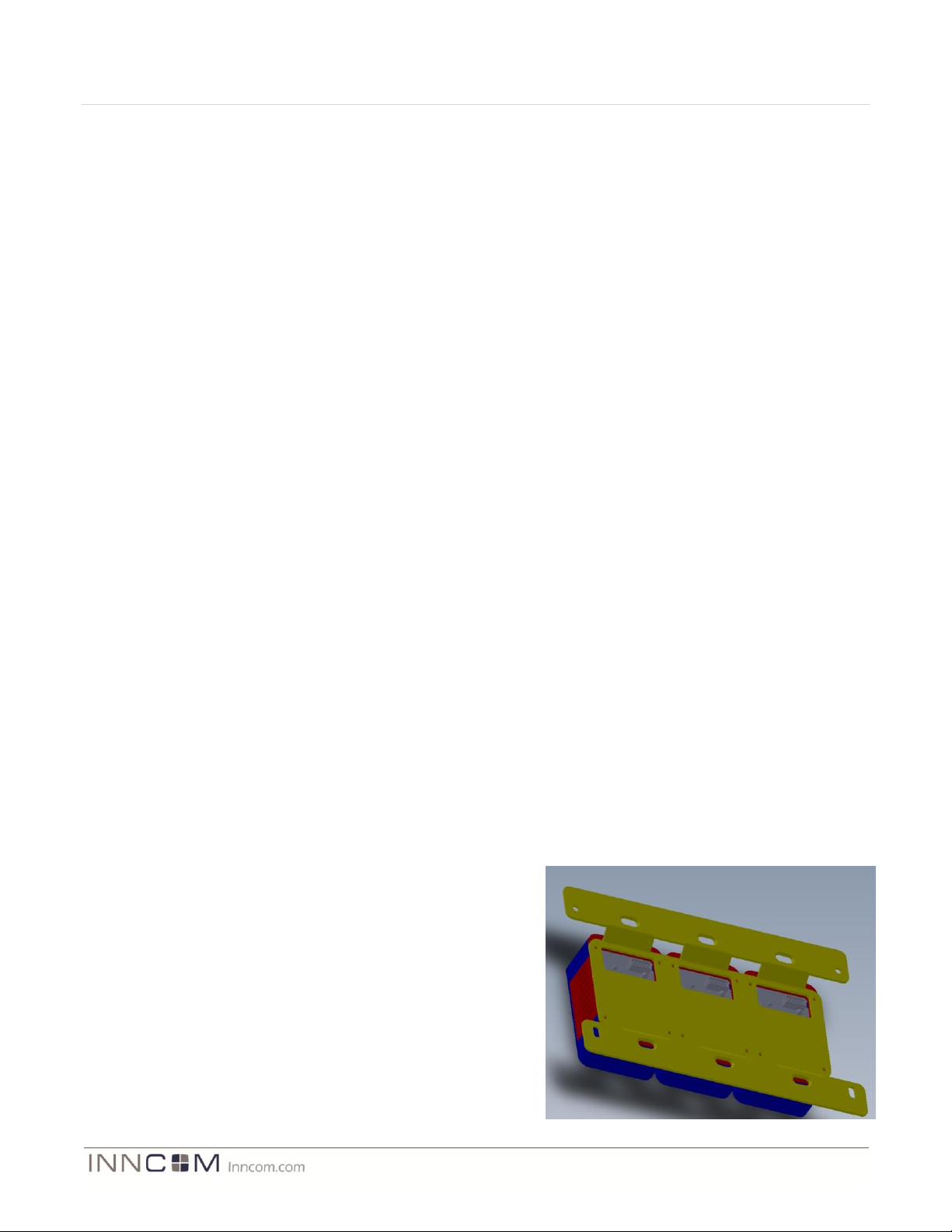

5 Load Assembly

The Load Assembly is the core of MODEVA system flexibility. The Load Assembly consists of mounting brackets

and WBI actuators that provide the mechanical platform and load bearing capability for the MODEVA system.

Each MODEVA (and each input located on the interface) can control any one of the individual actuators as part of

the Load Assembly located within the local gang box, or it can remotely control other actuators as part of the

guestroom network IRAS. This allows the designer to locate actuators with specifically designed functions

throughout the guestroom network and to have control over that actuator from any user interface in the

guestroom network. The MODEVA platform uses magnets located on the back side of the logic board that adhere

to the large flat metal surfaces of the Load Assembly brackets, allowing for screwless mounting that adds to the

aesthetic product design.

5.1 Categories of Load Assembly Load Switching

5.1.1 TRIAC Dimmer Power Supply

The TRIAC dimmer provides dimming control of

resistive light loads such as incandescent, halogen, and

TRIAC dimmable LEDs. The TRIAC dimmer can dim

100–120VAC loads up to 500W.

The TRIAC Actuator also provides a class-2, 12VDC

output used to power the MODEVA logic and touch

user interface and to provide connection and power for a

wired S5-bus IRAS network.

Page 6

M O D E V A R e f e r e n c e M a n u a l P a g e 6 o f 16

5.2.1 High-frequency noise

5.2.2 Low-frequency non-harmonics:

Caused by variable-speed motor drives, on-line UPS

systems.

Caused by signaling systems, power line carrier

communications.

5.1.2 MOSFET Dimmer Power Supply

The MOSFET dimmer is specifically designed to dim capacitive loads such as dimmable fluorescent

lamps and electronic ballast. Secondarily, it can also dim resistive loads such as incandescent, halogen,

and dimmable LEDs. The MOSFET dimmer is designed to dim 100–120VAC up to 350W.

The MOSFET Actuator also provides a class-2, 12VDC output used to power the MODEVA logic and touch

user interface and to provide connection and power for a wired S5-bus IRAS network.

5.1.3 Relay Switched Power Supply

The Relay power supply is specifically designed to switch capacitive, inductive, resistive, and general

purpose loads up to 500W.

The WBI Relay Actuator also provides a class-2, 12VDC output used to power the MODEVA logic and

touch user interface and to provide connection and power for a wired S5-bus IRAS network.

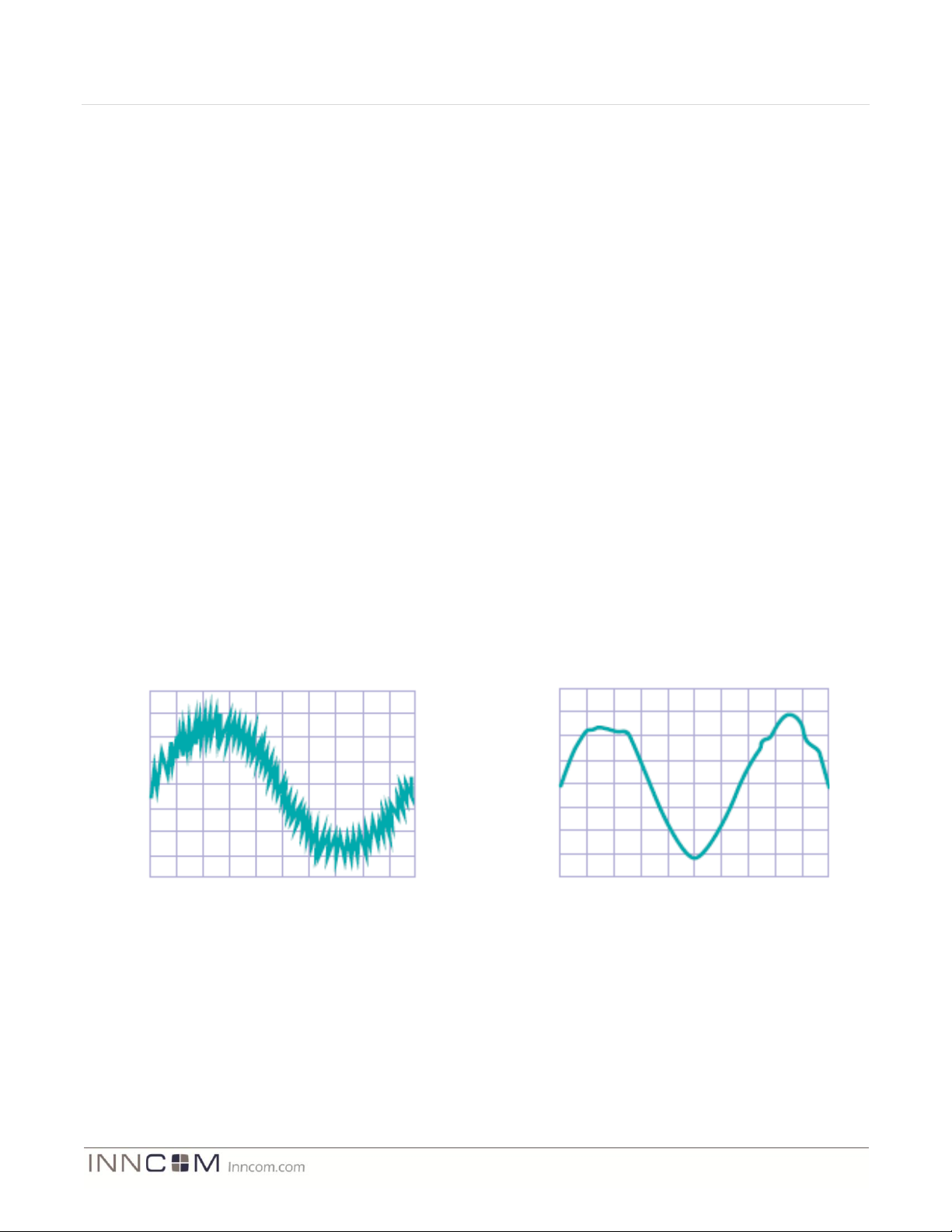

5.2 Load Assembly Dimming

With the MODEVA product offering, INNCOM presents a “lighting control system in a box” that provides a

multifaceted range of modular and component level flexibility competitors cannot offer. Because of this,

INNCOM’s lighting control hardware quality must be on par with or exceed the competitions’. To achieve the

highest level of smooth dimming operation with both the MOSFET and TRIAC dimmers, a clean power line must

be available for the Load Assembly actuators. Corrupt zero crossing information will affect turn-on points and

turn-on time of the TRIAC and MOSFET dimmers, which ultimately affects dimming quality. Zero crossing

information and accurate line frequencies are a problem for dimming products because they are more sensitive to

line voltage problems. AC line evaluation to ascertain that it meets INNCOM’s minimum technical requirements

for dimming light loads is essential.

Typically, there are six different types of power line noise that can be found in the industrial commercial and

hotel environments:

Page 7

M O D E V A R e f e r e n c e M a n u a l P a g e 7 o f 16

5.2.3 Variable baseline frequency

5.2.4 Impulse noise

Caused by backup generators and small power grids.

Caused by switch arcing (loads switching on and off).

5.2.5 RMS voltage changes

5.2.6 Notch and low frequency noise

Caused by heavy load switching.

Caused by elevators and large industrial loads

TRIAC and MOSFET dimmers can withstand certain levels of any one kind of the noises listed above. However, if

any single noise is present at a high magnitude, or multiple noise conditions occur simultaneously, the poor

quality conditions on the line will result in poor quality dimming performance. INNCOM application

engineering, operations, and customer service need to be aware of these property conditions to ensure proper

operation of the MODEVA light dimmers. A site survey that includes the evaluation of the line voltage at each

property must be conducted.

5.3 Air-Gap Switch

The TRIAC and MOSFET Load Assemblies are equipped with an air gap switch (relay) to ensure that the load is

safely turned off and that there is no leakage current to the fixture during routine lamp maintenance. The air gap

switch engages each time the load is dimmed completely off under normal operation.

5.4 Overload Protection

If a MOSFET or TRIAC Dimmer is continuously overloaded, a thermal shut down will occur to protect the solid

state circuitry. This thermal shutdown temperature can be configured and monitored with INNCOM

configuration tool such as the PC-501.

The MOSFET Dimmer is equipped with an additional overload detection circuit that detects a catastrophic

overload / short and shuts down the dimmer to protect the solid state circuitry.

Page 8

M O D E V A R e f e r e n c e M a n u a l P a g e 8 o f 16

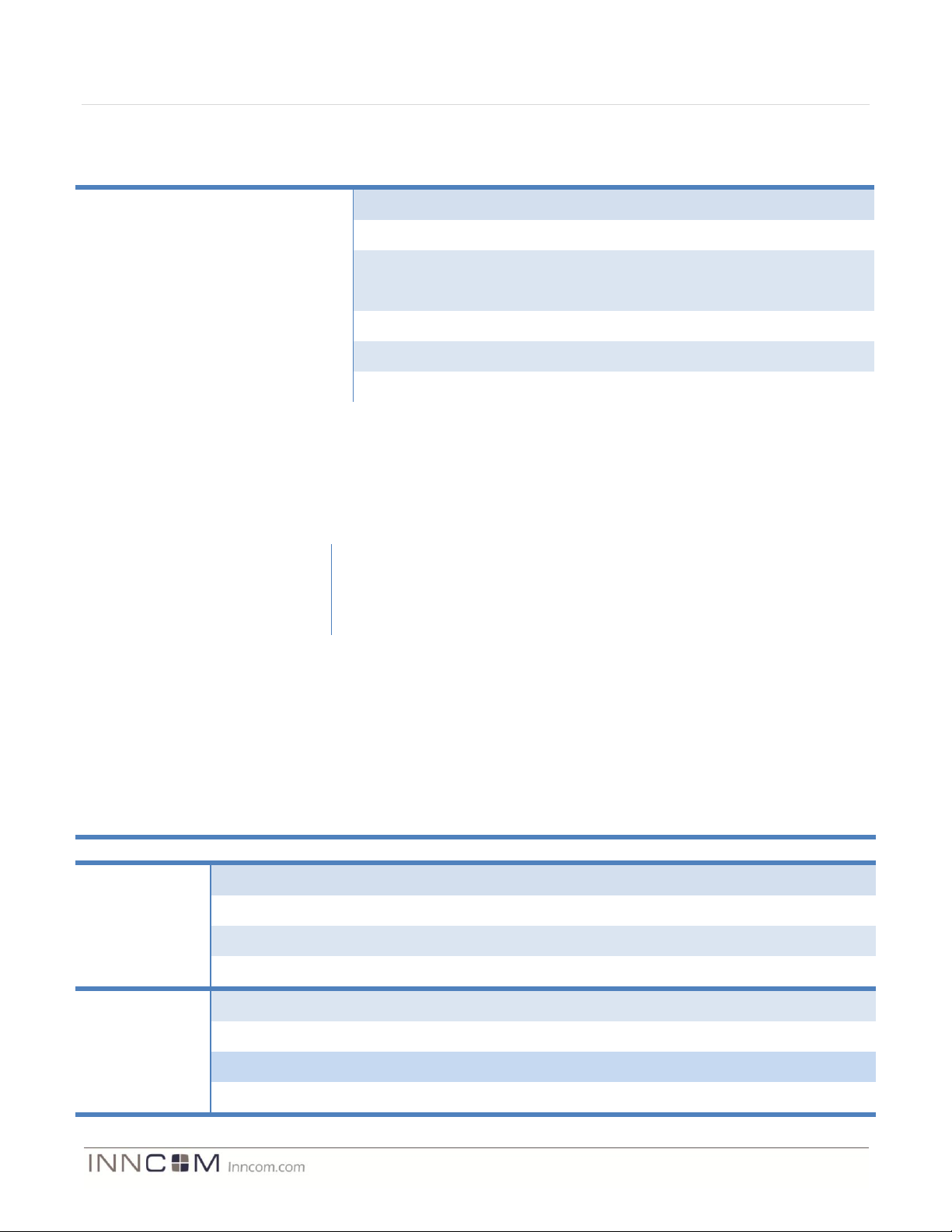

Hot

Neutral

120/240VAC

50/60Hz

Lighting Load

WBI Actuator 1

200mA

375mA550mA

WBI Actuator 2 WBI Actuator 3

12VDC

GND

R

Load

WBI MOSFET

Dimmer

WBI MOSFET

Dimmer

WBI MOSFET

Dimmer

Number of Load Assemblies

Nominal Voltage

Voltage at Maximum

Load

Output Rating

Single Actuator

+12VDC

+11.0VDC

200mA

Two Actuators

+12VDC

+11.0VDC

400mA

Three Actuators

+12VDC

+11.1VDC

600mA

Four Actuators

+12VDC

+11.1VDC

700mA

Five Actuators

+12VDC

+11.2VDC

800mA

Six Actuators

+12VDC

+11.2VDC

900mA

Mechanical Package

Length

Width

Height

American Single Gang

119mm

74mm

8.0mm

American Double Gang

119mm

124mm

8.0mm

American Triple gang

119mm

174mm

8.0mm

5.5 Load Assembly Parallel Power Supplies

Figure 5 Parallel Power Supplies

The WBI actuators operate in parallel to supply a higher load capacity than that achievable by a single actuator.

The total output power of the actuators in parallel is based on the voltage specifications at maximum load versus

the output current at maximum load and a nominal recover time after a fold back condition occurs. Therefore, the

sum of paralleled power supplies is not simply I1 + I2 + I3= I max. However, aggregate power of the paralleled

supplies is greater than that available from a single source.

The benefit of this design is the ability to aggregate actuators into a system that permits load sharing without

concern for back feeding voltage that typically occurs when more than one supply is used. A triple ganged

MODEVA system can provide up to 550mA to power 12VDC S5-bus devices in the circuit. INNCOM

recommends the use of up to seven power supplies in any given network segment. A disadvantage is that a short

condition on any one of the actuators will drag all of the actuators into a fold-back state until the short condition

is resolved.

6 MODEVA System Technical Specification

Page 9

M O D E V A R e f e r e n c e M a n u a l P a g e 9 o f 16

Glass Touch Surface Area

Length

Width

Height

American Single Gang

115mm

70mm

2.0mm

American Double Gang

115mm

120mm

2.0mm

American Triple gang

115mm

170mm

2.0mm

Electrical Characteristics

Parameter

User Interface

Capacitive touch sensor / slider

Maximum # of inputs

1-6 sensor inputs, or 1 slider per gang

Alternate User Interface

Keypad—traditional mechanical switches

Communications

1. Wired S5-bus

2. 2.4Ghz RF

3. IR Infrared (not IR5)

Output Power

12VDC, up to 200mA*

Micro controller

16Mhz, 32-bit ARM based MCU

Page 10

M O D E V A R e f e r e n c e M a n u a l P a g e 10 o f 16

Device

Peak Current Consumption

Logic Board (basic)

50mA

Logic Board w/ 1mW Radio

60mA

Logic board with IR transceiver

70mA

Capacitive Touch PCBA (02-7060)

10mA(n x 3.5mA) (logic board current plus the number of LEDs)

Load Assembly Relay Actuator

35mA

Load Assembly TRIAC Actuator

35mA

Load Assembly MOSFET Actuator

35mA

Logic Board w/ 1mW Radio

60mA

=121mA (Peak Current Consumption)

Capacitive Touch PCBA (02-7060)

10mA(6 x 3.5mA)=31mA

MOSFET Actuator

30mA

Actuator

Ratings

Voltage

Frequency

Power / Amperes

Load Type

Relay Actuator

120-240 Vac

50/60 Hz

4.1 A

Resistive

120-240 Vac

50/60 Hz

4.1 A

General Purpose

120-240 Vac

50/60 Hz

500 W

Tungsten / ELV

120-240 Vac

50/60 Hz

250 VA

Electric Ballast

TRIAC Dimmer

120 Vac

60 Hz

2.9 A

Resistive

120 Vac

60 Hz

2.9 A

General Purpose

120 Vac

60 Hz

500 W

Tungsten / ELV

120 Vac

60 Hz

250 VA

Electronic Ballast

6.1 MODEVA/Load Assembly Current Consumption Characteristics

For example, a MODEVA assembly that

uses the capacitive touch PCBA for a 6 input / output user interface,

communicates wirelessly using the 2.4Ghz radio, and

uses the MOSFET dimmer to actuate a load

would have a peak current consumption figured as follows:

The total DC load rating of a single actuator is 200mA. Therefore, a single actuator has 80mA remaining to

provide 12VDC power to S5-bus devices.

7 Load Specifications

7.1 Single gang installation

The following table provides load ratings at absolute maximum based on the load type in a single gang wall box.

Page 11

M O D E V A R e f e r e n c e M a n u a l P a g e 11 o f 16

Actuator

Ratings

Voltage

Frequency

Power / Amperes

Load Type

MOSFET

Dimmer

120 Vac

60 Hz

2.9 A

Resistive

120 Vac

60 Hz

2.9 A

General Purpose

120 Vac

60 Hz

350 W

Tungsten / ELV

120 Vac

60 Hz

250 VA

Electronic Ballast

Actuator

Ratings

Voltage

Frequency

Power / Amperes

Load Type

TRIAC Dimmer

120 Vac

60 Hz

2.9 A

Resistive

120 Vac

60 Hz

2.9 A

General Purpose

120 Vac

60 Hz

400 W

Tungsten

120 Vac

60 Hz

250 VA

Electronic Ballast

MOSFET

Dimmer

120 Vac

60 Hz

2 A

Resistive

120 Vac

60 Hz

2 A

General Purpose

120 Vac

60 Hz

250 W

Tungsten

120 Vac

60 Hz

250 VA

Electronic Ballast

Actuator

Ratings

TRIAC Dimmer

Voltage

Frequency

Power /

Amperes

Load Type

120 Vac

60 Hz

2.9 A

Resistive

120 Vac

60 Hz

2.9 A

General Purpose

120 Vac

60 Hz

400 W

Tungsten

120 Vac

60 Hz

250 VA

Electronic Ballast

MOSFET

Dimmer

Voltage

Frequency

Power /

Amperes

Load Type

120 Vac

60 Hz

2 A

Resistive

120 Vac

60 Hz

2 A

General Purpose

7.2 Multigang Installation

The MODEVA and Load Assembly comes in single, double and triple gang configurations; the double and triple

gang assemblies may be any combination of relay, switches, MOSFET Dimmer or TRIAC Dimmer. The table

below provides the derated output based on the configuration.

8 Multigang Installation Derating Chart

8.1 Actuator Ratings

Page 12

M O D E V A R e f e r e n c e M a n u a l P a g e 12 o f 16

Actuator

Ratings

120 Vac

60 Hz

250 W

Tungsten

120 Vac

60 Hz

250 VA

Electronic Ballast

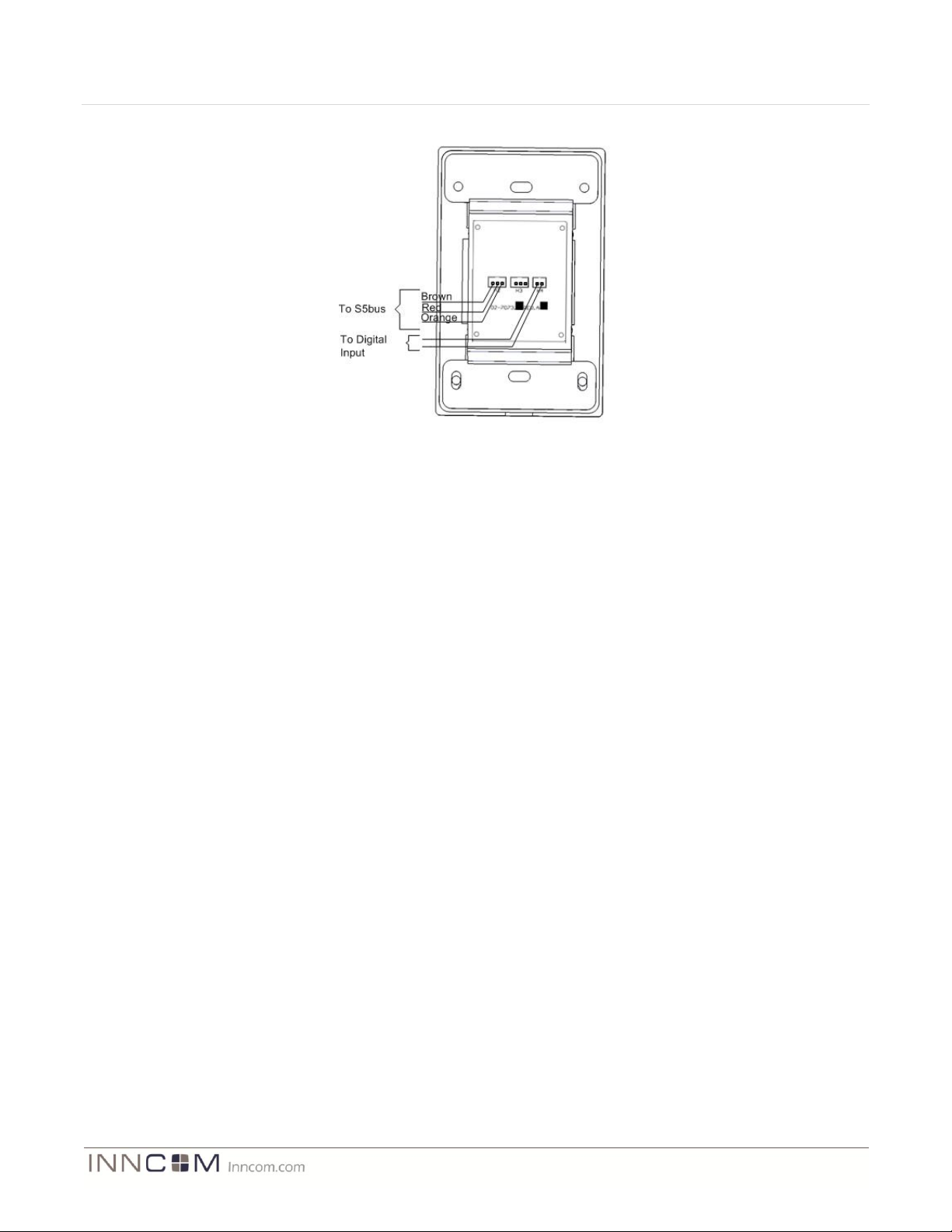

Figure 6 Single Gang Wiring Diagram

Brown

Red

Orange

To S5bus

To Digital

Input

To Digital Input

To Digital Input

Phase

120V 60Hz

Load

Load

Load

Neutral

Green

Yellow

Yellow

Yellow

White White White

Black Black Black

9 Standard Wiring

In Figure 6, the MODEVA and Load Assembly is configured for switching or dimming the level of AC power

delivered to a load, such as a Tungsten lighting load.

In Figure 7, the MODEVA and Load assembly is configured for switching or dimming the level of AC power

Figure 7 Double and Triple Gang Wiring Diagram

delivered to multiple loads, such as two or three tungsten lighting loads.

Page 13

M O D E V A R e f e r e n c e M a n u a l P a g e 13 o f 16

Figure 8 Single Gang Powered Remote Control

In the configuration shown in Figure 8, the MODEVA is used as a three-way switch to transmit S5bus or RF

signals to auxiliary INNCOM devices to manage in-room communications irrespective of the location of the

system devices. In this respect, the MODEVA provides remote control of auxiliary INNCOM devices.

In Figures 6, 7, and 8 each MODEVA is equipped with low voltage connections to provide +12VDC power to

other devices, communicate on the S5bus, or provide a digital input for a door switch.

10 FCC Statement

This device contains FCC ID: GTC027060TXR.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference, in which case the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by the party responsible for compliance could void the user's

authority to operate the equipment.

11 MODEVA User Interface Assembly Ordering Information

The MODEVA and Load Assembly are designed to be modular and can be completely independent of each other.

For instance, a double gang MODEVA user interface can be specified, while the system may only require a single

Load Assembly actuator. Therefore, the Ordering Part Numbers (OPN) for the MODEVA and Load Assembly are

separated. Both the MODEVA and Load Assembly are available in several operating ranges. The MODEVA OPN

is formed by a combination of the elements, as shown in the figure below:

Page 14

M O D E V A R e f e r e n c e M a n u a l P a g e 14 o f 16

03-7060

Assembly Part Number

03-7060 – Single Gang Assembly

03-7061 – Double Gang Assembly

03-7062 – Triple Gang Assembly

GHS1

Switch Model

Defined by project

R0

Frame Plate Color

WH = White

BK = Black

AL = Almond

XX = Custom Pantone Color

Radio

R0 = No Radio

R1 = Layer-1 Radio (02-9994.L1)

R2 = Layer-2 Radio (02-9894.L2- Not available)

R3 = Reserved for future application

R4 = Reserved for future application

R5= Reserved for future application

WH

Figure 9 User Interface Assembly Ordering Part Number

Examples:

03-7060.GHS1.R1.WH = MODEVA user interface assembly switch #1 designed for the Grand Hyatt New York

project that includes the CC2430 based radio circuit and a white framing plate. “GHS1” further defines the

attributes of the Touch User interface PCB model (ex. GS-765.XXX) in the following:

Number of capacitive touch keys or sliders

Locations of capacitive touch keys

Number of indicator LEDs

LED locations

LED colors

This information is found in the 03-7060.GHS1 Hardware Guide. Note that when a double and triple gang

assembly is designed (03-7062.xxx.xx.xx) it becomes more critical to refer to the hardware guide that defines the

touch user interface attributes for the left gang, center gang, and right gang. Again note that in a double and triple

gang assembly two and three touch user interface PCBA’s are required, but always only one logic board PCBA is

required.

03-7061.GHS2.R0.WH = A double gangMODEVA assembly configured for the Grand Hyatt Switch position #2

that does not include the CC2430 radio circuit, uses a white framing plate, and uses a GS-765.STD in the left

position, and a GS-765.NL01 in the right position. (See GS-765.STD and GS-765.NL01 hardware guide for specific

details of the touch user interface).

Page 15

M O D E V A R e f e r e n c e M a n u a l P a g e 15 o f 16

Assembly Part Number

03-7001 – Single Gang Assembly

03-7002 – Double Gang Assembly

03-7003 – Triple Gang Assembly

Actuator Type: Left Position (or Single Gang)

L – Low Voltage Adapter

0 - Relay Actuator

1 - Triac Actuator (400W dimmable)

2 - MOSFET Actuator (400W dimmable)

3 - Reserved for future application

4 - Reserved for future application

03-7 0 0 3

Actuator Type: Center Position (or Right in

Double Gang)

L – Low Voltage Adapter

0 - Relay Actuator

1 - Triac Actuator (dimmable)

2 - MOSFET Actuator (dimmable)

3 - Reserved for future application

4 - Reserved for future application

Actuator Type: Right Position

L – Low Voltage Adapter

0 - Relay Actuator

1 - Triac Actuator (dimmable)

2 - MOSFET Actuator (dimmable)

3 - Reserved for future application

4- Reserved for future application

2 0 1

12 MODEVA Load Assembly Ordering Information

12.1 Load Assembly Ordering Information

The Load Assembly system is available in several operating ranges but is based on the same fundamental

hardware platform. The ordering part numbers (OPN) are formed by a combination of the elements, as shown in

Figure 7 below.

Example:

03-7003.L01 = A triple gang MODEVA Load Assembly that includes a low voltage adapter in the left position, a

relay actuator in the center position and a TRIAC dimmer in the right position.

Figure 10 Load Assembly Ordering Part Number

Page 16

M O D E V A R e f e r e n c e M a n u a l P a g e 16 o f 16

Date

Changes

13-Oct-2009

First Draft

16-Oct-2009

Edited for content and composition

02-Mar-2010

Product information added and edited

09-Apr-2010

Updated Derating chart for UL

20-Apr-2010

Updated order guide to include radio option for logic components

18-Jun-2010

Update to reflect name changes; new ratings tables

07-Jul-2010

Replaced mechanical drawings of the brackets, label drawings, etc with

standard wiring drawings

23-Aug-2010

Updated FCC statement

13 Document Information and Revision History

Author Ryan Gardner

File \\Niantic\departments\R&D\Working Documents\Reference Manuals\MODEVA\Drafts

Loading...

Loading...