Honewell VR 46, VR 86 Control

VR46../VR86.. series

COMPACT AUTOMATIC COMBINATION GAS CONTROLS

PRODUCTHANDBOOK

APPLICATION

The Compact Automatichas been specially developed for application in domestic central heating boilers, warm air furnaces or

water heatergas appliances.

The Compact Automaticisusedina systemcontextin conjunction with either a direct spark ignition(DSI),intermittent pilot (IP)

or Hot Surface Ignition control module and associated devices to provide programmed safe light--up and supervision of the main

burner of an appliance.

Subject to change without notice. Printed in the Netherlands.

EN2R--9003 9510R2--NE

CONTENTS

General

Description 3...................................................................................................

Feature 4......................................................................................................

Technical

Specifications 5.................................................................................................

Capacity 6.....................................................................................................

Capacity curve C90 8............................................................................................

Capacity curve C100 9...........................................................................................

Capacity curve C110 10..........................................................................................

Capacity curve C120 11..........................................................................................

Capacity curve C130 12..........................................................................................

Capacity curve C170 13..........................................................................................

Capacity curve C200 14..........................................................................................

Capacity curve C210 15..........................................................................................

Capacity curve C220 16..........................................................................................

Capacity curve C230 17..........................................................................................

Capacity curve C240 18..........................................................................................

Capacity curve C250 19..........................................................................................

Capacity curve C260 20..........................................................................................

Capacity curve C270 21..........................................................................................

Capacity curve F20 22...........................................................................................

Capacity curve F30 23...........................................................................................

Capacity curve F40 24...........................................................................................

Capacity curve F50 25...........................................................................................

Electrical data low voltage 26.....................................................................................

Electrical data line voltage 27.....................................................................................

Performancecharacteristics 28....................................................................................

Dimensional drawing VR46../VR86..A/C, AB/CB 30...................................................................

Dimensional drawing VR46../VR86..B/D 31.........................................................................

Dimensional drawing VR46../VR86..A/C, AA/CA, AB/CB, VA 32........................................................

Dimensional drawing VR46../VR86..E/T,EA/TA 33...................................................................

Installation

Installation 34...................................................................................................

Adjustmentsand final checkout 35.................................................................................

Construction and working principles 36.............................................................................

Various

Qualityassurance statement 39...................................................................................

Approvals and standards 40......................................................................................

Ordering information 41..........................................................................................

2

EN2R--9003 9212R2--NE

DESCRIPTION

Compact Automatic combination gas controls performall the

functions required to safely regulate gas flow to the pilot

burner and the main burner of domestic central heating

equipment,warm air furnaces, back boilers and water

heaters.

Compact Automatic combination gas controls comprise a

standard body to which a range of sub--assemblies are

factoryfitted to give various system options. This makes boiler

system design much easier as technical s pecifications and

unit dimensions are the same for all system options. Options

include servo pressure regulation,throttle valve, (switchable)

softlite, electricalhigh--low control and electricalor mechanical

modulationfor the complete range of control applications.

Compact Automatic combination gas controls are available in

line or low voltage versions and in three capacity ratings for

totalsystem versatility. Customer specific voltage models are

also offered

Compact Automatic combination gas control consist of a first

direct electric on/off operator for opening the safety valve of

class A or class B according to EN 161 and a second electric

on/offservo operatorvalve for opening the main valve of class

B, C or class D according to EN 161 and comply with the

additionalrequirementof D’ valves according to EN 297.

Compact Automatic combination gas controls are rated for

gas families MFD Group A (G 110), MFD Group B (G 120),

NaturalH (G 20), NaturalL (G 25) and LP (G 30).

All measurements are carried out under standard c onditions,

unless otherwise is indicated.

Standardconditions

• P

• P

• T

• Outletorifice 2.8 mm

• Flow indication in m

• Recording of outlet pressure with a transducer connected

25 mbar nominal pressure, dry air of 20EC

inlet

1013 mbar

ambient

20EC

ambient

3

/

h

1

to a

/2” pipe with a length of 10 d with a short hose

at 5 d.

• Nominal voltage

• Upright position, i.e. the position when the operators are on

top.

3

EN2R--9003 9212R2--NE

FEATURES

General

:

Specially designed for use with gas appliances with a DSI,

HSI or IP system to light the main burner.

:

Incorporates time proven design concepts assuring

reliability.

:

ON/OFF control of main burner by electric on/off operator

and electricon/off servo operator.

:

At inlet side an internal fine mesh screen is incorporated in

the Compact Automatic. This screen is not intended to be

removable for cleaning. When flanges are used, removable

screens can be placed between the flanges and the

Compact Automatic.

:

Outletscreen (optional).

:

Various closing force models are available: B + B, B + D,

B+C,A+DandA+C.

:

All adjustments are located on the top of the Compact

Automatic.

:

9 mm outer diameter pressure tap at inlet and outlet side for

checking and adjusting burner pressure.

:

A wrench boss is incorporatedat the inlet side of the

Compact Automatic for pipe fitting.

:

Compact Automatic mounting orientation may be within 90

in any directionfrom the electric on/off operator upright

position.

:

Twothreaded mounting holes are at the bottom of the

Compact Automatic for rigid attachment to the appliance.

:

Main valve on/off servo operator with DIN faced electrical

connection has two threaded holes at the top for mounting

purposes (e.g. cover).

:

High, medium and low capacity models are available.

:

Main valve on/off servo operator employs DIN face

electrical connection which are also suitable for AMP

connections.

:

The coil of the electric on/off operatoris field replacable and

can also be positioned in other directions for better

accessability.

Gasconnectionoptions

:

Inlet and outlet connections are straight through and

threaded (standard model).

:

Inlet and outlet connections can receive flanges.

:

Side outlet options are available for both main and pilot gas.

:

The pilot gas connection for using break away connectors

for various O.D. tubing is located at the outlet end of the

Compact Automatic (standard model).

:

The pilot gas side outlet and special end outlet are suitable

for manifold connections.

:

High capacity model has straight through inlet and outlet

with Ø 23 mm bore.

Electricalconnection options

:

Both top face and bottom face AMP electrical connection

on electricon/off operator are available.

:

Single plugs are available with cable and strain reliefin

several versions (IP 40)

:

Seperate plugs on first and second electric on/off operator

are available (IP 40).

:

IP 44 connection by means of two DIN connectors is

possible.

:

Quick connect 6,3 mm fastons on both coils can be applied

in combination with single cover or separate covers with

E

strain relief.

:

Line voltage on/off servo operators are provided with a

ground screw and washer.

Functionaloptions

:

Servo pressure regulator provides stable outlet pressure.

:

Pressure feedback ensures constant burner

pressure(optional).

:

A throttle valve version is available,where unregulated

valves may be employed.

:

Softlite option to facilitate a smooth light up of burners.

:

Switchable softliteoption for changing over from one gas to

another and vice versa.

:

Electrical or mechanical modulation.

:

ElectricalHigh--Low control.

:

Incorporated pilot filter(optional).

:

Pilot outlet for IP system.

:

Suitable for use with Gas/Air ratio components.

4

EN2R--9003 9212R2--NE

SPECIFICATIONS

NOTE: Specificationsfor electrical modulation,

mechanical modulation, electrical high low,

switchable softliteand other features are

available on request.

Models

See model number chart on page 41

Pipe sizes

• Inlet and outlet

• Inlet 18,6 mm dia and outlet

pipe thread

• Inlet

1

/2” ISO 7/1 internal parallel pipe thread and outlet

1

/2” ISO 7/1 internal parallel pipe thread.

1

/2” ISO 7/1 internalparallel

18,6 mm dia

• Inlet and outlet Ø 23 mm bore (high capacity models only)

• Inlet and outlet can also be fitted with straightor elbow

flanges.

• Side outlet (optional)can only be fitted with a flange.

Ambient temperature

VR46../VR86..xA: 0 ... 70

VR46../VR86..x: 0 ... 60

VR46../VR86..xB: 0 ... 60

E

C

E

C

E

C

Pilotgas connection

Standard at end outlet:

M11x1for

1

/4”, 6 mm or 4 mm O.D. tubing.

Special connection:

Incorporated in the side outlet.

Pressure feedback connection

The servo pressure regulator has an M5 thread connection for

pressure feedback.

Enclosure

IP 40 with covers or plugs

IP 44 with DIN plugs according to DIN 43650

Dimensions

See Dimensional drawing

Maximum operating pressure

The P

indicationon the housing of the Compact

max

Automaticis the maximum pressure at which it functions

safely. However, the maximum operating pressure is limited

by the pressure range of the pressure regulator concerned

(see table 1.).

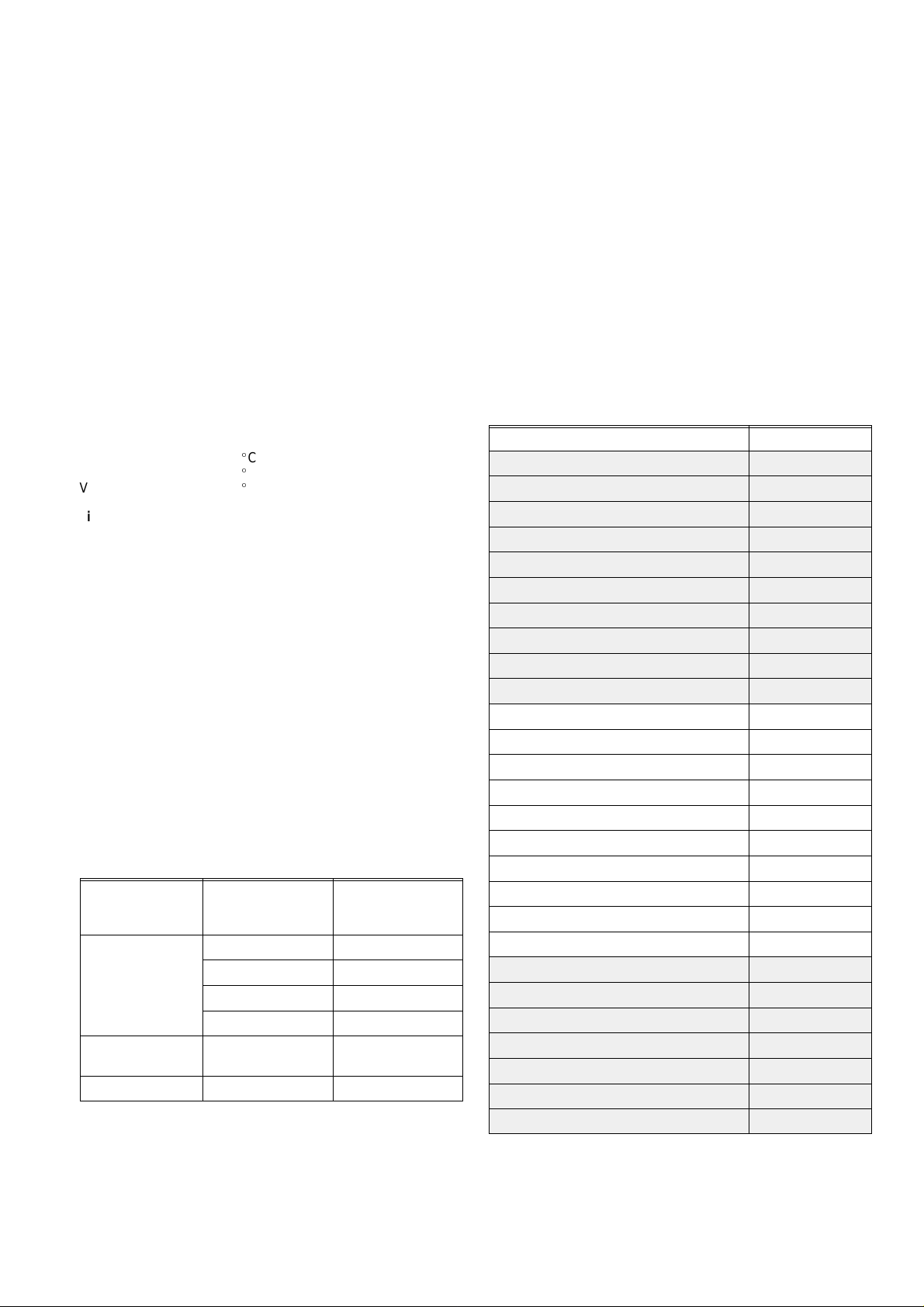

Table 1. Maximum operating pressure

Model

Pressure range

(mbar)

Maximum

operating

pressure (mbar)

with regulation 2.5 ... 20 30

3 ... 37* 45

5 ... 50* 60

10 ... 60* 100

without

-- 60

regulation

with throttle -- 60

* This type can also be used for non regulation mode in LP

applicationswhen pressure regulatoradjustment screw is

clockwise turned down until it stops.

Mountingholes

TwoM5 mounting holes are located on the bottom of the

Compact Automatic.

The four holes at inlet and outlet for mounting the flange on

the Compact Automatic are provided with M5 thread with min.

6.5 mm full thread.

The four holes for mounting the flange to the side outlet are

provided with M4 thread with minimum 6 mm full thread.

TwoM4 threaded holes on DIN faced electrical on/off servo

operatorare also for mounting purposes.

Minimumregulation capacity

3

0.31 m

/h

Minimumadjustable capacity (throttlevalve only)

0.6 m3/h air at ∆P of 20 mbar

3

Minimumdifferentialpressure at 0,31 m

Model*

/hair

∆Pmin(mbar)

VR4601/VR8601XA 1.8

VR4605/VR8605XA 1.8

VR4611/VR8611XA 3.9

VR4615/VR8615XA 3.9

VR4621/VR8621XA 3.9

VR4625/VR8625XA 3.9

VR4631/VR8631XA 1.8

VR4635/VR8635XA 1.8

VR4641/VR8641XA 3.9

VR4645/VR8645XA 3.9

VR4601/VR8601X 1.7

VR4605/VR8605X 1.7

VR4611/VR8611X 3.9

VR4615/VR8615X 3.9

VR4621/VR8621X 3.9

VR4625/VR8625X 3.9

VR4631/VR8631X 1.7

VR4635/VR8635X 1.7

VR4641/VR8641X 3.9

VR4645/VR8645X 3.9

VR4601/VR8601XB 1.7

VR4605/VR8605XB 1.7

VR4611/VR8611XB 3.9

VR4615/VR8615XB 3.9

VR4621/VR8621XB 3.9

VR4625/VR8625XB 3.9

VR4641/VR8641XB 3.9

* X = suffix letter

5

EN2R--9003 9212R2--NE

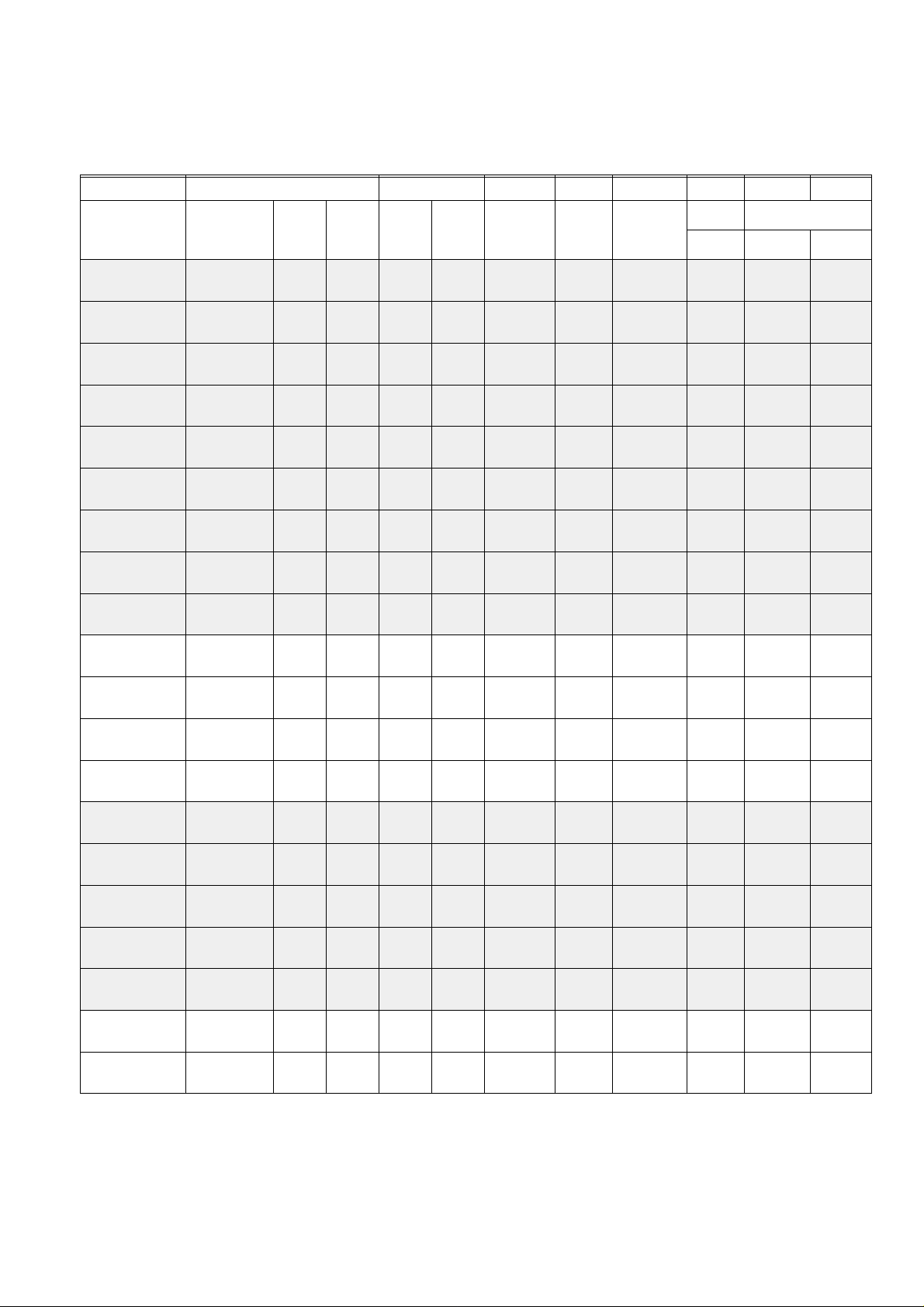

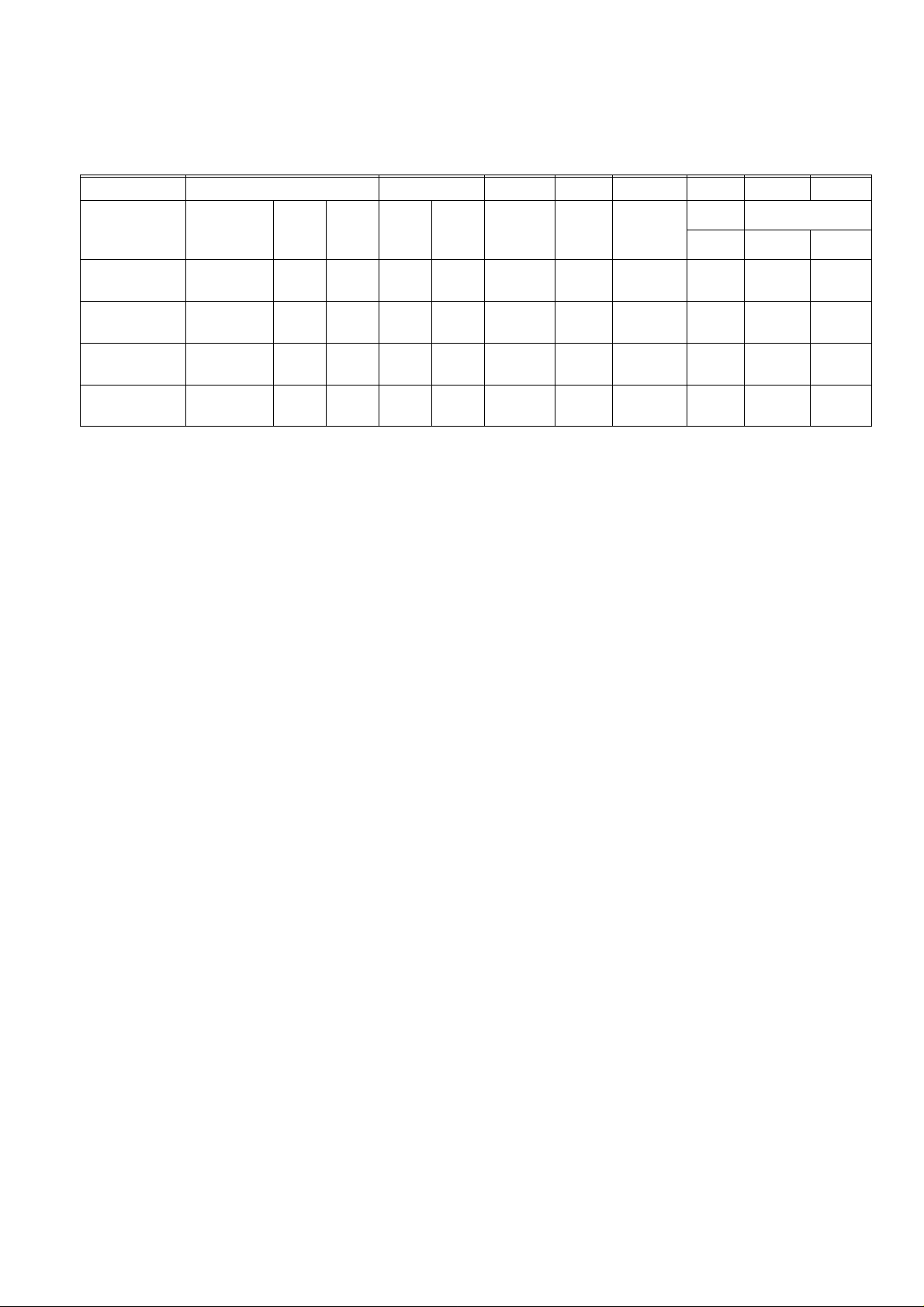

CAPACITY IN m3/hAIR ATPRESSURE DROPAS SHOWN.

(mm)

(mm)

(mbar)

(

3

/h)

SEE ALSO THE CORRESPONDING CAP ACITY CURVES

Safety valve Main valve

Model Remark Class Seat

VR460.XA

Standard B 11 D 17 C110 2.5 1.95

VR860.XA

VR460.XA

Upgraded B 17 D 17 C210* 3 2.7

VR860.XA

VR460.XA

Standard B 11 D 17 C220* 2.5 1.4

VR860.XA

VR461.XA

Standard B 11 C 17 C120 5 1.8

VR861.XA

VR461.XA

Upgraded B 17 C 17 C230* 5 2.5

VR861.XA

VR462.XA

Standard B 11 B 17 C240* 5 2

VR862.XA

VR462.XA

Upgraded B 17 B 17 C250* 5 2.5

VR862.XA

VR463.XA

Standard A 11 D 17 C110 2.5 1.95

VR863.XA

VR464.XA

Standard A 11 C 17 C120 5 1.8

VR864.XA

VR461.VA

Standard B 11 C 11 F40 10 4.1

VR861.VA

VR464.VA

Standard A 11 C 11 F20 10 4.1

VR864.VA

VR461.V

Standard B 17 C 11 F30 10 5.1

VR861.V

VR464.V

Standard A 17 C 11 F50 10 5.1

VR864.V

VR460.X

Standard B 17 D 17 C90 3 3.1

VR860.X

VR461.X

Standard B 17 C 17 C100 5 3

VR861.X

VR462.X

Standard B 17 B 17 C260* 5 3

VR862.X

VR463.X

Standard A 17 D 17 C90 3 3.1

VR863.X

VR464.X

Standard A 17 C 17 C100 5 3

VR864.X

VR460.XB

Standard B 18.5 D 17 C130 3 4.2 23 mm 23 mm

VR860.XB

VR461.XB

Standard B 18.5 C 17 C170 5 4.6 23 mm 23 mm

VR861.XB

* Capacity curve to be specified

Class Seat

Capacity

curve

number

∆P

Capacity3Inlet Outlet

m

Straight Side

1

/2”

1

/2”

1

/2” Flange

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

1

/2”

6

EN2R--9003 9212R2--NE

CAPACITY IN m3/hAIR ATPRESSURE DROPAS SHOWN.

(mm)

(mm)

(mbar)

(

3

/h)

SEE ALSO THE CORRESPONDING CAP ACITY CURVES

Safety valve Main valve

Model Remark Class Seat

VR460.EB

VR860.EB

VR460.TB

VR860.TB

VR461.EB

VR861.EB

VR461.TB

VR861.TB

* Capacity curve to be specified

Standard B 18.5 D 17 C200 3 4.2 23 mm 23 mm

Standard B 18.5 D 17 C200 3 4.2 23mm 23 mm

Standard B 18.5 C 17 C270* 5 4.0 23 mm 23 mm

Standard B 18.5 C 17 C270* 5 4.0 23 mm 23 mm

Class Seat

Capacity

curve

number

∆P

Capacity3Inlet Outlet

m

Straight Side

7

EN2R--9003 9212R2--NE

12

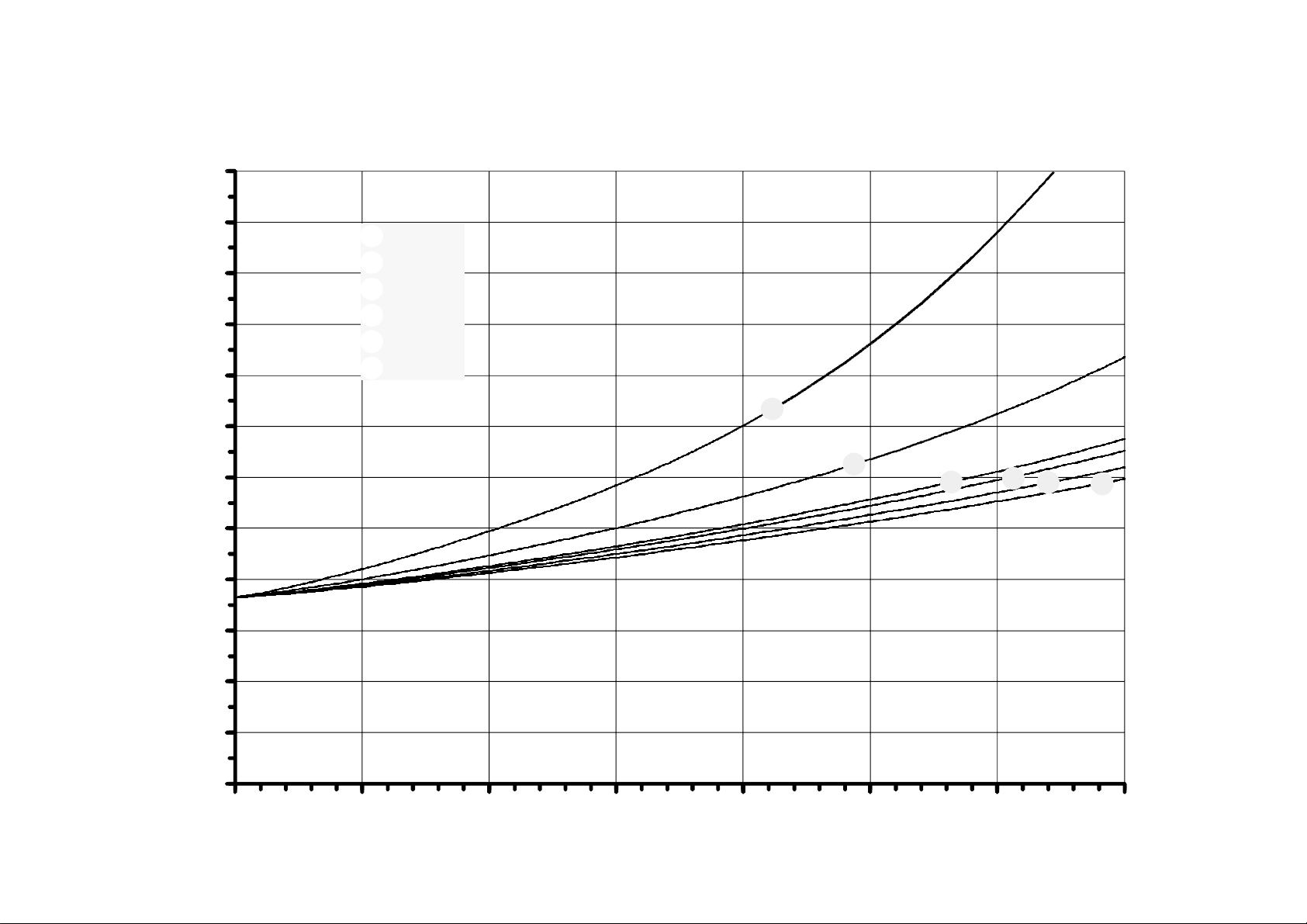

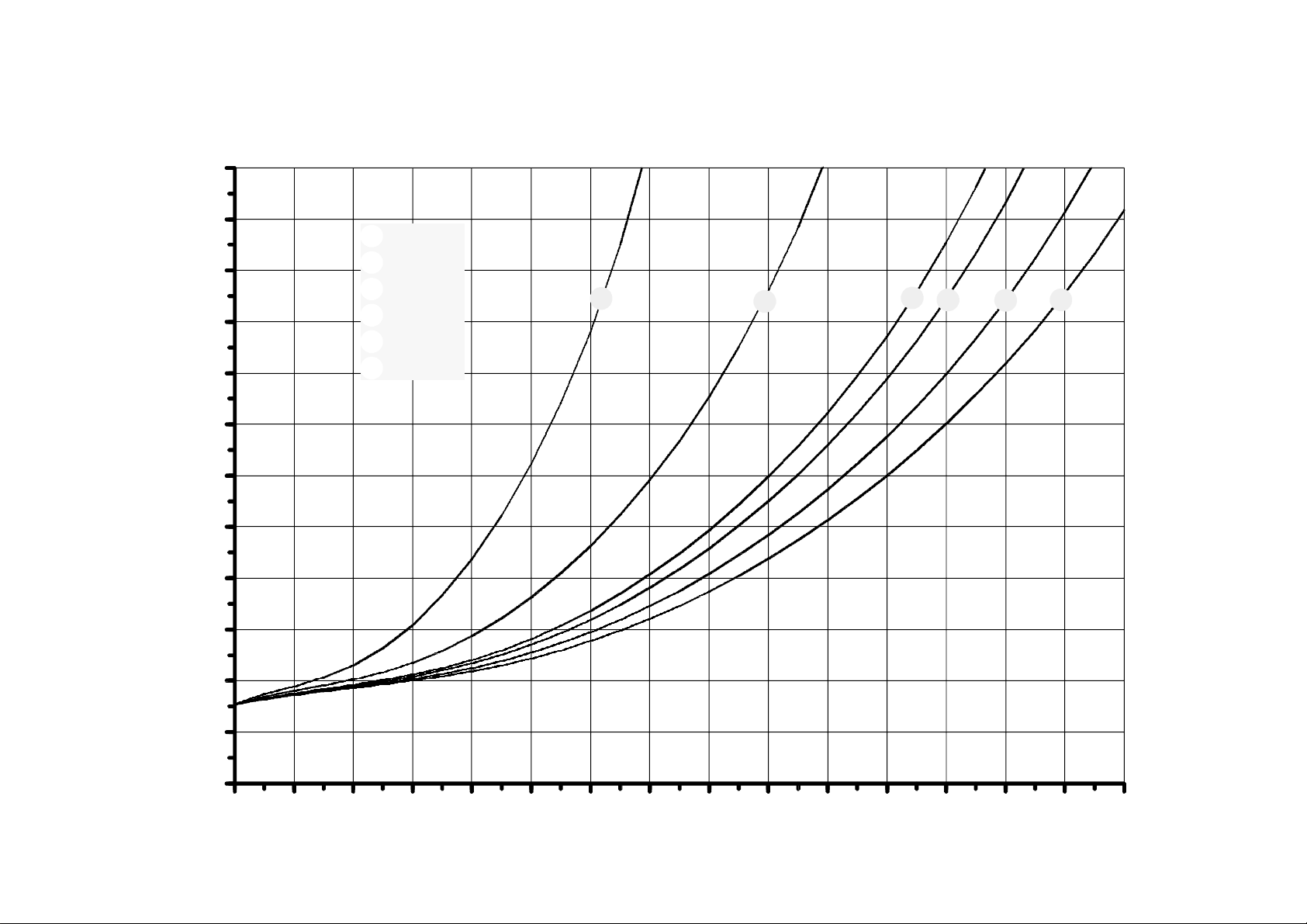

CAPACITY CURVE C90

11

10

9

8

7

8

6

5

Pressure drop (mbar)

4

3

1

2

3

4

5

6

G30

Air

G25

G20

G 140

G 110/120

1

2

3

4

5

6

2

EN2R--9003 9212R2--NE

1

0

012345

Flow (m /h at 1013 mbar and 15 C, dry)

3

E

67

12

CAPACITY CURVE C100

11

10

9

8

7

9

6

5

1

2

3

4

5

6

G30

Air

G25

G20

G 140

G 110/120

1

2

3

4

5

6

Pressure drop (mbar)

4

3

2

EN2R--9003 9212R2--NE

1

0

012345

Flow (m /h at 1013 mbar and 15 C, dry)

3

E

67

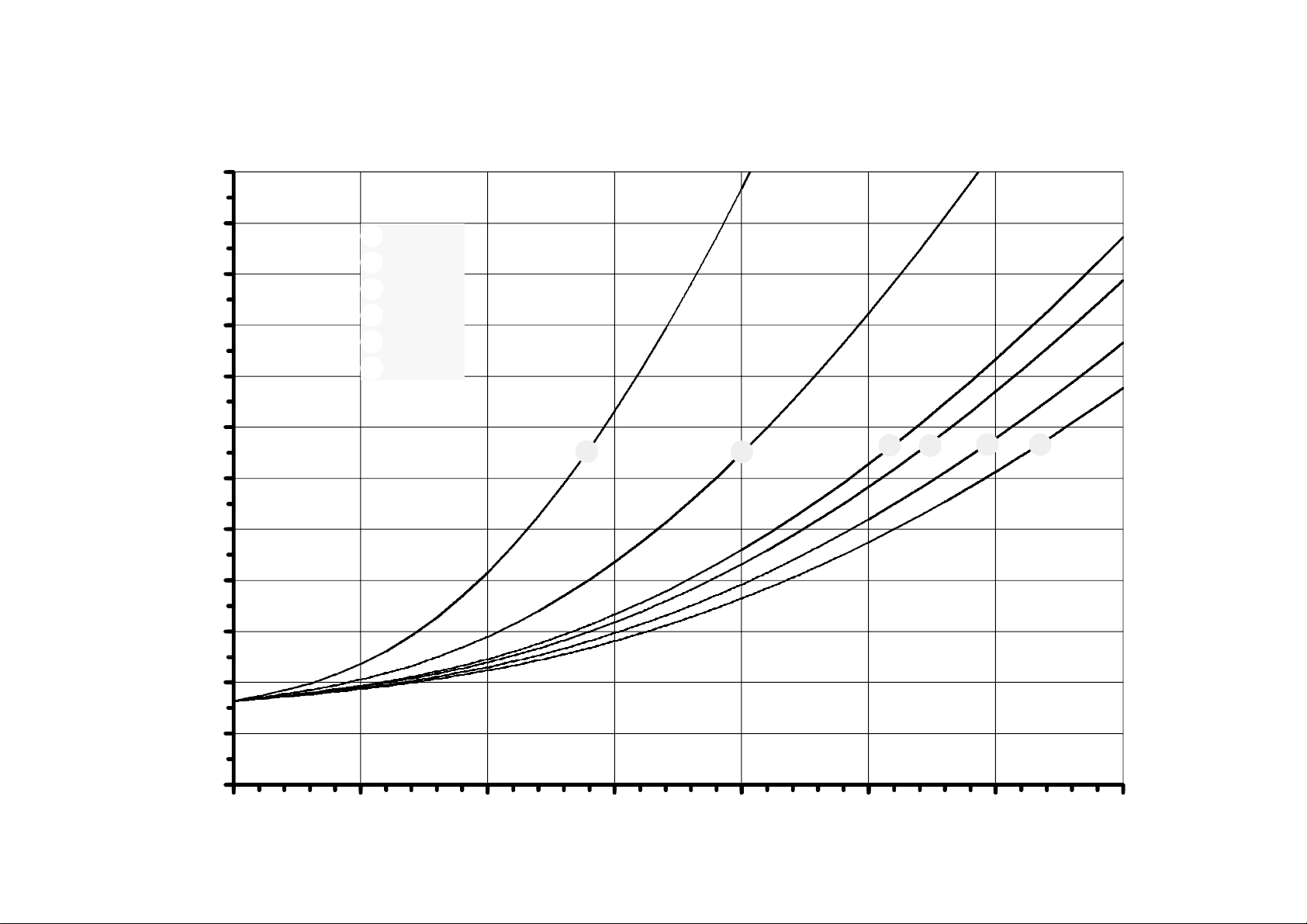

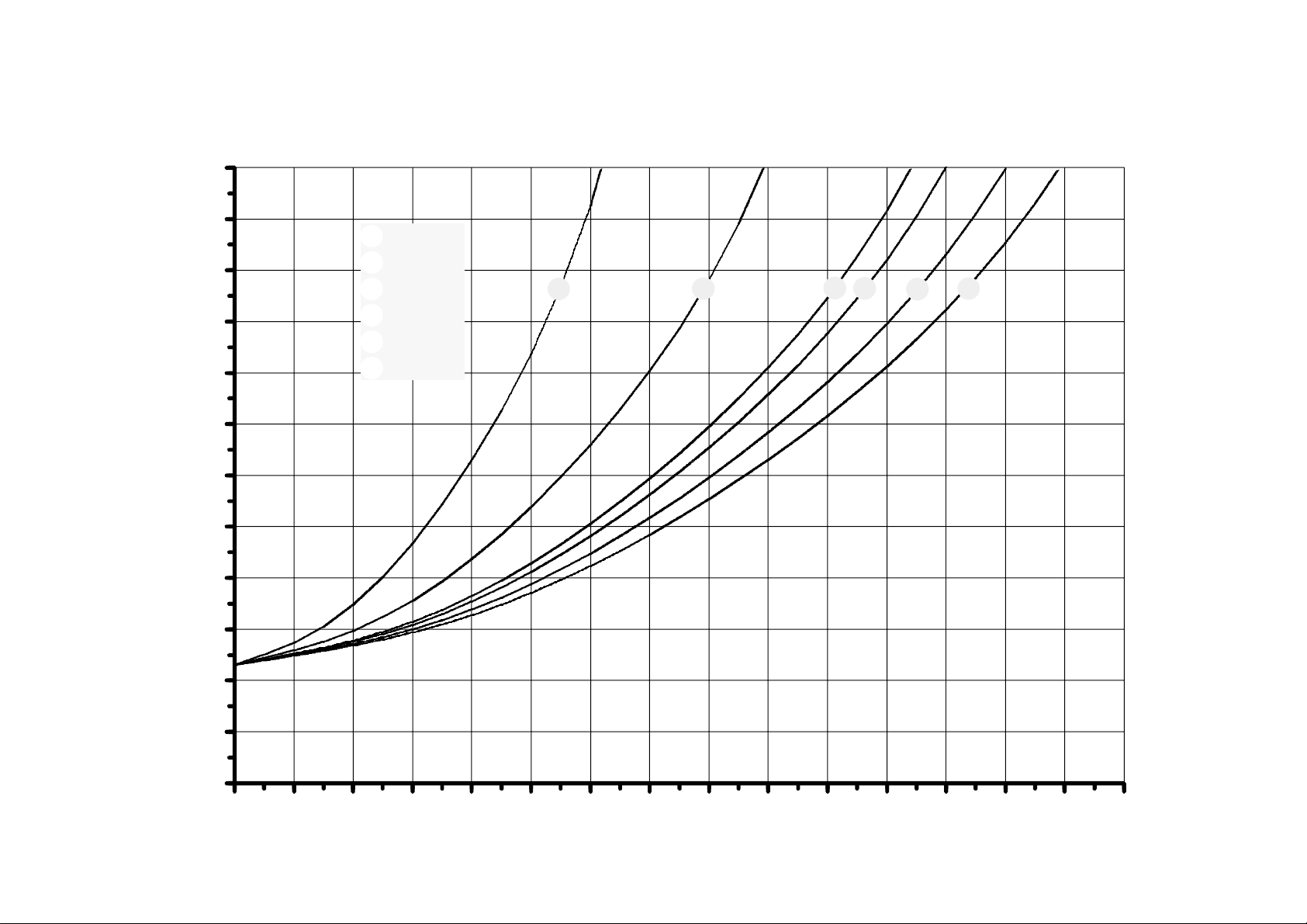

12

CAPACITY CURVE C110

10

11

10

9

8

7

6

5

Pressure drop (mbar)

4

3

1

2

3

4

5

6

G30

Air

G25

G20

G 140

G 110/120

4

1

2

3

5

6

2

EN2R--9003 9212R2--NE

1

0

012345

Flow (m /h at 1013 mbar and 15 C, dry)

3

E

67

12

CAPACITY CURVE C120

11

10

9

8

7

11

6

5

1

2

3

4

5

6

G30

Air

G25

G20

G 140

G 110/120

1

2

364

5

Pressure drop (mbar)

4

3

2

EN2R--9003 9212R2--NE

1

0

012345

Flow (m /h at 1013 mbar and 15 C, dry)

3

E

67

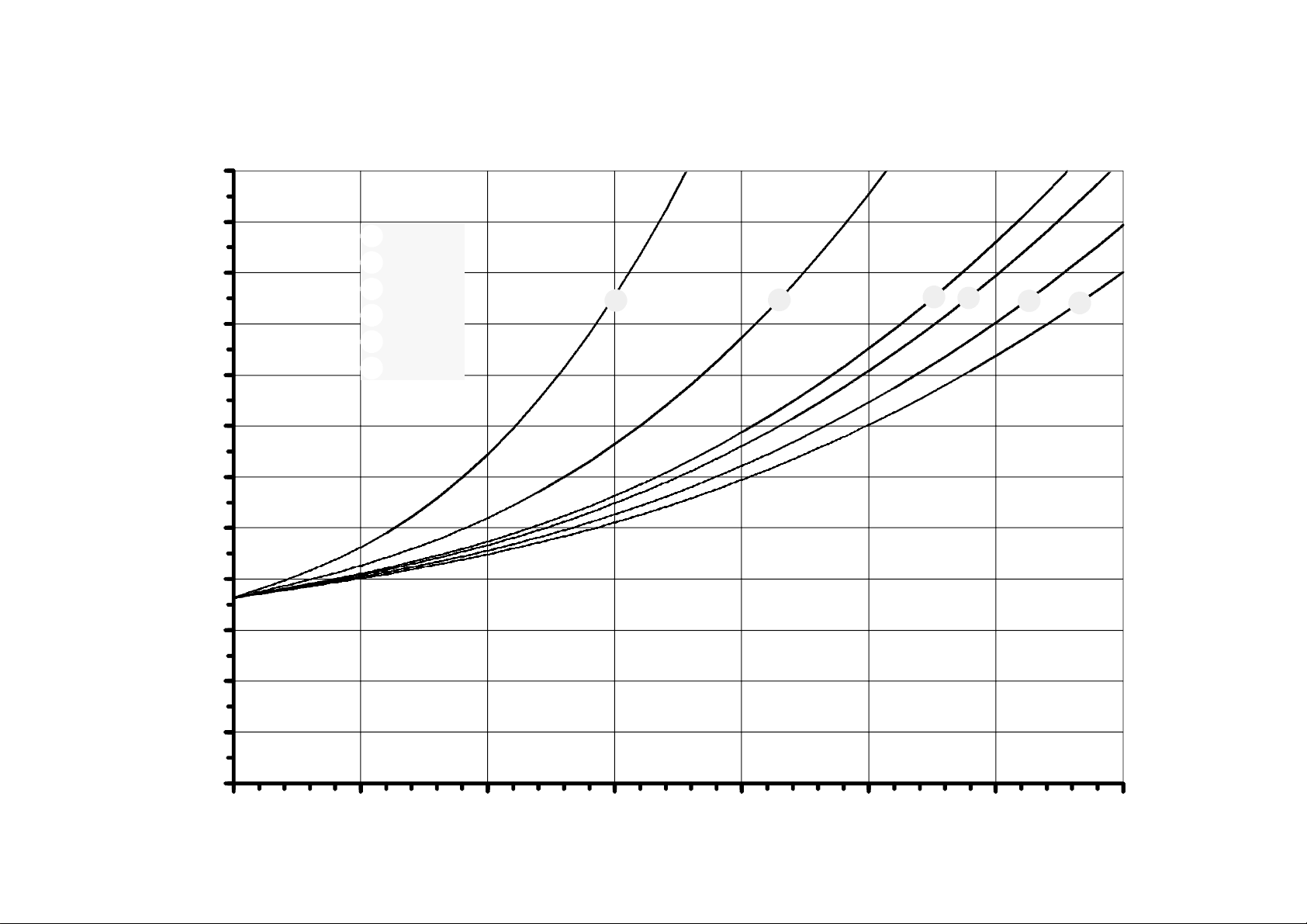

12

11

10

CAPACITY CURVE C130

G30

1

Air

2

3

G25

G20

9

8

7

4

5

6

G 140

G 110/120

1

2

3

5

64

12

EN2R--9003 9212R2--NE

6

5

Pressure drop (mbar)

4

3

2

1

0

012345

Flow (m /h at 1013 mbar and 15 C, dry)

3

67

8 9 10 11 12

E

13 14 15

12

11

10

CAPACITY CURVE C170

G30

1

Air

2

3

G25

G20

9

8

7

4

5

6

G 140

G 110/120

1

2

4

3

5

6

13

EN2R--9003 9212R2--NE

6

5

Pressure drop (mbar)

4

3

2

1

0

012345

Flow (m /h at 1013 mbar and 15 C, dry)

3

67

8 9 10 11 12

E

13 14 15

Loading...

Loading...