Page 1

ST3000

Smart Pressure Transmitter

Quick Start

Installation Guide

34-ST-25-24

October 2005

Industrial Measurement and Control

Page 2

SFC, Smartline, and ST 3000 are U.S. registered trademarks of Honeywell Inc.

®

HART

FOUNDATION™ is a trademark of the Fieldbus Foundation.

is a trademark of the Hart Communication Foundation.

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free of defective materials and faulty

workmanship. Contact your local sales office for warranty information. If warranted goods are returned to

Honeywell during the period of coverage, Honeywell will repair or replace without charge those items it

finds defective. The foregoing is Buyer's sole remedy and is in lieu of all other warranties, expressed

or implied, including those of merchantability and fitness for a particular purpose. Specifications

may change without notice. The information we supply is believed to be accurate and reliable as of this

printing. However, we assume no responsibility for its use.

While we provide application assistance personally, through our literature and the Honeywell web site, it

is up to the customer to determine the suitability of the product in the application.

Notices and Trademarks

Copyright 2005 by Honeywell

Revision 3 October 2005

About This Document

This document provides descriptions and procedures for the Quick Installation of your ST3000

Transmitter.

Various other documents are available for reference that describes how to Install, Configure, and Operate

the ST3000 Transmitter. These can be ordered on CD or hardcopy, or may be downloaded from

http://honeywell.silverw.com

ST3000 Smart Transmitter and SFC Smart Field Communicator Model STS103 34-ST-25-14

ST3000 FF Transmitter with Foundation Fieldbus Option Installation and

Device Reference Guide

ST3000 Smart Transmitter Release 300 with HART Communications Option User Manual 34-ST-25-17

SMV3000 Smart Multivariable Transmitter User’s Manual 34-SM-25-02

RMA Smart Meter User’s Manual 34-ST-25-08

Smart Field Communicator Model STS103 Operating Guide 34-ST-11-14

Smartline Confoguration Toolkit SCT3000 Installation and Start-up Guide 34-ST-10-08

MC Toolkit User Manual 34-ST-25-20

. (Registration is required at this site)

Document Title Document #

34-ST-25-15

ii ST3000 Transmitter Quick Start Installation Guide 10/05

Page 3

Contacts

World Wide Web

The following lists Honeywell’s World Wide Web sites that will be of interest to our customers.

Honeywell Organization WWW Address (URL)

Corporate Http://www.honeywell.com

Honeywell Process Solutions

International

http://hpsweb.honeywell.com/Cultures/en-US/

http://content.honeywell.com/imc/fi/

http://www.honeywell.com/business/global.asp

Telephone

Contact us by telephone at the numbers listed below.

United States and

Canada

Asia Pacific Honeywell Asia Pacific Inc. (852) 8298298 Hong Kong

Europe Honeywell PACE [32-2] 728-2111 Brussels

Latin America Honeywell Inc (305) 364-2355 Sunrise, Florida

Honeywell Inc. 1-800-343-0228 Sales

Organization Phone Number

1-800-525-7439 Service

USA

Technical Assistance

By Telephone Honeywell Solution Support Center Phone:

1-800-423-9883 (U.S. only)

Outside the U.S. call: 1-602-313-6510

Additional Help You may also seek additional help by contacting the Honeywell distributor who

supplied your ST 3000 transmitter.

By E Mail You can also e-mail your technical questions or comments about this product to:

Honeywell Solution Support Center e-mail: ace@honeywell.com

Problem Resolution If it is determined that a hardware problem exists, a replacement transmitter or

part will be shipped with instructions for returning the defective unit. Please do

not return your transmitter without authorization from Honeywell’s Solution

Support Center or until the replacement has been received.

10/05 ST3000 Transmitter Quick Start Installation Guide iii

Page 4

Symbol Definitions

The following table lists those symbols used in this document to denote certain conditions.

Symbol Definition

This CAUTION symbol on the equipment refers the user to the Product Manual for

additional information. This symbol appears next to required information in the manual.

WARNING

PERSONAL INJURY: Risk of electrical shock. This symbol warns the user of a

potential shock hazard where HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4

Vpeak, or 60 VDC may be accessible. Failure to comply with these instructions

could result in death or serious injury.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precautions for

handling electrostatic sensitive devices

Protective Earth (PE) terminal. Provided for connection of the protective earth (green

or green/yellow) supply system conductor.

Functional earth terminal. Used for non-safety purposes such as noise immunity

improvement. NOTE: This connection shall be bonded to protective earth at the source

of supply in accordance with national local electrical code requirements.

Earth Ground. Functional earth connection. NOTE: This connection shall be bonded to

Protective earth at the source of supply in accordance with national and local electrical

code requirements.

Chassis Ground. Identifies a connection to the chassis or frame of the equipment shall

be bonded to Protective Earth at the source of supply in accordance with national and

local electrical code requirements.

iv ST3000 Transmitter Quick Start Installation Guide 10/05

Page 5

Contents

1 MOUNTING THE TRANSMITTER......................................................................... 1

1.1 Typical Bracket mounted and Flange Mounted Installations .........................................................1

1.2 Bracket Mounting ...........................................................................................................................1

1.3 Flange Mounting.............................................................................................................................4

1.4 Flush Mounting...............................................................................................................................5

1.5 High Temperature Transmitter Mounting.......................................................................................5

1.6 Remote Seal Mounting ...................................................................................................................6

2 TRIM THE TRANSMITTER ...................................................................................7

2.1 Procedure to Trim the Transmitter..................................................................................................7

3 SET THE JUMPERS..............................................................................................8

3.1 Changing Default Failsafe Direction ..............................................................................................8

3.2 Optional Write Protect Jumper .......................................................................................................9

4 CONNECT THE WIRING AND POWER UP........................................................ 10

4.1 Summary.......................................................................................................................................10

4.2 Wiring Connections ......................................................................................................................11

4.3 Lightning Protection .....................................................................................................................11

4.4 Additional Considerations for Wiring SMV 3000 Transmitter ....................................................12

5 CERTIFICATIONS............................................................................................... 13

5.1 Product Certifications ...................................................................................................................13

5.1.1 Approved Manufacturing Locations ..................................................................................13

5.1.2 European Directive Information ........................................................................................13

5.2 Hazardous Location Certifications................................................................................................14

5.2.1 North American Certifications...........................................................................................14

5.2.2 Atex Certification...............................................................................................................16

5.2.3 SA (Standards Australia) Certification, Australia..............................................................19

5.2.4 Russia Certification, Russia ...............................................................................................19

5.2.5 INMETRO Certification, Brazil .........................................................................................19

10/05 ST3000 Transmitter Quick Start Installation Guide v

Page 6

vi ST3000 Transmitter Quick Start Installation Guide 10/05

Page 7

A

1 Mounting The Transmitter

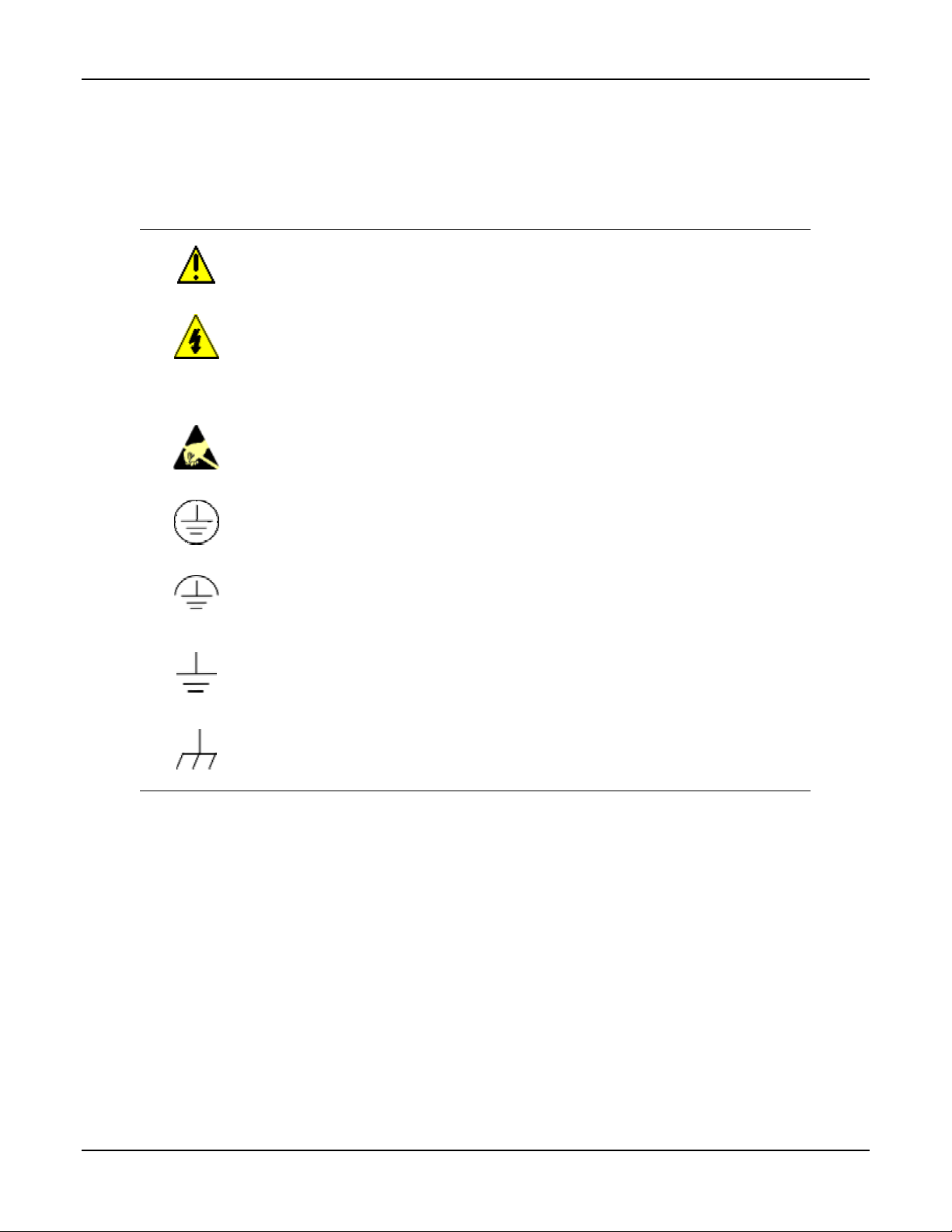

1.1 Typical Bracket mounted and Flange Mounted Installations

ngle

Mounting

Bracket

Tank

Wall

Flange

Connection

Horizontal Pipe

Transmitter

Flange

Fla t

Mounting

Bracket

Figure 1

1.2 Bracket Mounting

Optional mounting bracket, see Figure 2.

Existing mounting bracket, see Figure 3.

Rotate the transmitter housing, see Figure 4.

Level a transmitter with small absolute or differential pressure spans, see Figure 5.

10/05 ST3000 Transmitter Quick Start Installation Guide 1

Page 8

Optional Mounting Bracket

Position bracket on 2-inch (50.8

mm) or, and install “U” bolt

around pipe and through holes

in bracket. Secure with nuts and

lockwashers provided.

Figure 2 Example - Angle

mounting bracket secured to

horizontal or vertical pipe.

Mounting

Bracket

Horizontal Pipe

Nuts and

Lockwashers

U-Bolt

Nuts and

Lockwashers

Mounting

Bracket

Existing Mounting Bracket

Align appropriate mounting

holes in transmitter with holes in

bracket and secure with bolts

and washers provided.

NOTE: If the meter body is

hexagonal, you must use the

additional bracket supplied. If

meter body is round, discard

the bracket

Figure 3 Example – LGP model

transmitter mounted to optional

angle mounting bracket.

U-Bolt

Vertical Pipe

Figure 2

If Transmitter is…. Then….

DP type with double-ended

process heads and/or remote

seals

GP and AP with single-ended

head

In-line GP and AP (LGP model) Use smaller “U” bolt provided to

Dual head GP Use mounting holes in end of

LGP and LAP models

Use alternate mounting holes in

end of heads

Use mounting holes in side of

meter body

attach meter body to bracket

See Figure 3.

process head

Meter Body

Smaller

“U” bolt

Use bracket for

hexagonal meter body

Figure 3

2 ST3000 Transmitter Quick Start Installation Guide 10/05

Page 9

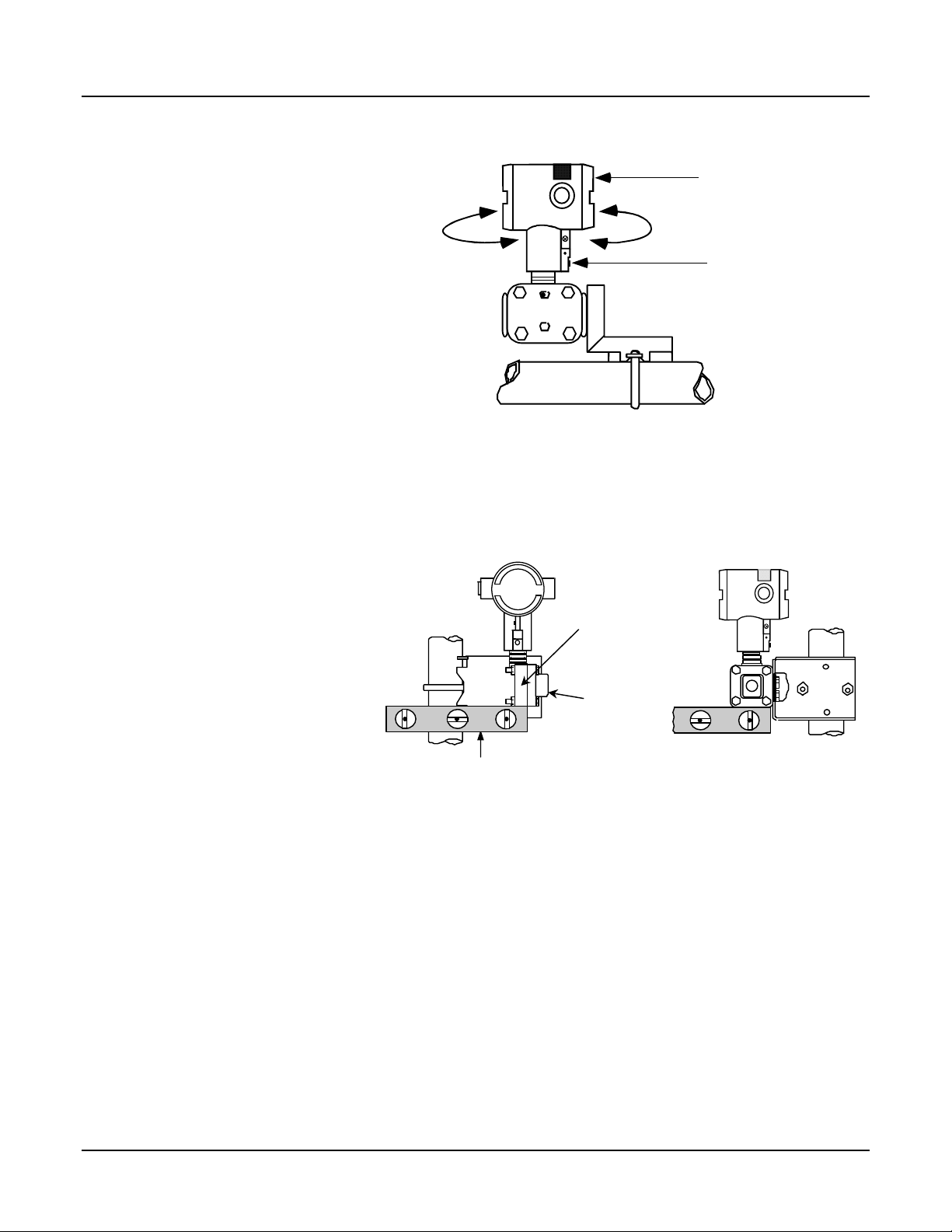

Rotating Transmitter Housing

Loosen set screw on outside

neck of transmitter one full turn.

Rotate Transmitter housing in

maximum of 180 degree

increment in left or right

direction from center to position

you require and tighten set

180 degrees

max.

180 degrees

max.

Electronics

Housing

Set Screw

screw (1.46 to 1.68 Nùm/13 to

15 lb-in).

Figure 4 Example – Rotating

Transmitter Housing.

Figure 4

Leveling Transmitters with Small Absolute or Differential Pressure Spans

Mounting position of these

transmitters is critical due to

the smaller transmitter spans.

To minimize these positional

effects on calibration (zero

shift), take the appropriate

mounting precautions that

follow for the given transmitter

model.

See Figure 5 and 5a for

suggestions on how to level

the transmitter using a spirit

balance.

To perform a Zero Trim after

leveling, refer to Section 2.

Models STA122 and STA922

Center

Section

Process

Head

Position spirit balance on

center section of meter

body only.

For a model STA122 or STA922 transmitter, you must ensure that the

transmitter is vertical when mounting it. You do this by leveling the

transmitter side-to-side and front-to-back.

Figure 5

10/05 ST3000 Transmitter Quick Start Installation Guide 3

Page 10

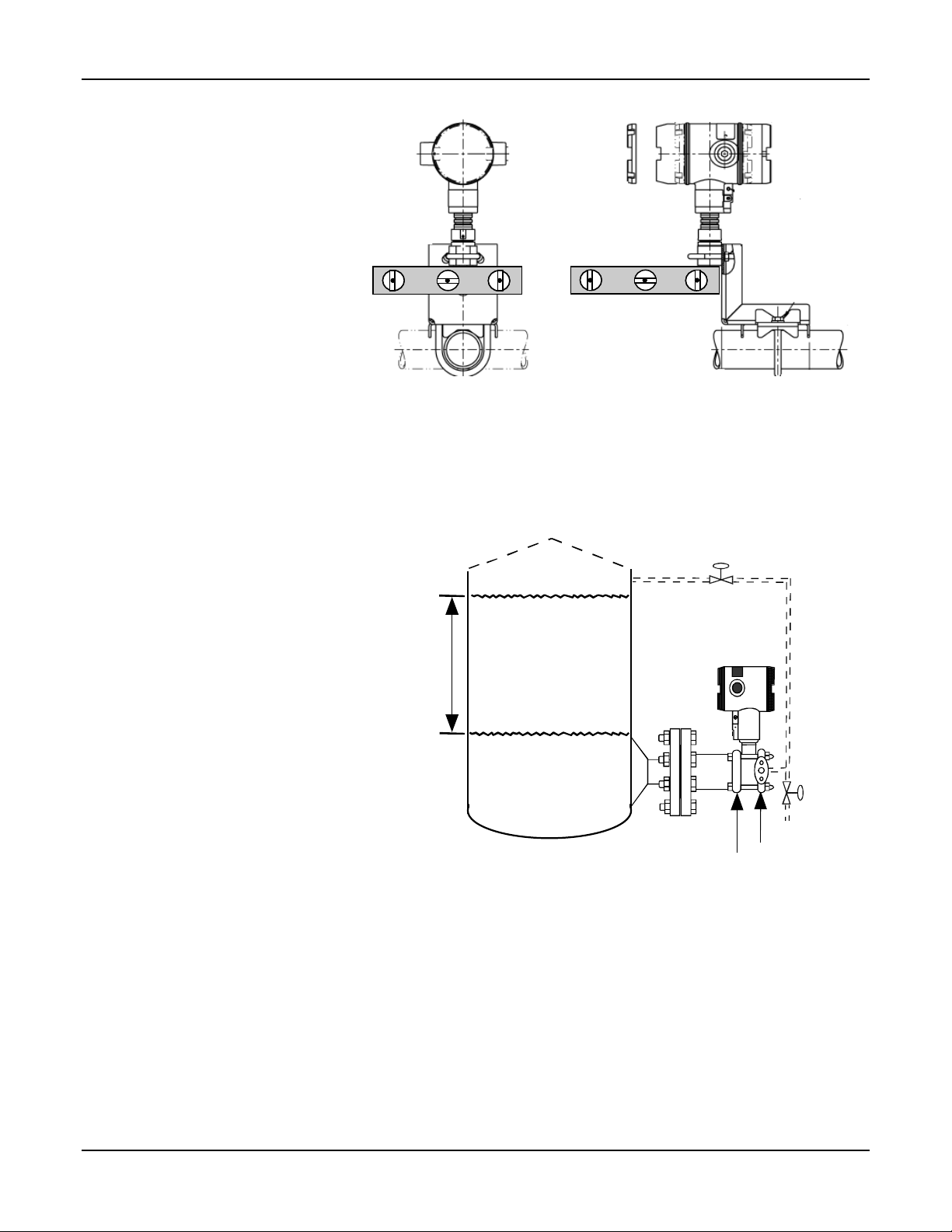

1.3 Flange Mounting

Mount transmitter vertically to assure best accuracy. Position spirit

balance on pressure connection surface of AP body.

Figure 5a

To mount a flange mounted

transmitter model, bolt the

transmitter’s flange to the flange

pipe on the wall of the tank.

On insulated tanks, remove

enough insulation to

accommodate the flange

extension.

It is the End User’s

responsibility to provide a flange

gasket and mounting hardware

that are suitable for the

transmitter’s service condition.

To prevent degradation of

performance in Flush-Mounted

Flanged Transmitters, exercise

care to ensure that the internal

diameter of the flange gasket

does not obstruct the sensing

diaphragm.

To prevent degradation of

performance in Extended Mount

Flanged Transmitters, ensure

that there is sufficient clearance

in front of the sensing

diaphragm body.

Variable

Head H1

Maximum Level

Minimum Level

Attention: Dotted area indicates use

with closed tank with reference leg.

Figure 6

HP Side

mounted

to tank

Reference

Leg

LP Side vented

to atmosphere

4 ST3000 Transmitter Quick Start Installation Guide 10/05

Page 11

1.4 Flush Mounting

To mount a flush mounted transmitter

model, cut a hole for a 1-inch standard

pipe in the tank or pipe where the

transmitter is to be mounted.

See Figure 7

Weld the 1-inch mounting sleeve to the

wall of the tank or to the hole cut on the

pipe. Insert the meter body of the

transmitter into the mounting sleeve and

secure with the locking bolt. Tighten the

bolt to a torque of 6,4 Nm+/- 0,30 Nm

[4.7 ft.-lbs. +/- 0.2 ft.-lbs.]

Once the transmitter is mounted, the

transmitter housing can be rotated to

the desired position. See Figure 4

On insulated tanks, remove enough

insulation to accommodate the

mounting sleeve.

1.5 High Temperature Transmitter Mounting

You can mount the high temperature

transmitter directly to the process flange

connection or the process piping. See

Figure 8.

To mount a flange mounted transmitter

model, bolt the transmitter’s flange to

the flange on the wall of the tank or

process pipe.

Tank

Wall

1” Pipe Mount 316 SS Weld Nipple

(standard option)

Figure 7

It is the End User’s responsibility to

provide a flange gasket and mounting

hardware that are suitable for the

transmitter’s service condition.

Once the transmitter is mounted, the

transmitter housing can be rotated to

Flange

Connection

Transmitter

Flange

the desired position. See Figure 4

On insulated tanks, remove enough

insulation to accommodate the

mounting sleeve.

Process Pipe

1/2" NPT

Connection

Figure 8

10/05 ST3000 Transmitter Quick Start Installation Guide 5

Page 12

1.6 Remote Seal Mounting

Mount the transmitter at a

remote distance determined by

length of capiliary tubing.

NOTE: The combination of tank

vacuum and high pressure

capillary head effect should not

exceed 9 psi (300 mm Hg)

absolute.

On insulated tanks, remove

enough insulation to

accommodate the mounting

sleeve.

Figure 3 Example – Typical

Remote Seal Transmitter

installation

If Transmitter Model Number

is….

Then connect remote seal

on….

STR93D or STR12D high pressure (HP) side of

transmitter to lower flange

mounting on tank wall for

variable head H1.

STR13D low pressure (LP) side of

transmitter to lower flange

mounting on tank wall for

variable head H1.

STR93D or STR12D low pressure (LP) side of

transmitter to upper flange

mounting on tank wall for fixed

or constant head H2.

STR13D high pressure (HP) side of

transmitter to upper flange

mounting on tank wall for fixed

or constant head H2.

It is the End User’s responsibility to provide a flange gasket and

mounting hardware that are suitable for the transmitter’s service

condition

LP Side

- Model STR93D

- Model STR12D

HP Side

- Model STR13D

Maximum Level

H2

Fixed

Ref. Leg

Minimum Level

HP Side

- Model STR93D

- Model STR12D

LP Side

- Model STR13D

Variable

Head H1

Figure 9

6 ST3000 Transmitter Quick Start Installation Guide 10/05

Page 13

2 Trim the Transmitter

2.1 Procedure to Trim the Transmitter

For a transmitter with a small

differential pressure span, you

must ensure that the transmitter is

vertical when mounting it. You do

this by leveling the transmitter

side-to-side and front-to-back. See

Figure 5 for suggestions on how to

level the transmitter using a spirit

balance. You must also zero the

transmitter by following the steps in

this table.

Step Action

1

2

3

4

5

6

7

Attach the transmitter to the mounting bracket but do not

completely tighten the mounting bolts

Connect a tube between the input connections in the high

pressure (HP) and low pressure (LP) heads to eliminate

the affects of any surrounding air currents.

Connect 24 Vdc power to the transmitter and connect a

digital voltmeter or SFC to read the transmitter’s output or

connect a voltmeter across the 250 ohm resistor, if desired.

Use applicable communicator to establish communications

with the transmitter. For DE transmitter use SFC, SCT, or

MCT. For Hart, use MCT or other Hart Communicator with

applicable Honeywell DD's. For Fieldbus, use NI FBUS

tools with applicable Honeywell DD's.

While reading the transmitter’s output on a communication

tool or a voltmeter, position the transmitter so the output

reading is at or near zero, then completely tighten the

mounting bolts.

Do an input zero correct function using the communication

tool. This corrects the transmitter for any minor error that

may occur after the mounting bolts are tightened.

Remove the tube from between the input connections, the

power, and the digital voltmeter or communication tool.

10/05 ST3000 Transmitter Quick Start Installation Guide 7

Page 14

3 Set the Jumpers

3.1 Changing Default Failsafe Direction

Transmitters are shipped with a

default failsafe direction of upscale.

This means that the transmitter’s

output will be driven upscale

(maximum output) when the

transmitter detects a critical status.

You can change the direction from

upscale to downscale (minimum

output) by cutting jumper W1 on

the printed wiring assembly. If your

transmitter is operating in the

analog mode, an upscale failsafe

action will drive the transmitter’s

output to greater than 21 mA or a

downscale action will drive its

output to less than 3.8 mA.

If your transmitter is operating in

the DE mode an upscale failsafe

action will cause the transmitter to

generate a “+ infinity” digital signal,

or a downscale failsafe action will

cause it to generate a “– infinity”

digital signal. The STIMV IOP

module interprets either signal as

“not a number” and initiates its own

configured failsafe action for the

control system. The STDC initiates

the failsafe mode configured

through the transmitter when either

signal is generated.

NOTE: The failsafe direction

display that you can access

through the SFC only shows the

state of the failsafe jumper in the

transmitter as it correlates to

analog transmitter operation. The

failsafe action of the digital control

system may be configured to

operate differently than indicated

by the state of the jumper in the

transmitter.

Step Action

1

2

3

4

5

Failsafe

Direction

Jumper

Figure 10

ATTENTION: Electrostatic Discharge (ESD) hazards.

Observe precautions for handling electrostatic sensitive

devices

With transmitter on bench and no power applied. Loosen

end-cap lock and unscrew end cap from electronics side of

transmitter housing.

If applicable, unsnap Local Smart Meter from PWA

mounting bracket and unplug cable from connector on

back of meter assembly.

Loosen two retaining screws and carefully pull mounting

bracket and PWA from housing.

Using retaining clip remove flex-tape connector from PWA

Remove 2-wire power connector from PWA, and then

remove PWA and mounting bracket assembly.

With component side of PWA facing you, locate failsafe

jumper W1 and cut it in half with small wire cutter such as

dykes. See Figure 10. This changes failsafe action from

upscale to downscale.

Reverse applicable previous steps to replace PWA.

Turn ON transmitter power.

Power

Connector

Meter

Connector

8 ST3000 Transmitter Quick Start Installation Guide 10/05

Page 15

3.2 Optional Write Protect Jumper

The ST 3000 transmitters are

available with a “write protect

option”. When the write

protect option is ordered,

transmitters are shipped with

a default jumper position for

read-only. This means that

the transmitter’s configuration

database can not be

overwritten. To allow

read/write access, the jumper

can be moved to the

read/write position. When the

write protect option is not

ordered access is read/write.

There is no need to check the

jumper position unless you

want to change it. Refer to

the steps in the table in

section 3.1 to remove the

PWA from the transmitter and

Figure 11 to reposition the

jumper.

Failsafe

Direction

Jumper

Figure 11

ATTENTION: Electrostatic Discharge (ESD) hazards.

Observe precautions for handling electrostatic sensitive

devices

W

R

Read and

Write

Read Only

Power

Connector

Meter

Connector

10/05 ST3000 Transmitter Quick Start Installation Guide 9

Page 16

4 Connect the Wiring and Power Up

4.1 Summary

The transmitter is designed to

operate in a two-wire

power/current loop with loop

resistance and power supply

voltage within the operating

range shown in Figure 12.

Loop wiring is connected to the

transmitter by simply attaching

the positive (+) and negative (–)

loop wires to the positive (+)

and negative (–) SIGNAL screw

terminals on the terminal block

in the transmitter’s electronics

housing shown in the table in

Section 4.2.

Each transmitter includes an

internal ground terminal to

connect the transmitter to earth

ground. A ground terminal can

be optionally added to the

outside of the electronics

housing. While it is not

necessary to ground the

transmitter for proper operation,

we suggest that you do so to

minimize the possible effects of

“noise” on the output signal and

provide additional protection

against lightning and static

discharge damage.

1440

1200

Loop

Resistance

(ohms)

800

650

450

250

0 10.8 16.28 20.63 25 28.3 37.0 42.4

Operating Voltage (Vdc)

Figure 12

= Operating

Area

NOTE: A minimum of

250 0hms of loop

resistance is

necessary to support

communications. Loop

resistance equals

barrier resistance plus

wire resistance plus

receiver resistance.

21012

10 ST3000 Transmitter Quick Start Installation Guide 10/05

Page 17

4.2 Wiring Connections

This procedure shows the steps for

connecting power to the

transmitter.

For loop wiring and external

wiring diagrams, refer to the

installation drawings presented in

the Transmitter Manual.

Detailed drawings are provided for

transmitter installation in nonintrinsically safe areas and for

intrinsically safe loops in

hazardous area locations.

ATTENTION

All wiring must comply with

local codes, regulations, and

ordinances.

If you will be using the

transmitter in a hazardous area,

be sure to review the hazardous

location reference data included

in Appendix B of the transmitter

manual before operating the

transmitter.

Step Action

1

Loosen end-cap lock using a 1.5 mm allen wrench and

remove end-cap cover from terminal block end of

transmitter housing.

2

Feed loop power leads through one of conduit entrances

on either side of transmitter housing. Plug whichever

entrance you do not use.

ATTENTION

The transmitter accepts up to 16 AWG

wire.

3

Observing polarity, connect positive loop power lead to

SIGNAL + terminal and negative loop power lead to

SIGNAL – terminal.

EXAMPLE - CONNECTING LOOP POWER TO

TRANSMITTER.

3-screw terminal block

Loop

Power

+

-

T

S

E

+

T

+

L

A

N

G

I

S

-

5-screw terminal block (option LP)

Loop

Power

4

Replace end-cap, and tighten end-cap lock

L

A

+

N

G

+

-

I

S

L

-

R

E

T

E

M

L

A

+

-

N

G

I

-

S

+

T

S

E

-

T

+

-

.

4.3 Lightning Protection

When your transmitter is

equipped with optional lightning

protection, you must connect a

wire from the transmitter to

ground as shown in

Figure 13 to make the

protection effective. We

recommend that you use a size

8 (American Wire Gage) or

(8.37mm

2

) bare or green

covered wire.

Figure 13

10/05 ST3000 Transmitter Quick Start Installation Guide 11

Electronics

Housing

Connect to

Earth Ground

Page 18

4.4 Additional Considerations for Wiring SMV 3000 Transmitter

Figure 14 SMV 3000 Transmitter Terminal Block

Connect RTD leads to the TC terminals 1, 2, 3, and 4 as appropriate for the given probe type.

Figure 15 RTD Input Wiring Connections.

Connect thermocouple leads to terminals 1 (–) and 3 (+), observing polarity.

Figure 16 Thermocouple Input Wiring Connections.

12 ST3000 Transmitter Quick Start Installation Guide 10/05

Page 19

5 Certifications

5.1 Product Certifications

5.1.1 Approved Manufacturing Locations

Honeywell Industrial Measurement & Control

Honeywell International Inc.

2500 West Union Hills Drive

Phoenix, AZ 85027 USA

Honeywell (Tianjin) Limited

66 BaiHe Road, Tianjin EconomicTechnological Development Area

Tianjin, 300457, P.R. China

TATA Honeywell Limited

55-A, 8 & 9 Hadapsar Industrial Estate

Pune 411 013, India

5.1.2 European Directive Information

The EC Declarations of Conformity for all applicable directives for this product can be found on the

Honeywell website at www.honeywell.com/imc. A hard copy may be obtained by contacting your local

Honeywell sales office.

European Pressure Equipment Directive (PED) 97/23/EC

The ST 3000 pressure transmitters are in conformity with the essential requirements of the PED. A formal

statement from TÜV Industry Service Group of TÜV America, Inc., a division of TÜV Süddeutschland, a

Notified Body regarding the Pressure Equipment Directive, is available upon request.

Electromagnetic Compatibility (EMC) 89/336/EEC

All ST 3000 Pressure Transmitters

EN 50081-1: 1992; EN 50082-2: 1995;

EN 61326: 1997 / A1: 1998 – Industrial

10/05 ST3000 Transmitter Quick Start Installation Guide 13

Page 20

5.2 Hazardous Location Certifications

5.2.1 North American Certifications

FM Approvals (USA)

Code Comm Description

1C

4-20 mA / DE

4-20 mA / HART

FOUNDATION™

Fieldbus

Intrinsically Safe for Class I, Division 1, Groups A, B, C, D, E, F & G,

ENTITY, when installed per Honeywell Control Drawing 51204241.

Nonincendive Class 1, Division 2, Groups A, B, C & D

T4, (Ta ≤ 93°C);

Explosionproof for Class I, Division 1, Groups A, B, C & D;

Dust-Ignitionproof for Class II, Division 1, Groups E, F & G;

Suitable for Class II, Division 2, Groups F & G and Class III

T5, (Ta ≤ 93°C); Seal all conduits within 18 inches, Group A only;

Enclosure Type 4X, IP 66/67

Intrinsically Safe for Class I, Division 1, Groups A, B, C, D, E, F & G,

ENTITY, when installed per Honeywell Control Drawing 51205784.

Nonincendive for Class 1, Division 2, Groups A, B, C & D

T4, (Ta ≤ 93°C)

Explosionproof for Class I, Division 1, Groups A, B, C & D

Dust-Ignitionproof for Class II, Division 1, Groups E, F & G

Suitable for Class II, Division 2, Groups F & G and Class III

T5, (Ta ≤ 93°C); Seal all conduits within 18 inches, Group A only;

Enclosure Type 4X, IP 66/67

Intrinsically Safe for Class I, Division 1, Groups A, B, C, D, E, F & G,

ENTITY, when installed per Honeywell Control Drawing 51204301.

Nonincendive Class 1, Division 2, Groups A, B, C & D

T4, (Ta -40 to 40°C), T3A, (Ta -40 to 93°C)

Explosionproof Class I, Division 1, Groups A, B, C & D

Dust-Ignitionproof, Class II, Division 1, Groups E, F & G

Suitable for Class II, Division 2, Groups F & G and Class III

T4, (Ta -40 to 40°C), T3A, (Ta -40 to 93°C); Seal all conduits within 18

inches, Group A only; Enclosure Type 4X, IP 66/67

14 ST3000 Transmitter Quick Start Installation Guide 10/05

Page 21

Canadian Standards Association (CSA)

Code Comm Description

2J

4-20 mA / DE

4-20 mA / HART

FOUNDATION™

Fieldbus

Intrinsically Safe, Class I, Division 1, Groups A, B, C & D, Class II, Division

1, Groups E, F & G, Class III, Divisions 1 & 2, when installed per

Honeywell Control Drawing 51204242

Non-Incendive Class I, Division 2, Groups A, B, C & D, Class II, Division 2,

Groups E, F & G and Class III, Division 2

T4 (Ta ≤ 93°C)

Explosion Proof for Class I, Division 1, Groups B, C & D

Dust-Ignitionproof for Class II, Division 1, Groups E, F & G and Class III,

Division 1

T4 (Ta ≤ 93°C) ; Enclosure Type 4X, IP 66/67

Intrinsically Safe, Class I, Division 1, Groups A, B, C & D, Class II, Division

1, Groups E, F & G, Class III, Divisions 1 & 2, when installed per

Honeywell Control Drawing 51450806

Non-Incendive Class I, Division 2, Groups A, B, C & D, Class II, Division 2,

Groups E, F & G and Class III, Division 2

T4 (Ta ≤ 93°C)

Explosion Proof for Class I, Division 1, Groups B, C & D

Dust-Ignitionproof for Class II, Division 1, Groups E, F & G and Class III,

Division 1

T4 (Ta ≤ 93°C) ; Enclosure Type 4X, IP 66/67

Intrinsically Safe, Class I, Division 1, Groups A, B, C & D, Class II, Division

1, Groups E, F & G, Class III, Divisions 1 & 2, when installed per

Honeywell Control Drawing 51204302.

Nonincendive Class 1, Division 2, Groups A, B, C & D

T4, (Ta -40 to 40°C), T3A, (Ta -40 to 93°C)

Explosion Proof Class I, Division 1, Groups A, B, C & D

Dust-Ignitionproof, Class II, Division 1, Groups E, F & G

Suitable for Class II, Division 2, Groups F & G and Class III

T4, (Ta -40 to 40°C), T3A, (Ta -40 to 93°C) ; Enclosure Type 4X, IP 66/67

10/05 ST3000 Transmitter Quick Start Installation Guide 15

Page 22

5.2.2 Atex Certification

ATEX Certification, Europe (Assembled in Phoenix, AZ USA)

Code Comm Description

3D ALL

3N ALL

3S 4-20 mA / DE

3S 4-20 mA / HART

LCIE 02 ATEX 6099, Ex II 2 G - Flameproof, EEx d IIC T5, (Ta -50 to

93°C), T6, (Ta -50 to 78°C); Enclosure IP 66/67

ATEX-Z2-51452622, Ex II 3 G - Non-Sparking, EEx nA, IIC, T5, (Ta -40 to

93°C), T6, (Ta -40 to 78°C); Enclosure IP 66/67

Special Conditions for Safe Use:

The installation of this equipment in Zone 2 hazardous areas must comply

with IEC 60079-14, EN 50021 and/or valid national standards for

installation and operation.

The power supply voltage cannot exceed the 42 Vdc maximum for 4-20

mA analog, DE and HART equipment, and 24 Vdc for Fieldbus equipment.

The electronic assemblies in these units are non-repairable items and if

faulty must be replaced. The electrical power supply must be switched off

before any replacement and during any time that the wiring terminations

are being connected or disconnected.

The technical data supplied by the manufacturer must be adhered to.

LCIE 02 ATEX 6100X, Ex II 1 G - Intrinsically Safe, EEx ia IIC T4, (Ta -50

to 93°C), T5, (Ta -50 to 85°C), T6, (Ta -50 to 70°C); Enclosure IP 66/67

Special Conditions for Safe Use (X):

The transmitter is intrinsically safe apparatus; it may be installed in

potentially explosive atmospheres.

For safety purposes, terminals + and – must be considered as eventually

connected to ground.

The power terminals (+ and -) must only be connected to certified

associated intrinsically safe equipment. The combinations must be

compatible in accordance with intrinsic safety rules.

LCIE 02 ATEX 6101X, Ex II 1 G - Intrinsically Safe, EEx ia IIC T4, (Ta -50

to 93°C), T5, (Ta -50 to 63°C), T6, (Ta -50 to 48°C); Enclosure IP 66/67

Special Conditions for Safe Use (X):

The transmitter is intrinsically safe apparatus; it may be installed in

potentially explosive atmospheres.

For safety purposes, terminals + and – must be considered as eventually

connected to ground.

The power terminals (+ and -) must only be connected to certified

associated intrinsically safe equipment. The combinations must be

compatible in accordance with intrinsic safety rules.

16 ST3000 Transmitter Quick Start Installation Guide 10/05

Page 23

Code Comm Description

3S FOUNDATION™

Fieldbus

LCIE 03 ATEX 6175X, Ex II 1 G - Intrinsically Safe, EEx ia IIC T3, (Ta -50

to 93°C), T4, (Ta -50 to 40°C); Enclosure IP 66/67

Special Conditions for Safe Use (X):

The transmitter is intrinsically safe apparatus; it may be installed in

potentially explosive atmospheres.

For safety purposes, terminals + and – must be considered as eventually

connected to ground.

The power terminals (+ and -) must only be connected to certified

associated intrinsically safe equipment. The combinations must be

compatible in accordance with intrinsic safety rules.

The electrical parameters of certified equipment which can be connected

to the transmitter exceed the following values:

Uo ≤ 24 V; Io ≤ 250 mA; Po ≤ 1,2 W.

ATEX Certification, Europe (Assembled in Tianjin, P.R. China)

Code Comm Description

3D ALL

3N ALL

3S 4-20 mA / DE

LCIE 03 ATEX 6396, Ex II 2 G - Flameproof, EEx d IIC T5, (Ta -50 to

93°C), T6, (Ta -50 to 78°C); Enclosure IP 66/67

ATEX-Z2-51453605, Ex II 3 G - Non-Sparking, EEx nA, IIC, T5, (Ta -40 to

93°C), T6, (Ta -40 to 78°C); Enclosure IP 66/67

Special Conditions for Safe Use:

The installation of this equipment in Zone 2 hazardous areas must comply

with IEC 60079-14, EN 50021 and/or valid national standards for

installation and operation.

The power supply voltage cannot exceed the 42 Vdc maximum for 4-20

mA analog, DE and HART equipment, and 24 Vdc for Fieldbus equipment.

The electronic assemblies in these units are non-repairable items and if

faulty must be replaced. The electrical power supply must be switched off

before any replacement and during any time that the wiring terminations

are being connected or disconnected.

The technical data supplied by the manufacturer must be adhered to.

LCIE 03 ATEX 6397X, Ex II 1 G - Intrinsically Safe, EEx ia IIC T4, (Ta -50

to 93°C), T5, (Ta -50 to 85°C), T6, (Ta -50 to 70°C); Enclosure IP 66/67

Special Conditions for Safe Use (X):

The transmitter is intrinsically safe apparatus; it may be installed in

potentially explosive atmospheres.

For safety purposes, terminals + and – must be considered as eventually

connected to ground.

The power terminals (+ and -) must only be connected to certified

associated intrinsically safe equipment. The combinations must be

compatible in accordance with intrinsic safety rules.

10/05 ST3000 Transmitter Quick Start Installation Guide 17

Page 24

Code Comm Description

3S 4-20 mA / HART

LCIE 03 ATEX 6398X, Ex II 1 G – Intrinsically Safe, Eex ia IIC T4, (Ta –50

to 93°C), T5, (Ta –50 to 63°C), T6, (Ta –50 to 48°C); Enclosure IP 66/67

Special Conditions for Safe Use (X):

The transmitter is intrinsically safe apparatus; it may be installed in

potentially explosive atmospheres.

For safety purposes, terminals + and – must be considered as eventually

connected to ground.

The power terminals (+ and -) must only be connected to certified

associated intrinsically safe equipment. The combinations must be

compatible in accordance with intrinsic safety rules.

3S FOUNDATION™

Fieldbus

LCIE 04 ATEX 6118X, Ex II 1 G – Intrinsically Safe, Eex ia IIC T3, (Ta –50

to 93°C), T4, (Ta –50 to 40°C); Enclosure IP 66/67

Special Conditions for Safe Use (X):

The transmitter is intrinsically safe apparatus; it may be installed in

potentially explosive atmospheres.

For safety purposes, terminals + and – must be considered as eventually

connected to ground.

The power terminals (+ and -) must only be connected to certified

associated intrinsically safe equipment. The combinations must be

compatible in accordance with intrinsic safety rules.

The electrical parameters of certified equipment which can be connected

to the transmitter exceed the following values:

Uo ≤ 24 V; Io ≤ 250 mA; Po ≤ 1,2 W.

ATEX Certification (Apparatus Marked with Multiple Types of Protection)

Code Description

3H

The 3H code provides a certification nameplate listing three types of

protection: 3D – flameproof (zone 1), 3N – non-sparking (zone 2), and 3S

– intrinsically safe (zones 0/1).

The user must determine the type of protection required for installation of

the equipment. The user shall then permanently mark the box [D]

adjacent to the type of protection used on the equipment certification

nameplate. Once a type of protection has been checked on the

nameplate, the equipment must not be reinstalled using any of the other

unmarked certification types.

18 ST3000 Transmitter Quick Start Installation Guide 10/05

Page 25

5.2.3 SA (Standards Australia) Certification, Australia

Code Comm Description

4G 4-20 mA / DE

4N 4-20 mA / DE

AUS-Ex 1371X-06, Intrinsically Safe, Ex ia IIC T4 (Ta ≤ 93°C); NonSparking, Ex n IIC T4 (Ta ≤ 93°C); Enclosure IP 66/67

Special Conditions for Safe Use (X):

The system installation instructions shall be followed when installing this

equipment.

Cables are to be connected using a cable gland with IP rating of IP66 or

greater.

If the temperature under rated conditions exceeds 75°C at the cable or

conduit entry point or at the branching point of the conductors, a label shall

be provided on the outside of the unit as a guide to the selection of the

cable or the wiring in the conduit.

AUS Ex 3781X, Non-Sparking, Ex n IIC T4 (Ta ≤ 93°C); Enclosure IP

66/67

Special Conditions for Safe Use (X):

The Maximum Input Voltage must not exceed 42 V.

The system installation instructions shall be followed when installing this

equipment.

Tampering and replacement with non-factory components may adversely

affect the safe use of the system.

Cables are to be connected using a cable gland with IP rating of IP66 or

greater.

If the temperature under rated conditions exceeds 75°C at the cable or

conduit entry point or at the branching point of the conductors, a label shall

be provided on the outside of the unit as a guide to the selection of the

cable or the wiring in the conduit.

5.2.4 Russia Certification, Russia

Code Comm Description

5D ALL

5S ALL

RU-230, Flameproof, 1ExdIICT6X, T6 (Ta ≤ 93°C), Enclosure IP 66/67

RU-306, Intrinsically Safe, 0ExiaIICT5X, T5 (Ta ≤ 93°C), Enclosure IP

66/67

5.2.5 INMETRO Certification, Brazil

Code Comm Description

6D ALL

10/05 ST3000 Transmitter Quick Start Installation Guide 19

INMETRO-2002EC02CP031, CERTSUP/INMETRO, Flameproof, Ex d IIC

T5, (Ta -50 to 93°C); Enclosure IP 66/67

Page 26

20 ST3000 Transmitter Quick Start Installation Guide 10/05

Page 27

ST 3000 Smart Pressure Transmitter,

Quick Start Installation Guide

Write-protect option

Overview

Approx.

Page # in

User

Manual

9

3.2 Optional Write Protect

Jumper

The ST3000 Pressure Transmitter (DE or HART) is now being shipped with a newly

designed printed wiring assembly (PWA) that allows user access to the optional write

protect jumper without removing the PWA. This version of the PWA is functionally

identical to the previous version, with the same performance and specifications. The

new version PWA differs only in location of the optional write protect jumper and the

associated bracket and hardware.

Section Description of Change

Do not remove the PWA as described in Section 3.1 Changing Default

Failsafe Direction. Instead, follow the following steps.

34-ST-99-44

10/6/05

Addendum

(to User Manual

34-ST-25-24)

ATTENTION: Electrostatic Discharge (ESD) hazards. Observe

precautions for handling electrostatic sensitive devices.

WARNING! PERSONAL INJURY: Risk of electrical shock.

Disconnect power before proceeding. HAZARDOUS LIVE voltages

greater than 30 Vrms, 42.4 Vpeak, or 60 VDC may be accessible.

Failure to comply with these instructions could result in death or

serious injury.

Step 1 Place transmitter on bench. Remove power. Loosen end-cap

lock and unscrew end-cap from electronics side of transmitter

housing.

Step 2 If applicable, unsnap local smart meter from PWA mounting

bracket.

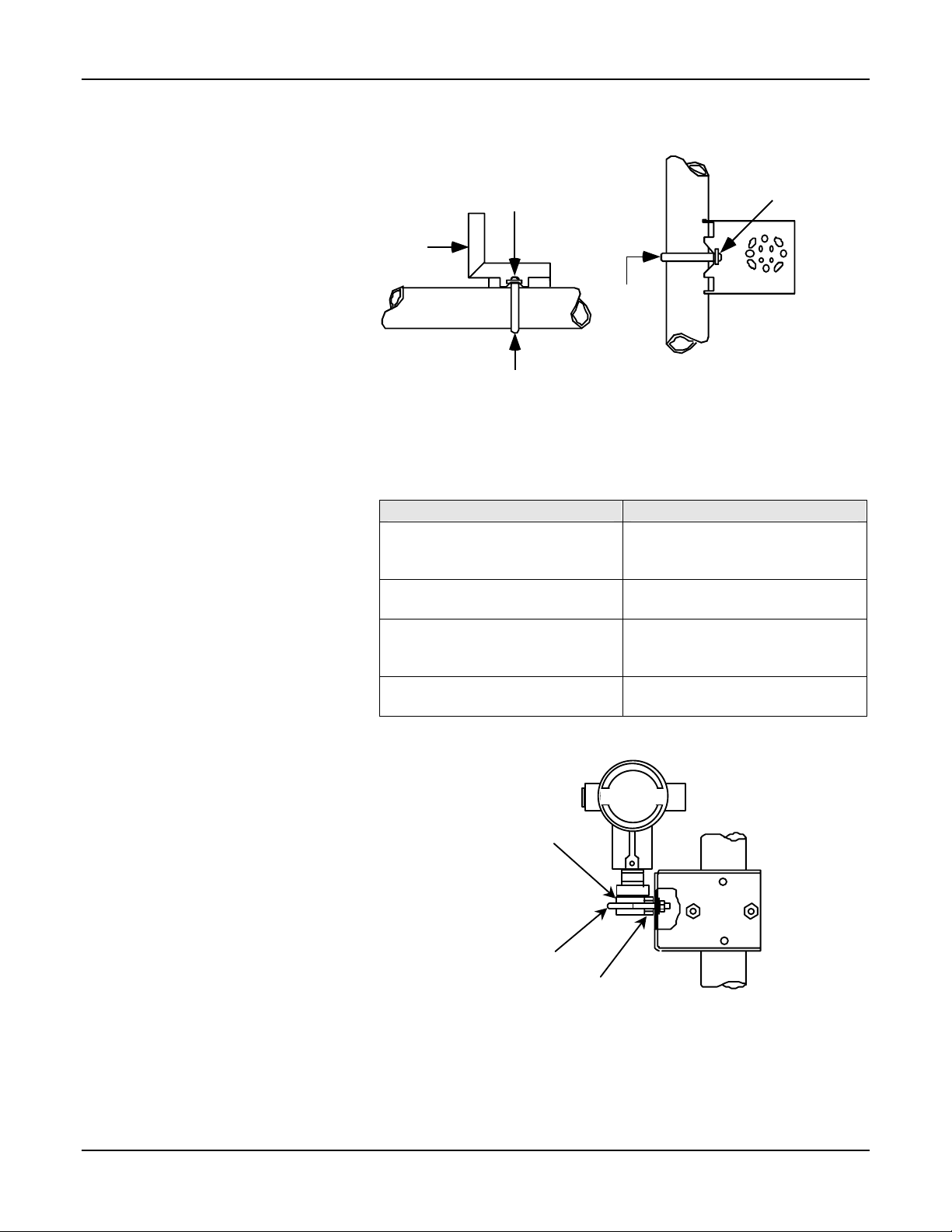

Step 3 Find the write protect jumper shown in Figure 11 below.

Position the jumper for read-only or read/write.

Step 4 Reverse applicable previous steps to install smart meter and

end-cap.

Step 5 Re-connect transmitter power.

10/6/05 34-ST-99-44 (Addendum to 34-ST-25-24) 1 of 2

Page 28

Approx.

Page # in

User

Manual

Section Description of Change

Figure 11

2 of 2 34-ST-99-44 (Addendum to 34-ST-25-24) 10/6/05

Page 29

Page 30

Page 31

Page 32

Industrial Measurement and Control

Honeywell International, Inc

2500 Union Hills Drive

Phoenix, Arizona 85027

34-ST-25-24 Rev. 3 10 05 Printed in USA www.honeywell.com/imc

Loading...

Loading...