Page 1

Release 100.3

Safety Manager

Safety Manual

EP-SM.MAN.6283

100.3

25 January 2005

Page 2

Document Release Date

EP-SM.MAN.6283 100.3 January 2005

Notice

This document contains Honeywell proprietary information. Information

contained herein is to be used solely for the purpose submitted, and no part of this

document or its contents shall be reproduced, published, or disclosed to a third

party without the express permission of Honeywell Safety Management Systems.

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability and fitness for a

purpose and makes no express warranties except as may be stated in its written

agreement with and for its customer.

In no event is Honeywell liable to anyone for any direct, special, or consequential

damages. The information and specifications in this document are subject to

change without notice.

Copyright 2004 – Honeywell Safety Management Systems, a division of

Honeywell Aerospace B.V.

Honeywell trademarks

Safety Manager

Experion PKS

U.S. registered trademarks of Honeywell International Inc.

™

is a trademark of Honeywell International Inc.

®

, PlantScape®, SafeBrowse®, TotalPlant® and TDC 3000® are

Other trademarks

Microsoft and SQL Server are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

Trademarks that appear in this document are used only to the benefit of the

trademark owner, with no intention of trademark infringement.

ii

Page 3

Support and other contacts

United States and Canada

Contact: Honeywell IAC Solution Support Center

Phone: 1-800 822-7673. In Arizona: (602) 313-5558

Facsimile: (602) 313-5476

Mail: Honeywell IS TAC, MS P13

Europe

Contact: Honeywell PACE TAC

Phone: +32-2-728-2657

Facsimile: +32-2-728-2278

Mail: Honeywell PACE TAC

Calls are answered by dispatcher between 6:00 am and 4:00 pm Mountain

Standard Time. Emergency calls outside normal working hours are

received by an answering service and returned within one hour.

2500 West Union Hills Drive

Phoenix, AZ, 85027

Avenue du Bourget, 1

B-1140 Brussels, Belgium

Pacific

Contact: Honeywell Global TAC - Pacific

Phone: 1300-300-4822 (toll free within Australia)

+61-2-9353-7255 (outside Australia)

Facsimile: +61-2-9353-8044

Mail: Honeywell Global TAC - Pacific

5 Thomas Holt Drive

North Ryde, NSW, 2113, Australia

Email GTAC@honeywell.com

iii

Page 4

India

Contact: Honeywell Global TAC - India

Phone: +91-20-687-5531

Facsimile: +91-20-687-9404

Mail: TATA Honeywell Ltd.

55 A8 & 9, Hadapsar Industrial

Hadapsar, Pune -411 013, India

Email Global-TAC-India@honeywell.com

Korea

Contact: Honeywell Global TAC - Korea

Phone: +82-2-799-6317

+82-11-743-6016

Facsimile: +82-2-792-9015

Mail: Honeywell IAC SBE, CRC

17F, Kikje Center B/D,

191, Hangangro-2Ga

Yongsan-gu, Seoul, 140-702, Korea

Email Global-TAC-Korea@honeywell.com

People’s Republic of China

Contact: Honeywell Global TAC - China

Phone: +86-10-8458-3280 ext. 361

Mail: Honeywell Tianjin Limited

17 B/F Eagle Plaza

26 Xiaoyhun Road

Chaoyang District

Beijing 100016, People's Republic of China

Email Global-TAC-China@honeywell.com

iv

Page 5

Singapore

Contact: Honeywell Global TAC - South East Asia

Phone: +65-580-3500

Facsimile: +65-580-3501

+65-445-3033

Mail: Honeywell Private Limited

Honeywell Building

17, Changi Business Park Central 1

Singapore 486073

Email GTAC-SEA@honeywell.com

Tai wan

Contact: Honeywell Global TAC - Taiwan

Phone: +886-7-323-5900

Facsimile: +886-7-323-5895

+886-7-322-6915

Mail: Honeywell Taiwan Ltd.

10F-2/366, Po Ai First Rd.

Kaohsiung, Taiwan, ROC

Email Global-TAC-Taiwan@honeywell.com

Japan

Contact: Honeywell Global TAC - Japan

Phone: +81-3-5440-1303

Facsimile: +81-3-5440-1430

Mail: Honeywell K.K

1-14-6 Shibaura Minato-Ku

Tokyo 105-0023

Japan

Email Global-TAC-JapanJA25@honeywell.com

Elsewhere

Call your nearest Honeywell office.

World Wide Web

Honeywell Solution Support Online:

http://www.ssol.acs.honeywell.com

v

Page 6

Training classes

Honeywell holds technical training classes on Safety Manager. These classes are

taught by experts in the field of process control systems. For more information

about these classes, contact your Honeywell representative, or see

http://www.automationcollege.com.

Related Documentation

The following guides are available for Safety Manager.

The guide in front of you is Safety Manual.

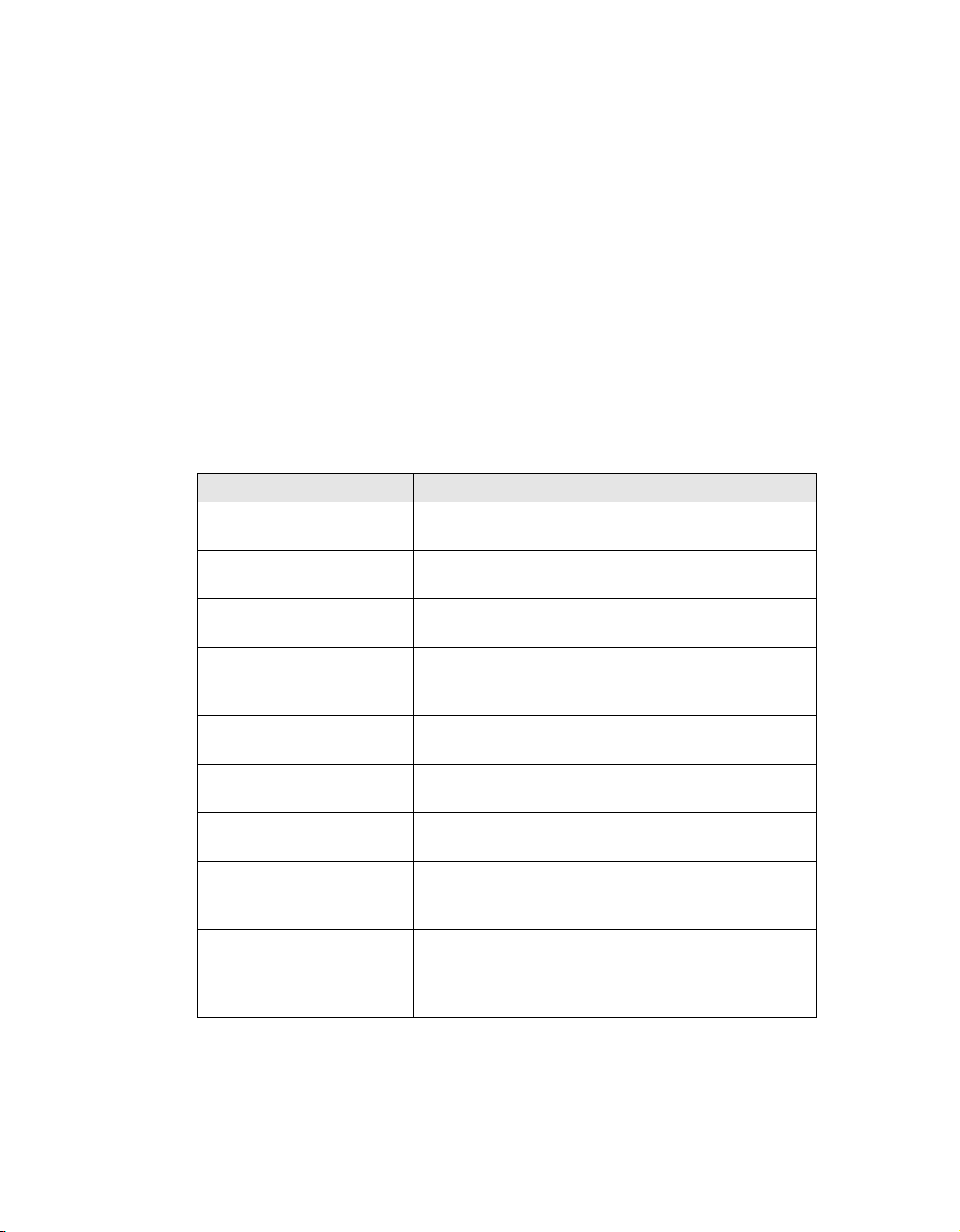

Guide Description

The Overview Guide This guide describes the general knowledge required, the

The Safety Manual This guide describes the specifications, design guidelines,

The Planning and Design

Guide

The Installation and Upgrade

Guide

The Troubleshooting and

Maintenance Guide

The System Administration

Guide

The Hardware Reference This guide specifies the hardware components that build a

The Software Reference This guide specifies the software functions that build a

The On-line Modification

Guide

basic functions of, and the tasks related to Safety Manager.

and safety aspects related to Safety Manager.

This guide describes the tasks related to planning and

designing a Safety Manager project.

This guide describes the tasks related to installing,

replacing and upgrading hardware and software as part of

a Safety Manager project.

This guide describes the tasks related to troubleshooting

and maintaining Safety Manager.

This guide describes the task related to administrating the

computer systems used in a Safety Manager project.

Safety Manager project.

Safety Manager project and contains guidelines on how to

operate them.

This guide describes the theory, steps and tasks related to

upgrading Safety Builder and embedded software and

modifying an application online in a redundant Safety

Manager.

vi

Page 7

Task-oriented guides

A task-oriented guide provides both procedural and basic knowledge. A task can

inform the reader on how to perform the task in terms of steps to follow.

Additionally a task can describe what important considerations to make or what

options to choose from when performing a task.

A task-oriented guide lists the required skills and knowledge that people must

master to qualify for the described tasks.

It is common for task oriented guides to refer to reference guides for details.

Reference guides

A reference guide provides detailed information or solutions regarding its scope.

A reference guide is a Safety Manager related guide and provides background

information to support tasks as described in task-oriented guides.

A reference guide does not describe tasks in terms of how to perform the task in

terms of steps to follow.

Available electronic format

All guides are accessible via the Safety Manager Knowledge Builder; an Internet

Explorer based viewer with extensive search and indexing options.

The Knowledge Builder contains guides stored as:

• web pages

• Adobe PDF guides

The information stored on the Safety Manager Knowledge Builder CD-ROM can

be installed as stand-alone or merged with other Knowledge Builder booksets on

a server.

Conventions

Symbols

The following symbols are used in Safety Manager documentation:

Attention

This symbol is used for information that emphasizes or supplements important points of

the main text.

Tip

This symbol is used for useful, but not essential, suggestions.

vii

Page 8

Note

This symbol is used to emphasize or supplement important points of the main text

Caution

This symbol warns of potential damage, such as corruption of the database.

Warning

This symbol warns of potentially hazardous situation, which, if not avoided, could result

in serious injury or death.

ESD

This symbol warns for danger of an electro-static discharge to which equipment may be

sensitive

Fonts

The following fonts are used in Safety Manager documentation:

Emphasis

• “... inform the reader on how to perform

the task in terms of...”

• “...see the Overview Guide”

Label

“The Advanced tab of the Properties

window has..”

Steps

Take the following steps:

1. Create a plant and set its properties.

2. ....

Value

“Low is the fault reaction state for

digital inputs and digital outputs.”

Variable

“The syntax is: filename [-s] [-p]“

http://www.honeywellsms.com This font is used to identify a URL, directing

Emphasised text is used to:

• emphasise important words in the text,

• identify document titles.

This font is used to identify labels.

Labels are used for Dialog box labels, menu

items, names of properties, and so on.

This font is used to identify steps.

Steps indicate the course of action that must

be adhered to, to achieve a certain goal.

This font is used to indicate a value.

Value is a variable that the reader must

resolve by choosing a pre-defined state.

This font is used to identify a variable.

Variables are used in syntax and code

examples.

a reader to a website that can be referred to.

viii

Page 9

Contents

1The Safety Manual 1

Content of Safety Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Basic skills and knowledge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Prerequisite skills. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety standards for Process & Equipment Under Control (PUC, EUC) . . . . . . . . . . . . . . . . . . . 4

Safety Integrity Level (SIL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Equipment Under Control (EUC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Process Under Control (PUC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Application design conform IEC 61131-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

The IEC 61508 and IEC 61511 standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2Introduction 9

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Standards compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

EU Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

EMC directive (89/336/EEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Low voltage directive (73/23/EEC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Machine safety directive (89/392/EEC)). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 Safety Manager architectures 29

Safety Manager basic architectures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Dual Modular Redundant (DMR) architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Quadruple Modular Redundant (QMR) architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

System architectures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Overall safety life cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4 Design phases for an E/E/PE safety-related system 45

Specifying the safety integrity level of the process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Specifying the field instrumentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Specifying the safety-related system functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Approval of the specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Safety Manager Safety Manual ix

Page 10

Contents

5 Design and implementation phases of Safety Manager 53

Safety Manager project configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Safety Manager configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Specification of input and output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Implementation of the application software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Application verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6 Safety Manager special functions 63

Forcing of IO signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Communication with third party Control systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

On-line modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7 Safety Manager fault detection and response 69

Principle of fault detection and response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Principle of fault detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Principle of fault response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Watchdog and redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Safety Manager alarm markers, registers and diagnostic inputs . . . . . . . . . . . . . . . . . . . . . . . . . 80

System markers and registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Alarm markers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Diagnostic inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

SM IO faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Digital input faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Analog input faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Digital output faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Analog output faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

IO compare errors and system response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Compare error detection and synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

SM Controller faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

QPP faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

USI faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

BKM faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

PSU faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Communication faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Calculation errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Rules of thumb with respect to safety and availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

IO settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

System settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8 Using Safety Manager alarm markers and diagnostic inputs 109

Shutdown at assertion of Safety Manager alarm markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Unit shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Diagnostic status exchange with DCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

x Release 100.3

Page 11

Contents

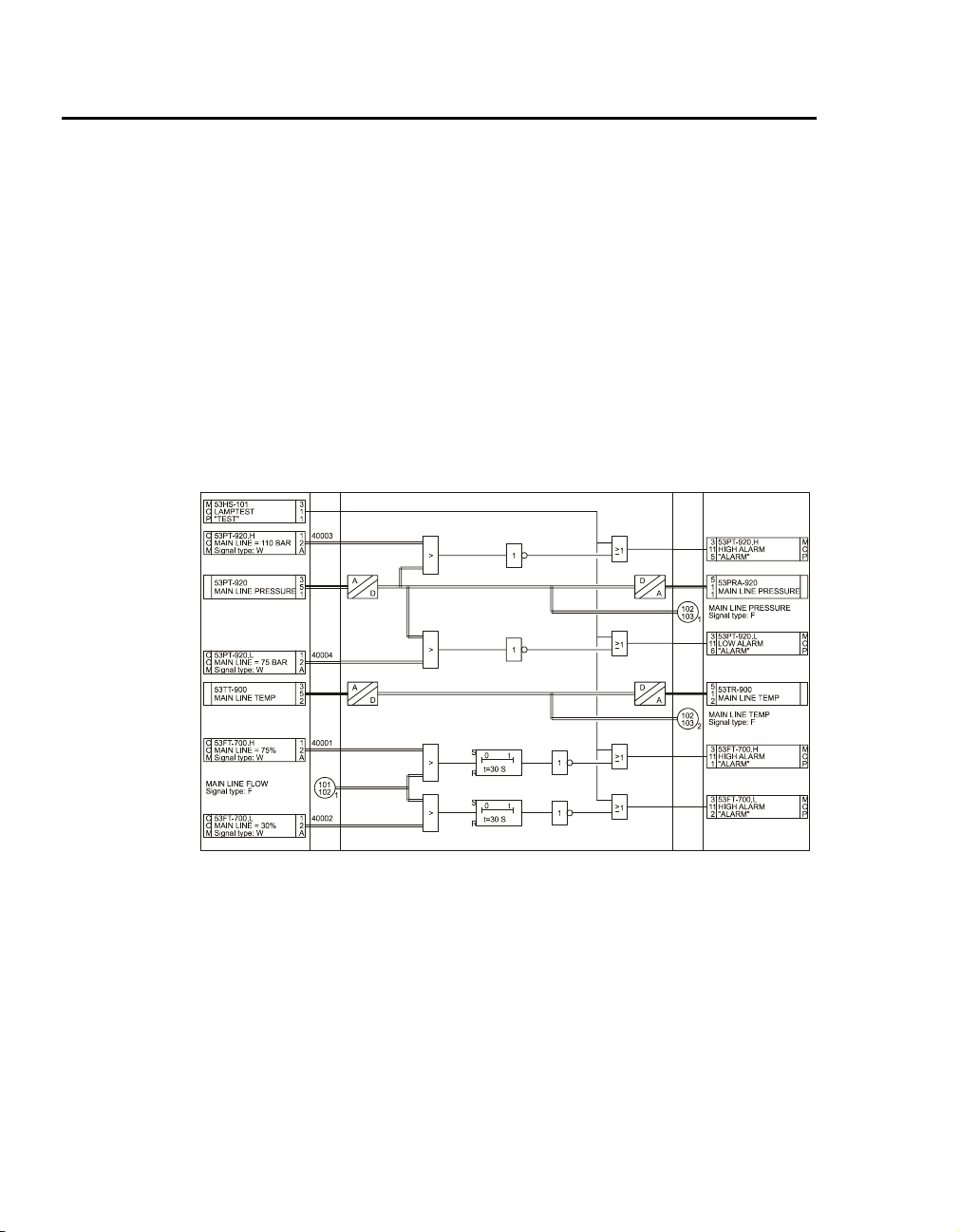

9 Fire and gas application example 117

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

General system and Fire and Gas alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Input loops. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Loop status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Output loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Monitoring for alarm status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Monitoring for failure status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Inhibit function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

10 Special requirements for TUV-approved applications 141

List of abbreviations 147

Safety Manager Glossary 149

Safety Manager Safety Manual xi

Page 12

Contents

xii Release 100.3

Page 13

Figures

Figure 1 Example FLD layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2 CE mark. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 3 Failure model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 4 Programmable electronic system (PES): structure and terminology. . . . . . . . . . . . . . . . . . . 24

Figure 5 Functional diagram: DMR architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 6 Functional diagram: QMR architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 7 Functional diagram: non-redundant Controller, non-redundant IO. . . . . . . . . . . . . . . . . . . . 33

Figure 8 Non-redundant Controller, non-redundant IO configuration . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 9 Functional diagram: redundant Controller, non-redundant IO . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 10 Redundant Controller, non-redundant IO configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 11 Functional diagram: redundant Controller, redundant IO . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 12 Redundant Controller, redundant IO configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 13 Redundant Controller with redundant and non-redundant IO configuration . . . . . . . . . . . . 37

Figure 14 Functional diagram: redundant Controller with redundant and non-redundant IO. . . . . . . . 38

Figure 15 Overall safety life cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 16 E/E/PES safety life cycle (in realization phase) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 17 Software safety life cycle (in realization phase) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 18 Relationship of overall safety life cycle to E/E/PES and software safety life cycles . . . . . . 41

Figure 19 Example of Functional Logic Diagram (FLD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 20 Example of a Safety Builder configurator screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 21 Safety Builder Point Configurator main screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 22 Example of Functional Logic Diagram (FLD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 23 The forcing sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 24 Schematic diagram of a SMOD with 4 channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 25 Each watchdog has 2 outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 26 Input failure alarm marker function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 27 Intended square-root function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Figure 28 Square-root function with validated input value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Figure 29 Square-root function with validity check in function block . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 30 Properties of an analog output module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 31 Point detail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 32 Diagram to shut down system in case of output compare error . . . . . . . . . . . . . . . . . . . . . 110

Figure 33 Wiring diagram for unit shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Figure 34 Functional logic diagram of unit shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure 35 Safety Manager system information to DCS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Figure 36 FLD2000 system alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Safety Manager Safety Manual xiii

Page 14

Figures

Figure 37 FLD2002 general fault alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Figure 38 FLD2004 general fire/gas alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Figure 39 FLD530 smoke detector input loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Figure 40 FLD120 gas detector input loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Figure 41 FLD230 common low level alarm Area 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 42 FLD232 common F&G detector fault Area 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Figure 43 FLD240 sounders and beacons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Figure 44 FLD290 deluge valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 45 FLD162 status signals deluge valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 46 FLD160 status signals fire suppression system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Figure 47 FLD260 start firewater pump(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Figure 48 FLD262 discrepancy alarm firewater pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Figure 49 FLD250 alarm signal to PA/GA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Figure 50 FLD680 HVAC trip signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 51 FLD690 close fire damper signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Figure 52 FLD250 grouping of alarm signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Figure 53 FLD2004 Fire and Gas alarm lamp and buzzer on mimic panel. . . . . . . . . . . . . . . . . . . . . 134

Figure 54 FLD240 audible and visual alarm signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Figure 55 FLD232 grouping of detector fault signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure 56 FLD2002 general fault alarm lamp and buzzer on mimic panel. . . . . . . . . . . . . . . . . . . . . 137

Figure 57 FLD101 inhibit M-out-of-N function F&G detector devices . . . . . . . . . . . . . . . . . . . . . . . 138

Figure 58 FLD234 common F&G detector inhibited Area 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Figure 59 FLD236 common F&G outputs inhibited Area 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Figure 60 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Figure 61 Multidrop link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

xiv Release 100.3

Page 15

Tables

Table 1 Safety Manager compliance to standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 2 Safety integrity levels: target failure measures for a safety function, allocated to the E/E/PE

Safety Related System operating in low demand mode of operation . . . . . . . . . . . . . . . . . . 25

Table 3 Safety integrity levels: target failure measures for a safety function, allocated to the E/E/PE

Safety Related System operating in high demand or continuous mode of operation . . . . . . 25

Table 4 Safety Manager architectures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 5 Overall safety life cycle overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 6 Example specification of IO signals of Safety Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 7 Relation between SIL and AK Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 8 Example of safety relation of IO signals with location COM. . . . . . . . . . 67

Table 9 Fault Reaction settings for hardware IO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table 10 Fault Reaction settings for communication IO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 11 Safety Manager system markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 12 Safety Manager system registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Table 13 Safety Manager alarm markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Table 14 Safety Manager alarm registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Table 15 Diagnostic inputs (channel status). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 16 Diagnostic inputs (loop status) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Table 17 Explanation of a “Controller response to faults” table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Table 18 Controller response to digital input faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Table 19 Controller response to analog input faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 20 Controller response to digital output fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 21 Controller response to Analog output faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table 22 Explanation of a “Controller response to compare error” table . . . . . . . . . . . . . . . . . . . . . . 91

Table 23 Controller response to IO compare faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Table 24 Explanation of a “response to Controller faults” table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 25 Controller response to QPP faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Table 26 Controller response to USI faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 27 Controller response to BKM faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 28 Controller response to PSU faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Table 29 Controller response to communication faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Safety Manager Safety Manual xv

Page 16

Tables

xvi Release 100.3

Page 17

The Safety Manual

The Safety Manual is intended primarily for the people responsible for and

performing tasks related to Safety Manager.

This guide provides directions as how to configure and use Safety Manager the

way it is intended. It provides design guidelines, lists the boundaries of Safety

Manager, and advises the best hardware for certain functions.

Typical readers are all people involved in planning and design, engineering,

troubleshooting and maintenance as well as operating Safety Manager.

It is assumed that the reader masters the required skills and knowledge as

described herein.

This section contains the following information about this guide:

Topic See

Content of Safety Manual page 2

Basic skills and knowledge page 3

Safety standards for Process & Equipment Under Control (PUC,

EUC)

Application design conform IEC 61131-3 page 6

The IEC 61508 and IEC 61511 standards page 7

1

page 4

Note

This guide does not contain information related to other Honeywell Experion PKS

systems and third-party controllers such as Allen-Bradley, Series 9000, TDC 3000, Data

Hiway, UDC, and so on.

For information about these systems, see the manufacturers bookset.

Safety Manager Safety Manual 1

Page 18

1 – The Safety Manual

Content of Safety Manual

The Safety Manual guide is a reference guide providing detailed information

regarding how safety aspects are met in Safety Manager. A reference guide is a

Safety Manager related guide and does not describe tasks in terms of how to

perform the task in terms of steps to follow. A reference guide can provide input

to support decisions required to achieve a certain objective.

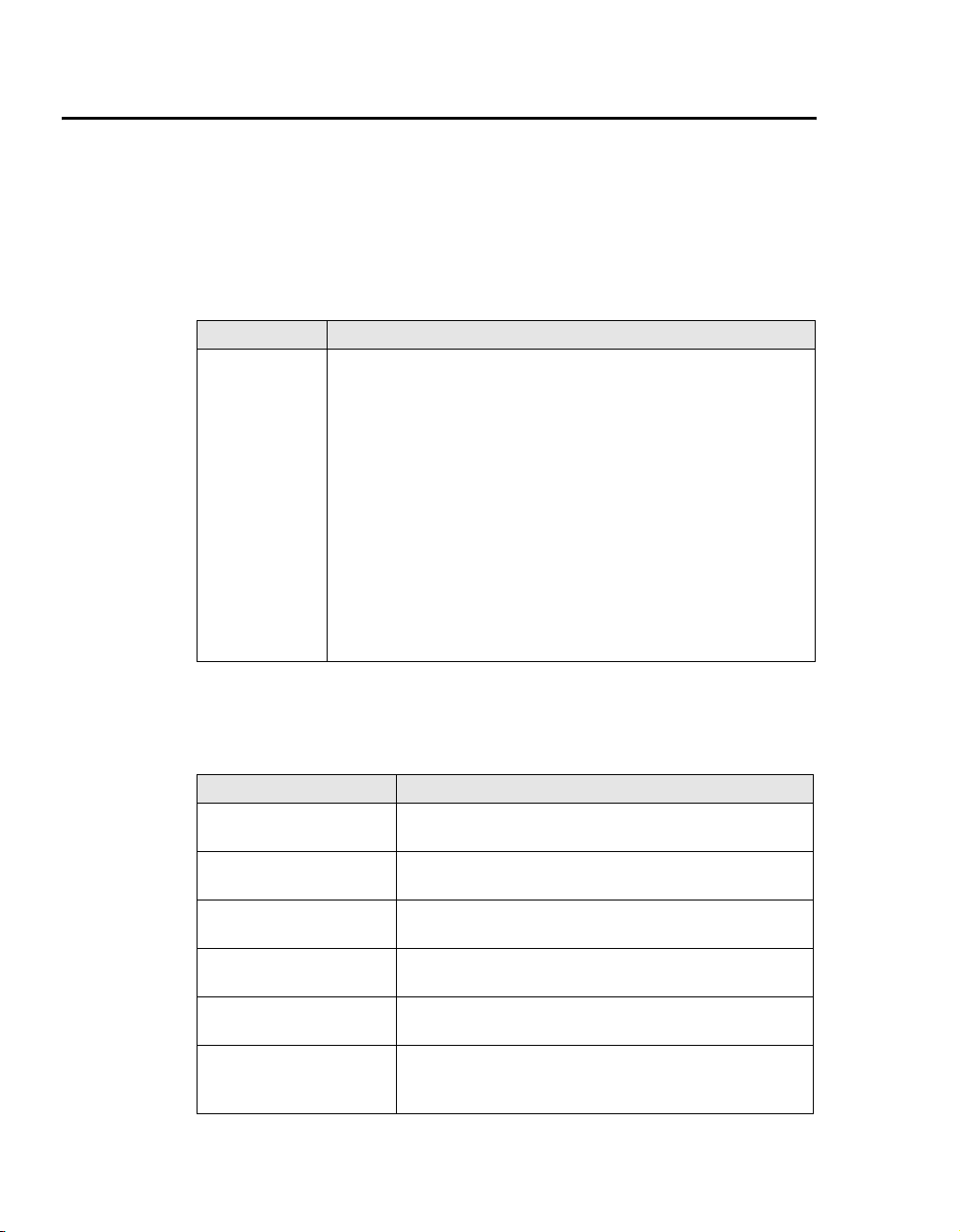

Guide subjects

Safety Manual

• “Introduction” on page 9

• “Safety Manager architectures” on page 29

• “Design phases for an E/E/PE safety-related system” on page 45

• “Design and implementation phases of Safety Manager” on

page 53

• “Safety Manager special functions” on page 63

• “Safety Manager fault detection and response” on page 69

• “Using Safety Manager alarm markers and diagnostic inputs” on

page 109

• “Fire and gas application example” on page 117

• “Special requirements for TUV-approved applications” on

page 141

References

The following guides may be required as reference materials:

Guide Description

The Overview Guide This guide describes the general knowledge required, the

The Planning and Design

Guide

The Troubleshooting and

Maintenance Guide

The System Administration

Guide

The Hardware Reference This guide specifies the hardware components that build a

The Software Reference This guide specifies the software functions that build a

2 Release 100.3

basic functions of, and the tasks related to Safety Manager.

This guide describes the tasks related to planning and

designing a Safety Manager project.

This guide describes the tasks related to troubleshooting and

maintaining Safety Manager.

This guide describes the task related to administrating the

computer systems used in a Safety Manager project.

Safety Manager project.

Safety Manager project and contains guidelines on how to

operate them.

Page 19

Basic skills and knowledge

Before performing tasks related to Safety Manager you need to:

• Understand basic Safety Manager concepts as explained in the Overview

Guide and the Glossary.

• Have a thorough understanding of the Safety Manual.

• Have had appropriate training related to Safety Manager that certifies you for

your tasks (see the Planning and Design Guide).

Prerequisite skills

When you perform tasks related to Safety Manager, it is assumed that you have

appropriate knowledge of:

• Site procedures

• The hardware and software you are working with. These may i.e be:

computers, printers, network components, Controller and Station software.

• Microsoft Windows operating systems.

• Programmable logic controllers (PLCs).

• Applicable safety standards for Process & Equipment Under Control.

• Application design conform IEC 61131-3.

• The IEC 61508 and IEC 61511 standards.

This guide assumes that you have a basic familiarity with the process(es)

connected to the equipment under control.

Basic skills and knowledge

Training

Most of the skills mentioned above can be achieved by appropriate training. For

more information, contact your Honeywell SMS representative or see:

• http://www.honeywellsms.com or

• http://www.automationcollege.com.

Safety Manager Safety Manual 3

Page 20

1 – The Safety Manual

Safety standards for Process & Equipment Under Control (PUC, EUC)

Safety Manager is a PLC based Safety Instrumented System (SIS) performing

specific safety functions to ensure risks are kept at predefined levels.

A SIS measures, independently from the Basic Process Control System, a couple

of relevant process signals like temperature, pressure, level in a tank or the flow

through a pipe. The values of these signals are compared with the predefined safe

values, and if needed, the SIS gives an alarm or takes action. In such cases the SIS

controls the safety of the process and lowers the chance of an unsafe situation.

The logic in Safety Manager defines the response to process parameters.

In this context the following terms are explained in this section:

• Safety Integrity Level (SIL)

• Equipment Under Control (EUC)

• Process Under Control (PUC)

Safety Integrity Level (SIL)

The IEC 61508 standard specifies 4 levels of safety performance for safety

functions. These are called safety integrity levels. Safety integrity level 1 (SIL1)

is the lowest level of safety integrity, and safety integrity level 4 (SIL4) the

highest level. If the level is below SIL 1, the IEC 61508 and IEC 61511 do not

apply.

Safety Manager can be used for processes requiring a SIL1, SIL2 and SIL3.

To achieve the required safety integrity level for the E/E/PE safety-related

systems, an overall safety life cycle is adopted as the technical framework (as

defined in IEC 61508). For more information see inside the Safety Manual.

Equipment Under Control (EUC)

EUC is the equipment controlled by Safety Manager.

Safety-related systems are designed to prevent the EUC from going into a

dangerous state. Safety-related systems can broadly be divided into:

• Emergency shutdown systems.

• Fire and Gas detection and control systems.

Safety-related systems interface with the process through sensors and actuators.

The required safety integrity level may be achieved by implementing the safety

4 Release 100.3

Page 21

Safety standards for Process & Equipment Under Control (PUC, EUC)

functions in the process control system or by using separate and independent

systems dedicated to safety.

During the various phases of the safety cycle different knowledge and skills are

required with respect to EUC. For more information see inside the Safety Manual.

Process Under Control (PUC)

A Process Under Control is Equipment Under Control expanded with additional

regulations for the process (i.e. refining).

• Where EUC is concerned, the emphasis is on keeping the equipment safe.

• Where PUC is concerned, the emphasis is on keeping the process safe

(broader perspective).

Where PUC is concerned, Safety Manager monitors the process for abnormal

situations. Safety Manager is able to initiate safety actions and process alarms. An

alarm can be caused by abnormal situations in the:

• Process

• Safety loops

• Safety system itself

Safety Manager Safety Manual 5

Page 22

1 – The Safety Manual

Application design conform IEC 61131-3

The IEC 61131 standard defines, as a minimum set, the basic programming

elements, syntactic and semantic rules for the most commonly used programming

languages, including graphical languages of:

• Ladder Diagram,

• Functional Block Diagram and,

• Textual languages of Instruction List and structured Text;

For more information see the IEC web site.

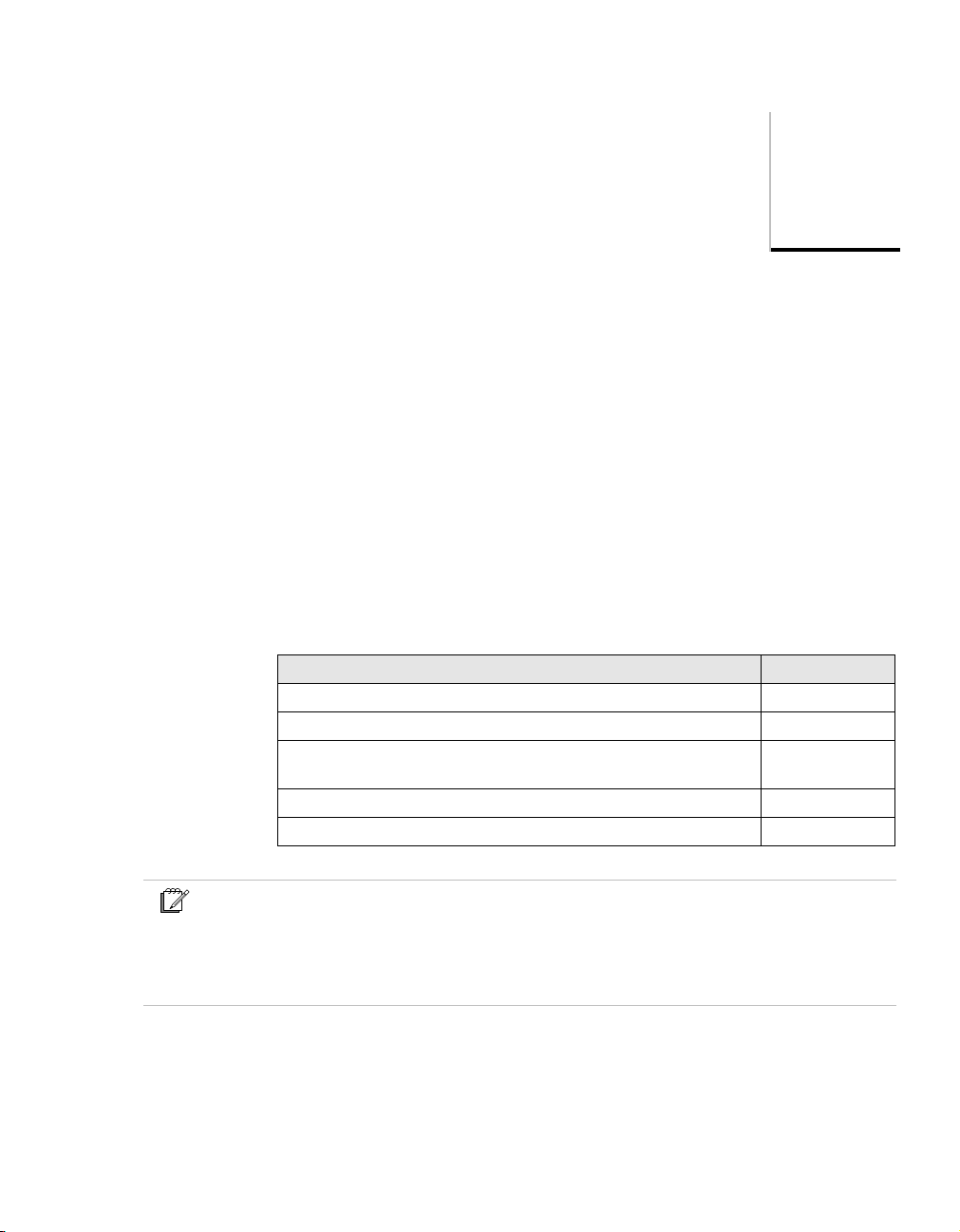

Figure 1 on page 6 shows how Safety Manager uses the graphical programming

method, based on Functional Block Diagram as defined by the IEC 61131-3.

Figure 1 Example FLD layout

6 Release 100.3

Page 23

The IEC 61508 and IEC 61511 standards

The IEC 61508 and IEC 61511 standards

SISs have been used for many years to perform safety functions e.g. in chemical,

petro-chemical and gas plants. In order for instrumentation to be effectively used

for safety functions, it is essential that the instrumentation meets certain minimum

standards and performance levels.

To define the characteristics, main concepts and required performance levels,

standards IEC 61508 and IEC 61511 have been developed. The introduction of

Safety Integrity level (SIL) is one of the results of these standards.

This brief provides a short explanation of each standard. Detailed information

regarding IEC 61508 and 61511 can be found on the IEC web site.

Tip

For more information regarding, or help on, implementing or determining, the applied

safety standards for your plant/process please contact your Honeywell affiliate. Our

Safety Consultants can help you to e.g.:

• perform a hazard risk analysis

• determine the SIL requirements

• design the Safety Instrumented System

• validate and verify the design

• train your local safety staff

IEC 61508, the standard for all safety related systems

The IEC 61508 is called “Functional safety of

electrical/electronic/programmable electronic safety-related systems”

IEC 61508 covers all safety-related systems that are electrotechnical in nature

(i.e. electromechanical systems, solid-state electronic systems and

computer-based systems).

The standard is generic and can be used directly by industry (as a “standalone”

standard) and serves as a basis for the development of sector standards (e.g. for

the machinery sector, the process sector the nuclear sector, etc.).

SIL

IEC 61508 details the design requirements for achieving the required Safety

Integrity Level (SIL).

The safety integrity requirements for each individual safety function may differ.

The safety function and SIL requirements are derived from the hazard analysis

and the risk assessment.

The higher the level of adapted safety integrity, the lower the likelihood of

dangerous failure of the SIS.

Safety Manager Safety Manual 7

Page 24

1 – The Safety Manual

This standard also addresses the safety-related sensors and final elements

regardless of the technology used.

IEC 61511, the standard for the process industry

The IEC 61511 is called “Functional safety - Safety instrumented systems for the

process industry sector”.

This standard addresses the application of SISs for the process industries. It

requires a process hazard and risk assessment to be carried out, to enable the

specification for SISs to be derived. In this standard a SIS includes all

components and subsystems necessary to carry out the safety instrumented

function from sensor(s) to final element(s).

The standard is intended to lead to a high level of consistency in underlying

principles, terminology and information within the process industries. This

should have both safety and economic benefits.

It is strongly recommended that attention is paid to the IEC 61508 as the

IEC 61511 sits within the framework of IEC 61508.

8 Release 100.3

Page 25

Introduction

The Safety Manual describes the specifications, design guidelines, and safety

aspects related to Safety Manager.

It is created to ensure that the required safety knowledge for designing,

engineering and constructing Safety Manager is transferred to the user.

This section describes the following topics:

Topic See

System overview page 10

Certification page 11

Standards compliance page 13

Definitions page 20

2

Safety Manager Safety Manual 9

Page 26

2 – Introduction

System overview

Safety Manager is a Safety Instrumented System (SIS). The SIS can be used in a

number of different basic architectures (DMR, QMR) depending on the required

availability level.

The safety of Safety Manager is obtained through its specific design for these

applications. This design includes facilities for self-testing of all Safety Manager

modules through software and specialized hardware based on a failure mode

effect analysis (FMEA) for each module. Additional software diagnostic routines

are included to guarantee proper execution of the hardware. This approach can be

classified as software diversity. These features maintain the highest level of safety

operation of Safety Manager even in the single-channel configurations. By

placing these single-channel versions in parallel, one not only gets safety but also

availability: proven availability.

Safety Manager and Safety Station from Honeywell SMS provide the means to

guarantee optimal safety and availability. To achieve these goals, it is essential

that the system is operated and maintained by authorized and qualified staff. If it

is operated by unauthorized or unqualified persons, severe injuries or loss of

production could be the result. This Safety Manual covers the applications of

Safety Manager for Safety Integrity Levels (SIL) 1 to 3 in compliance with the

international standard IEC 61508.

Tip

More overview information regarding Safety Manager can be found in the Overview

Guide.

10 Release 100.3

Page 27

Certification

The advantage of applying and complying to standards is obvious:

• International standards force companies to evaluate and develop their

• Products certified conform these international standards guarantee a certain

Since functional safety is the core of the Safety Manager design, the system has

been certified for use in safety applications all around the world. Safety Manager

has been developed specifically to comply with the IEC61508 functional safety

standards, and has been certified by TUV for use in SIL1 to SIL3 applications.

Safety Manager has also obtained certification in the United States for the UL

1998 and ANSI/ISA S84.01 standards.

For a full list of all these and other certifications see “Certification” on page 11.

Certification

Safety Manager has been certified to comply with the following standards:

Certification

products and processes according a consistent and uniform way.

degree of quality and product reliability that other products lack.

International Electronical Commission (IEC) — The

design and development of Safety Manager are compliant

with IEC 61508 (as certified by TUV).

Instrument Society of America (ISA) — Certified to

fulfill the requirements laid down in ANSI/ISA S84.01.

CE compliance — Complies with CE directives

89/336/EEC (EMC) and 73/23/EEC (Low Voltage),

89/392/EEC (Machine Safety)

European Committee for Standardization — CEN,

CENELEC

Safety Manager Safety Manual 11

Page 28

2 – Introduction

Lloyds Register of Shipping — Test specification nr 1

(LRS), 96/98/EEC (EEC Marine directive)

TUV (Germany) — Certified to fulfill the requirements

of SIL3 safety equipment as defined in the following

documents: IEC61508, IEC60664-3, EN50156, EN 54-2,

EN50178, IEC 60068, IEC 61131-2, IEC 61131-3,

IEC60204.

Canadian Standards Association (CSA) — Complies

with the requirements of the following standards:

• CSA Standard C22.2 No. 0-M982 General

Requirements – Canadian Electrical Code, Part II;

• CSA Standard C22.2 No. 142-M1987 for Process

Control Equipment.

Underwriters Laboratories (UL) — Certified to fulfill

the requirements of UL 508, UL 991, UL 1998, and

ANSI/ISA S84.01.

12 Release 100.3

Factory Mutual (FM) — Certified to fulfill the

requirements of FM 3611 and FM3600 (non-incentive

field wiring circuits for selected modules and installation

in Class 1 Div 2 environments).

Page 29

Standards compliance

This subsection lists the standards Safety Manager complies with, and gives some

background information on the relevant CE marking (EMC directive and Low

Voltage directive).

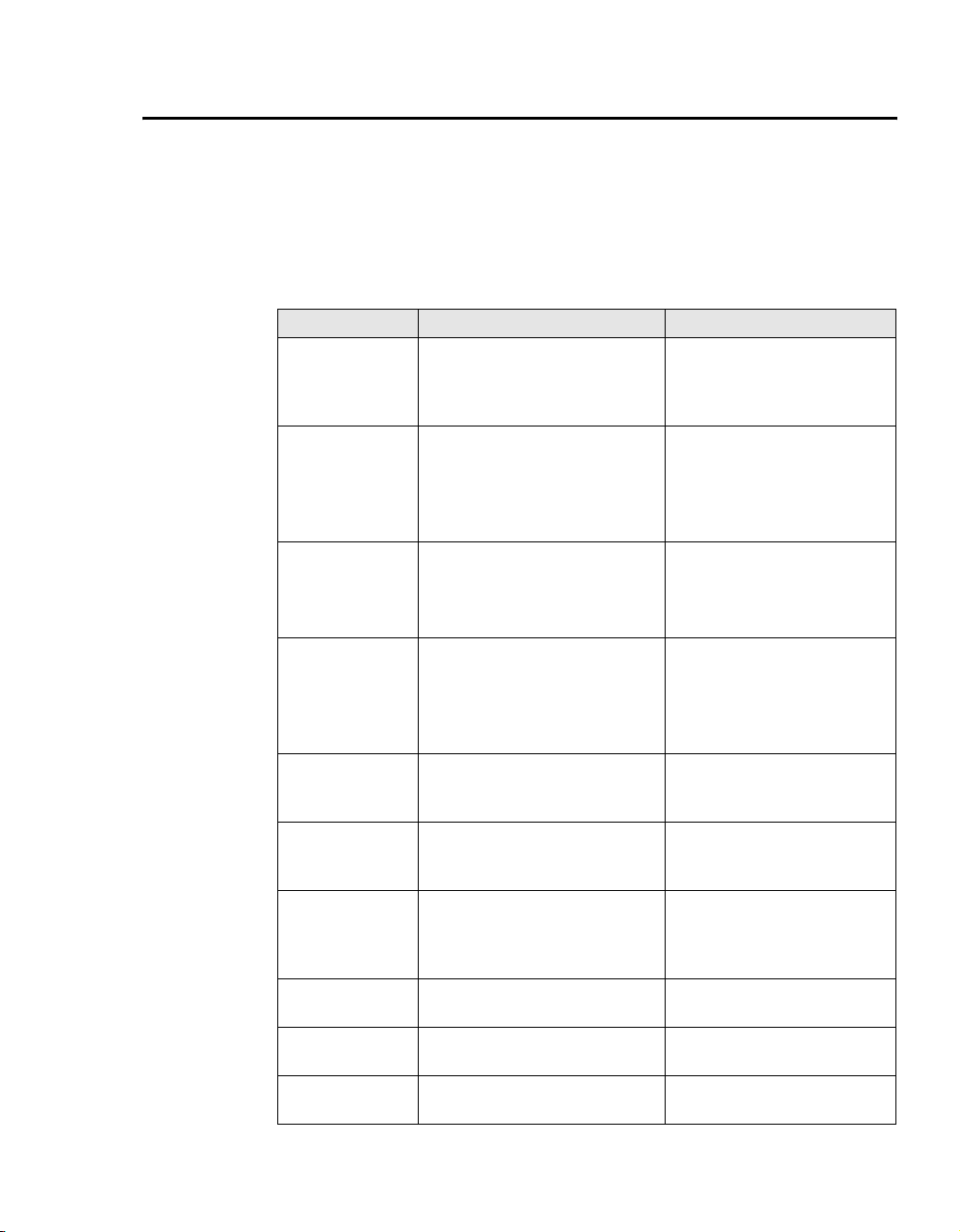

Standard Title Remarks

IEC61508

(S84.01)

DIN V 0801 (1/90)

and Amendment A

(10/94)

VDE 0116 (10/89) Electrical equipment of furnaces.

EN 54 part 2

(01/90)

EN 50081-2-1994 Electromagnetic compatibility –

EN 50082-2-1995 Electromagnetic compatibility –

IEC 61010-1-1993 Safety Requirements for Electrical

IEC 61131-2-1994 Programmable controllers. Part 2:

UL 1998 Safety-related software, first

UL 508 Industrial control equipment,

Functional safety of

electrical/electronic/

programmable electronic (E/E/PE)

safety-related systems.

Principles for computers in

safety-related systems.

(German title: Grundsätze für

Rechner in Systemen mit

Sicherheitsaufgaben)

(German title: Elektrische

Ausrüstung von

Feuerungsanlagen)

Components of automatic fire

detection systems, Introduction.

(German title: Bestandteile

automatischer

Brandmeldeanlagen)

Generic emission standard, Part 2:

Industrial environment.

Generic immunity standard, Part 2:

Industrial environment.

Equipment for Measurement,

Control and Laboratory Use, Part

1: General Requirements.

Equipment requirements and tests.

edition.

sixteenth edition.

Standards compliance

Table 1 Safety Manager compliance to standards

Microprocessor-based safety

systems.

Underwriters Laboratories.

Underwriters Laboratories.

Safety Manager Safety Manual 13

Page 30

2 – Introduction

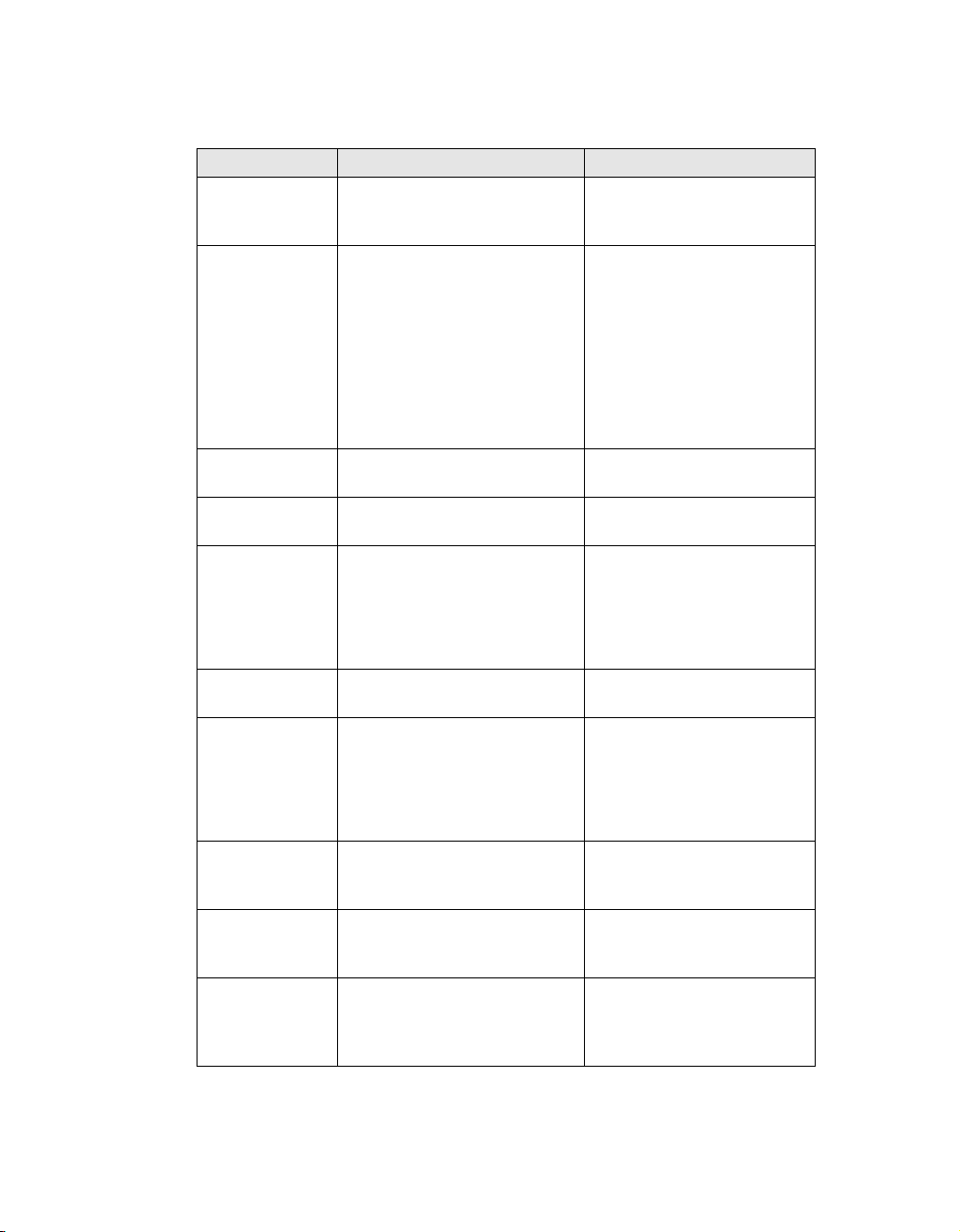

Tab le 1 Safety Manager compliance to standards

Standard Title Remarks

UL 991 Test for safety-related controls

employing solid-state devices,

second edition.

FM3600, FM 3611

Class I, Division 2,

Groups A, B, C &

D

Class II,

Division 2,

Groups F & G

CSA C22.2 Process control equipment.

IEC 60068-1 Basic environmental testing

IEC 60068-2-1 Cold test. 0°C (32°F); 16 hours; system in

IEC 60068-2-1 Cold test. –10°C (14°F); 16 hours; system

IEC 60068-2-2 Dry heat test. up to 65°C (149°F); 16 hours;

IEC 60068-2-3 Test Ca: damp heat, steady state. 21 days at +40°C (104°F), 93%

IEC 60068-2-3 Test Ca: damp heat, steady state. 96 hours at +40°C (104°F), 93%

IEC 60068-2-14 Test Na: change of temperature –

Electrical equipment for use in

• Class I, Division 2,

• Class II, Division 2, and

• Class III, Division 1 and 2,

hazardous locations.

Industrial products.

procedures.

withstand test.

Underwriters Laboratories.

Factory Mutual Research.

Applies to the field wiring

circuits of the following

modules:

SDI-1624, SAI-0410,

SAI-1620m, SDIL-1608 and

SAO-0220m, and installation of

the Controller in these

environments.

Canadian Standards Association

No. 142 (R1993).

operation; reduced power supply

voltage:

(–15%): U=20.4 Vdc or

(–10%): U=198 Vac.

in operation.

system in operation; increased

power supply voltage:

(+15%): U=27.6 Vdc or

(+10%): U=242 Vac.

relative humidity; function test

after cooling.

relative humidity; system in

operation.

–25°C—+55°C (–13°F—

+131°F), 12 hours, 95% relative

humidity, recovery time: max. 2

hours.

14 Release 100.3

Page 31

Table 1 Safety Manager compliance to standards

Standard Title Remarks

IEC 60068-2-30 Test Db variant 2: cyclic damp

heat test.

IEC 60068-2-6 Environmental testing – Part 2:

Tests – Test.

Fc: vibration (sinusoidal).

IEC 60068-2-27 Environmental testing – Part 2:

Tests – Test.

Ea: shock.

+25°C—+55°C (+77°F—

+131°F), 48 hours, 80-100%

relative humidity, recovery time:

1—2 hours.

Excitation: sine-shaped with

sliding frequency;

Frequency range: 10—150 Hz.

Loads:

• 10—57 Hz; 0.075 mm.

• 57—150 Hz; 1 G.

Duration: 10 cycles (20 sweeps)

per axis.

No. of axes: 3 (x, y, z).

Traverse rate: 1 oct/min in

operation.

Half sine shock.

2 shocks per 3 axes (6 in total).

Maximum acceleration: 15 G.

Shock duration: 11 ms.

Safety Manager in operation.

Standards compliance

Safety Manager Safety Manual 15

Page 32

2 – Introduction

EU Standards

This section explains the major EU standards that apply to Safety Manager.

These standards are:

Topic See

CE marking page 16

EMC directive (89/336/EEC) page 17

Low voltage directive (73/23/EEC) page 18

Machine safety directive (89/392/EEC)) page 18

CE marking

The CE mark (see Figure 2 on page 16) is a compliance symbol, which indicates

that a product meets the requirements of the EU directives that apply to that

product. CE (Conformité Européenne) marking is a legal requirement for selling

products in the European Union.

EU directives documentation is issued on the authority of the Council of the

European Union. It contains requirements and regulations for certain categories

of products or problem areas. The directives apply not only to member countries

of the European Union but also to the whole European Economic Area (EEA).

The European directives have the following key objectives:

• Free movement of goods within the EU/EEA geographical regions through

harmonization of standards and elimination of trade barriers.

• Safety of persons, their property and of animals.

• Protection of the environment.

For control products like Safety Manager, a number of EU directives apply.

Safety Manager is compliant with: the Electromagnetic Compatibility (EMC)

Directive (89/336/EEC), the Low Voltage Directive (73/23/EEC), Marine

Directive (96/98/EEC) and Machine Safety Directive (89/392/EEC). Some are

16 Release 100.3

Figure 2 CE mark

Page 33

discussed in more detail below. An item of equipment may only display the CE

mark when the equipment satisfies all relevant directives.

EMC directive (89/336/EEC)

One of the EU directives Safety Manager complies with is the EMC directive, or

Council Directive 89/336/EEC of 3 May 1989 on the approximation of the laws of

the Member States relating to electromagnetic compatibility as it is officially

called. It “applies to apparatus liable to cause electromagnetic disturbance or the

performance of which is liable to be affected by such disturbance” (Article 2).

The EMC directive defines protection requirements and inspection procedures

relating to electromagnetic compatibility for a wide range of electric and

electronic items.

Within the context of the EMC directive, ‘apparatus’ means all electrical and

electronic appliances together with equipment and installations containing

electrical and/or electronic components. ‘Electromagnetic disturbance’ means

any electromagnetic phenomenon which may degrade the performance of a

device, unit of equipment or system. An electromagnetic disturbance may be

electromagnetic noise, an unwanted signal or a change in the propagation medium

itself.

‘Electromagnetic compatibility’ is the ability of a device, unit of equipment or

system to function satisfactorily in its electromagnetic environment without

introducing intolerable electromagnetic disturbances to anything in that

environment.

There are two sides to electromagnetic compatibility: emission and immunity.

These two essential requirements are set forth in Article 4, which states that an

apparatus must be constructed so that:

1. The generated electromagnetic disturbance does not exceed a level allowing

radio and telecommunications equipment and other apparatus to operate as

intended.

2. The apparatus has an adequate level of intrinsic immunity of electromagnetic

disturbance to enable it to operate as intended.

The EMC directive was originally published in the Official Journal of the

European Communities on May 23, 1989. As of January 1, 1996 compliance with

the EMC directive is mandatory (a legal requirement). All electronic products

may now only be marketed in the European Union if they meet the requirements

laid down in the EMC directive. This also applies to Safety Manager cabinets.

EU Standards

Safety Manager Safety Manual 17

Page 34

2 – Introduction

Low voltage directive (73/23/EEC)

Safety Manager also complies with the low voltage directive, or Council

Directive 73/23/EEC of 19 February 1973 on the harmonization of the laws of the

Member States relating to electrical equipment designed for use within certain

voltage limits as it is officially called. It states that “electrical equipment may be

placed on the market only if, having been constructed in accordance with good

engineering practice in safety matters in force in the Community, it does not

endanger the safety of persons, domestic animals or property when properly

installed and maintained and used in applications for which it was made” (Article

2).

The low voltage directive defines a number of principal safety objectives that

electrical equipment must meet in order to be considered “safe”.

Within the context of the low voltage directive, ‘electrical equipment’ means any

equipment designed for use with a voltage rating of between 50 and 1,000 V for

alternating current (AC) and between 75 and 1,500 V for direct current (DC).

The low voltage directive was originally published in the Official Journal of the

European Communities on March 26, 1973. It was amended by Council Directive

93/68/EEC. As of January 1, 1997 compliance with the low voltage directive is

mandatory (a legal requirement). All electronic products may now only be

marketed in the European Union if they meet the requirements laid down in the

low voltage directive. This also applies to Safety Manager cabinets.

Machine safety directive (89/392/EEC))

The directive holds the requirements for machinery safety in every country within

the European Economic Area (EEA). The Directive applies to all machinery and

to safety components. A machine is defined as “an assembly of linked parts or

components, at least one of which moves…”

Machinery meeting the requirements of the Directive is required to have the CE

symbol clearly affixed to indicate compliance. An item of equipment may only

display the CE mark when the equipment satisfies all relevant directives.

The Directive requires the machines manufacturer to produce a Technical File

containing documentary evidence that the machinery complies with the directive.

The Directive also effectively allows a period of grace in which the file can be

assembled after it has been requested by the authorities.

The Directive gives a comprehensive list of the potential hazards (annex I) which

may arise from the design and operation of machinery, and gives general

instructions on what hazards must be avoided. Detailed requirements are laid out

in a series of safety standards.

18 Release 100.3

Page 35

EU Standards

Because so many standards are required to cover the full range of machines

within the scope of the Directive, the European standards bodies devised a

hierarchy which can be applied in every situation:

• ‘Type A’ are the most basic standards set out the requirements for the safety of

machines only in the most general terms: part 2 of EN292 is essentially a

reproduction of annex 1 of the Machinery Directive.

• ‘Type B’ standards deal with more specific issues: design of emergency stops

(EN418); prevention of unexpected start-up (EN1037); pneumatic systems

(EN983); temperature of touchable surfaces (EN563) and many others.

• ‘Type C’ standards deal with specific classes of machinery: for example,

EN1012 deals with safety of compressors and vacuum pumps; EN 792 deals

with pneumatic hand tools.

Safety Manager Safety Manual 19

Page 36

2 – Introduction

Definitions

Dangerous failure

Error

This section provides a list of essential safety terms that apply to Safety Manager.

All definitions have been taken from IEC 61508-4, published in 2000.

Failure which has the potential to put the safety-related system in a hazardous or

fail-to-function state.

Note

Whether or not the potential is realized may depend on the channel architecture of the

system; in systems with multiple channels to improve safety, a dangerous hardware

failure is less likely to lead to the overall dangerous or fail-to-function state.

Discrepancy between a computed, observed or measured value or condition and

the true, specified or theoretically correct value or condition.

EUC risk

Failure

Risk arising from the EUC or its interaction with the EUC control system.

The termination of the ability of a functional unit to perform a required function.

Note

• The definition in IEV 191-04-01 is the same, with additional notes.

• See Figure 3 on page 21 for the relationship between faults and failures, both in

IEC 61508 and IEV 191.

• Performance of required functions necessarily excludes certain behavior, and some

functions may be specified in terms of behavior to be avoided. The occurrence of such

behavior is a failure.

• Failures are either random (in hardware) or systematic (in hardware or software).

20 Release 100.3

Page 37

Fault

Functional safety

Definitions

Abnormal condition that may cause a reduction in, or loss of, the capability of a

functional unit to perform a required function.

Note

IEV 191-05-01 defines “fault” as a state characterized by the inability to perform a

required function, excluding the inability during preventative maintenance or other

planned actions, or due to lack of external resources.

Part of the overall safety relating to the EUC and the EUC control system which

depends on the correct functioning of the E/E/PE safety-related systems, other

technology safety-related systems and external risk reduction facilities.

Figure 3 Failure model

L (i-1) FU

L (i FU

L (i+1) FU L (i+1) FU

L (i+1) FUL (i+1) FU

L= level, i=1,2,3, etc.; FU=Functional Unit

A) Configuration of a Functional Unit

Level(i) Level(i-1)

failure

fault

C) IEC 61508's and ISO/IEC 2382-14's view

L (i FU

L (i+1) FU L (i+1) FU

"Entity X"

failure

fault

Level(i) Level(i-1)

"F" state

"Entity X"

L (i+1) FUL (i+1) FU

"F" state

failure

cause

B) Generalized view

Level(i) Level(i-1)

fault

failure

failure cause

"Entity X"

D) IEC 50(191)'s view

failure

cause

fault

failure

failure cause

Safety Manager Safety Manual 21

Page 38

2 – Introduction

Notes for Figure 3 on page 21

• As shown in A), a functional unit can be viewed as a hierarchical composition of

multiple levels, each of which can in turn be called a functional unit. In level (i), a

“cause” may manifest itself as an error (a deviation from the correct value or state)

within this level (i) functional unit, and, if not corrected or circumvented, may cause a

failure of this functional unit, as a result of which it falls into an “F” state where it is no

longer able to perform a required function (see B)). This “F” state of the level (i)

functional unit may in turn manifest itself as an error in the level (i-1) functional unit

and, if not corrected or circumvented, may cause a failure of this level (i-1) functional

unit.

• In this cause and effect chain the same thing (“Entity X”) can be viewed as a state (“F”

state) of the level (i) functional unit into which it has fallen as a result of its failure, and

also as the cause of the level (i-1) functional unit. This “Entity X” combines the

concept of “fault” in IEC 61508 and ISO/IEC 2382-14, which emphasizes its cause

aspect as illustrated in C), and that of “fault” in IEC 50(191), which emphasizes its

state aspect as illustrated in D). The “F” state is called fault in IEC 50(191), whereas it

is not defined in IEC 61508 and ISO/IEC 2382-14.

• In some cases, a failure may be caused by an external event such as lightning or

electrostatic noise, rather than by an internal fault. Likewise, a fault (in both

vocabularies) may exist without a prior failure. An example of such a fault is a design

fault.

Functional safety assessment

Investigation, based on evidence, to judge the functional safety achieved by one

or more E/E/PE safety-related systems, other technology safety-related systems

or external risk reduction facilities.

Human error

Mistake.

Human action or inaction that produces an unintended result.

Hardware safety integrity

Part of the safety integrity of the safety related systems relating to random

hardware failures in a dangerous mode of failure.

Note

The term relates to failures in a dangerous mode. That is, those failures of a safety-related

system that would impair its safety integrity. The two parameters that are relevant in this

context are the overall dangerous failure rate and the probability of failure to operate on

demand. The former reliability parameter is used when it is necessary to maintain

continuous control in order to maintain safety, the latter reliability parameter is used in the

context of safety-related protection systems.

22 Release 100.3

Page 39

Mode of operation

Way in which a safety-related system is intended to be used, with respect to the

frequency of demands made upon it in relation to the proof check frequency,

which may be either:

• Low demand mode - where the frequency of demands for operation made on

a safety-related system is not significantly greater than the proof check

frequency; or

• High demand or continuous mode - where the frequency of demands for

operation made on a safety-related system is significantly greater than the

proof check frequency.

Note

Typically for low demand mode, the frequency of demands on the safety-related system is

the same order of magnitude as the proof test frequency (i.e. months to years where the

proof test interval is a year). While typically for high demand or continuous mode, the

frequency of demands on the safety-related system is hundreds of times the proof test

frequency (i.e. minutes to hours where the proof test interval is a month).

Programmable electronic system (PES)

System for control, protection or monitoring based on one or more programmable

electronic devices, including all elements of the system such as power supplies,

sensors and other input devices, data highways and other communication paths,

and actuators and other output devices (see Figure 4 on page 24).

Definitions

Note

The structure of a PES is shown in Programmable electronic system (PES): structure and

terminology A). Programmable electronic system (PES): structure and terminology B)

illustrates the way in which a PES is represented in IEC 61508, with the programmable

electronics shown as a unit distinct from sensors and actuators on the EUC and their

interfaces, but the programmable electronics could exist at several places in the PES.

Programmable electronic system (PES): structure and terminology C) illustrates a PES

with two discrete units of programmable electronics. Programmable electronic system

(PES): structure and terminology D) illustrates a PES with dual programmable electronics

(i.e. two channel), but with a single sensor and a single actuator.

Safety Manager Safety Manual 23

Page 40

2 – Introduction

Figure 4 Programmable electronic system (PES): structure and terminology

Risk

Safe failure

Output interfaces

D-A converters

Output devices/final elements

(eg actuators)

PE

2

D) Single PES with dual program-

mable electronic devices but with

shared sensors and final elements (ie

one PES comprised of two channels

of programmable electronics)

PE

PE

1

2

PE

Input interfaces

A-D converters

Input devices

(eg sensors)

Extend

of PES

B) Single PES with single program-

mable electronic device (ie one PES

comprised of a single channel of

programmable electronics)

Communications

Programmable

electronics

(see note)

A) Basic PES structure

PE

1

C) Single PES with dual program-

mable electronic devices linked in a

serial manner (eg intelligent sensor

and programmable controller)

Combination of the probability of occurrence of harm and the severity of that

harm.

Failure which does not have the potential to put the safety-related system in a

hazardous or fail-to-function state.

Note

Whether or not the potential is realized may depend on the channel architecture of the

system; in systems with multiple channels to improve safety, a safe hardware failure is

less likely to result in an erroneous shutdown.

Safety

Freedom from unacceptable risk.

Safety integrity level (SIL)

Discrete level (one out of a possible four) for specifying the safety integrity

requirements of the safety functions to be allocated to the E/E/PE safety-related

24 Release 100.3

Page 41

Definitions

systems, where safety integrity level 4 has the highest level of safety integrity and

safety integrity level 1 has the lowest.

Note

• The target failure measures for the safety integrity levels are specified in Safety

integrity levels: target failure measures for a safety function, allocated to the E/E/PE

Safety Related System operating in low demand mode of operation and Safety

integrity levels: target failure measures for a safety function, allocated to the E/E/PE

Safety Related System operating in high demand or continuous mode of operation.

Table 2 Safety integrity levels: target failure measures for a safety function, allocated to the E/E/PE

Safety Related System operating in low demand mode of operation

Safety integrity level Low demand mode of operation

(average probability of failure to perform its design function

on demand)

4 ≥ 10

-5

3 ≥ 10-4 to < 10

2 ≥ 10-3 to < 10

1 ≥ 10-2 to < 10

NOTE: see notes below for details on interpreting this table.

to < 10

-4

-3

-2

-1

Table 3 Safety integrity levels: target failure measures for a safety function, allocated to the E/E/PE

Safety Related System operating in high demand or continuous mode of operation

Safety integrity level High demand or continuous mode of operation (probability

of a dangerous failure per hour)

4 ≥ 10

-9

3 ≥ 10-8 to < 10

2 ≥ 10-7 to < 10

1 ≥ 10-6 to < 10

to < 10

-8

-7

-6

-5

NOTE: see notes below for details on interpreting this table.

Safety Manager Safety Manual 25

Page 42

2 – Introduction

Note

1. The parameter in Safety integrity levels: target failure measures for a safety function,

allocated to the E/E/PE Safety Related System operating in high demand or continuous

mode of operation, probability of a dangerous failure per hour, is sometimes referred

to as the frequency of dangerous failures, or dangerous failure rate, in units of

dangerous failures per hour.

2. This document sets a lower limit on the target failure measures, in a dangerous mode

of failure, than can be claimed. These are specified as the lower limits for safety

integrity level 4 (that is an average probability of failure of 10

function on demand, or a probability of a dangerous failure of 10

possible to achieve designs of safety-related systems with lower values for the target

failure measures for non-complex systems, but it is considered that the figures in the

table represent the limit of what can be achieved for relatively complex systems (for

example programmable electronic safety-related systems) at the present time.

3. The target failure measures that can be claimed when two or more E/E/PE

safety-related systems are used may be better than those indicated in Safety integrity

levels: target failure measures for a safety function, allocated to the E/E/PE Safety

Related System operating in low demand mode of operation and Safety integrity

levels: target failure measures for a safety function, allocated to the E/E/PE Safety

Related System operating in high demand or continuous mode of operation providing

that adequate levels of independence are achieved.

4. It is important to note that the failure measures for safety integrity levels 1, 2, 3 and 4

are target failure measures. It is accepted that only with respect to the hardware safety

integrity will it be possible to quantify and apply reliability prediction techniques in

assessing whether the target failure measures have been met. Qualitative techniques

and judgements have to be made with respect to the precautions necessary to meet the

target failure measures with respect to the systematic safety integrity.

5. The safety integrity requirements for each safety function shall be qualified to indicate

whether each target safety integrity parameter is either:

• the average probability of failure to perform its design function on demand (for a low

demand mode of operation); or

• the probability of a dangerous failure per hour (for a high demand or continuous mode

of operation).

-5

to perform its design

-9

per hour). It may be

Safety life cycle

Necessary activities involved in the implementation of safety-related systems,

occurring during a period of time that starts at the concept phase of a project and

finishes when all of the E/E/PE safety-related systems, other technology

safety-related systems and external risk reduction facilities are no longer

available for use.

Safety-related system

Designated system that both:

• implements the required safety functions necessary to achieve or maintain a

safe state for the EUC, and

26 Release 100.3

Page 43

Definitions

• is intended to achieve, on its own or with other E/E/PE safety-related systems,

other technology safety-related systems or external risk reduction facilities,

the necessary safety integrity for the required safety functions.

Note

1. The term refers to those systems, designated as safety-related systems, that are

intended to achieve, together with the external risk reduction facilities, the necessary

risk reduction in order to meet the required tolerable risk.

2. The safety-related systems are designed to prevent the EUC from going into a

dangerous state by taking appropriate action on receipt of commands. The failure of a

safety-related system would be included in the events leading to the identified hazard

or hazards. Although there may be other systems having safety functions, it is the