Page 1

Excel 500/600

CONTROL SYSTEM

HONEYWELL EXCEL 5000 OPEN SYSTEM

INSTALLATION INSTRUCTIONS

CONTENTS

Revision Overview ....................................................................................................................................................................... 3

Safety Instructions ....................................................................................................................................................................... 4

MOUNTING.................................................................................................................................................................................... 5

Control Unit Installation............................................................................................. 5

Excel 500/600 Housing Layout (not XCL5010)......................................................... 5

Excel 500/600 Internal Bus Wiring (not XCL5010).................................................... 5

Module Locations (not XCL5010) ............................................................................. 6

Coding the Terminal Block (not XCL5010) ............................................................... 6

Setting the Module Address (not XCL5010) ............................................................. 7

Installation Inside a Control Panel ............................................................................ 7

Excel 500/600 ...................................................................................................... 7

XCL5010 .............................................................................................................. 8

XDL505 Application Module ................................................................................. 9

Installation through a Control Panel Door (not XCL5010)......................................... 9

External Installation of XI582 .................................................................................. 10

Backlight ................................................................................................................. 11

Distributed I/O Installation....................................................................................... 11

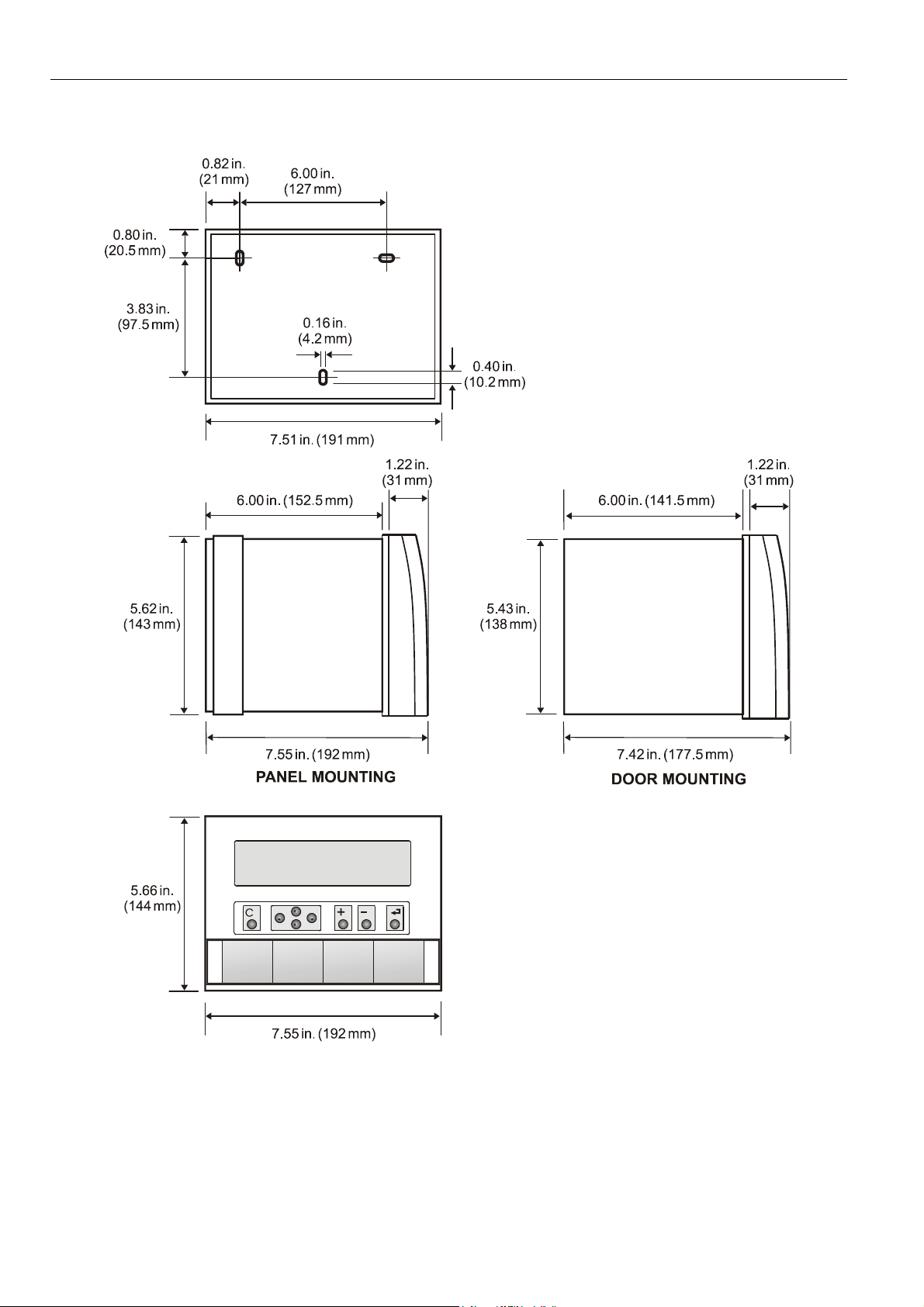

Dimensions............................................................................................................. 12

Excel 500/600 .................................................................................................... 12

XCL5010 ............................................................................................................ 13

XI582.................................................................................................................. 14

Battery Activation during Commissioning (XC6010, only)....................................... 14

Replacing the Battery ............................................................................................. 15

Dismantling the Control Panel Unit ......................................................................... 15

Dismantling the Control Panel Door Unit ................................................................ 15

Dismantling the Housing Cover .............................................................................. 15

Dismantling the XCL5010 CPU .............................................................................. 16

Dismantling the XI582 Operator Interface............................................................... 16

Electrical Connections............................................................................................................................................................... 16

Cable Routing......................................................................................................... 17

Shielding I/O Module, Power Supply Cables .......................................................... 17

Shielding of Data-Transmitting Cables ................................................................... 17

Grounding (XC5010C / XC6010, only).................................................................... 17

System Ground....................................................................................................... 17

RFI Suppression ..................................................................................................... 17

XC5010C/XC6010 Cable Lengths and Sizes ......................................................... 17

Lightning Protection ................................................................................................ 17

Summary of Internal Modules................................................................................. 18

Line Power Supply ............................................................................................. 19

® U.S. Registered Trademark

Copyright © 2008 Honeywell Inc. • All Rights Reserved EN1R-1047GE51 R0308

Page 2

EXCEL 500/600 INSTALLATION INSTRUCTIONS

XC6010 Computer Module .................................................................................19

XC5010C CPU Module .......................................................................................20

XP502 Power Supply Module .............................................................................21

RIN-APU24 Uninterruptable Power Supply.........................................................21

XF521A Analog Input Module .............................................................................21

XF526 Analog Input Module................................................................................22

XF523A Digital Input Module ..............................................................................23

XF522A and XF527 Analog Output Modules ......................................................24

XF524A and XF529 Digital Output Modules .......................................................24

XF525A Three-Position Output Module ..............................................................25

XCL5010 .................................................................................................................25

Serial Port ...........................................................................................................25

MMI Connection..................................................................................................26

Power Supply......................................................................................................26

Screw Terminal Block Installation Procedure......................................................27

Pull-Up Resistor Handling...................................................................................29

Communications .........................................................................................................................................................................31

LONW

ORKS

Bus Wiring.............................................................................................31

LONW

ORKS

Bus Termination ...............................................................................32

System Bus (C-Bus)................................................................................................32

Submodule Selection (XC6010)..........................................................................33

System Bus Cable Specification .........................................................................33

C-Bus Termination (XC6010)..............................................................................33

C-Bus Termination (XC5010C) ...........................................................................33

C-Bus Termination (XCL5010)............................................................................34

XC6010 Cable Specifications ..................................................................................34

XC5010C Cable Specifications ...............................................................................34

XCL5010 Cable Specifications ................................................................................35

MMI Cables.........................................................................................................35

Modem or ISDN Terminal Adapter Connections .................................................35

Changing Between MMI and Modem Connection...............................................35

Remote Communications...........................................................................................................................................................37

Modem or ISDN Terminal Adapter Connections .....................................................37

Modem Requirements .............................................................................................37

No Set-Up for Standard Modem Behavior ..........................................................37

Automatic Baudrate Synchronization ..................................................................38

Auto / Manual Answer Detection.........................................................................38

Resetting the Modem..........................................................................................38

Set-Up for Special Modem Behavior...................................................................38

Set-Up for In-House Telephone Systems ...........................................................38

Set-Up for Limited Communication Speed..........................................................38

Troubleshooting ..................................................................................................38

Trademark Information Echelon, LON, L

LonTalk, LonUsers, LonPoint, Neuron, 3120, 3150, the Echelon logo, the L

logo, and the LonUsers logo are trademarks of Echelon Corporation registered in

the United States and other countries. LonLink, LonResponse, LonSupport, and

LonMaker are trademarks of Echelon Corporation.

ONMARK

, LONW

ORKS

, LonBuilder, NodeBuilder, LonManager,

ONMARK

EN1R-1047GE51 R0308 2

Page 3

EXCEL 500/600 INSTALLATION INSTRUCTIONS

REVISION OVERVIEW

On the following pages, changes have been made compared to the previous release of this document:

Page: Change:

throughout All references to TCP/IP and GSM communication have been eliminated.

3 EN1R-1047GE51 R0308

Page 4

EXCEL 500/600 INSTALLATION INSTRUCTIONS

SAFETY INSTRUCTIONS

— When performing any work (installation, mounting, start-

up), all instructions given by the manufacturer and in

particular the safety instructions provided in the

Installation Instructions are to be observed.

— The Excel 500/600 controller may be installed and

mounted only by authorized and trained personnel.

— If the unit is modified in any way, except by the

manufacturer, all warranties concerning operation and

safety are invalidated.

— Make sure that certain local standards and regulations

are observed at all times. Examples of such regulations

are VDE 0800 and VDE 0100.

— Use only accessory equipment which comes from or has

been approved by Honeywell.

CAUTION

Risk of electric shock! Disconnect the power supply

before you start to install the Excel 500/600 Controller

and do not reconnect the power supply until you have

completed installation. NOTE: More than one

disconnect switch may be required to de-energize the

device.

ATTENTION

Risque de choc électrique. Il peut être nécessaire de

couper l'alimentation à plus d'un interrupteur pour

effectuer le désamorçage de ce dispositif.

CAUTION

Disconnect the power supply before plugging in or

removing the XDL505 Application Module.

EN1R-1047GE51 R0308 4

Page 5

MOUNTING

Control Unit Installation

The Excel 500 and 600 controllers have the same housing

and can be installed two different ways:

— Installation inside a control panel (see page 7).

— Installation through a control panel door (see page 9).

EXCEL 500/600 INSTALLATION INSTRUCTIONS

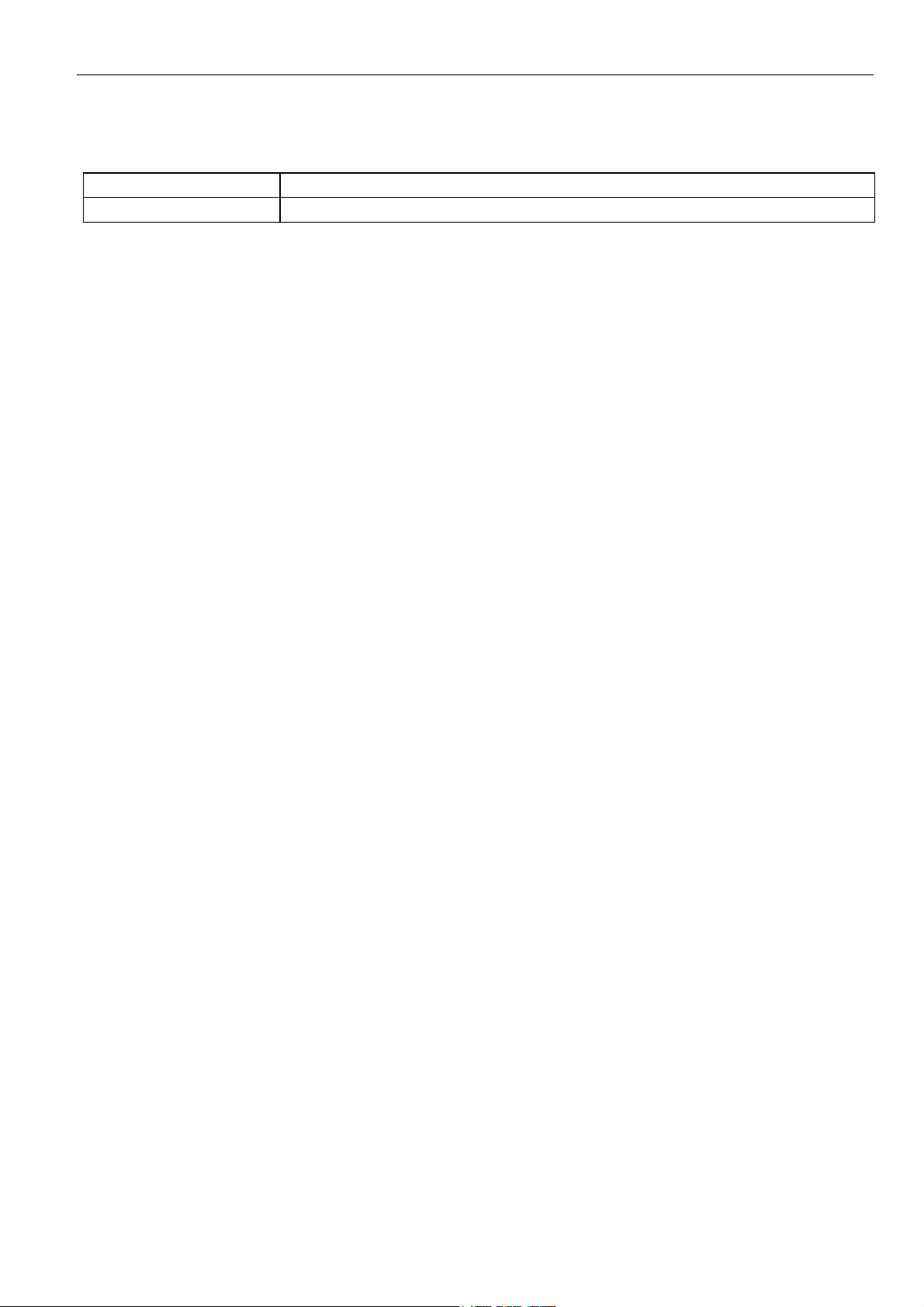

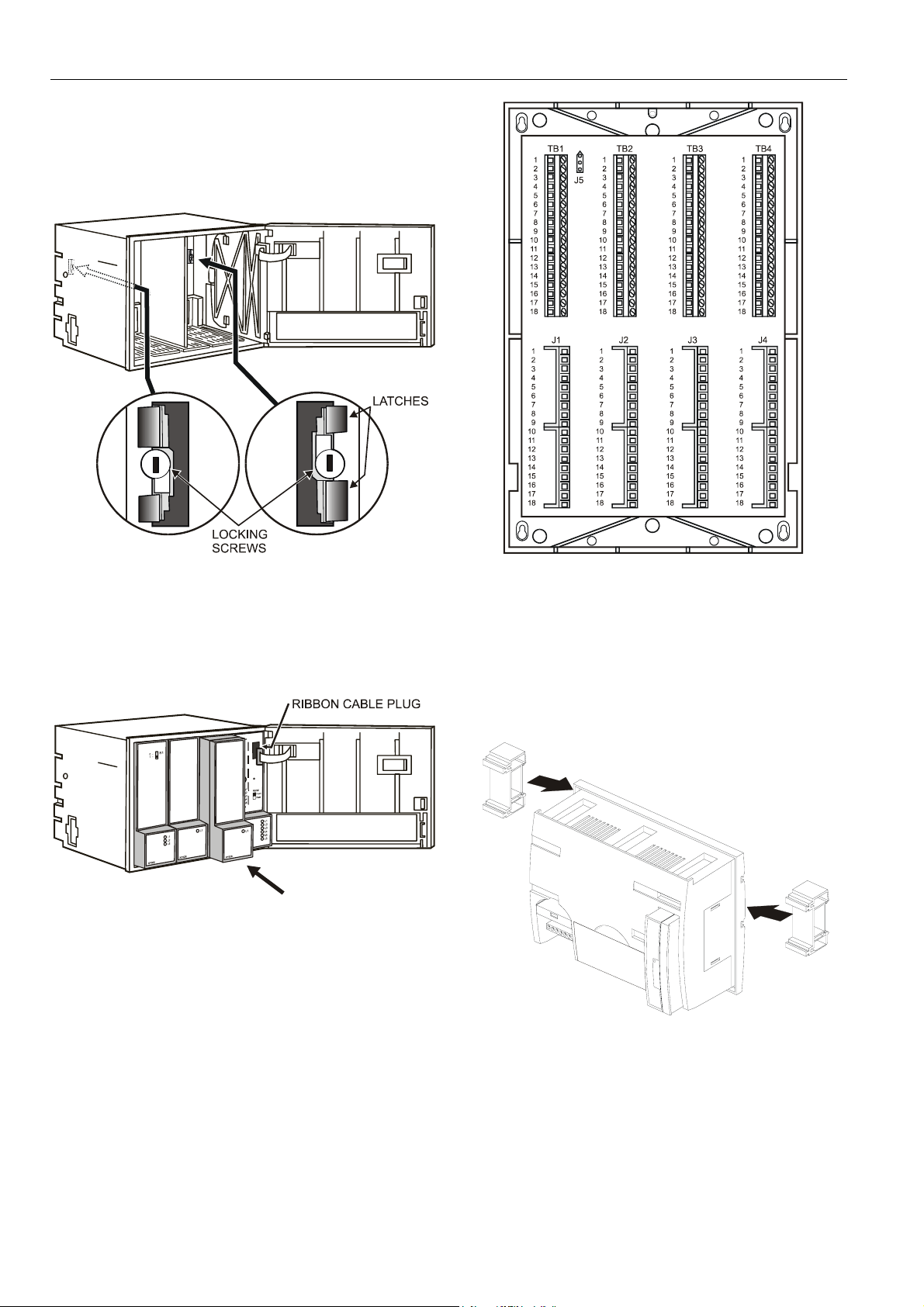

Fig. 1. Excel 500/600 panel door mounting

The XCL5010 can be mounted only on a DIN rail; control

panel door installation is not possible.

Fig. 2. XCL5010 DIN rail mounting

Excel 500/600 Housing Layout (not XCL5010)

A controller comprises from one to a max. of five housings.

The housings may be fitted alongside one another or, one

above the other. Any combination is possible.

Fig. 3. Up to five housings can be connected together

When housings are alongside one another, provide for a min.

spacing of 1.5 in. (35 mm) to enable the hinged cover to be

opened. The max. spacing between housings is limited by

tailor-made internal bus cables (see Fig. 3.

Excel 500/600 Internal Bus Wiring (not

XCL5010)

Each housing has four plug-in module locations. The

individual modules are connected by an internal bus in the

housing.

Configurations comprising more than one housing must have

the individual busses in the housings connected to one

another.

Fig. 4. Excel 500/600 bus wiring

The connection is made via tailor-made ribbon cables. Two

different types are available:

— Type XW568 3 in. (80 mm) long (for housings alongside

one another)

— Type XW569 13 in. (330 mm) long (for housings one

above the other)

5 EN1R-1047GE51 R0308

Page 6

EXCEL 500/600 INSTALLATION INSTRUCTIONS

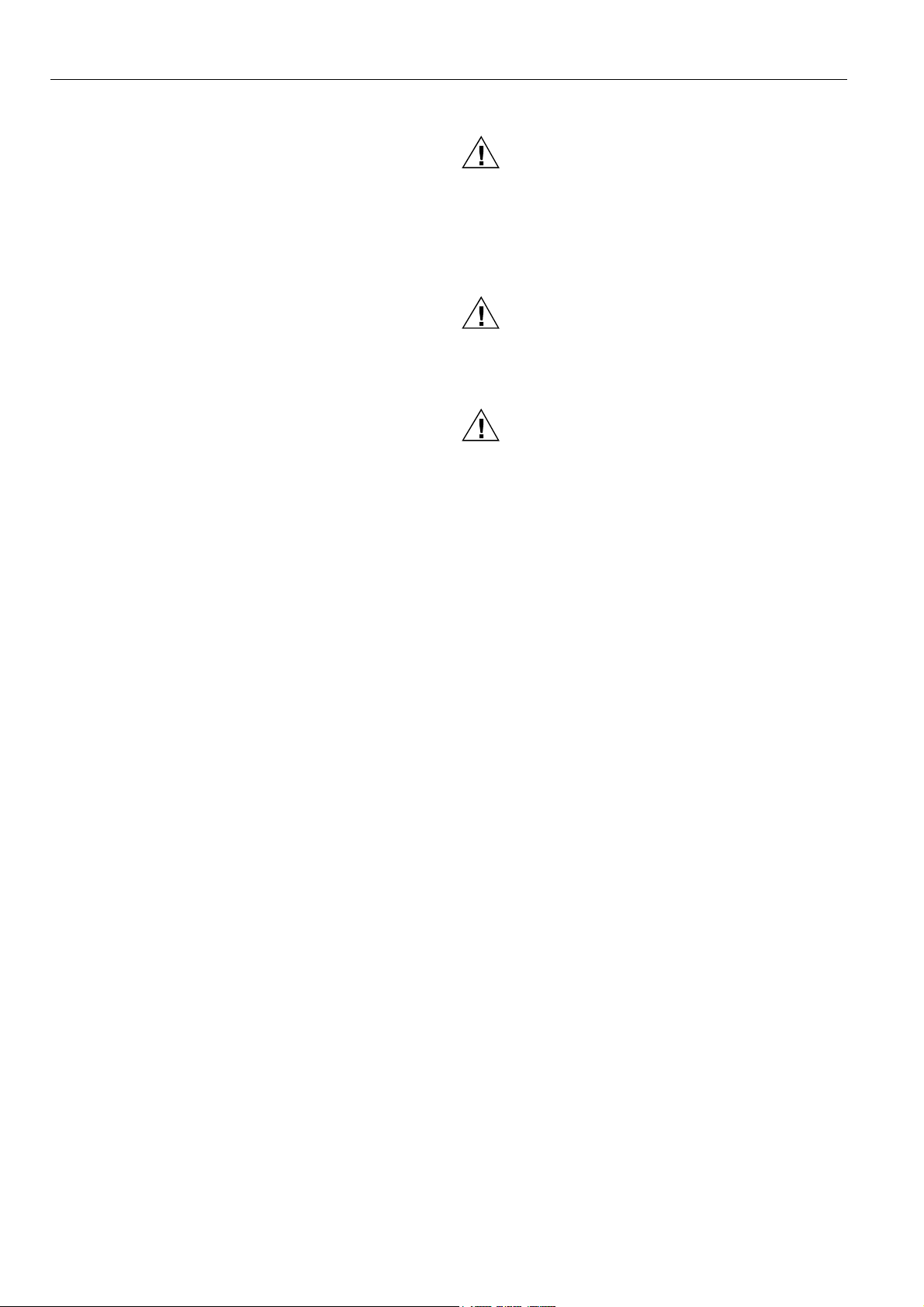

CAUTION

Incorrectly inserted bus cables can destroy the

modules installed.

The internal bus begins at the first housing, containing the

power supply and CPU modules, and ends at the last

housing.

The protective bus connection covers must be removed.

Table 1. Internal module locations

module type module location

CPU

power

supply

AI XF521A / XF526 any

AO XF522A / XF527 any

DI XF523A any

DO XF524A / XF529 not in 1st housing

XC5010C /

XC6010

XP502 1st housing, location 1

1st housing, location 4

Fig. 5. Removal of bus connection cover

The overall internal bus length (bus cable and bus in the

housings) must not exceed 6 ft (2 m).

Bus cables must be routed at least 2 in. (50 mm) away from

power cables to prevent possible inductive and capacitive

interference.

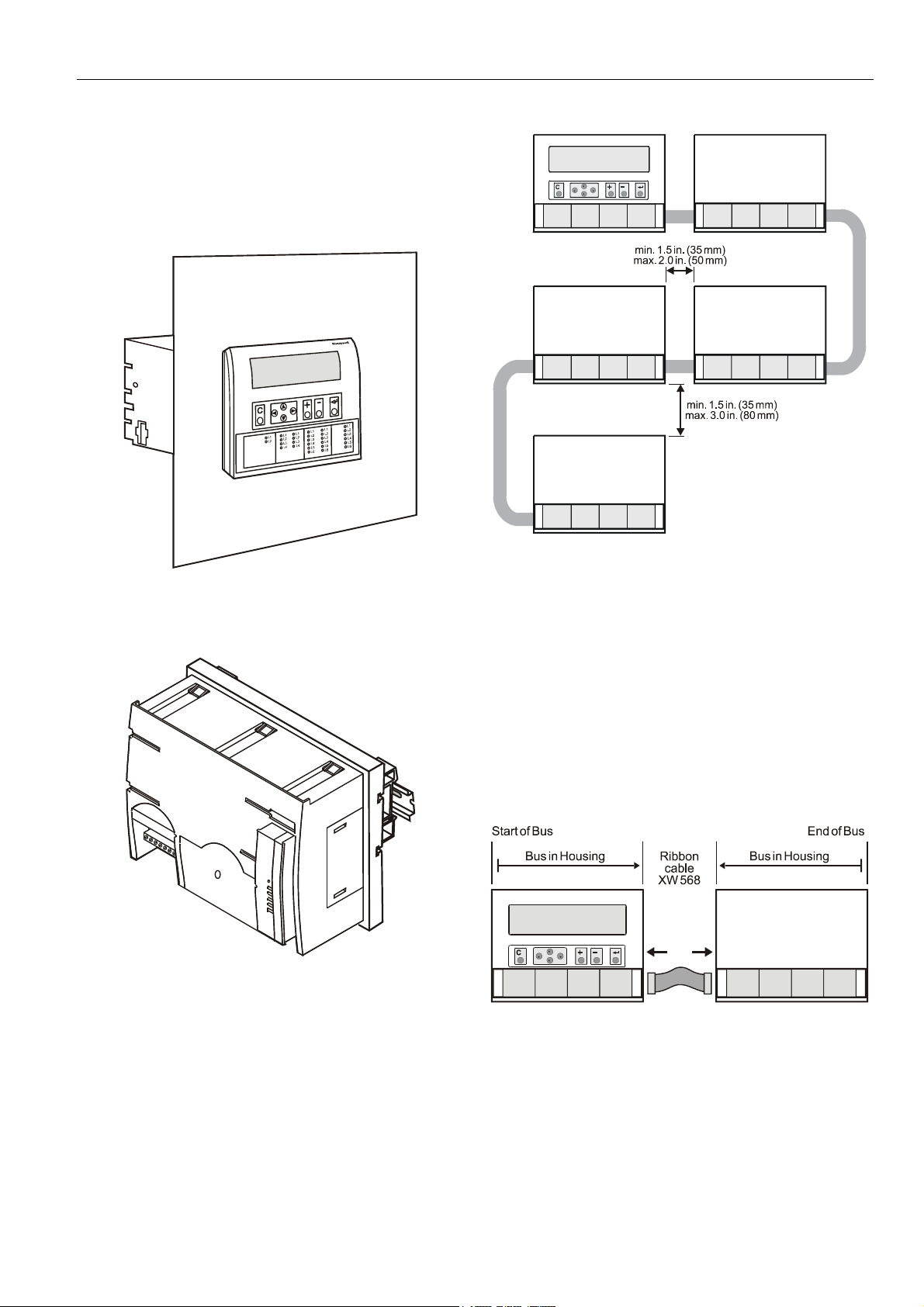

Module Locations (not XCL5010)

Each housing has four plug-in module locations.

3-position

output

XF525A

not in 1st module

housing

Coding the Terminal Block (not XCL5010)

The terminal block is coded with pins to prevent mixing the

module types during commissioning or servicing. Mixing the

modules can damage them.

You can code the terminal block by inserting pins into

designated location holes on the terminal block in the base.

Fig. 7. Inserting the code pin in the terminal block

Fig. 6. Internal module numbering

Table 1 shows the plug-in location to which each module may

be assigned:

EN1R-1047GE51 R0308 6

Table 2 shows the coding pin positions for the individual

module types:

Table 2. Code pin position by module type

module type pin position

CPU XC5010C, XC6010 08

power supply XP502 06

AI XF521A, XF526 07

AO XF522A, XF527 11

DI XF523A 09

DO XF524A, XF529 10

3-position output XF525A 12

NOTE: Distributed I/O modules are coded differently. See

Distributed I/O Product Data (EN0B-0090GE51).

Page 7

EXCEL 500/600 INSTALLATION INSTRUCTIONS

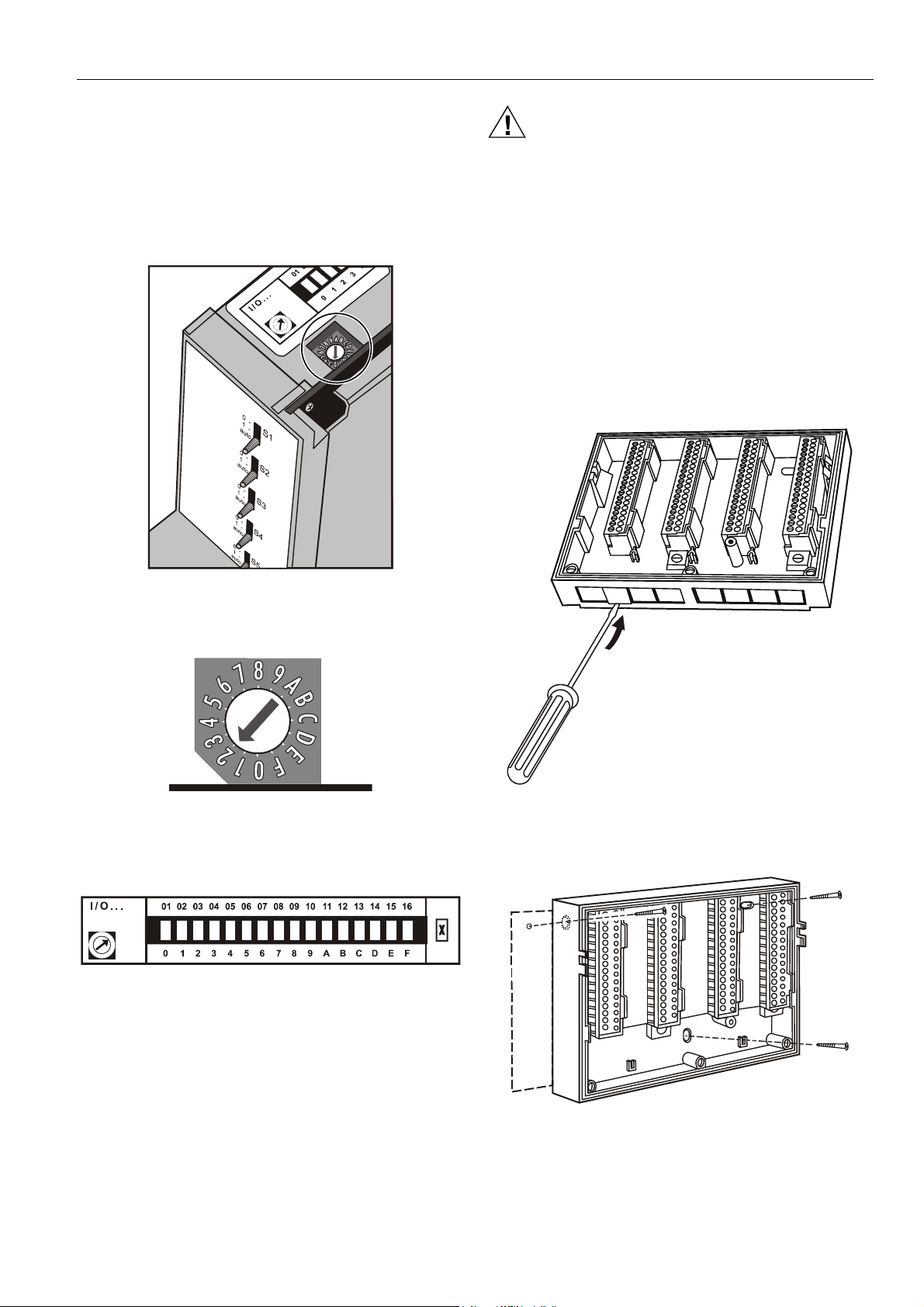

Setting the Module Address (not XCL5010)

In the case of an application prior to CARE 4.0, you can set

the module address using the rotary HEX switches located on

the upper surface of the respective input and output modules.

The rotary HEX switch of Distributed I/O modules is situated

within the housing. The XP502 power supply module and the

XC5010C/XC6010 CPU modules do not need a hardware

address.

Fig. 8. Internal module HEX switch location

CAUTION

Unplugging a module before switching OFF the power

supply could destroy the module. Do not unplug

modules with the power still connected. First switch

S1 on the power supply module to the 0 position.

Installation Inside a Control Panel

Excel 500/600

IMPORTANT

When installing more than one housing, observe the

min. spacing of 1.5 in. (35 mm). Do not exceed the

max. spacing; otherwise, the tailor-made internal bus

cables will be too short.

1. Break off cable entry strip segments.

The 16 I/O modules (max. including Distributed I/O) are

addressed by means of the rotary HEX switch settings 0 to F.

Fig. 9. Close-up of HEX addressing switch

The relationship between the rotary HEX switch and the

module address can be seen on the label located next to the

rotary HEX switch.

Fig. 10. HEX switch label

Care should be taken to ensure that each module gets its

own module address. Addressing the modules in ascending

order 0 through F is recommended for the sake of clarity for

maintenance personnel.

Fig. 11. Cable entry strip segments

2. Install the base.

Fig. 12. Installing the base in the panel

7 EN1R-1047GE51 R0308

Page 8

EXCEL 500/600 INSTALLATION INSTRUCTIONS

3. Code the terminal block (see section "Coding the

Terminal Block (not XCL5010)" on page 6).

4. Make sure that the locking screws are positioned as

shown in Fig. 13.

5. Plug in the enclosure.

Fig. 13. Housing locking screws and latches

6. Shift latches inwards until the housing is released.

7. Set the module addresses (see section "Setting the

Module Address (not XCL5010)" on page 7).

8. Insert the modules.

Fig. 14. Modules and ribbon cable

9. Plug the ribbon cable onto the CPU module.

10. Close the cover.

Extended wiring base (wall-mounting, only; US, only):

As an alternative to the base plate, an extended wiring base

may be used. This is available for the U.S. market, only, and

can be ordered without cover plate (OS No. 14507274-001)

or with cover plate (OS No. 14507274-002).

Fig. 15. Excel 500/600 extended wiring base

Using the extended wiring base the I/O terminals are

accessible at run-time.

XCL5010

1. Attach the DIN rail mounting clips to the housing.

2. Mount the controller on the DIN rail.

Fig. 16. Mounting XCL5010 on DIN rail (a)

EN1R-1047GE51 R0308 8

Page 9

1

2

Fig. 17. Mounting XCL5010 on DIN rail (b)

XDL505 Application Module

EXCEL 500/600 INSTALLATION INSTRUCTIONS

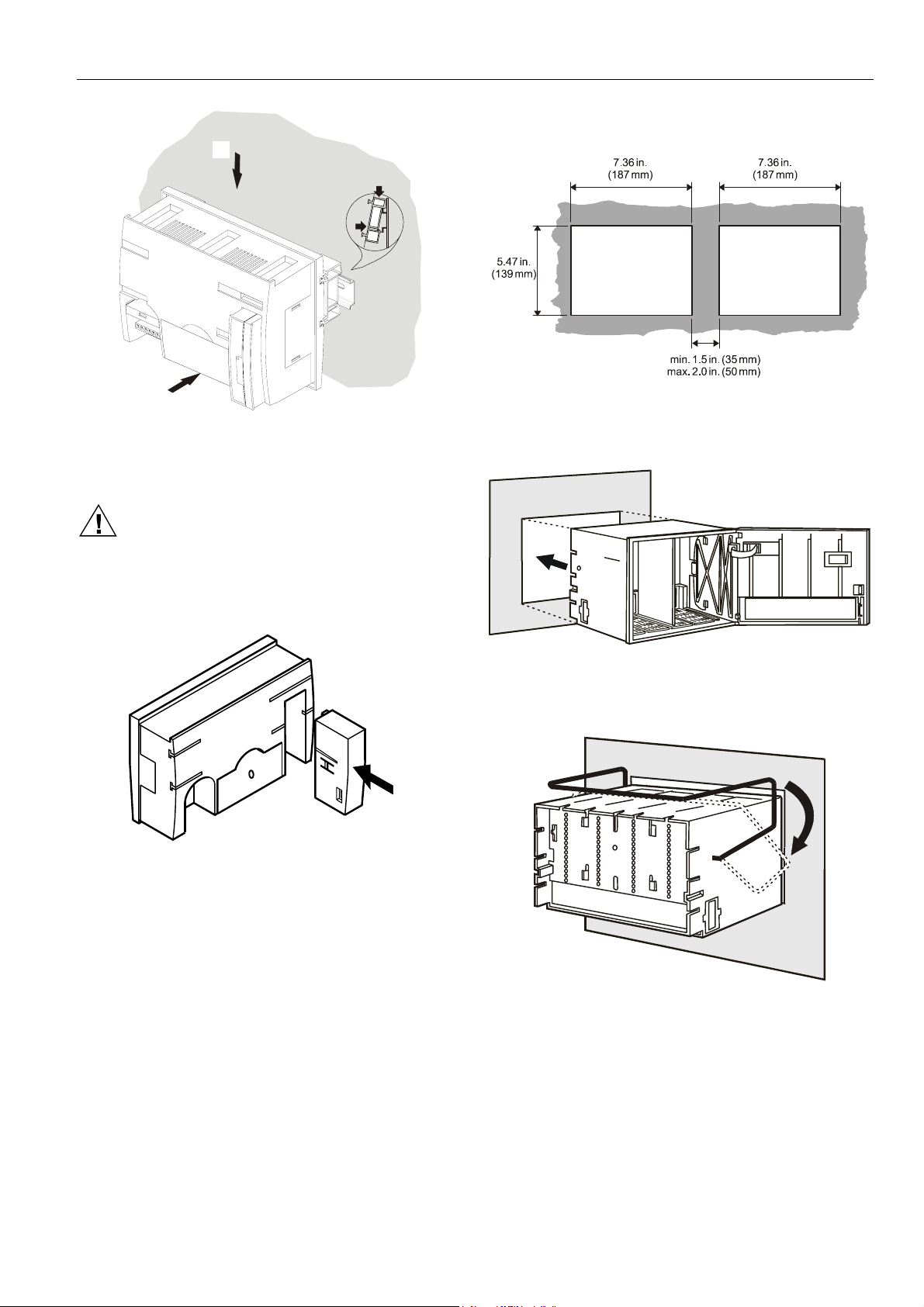

1, Prepare the door in accordance with the following.

dimensions.

Fig. 19. Panel door mounting dimensions

2. Insert the housing.

CAUTION

Always plug in the application module before

connecting the power supply.

Always disconnect the power supply before

unplugging the application module.

0000043a

Fig. 18. Inserting the application module

Plug in the application module until it snaps into the controller

housing

NOTE: If the application module has been replaced or

pulled out and plugged in again, push the reset

button after power on.

Installation through a Control Panel Door

(not XCL5010)

IMPORTANT

When installing more than one housing, observe the

min. spacing of 1.5 in. (35 mm). Do not exceed the

max. spacing; otherwise, the tailor-made internal bus

cables will be too short.

Fig. 20. Inserting the housing in the panel door

3. Insert the retaining clamp.

Fig. 21. Housing retaining clamp

4. Turn retaining clamp to fix housing.

5. Code the terminal block (see page 6).

6. Install the base.

9 EN1R-1047GE51 R0308

Page 10

EXCEL 500/600 INSTALLATION INSTRUCTIONS

A

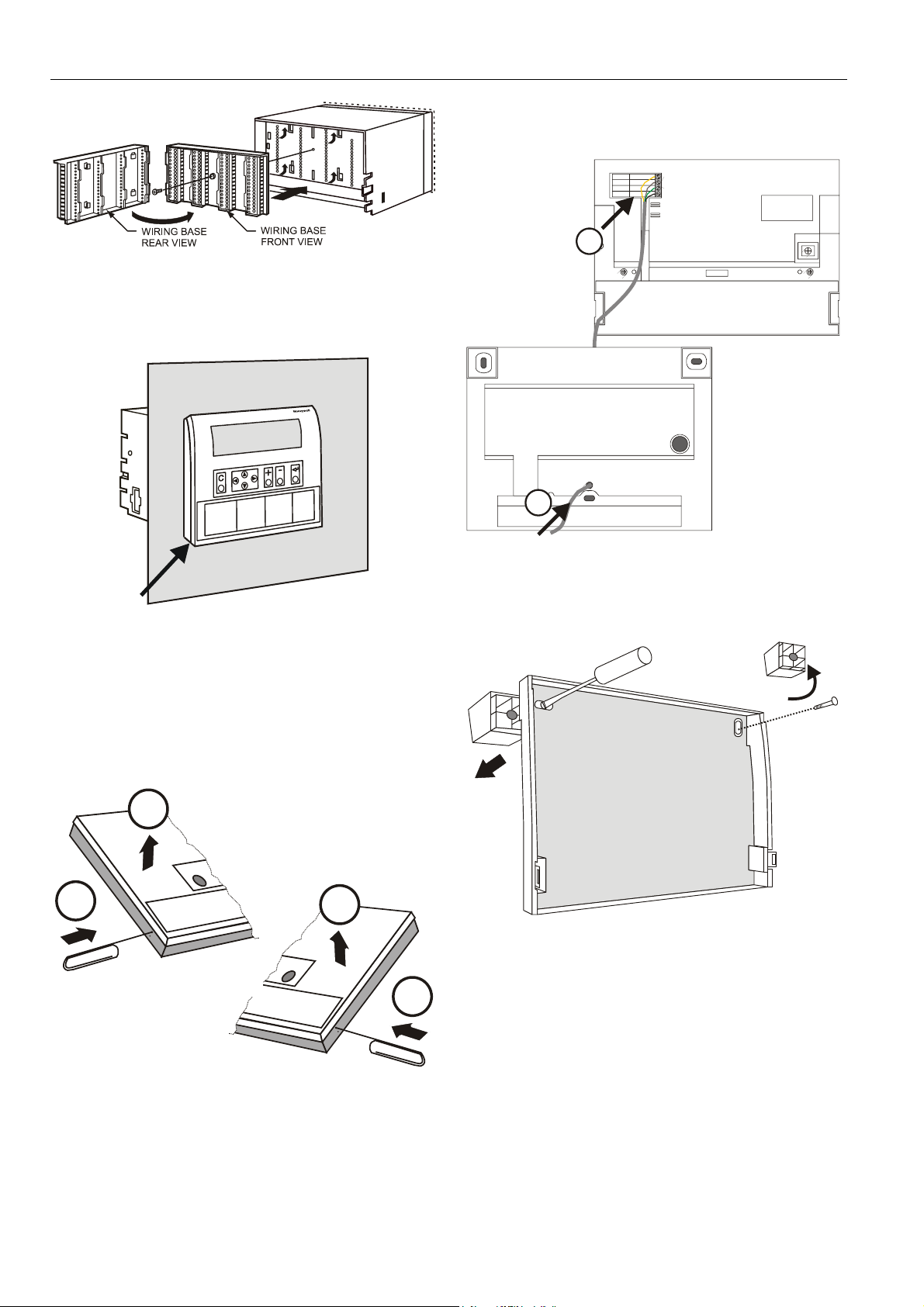

2. Route cable from the CPU module (XC6010, XC5010C,

XCL5010).

TxD(CPU)

YELLOW

BROWN

+VE

RxD(CPU)

GREEN

WHITE

GND

Fig. 22. Installing the wiring base

7. Complete electrical wiring.

8. Lock the cover.

Fig. 23. Locking the MMI cover

External Installation of XI582

1. Remove the front cover from the XI582 by inserting tip

of an awl (or a similar narrow, pointed object) into the

small hole on one side of the operator terminal. When

the latch releases, insert the awl into the small hole on

the other side of operator terminal and pry off the cover.

B

A

Fig. 25. Routing the cable

3. If mounting on a wall, remove feet.

B

A

Fig. 24. Removing the cover

EN1R-1047GE51 R0308 10

B

Fig. 26. Removing feet

4. Attach the housing to the wall.

Page 11

EXCEL 500/600 INSTALLATION INSTRUCTIONS

Fig. 27. Attaching to wall

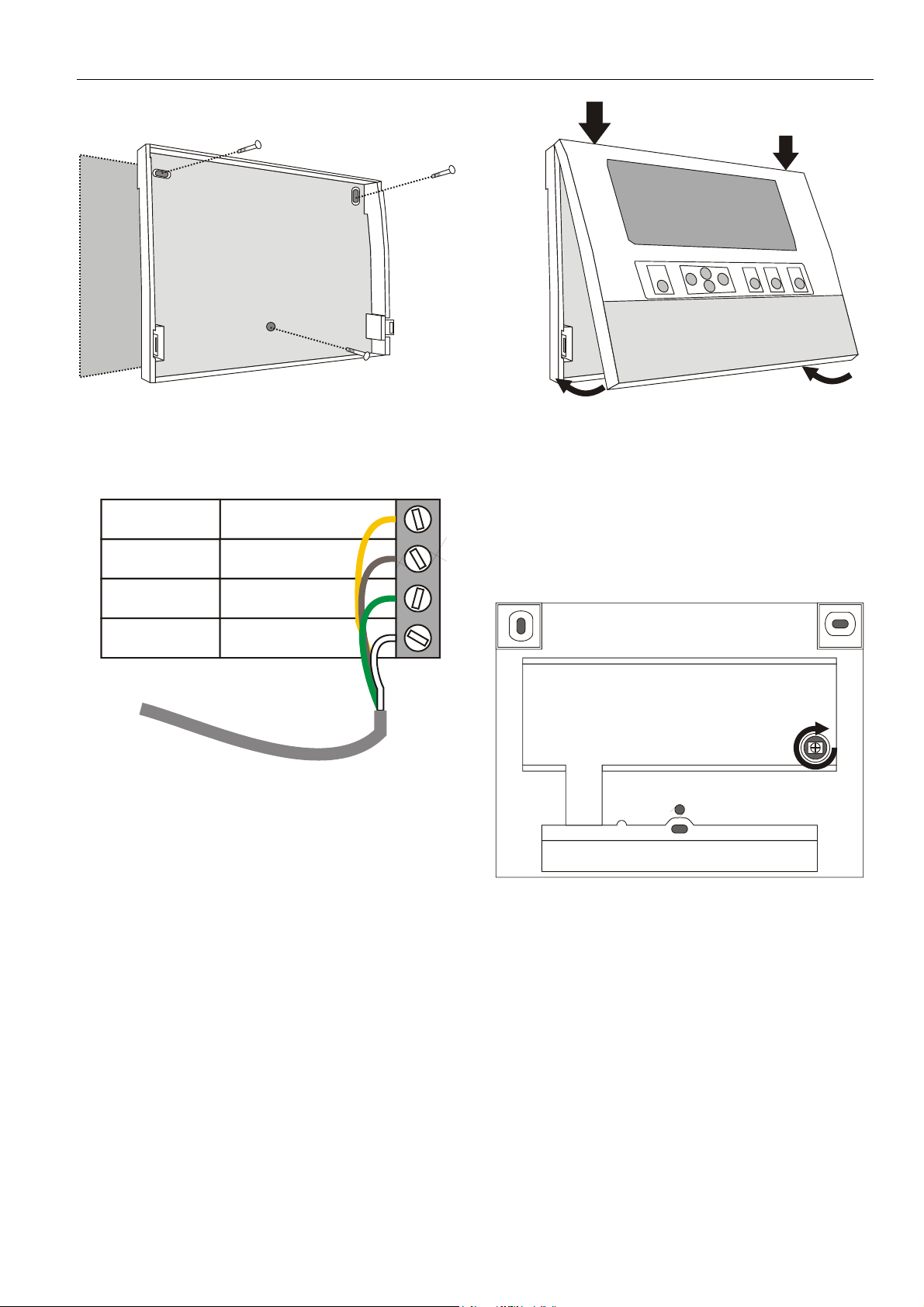

5. Make electrical connections (black/gray wire not used).

YELLOW

BROWN

GREEN

WHITE

Fig. 28. Making electrical connections

6. Reattach the cover.

TxD(CPU)

+VE

RxD(CPU)

GND

Fig. 29. Reattaching cover

Backlight

The contrast of the display can be adjusted by rotating the

corresponding knob accessible through a hole at the rear of

the device (see Fig. 30). Pressing any of the eight operating

keys activates the backlight. If no entries are made for

approx. ten minutes, the backlight turns itself off automatically

until a key is pressed again.

Fig. 30. Contrast potentiometer

Distributed I/O Installation

Please refer to Distributed I/O Product Data sheet (EN0B0090GE51) for more information.

11 EN1R-1047GE51 R0308

Page 12

EXCEL 500/600 INSTALLATION INSTRUCTIONS

Dimensions

Excel 500/600

Fig. 31. Excel 500/600 outside dimensions

EN1R-1047GE51 R0308 12

Page 13

XCL5010

EXCEL 500/600 INSTALLATION INSTRUCTIONS

Fig. 32. XCL5010 dimensions

13 EN1R-1047GE51 R0308

Page 14

EXCEL 500/600 INSTALLATION INSTRUCTIONS

XI582

Fig. 33. XI582 dimensions

Battery Activation during Commissioning

(XC6010, only)

The controller is delivered from the factory with the battery in

the CPU module electrically isolated from the internal circuitry

by a safety tag to prevent the battery from discharging in

transit.

1. Unscrew the CPU module cover with a screwdriver.

Fig. 34. Accessing the battery compartment

EN1R-1047GE51 R0308 14

Page 15

EXCEL 500/600 INSTALLATION INSTRUCTIONS

NOTE: In the event that your fingers touch the battery

contacts, please clean the contacts with cleaning

agent.

1. Unscrew the CPU module cover with a screwdriver as

shown in the previous section.

2. Release the latch holding the battery in its compartment

(See Fig. 36).

3. Remove the old battery.

4. Insert the new battery with the positive contact pointing

upwards.

Battery type:

Lithium battery 3 V, 1000 mAh, e.g. VARTA lithium battery

Fig. 35. Removing the faceplate

CR1/2 AA – 3 V, 1000 mAh

NOTE: The XC5010C and XCL5010 CPU modules do not

contain a battery. RAM is buffered for 3 days by a

capacitor.

Dismantling the Control Panel Unit

Before dismantling the controller, the low voltage switch S1 of

the power supply module must be switched OFF (position 0).

To dismantle the control panel unit, reverse the steps of the

installation procedure (see page 7). To release the locking

screws in order to remove the wiring base, turn them clockwise as shown in Fig. 37.

Fig. 36. Battery compartment

2. Remove the safety tag.

3. Install the cover.

Replacing the Battery

IMPORTANT

Batteries must not be disposed of as household

waste. The law requires that you as the consumer

return the waste batteries. Dispose of the battery

according to legal regulations

During normal operation, the battery is periodically tested

under load. If the battery voltage falls below a threshold of

2.45 V during operation or under load, the CPU module

generates an error message which is displayed on the MMI

as a system alarm. The battery must be replaced as soon as

possible after the system alarm.

IMPORTANT

The line power supply must not be interrupted while

replacing the battery; otherwise, all data held in RAM

is lost.

Fig. 37. Releasing housing locking screws

Dismantling the Control Panel Door Unit

Before dismantling the system, disconnect the power supply.

To dismantle the control panel unit, reverse the steps of the

installation procedure (see page 9).

Dismantling the Housing Cover

1. Release the metal retaining clamp.

15 EN1R-1047GE51 R0308

Page 16

EXCEL 500/600 INSTALLATION INSTRUCTIONS

A

1.

Dismantle the controller housing as depicted.

2.

Pull the lower part of the housing off the control panel.

3.

Lift the housing from DIN rail.

Dismantling the XI582 Operator Interface

Remove the front cover from the XI582 by inserting tip of an

awl (or a similar narrow, pointed object) into the small hole on

one side of the operator terminal. When the latch releases,

insert the awl into the small hole on the other side of operator

terminal and pry off the cover.

B

Fig. 38. Housing cover retaining clamp

2. Pull off the cover.

Dismantling the XCL5010 CPU

Before dismantling the system, disconnect the power supply

(e.g. by removing the terminal block or by an additional 3

party switch which should be installed onto the DIN rail close

to the controller; see also warnings and notes in section

"Electrical Connections" on page 16).

rd

-

CAUTION

Always plug in the application module before

connecting the power supply.

Always disconnect the power supply before

unplugging the application module.

2

A

Fig. 40. Opening the XI582 Operator Interface unit

B

ELECTRICAL CONNECTIONS

When connecting the controller, both VDE, National Electric

Code NEC (or equivalent) and any local regulations concerning grounding and zero voltage must be observed.

Electrical work should be carried out by a qualified electrician.

Under no circumstances should spare controller terminals be

used as wiring support points. Doing so could damage the

modules.

The electrical connections must be made at the terminal

blocks. Maximum torque for fastening the wiring terminal

screws is 0.5 Nm (4.5 lb-in). The corresponding connection

diagrams are on the individual modules.

2

1

0000079b

1

Fig. 39. Removing XCL5010 from DIN rail

EN1R-1047GE51 R0308 16

WARNING

Switch power OFF before making connections to or

removing connections from terminals to avoid

electrical shock or equipment damage.

Page 17

EXCEL 500/600 INSTALLATION INSTRUCTIONS

IMPORTANT (FOR EUROPE, ONLY)

To comply with CE requirements, devices with a

voltage in the range of 50...1000 Vac or

75...1500 Vdc which are not provided with a supply

cord and a plug or with other means for disconnection from the supply having a contact separation

of at least 3 mm in all poles, must have the means

for disconnection incorporated in the fixed wiring.

Cable Routing

The min. distance to power mains cables is 0.4 in. (10 mm)

for shielded cable and 4 in. (10 cm) for unshielded cable.

All low-voltage signal and output cables should be regarded

as communication circuits in accordance with VDE 0100 and

VDE 0800 (or NEC or other equivalent), and should therefore

be routed separately from mains cables.

Joining sensor cables should be avoided.

Shielding I/O Module, Power Supply Cables

Shielding input and output module and power supply cables

is not necessary if the general guidelines for cable routing are

observed. If, in certain cases, the routing guidelines cannot

be observed, then shielded cable must be used.

The shield must not be terminated at a controller; instead, to

avoid ground loops, the shield must be grounded (at only one

end) at the control panel.

To prevent ground loops, shielding of input/output cables

leading to peripheral devices must be grounded only at the

control panel end.

Shielding of Data-Transmitting Cables

Connect the shield of the system bus (C-Bus) to system

ground on both ends. Each end of the shield on the system

bus should be connected to the system ground terminal of the

respective CPU module. Do not connect it to the control panel

earth or any other earth ground points.

NOTE:

The LONW

CPU side.

To connect remote operator interface units, ready-made

cables are available (XW565; XW582, XW583, etc.) with the

shield already connected to the CPU module plug end.

ORKS

bus must not be grounded on the

Grounding (XC5010C / XC6010, only)

The controller should be grounded using as short a cable as

possible (min. 16 AWG [1.5 mm²]) between the control panel

and terminal 3 of the power supply module.

System Ground

WARNING

High voltage

Risk of electrical shock or equipment damage.

The controller's system ground must have no

connection with the control cabinet ground!

NOTE:

A document providing additional information on

system grounding (if required) is available via the

Honeywell Technical Assistance Center (TAC) or, for

Honeywell employees, on the Docu Server under:

http://web.ge51.honeywell.de/dep/mc/TAC_Tips.

RFI Suppression

Honeywell actuators are RFI (Radio Frequency Interference)

suppressed as standard in accordance with VDE 0871/B and

VDE 0875/N.

XC5010C/XC6010 Cable Lengths and Sizes

Table 3. Cable sizing (use only copper cables)

cross-sectional area

type of signal

24 Vac power

supply

low voltage

signals*

*0…10 V sensors, totalizers, digital inputs, 0 to 10 V signals for

A cable length of 1300 ft (400 m) with a cross sectional area

of 0.75 mm

0…10 Vdc signal cable.

For cable lengths exceeding 1300 ft (400 m) between the

transformer and the field device, see NOTE in section

"System Ground".

actuators, etc.

PRIMARY

VOLTAGE

24 Vac

24 Vac

TRANSFORMER

Fig. 41. Power for XC5010C/XC6010 (XP502 power supply

2

(18 AWG) is permissible for a two-core,

≤

300 ft

(100 m)

16 AWG

(1.5 mm

GND

GND

module) with 24 V actuator

2

)

14 – 18 AWG (2.5 – 0.75 mm2)

≤

550 ft

(170 m)

14 AWG

(2.5 mm2)

max. 400 m

min. 0.75 mm

Y (0...10 Vdc)

GND

24 Vac

2

≤

1300 ft

(400 m)

-

Lightning Protection

Please contact your local Honeywell representative for

information on lightning protection.

17 EN1R-1047GE51 R0308

Page 18

EXCEL 500/600 INSTALLATION INSTRUCTIONS

Summary of Internal Modules

Table 4. Summary of Excel 500/600 internal modules

module name inputs outputs manual override switches LED display

ONWORKS

L

C-Bus transmit

Reset button

CPU module XC5010C

CPU module XC6010 Reset button

power supply module XP502 1 0 (1 x)

analog input module XF521A 8

analog input module XF526 8 CPU active

analog output module XF522A 8

analog output module XF527 8 8 x output intensity

LONW

ORKS

service button

RS232 front-rear switch

0 (5 x)

1

Auto

C-Bus receive

normal

system error

RS232 transmit

RS232 receive

ground loop error

normal

system error

RS232 transmit

RS232 receive

C-Bus transmit

C-Bus receive

power supply

watchdog

ext. battery operation

8 x output intensity

Service LED

digital input module XF523A 12 12 x status, invertible

digital output module XF524A

digital output module XF529

three-position output module XF525A 3 three-position

NOTE:

With XC6010 CPU only, there are submodules for system bus combination, XD505A (10 KBit) / XD508 (1 MBit).

5 changeover

1 NO contact

5 changeover

1 NO contact

0 (5 x)

1

Auto

6 x status

+ (3 x)

0

Auto

6 x status

3 x open close

EN1R-1047GE51 R0308 18

Page 19

EXCEL 500/600 INSTALLATION INSTRUCTIONS

Line Power Supply

WARNING

A separate CRT 6 or 1450 series (U.S.) transformer must be

used for each of the EXCEL 500/600 controller's 24 V

supplies.

No additional loads may be connected!

Each additional XL500/600 controller requires its own

transformer.

An additional transformer, appropriate to the power require-

ments, should be used to power input/output peripherals (e.g.

actuators). See also Fig. 41.

PRIMARY VOLTAGE SECONDARY VOLTAGE

TRANSFORMER (CRT)

Fig. 42. Excel 500/600 power supply (CRT)

XC6010 Computer Module

CAUTION

Do not unplug the CPU module with the power still

connected, since this could destroy the module. First,

switch S1 on the power supply module to the 0

position.

If one of the C-bus submodules XD505A or XD508 is installed

on the XC6010, follow Fig. 43.

To avoid interference, the cable between the transformer and

the power supply module should be kept as short as possible

(max. 6 ft [2 m]). The transformer should therefore be

positioned close to the power supply module.

Fuse the transformer primary with its own fast-acting 10 A

back-up fuse (or H 16 or L 16 miniature circuit breaker).

The primary coil of the CRT 6 contains a 0.8 A / 250 V quickblow fuse.

Table 5 gives an overview of the transformers of the 1450

series (U.S.):

Table 5. 1450 series transformers data

part #

1450 7287

-001 120 Vac 24 Vac, 50 VA

-002 120 Vac

-003 120 Vac

-004 240/220 Vac 24 Vac, 50 VA

-005 240/220 Vac

-006 240/220 Vac

The 1450 series includes built-in fuses, line transient /surge

protection and AC convenience outlet, it meets NEC class 2

requirements.

primary side

2 x 24 Vac, 40 VA, and 100 VA

from separate transformer

24 Vac, 100 VA, and 24 Vdc;

600 mA

2 x 24 Vac, 40 VA, and 100 VA

from separate transformer

24 Vac, 100 VA, and 24 Vdc;

600 mA

secondary side

Fig. 43. Excel 600 CPU module C-Bus connections

The system bus is connected to terminal 16 (C+) and terminal

17 (C-). See also section "C-Bus Termination (XC6010)" on

page 33.

Fig. 44. Excel 600 CPU modem connection

The XC6010 has two EPROMs for the operating system and

one flash EPROM for the application software. Their locations

are shown in Fig. 45.

19 EN1R-1047GE51 R0308

Page 20

EXCEL 500/600 INSTALLATION INSTRUCTIONS

Fig. 45. Excel 600 EPROM locations

Communication between several Excel 600 controllers is

possible only if the system bus submodule is plugged into

every CPU module printed circuit board. This submodule

must be installed when joining several controllers or when

monitoring via a central. XD505A or XD508 can be used for

local bus communication. A stand-alone controller can be

operated without a submodule.

Fig. 46. Excel 600 submodule mounting location

For information pertaining to system bus baud rates and

termination switch settings, see section "C-Bus Termination

(XC6010)" on page 33.

XC5010C CPU Module

Fig. 47. Excel 500 CPU module pin-out

The system bus is connected to terminal 16 (C+) and terminal

17 (C-). The field bus (L

terminals 12 and 13. The L

there is no + or – pin. See section "C

LonWorks Bus Wiring" (page 31) and "System Bus (C-Bus)"

(page 32) for more information.

NOTE:

The cable for the LONW

shielding.

The serial port connections at the back of the module can be

used to connect an XI582 MMI or, for CPUs with firmware

version V2.1.0 or newer, a modem or ISDN terminal adapter.

See section "Remote Communications" on page 37 for more

information.

Each XC5010C contains an application submodule that is

different from the XD505A/XD508 submodule. The submodule for the XC5010C contains the C-Bus, L

as well as part of the RAM and flash EPROMs. For information on C-Bus baud rates and the bus termination switch,

see section "C-Bus Termination (XC5010C)" on page 33.

ONWORKS

bus) is connected to

ONWORKS

bus is non-polarized, i.e.

OMMUNICATIONS

ORKS

bus does not require

ONWORKS

bus,

CAUTION

Do not unplug the CPU module with the power still

connected, since this could destroy the module. First,

switch S1 on the power supply module to the 0

position.

The XC5010C CPU module contains both the system bus

and the field bus. Fig. 47 shows the pin-out of the module.

EN1R-1047GE51 R0308 20

Page 21

EXCEL 500/600 INSTALLATION INSTRUCTIONS

RESET BUTTON

LA1

LA2

LA3

LA4

LA5

XC 5010C

RS232

LA1: Wink LED

LA2: C-Bus transmit

FRONT

LA3: C-Bus receive

REAR

LA4: Not used

LA5: Not used

L1

L1: Normal

L2

L2: System error

L3

L3: RS232 transmit

L4: RS232 receive

L4

L5: Not used

L5

L6: Ground loop

L6

Fig. 48. Excel 500 CPU module front panel

The operator interface on the front of the CPU modules

allows connection of the Xl581/XI582 Operator Interface or

the XL-Online PC MMI. As an option, the XI582 can be

connected at the rear of the XC5010C. When connecting at

the rear, the switch on the front panel of the XC5010C must

be set to "Rear".

XP502 Power Supply Module

Fig. 49 shows the pin-out of the XP502 Power Supply

module.

Fig. 49. XP502 Power supply module and watchdog

circuit

To monitor the line power supply, the watchdog alarm must

be provided with its own power or battery supply.

Controller in operation:

Watchdog relay terminals 17 and 18

connected.

Controller non-operational:

Watchdog relay terminals 16

and 17 connected.

RIN-APU24 Uninterruptable Power Supply

The RIN-APU24 Uninterruptable Power Supply can be wired

to an XP502 in order to power XC5010C/XC6010 controllers.

In this context, a distinction must be made between the

following three different possible cases:

• wiring of the RIN-APU24 to an XP502 powering

XC5010C/XC6010 controllers equipped with internal

modules, but not connected to Distributed I/O's;

• wiring of the RIN-APU24 to an XP502 powering

XC5010C controllers connected to Distributed I/O's, but

not equipped with internal modules; and

• wiring of the RIN-APU24 to an XP502 powering

XC5010C controllers equipped with internal modules and

connected with Distributed I/O's.

Further, in the case of the XCL5010, the RIN-APU24 can

provide power directly (i.e. without recourse to an XP502). In

this case, no distinction need be made between controllers

with (or without) internal modules and/or connected (or not

connected) to Distributed I/O's.

Table 6. Power consumption of Excel 500 controllers

devices powered

XP502, XC5010C, XI581

(backlight ON)

supply voltage

24 Vdc 28.8 Vdc

170 mA 155 mA

XP502, XC5010C 140 mA 130 mA

See also RIN-APU24 Uninterruptable Power Supply –

Mounting Instructions (MU1B-0258GE51) for detailed wiring

diagrams covering all of the aforementioned cases.

XF521A Analog Input Module

Technical Specifications

Number:

eight inputs (AI1 – AI8)

Input:

0...10 Vdc (low-input impedance, 25 kΩ to 10 V /

200 kΩ to GND);

0...20 mA (via external 500-Ω resistor);

4...20 mA (via external 500-Ω resistor);

NTC 20 kΩ(-50...+150 °C);

PT1000 (-50...+150 °C)

Protection:

up to 40 Vdc / 24 Vac

Resolution:

12-bit resolution

Accuracy:

±75 mV or 0.75% (0...10 V)

21 EN1R-1047GE51 R0308

Page 22

EXCEL 500/600 INSTALLATION INSTRUCTIONS

Table 7. Accuracy of analog input sensors

measurement error (without

range

-58...-4 °F (-50...-20 °C) ≤ 1.2 K ≤ 5.0 K

-4...+32 °F (-20...0 °C) ≤ 0.7 K ≤ 1.0 K

+32...86 °F (0...30 °C) ≤ 0.5 K ≤ 0.3 K

86...158 °F (30...70 °C) ≤ 0.7 K ≤ 0.5 K

158...212 °F (70...100 °C) ≤ 1.2 K ≤ 1.0 K

212...266 °F (100...130 °C) ≤ 1.2 K ≤ 3.0 K

266...302 °F (130...150 °C) ≤ 1.2 K ≤ 5.5 K

With current sensors, a terminating resistor of R1 = 499 Ω ±

0.25% must be connected.

Terminal 18 is an auxiliary output voltage (+10 Vdc, I

5 mA) available for various sensor circuits.

sensor tolerance)

PT1000 NTC 20K

=

max

Fig. 51. XF521A connection examples

Fig. 52 shows connections to a TF26.

Terminals 1, 3: temperature adjustment

Terminals 5, 3: room sensor

Terminals 6, 3: LED

Fig. 50. XF521A Analog Input module connections

Fig. 51 shows several connection examples for various

sensors: WS21 Wind Sensor; SAF 25 Solar Sensor; and VMP

Feedback Potentiometer.

EN1R-1047GE51 R0308 22

Fig. 52. XF521A and TF26 example

XF526 Analog Input Module

Technical Specifications

Number:

eight inputs (AI1 – AI8)

Input:

0...10 Vdc (low-input impedance, 25 kΩ to 10 V /

200 kΩ to GND);

0...20 mA (via external 500-Ω resistor);

4...20 mA (via external 500-Ω resistor);

NTC 20 kΩ (-50...+150 °C);

Page 23

EXCEL 500/600 INSTALLATION INSTRUCTIONS

PT1000 (-50...+150 °C)

PT1000 (0...+400 °C)

PT100 (-50...+150 °C)

PT3000 (-50...+150 °C)

Balco 500 (-50...+150 °C)

Protection:

up to 40 Vdc / 24 Vac

Resolution:

12-bit resolution

Accuracy:

±75 mV or 0.75% (0...10 V)

See also Table 7.

With current sensors, a terminating resistor of R1 = 499 Ω

±0.25% must be connected.

Terminal 18 is an auxiliary output voltage (+10 Vdc,

I

= 5 mA) available for various sensor circuits.

max

XF523A Digital Input Module

The digital input module can process DC or AC voltage

signals. The module has 12 digital inputs. When the input

voltage reaches 5 V, the digital signal is set to a status of "1".

With a hysteresis of 2.5 V, the digital input signal must fall

below 2.5 V before a digital status of "0" is reported.

Fig. 54. Digital input hysteresis

The LED functionality of each digital input channel can be

altered via 12 internal DIP switches. In the ON position

(default), the LED will illuminate when energized (normallyopen contacts). In the OFF position, the LED will illuminate

when de-energized (normally-closed contacts).

Max. signal voltage from non-Honeywell voltage sources:

DC Voltage: V

AC Voltage: V

Input resistance:

Ri = 15 kΩ

= 40 V

max

= 28 V / ≥ 50 Hz

max

Fig. 53. XF526 Analog Input module connections

Fig. 55. XF523A connection examples

23 EN1R-1047GE51 R0308

Page 24

EXCEL 500/600 INSTALLATION INSTRUCTIONS

If the inputs are used as totalizers, Table 8 applies.

Table 8. Totalizer inputs specifications

input frequency pulse duration pulse internal chatter time

1, 2 max. 15 Hz min. 20 ms min. 33 ms max. 5 ms

3 to 12 max. 0.4 Hz min. 1.25 s min. 1.25 s max. 50 ms

The inputs shown in row one (Input 1 to 2) may be used as fast totalizers. In this case, the input signal characteristics of row one

are valid. If they are not used as fast totalizers, the values of row two (Inputs 3 to 12) apply to them as well.

XF522A and XF527 Analog Output Modules

Technical Specifications

Number:

eight analog outputs

Voltage rating:

0…10 V, max. 11 V

Current rating:

max. 1 mA

Resolution:

8 bit

Accuracy:

±150 mV or 1.5% deviation from output voltage

Manual override switches:

XF522A 5 manual override switches (AO1 to AO5)

XF527 No manual override switches

XF524A and XF529 Digital Output Modules

Technical Specifications

Number:

six digital outputs

Voltage rating:

max. 240 Vac per contact and per module

Current rating:

max. 4 A at 240 Vac; max. 12 A per module

max. 4 A at up to 35 Vdc

max. 3 A at up to 40 Vdc

max. 2 A at up to 50 Vdc

max. 1 A at up to 70 Vdc

max. 0.6 A at up to 100 Vdc

max. 12 A per module

Relay contacts:

K1 to K5: changeover contact (voltage-free)

K6: Normally-open contact (voltage-free)

Fig. 56. XF522A and XF527 Analog Output modules

NOTE:

NOTE:

EN1R-1047GE51 R0308 24

The max. output current of 1 mA must not be

exceeded.

Both modules are fully pin-compatible.

Fig. 57. XF524A and XF529 Digital Output module

NOTE:

NOTE:

Beginning with V3.04.00 firmware, the online point attribute

normally-open/normally-closed (NO/NC) defines the relation

The max. voltage for U.S. is 24 V.

Both modules are fully pin-compatible.

Page 25

EXCEL 500/600 INSTALLATION INSTRUCTIONS

,

between the physical input signal and its logical status. See

Table 9.

Table 9. NO/NC attribute and output characteristic

relay ON/OFF NO/NC attribute logical status

ON NO 1

OFF NO 0

ON NC 0

OFF NC 1

XF525A Three-Position Output Module

Technical Specifications

Voltage rating:

max.240 Vac or 28 Vdc

Current rating:

max. 4 A at 240 Vac; max. 12 A per module

max. 4 A at up to 35 Vdc

max. 3 A at up to 40 Vdc

max. 2 A at up to 50 Vdc

max. 1 A at up to 70 Vdc

max. 0.6 A at up to 100 Vdc

max. 12 A per module

XCL5010

NOTE:

The XCL5010 has Pollution Degree 2, making it

suitable for use in residential controls, commercial

controls, in a clean environment, or non-safety

controls for installation on or in appliances.

The XCL5010 housing comprises a removable screw terminal

block for direct power supply wiring. For proper installation of

the terminal block, follow these instructions:

1.

Read the complete chapter "Installation" carefully.

2.

Follow the instructions from the chapter Screw Terminal

Block Installation Procedure on page 27.

The screw terminal block is attached directly to the controller

housing.

Fig. 59. XCL5010 terminal block location

Fig. 58. XF525A Three-position output module

An L 16 miniature circuit breaker or G 10 A quick blow fuse

should be used to protect the 240 Vac mains supply.

NOTE:

The max. voltage for the U.S. is 24 V.

Serial Port

COMMUNICATION

MODULE

C-BUS

CONNECTOR

LON-BUS

CONNECTOR

EXCEL 500XCL5010

HOUSING

SERIAL PORT

FOR EXTERNAL MMI

MODEM, OR ISDN

TERMINAL ADAPTER

Fig. 60. Serial port

The serial port has a 9-pin sub-D connector and has a default

communication speed of 9.6 Kbaud.

Comm_Prt

25 EN1R-1047GE51 R0308

Page 26

EXCEL 500/600 INSTALLATION INSTRUCTIONS

Table 10. Signals of serial port

signal type controller output controller input

signal ground

transmit x

PRIMARY

VOLTAGE

receive x

carrier detect x

clear to send x

data terminal

ready

5 V x

x

Fig. 62. Power for XCL5010 with 24 V actuator (single

MMI Connection

For direct communication the external operator interface

XI582 and the XL-Online PC MMI can be connected to the

serial port.

Power Supply

PRIMARY

The XCL5010 is powered by an external transformer.

IMPORTANT

Only the terminals 1 and 2 of the terminal block may

be used for power supply. Do not wire any of the

terminals 3 to 14.

VOLTAGE

Fig. 63. Power for XCL5010 with 24 V actuator (separate

GND

24 Vac

TRANSFORMER

GND

24 Vac

TRANSFORMER

transformer)

transformer)

max. 170 m

min. 0.75 mm

Y (0...10 Vdc)

GND

24 Vac

max. 400 m

min. 0.75 mm

Y (0...10 Vdc)

GND

24 Vac

GND

TRANSFORMER

2

2

PRIMARY

VOLTAGE

Fig. 61. XCL5010 power terminals location

Terminal 2 is protected by a 4 A quick-acting fuse.

Transformer requirements for one XCL5010:

Voltage: 21…30 Vdc or 24 Vac ± 20%

Current: 5 VA

The transformer, already installed in the cabinet, can be used

to supply several controllers, communication devices, or peripherals like actuators, etc. if the transformer provides

sufficient power.

Use quick-acting backup fuse 10 A (or automatic H16 or L16)

to protect transformer primary side. On the primary side of the

CRT 2, there is a fusible output of type M 0.315 A (T) 250 V

for the purpose of fine fusing.

NOTE:

When selecting the appropriate transformer, con-

sider the number of Distributed I/O modules (see

worst-case power consumption information below) to

be used as well as the power requirements of all

active sensors and actuators connected to the

transformer.

CRT-Series

Table 11. Overview of CRT Series AC/DC current

transformer max. AC current max. DC current

CRT 2 2 A 0.5 A = 500 mA

CRT 6 6 A 1.3 A = 1300 mA

CRT 12 12 A 2.5 A = 2500 mA

EN1R-1047GE51 R0308

26

Page 27

Fig. 64. AC/DC current graphs

1450 Series

All transformers of the 1450 series are designed for 50/60 Hz

AC and have insulated accessory outputs. The transformers

include built-in fuses, line transient/surge protection and AC

convenience outlets and meet NEC class 2 requirements.

Table 12. 1450 Series transformers

part #

1450 7287

-001 120 Vac 24 Vac, 50 VA

-002 120 Vac

-003 120 Vac

-004 240/220 Vac 24 Vac, 50 VA

-005 240/220 Vac

-006 240/220 Vac

Standard Transformers

Standard commercially available transformers must fulfill the

specifications stated in Table 13.

primary side secondary side

2 x 24 Vac, 40 VA and 100 VA

from separate transformer

24 Vac, 100 VA and 24 Vdc

600 mA

2 x 24 Vac, 40 VA and 100 VA

from separate transformer

24 Vac, 100 VA and 24 Vdc

600 mA

EXCEL 500/600 INSTALLATION INSTRUCTIONS

2.

Make sure that the power supply of the cabinet is

disconnected and the application module is plugged in

the housing.

IMPORTANT

3. If the distance between the controller and an actuator or

5. Make sure that the application module is attached to

IMPORTANT

When installing a separate external transformer, do

not connect the cabinet ground to the controller

system ground.

sensor with 24 Vac supply is greater than 550 ft

(170 m):

a) Choose a transformer from the transformers

listed in section "Power Supply" on page 26.

b) Connect the chosen transformer directly to the

actuator or sensor.

4.

Select one of the transformers of the CRT-series or

1450 series from the tables on the previous page or

take a commercially available standard transformer

fulfilling the requirements listed in Table 13.

the controller housing.

The transformer feeding the Excel 500 Controller

must be in the same cabinet. For the selection of the

transformer, the max. DC current must be

considered if field devices with DC load are used.

The secondary side of the transformer must not be

connected to earth ground.

Table 13. Requirements for standard transformers

output voltage impedance AC current

24.5 Vac to 25.5 Vac

24.5 Vac to 25.5 Vac

24.5 Vac to 25.5 Vac

≤ 1.15 Ω

≤ 0.40 Ω

≤ 0.17 Ω

max. 2 A

max. 6 A

max. 12 A

Screw Terminal Block Installation Procedure

WARNING

High Voltage

Risk of death or electrical shock.

— Do not connect line power supply directly to the

terminals.

— Insulate devices with 120 Vac / 230 Vac by a

transformer.

1.

Make sure that the power supply of the cabinet is

disconnected.

Fig. 65. Connecting the power supply

6.

Connect the 24 Vac (-) on the secondary side of the

transformer to terminal 1 on the Screw Terminal Block.

7.

Connect the 24 Vac on the secondary side of the

transformer to terminal 2 on Screw Terminal Block.

27 EN1R-1047GE51 R0308

Page 28

EXCEL 500/600 INSTALLATION INSTRUCTIONS

Fig. 66. Connecting to a screw terminal

IMPORTANT

If there already are additional transformers, for

example supplying actuators or active sensors,

connect the 24 Vac (-) (secondary side) of the

transformers together.

8.

Attach the terminal blocks to the housing as shown in

Fig. 67.

Fig. 67. Attaching screw terminal block

Table 14. Accuracy of analog input sensors

measurement error

range

(without sensor tolerance)

Pt1000 NTC (20k ohms)

-58 to –4 °F (-50 to –20 °C)

-4 to 32 °F (-20 to 0 °C)

32 to 86 °F (0 to 30 °C)

86 to 158 °F (30 to 70 °C)

158 to 212 °F (70 to 100 °C)

≤

1.2 K

≤

0.7 K

≤

0.5 K

≤

0.7 K

≤

1.2 K

212 to 266 °F (100 to 130 °C) ≤ 1.2 K

266 to 302 °F (130 to 150 °C) ≤ 1.2 K

≤

5.0 K

≤

1.0 K

≤

0.3 K

≤

0.5 K

≤

1.0 K

≤

3.0 K

≤

5.5 K

EN1R-1047GE51 R0308

28

Page 29

Pull-Up Resistor Handling

EXCEL 500/600 INSTALLATION INSTRUCTIONS

10 V

Case 1 Case 2 Case 3

24.9 k

Ω

(pull-up)

A

150 k

Ω

49.9 k

D

Ω

10 V

24.9 k

(pull-up)

150 k

Ω

A

Ω

49.9 k

D

Ω

5 V

18.2 k

(pull-up)

100 k

Ω

A

Ω

100 k

D

Ω

Fig. 68. Input circuit diagram

Table 15. Pull-up resistor handling

pull-up load-free voltage

device

voltage hardware

de-

activated

by @(8

XF521,

XF521A

XF526 fixed NO

10 V

XFL521,

XFL521A/B

Smart I/O

XFC

5 V

fixed NO YES case 2 8.89 V

optional

switch-off

YES

YES

configured

by DIP

switch

(3

config.(6 case 1

(4

NO

configured

by plug-in

NO

YES

input

activated

for DI on AI

circuit

diagram

(Fig. 68)

YES case 2 8.89 V

with NTC

or low-

impedance

input

8.89 V

YES(7 case 3 5 V

for voltage

input or

high-

impedance

input

0 V

XL20 fixed NO YES case 2 8.89 V

XL50

XL100,

10 V

XL100A

XL100B

XL100C

(1

controller firmware ≥ 2.03;

(2

controller firmware ≥ 2.02;

(3

controller firmware ≥ 2.03 (local/shared mode), CARE ≥ 5.00.01 (open mode);

(4

CARE ≥ 5.00.01;

(5

controller firmware < 2.04;

(6

controller firmware < 2.04 (local/shared mode), CARE ≥ 5.01.xx (open mode);

(7

CARE ≥ 5.01.xx;

(8

Assigning "@" as first digit of input characteristic name (e.g.: "@0-10V") in CARE text editor disables the pull-up resistor.

optional

switch-off

fixed

optional

switch-off

YES(2 YES(5 case 1 0 V

NO

YES configurable

YES(1 NO

NO

YES case 2 8.89 V

YES(5

case 1

8.89 V

0 V

29 EN1R-1047GE51 R0308

Page 30

EXCEL 500/600 INSTALLATION INSTRUCTIONS

Sensors and Transducers

Table 16. Sensors suitable for use with Excel 500/600 (external transducer not required)

sensor type

range

characteristic in controller

(set using CARE)

AF20 Outside Air Temperature Sensor -20…+30° C

VF20A Strap-On Temperature Sensor 0…+110° C

KTF20 Boiler Temperature Sensor 0…+100° C

NTC

LF20 Duct Temperature Sensor -30…+100° C

AQS51 or C7110C1001 CO2 Sensor 0...2000 ppm CO2 0…10 V = 0..2000 ppm

C7110A1005 Air Quality (Mixed Gas) Sensor 0…100% 0…10 V = 0…100%

T7560C1006 Combined Room Temp. / Humidity Sensor

or H7012B1023 Room Humidity Sensor

6…40°C NTC

20...95% relative humidity 0..10 V = 0...100%

Table 17. Room Temperature Sensors suitable for use with Excel 500/600 (external transducer not required)

sensor type range

T7460A1001 Room Temperature Sensor

T7460B1009 Room Temperature Sensor

6...40°C NTC

setpoint wheel linear input

characteristic in controller

(set using CARE)

6…40°C NTC

TF22 Room Temperature Sensor

setpoint wheel linear input

operating knob -

6...40°C NTC

T7460C1007 Room Temperature Sensor

setpoint wheel linear input

occupancy button* -

6...40°C NTC

T7460E1002 Room Temperature Sensor

setpoint wheel linear input

occupancy button*

fan speed, 3 stages

-

6...40°C NTC

T7460F1000 Room Temperature Sensor

setpoint wheel linear input

occupancy button*

fan speed, 5 stages

-

6...40°C NTC

T7460A1000 Room Temperature Sensor

setpoint wheel linear input

occupancy button*

fan speed, 5 stages

-

6…40°C NTC T7460C1006 Combined Room Temperature / Humidity

Sensor

20...95% r.h. 0..10 V = 0…100%

6..40°C NTC

C7110D1009 Combined Room Temperature / Humidity

Sensor

0...2000 ppm CO2 0..10 V = 0…2000 ppm

setpoint wheel linear input

occupancy button* -

6...40°C NTC

T7560B1008 Combined Room Temperature / Humidity

Sensor

20...95% r.h. 0...10 V = 0...100%

setpoint wheel linear input

occupancy button*

fan speed, 5 stages

-

*supported in AH03

Table 18. Humidity Sensor suitable for use with Excel 500/600 (external transducer not required)

sensor type

H7015B1020 Duct Humidity Sensor

H7508A1042 Outside Humidity Sensor

EN1R-1047GE51 R0308

characteristic in controller

(set using CARE)

additional remarks

0..10 V = 0...100% set jumper to 0...10 V

30

Page 31

EXCEL 500/600 INSTALLATION INSTRUCTIONS

Table 19. Flue Gas Sensors suitable for use with Excel 500/600 (external transducer required)

sensor type

AGF1 0...10 V = 0…400 °C

Table 20. Differential (+ Static Duct) Pressure Sensor suitable for use with Excel 500/600 (no external transducer

sensor type

Pressure Sensor

Table 21. Differential Pipe Pressure Sensors suitable for use with Excel 500/600 (external transducer not required)

sensor type

FHBN 3+ED1 0 – 2.5 bar 0...10 V = 0...250 kPa

FHBN 5 +ED1 0 – 5 bar 0...10 V = 0...500 kPa

FHBN 10 +ED1 0 – 10 bar 0...10 V = 0...1000 kPa

COMMUNICATIONS

LONWORKS Bus Wiring

Connection between the Distributed I/O modules and the

CPU are made from the L

XSL511. The L

ONWORKS

uses transformer isolation so that the bus wiring does not

have a polarity; that is, it is not important which of the two

L

ONWORKS

bus terminals are connected to each wire of the

twisted pair.

The LONW

ORKS

bus can be wired in daisy chain, star, loop or

any combination thereof as long as the max. wire length

requirements given below are met. The recommended

configuration is a daisy chain with two bus terminations. This

layout allows for max. LONW

structure presents the least number of possible problems,

particularly when adding on to an existing bus.

Table 22. Doubly-terminated bus specifications

cable type max. bus length

Belden 85102 2700 m (8900 ft)

Belden 8471 2700 m (8900 ft)

Level IV, 22 AWG 1400 m (4600 ft)

JY (St) Y 2x2x0.8 900 m (3000 ft)

TIA568A Cat. 5 24AWG, twisted pair 900 m (3000 ft)

NOTES:

The cable types listed above are as recommended

by Echelon in their FTT-10A User Guide. The cable

recommended by Honeywell is the level IV, 22

AWG, solid core, nonshielded cable. Belden part

numbers are 9H2201504 (plenum) and 9D220150

(non-plenum).

ONWORKS

connector module

bus is a 78-kilobit serial link that

ORKS

bus length, and its simple

characteristic in controller

(set using CARE)

additional remarks

requires LC-MV-1xPT1000.0-400°C: converts

PT1000 to 0…10 V: order from: www.rinck-

electronic.de

required)

range

characteristic in controller

(set using CARE)

additional remarks

0...500 Pa 0..10 V = 0...500 Pa set jumper to 0...500 Pa DPT500 Differential (+ Static Duct)

0... 1000 Pa 0..10 V = 0...1000 Pa set jumper to 0...1000 Pa

range

characteristic in controller

(set using CARE)

additional remarks

ED1 is an integrated transducer

with 0…10 V output

IMPORTANT

It is recommended that ferrules not be used to

terminate stranded wires inserted in the Distributed

I/O Terminal blocks spring-clamp terminals.

The FTT specification includes two components that must be

met for proper system operation. The distance from each

transceiver to all other transceivers and to the termination

must not exceed the max. node-to-node distance. If multiple

paths exists, the max. total wire length is the total amount of

wire used.

Table 23. Free topology (singly-terminated) specifications

cable type

max. node-to-

node distance

max. total wire

length

Belden 85102 1650 ft (500 m) 1650 ft (500 m)

Belden 8471 1300 ft (400 m) 1650 ft (500 m)

Level IV, 22AWG 1300 ft (400 m) 1650 ft (500 m)

JY (St) Y 2x2x0.8 1050 ft (320 m) 1650 ft (500 m)

TIA568A Cat. 5

24AWG, twisted pair

825 ft (250 m) 1500 ft (450 m)

IMPORTANT

Do not use different wire types or gauges on the

same L

ONWORKS

network segment. The step

change in line impedance characteristics would

cause unpredictable reflections on the bus.

NOTE:

In the event that the limit on the total wire length is

exceeded, then FTT physical layer repeaters

(FTT 10A) can be added to interconnect segments

and increase the overall length by an amount equal

to the original specification for that cable type and

bus type for each repeater used. For example,

adding repeaters for a doubly-terminated bus using

JY (St) Y 2x2x0.8 cable increases the max. length

3000 ft (900 m) for each repeater.

31 EN1R-1047GE51 R0308

Page 32

EXCEL 500/600 INSTALLATION INSTRUCTIONS

In the case of the XCL5010, the LONW

ORKS

bus connections

are located on the application module as shown in Fig. 69:

LonWorks service button

POWER, GREEN

LonWorks service LED, RED

C-BUS TxD, YELLOW

C-BUS RxD, YELLOW

RESERVED

XDL5050

C-BUS TERMI-

NATION SWITCH

1 2 3

LonWorks

BUS

4 5 6

C-BUS

A1

A2

C-

C+

SHIELD

not used

Fig. 69. XDL5050 application module LEDs and ports

LONW

ORKS

Bus Termination

Depending upon the configuration, either one or two

termination modules are required for terminating a L

bus with FTT devices on it. The following two different

LONW

ORKS

termination units are available for this purpose:

• 209541B LONW

ORKS

Bus Termination Module (see Fig.

70 and Fig. 71) and

• XAL-Term L

ONWORKS

connection and termination

module (see Fig. 72), which can be mounted on DIN rails

and in fuse boxes.

TOP

MIDDLE

BOTTOM

ONWORKS

LEDs

l

l

e

w

removable screw-type

3-pole terminal block

y

e

n

o

H

m

r

e

T

-

L

A

X

4

3

L

L

O

O

N

N

shield shield

plug-in

jumper

34

15

06

Termination

Fig. 72. XAL-Term

In the case of either a daisy chain or free-topology LONW

bus layout, the max. lengths described above must be

adhered to.

System Bus (C-Bus)

Up to 30 controllers can communicate with one another and a

PC central via the system bus. Instead of an Excel 500 / 600 /

800 controller, other system bus compatible components can

also be connected. (Excel IRC Multicontroller; Excel EMC).

The system bus must be connected through the individual

controllers (open ring).

Excel 800 Excel 100 Excel 500 Excel 50

LON

FTT/LPT Bus

FTT/LPT Free

Park Position

ORKS

Fig. 70. Termination Module 209541B connections for

doubly-terminated FTT network

Fig. 71. Termination Module 209541B connections for a

singly-terminated FTT network

Fig. 73. C-bus topology

IMPORTANT

Star connection is not permissible because

uncontrollable line reflections may occur.

For setting up the system bus in the right way, three steps

have to be followed:

1.

Select submodule for system bus communication

(XC6010, only)

2.

Specify cable for system bus.

3. Set up submodule (XC6010), CPU module (XC5010C),

or application submodule (XCL5010).

EN1R-1047GE51 R0308

32

Page 33

EXCEL 500/600 INSTALLATION INSTRUCTIONS

Submodule Selection (XC6010)

Two submodules for system bus communication are

available. The selection depends on the communication

speed.

Table 24. C-Bus submodule baud rates

submodule possible baud rates

XD505A 9600 baud

XD508 9600 baud

19200 baud

76800 baud

If the system bus speed throughout the system life-time is

restricted to 9600 baud, then a submodule XD505A should be

chosen. Otherwise, the XD508 must be used.

NOTE:

All communication submodules on one bus must be

of the same type, i.e. either uniquely XD505A or

uniquely XD508. Do not use a mix between

submodules XD505A and XD508 on the same bus.

IMPORTANT

For communication with more than 9600 baud it is

required to enable the termination of the first and the

last device on the C-bus (see the following sections).

The controllers with termination must be switched

ON prior to the controllers in the middle of the C-bus.

The C-bus might not work if the controllers with

termination are switched OFF.

The max. communication speed of the XC5010C/XCL5010 is

76800 baud. The XC5010C/XCL5010 can be mounted

together with the XC6010 (with XD505A or XD508

submodule) since the XC5010C/XCL5010 communication

speed can be changed to match either submodule.

NOTE:

When changing the baud rate of bus devices, proper

communication cannot be ensured until all bus

devices are set to the same baud rate again.

NOTE:

When adding or removing a controller to/from the C-

Bus, it may take up to two minutes to re-initialize the

bus. During this time, communication on the C-bus is

lost.

System Bus Cable Specification

The max. cable length is 4000 ft (1200 m). There are regional

differences as to whether shielded or unshielded cable

must/can be used.

IMPORTANT

In Europe, only shielded cable is permitted, while in

the US, shielded or unshielded cable can be used.

Inside the cabinet:

J-Y-(ST)Y 2 x 2 x 0.8

Outside the cabinet:

A-Y-(ST) 2 x 2 x 0.8

In principle, data transmitting cables should be shielded in

case of RFI.

The following summarizes cable types and gives selection

guidance. Note that baud rate and max. bus length are

related to each other.

cable type description recommended for

J-Y-(ST)Y

2 x 2 x 0.8

A-Y-(ST)Y

2 x 2 x 0.8

AK 3702

AK 3740A shielded

Belden 9842 twisted pair

Belden 9841 shielded US

AK 3702

AK 3740A shielded

Each end of the shield on the C-Bus should be connected to

the shield terminal of the respective device. Do not connect it

to the cabinet ground or any other ground points.

C-Bus Termination (XC6010)

The XC6010 CPU module may have either the XD505A or

the XD508 submodules mounted on them for C-Bus

communication. Table 24 provides baud rate information for

selecting the module.

The XD508 submodule is equipped with a DIP switch which

activates (ON position) deactivates (OFF position) a

terminating resistor. Depending on where the controller is

located on the bus the DIP switch settings must be as follows:

Table 26. XD508 DIP switch settings for C-Bus

controller location DIP switch setting

beginning or end of bus ON

middle of bus OFF

C-Bus Termination (XC5010C)

The XC5010C CPU module contains a switch for setting

different C-Bus baud rates.

Table 25. C-Bus cable types

shielded,

twisted pair

shielded,

twisted pair

unshielded,

twisted pair

unshielded,

twisted pair

termination

Europe

Inside cabinet

Europe

Outside cabinet

US

not approved for Europe

US (low-cost)

not approved for Europe

Europe

US also possible

US

not approved for Europe

US (low-cost)

not approved for Europe

33 EN1R-1047GE51 R0308

Page 34

EXCEL 500/600 INSTALLATION INSTRUCTIONS

Fig. 74. XC5010C C-Bus termination switch location

The bus termination switch for setting the baud rate has three

settings:

Table 27. XC5010C C-Bus termination switch settings

switch

setting

S1

S2

S3 up to 9600 baud

baud rate notes

up to 76800 baud

with bus termination

up to 76800 baud

without bus

termination

same functionality as

XD508A, up to 76800 baud

same functionality as

XD508A, up to 76800 baud

same functionality as

XD505A -

Default setting

C-Bus Termination (XCL5010)

The XDL505 application module features a DIP switch for the

C-Bus to set the bus termination appropriate for the

communication speed (see Fig. 69).

Table 28. DIP switch settings for C-Bus termination

(XCL5010)

DIP switch

setting

up max. 9.6 Kbaud -

middle max. 76.8 Kbaud

down max. 76.8 Kbaud

communication

speed

controller

location

middle of

bus

beginning or

end of bus

com-

patibility

XD505A,

XL20XD

XD508,

XL20XD508

XD508,

XL20XD508

NOTE:

Modules listed in Compatibility column are used in

Excel 20/100B/500/600 Controllers.

XC6010 Cable Specifications

For connection of the XC6010 to the XI582 Operator

Interface, two tailor-made cables are available.

XW564

—

—

cable, length 7 ft (2.5 m)

XW565

cable, length 15 ft (5 m)

to XC6010

(front)

1

3

5

2

4

6

SHIELD

Y

B

E

R

G

W

L

O

L

W

O

E

E

R

T

I

H

to XI582

W

N

N

E

XW564 or XW565 (max. 15 m)

Fig. 75. Connecting front of XC6010 via XW564 or XW565

to XI582

For connection to the XL-Online PC MMI, a tailor-made cable

is available with plugs on both ends.

XW567

—

cable, length 7 ft (2.5 m)

to XC6010

(rear)

1

3

5

971

SHIELD

2

4

6

8

0

to XL-Online

O

L

L

E

Y

W

N

E

E

R

G

R

G

A

Y

R

x

x

T

N

G

XW567 (max. 15 m)

Fig. 76. Connecting rear of XC6010 via XW567 to the XL-

Online PC MMI

XC5010C Cable Specifications

The XI582 Operator Interface can be connected to either the

front or the back of the XC5010C.

XW582

—

—

to XC5010C

1

2

3

4

5

Fig. 77. Connecting front of XC5010C via XW582 to XI582

cable, front connection, length 15 ft (5 m)

XW583

cable, back connection, length 15 ft (5 m)

SHIELD

6

7

8

9

XW582

Y

W

O

L

L

E

W

O

R

B

N

N

E

E

R

G

W

H

E

T

I

D

x

R

+

V

5

T

D

x

N

G

1

E

2

3

D

4

1

6

2

D

D

D

7

3

8

4

9

5

XI582

T

D

x

V

+

5

D

x

R

N

G

1

E

2

3

4

D

EN1R-1047GE51 R0308

34

Page 35

to XC5010C

2

3

4

5

SHIELD

L

L

E

Y

O

R

B

R

G

E

W

H

I

XI582

O

T

x

W

D

E

V

+

5

W

N

D

x

R

N

E

N

E

G

D

T

XW583

Fig. 78. Connecting back of XC5010C via XW583 to XI582

The XL-Online PC MMI can be connected to the front of the

XC5010C CPU module with the following cable:

XW585

—

cable, length 15 ft (5 m)

to XC5010C to XL-Online

1

6

2

7

+5V

3

8

4

9

5

SHIELD

1

R

x

D

S

R

T

D

x

T

D

N

G

2

3

4

5

EXCEL 500/600 INSTALLATION INSTRUCTIONS

For connection to the XL-Online PC MMI, a standard null

modem cable may be used.

1

2

3

4

6

7

8

9

to XCL5010

1

6

2

7

3

8

4

9

5

SHIELD

XW582

Fig. 80. Connecting XCL5010 via XW582 to XI582

to XCL5010 to XL-Online

1

6

2

7

+5V

3

8

4

9

5

SHIELD

XI582

O

L

L

E

x

T

Y

W

B

G

W

D

R

x

R

N

E

E

T

D

I

N

H

E

G

D

V

+

5

W

N

O

R

1

E

2

3

4

1

6

x

R

D

S

R

T

D

x

T

N

G

D

2

7

3

8

4

9

5

XW585

Fig. 79. Connecting front of XC5010C via XW585 to the

XL-Online PC MMI

NOTE:

You can also use a standard null modem cable.

An adapter cable XW584 is needed when the same MMI unit