Page 1

620 WinLoader,

Version 5.4,

User Manual

620-8982

Rev. A

Page 2

620 WinLoader

620 WinLoader

Overview

LDR001

4/05

Page 3

Copyright, Notices, and Trademarks

Printed in U.S.A. – © Copyright 2005 by Honeywell Inc.

Revision 01 – April 1, 2005

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in

its written agreement with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special, or

consequential damages. The information and specifications in this document are

subject to change without notice.

This document was prepared using Information Mapping® methodologies and

formatting principles.

Compaq® and Compaq Plus® are registered trademarks of Compaq Computer

Corp.

IBM AT® and PS2® are registered trademarks of IBM Corp.

Information Mapping is a trademark of Information Mapping, Inc.

Tandy 3000® and Tandy 4000® are registered trademarks of Tandy Corp.

Terminal Emulator® is a registered trademark of Honeywell, Inc.

Honeywell

Industrial Automation and Control

Automation College

1100 Virginia Drive

Fort Washington, PA 19034

ii 620 WinLoader Overview 4/05

Page 4

About This Publication

This manual presents:

• Brief overview of 620 WinLoader;

• Guidelines on how to use 620 WinLoader, Version 5.4, User

Manual;

• General characteristics of 620 WinLoader hardware;

• Overview of 620 WinLoader software, and

• Description of compatible personal computers and printer options.

4/05 620 WinLoader Overview iii

Page 5

iv 620 WinLoader Overview 4/05

Page 6

Table of Contents

SECTION 1 – INTRODUCTION TO 623 WINLOADER .....................................................1

1.1 Overview....................................................................................................... 1

1.2 623 WinLoader ............................................................................................. 2

1.3 623 WinLoader, Version 5.X, User Manual.................................................. 6

SECTION 2 – 623 WINLOADER HARDWARE ................................................................. 9

2.1 Overview....................................................................................................... 9

2.2 WinLoader Hardware Charactristics ..........................................................11

2.3 Personal Computer and Printer Hardware Characteristics........................ 15

2.4 620 LC Networks........................................................................................ 16

SECTION 3 – 623 WINLOADER SOFTWARE ................................................................ 17

3.1 Overview..................................................................................................... 17

3.2 Software Characteristics ............................................................................18

4/05 620 WinLoader Overview

v

Page 7

Tables

Table 2-1 623-6020 Shipping Contents ..................................................................... 12

Table 2-2 629-6019 Converter Specifications............................................................ 14

Table 2-3 Personal Computer Specifications............................................................. 15

Table 3-1 623 WinLoader Files .................................................................................. 20

Table 3-2 623 WinLoader file extensions................................................................... 21

vi 620 WinLoader Overview 4/05

Page 8

Acronyms

ABC ............................................................................................. Asynchronous Byte Count

ASCII ................................................American Standard Code for Information Interchange

CIM................................................................................. Communications Interface Module

CPM ............................................................................................Control Processor Module

CTS .................................................................................................................Clear-to-send

DOS.................................................................................................. Disk Operating System

EOS.................................................................................................................... End of Skip

I/O...................................................................................................................... Input/Output

JSR........................................................................................................ Jump to Subroutine

LAN ....................................................................................................... Local Area Network

LC................................................................................................................ Logic Controller

MS ..........................................................................................................................MicroSoft

NSKD ............................................................................................Not Skip and Deenergize

NSKR ....................................................................................................Not Skip and Retain

OEM .................................................................................Original Equipment Manufacturer

PC...........................................................................................................Personal Computer

PID.............................................................................. Proportional, Integral, and Derivative

RTS ............................................................................................................Request-to-send

RTU ....................................................................................................Remote Terminal Unit

SLM ......................................................................................................... Serial Link Module

SUB ..................................................................................................................... Subroutine

4/05 620 WinLoader Overview vii

Page 9

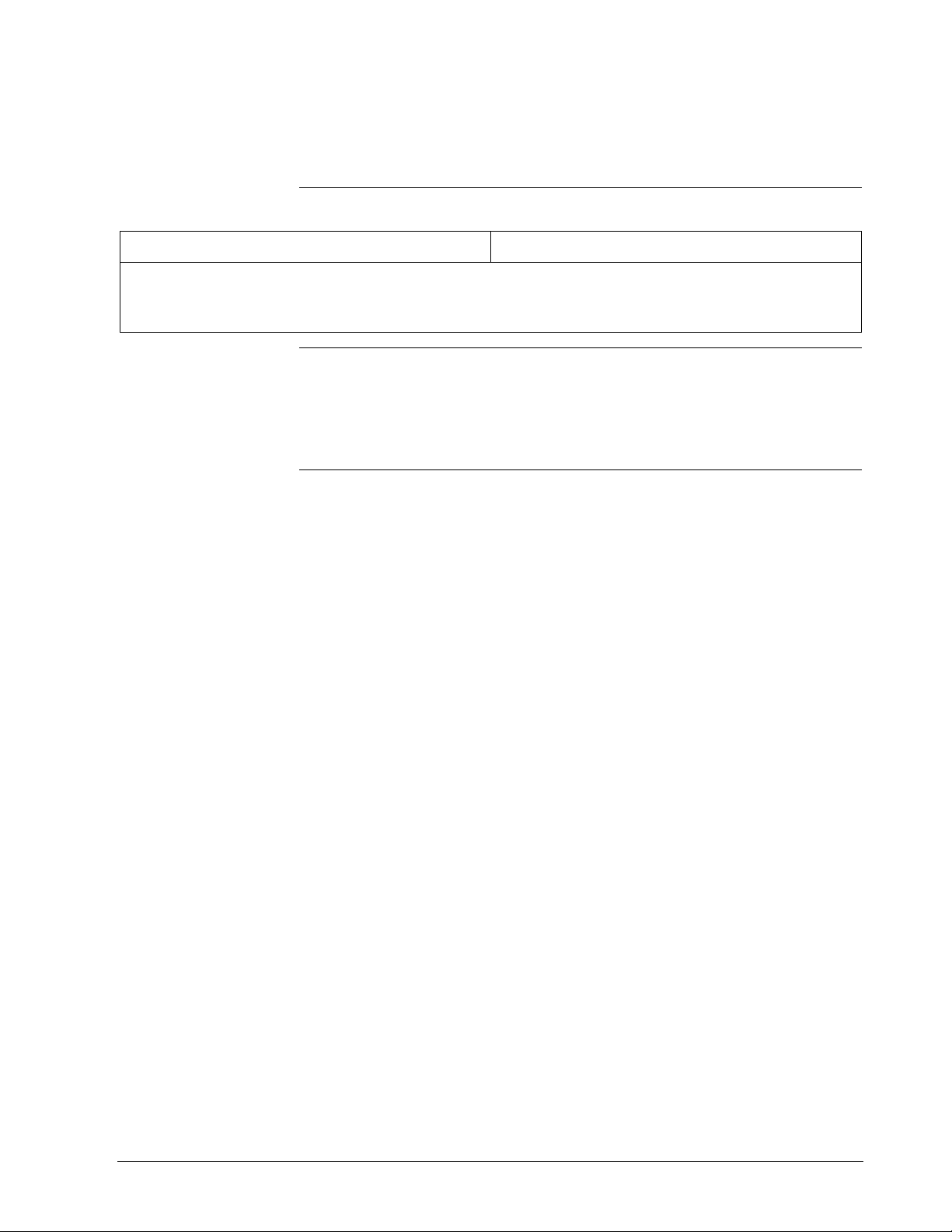

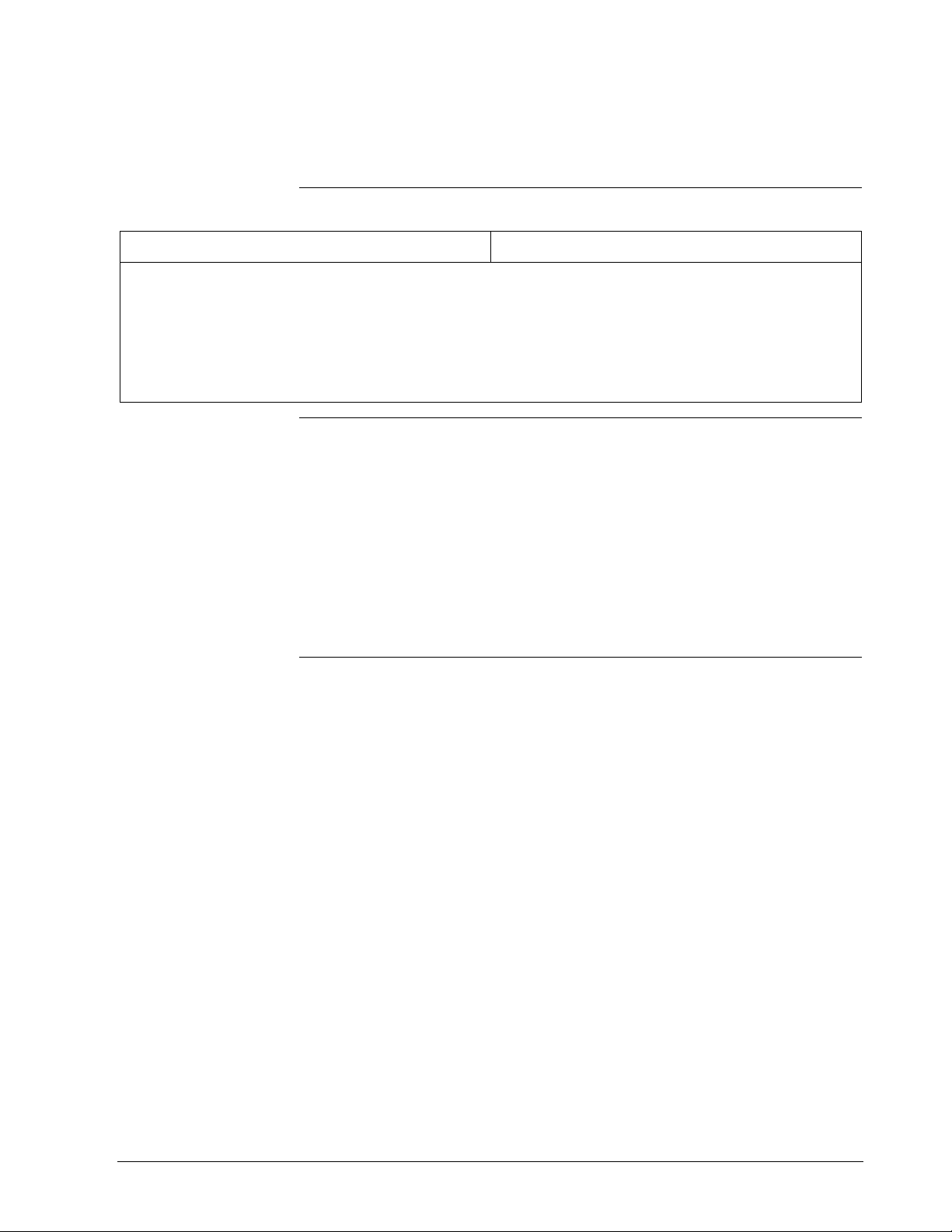

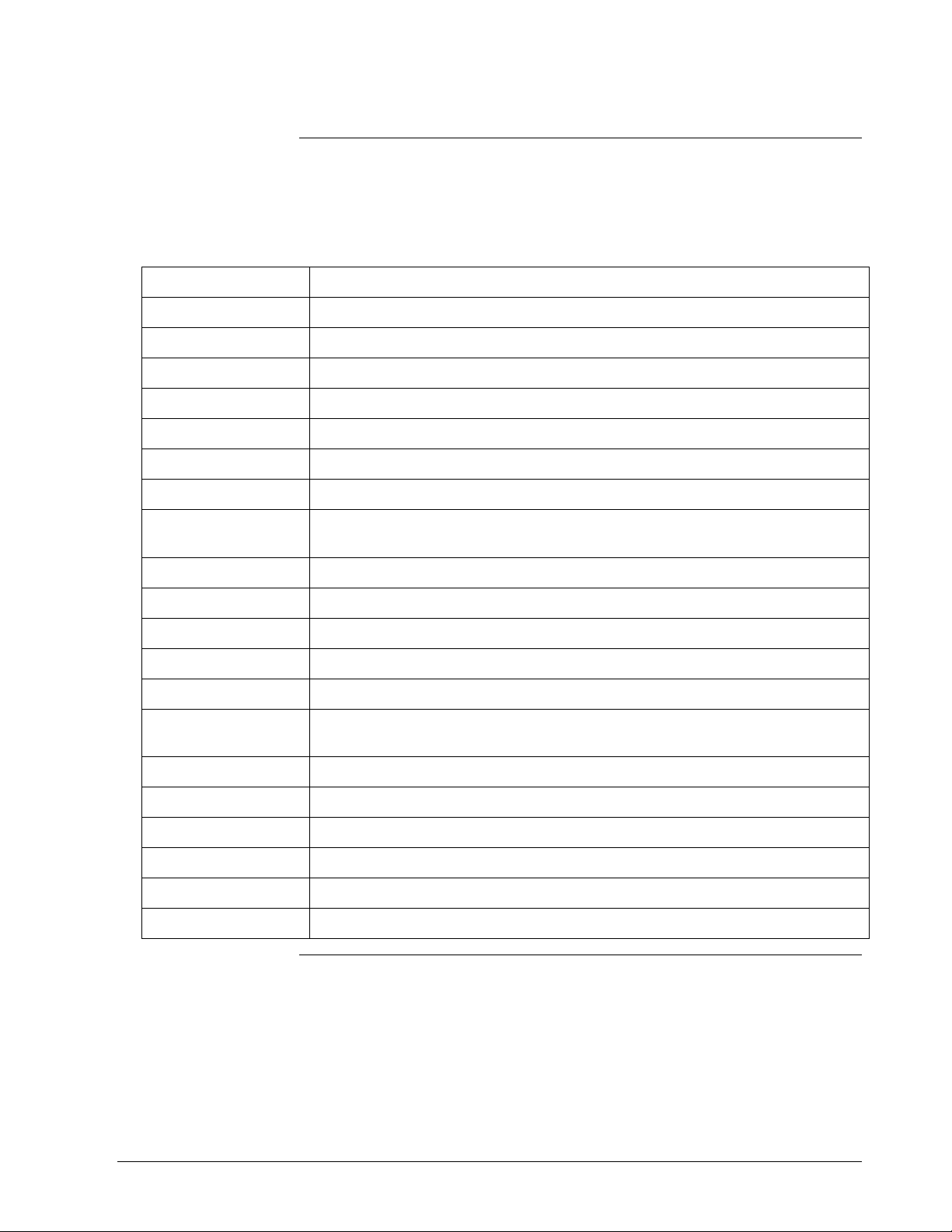

References

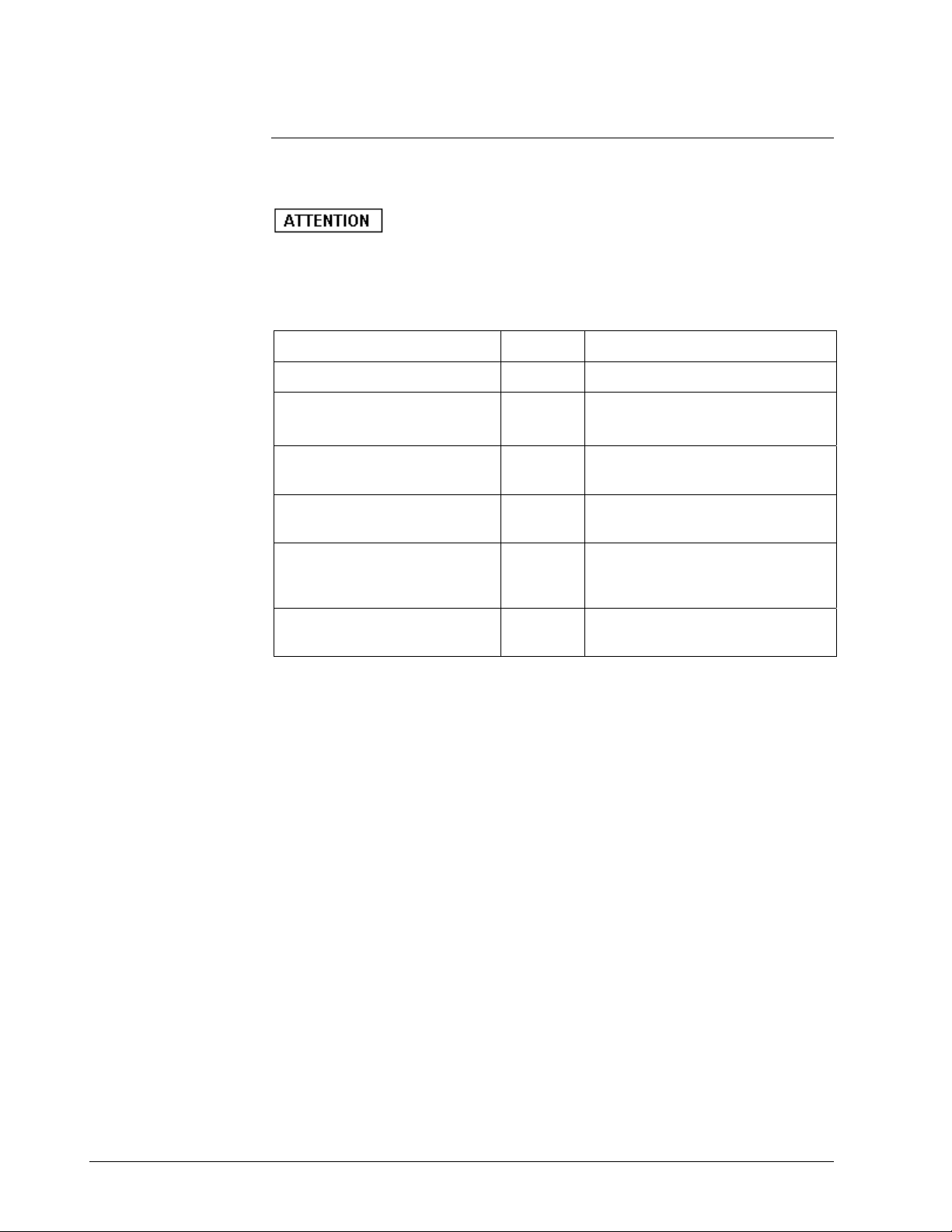

Publication

Title

Publication

Number

Binder

Title

Binder

Number

620-0043 Communications Interface

Module User Manual

620 WinLoader Installation LDR002 620 WinLoader 620-8983

620 WinLoader Implementation LDR003 620 WinLoader 620-8983

620 WinLoader Programming

Reference

620 WinLoader Edit/Display Functions LDR005 620 WinLoader 620-8983

620 WinLoader Function Blocks LDR006 620 WinLoader 620-8983

620 WinLoader Documentation

Functions

620 WinLoader Networking Functions LDR008 620 WinLoader 620-8983

620 WinLoader Utility Functions LDR009 620 WinLoader 620-8983

620-6041 Terminal Emulator User

Manual

620-8986 620 LC & S9000 Reference MAS-8990

LDR004 620 WinLoader 620-8983

LDR007 620 WinLoader 620-8983

620-8989

viii 620 WinLoader Overview 4/05

Page 10

Section 1 – Introduction to 620 WinLoader

1.1 Overview

Section contents

1.1 Overview ...................................................................................................... 1

1.2 620 WinLoader............................................................................................. 2

1.3 620 WinLoader, Version 4.X, User Manual ................................................. 6

Purpose of this

section

These are the topics covered in this section:

This section presents:

• Brief overview of 620 WinLoader, and

• Guidelines on how to use 620 WinLoader, Version 5.4, User Manual.

Topic See Page

4/05 620 WinLoader Overview

1

Page 11

1.2 620 WinLoader

General description

The 620 WinLoader is a software/hardware package that gives any

Windows compatible personal computer the capability to program and

monitor all 620 LCs using relay ladder logic. The WinLoader interfaces

with the 620 LC via an external converter.

The WinLoader includes a powerful software program that combines

menu-driven procedures and on-line monitoring with integrated

programming and documentation. This ladder logic program lets you

define the discrete control functions for your control strategy through

relay ladder logic using familiar logic elements such as contacts, coils,

timers, and counters.

• Refer to Section 2 of this manual for a complete overview of and

specifications for the 620 WinLoader hardware platforms, to include

—

623-6225 WinLoader, which comes with an RS232/422 Converter.

• In both hardware configurations, the WinLoader package consists of

the following:

620-6150A

Loader/Terminal

one RS232/422 Converter and associated cables (623-6225).

• Refer to Section 3 of this manual for a complete overview of the 620

WinLoader, version 5.4, software program, which is provided with both

hardware platforms.

The 620-6150A Loader/Terminal is an industrially-hardened portable

hardware platform offered by Honeywell that has the latest version of

620 WinLoader software loaded on the internal hard disk.

• Comes with an RS232/422 External Converter Box to be installed

through 620-6150A Loader/Terminal's serial port.

• When power is applied, the unit immediately responds as a 620

WinLoader/Terminal.

• Refer to the separate documentation supplied with 620-6150A

Loader/Terminal for appropriate specifications and operating

procedures.

Continued on next page

2 620 WinLoader Overview 4/05

Page 12

1.2 620 WinLoader, Continued

How can I benefit

from WinLoader?

The 620 WinLoader software program offers a full variety of features

that turn your personal computer into an industrial programming device;

features and benefits of the package include:

• Easy to use:

– completely menu-driven,

– offers a series of "Help" screens, and

– minimal training required.

• Integrated programming/documentation:

– provides comprehensive link between ladder logic and

documentation.

• Stand-alone programming:

– may be used to develop ladder logic without being connected to a

620 Logic Controller (LC).

• On-line monitoring:

– monitors status of ladder logic as it is executing.

• Augmented Run Mode Programming:

– enables adding to or deleting from control program while 620 LC is

in Run/Program mode.

• Built-in Terminal Emulator:

– allows WinLoader to:

– accurately emulate Terminal mode of 620-50/51

Loader/Terminal, and

– program, configure, and/or transfer files to and from all

Honeywell 627 MiniCOP industrially-rated, microprocessorbased computing modules and related products.

• Time-saving Search functions:

– locates contacts by:

– line number,

– element type,

– element address, and/or

– element label.

• Extensive Documentation features:

– provides printout that includes additional descriptive data, such as –

– complete cross-references,

– unused addresses,

– conflicting addresses, and

– listings of all forms of text documentation.

Continued on next page

4/05 620 WinLoader Overview 3

Page 13

1.2 620 WinLoader, Continued

How can I benefit

from WIN Loader?,

continued

• Ladder logic addressing feature:

– uses 7-character label per ladder logic element in lieu of numeric

address when developing ladder logic.

• Free-format editing of documentation:

– allows you to –

– enter up to 20 lines of documentation (67 characters each line) via

ladder logic line and address;

– edit comments while editing or monitoring ladder logic.

• Powerful Search & Exchange function:

– enables searching for and exchanging address and/or logic

instruction of an existing logic element every time it is found in the

ladder logic program;

– requires only a few keystrokes.

• Expanded Block editing functions:

– allows readdressing logic element in a block of ladder logic while

logic is being loaded into memory;

– up to eight different groups of addresses may be reassigned to

different address ranges.

• Function Block programming features:

– allows creating ladder logic programs in modular format, which

offers the following benefits –

– reduces time required to assemble programs,

– helps standardize functions for special operations,

– makes programs easier to read and understand,

– saves time during testing since Function Blocks are pretested and

have fewer faults,

– makes ladder logic programs easy to generate, maintain, and

invoke, and

– also provides Function Block Library, which contains the ladder

logic of all available Honeywell Function Blocks.

• Flexible configuration feature:

– allows specifying different parameters for WinLoader software to

use for display, editing, and data storage functions based on

requirements of individual applications;

– offers an easy-to-use menu structure.

• Universal 620 LC interface:

– supports all 620 LCs for both on-line

programming and monitoring

and stand-alone operations.

4 620 WinLoader Overview 4/05

Page 14

1.2 620 WinLoader, Continued

How can I benefit

from WinLoader?,

continued

• Data Display function:

– permits monitoring up to 126 addresses regardless of locations in

program;

– offers ability to:

– read and write addresses (write to register address only),

– save 'snapshot' of system conditions, and

– create 'recipe file' for presetting register data values.

• External RS232/422 PC/620 LC converter device:

– may be used with any IBM-compatible personal computer that uses

Windows 2000 and Windows XP operating systems

• Multidrop 620 LC option:

– allows configuring network of up to thirty-one 620 LC devices and

connecting them to one WinLoader.

4/05 620 WinLoader Overview 5

Page 15

1.3 620 WinLoader, Version 5.4, User Manual

How to use 620

WinLoader user

manual

The documentation supplied with the 620 WinLoader includes the

following user manuals; refer to each appropriate manual to access the

desired information or any particular operating procedure.

• 620 WinLoader Overview (LDR001) – which presents:

– brief overview of 620 WinLoader,

– guidelines on how to use 620 WinLoader, Version 5.4, User Manual,

– general characteristics of 620 WinLoader hardware,

– overview of 620 WinLoader software, and

– descriptions of compatible personal computers and printer options.

• 620 WinLoader Installation (LDR002) – which provides installation

procedures for:

– installing 629-6019 External Converter Box, which is provided with

620-6020 WinLoaders and 620-6150A Loader/Terminals, and must

be installed through a serial communications port of a personal

computer or the 620-6150A Loader/Terminal;

– installing cabling to RS232 serial printers;

– installing cabling to Serial Link Selector in redundant applications;

and

– installing WinLoader software, which is used 620-6020

WinLoaders.

• 620 WinLoader Implementation (LDR003) – which provides:

– general start-up procedure for 620 WinLoader

– overall description of WinLoader's Main Menu, to include

individual descriptions of Main Menu selections and descriptions

of each available function and sub-menu accessible from the Main

Menu; and

– overall description of WinLoader's Main Screen Display, to include

procedure for entering Main Screen Display and descriptions of

individual Main Screen Display components.

Continued on next page

6 620 WinLoader Overview 4/05

Page 16

1.3 620 WinLoader, Version 5.4, User Manual, Continued

How to use 620

WinLoader user

manual, continued

• 620 WinLoader Programming Reference (LDR004) – which presents:

– general overview of ladder logic entry and editing procedures which

are required for programming 620 LC instructions;

– general overview of the different categories of ladder logic

instructions which are available for 620 LCs;

– descriptions of each instruction in the 620 LC instruction set, to

include methods for entering each instruction; and

– descriptions of –

– 620 LC data representation,

– 16-bit error/status word used to indicate any conditions or errors

associated with programming operations, and

– conditional data handling, whereby conditional contacts are used

to control 620 LC arithmetic or comparison operations.

• 620 WinLoader Edit & Display Functions (LDR005) – which presents:

– general overview of WinLoader's ten different categories of edit and

display functions which are available for use when programming

620 LC ladder logic programs; and

– detailed overview of Auxiliary Function Menu functions, which are

accessible from the WinLoader's Edit & Display Functions Menu.

• 620 WinLoader Function Blocks (LDR006) – which presents:

– general guidelines and operating procedures for programming,

editing, displaying, and uploading/saving Function Blocks in an

WinLoader ladder logic control program; and

– procedures for implementing Honeywell's predefined Function

Block control programs.

• 620 WinLoader Documentation Functions (LDR007) – which presents:

– general characteristics of documentation types used in ladder logic

programming with the 620 WinLoader, to include descriptions of

address labels and address descriptions, address comments, line

comments, and line numbers;

– descriptions of each available documentation function that is

accessible from the Documentation Functions Menu when the

Documentation Functions Menu is accessed from the WinLoader's

Main Menu; and

– descriptions of each available function that is accessible from the

Documentation Functions Menu when the Documentation Functions

Menu is accessed from the WinLoader's Auxiliary Function Menu.

Continued on next page

4/05 620 WinLoader Overview 7

Page 17

1.3 620 WinLoader, Version 5.4, User Manual, Continued

How to use 620

WinLoader user

manual, continued

• 620 WinLoader Networking Functions (LDR008) – which provides:

– detailed information on the following communications networks

which are available from Honeywell for the interconnection of 620

LCs and associated peripheral devices –

– Multidrop Loader Network

8 620 WinLoader Overview 4/05

Page 18

Section 2 – 620 WinLoader Hardware

2.1 Overview

Section contents

Overview ...................................................................................................... 9

2.1

2.2 WinLoader Hardware Charactristics.......................................................... 11

2.3 Personal Computer and Printer Hardware Characteristics ....................... 15

2.4 620 LC Networks ....................................................................................... 16

3.1 Overview .................................................................................................... 17

3.2 Software Characteristics ............................................................................ 18

Purpose of this

section

These are the topics covered in this section:

This section presents:

• Detailed hardware description, specifications, and shipping contents of

620-6020 WinLoader;

Topic See Page

• Additional hardware characteristics, to include:

– compatible personal computers,

– personal computer specifications, and

– printer options; and

• Available 620 LC networks.

Continued on next page

4/05 620 WinLoader Overview

9

Page 19

2.1 Overview, Continued

Background

Depending on the type of control strategy you have configured for your

application, the WinLoader software program may be provided by

Honeywell as part of either of the following control system hardware

platforms:

• 620-60 WinLoader — provides a user-supplied DOS-compatible

personal computer with the capability to program and monitor all 620

Logic Controller CPMs, and is available in the following two versions:

– 620-6020 WinLoader, which comes with an RS232/RS422 External

Converter Box to be installed through a PC's RS232 serial

communications port.

– Refer to subsection 2.3 for additional hardware description,

specifications, and shipping contents of the 620-6020 WinLoader.

• 620-6150A Loader/Terminal — an industrially-hardened laptop

computer capable of all WinLoader functions.

– Comes with an RS232/422 External Converter Box to be installed

through the 620-6150A Loader/Terminal's serial port.

– Refer to the separate 620-6150A Loader/Terminal User Manual

(620-8940) for hardware description, system components, and

operating instructions for the 620-6150A Loader/Terminal.

10 620 WinLoader Overview 4/05

Page 20

2.2 620-6020 WinLoader Hardware Characteristics

620-6020 WinLoader

hardware

620-6020 WinLoader hardware includes:

• 629-6019 External Converter Box —

– provides RS232/422 interface;

– must be installed through PC's serial communications port; and

– requires 5VDC, 250mA power supply.

• 10-foot Loader/Terminal cable (Model number 628-3000) —

– shielded cable that connects PC's interface card to Loader/Terminal

port on 620 CPM;

– if desired, you may also build your own custom length cable up to a

maximum length of 2000 feet (610m).

• 12-inch converter communications cable (Model number 628-6020) —

– provides communications between PC's serial port and 629-6019

External Converter Box.

• Power splitter cable (Model number 628-6021) —

– common connector plugs into PC's keyboard jack; and

– one end of split is connected to keyboard cable, other end to

converter box.

Continued on next page

4/05 620 WinLoader Overview 11

Page 21

2.2 620-6020 WinLoader Hardware Characteristics, Continued

620-6020 WinLoader

shipping contents

Refer to Table 2-1 below for shipping contents of the 620-6020

WinLoader.

• Site licenses are available for 620-6020 WinLoader.

• Site License Agreement (Model Number 620-8000) is optional.

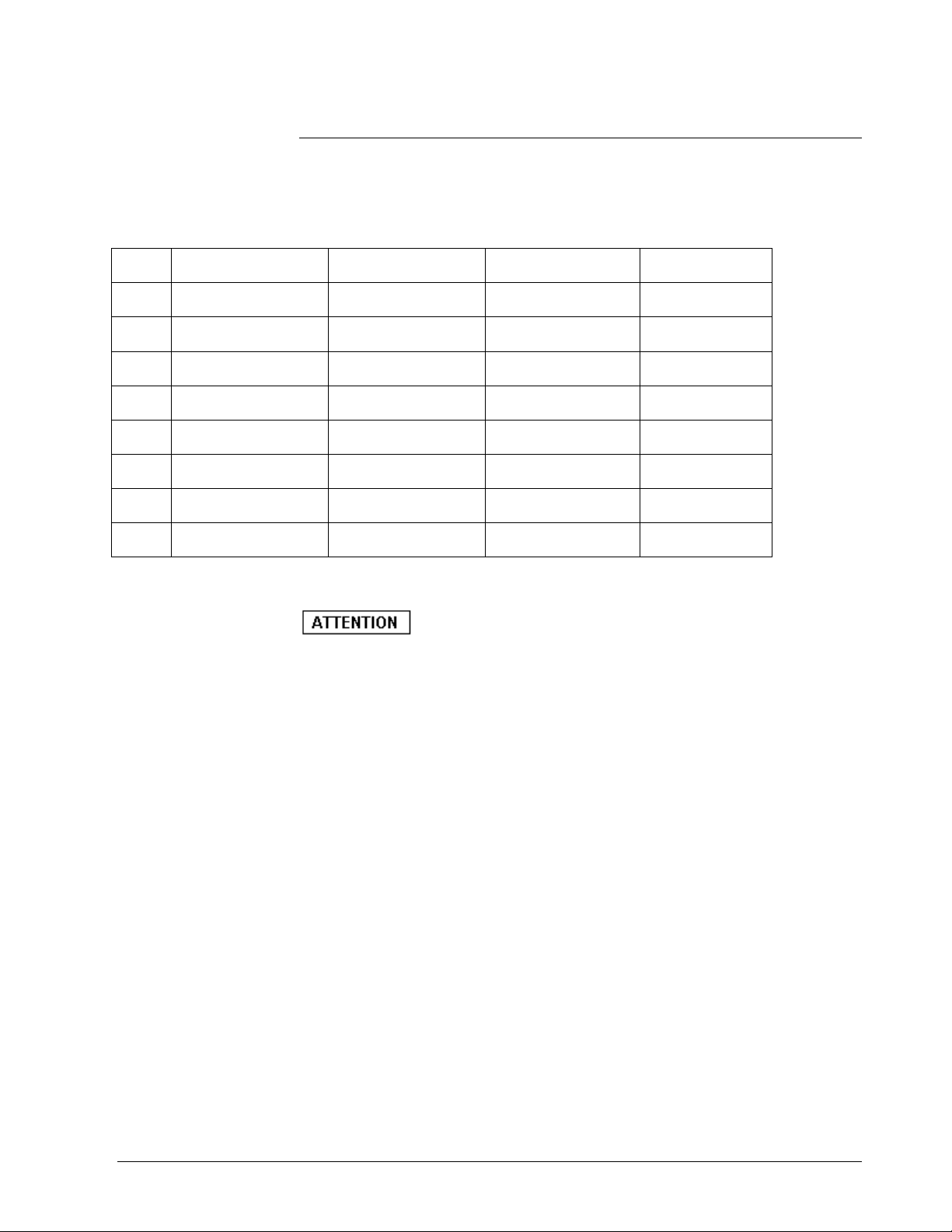

Table 2-1 620-6020 Shipping Contents

Part Quantity Description

RS232/422 Converter

Shielded Cable

PC/620 LC Converter

Communications Cable

PC/620 LC Converter Power

Cable

620 WinLoader,

Version 5.4,

User Manual

Function Block Library

Specifications

1 • Model Number 629-6019

1 • 10-foot (3m)

• Model number 628-3000

1 • Model number 628-6020

1 • Model Number 628-6021

1

1

Form 620-8983

Continued on next page

12 620 WinLoader Overview 4/05

Page 22

2.2 620-6020 WinLoader Hardware Characteristics, Continued

629-6019 Converter

The 629-6019 External Converter Box is provided with the 620-6020

WinLoader and must be installed through a serial communications port

of your personal computer.

• 629-6019 External Converter Box is factory-configured for

communications operation between personal computer's serial port and

Loader/Terminal port on CPM.

The interface port on the 629-6019 External Converter Box is a 9-pin

female sub-D connector with a tin-plated shell and a latching mechanism.

The interface port has both transmit and receive capabilities along with

clear-to-send and request-to-send control, and is used to communicate

with 620 LCs using the 10-foot Loader/Terminal cable; however, you may

wish to extend this length by constructing a cable according to the pin

assignments specified in 620 WinLoader Installation (LDR002). The 6296019 External Converter Box may operate at a maximum distance of 2000

feet (610m).

• Interface port is essential for 620-6020 WinLoader operation;

– 620-6020 WinLoader software will not communicate with a 620 LC

unless an interface port is installed in your personal computer.

Continued on next page

4/05 620 WinLoader Overview 13

Page 23

2.2 620-6020 WinLoader Hardware Characteristics, Continued

629-6019 Converter

specifications

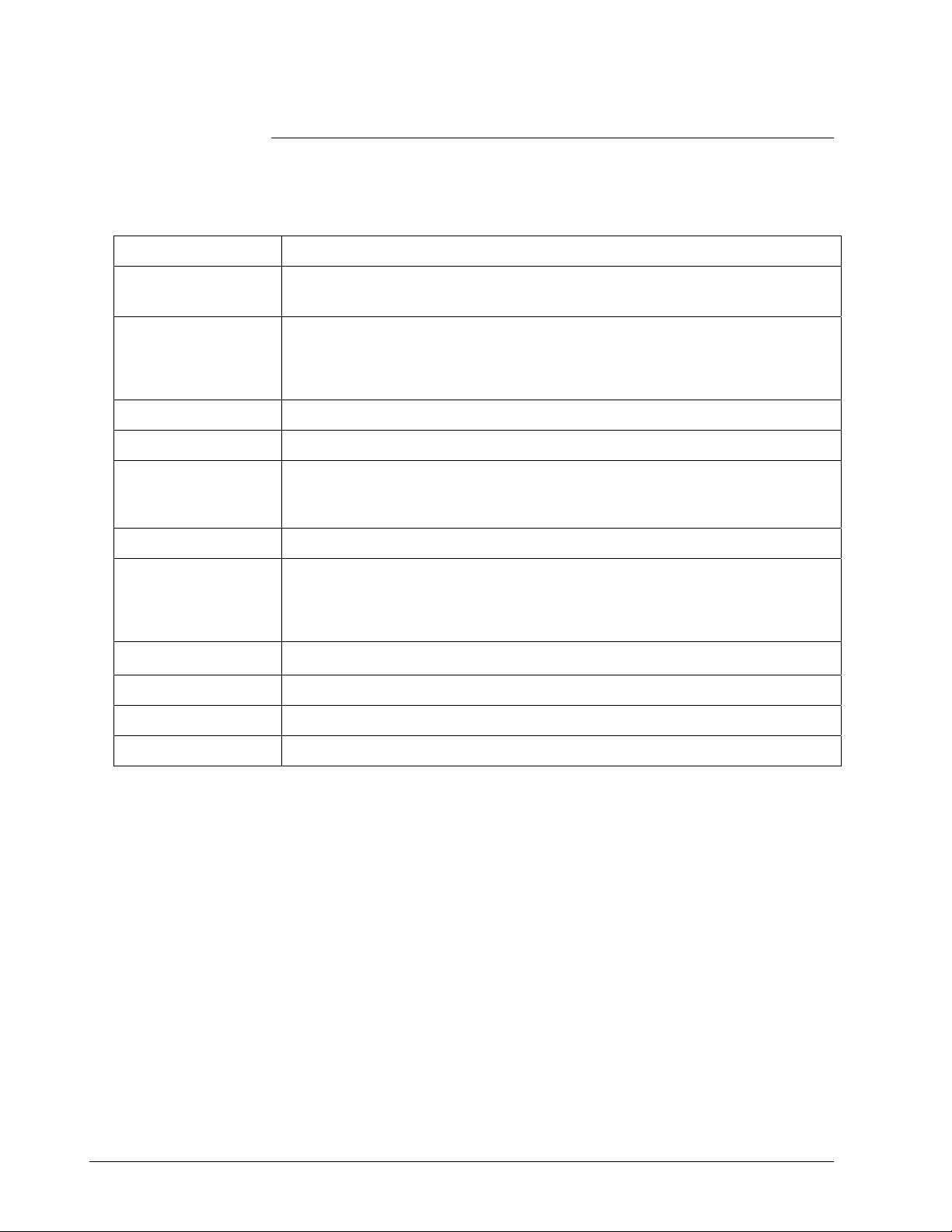

Refer to Table 2-4 below for specifications for the 629-6019 Converter

that is used with 620-6020 WinLoaders.

Table 2-2 629-6019 Converter Specifications

Specification Description

5-Pin Circular DIN

Male Connector

9-Pin Subminiature

D-Type Male

Connector

9-Pin Subminiature

D-Type Female

Connector

Environmental

Specifications

Specification Description

Supply Voltage 4.75-5.25 VDC @

0° to 60° C

(32° to 140° F)

Supply Input Current 250mA @

0° to 60° C

(32° to 140° F)

Specification Description

Maximum Cable Length 50 feet (15m)

Interface Type RS232

Input/Output Data Rate Up to 9600 baud

Specification Description

Maximum Cable Length 2000 feet (610m)

Interface Type RS422

Input/Output Data Rate Up to 9600 baud

Specification Description

Operating Temperature 0° to 60° C

32° to 140°F

Humidity 5-95%

(non-condensing)

14 620 WinLoader Overview 4/05

Page 24

2.3 Personal Computer and Printer Hardware

Characteristics

620-60 WinLoadercompatible PCs

Personal computer

specifications

The personal computer used to support the 620-6020 WinLoader

program must be 100% compatible with the Windows 2000 and

Windows XP operating systems

Refer to Table 2-3 for specifications for the WinLoader's personal

computer.

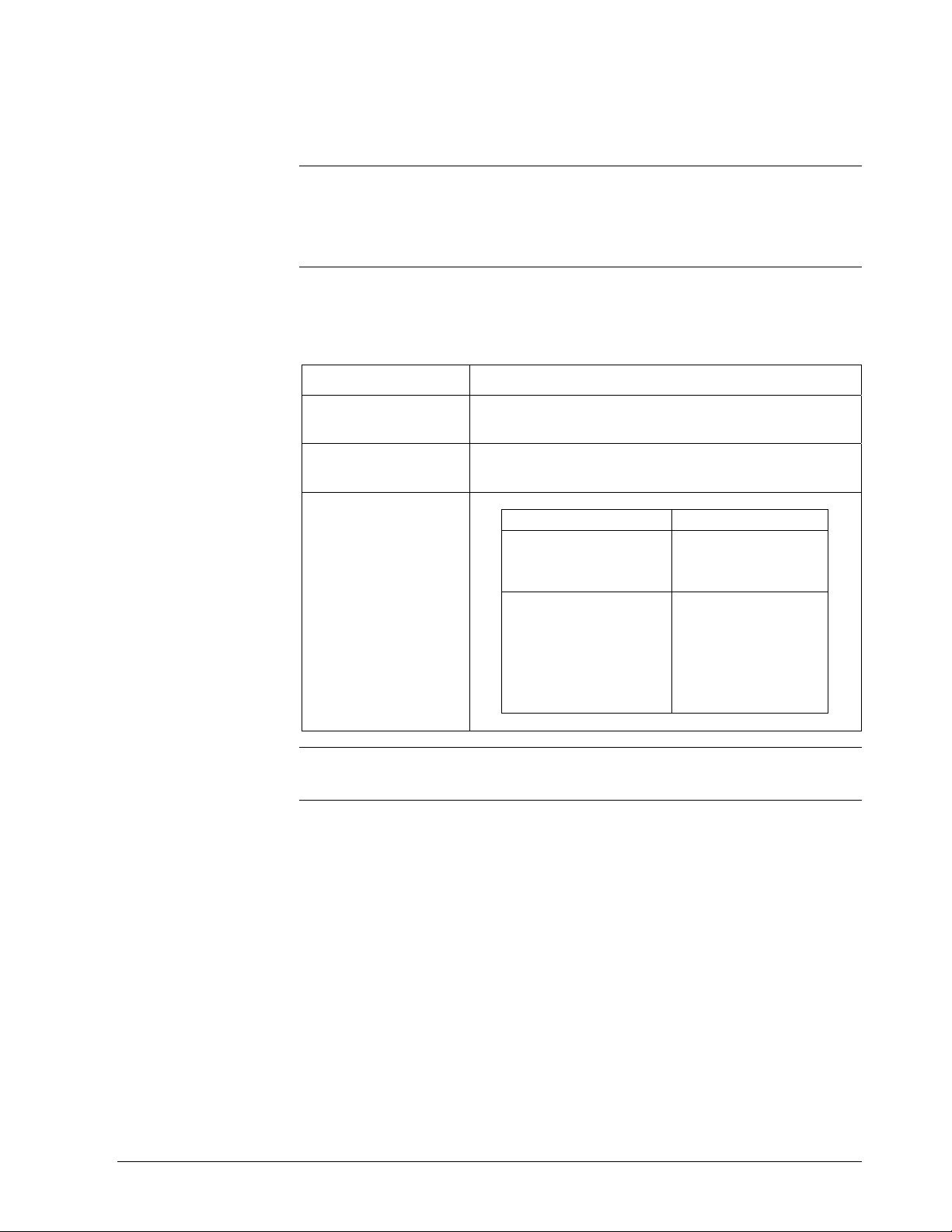

Table 2-3 Personal Computer Specifications

Specification Description

Personal Computer

Requirements

Memory

Requirements

Mass Storage

Requirements

Windows software and hardware-compatible

computers

640K RAM (minimum)

Category Description

Floppy-Only Systems Disk capacity of

1.2M bytes or

greater.

Hard Disk Systems 1 floppy with 360K

bytes capacity or

greater and a

minimum of 1.2M

bytes of available

hard disk storage.

Printer options

4/05 620 WinLoader Overview 15

Any IBM-compatible printer will work with the WinLoader program.

Page 25

2.4 620 LC Networks

Available 620 LC

networks

The following communications networks are provided by Honeywell to

allow for the interconnection of 620 LCs and associated peripheral

devices:

• Multidrop Loader Network – allows a single WinLoader to be

multidrop-connected to up to thirty-one 620-12/1633/36 LCs via the

RS-485 electrical specifications using a version 4.1 (or greater)

WinLoader and a 3.1 (or greater) 620 LC CPM version.

for detailed information on each of these communications networks.

Refer to 620 WinLoader Networking Functions (LDR008)

16 620 WinLoader Overview 4/05

Page 26

Section 3 – 620 WinLoader Software

3.1 Overview

Section contents

1.1 Overview ...................................................................................................... 1

1.2 623 WinLoader............................................................................................. 2

1.3 623 WinLoader, Version 5.X, User Manual ................................................. 6

2.1 Overview ...................................................................................................... 9

2.2 WinLoader Hardware Charactristics.......................................................... 11

2.3 Personal Computer and Printer Hardware Characteristics ....................... 15

2.4 620 LC Networks ....................................................................................... 16

3.1 Overview .................................................................................................... 17

3.2 Software Characteristics ............................................................................ 18

Purpose of this

section

These are the topics covered in this section:

This section presents:

• Overview of 620 WinLoader software,

• 620 WinLoader software specifications, and

• Listings of WinLoader files and file extensions.

4/05 620 WinLoader Overview 17

Page 27

3.2 Software Characteristics

620 WinLoader

software

620 WinLoader

instruction set

620 WinLoader

documentation

functions

The software program 623-6226 is provided in a CD.

• Refer to the following manuals for more information on the main

620 WinLoader program:

– 620 WinLoader Implementation (LDR003)

– 620 WinLoader Programming Reference (LDR004)

– 620 WinLoader Edit & Display Functions (LDR005)

Ten different categories of ladder logic instructions are available for use

by the 620 LC (to include contacts, coils, single/multiple data words,

timers, counters, sequencers, and other logic groups). Refer to 620

WinLoader Programming Reference (LDR004) for more information on

the 620 WinLoader instruction set.

620 WinLoader documentation functions allow you to add labels,

descriptions, and comments to your ladder logic program and to program

printouts. Refer to 620 WinLoader Documentation Functions (LDR007)

for information on the documentation program.

18 620 WinLoader Overview 4/05

Page 28

3.2 Software Characteristics, Continued

WinLoader files

Sl.No .EXE Files .CFG Files .DAT Files .HLP Files

LOADER.EXE LOADER.CFG SCR (LD) I.DAT LOADER.HLP

1

DCMNTED.EXE MODCNFIG.CFG SCR (LD) R.DAT 620-0025.HLP

2

CONFIG.EXE STR (LD) I.DAT

3

MODCNFIG.EXE STR (LD) R.DAT

4

620-0025.EXE

5

620-0020.EXE

6

The following files from the WinLoader are found with the Install Shield

• Refer to Table 3-1 (next page) for descriptions of each of these files.

• Refer to Table 3-2 for a list of WinLoader file extensions.

Continued on next page

4/05 620 WinLoader Overview 19

Page 29

3.2 Software Characteristics, Continued

WinLoader files,

continued

Table 3-1 620 WinLoader File Descriptions

File Description

CONFIG.EXE • Allows setting certain default conditions;

– Loader and Utility software read these conditions before execution.

DCMNTED.EXE • Allows editing:

– Address, skip, and subroutine labels,

– Descriptions,

– Address and line comments.

LOADER.CFG Contains configuration data.

LOADER.EXE Performs all ladder logic programming and some documentation functions.

LOADER.HLP • Contains WinLoader Help Screen text;

– must be resident on same drive or directory from which WinLoader

software is loaded and executed.

MODCNFIG.EXE Contains configuration utilities for 621-0020R and 621-0025R I/O Modules.

SCR (LD) I.DAT

SCR (LD) R.DAT

STR (LD) I.DAT

STR (LD) R.DAT

621-0025.EXE Supports RTDM

621-0020.EXE Supports UAIM

621-0025.HLP Help screens for RTDM

MODCNFIG.CFG Contains the configuration data for RTDM and UAIM.

These files are necessary WinLoader screen and text support files.

20 620 WinLoader Overview 4/05

Page 30

3.2 Software Characteristics, Continued

WinLoader file

extensions

Table 3-2 620 WinLoader File Extensions

File Description

Filename.ACE Logic Element Address Comment

Filename.BCE Bit Read/Write Instruction Comment File

Filename.BLB Bit Read/Write Instruction Label File

Filename.CFG Loader Configuration Files

Filename.ERR Ladder Logic Load Error File

Filename.FBL Function Block Ladder File.

Filename.FBR Function Block Register File

Refer to Table 3-2 below for a list of 620 WinLoader file extensions.

Filename.IOC Input/Output Configuration

(620-11/12/14/16/36 LCs only)

Filename.JSR Subroutine documentation (JSR, SUB, RTS)

Filename.LBL Logic Element Address Labels

Filename.LCE Ladder Logic Line Comments

Filename.LDR Ladder Logic File

Filename.PIN Printer Initialization File

Filename.PRC Processor Configuration

(620-11/12/14/16/36 LCs only)

Filename.PRN Printer File (stored to disk)

Filename.REG Register Value File

Filename.RVR Register Compare File

Filename.SKP Skip Documentation (NSKR, NSKD, EOS)

Filename.VER Logic and/or Data Verification Miscompare File

Filename.VUE Data Display Files

Continued on next page

4/05 620 WinLoader Overview 21

Page 31

3.2 Software Characteristics, Continued

WinLoader menu

selections

• Refer to Appendix A for an overview of WinLoader menu selections.

• Refer to Appendix B for an overview of ladder logic programming

mode menu selections.

22 620 WinLoader Overview 4/05

Page 32

Appendix A – Overview of 620 WinLoader Menu Selections

4/05 620 WinLoader Overview 23

Page 33

24 620 WinLoader Overview 4/05

Page 34

4/05 620 WinLoader Overview 25

Page 35

26 620 WinLoader Overview 4/05

Page 36

4/05 620 WinLoader Overview 27

Page 37

28 620 WinLoader Overview 4/05

Page 38

4/05 620 WinLoader Overview 29

Page 39

Appendix B – Overview of Ladder Logic Programming

Mode Menu Selections

30 620 WinLoader Overview 4/05

Page 40

4/05 620 WinLoader Overview 31

Page 41

32 620 WinLoader Overview 4/05

Page 42

4/05 620 WinLoader Overview 33

Page 43

34 620 WinLoader Overview 4/05

Page 44

Industrial Automation and Control

Honeywell, Inc.

1100 Virginia Drive

Fort Washington, Pennsylvania 19034

Page 45

V

620 WinLoader,

ersion 5.4,

User Manual

620-8983

Rev. D

Page 46

620 WinLoader

620 WinLoader

Installation

LDR002

4/05

Page 47

Copyright, Notices, and Trademarks

Printed in U.S.A. – © Copyright 2005 by Honeywell Inc.

Revision 01 – April 01, 2005

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in

its written agreement with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special or consequential

damages. The information and specifications in this document are subject to

change without notice.

This document was prepared using Information Mapping® methodologies and

formatting principles.

IBM AT is a registered trademark of IBM Corporation

Information Mapping is a trademark of Information Mapping, Inc.

Terminal Emulator is a registered trademark of Honeywell, Inc.

Honeywell

Industrial Automation and Control

Automation College

1100 Virginia Drive

Fort Washington, PA 19034

ii 620 WinLoader Installation 4/05

Page 48

About This Publication

This manual provides:

• Installation procedure for 629-6019 External Converter Box, which is provided with 620-6020

WinLoader and 620-6150A Loader/Terminals and must be installed through a serial

communications port of a personal computer or the 620-6150A Loader/Terminal.

• Additional WinLoader hardware installation procedures to include:

– Installing cabling to RS232 serial printers, and

– Installing cabling to Serial Link Selector in redundant applications.

• Installation procedure for WinLoader software, which is used with 620-6020 WinLoader.

4/05 620 WinLoader Installation iii

Page 49

Table of Contents

SECTION 1 – WINLOADER INSTALLATION OVERVIEW .............................................. 1

1.1 Overview ...................................................................................................... 1

SECTION 2 – HARDWARE INSTALLATION AND CONFIGURATION ........................... 3

2.1 Overview ...................................................................................................... 3

2.3 629-6019 External Converter Box ............................................................... 4

2.4 Cabling to RS232 Serial Printers ............................................................... 13

SECTION 3 – SOFTWARE INSTALLATION................................................................... 17

3.1 Overview .................................................................................................... 17

3.2 WinLoader Installation ............................................................................ 18

iv 620 WinLoader Installation 4/05

Page 50

Figures and Tables

Figure 1 Rear View of 620-6150A Loader/Terminal.................................................... 4

Figure 2 Cable Construction.......................................................................................... 5

Figure 3 629-6019 Converter Cable Pin Assignments .................................................. 6

Figure 4 Communications Cable Connections .............................................................. 8

Figure 5 Loader/Terminal Cable Connections ............................................................10

Figure 6 Power Splitter Cable Connections ................................................................12

Figure 7 Cabling to RS232 Serial Printer Using 25-Pin Female Connector ............... 13

Figure 8 Cabling to RS232 Serial Printer Using Parallel/Serial Adapter 9-Pin Female

Connector. ...................................................................................................................................... 13

Figure 9 Recommended WinLoader Installation in a 620 Redundant Control System14

Figure 10 Recommended WinLoader Installation in a 620 Redundant Control System15

Table 1 Installing 629-6019 External Converter Box .................................................. 7

4/05 620 WinLoader Installation v

Page 51

Acronyms

620 LC ..................................................................................................620 Logic Controller

CPM ............................................................................................ Control Processor Module

CTS................................................................................................................. Clear-to-send

DIN...........................................Deutsche Industrie-Normen [German Industrial Standards]

DTR..................................................................................................... Data Terminal Ready

GND .......................................................................................................................... Ground

I/O ..................................................................................................................... Input/Output

LC ................................................................................................................Logic Controller

MS.......................................................................................................................... MicroSoft

PC .......................................................................................................... Personal Computer

PID ..............................................................................Proportional, Integral, and Derivative

RCV ......................................................................................................................... Receive

RTS.............................................................................................................Request-to-send

RXD .................................................................................................................Receive Data

SLS ........................................................................................................ Serial Link Selector

TXD.................................................................................................................Transmit Data

XMIT ....................................................................................................................... Transmit

vi 620 WinLoader Installation 4/05

Page 52

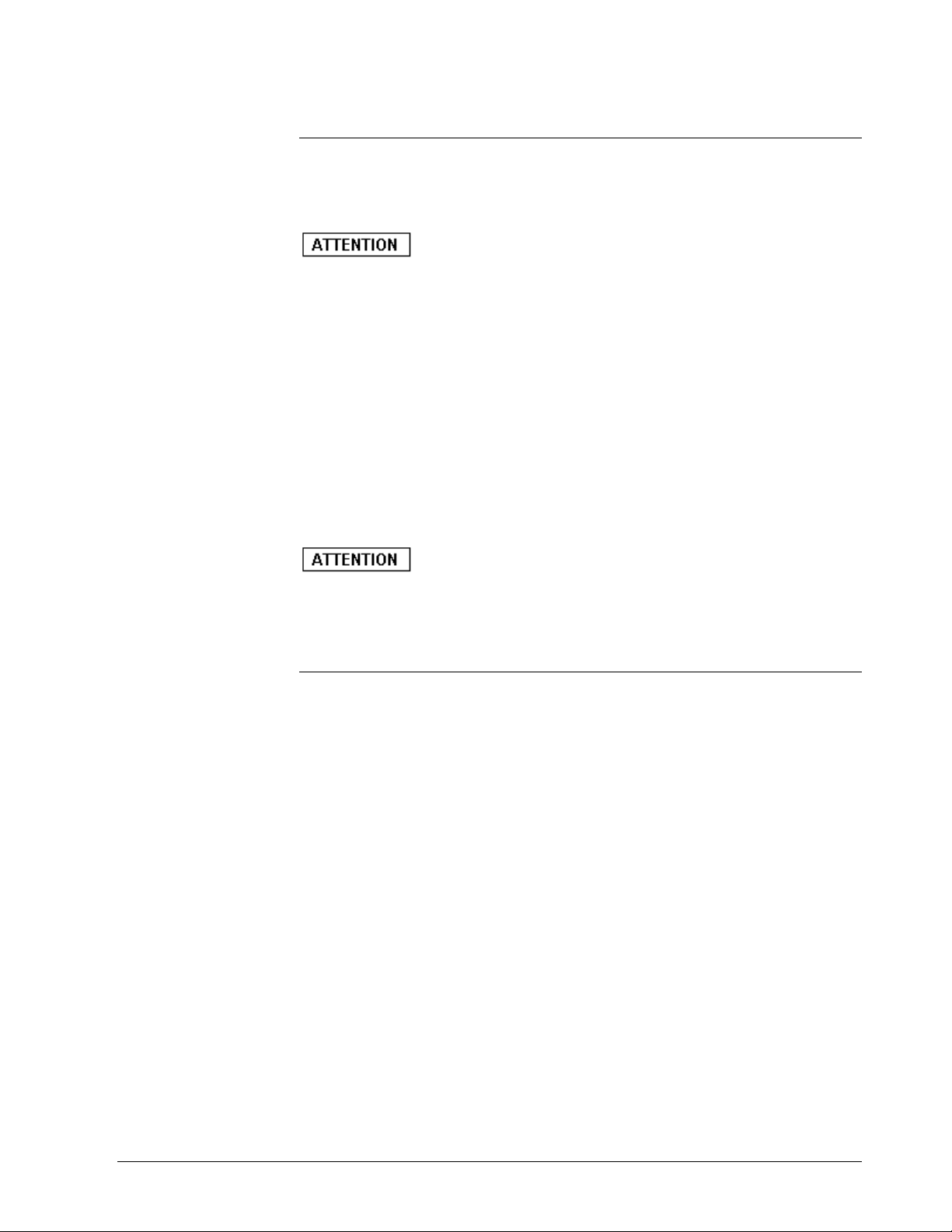

References

Publication

Title

620 WinLoader Overview LDR001 620 WinLoader 620-8983

620 WinLoader Implementation LDR003 620 WinLoader 620-8983

Publication

Number

Binder

Title

Binder

Number

620 WinLoader Programming

Reference

620 WinLoader Edit/Display Functions LDR005 620 WinLoader 620-8983

620 WinLoader Function Blocks LDR006 620 WinLoader 620-8983

620 WinLoader Documentation

Functions

620 WinLoader Networking Functions LDR008 620 WinLoader 620-8983

620 WinLoader Utility Functions LDR009 620 WinLoader 620-8983

620-6041 Terminal Emulator User

Manual

LDR004 620 WinLoader 620-8983

LDR007 620 WinLoader 620-8983

620-8989

4/05 620 WinLoader Installation vii

Page 53

Section 1 – WinLoader Installation Overview

1.1 Overview

Introduction

The WinLoader includes a powerful software program that combines

menu-driven procedures and on-line monitoring with integrated

programming and documentation. This ladder logic program lets you

define the discrete control functions for your control strategy through

relay ladder logic using familiar logic elements such as contacts, coils,

timers, counters, and various other logic elements.

Depending on the type of control strategy you have configured for your

application, the WinLoader software program may be provided by

Honeywell as part of either of the following control system platforms:

• 620-60 WinLoader — provides a user-supplied Windows-compatible

personal computer with the capability to program and monitor all 620

Logic Controller CPMs, and is available in the following two versions:

– 620-6020 WinLoader, which comes with an RS232/RS422 External

Converter Box to be installed through a PC's RS232 serial

communications port.

– more complete hardware descriptions,

– a list of compatible personal computers that can be used with each

version, and

– a description of the 620 WinLoader software that is provided.

• 620-6150A Loader/Terminal — an industrially-hardened laptop

computer capable of all WinLoader functions;

– 620-6150A Loader/Terminal is sold as a spare part.

– comes with an RS232/422 External Converter Box to be installed

through the 620-6150A Loader/Terminal's serial port.

The WinLoader software program is factory-installed on

the 620-6150A Loader/Terminal; if your system includes a 620-6150A

Loader/Terminal, you do not have to install any additional software.

Although version 5.4 (and greater) WinLoaders are shipped and is set for

point-to-point operation. This section is not supporting Multidrop feature

, therefore, presents information that pertains only for point-to-point

operation.

4/05 620 WinLoader Installation 1

Page 54

1.1 Overview, Continued

620-6020 WinLoader

hardware

620-6020 WinLoader hardware includes:

• 629-6019 External Converter Box —

– provides RS232/422 interface;

– must be installed through PC's serial communications port; and

– requires 5VDC, 250mA power supply.

• 10-foot Loader/Terminal cable (628-3000) —

– shielded cable that connects External Converter Box to

Loader/Terminal port on 620 CPM;

– if desired, you can also build your own custom length cable up to a

maximum length of 2000 feet (610m).

• 12-inch converter communications cable —

Continued on next page

620-60 WinLoadercompatible PCs

– provides communications between PC's serial port and 629-6019

External Converter Box.

• Power splitter cable —

– common connector plugs into PC's keyboard jack; and

– one end of split is connected to keyboard cable, other end to

converter box.

Refer to subsection 2.3 of this manual for information on

installing the RS232/422 External Converter Box.

The personal computer used to support the 620-6020 WinLoader

program must be 100% compatible with the Windows XP and 2K

operating systems

2 620 WinLoader Installation 4/05

Page 55

Section 2 – Hardware Installation and Configuration

2.1 Overview

Section contents

Overview ...................................................................................................... 3

2.1

2.2 629-6019 External Converter Box ............................................................... 4

2.3 Cabling to RS232 Serial Printers ............................................................... 13

Purpose of this

section

These are the topics covered in this section:

Topic See Page

This section presents procedures for:

• Installing the 629-6019 External Converter Box, which is provided

with the 620-6020 WinLoader and must be installed through a serial

communications port of the personal computer or the 620-6150A

Loader/Terminal;

• Installing cabling from the WinLoader to typical RS232 serial printers;

and

• Installing cabling to a Serial Link Selector in a redundant control

system.

4/05 620 WinLoader Installation 3

Page 56

2.2 629-6019 External Converter Box

Description

Figure 1

Rear View of 620-6150A Loader/Terminal

The 629-6019 External Converter Box converts an RS232 signal from a

PC to an RS485 signal compatible with a device on an RS485 network in

a 620 LC system. It is provided with the 620-6020 WinLoader and the

620-6150A Loader/Terminal and must be installed through a serial

communications port of your personal computer or the 620-6150A

Loader/Terminal; Figure 1 (below) provides a rear view of the 6206150A Loader/Terminal.

The External Converter Box is factory-configured for

communications operation between either the personal computer's or the

620-6150A Loader/Terminal's serial port and the Loader/Terminal port on

the CPM; no further settings are required or can be made to the hardware.

Continued on next page

4 620 WinLoader Installation 4/05

Page 57

2.3 629-6019 External Converter Box, Continued

Interface port for

629-6019 External

Converter Box

Figure 2 Cable Construction

The interface port on the 629-6019 External Converter Box is a 9-pin

female sub-D connector with a tin-plated shell and a latching mechanism.

The interface port has both transmit and receive capabilities along with

clear-to-send and request-to-send control, and is used to communicate

with 620 LCs using the 10-foot Loader/Terminal cable; however, you

may wish to extend this length by constructing a cable according to the

pin assignments specified in Figures 2 and 3. The 629-6019 External

Converter Box can operate at a maximum distance of 2000 feet (610m).

The interface port is essential for 620-6020 WinLoader

operation; 620-6020 WinLoader software will not communicate with a

620 LC unless an External Converter Box is installed in your personal

computer.

Continued on next page

4/05 620 WinLoader Installation 5

Page 58

2.3 629-6019 External Converter Box, Continued

Interface port for 6296019 External

Converter Box,

continued

Figure 3 629-6019 Converter Cable Pin Assignments

Continued on next page

6 620 WinLoader Installation 4/05

Page 59

2.3 629-6019 External Converter Box, Continued

Installing 629-6019

External Converter

Box

Perform the Table 1 procedure to install the 629-6019 External Converter

Box.

• If you are installing the External Converter Box on a personal

computer, consult the PC's users manual for any specific instructions

regarding connections to its serial ports.

• If you are connecting the external converter box to a 620-6150A

Loader/Terminal, refer to the 620-6150A Loader/Terminal User

Manual for additional information;

• Note that the installation procedure presented in Table 1 includes steps

which are generic in nature and can be applied to any personal

computer to which you are installing the External Converter Box.

Table 1 Installing 629-6019 External Converter Box

Step Action

Turn off the personal computer or 620-6150A Loader/Terminal,

1

remember to close any and all running applications programs, and

disconnect power cords from power source.

Install the 12-inch communications cable (shown in Figure 4) as

2

described below:

Step Action

2A Attach one end of communications cable to

external converter box port labelled "PC"

(see Figure 4).

2B Attach other end of communications cable to

serial port on PC or 620-6150A Loader/

Terminal –

– if connecting to a PC, use COM 1;

(your PC may also require using a

25-pin to 9-pin adapter);

– if connecting to a 620-6150A Loader/

Terminal, use COM 2.

4/05 620 WinLoader Installation 7

Page 60

2.3 629-6019 External Converter Box, Continued

Figure 4 Communications Cable Connections

8 620 WinLoader Installation 4/05

Page 61

2.3 629-6019 External Converter Box, Continued

Installing 629-6019

External Converter

Box, continued

Table 1 Installing 629-6019 External Converter Box, Continued

Step Action

Install the 10-foot Loader/Terminal cable as shown in Figure 5 and

3

as described below:

Step Action

3A Attach the cable's straight connector to the 9-pin

port labelled "620" on the external converter box

(see Figure 5);

3B Attach the angled connector of the cable to the

9-pin Loader/Terminal port on the CPM;

4/05 620 WinLoader Installation 9

Page 62

2.3 629-6019 External Converter Box, Continued

Figure 5 Loader/Terminal Cable Connections

10 620 WinLoader Installation 4/05

Page 63

2.3 629-6019 External Converter Box, Continued

Installing 629-6019

External Converter

Box, continued

Table 1 Installing 629-6019 External Converter Box, Continued

Step Action

Provide a power connection as appropriate:

4

• If your PC is not capable of supplying 5VDC at 650mA through its

keyboard jack, use a compatible external power supply (not

supplied by Honeywell) that has been fitted with a 5-pin female

standard DIN connector.

It is your responsibility to determine if your PC has

a compatible keyboard port with +5VDC on the appropriate pins

and if it is capable of supplying the 650mA necessary to operate

the 629-6019 converter.

• If your PC is capable of supplying 5VDC at 650mA through its

keyboard jack, use the power splitter cable as follows

(see Figure 6):

Step Action

4A Disconnect keyboard cable from PC.

4B Attach common power splitter cable to PC's

keyboard port.

4C Attach one of the split connectors to the

keyboard cable.

4D Attach other split connector to external

converter box port labelled "5VDC INPUT".

Reconnect power cords that were disconnected in step 1 of this

5

procedure.

To prevent the potentially damaging effects of

ground loop currents, ensure that the personal computer or 6206150A Loader/Terminal, and any connected devices (including the

620 LC system), are powered from a source that has a common

ground reference.

Continued on next page

4/05 620 WinLoader Installation 11

Page 64

2.3 629-6019 External Converter Box, Continued

Figure 6 Power Splitter Cable Connections

12 620 WinLoader Installation 4/05

Page 65

2.4 Cabling to RS232 Serial Printers

Installing cabling from

WinLoader to serial

printer

Figure 7 Cabling to RS232 Serial Printer Using 25-Pin Female Connector

Refer to Figures 7 and 8 for pin-outs that illustrate WinLoader cabling to

typical RS232 serial printers; the Figure 7 configuration uses a 25-pin

female connector; the Figure 8 configuration illustrates an IBM PC AT

parallel/serial adapter 9-pin female connector.

Figure 8 Cabling to RS232 Serial Printer Using Parallel/Serial Adapter 9-Pin Female Connector.

2.5 Cabling to Serial Link Selector in Redundant

Applications

Installing cabling to

Serial Link Selector in

a redundant control

system

Refer to Figure 9 for cable wiring to a Serial Link Selector (SLS) in a

redundant control system. The first cable wiring diagram (next page)

shows cable wiring from the 620-6150A Loader/Terminal to the 6219928 SLS; the second cable wiring diagram (next page) shows cable

wiring from a 620 LC to an SLS (required for redundant applications

only).

4/05 620 WinLoader Installation 13

Page 66

Figure 9 Recommended WinLoader Installation in a 620 Redundant Control System

14 620 WinLoader Installation 4/05

Page 67

2.5 Cabling to Serial Link Selector in Redundant

Applications,

Installing cabling to

Serial Link Selector in

a redundant control

system, continued

Figure 10 Recommended WinLoader Installation in a 620 Redundant Control System

Continued

4/05 620 WinLoader Installation 15

Page 68

16 620 WinLoader Installation 4/05

Page 69

Section 3 – Software Installation

3.1 Overview

Section contents

3.1 Overview .................................................................................................... 17

3.2 WinLoader Installation ............................................................................... 18

Purpose of this

section

These are the topics covered in this section:

Topic See Page

This section presents a procedure for installing the WinLoader software

program onto your personal computer. Note that the WinLoader is

already factory-installed on the 620-6150A Loader/Terminal; if your

system includes the 620-6150A Loader/Terminal, you do not have to

perform the installation procedure.

4/05 620 WinLoader Installation 17

Page 70

3.2 WinLoader Installation

Un-installing Winloader:

620 WinLoader

un-installation

Step Action

5.x installation provides you the option to uninstall any existing 5.x.

application. If you already have any 5.x application on your system, doubleclick the Win Loader installer. A confirmation screen is displayed as shown

below:

1

2

To uninstall click Yes. You can either choose to uninstall or not. If you do not

want to uninstall, click No and the installer exits without making any changes.

Click Yes to uninstall the application. A confirmation screen appears as shown

below:

Click Finish. The un-installation is completed successfully.

3

Alternately, you can also use the Windows Add/Remove program feature to

uninstall 5.x. If you uninstall, you can install the latest by referring the

installation procedure.

18 620 WinLoader Installation 4/05

Page 71

3.2 WinLoader Installation, Continued

Installing Win Loader

620 WinLoader

Installation

loader application. DO NOT use 4.x and 5.x on the same machine.

Follow this procedure to install WinLoader on your PC

Step Action

1

2

Insert the WinLoader CD in your PC.

Double-click the WinLoader Setup icon to display the 620 WinLoader Install

shield’s welcome screen.

5.x installation does NOT uninstall 4.x or earlier DOS based

3

Click Next to continue the installation.

4/05 620 WinLoader Installation 19

Page 72

3.2 WinLoader Installation, Continued

The Customer Information screen is displayed. Enter the User Name and

Company Name and click Next.

4

20 620 WinLoader Installation 4/05

Page 73

3.2 WinLoader Installation, Continued

5

The Choose Destination Location screen is displayed. Click Browse and

navigate to the folder where you want to store the application files.

6

7

Click Next to continue with the installation.

The Installation Wizard Complete screen is displayed on successful

installation.

4/05 620 WinLoader Installation 21

Page 74

3.2 WinLoader Installation, Continued

8

9

Select Launch readme file to install the release notes in the folder where you

have installed the WinLoader application.

Click Finish to complete the installation.

Click Cancel at any point during the installation if you

want to cancel the installation and exit the 620 Win Loader Install shield.

Click Back if you want to return to the previous screen at any point

during the installation.

22 620 WinLoader Installation 4/05

Page 75

Industrial Automation and Control

Honeywell, Inc.

1100 Virginia Drive

Fort Washington, Pennsylvania 19034

Page 76

V

620 WinLoader,

ersion 5.4,

User Manual

620-8983

Page 77

620 WinLoader

620 WinLoader

Implementation

LDR003

4/05

Page 78

Copyright, Notices, and Trademarks

Printed in U.S.A. – © Copyright 2005 by Honeywell Inc.

Revision 01 – April 01, 2005

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in

its written agreement with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special or consequential

damages. The information and specifications in this document are subject to

change without notice.

This document was prepared using Information Mapping® methodologies and

formatting principles.

IBM AT is a registered trademark of IBM Corporation.

Information Mapping is a trademark of Information Mapping, Inc.

Terminal Emulator is a registered trademark of Honeywell, Inc.

Honeywell

Industrial Automation and Control

Automation College

1100 Virginia Drive

Fort Washington, PA 19034

4/05 620 WinLoader Implementation ii

Page 79

About This Publication

This manual provides:

• Overall description of WinLoader Main Menu, to include individual

descriptions of Main Menu selections and descriptions of each

available function and sub-menu accessible from the Main Menu; and

• Overall description of WinLoader Main Screen Display, to include

procedure for entering Main Screen Display, and descriptions of

individual Main Screen Display components.

iii 620 WinLoader Implementation 4/05

Page 80

Table of Contents

SECTION 1 – WINLOADER IMPLEMENTATION OVERVIEW ........................................ 1

1.1 Overview ...................................................................................................... 1

1.2 WinLoader Start-up...................................................................................... 2

SECTION 2 – WINLOADER MAIN MENU......................................................................... 1

2.1 Overview ...................................................................................................... 1

2.2 620 Loader/Monitor...................................................................................... 4

2.3 620 Stand Alone Loader(F2) ..................................................................... 18

2.4 Documentation Functions (F3) .................................................................. 22

2.5 Password & Security Functions ................................................................. 25

2.6 I/O Configuration Utility (F5) ...................................................................... 29

2.7 623-60 Software Configuration (F6) .......................................................... 30

2.8 Terminal Emulator (F7) .............................................................................. 46

2.9 Utility Functions (F8) .................................................................................. 47

SECTION 3 – WINLOADER MAIN SCREEN DISPLAY ................................................. 51

3.1 Overview .................................................................................................... 51

3.2 Main Screen Display .................................................................................. 52

4/05 620 WinLoader Implementation iv

Page 81

Figures

Figure 2-1 623 WIN Loader Main Menu ........................................................................2

Figure 2-2 620 Selection Menu...................................................................................... 5

Figure 2-3 Accessing Processor Configuration Menu ................................................... 8

Figure 2-4 Accessing Multidrop Configuration Menu................................................... 11

Figure 2-5 Accessing I/O Configuration Menu............................................................. 13

Figure 2-6 I/O Slot Assignments for 620-3691 Processor Rack.................................. 15

Figure 2-7 I/O Slot Assignments for Processor Racks ............................................... 16

Figure 2-8 620 Selection Menu - Stand-Alone Mode(F1-F5) ...................................... 18

Figure 2-9 620 Selection Menu - Stand-Alone Mode(F5-F8) ...................................... 20

Figure 2-10 Documentation Functions Menu ............................................................. 23

Figure 2-11 Security Selection Menu .........................................................................25

Figure 2-12 623-60 Software Configuration Menu ..................................................... 30

Figure 2-13 Paths and Files Menu .............................................................................32

Figure 2-14 Operational Modes Menu........................................................................ 35

Figure 2-15 System Types and File Loads Menu....................................................... 38

Figure 2-17 Multidrop Node Names Menu .................................................................43

Figure 2-18 Load Configuration Example................................................................... 44

Figure 2-19 Save Configuration Example ..................................................................45

Figure 2-20 Exit ..........................................................................................................48

Figure 2-21 Typical WinLoader Help Screen .............................................................49

Figure 3-1 Typical Title Page Display .......................................................................... 55

Figure 3-2 Name Check...............................................................................................56

Figure 3-3 Loading Operation Messages ....................................................................57

Figure 3-4 Main Screen Display ..................................................................................58

Figure 3-5 Main Screen Display Banner...................................................................... 60

Figure 3-6 Main Screen Display Program Area........................................................... 61

Figure 3-7 9 x 5 x Ladder Logic Matrix ........................................................................ 62

Figure 3-8 Logic Group Selection Menu...................................................................... 64

Figure 3-9 Edit and Display Functions.........................................................................65

Figure 3-10 Program Area Integer Display................................................................. 66

Figure 3-11 Main Screen Display Status Line ............................................................ 67

v 620 WinLoader Implementation 4/05

Page 82

Tables

Table 1-1 Methods for Starting WinLoader .................................................................. 2

Table 1-2 Specifying Loader Configuration Filename.................................................. 5

Table 1-3 Entering Loader/Monitor Mode .................................................................... 6

Table 1-5 Entering Stand-Alone Mode......................................................................... 6

Table 2-1 WinLoader Main Menu Selections ............................................................... 3

Table 2-2 620 Selection Menu Selections ................................................................... 6

Table 2-3 Processor Configuration Menu Selections .................................................. 9

Table 2-4 Multidrop Configuration Menu Selections.................................................. 10

Table 2-5 I/O Configuration Menu Selections ............................................................ 14

Table 2-6 620 Selection Menu Selections – Stand-Alone Mode (F1-F5) .................. 19

Table 2-7 620 Selection Menu Selections – Stand-Alone Mode (F5-F8)........................ 21

Table 2-8 Documentation Functions Menu Selections .............................................. 24

Table 2-9 Accessing Password and Security Functions............................................ 26

Table 2-10 Changing the Password............................................................................. 27

Table 2-11 623-60 Software Configuration Menu Selections...................................... 31

Table 2-12 Paths and Files Menu Selections .............................................................. 33

Table 2-13 Operational Modes Menu Selections......................................................... 36

Table 2-14 System Type and File Loads Menu Selections ......................................... 39

Table 2-15 Stand-Alone Parameters Menu Selections................................................ 41

Table 2-16 623-60 Software Configuration Menu Selections...................................... 43

Table 3-1 Entering Main Screen Display Via [F1] 620 Loader/Monitor ..................... 53

Table 3-2 Entering Main Screen Display Via [F2] 620 Stand Alone Loader.............. 54

Table 3-3 Status Line Information .............................................................................. 68

Table 3-4 Periodic Statuses ....................................................................................... 71

4/05 620 WinLoader Implementation vi

Page 83

Acronyms

620 LC.................................................................................................. 620 Logic Controller

ABC ...............................................................................Asynchronous Byte Count Protocol

ANSI ......................................................................... American National Standards Institute

CAM .............................................................................................Controller Access Module

CGA................................................................................................. Color Graphics Adaptor

CIM...................................................................................Communication Interface Module

CPM ............................................................................................Control Processor Module

DOS.................................................................................................. Disk Operating System

EIM .............................................................................................. Ethernet Interface Module

EPROM ......................................................... Erasable Programmable Read-Only Memory

IAC................................................................................. Industrial Automation and Controls

IMS ................................................................................. Interprocessor Messaging Service

I/O...................................................................................................................... Input/Output

IRQ ............................................................................................................ Interrupt Request

KEYSW .................................................................................................................Keyswitch

LAN ....................................................................................................... Local Area Network

LC................................................................................................................ Logic Controller

MAS......................................................................................... Modular Automation System

MS ..........................................................................................................................MicroSoft

NOP................................................................................................................. No Operation

OEM .................................................................................Original Equipment Manufacturer

PRG......................................................................................................................... Program

RAM ............................................................................................. Random Access Memory

RTDM ................................................................ Resistance Temperature Detector Module

RTS ............................................................................................................Request-to-send

RTU ....................................................................................................Remote Terminal Unit

SIOM .........................................................................................................Serial I/O Module

SLM ......................................................................................................... Serial Link Module

STF............................................................................................................. Self-Test Failure

SPM................................................................................................Software Program Mode

UAIM ....................................................................................Universal Analog Input Module

UMS .................................................................................................. User Memory Session

vii 620 WinLoader Implementation 4/05

Page 84

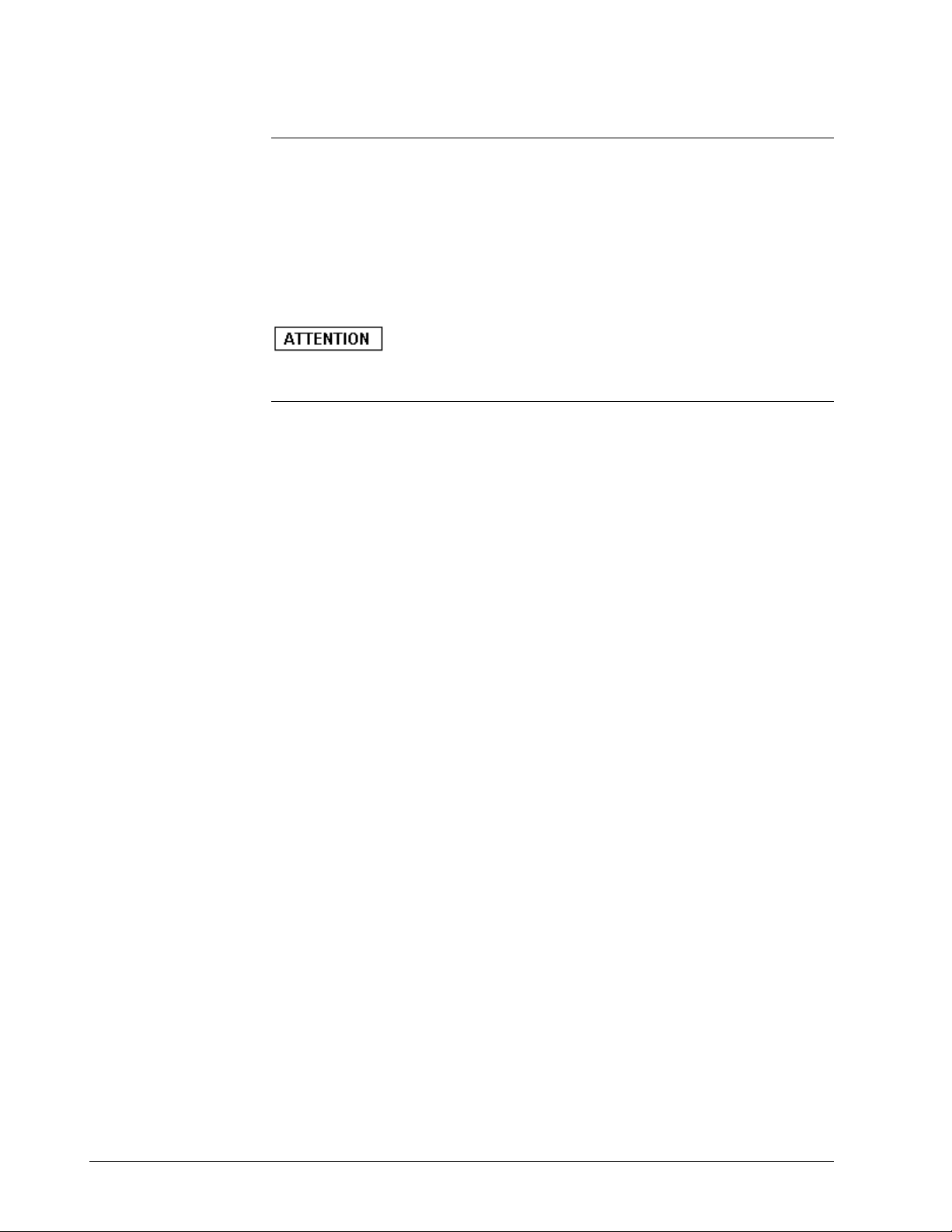

References

Publication

Title

Publication

Number

Binder

Title

Binder

Number

620-0048 & 620-0052 Data Collection

Modules User Manual

620-12/1633/36 Logic Controller User

Manual

621-0020R Universal Analog Input

Module and 620-0020 Configuration

Utility User Manual

621-0025R Resistance Temperature

Detector Module and 620-0025

Configuration Utility Manual

620 WinLoader Overview LDR001 620 WinLoader 620-8983

620 WinLoader Installation LDR002 620 WinLoader 620-8983

620 WinLoader Programming

Reference

620 WinLoader Edit & Display

Functions

620 WinLoader Function Blocks LDR006 620 WinLoader 620-8983

620 WinLoader Documentation

Functions

620-8980 620 LC & S9000 Reference MAS 8990

620-8964 620 Logic Controller MAS 8991

621-8989 620 LC & S9000 Reference MAS 8990

621-8985 620 LC & S9000 Reference MAS 8990

LDR004 620 WinLoader 620-8983

LDR005 620 WinLoader 620-8983

LDR007 620 WinLoader 620-8983

620 WinLoader Networking Functions LDR008 620 WinLoader 620-8983

620 WinLoader Utility Functions LDR009 620 WinLoader 620-8983

620-6041 620-8989

4/05 620 WinLoader Implementation viii

Page 85

Section 1 – WinLoader Implementation Overview

1.1 Overview

Section contents

1.1 Overview ...................................................................................................... 1

1.2 WinLoader Start-up...................................................................................... 2

Purpose of this

section

These are the topics covered in this section:

Topic See Page

This section describes how to start-up the Winloader Loader from

prompt. Note that the procedures presented in this section assume that

the 620 WinLoader software program has been previously installed on

your PC. For information on how to install the 620 WinLoader software

program, refer to 620 WinLoader Installation (LDR002).

4/05 620 WinLoader Implementation 1

Page 86

1.2 WinLoader Start-up

Starting up

WinLoader

from DOS prompt

Refer to Table 1-1 for the three methods that can be used to start-up the

WinLoader. Note that each of the three methods is performed after

changing the current path to the one where the

WinLoader software is located (refer to Table 1-2, 1-3, 1-4, or 1-5, as

appropriate, for respective procedure).

Table 1-1 Methods for Starting WinLoader

Start-up

Method

Method 1 Select Program>

620Winloader>Loader.exe To

execute the loader program.

Description

Refer to:

Continued on next page

2 620 WinLoader Implementation 4/05

Page 87

1.2 WinLoader Start-up, Continued

Executing Loader

program

Click the WinLoader icon or navigate to the folder where you have

installed the 620 WinLoader and select the Loader.exe file.

4/05 620 WinLoader Implementation 3

Page 88

1.2 WinLoader Start-up, Continued

Figure 1-1 WinLoader's Proprietary Information Screen

Figure 1-2 620 WinLoader Main Menu

Continued on next page

4 620 WinLoader Implementation 4/05

Page 89

1.2 WinLoader Start-up, Continued

Specifying Loader

configuration

filename upon startup

The ability to specify the configuration filename when starting the

WinLoader program enables you to change the environment in which the

software operates in order to accommodate multiple projects or other

functional variations of the program.

Perform the Table 1-2 procedure to specify a Loader configuration

filename.

Table 1-2 Specifying Loader Configuration Filename Upon Start-up

Step Action

1 Execute the LOADER.EXE the software loads into PC's main

memory and begins executing by displaying proprietary information

screen (see Figure 1-1).

2 Press [ENTER] (after reading) to acknowledge and clear display.

Continued on next page

4/05 620 WinLoader Implementation 5

Page 90

1.2 WinLoader Start-up, Continued

Specifying Loader

mode of operation

upon start-up

Specifying the appropriate parameter upon start-up allows the

WinLoader to automatically enter either Loader/Monitor or Stand-Alone

mode.

• Refer to subsection 2.2 for description of Loader/Monitor mode and to

subsection 2.3 for description of Stand-Alone mode.

• By using Table 1-4 or 1-5 procedure –

– you may reduce number of keystrokes necessary to begin monitoring

or editing ladder logic program and can specify working

environment for those operations;