Honda Power Equipment WMP20X User Manual

This owner’s manual is considered a permanent part of the

pump. It must be available to all operators of the pump and

should remain with the pump if resold.

The information and specifications in this publication are

based on the latest product information available at the time

of printing. American Honda Motor Co., Inc. reserves the

right to make changes at any time without notice and without

incurring any obligation. No part of this publication may be

reproduced without written permission.

It is illegal in some areas to operate an engine without a

U.S.D.A. qualified spark arrester; check local laws and

regulations. An optional spark arrester for this pump is

available from your authorized Honda water pump dealer.

@American Honda Motor Co., Inc.

I

Congratulations on your selection of the Honda WMP20X

multi-purpose pump. We are certain you will be pleased with

your purchase.

You can enhance the perfomance of your new pump by

taking time to study this manual. In it you’ll learn how to use

it safely and efficiently. The service interval and maintenance

recommendations in this manual were developed to provide

you with the optimum performance and service from your

pump. We suggest you follow them.

When your pump needs scheduled maintenance, keep in

mind that your Honda water pump dealer is specially trained

in servicing Honda pumps and is supported by the parts and

service divisions of American Honda. Your Honda dealer is

dedicated to your satisfaction and will be pleased to answer

your questions and concerns.

Please take the time to read the warranty policy to fully

understand its coverage and your responsibilities of

ownership. The warranty policy is a separate document that

should have been given to you by your dealer.

When you contact your Honda water pump dealer about

your multi-purpose pump, they will need to know the engine

and frame serial numbers. Write those numbers in the space

below for future reference (see page 6 for engine and frame

serial number location).

Best wishes,

Power Equipment Division

American Honda Motor Co., Inc.

Engine serial number

Frame serial number

II

Safety Messages

Your safety and the safety of others is very important. We

have provided important safety messages in this manual and

on the pump. Please read these messages carefully.

A safety message alerts you to potential hazards that could

hurt you or others. Each safety message is preceded by a

safety alert symbol A and one of three words: DANGER,

WARNING, or CAUTION.

You WILL be KILLED or SERIOUSLY

HURT if you don’t follow instructions.

You CAN be KILLED or SERIOUSLY

HURT if you don’t follow instructions.

You CAN be HURT if you don’t follow

instructions.

Each message tells you what the hazard is, what can

happen, and what you can do to avoid or reduce injury.

Damage Prevention Messages

You will also see other important messages that are

preceded by the word NOTICE.

This word means:

pEiEq

The purpose of these messages is to help prevent damage

to your pump, other property, or the environment.

Your pump or other property could be

damaged if you don’t follow instructions.

Ill

CONTENTS

Turn to the beginning of each section for a complete list

of subjects.

WATER PUMP SAFETY 1

Important information about some specific hazards,

and what you can do to prevent injury.

CONTROLS

lden tifica tion of components and information about

how the controls work.

PRE-OPERATION CHECK

How to fuel and check your pump to be sure it is

ready.

OPERATION

Preparing the pump, starting and stopping the

engine, and pumping tips.

MAINTENANCE

When and how to perform routine inspections and

service to keep your pump in good condition.

TRANSPORTING/STORAGE

How to safe/y transport and store your pump.

TROUBLESHOOTING

How to troubleshoot the engine if it won’t start or

when the pump will not perform properly.

SPECIFICATIONS

This section provides you with dimensions,

capacities, and other technical information.

5

9

17

25

35

41

45

ADDITIONAL INFORMATION

This section gives you sources for more information

about your pump.

INDEX

IV

49

53

PUMP SAFETY

This section explains what you need to know to operate

your multi-purpose pump safely.

Safety Information

Safety Label Locations

2

4

1

PUMP SAFETY

SAFETY INFORMATION

Your Honda multi-purpose pump is designed to give safe

and dependable service if operated according to instructions.

Read and understand this owner’s manual before operating

your pump. You can help prevent accidents by being familiar

with your pump’s controls, and by observing safe operating

procedures

Operator Responsibility

Know how to stop the pump quickly in case of emergency.

Understand the use of all controls and connections.

Be sure that anyone who operates the pump receives proper

instruction. Do not let children operate the pump without

parental supervision. Keep pets away from the area of

operation.

Pump Operation

Never pump flammable liquids such as gasoline or fuel oils.

An explosion may result causing serious injury.

Pump only those chemicals listed on pages 20 and 21 of

this manual.

Operate the pump on level surface. If the engine is tilted, fuel

may spill.

Prime the pump before operation. Operating the pump dry

will cause seal damage.

Do not enclose the pump in any structure.

The exhaust system gets hot enough to ignite some

materials. Keep the pump at least 1 meter (3 feet) away from

buildings and other equipment during operation.

Carbon Monoxide Hazards

Exhaust contains poisonous carbon monoxide, a colorless

and odorless gas. Breathing exhaust can cause loss of

consciousness and may lead to death.

If you run the pump in an area that is confined, or even

partially enclosed, the air you breathe could contain

dangerous amounts of exhaust gas. To keep exhaust gas

from building up, provide adequate ventilation.

2

PUMP SAFETY

REFUEL WITH CARE

Gasoline is extremely flammable and gasoline vapor can

explode. Refuel only outdoors, in a well-ventilated area with

the engine stopped. Never smoke near gasoline, and keep

other flames and sparks away. Always store gasoline in an

approved container.

3

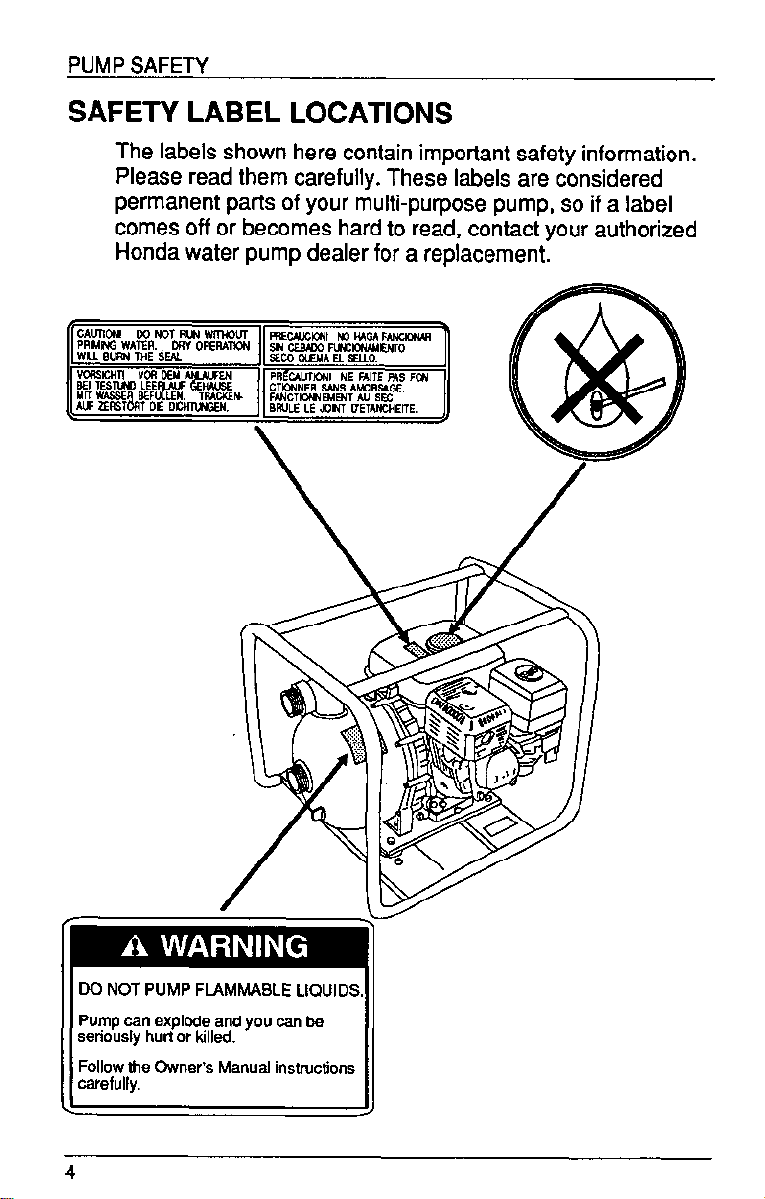

PUMP SAFETY

SAFETY LABEL LOCATIONS

The labels shown here contain important safety information.

Please read them carefully. These labels are considered

permanent parts of your multi-purpose pump, so if a label

comes off or becomes hard to read, contact your authorized

Honda water pump dealer for a replacement.

CONTROLS

This section shows you where controls are located and

tells you what they do and how they work.

CONTROLS

Component Identification

Controls

Throttle lever

Choke lever

Fuel valve

Ignition switch

Oil Alert system

Recoil starter

................. 7

..................

...................

................. 8

................ 8

................. 8

6

7

7

7

5

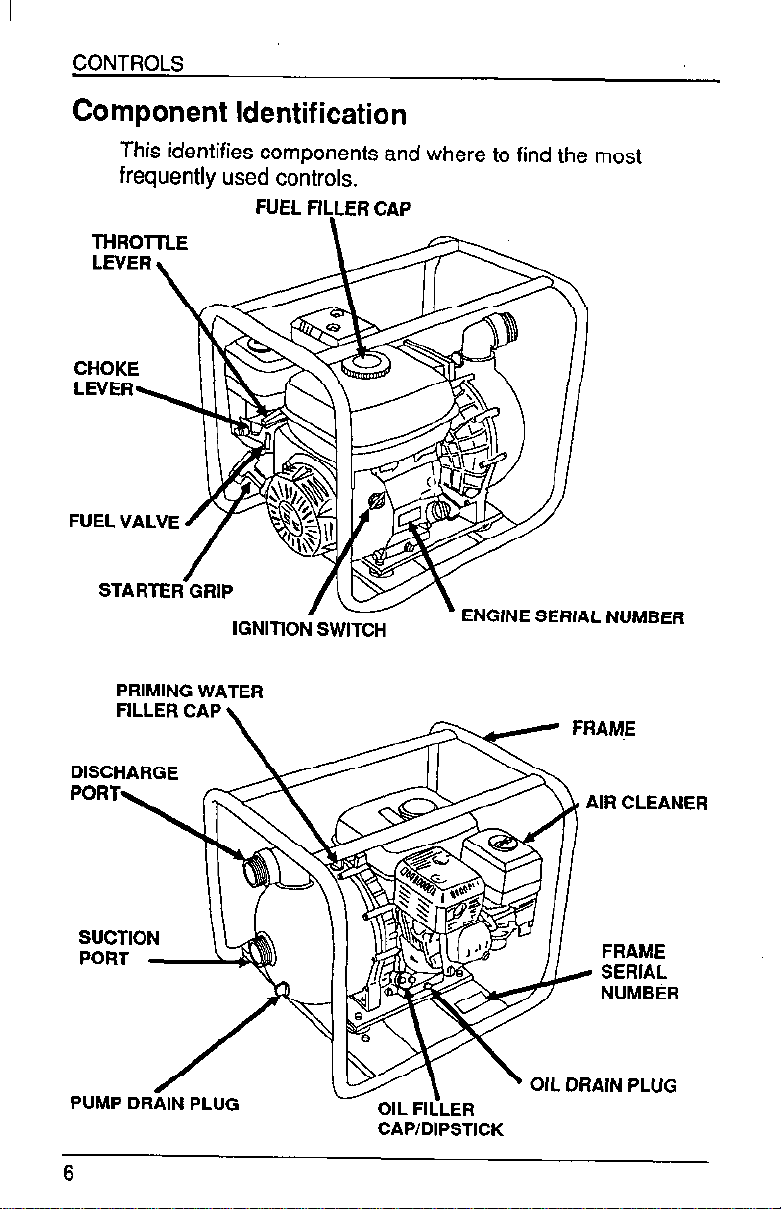

CONTROLS

Component Identification

This identifies components and where to find the most

frequently used controls.

FUEL FILLER CAP

FUEL VALVE

STARTER GRIP

rnlMINQ WA I Cll

DISCHARGE

POR~~~~~~LEANER

1

/-

IGNITIOiiWITCH

- ENGINE SERIAL NUMBER

FRAME

SERIAL

NUMBER

OIL DRAIN PLUG

CAP/DIPSTICK

6

Controls

You will use these controls every time you operate your

multi-purpose pump.

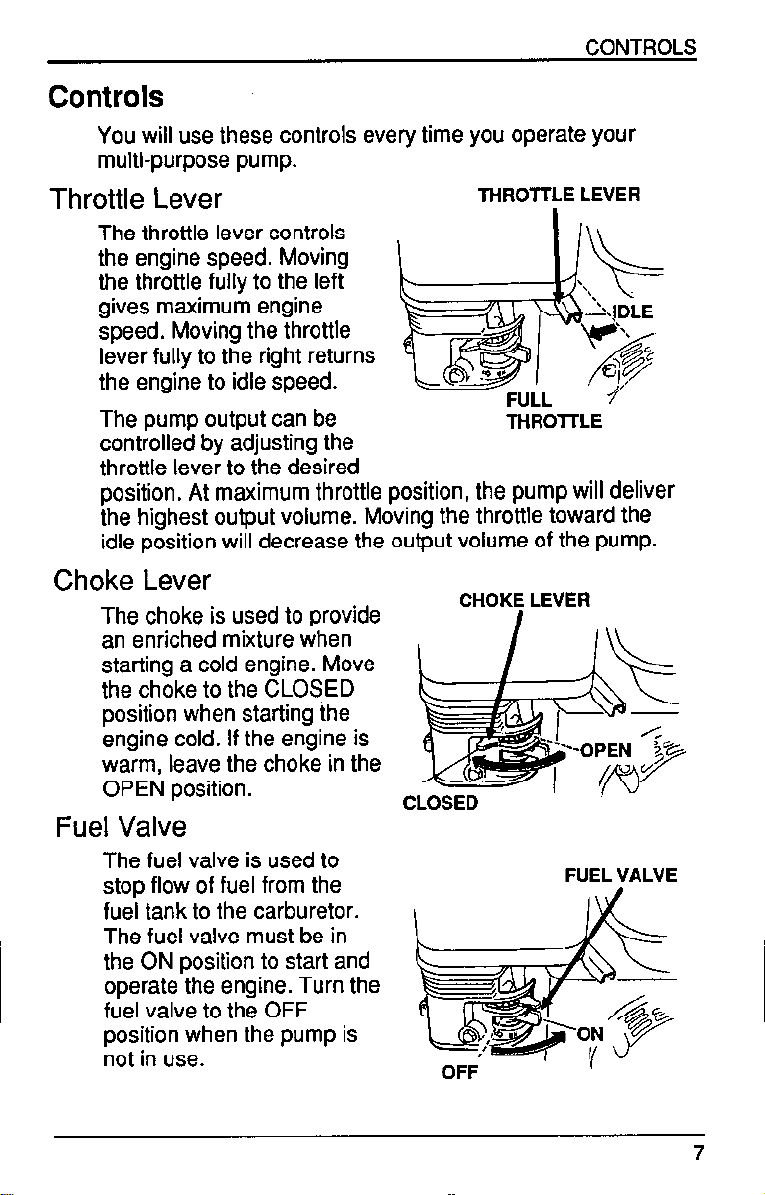

Throttle Lever

The throttle lever controls

the engine speed. Moving

the throttle fully to the left

gives maximum engine

speed. Moving the throttle

lever fully to the right returns

the engine to idle speed.

THRO’ITLE LEVER

CONTROLS

I

The pump output can be

THROlTLE

controlled by adjusting the

throttle lever to the desired

position. At maximum throttle position, the pump will deliver

the highest output volume. Moving the throttle toward the

idle position will decrease the output volume of the pump.

Choke Lever

The choke is used to provide

an enriched mixture when

starting a cold engine. Move

the choke to the CLOSED

position when starting the

engine cold. If the engine is

warm, leave the choke in the

OPEN position.

CHoK: LEVER

CLOSED

Fuel Valve

The fuel valve is used to

stop flow of fuel from the

fuel tank to the carburetor.

The fuel valve must be in

the ON position to start and

operate the engine. Turn the

fuel valve to the OFF

position when the pump is

not in use.

OFF

FUEL VALVE

’

7

CONTROLS

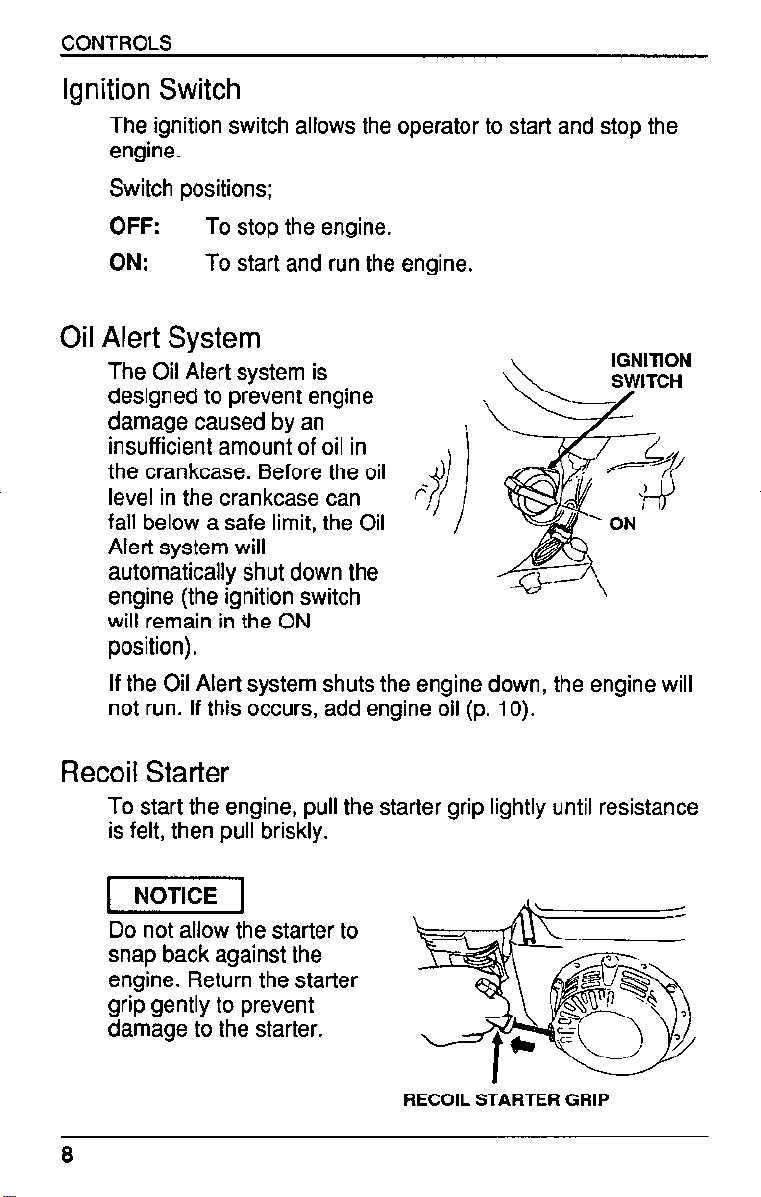

Ignition Switch

The ignition switch allows the operator to start and stop the

engine.

Switch positions;

OFF: To stop the engine.

ON: To start and run the engine.

Oil

Alert System

The Oil Alert system is

designed to prevent engine

damage caused by an

insufficient amount of oil in

the crankcase. Before the oil

level in the crankcase can

fall below a safe limit, the Oil

Alert system will

automatically shut down the

engine (the ignition switch

will remain in the ON

position).

If the Oil Alert system shuts the engine down, the engine will

not run. If this occurs, add engine oil (p. 10).

Recoil Starter

To start the engine, pull the starter grip lightly until resistance

is felt, then pull briskly.

piGiq

Do not allow the starter to

snap back against the

engine. Return the starter

grip gently to prevent

damage to the starter.

RECOIL STARTER GRIP

8

PRE-OPERATION CHECKS

PRE-OPERATION CHECKS

This section shows you how to check and prepare your

pump for operation.

Engine oil

Fuel

Refueling . . . . . . . . . . . . . . . . . . . . . 12

Fuel recommendations . . . . . . . . . . . . . . 73

Oxygenated fuels . . . . . . . . . . . . . . . . . 14

Air cleaner

High elevation operation

10

12

15

16

9

PRE-OPERATION CHECKS

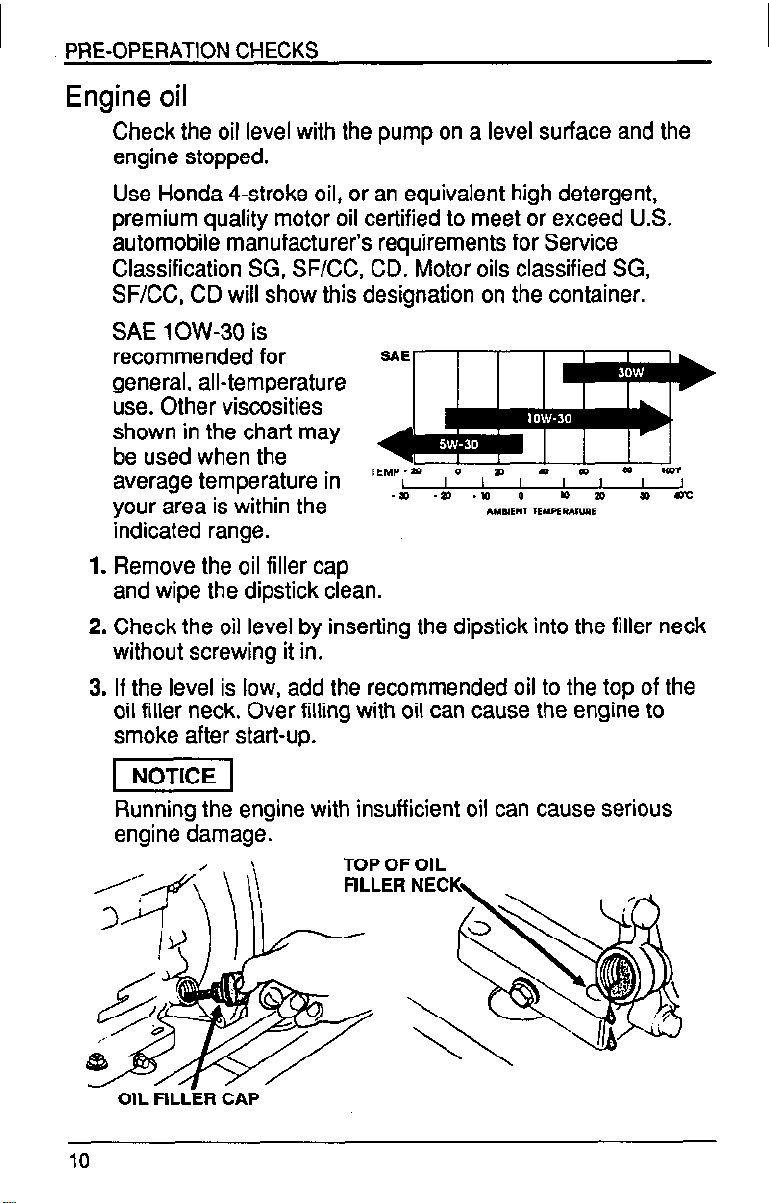

Engine oil

Check the oil level with the pump on a level surface and the

engine stopped.

Use Honda 4-stroke oil, or an equivalent high detergent,

premium quality motor oil certified to meet or exceed U.S.

automobile manufacturer’s requirements for Service

Classification SG, SF/CC, CD. Motor oils classified SG,

SF/CC, CD will show this designation on the container.

SAE low-30 is

recommended for

general, all-temperature

use. Other viscosities

shown in the chart may

be used when the

average temperature in

your area is within the

indicated range.

1. Remove the oil filler cap

and wipe the dipstick clean.

2. Check the oil level by inserting the dipstick into the filler neck

without screwing it in.

SAE

3. If the level is low, add the recommended oil to the top of the

oil filler neck. Over filling with oil can cause the engine to

smoke after start-up.

piE?iEq

Running the engine with insufficient oil can cause serious

engine damage.

TOP OF OIL

OIL FILLER CAP

10

PRE-OPERATION CHECKS

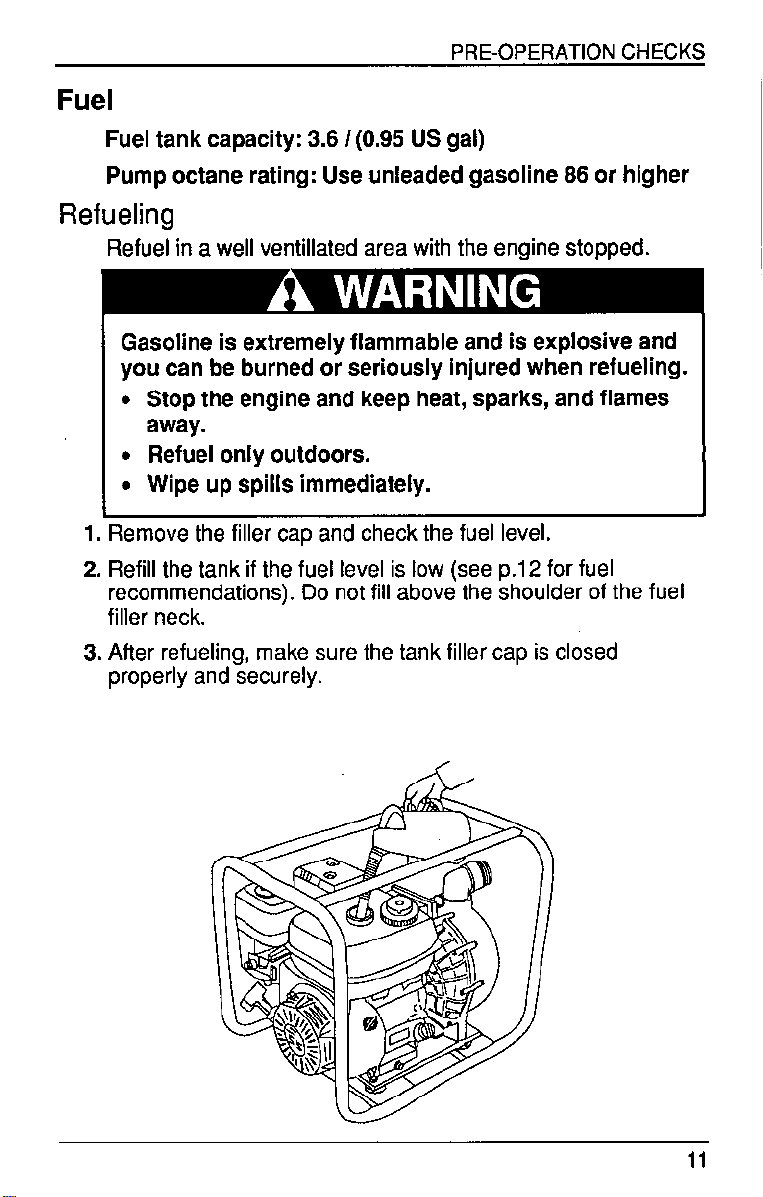

Fuel

Fuel tank capacity: 3.6 I(0.95 US gal)

Pump octane rating: Use unleaded gasoline 86 or higher

Refueling

Refuel in a well ventillated area with the engine stopped.

Gasoline is extremely flammable and is explosive and

you can be burned or seriously injured when refueling.

l Stop the engine and keep heat, sparks, and flames

away.

l Refuel only outdoors.

l Wipe up spills immediately.

1. Remove the filler cap and check the fuel level.

2. Refill the tank if the fuel level is low (see p.12 for fuel

recommendations). Do not fill above the shoulder of the fuel

filler neck.

3. After refueling, make sure the tank filler cap is closed

properly and securely.

11

PRE-OPERATION CHECKS

Fuel Recommendation

We recommend unleaded gasoline because it produces

fewer engine and spark plug deposits and extends exhaust

system life.

Never use stale or contaminated gasoline or oil/gasoline

mixture. Avoid getting dirt or water in the fuel tank.

Occasionally you may hear light “spark knock” or “pinging”

(metallic rapping noise) while operating under heavy loads.

This is no cause for concern.

If spark knock or pinging occurs at a steady engine speed,

under normal load, change brands of gasoline. If spark

knock or pinging persists, see an authorized Honda water

pump dealer.

p?Eiq

Running the engine with persistent spark knock or pinging

can cause engine damage.

Running the engine with persistent spark knock or pinging is

misuse, and the Distributor’s Limited Warranty does not

cover parts damaged by misuse.

12

PRE-OPERATION CHECKS

Oxygenated Fuels

Some gasolines are blended with alcohol or an ether

compound. These gasolines are collectively referred to as

oxygenated fuels. To meet clean air standards, some areas

of the United States and Canada use oxygenated fuels to

help.

If you use an oxygenated fuel, be sure its pump octane

rating is 86 or higher.

Before using an oxygenated fuel, try to confirm the fuel’s

contents. Some states/provinces require this information to

be posted on the pump.

The following are the EPA approved percentages of

oxygenates:

l Ethanol (ethyl or grain alcohol) 10% by Volume

You may use gasoline containing up to 10% ethanol by

volume. Gasoline containing ethanol may be marketed

under the name “Gasohol”.

l MTBE (methyl tertiary butyl ether) 15% by Volume

You may use gasoline containing up to 15% MTBE by

volume.

l Methanol (methyl or wood alcohol) 5% by Volume

You may use gasoline containing up to 5% methanol by

volume as long as it contains cosolvents and corrosion

inhibitors to protect the fuel system. Gasoline containing

more than 5% methanol by volume may cause starting

and/or performance problems. It may also damage

metal, rubber and plastic parts of your fuel system.

If you notice any undesirable operating symptoms, try

another service station or switch to another brand of

gasoline.

Fuel system damage or performance problems resulting

from the use of an oxygenated fuel containing more than the

percentages of oxygenates mentioned are not covered

under warranty.

13

PRE-OPERATION CHECKS

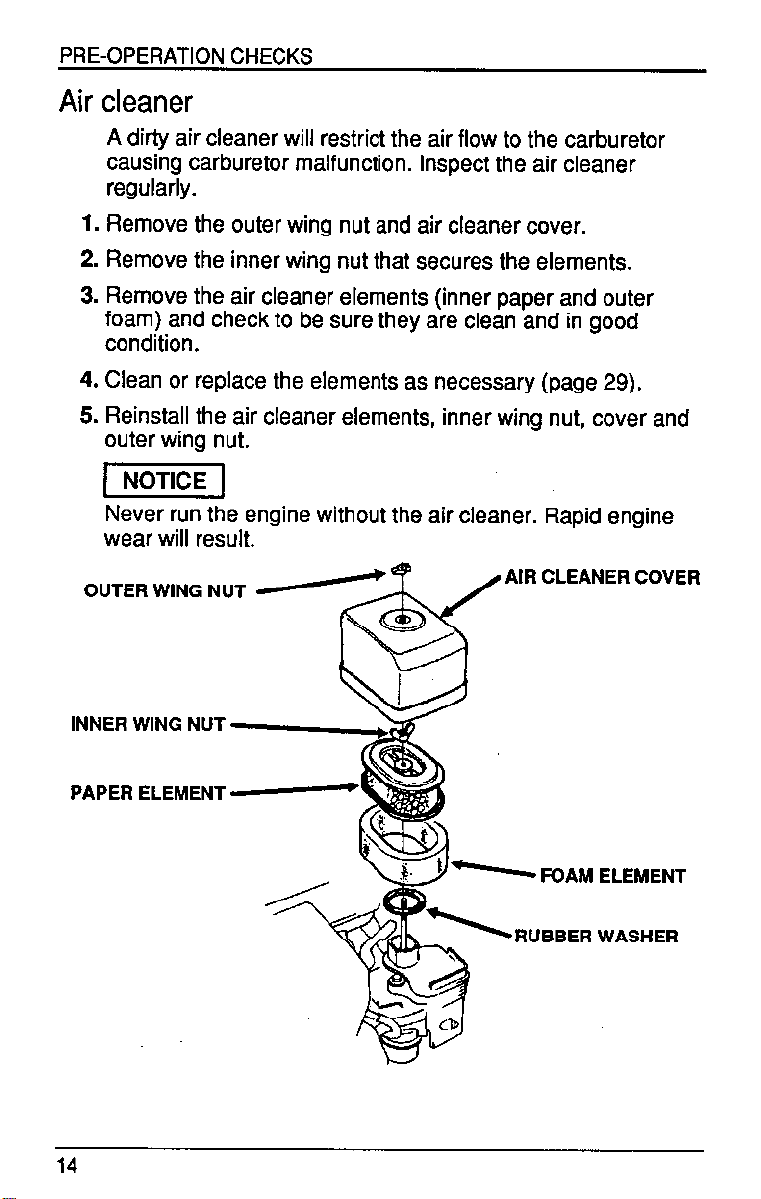

Air cleaner

A dirty air cleaner will restrict the air flow to the carburetor

causing carburetor malfunction. Inspect the air cleaner

regularly.

1. Remove the outer wing nut and air cleaner cover.

2. Remove the inner wing nut that secures the elements.

3. Remove the air cleaner elements (inner paper and outer

foam) and check to be sure they are clean and in good

condition.

4. Clean or replace the elements as necessary (page 29).

5. Reinstall the air cleaner elements, inner wing nut, cover and

outer wing nut.

jl

Never run the engine without the air cleaner. Rapid engine

wear will result.

OUTER WING NUT

INNER WING NUT

PAPER ELEMENT

AIR CLEANER COVER

- FOAM ELEMENT

RUBBER WASHER

14

Loading...

Loading...