Honda Power Equipment WD20X User Manual

Thank you for purchasing a Honda water pump. We want to help you get

the best results from your new water pump and to operate it safely. This

manual contains the information on how to do that; please read it carefully.

This manual covers the operation and maintenance of Honda water pump:

W D20X/W D30X

All information in this publication is based on the latest product

information available at the time of printing. Honda Motor Co., Ltd.

reserves the right to make changes at any time without notice and

without incurring any obligation. No part of this publication may be

reproduced without written permission.

This manual should be considered a permanent part of the water pump

and should remain with it if it is resold.

Safety Messages

Your safety and the safety of others is very important. We have provided

important safety messages in this manual and on the water pump. Please

read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or

others. Each safety message is preceded by a safety alert symbol

A and one of three words: DANGER, WARNING, or CAUTION.

m

instructions.

B You CAN be KILLED or SERIOUSLY HURT if you don’t

follow instructions.

You WILL be KILLED or SERIOUSLY HURT if you don’t follow

- You CAN be HURT if you don’t follow instructions.

Each message tells you what the hazard is, what can happen, and what

you can do to avoid or reduce injury.

Damage Prevention Messages

You will also see other important messages that are preceded by the word

NOTICE.

This word means:

( NOTICE 1

don’t follow instructions.

The purpose of these messages is to help prevent damage to your water

pump, other property, or the environment.

It is illegal in some areas to operate an engine without a U.S.D.A. qualified

spark arrester: Check local laws and regulations. An optional spark

arrester for this water pump is available from your authorized Honda

water pump dealer.

Your water pump or other property could be damaged if you

1

CONTENTS

1. WATER PUMP SAFETY

2. COMPONENT IDENTIFICATION..

3. PRE-OPERATION CHECK ............................................................................

4. STARTING THE

5. OPERATION

0 High altitude operation ..........................................................................

6. STOPPING THE

7. MAINTENANCE

8. TRANSPORTING/STORAGE..

9. TROUBLESHOOTING..

10. SPECIFICATIONS..

11. CUSTOMER SERVICE

12. INDEX

..........................................................................................................

ENGINE ..........................................................................

................................................................................................

ENGINE ............................................................................

.........................................................................................

..............................................................................

...............................................................

..................................................................

..............................................................................

....................................................................................

INFORMATION.. .................................................

3

.5

6

.l 1

13

14

15

.16

.22

.25

.27

.29

30

2

I. WATER PUMP SAFETY

To ensure safe operation -

l For safety, never pump flammable or corrosive liquids such as gasoline

or acid. Also, to avoid pump corrosion, never pump sea water, muddy

water, chemical solutions, or caustic liquids such as used oil, wine, or

milk.

l Operate the pump on a level surface. If the engine is tilted, fuel spillage

may result.

l ?o prevent fire hazards and to provide adequate ventilation, keep the

pump at least 1 meter (3 feet) away from building walls and other

equipment during operation. Do not place flammable objects close to

the pump.

l Do not allow children to operate the pump. Keep children and pets

away from the area of operation.

l Know how to stop the pump quickly, and understand the operation of

all controls. Never permit anyone to operate the pump without proper

instructions.

l Gasoline is extremely flammable and is explosive under certain

conditions.

- Refuel in a well-ventilated area with the engine stopped. Do not

smoke or allow flames or sparks in the area where the engine is

refueled or where gasoline is stored.

- Do not overfill the fuel tank1 there should be no fuel in the filler neck 1.

After refueling, make sure the tank cap is closed properly and

securely.

l Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor may

ignite. If any fuel is spilled, make sure the area is dry before starting the

engine.

l Never run the engine in an enclosed or confined area. Exhaust gas

contains poisonous carbon monoxide gas; exposure can cause loss of

consciousness and may lead to death.

l The muffler becomes very hot during operation and remains hot for a

while after stopping the engine. Be careful not to touch the muffler

while it is hot. Let the engine cool before storing the pump indoors.

l A spark arrester is available as an optional part for this pump. It is illegal

in some areas to operate an engine without a spark arrester. Check

local laws and regulations before operating.

l Exhaust gas contains poisonous carbon monoxide. Avoid inhalation of

exhaust gas. Never run the pump in a closed garage or confined area.

3

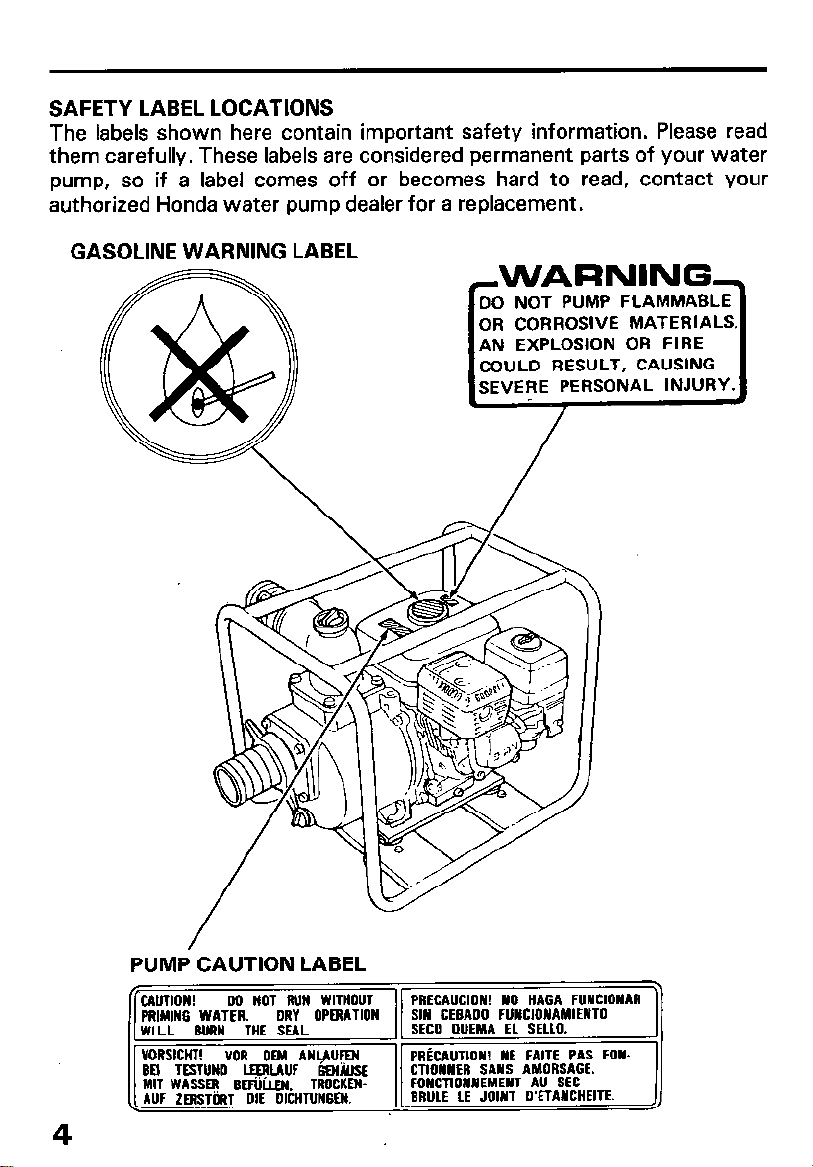

SAFETY LABEL LOCATIONS

The labels shown here contain important safety information. Please read

them carefully. These labels are considered permanent parts of your water

pump, so if a label comes off or becomes hard to read, contact your

authorized Honda water pump dealer for a replacement.

GASOLINE WARNING LABEL

NOT PUMP FLAMMABLE

PUMP CAUTION LABEL

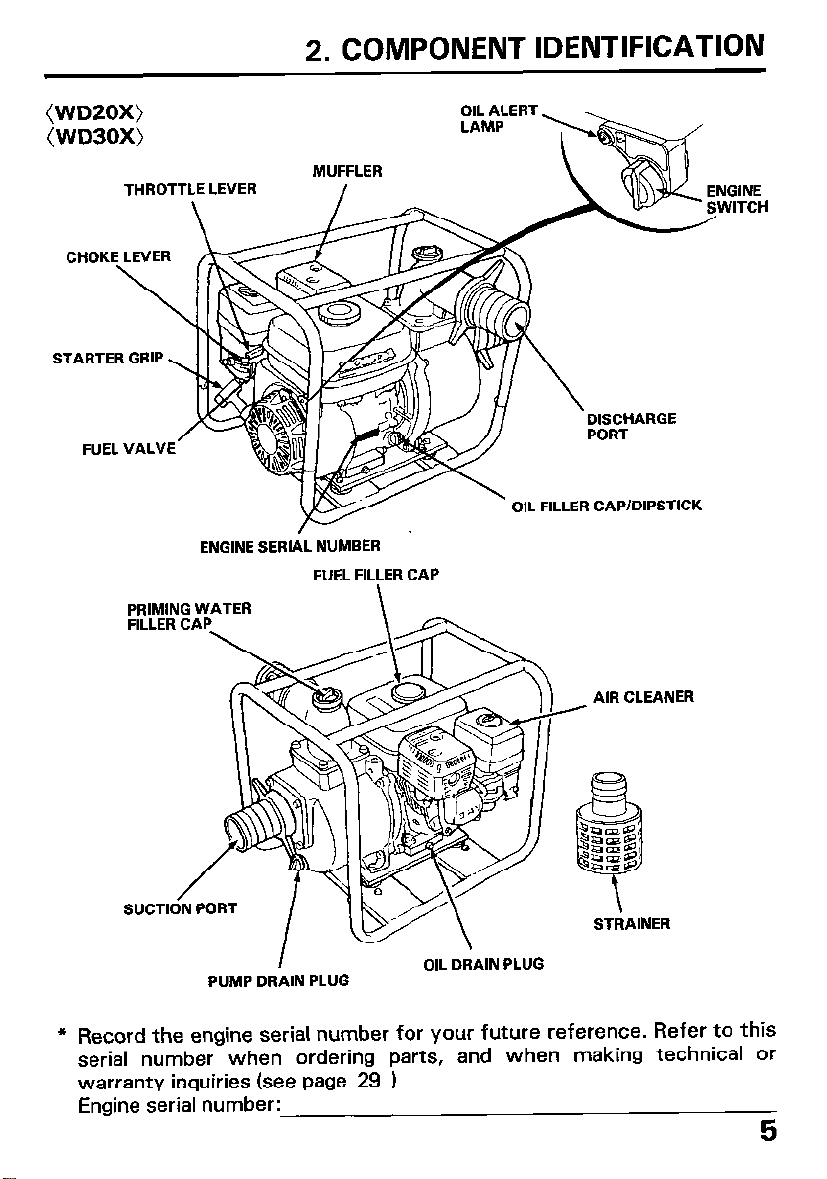

(WDZOX)

(WD30X)

THROTTLE LEVER

CHOKE LEVER

\

STARTER GRIP \

2. COMPONENT IDENTIFICATION

MUFFLER

/

ENGINE

2WlTCH

FUEL VALVE’

PRIMIN

w

ENGINE SERIAL NUMBER

FUEL FILLER CAP

IG WATER

I

PUMP DRAIN PLUG

OIL FILLER CAP/DIPSTICK

.

\

AIR CLEANER

STRAINER

OIL DRAIN PLUG

* Record the engine serial number for your future reference. Refer to this

serial number when ordering parts, and when making technical or

warranty inquiries (see page 29 1

Engine serial number:

5

3. PRE-OPERATION CHECK

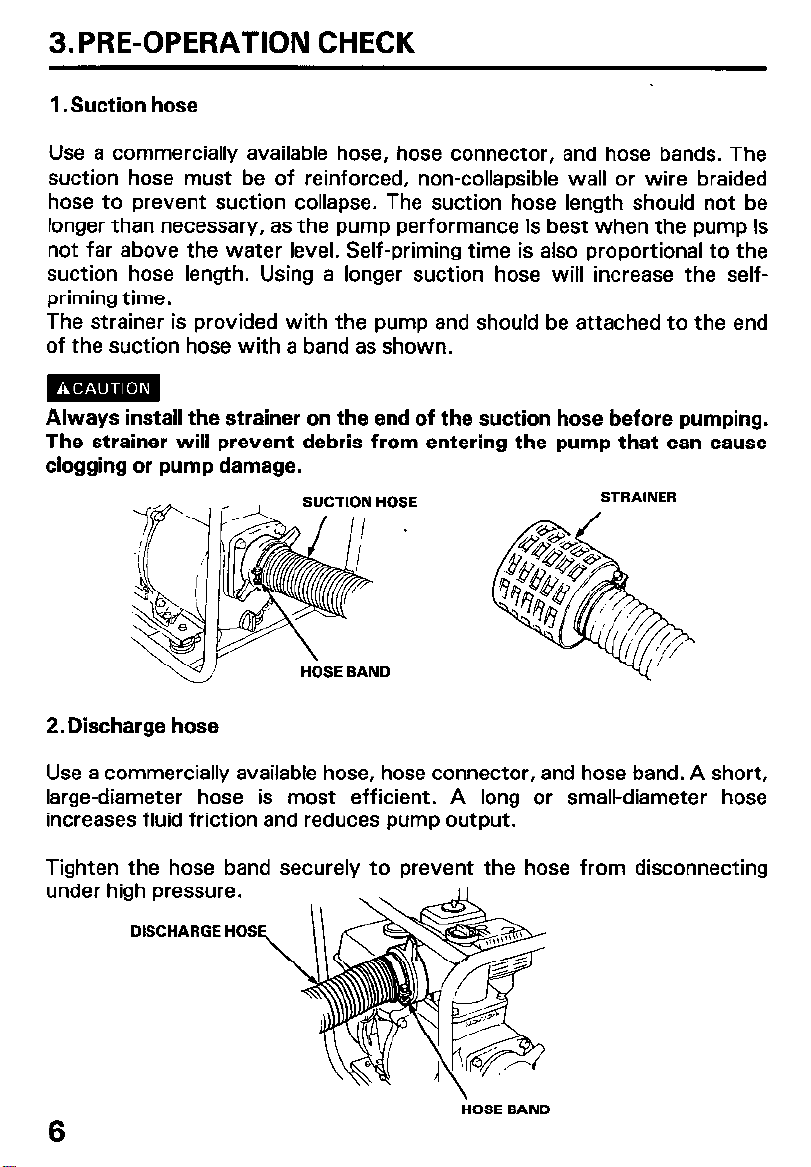

1. Suction hose

Use a commercially available hose, hose connector, and hose bands. The

suction hose must be of reinforced, non-collapsible wall or wire braided

hose to prevent suction collapse. The suction hose length should not be

longer than necessary, as the pump performance is best when the pump is

not far above the water level. Self-priming time is also proportional to the

suction hose length. Using a longer suction hose will increase the selfpriming time.

The strainer is provided with the pump and should be attached to the end

of the suction hose with a band as shown.

Always install the strainer on the end of the suction hose before pumping.

The strainer will prevent debris from entering the pump that can cause

clogging or pump damage.

SUCTION HOSE

STRAINER

2. Discharge hose

Use a commercially available hose, hose connector, and hose band. A short,

large-diameter hose is most efficient. A long or small-diameter hose

increases fluid friction and reduces pump output.

Tighten the hose band securely to prevent the hose from disconnecting

under high pressure.

DISCHARGE HOS

HOSE BAND

6

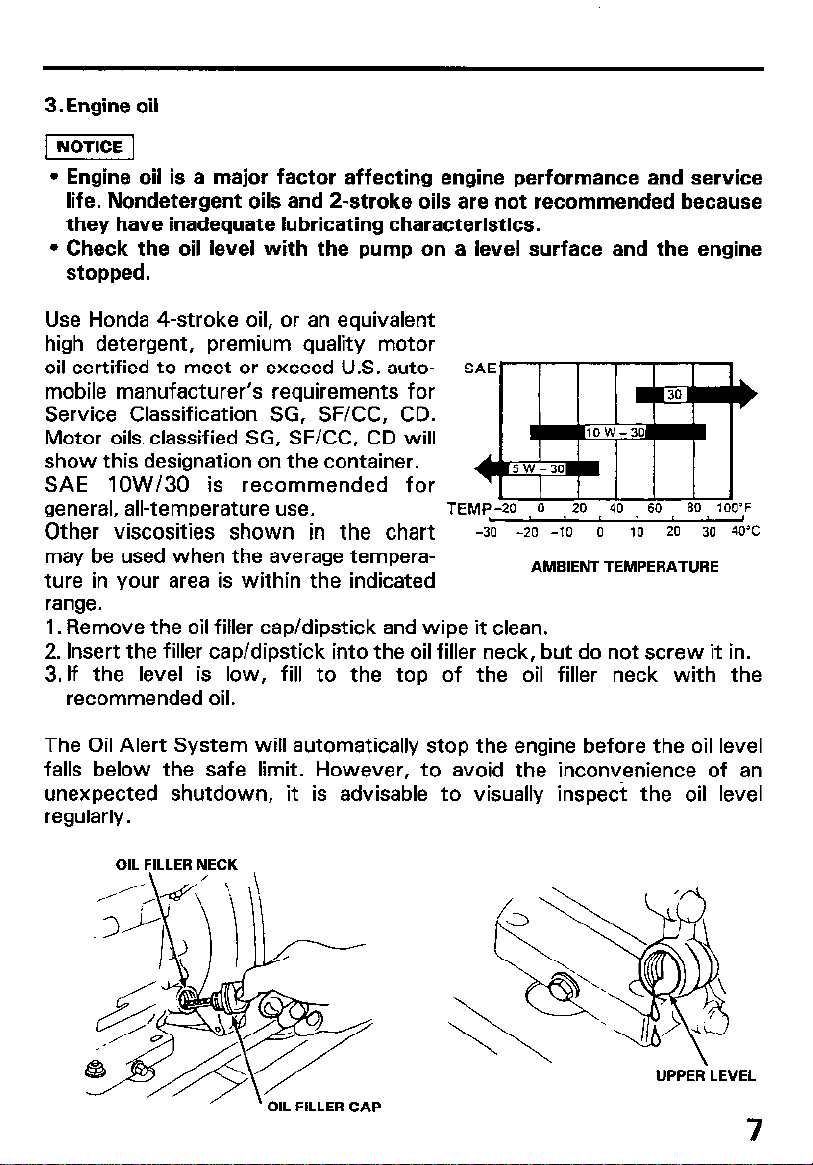

3. Engine oil

1

l Engine oil is a major factor affecting engine performance and service

I

life. Nondetergent oils and 2-stroke oils are not recommended because

they have inadequate lubricating characteristics.

l Check the oil level with the pump on a level surface and the engine

stopped.

Use Honda 4-stroke oil, or an equivalent

high detergent, premium quality motor

oil certified to meet or exceed U.S. automobile manufacturer’s requirements for

Service Classification SG, SF/CC, CD.

Motor oils classified SG, SF/CC, CD will

show this designation on the container.

SAE lOW/30 is recommended for

general, all-temperature use.

Other viscosities shown in the chart

may be used when the average temperature in your area is within the indicated

TEMP-20 0 20 40 , 60 80 1OO'F

-30

-20 -10 0 10 20

AMBIENT TEMPERATURE

L

30 40%

J

range.

1. Remove the oil filler cap/dipstick and wipe it clean.

2. Insert the filler cap/dipstick into the oil filler neck, but do not screw it in.

3.If the level is low, fill to the top of the oil filler neck with the

recommended oil.

The Oil Alert System will automatically stop the engine before the oil level

falls below the safe limit. However, to avoid the inconvenience of an

unexpected shutdown, it is advisable to visually inspect the oil level

regularly.

OIL FILLER NECK

OIL FILLER CAP

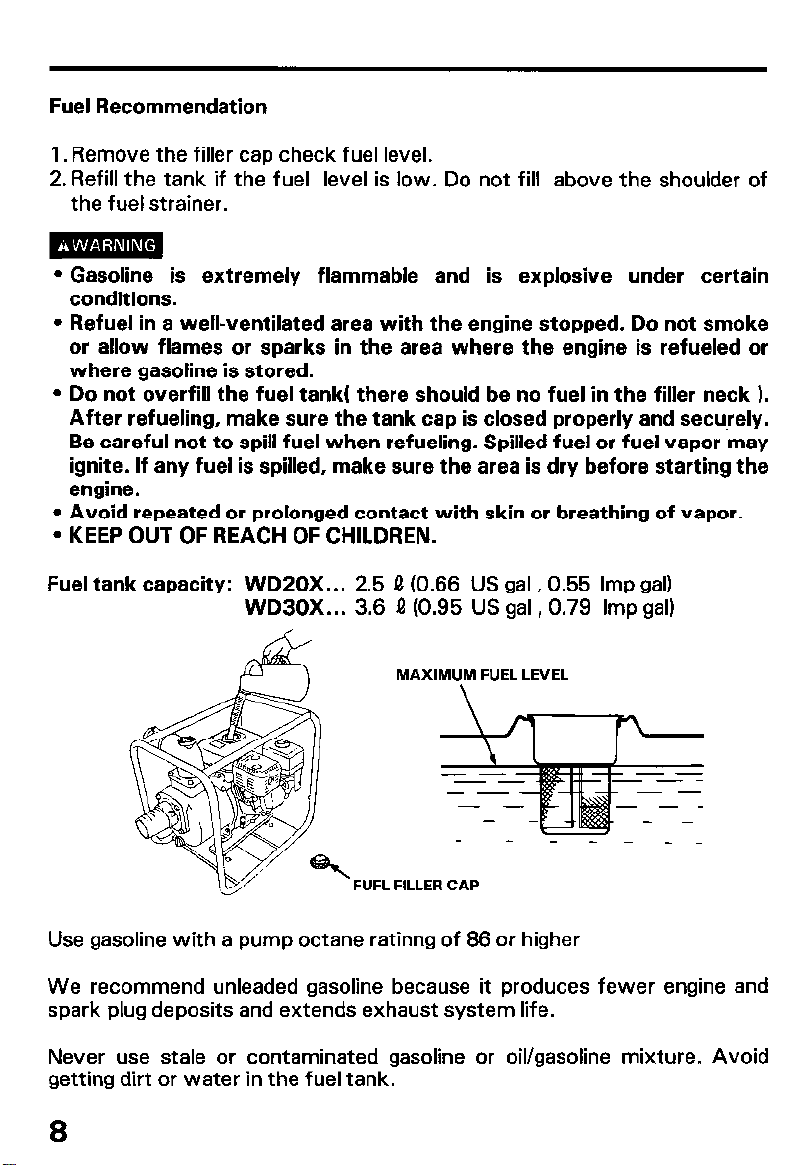

Fuel Recommendation

1. Remove the filler cap check fuel level.

2. Refill the tank if the fuel level is low. Do not fill above the shoulder of

the fuel strainer.

l Gasoline is extremely flammable and is explosive under certain

conditions.

l Refuel in a well-ventilated area with the engine stopped. Do not smoke

or allow flames or sparks in the area where the engine is refueled or

where gasoline is stored.

l Do not overfill the fuel tank( there should be no fuel in the filler neck 1.

After refueling, make sure the tank cap is closed properly and secqrely.

Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor may

ignite. If any fuel is spilled, make sure the area is dry before starting the

engine.

l Avoid repeated or prolonged contact with skin or breathing of vapor.

l KEEP OUT OF REACH OF CHILDREN.

Fuel tank capacity: WD20X.. . 2.5 0 (0.66 US gal, 0.55 Imp gal)

WDSOX... 3.6

4 (0.95 US gal, 0.79 Imp gal)

MAXIMUM FUEL LEVEL

yy

-FUFL FILLER CAP

Use gasoline with a pump octane ratinng of 86 or higher

We recommend unleaded gasoline because it produces fewer engine and

spark plug deposits and extends exhaust system life.

Never use stale or contaminated gasoline or oil/gasoline mixture. Avoid

getting dirt or water in the fuel tank.

8

Occasionally you may hear light “spark knock” or “pinging” 1 metallic

rapping noise ) while operating under heavy loads. This is no cause for

concern.

If spark knock or pinging occurs at a steady engine speed, under normal

load, change brands of gasoline. If spark knock or pinging persists, see an

authorized Honda water pump dealer.

j-iciq

Running the engine with persistent spark knock or pinging can cause

engine damage.

Running the engine with persistent spark knock or pinging is misuse, and

the Distributor’s Limited Warranty does not cover parts damaged by

misuse.

Oxygenated Fuels

Some gasolines are being blended with alcohol or an ether compound to

increase the octane. These gasolines are collectively referred to as

oxygenated fuels. Some areas of the United States use oxygenated fuels

to help meet clean air standards.

If you use an oxygenated fuel, be sure its pump octane rating is 86 or

higher.

Ethanol 1 ethyl or grain alcohol 1

Gasoline containing more than 10% ethanol by volume may cause starting

and/or performance problems. Gasoline containing ethanol may be

marketed under the name “Gasohol”.

Methanol ( methyl or wood alcohol)

Gasoline containing methanol must contain cosolvents and corrosion

inhibitors to protect the fuel system. Gasoline containing more than 5%

methanol by volume may cause starting and/or performance problems and

may damage metal, rubber, and rjlastic parts of your fuel system.

MTBE (methyl tertiary butyl ether)

You may use gasoline containing up to 15% MTBE by volume.

Before using an oxygenated fuel, try to confirm the fuel’s contents. Some

states (provinces in Canada) require this information to be posted on the

pump. If you notice any undersirable operating symptoms, switch to a

convertional unleaded gasoline. Fuel system damage or performance

problems resulting from the use of an oxygenated fuel are not the

responsibility or Honda and are not covered under warranty.

jTimEq

Oxygenated fuels can damage paint and plastic. Be careful not to spill

fuel when filling your fuel tank. Damage caused by spilled fuel is not

convered under warranty.

9

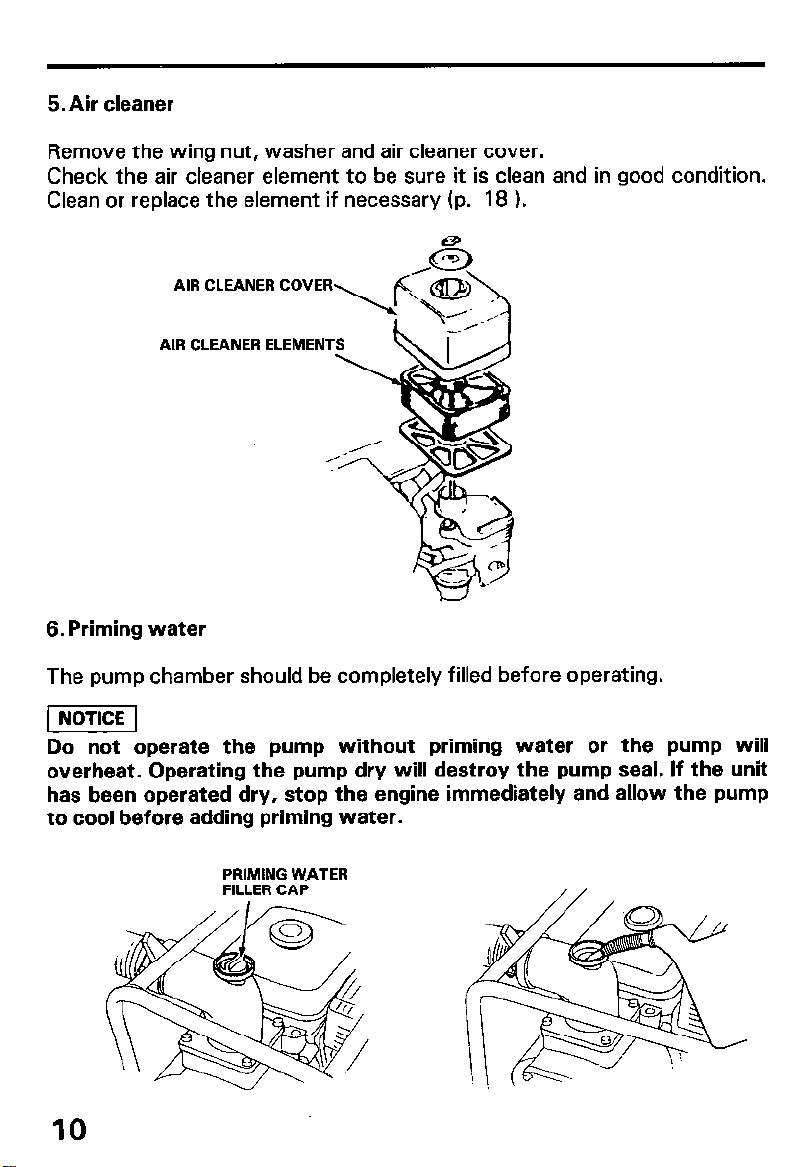

5. Air cleaner

Remove the wing nut, washer and air cleaner cover.

Check the air cleaner element to be sure it is clean and in good condition.

Clean or replace the element if necessary (p. 18 1.

AIR CLEANER COVER

AIR CLEANER ELEMENT

6. Priming water

The pump chamber should be completely filled before operating.

[NOTICE 1

Do not operate the pump without priming water or the pump will overheat. Operating the pump dry will destroy the pump seal. If the unit has been operated dry, stop the engine immediately and allow the pump

to cool before adding priming water.

PRIMING WATER

FILLER CAP

10

Loading...

Loading...