Honda Power Equipment WB20XT2A user guide

_

Honda

WB20XT, WB30XT

OWNER’S MANUAL

Original instructions

MANUEL DE L’UTILISATEUR

Notice originale

BEDIENUNGSANLEITUNG

Originalbetriebsanleitung

MANUAL DE EXPLICACIONES

Manual original

The‘‘e-SPEC’’mark symbolizes environmentally

responsible technologies applied to Honda power

equipment, which contains our wish to ‘‘preserve

nature for generations to come.’’

09/08/01 11:40:13 32YG3610_002

Thank you for purchasing a Honda water pump.

This manual covers the operation and maintenance of Honda water

pump:

WB20XT/WB30XT

All information in this publication is based on the latest product

information available at the time of approval for printing.

Honda Motor Co., Ltd. reserves the right to make changes at any time

without notice and without incurring any obligation.

No part of this publication may be reproduced without written

permission.

This manual should be considered a permanent part of the pump and

should remain with the pump if it is resold.

The illustrations in this manual are based on:

WB20XT

Pay special attention to statements preceded by the following words:

Indicates a strong possibility of severe personal injury or

death if instructions are not followed.

Indicates a possibility of equipment or property damage if

instructions are not followed.

Gives helpful information.

If a problem should arise, or if you have any questions about the

pump, consult an authorized Honda dealer.

Honda water pump is designed to give safe and dependable service if

operated according to instructions.

Read and understand the O wner’s Manual before operating the water pump. Failure to do so could result in personal injury or equipment damage.

The illustration may vary according to the type.

09/08/01 11:40:16 32YG3610_003

Disposal

To protect the environment, do not dispose of this product,

battery, engine oil, etc. carelessly by leaving them in the waste.

Observe the local laws and regulations or consult your authorized

Honda dealer for disposal.

1

09/08/01 11:40:19 32YG3610_004

CONTENTS

.......................................................................................6. OPERATION .18

.................................................................................8. MAINTENANCE .20

EC Declaration of Conformity

.......................................................................1. SAFETY INSTRUCTION .3

..............................................................2. SAFETY LABEL LOCATIONS .5

.....................................................CE mark and noise label locations .6

.........................................................3. COMPONENT IDENTIFICATION .7

......................................................4. PRE-OPERATION FOR STARTING .9

...................................................................5. STARTING THE ENGINE .15

..................................................................High altitude operation .17

...................................................................7. STOPPING THE ENGINE .19

.............................................................9. TRANSPORTING/STORAGE .27

........................................................................10. TROUBLESHOOTING .29

...............................................................................11. SPECIFICATIONS .31

................MAJOR Honda DISTRIBUTOR ADDRESSES .Inside back cover

.......‘‘ ’’ CONTENT OUTLINE . Inside back cover

2

09/08/01 11:40:27 32YG3610_005

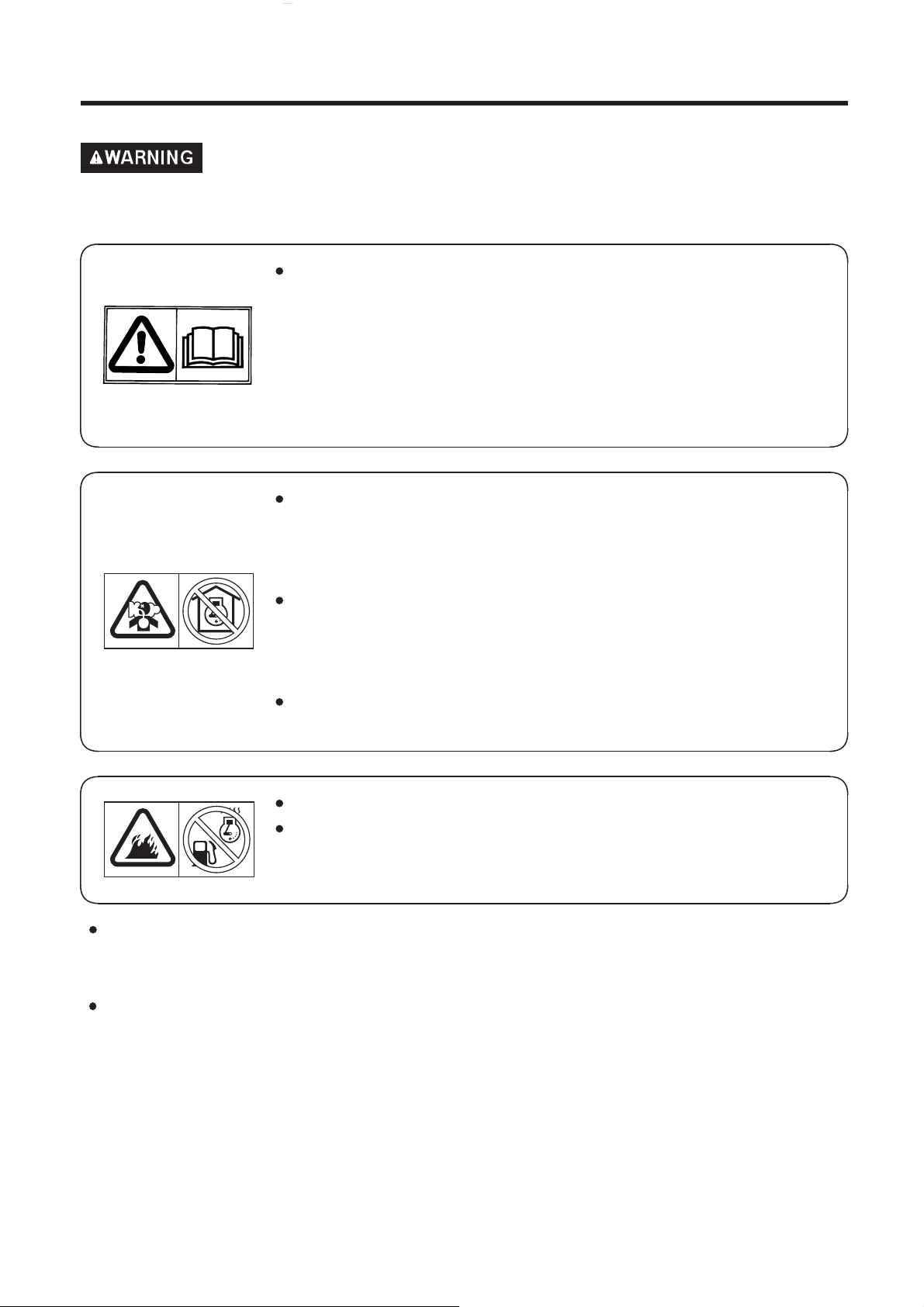

SAFETY INSTRUCTION1.

To ensure safe operation

Honda water pump is designed to give safe and

dependable service if operated according to instructions.

Read and understand the Owner’s Manual before operating the w at er pump. Failure to do so

could result in personal injury or equipment damage.

Exhaust contains poisonous carbon monoxide, a

colorless, od orless gas. Brea thing c arbon

monoxide can cause loss of consciousness and

may lead to death.

If you run the pump in an area that is confined,

or even partially enclosed area, the air you

breathe could contain a dangerous amount of

exhaust gas.

Never run your pump inside a garage, house or

near open windows or doors.

−

Stop the engine before refueling.

Gasoline is extremely flammable and explosive

under certain conditions. Refuel in a well

ventilated area with the engine stopped.

Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor

may ignite. If any fuel is spilled, make sure the area is dry before

starting the engine.

Never run the engine in an enclosed or confined area. Exhaust gas

contains poisonous carbon monoxide gas; exposure can cause loss

of consciousness and may lead to death.

3

09/08/01 11:40:33 32YG3610_006

To ensure safe operation

Always make a pre-operation inspection (page ) before you start

the engine. You may prevent an accident or equipment damage.

For safety, never pump flammable or corrosive liquids such as

gasoline or acid. Also, to avoid pump corrosion, never pump sea

water, chemical solutions, or caustic liquids such as used oil, wine,

or milk.

Place the pump on a firm, level surface. If the pump is tilted or

overturned, fuel spillage may result.

To prevent fire hazards and to provide adequate ventilation, keep

the pump at least 1 meter (3 feet) away from building walls and

other equipment during operation. Do not place flammable objects

close to the pump.

Children and pets must be kept away from the area of operation

due to a possibility of burns from the hot engine components.

Know how to stop the pump quickly, and understand the operation

of all controls. Never permit anyone to operate the pump without

proper instructions.

−

9

4

09/08/01 11:40:41 32YG3610_007

These labels warn you of potential hazards that can cause serious injury. Read the labels and safety notes and precautions described in this

manual carefully.

If a label comes off or becomes hard to read, contact your Honda dealer for a replacement.

OPERATOR CAUTION [For European types]

SAFETY LABEL LOCATIONS2.

PUMP CAUTION [For Australian types]

5

09/08/01 11:40:47 32YG3610_008

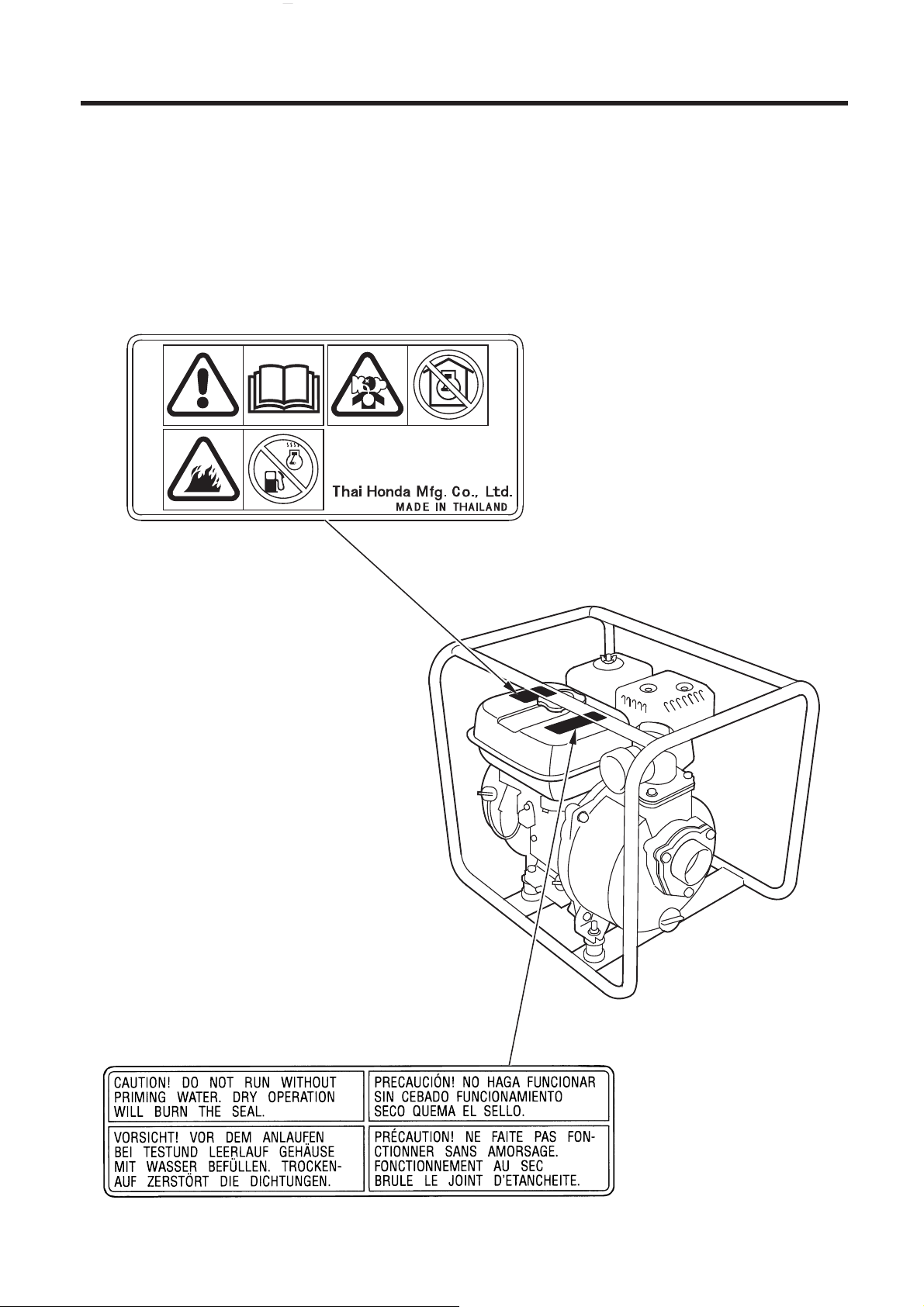

CE mark and noise label locations

[For European types]

CE MARK [Example: WB20XT]

Manufacturer and address

Model

Sales agency and address

Year of manufacture

Dry mass

6

NOISE LABEL

[Example: WB20XT]

09/08/01 11:40:54 32YG3610_009

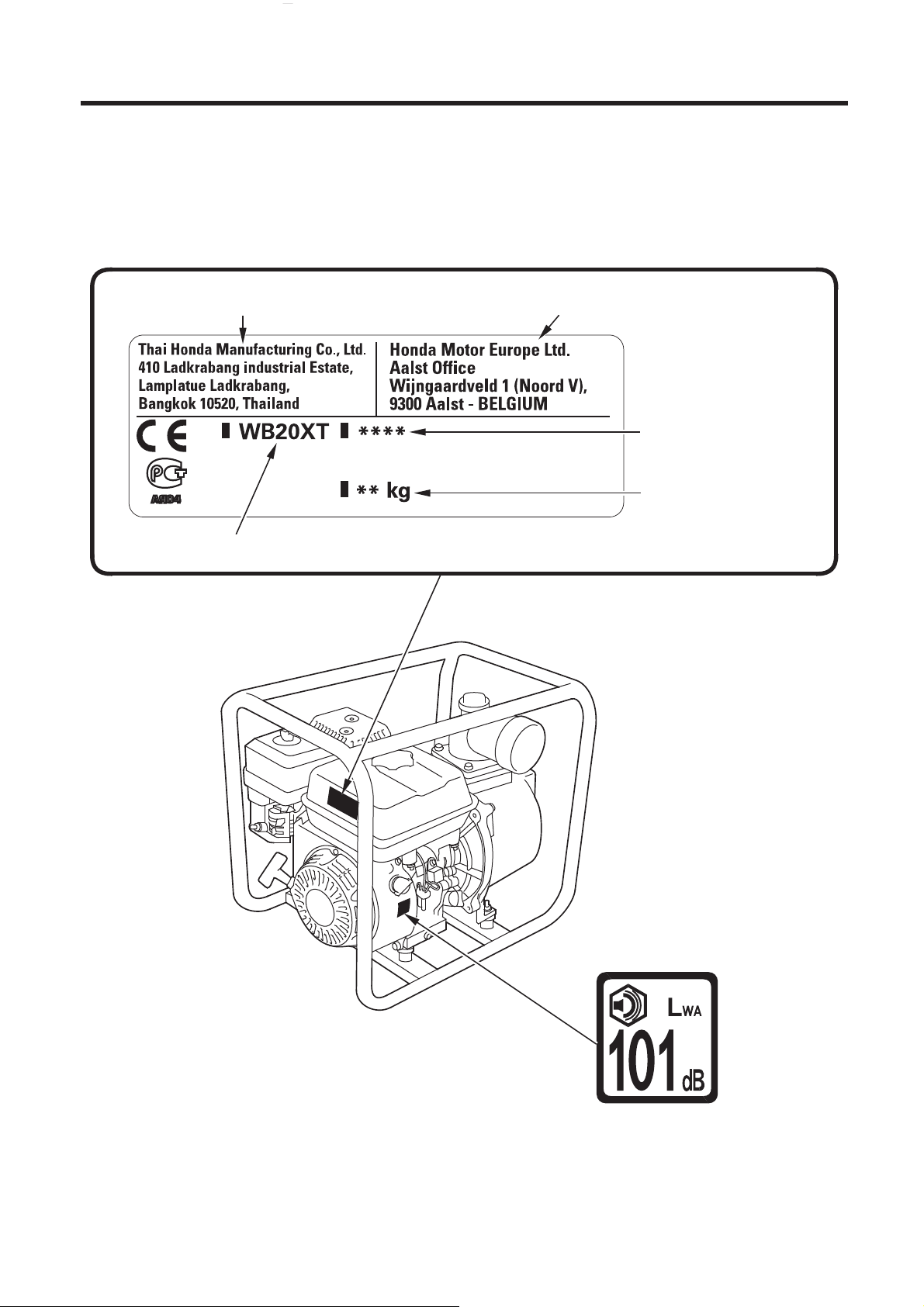

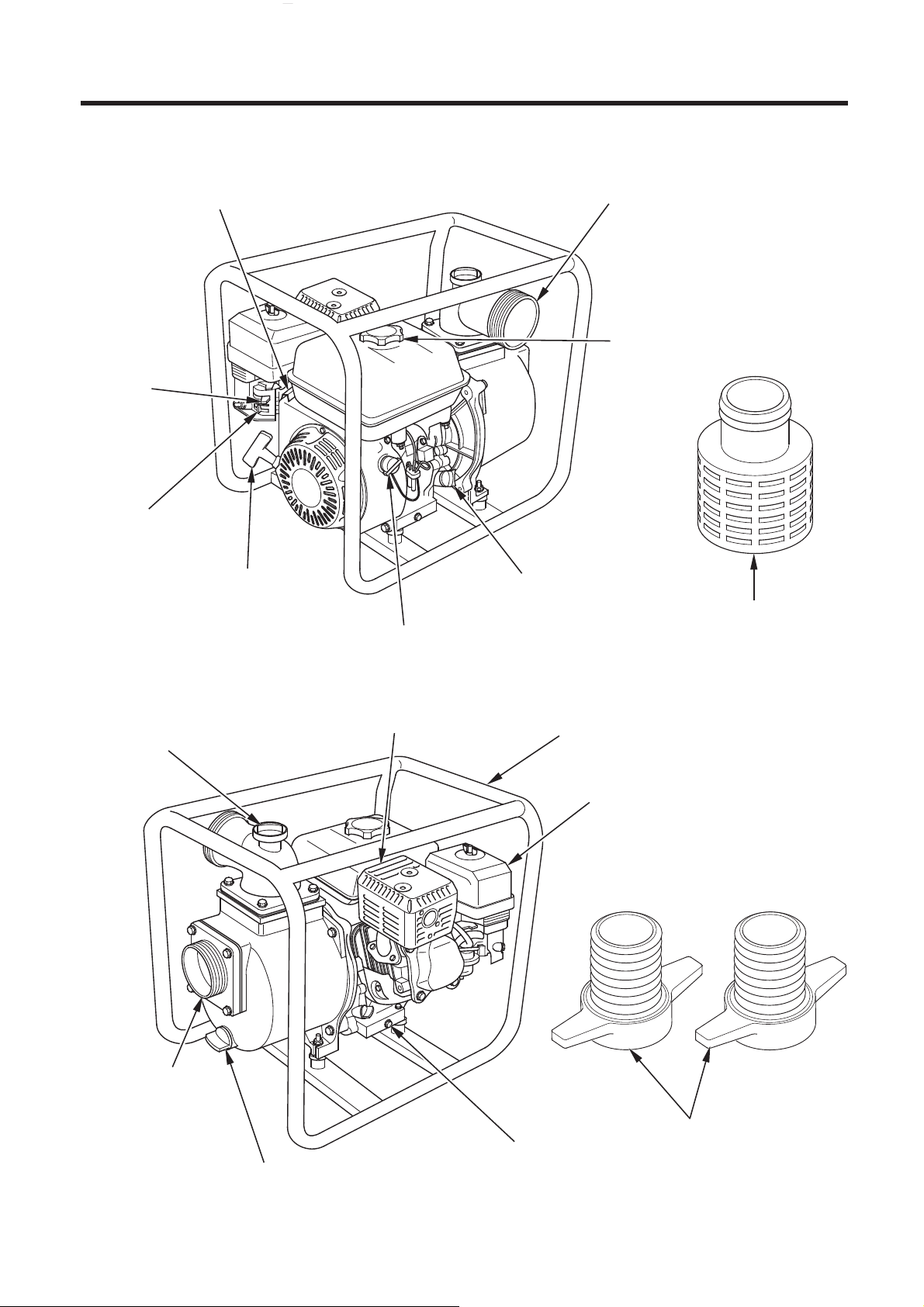

〈〉

WB20XT

THROTTLE LEVER

COMPONENT IDENTIFICATION3.

DISCHARGE PORT

CHOKE

LEVER

FUEL VALVE LEVER

STARTER GRIP

PRIMING WATER

FILLER CAP

FUEL FILLER CAP

OIL FILLER CAP/

DIPSTICK

STRAINER

ENGINE SWITCH

MUFFLER FRAME

AIR CLEANER

SUCTION PORT

PUMP DRAIN PLUG

OIL DRAIN PLUG

HOSE

CONNECTOR

7

09/08/01 11:41:00 32YG3610_010

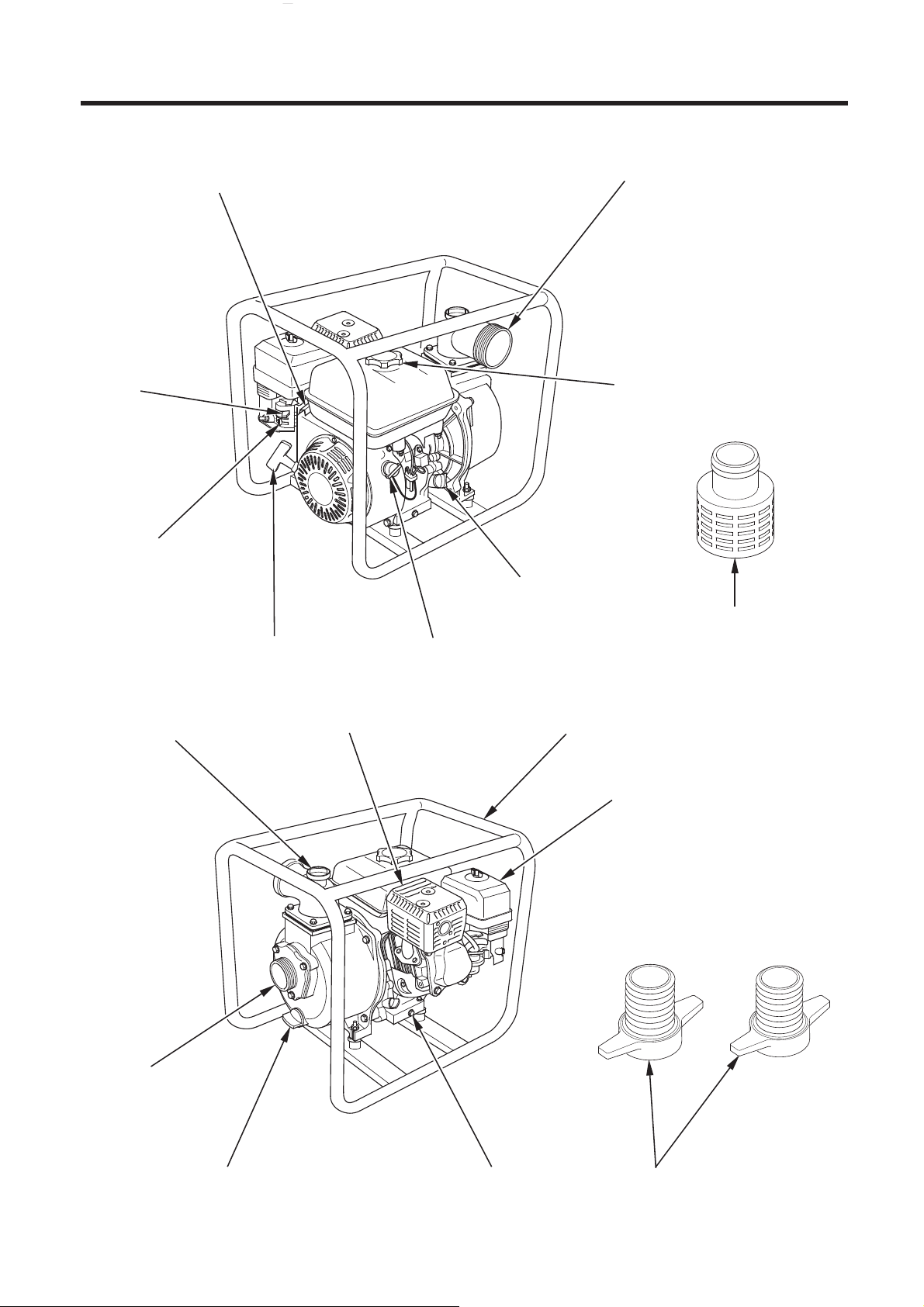

〈〉

WB30XT

THROTTLE LEVER

CHOKE

LEVER

FUEL VALVE

LEVER

STARTER GRIP

DISCHARGE PORT

FUEL FILLER CAP

OIL FILLER CAP/

DIPSTICK

STRAINER

ENGINE SWITCH

PRIMING WATER

FILLER CAP

SUCTION PORT

PUMP DRAIN PLUG

MUFFLER

FRAME

AIR CLEANER

HOSE CONNECTOR

OIL DRAIN PLUG

8

09/08/01 11:41:08 32YG3610_011

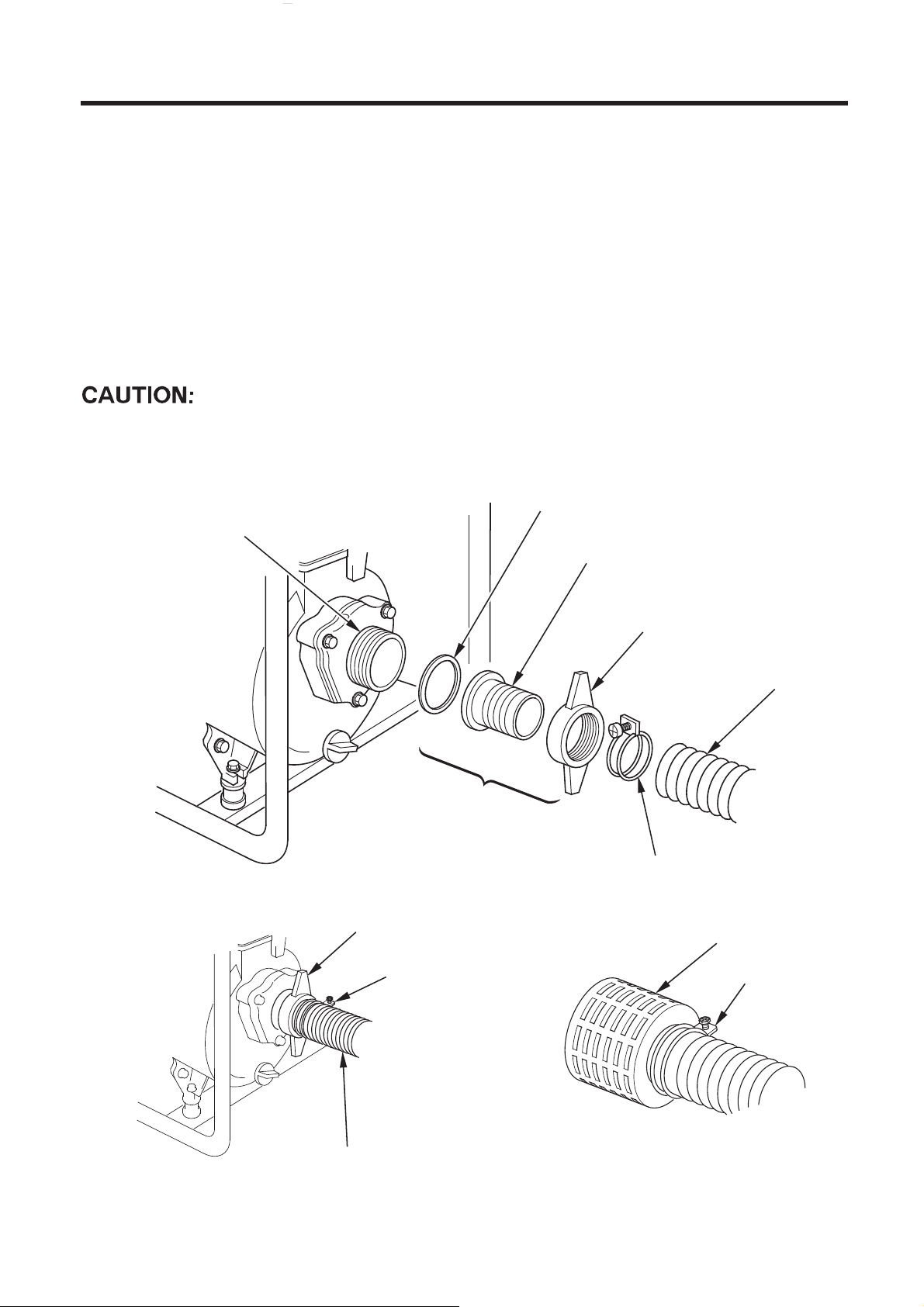

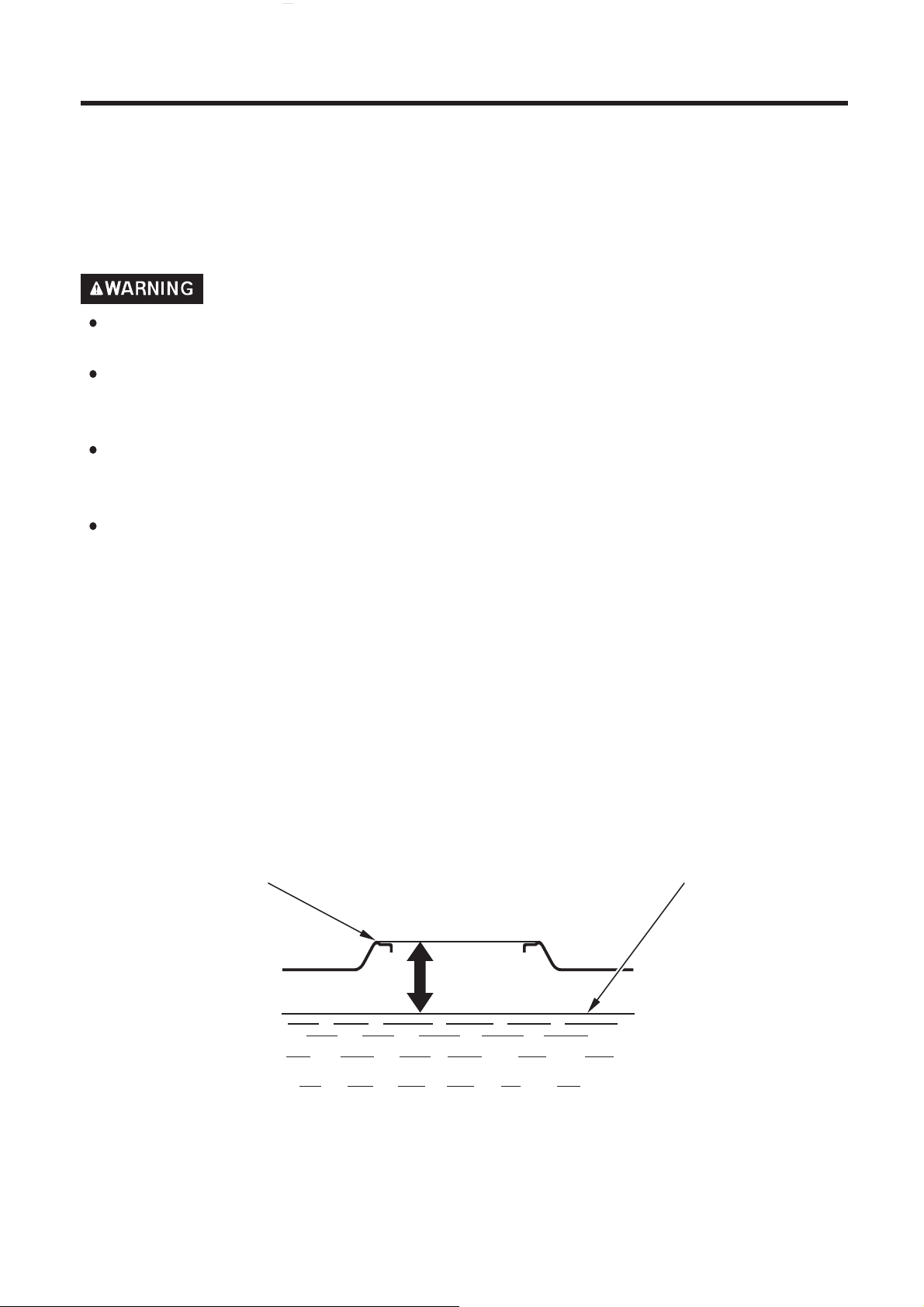

Connect the suction hose.

1.

Use commercially available hose, hose connector, and hose bands.

The suction hose must be of reinforced, noncollapsible construction.

Suction hose length should not be longer than necessary, as pump

performance is best when the pump is not far above the water level.

Self-priming time is also proportional to hose length.

The strainer that is provided with the pump should be attached to the

end of the suction hose with a band, as shown.

Always install the strainer on the end of the suction hose before

pumping. The strainer will exclude debris that can cause clogging or

impeller damage.

SUCTION PORT

PRE-OPERATION FOR STARTING4.

SEALING WASHER

HOSE

CONNECTOR

HOSE CONNECTOR

HOSE BAND

HOSE COUPLING

HOSE CLAMP RING

SUCTION HOSE

HOSE BAND

STRAINER

HOSE BAND

SUCTION HOSE

9

09/08/01 11:41:16 32YG3610_012

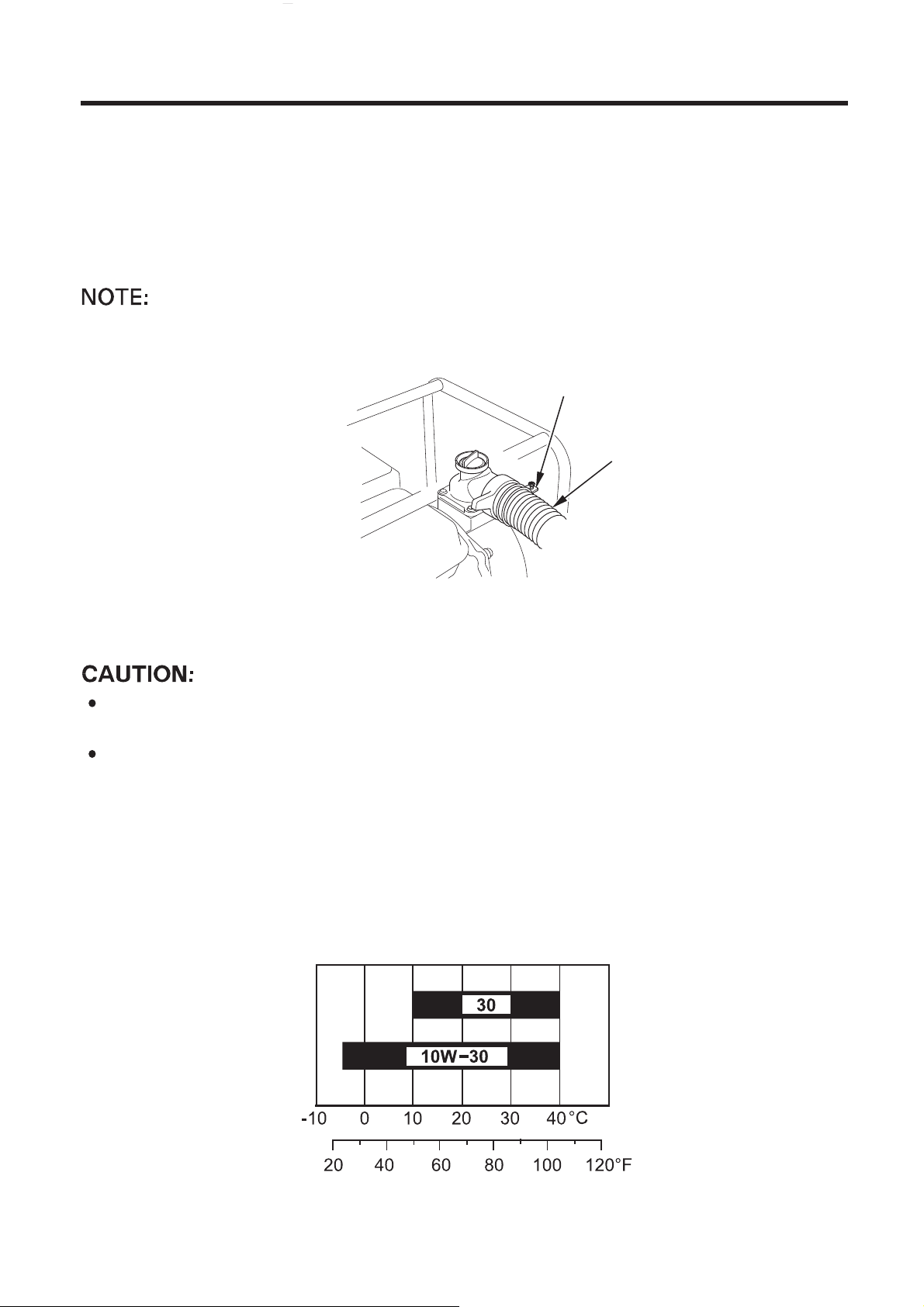

Connect the discharge hose.

2.

Use a commercially available hose, hose connector, and hose band. A

short, large-diameter hose is most efficient. Long or small-diameter

hose increases fluid friction and reduces pump output.

Tighten the hose band securely to prevent the hose from

disconnecting under high pressure.

HOSE BAND

DISCHARGE HOSE

Check the engine oil level.

3.

Engine oil is a major factor affecting engine performance and

service life. Nondetergent or vegetable oils are not recommended.

Check the oil level with the pump on a level surface and the engine

stopped.

Use high-detergent, premium quality 4-stroke engine oil, certified to

meet or exceed U.S. automobile manufacturer’s requirements for API

service category SE or later (or equivalent).

Select the appropriate viscosity for the average temperature in your

area.

10

AMBIENT TEMPERATURE

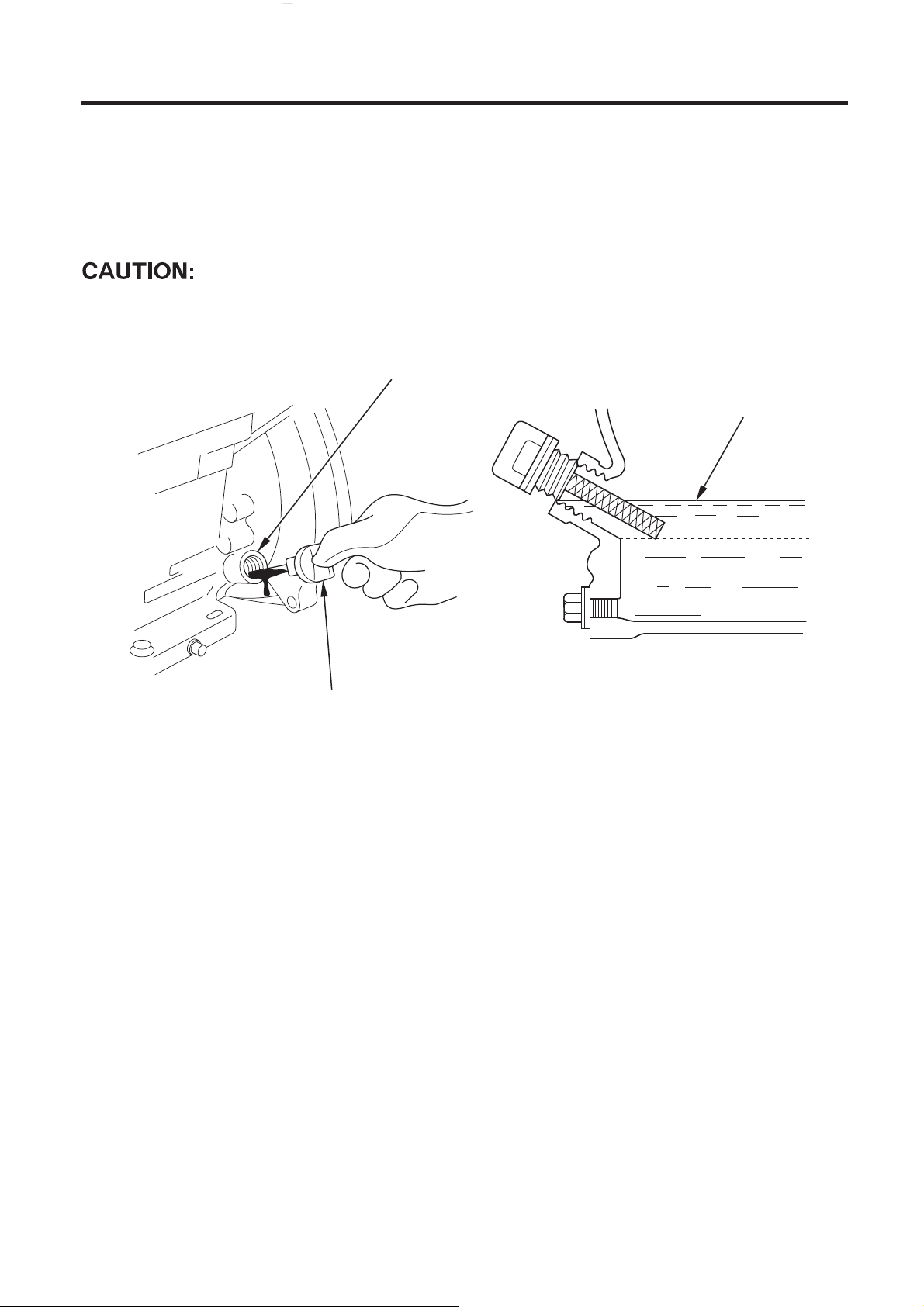

09/08/01 11:41:22 32YG3610_013

Remove the oil filler cap/dipstick and wipe it clean.

Insert the filler cap/dipstick into the oil filler neck, but do not screw it in.

If the level is low, fill to the top of the oil filler neck with the recommended oil.

Running the engine with insufficient oil can cause serious engine

damage.

OIL FILLER NECK

UPPER LIMIT

OIL FILLER CAP

Oil Alert System (Where equipped)

The Oil Alert System is designed to prevent engine damage caused by

an insufficient amount of oil in the crankcase. Before the oil level in the

crankcase can fall below a safe limit, the Oil Alert System will automatically stop the engine (the engine switch will remain in the ON

position).

If the engine stops and will not restart, check the engine oil level

before troubleshooting in other areas.

11

09/08/01 11:41:30 32YG3610_014

Check the fuel level.

4.

Use automotive unleaded gasoline with a Research Octane Number of

91 or higher (a Pump Octane Number of 86 or higher).

Never use stale or contaminated gasoline or an oil/gasoline mixture.

Avoid getting dirt or water in the fuel tank.

Gasoline is extremely flammable and is explosive under certain

conditions.

Refuel in a well-ventilated area with the engine stopped. Do not

smoke or allow flames or sparks in the refueling area or where

gasoline is stored.

Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor

may ignite. If any fuel is spilled, make sure the area is dry before

starting the engine.

Avoid repeated or prolonged contact with skin or breathing of

vapor.

KEEP OUT OF REACH OF CHILDREN.

With the engine stopped and on a level surface, remove the fuel tank

cap and check the fuel level.

Refill the tank if the fuel level is low.

Do not fill the fuel tank completely. Fill tank to approximately 25 mm (1

inch) below the top of the fuel tank to allow for fuel expansion. If may

be necessary to lower the fuel level depending on operating

conditions.

After refueling, make sure the tank cap is closed properly and securely.

FUEL TANK TOP MAXIMUM FUEL LEVEL

25 mm

(1 inch)

12

Loading...

Loading...