Honda Power Equipment TPG-2900H-DX, TPG-7000H-DXE User Manual

OPERATION, SERVICE, AND

REPAIR MANUAL

FOR TSURUMI TPG-SERIES

PORTABLE GENERATORS

MODELS

TPG-2900H-DX

TPG-4300H-DX

TPG-6000H-DX

TPG-7000H-DXE

LIMITED WARRANTY

TSURUMI MANUFACTURING CO., LTD. (“TSURUMI”) warrants to the original end purchaser during

the warranty period, every new TSURUMI generator or product to be free from defects in material and

workmanship under normal use and service, when properly installed, used, and maintained (in accordance with Tsurumi’s Operation, Service, and Repair Manual) for a period of two years from the date

the unit was first installed or twenty six months from the date of shipment by TSURUMI to wholesaler,

whichever comes first.

TSURUMI’S sole obligation under this warranty is to repair or replace at TSURUMI’S option, with new

or remanufactured parts, any part(s) that fail or that are found to be defective during the warranty period. No allowance will be made for shipping charges, damages, labor, or other charges due to failure,

repair or replacement.

This warranty does not apply to any TSURUMI product that has been disassembled without prior

approval of TSURUMI nor does it apply to any product that has been subjected to misuse, neglect,

alteration, misapplication, accident or act of God.

TSURUMI assumes no responsibility for compliance with any regulations, codes, standards, or ordinances applicable to the installation, location, operation or maintenance of its products.

No other warranty, expressed or implied, is authorized by, or applicable to, the seller. No person, agent

or dealer is authorized to enlarge upon this warranty.

TSURUMI expressly disclaims liability for consequential or incidental damages or breach of expressed

or implied warranty; and any implied warrant of fitness for a particular purpose and merchantability

shall be limited to the duration of the expressed warranty.

Some states do not allow limitations on the duration of an implied warranty, so the above limitation or

exclusion may not apply to you. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation of exclusion may not apply to you.

This warranty gives you specific legal rights and you may also have other rights, which vary from state

to state.

Tsurumi Manufacturing Co., Ltd.

TABLE OF CONTENTS

Section/Title Page

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

A. Precautions and Placards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

B. Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

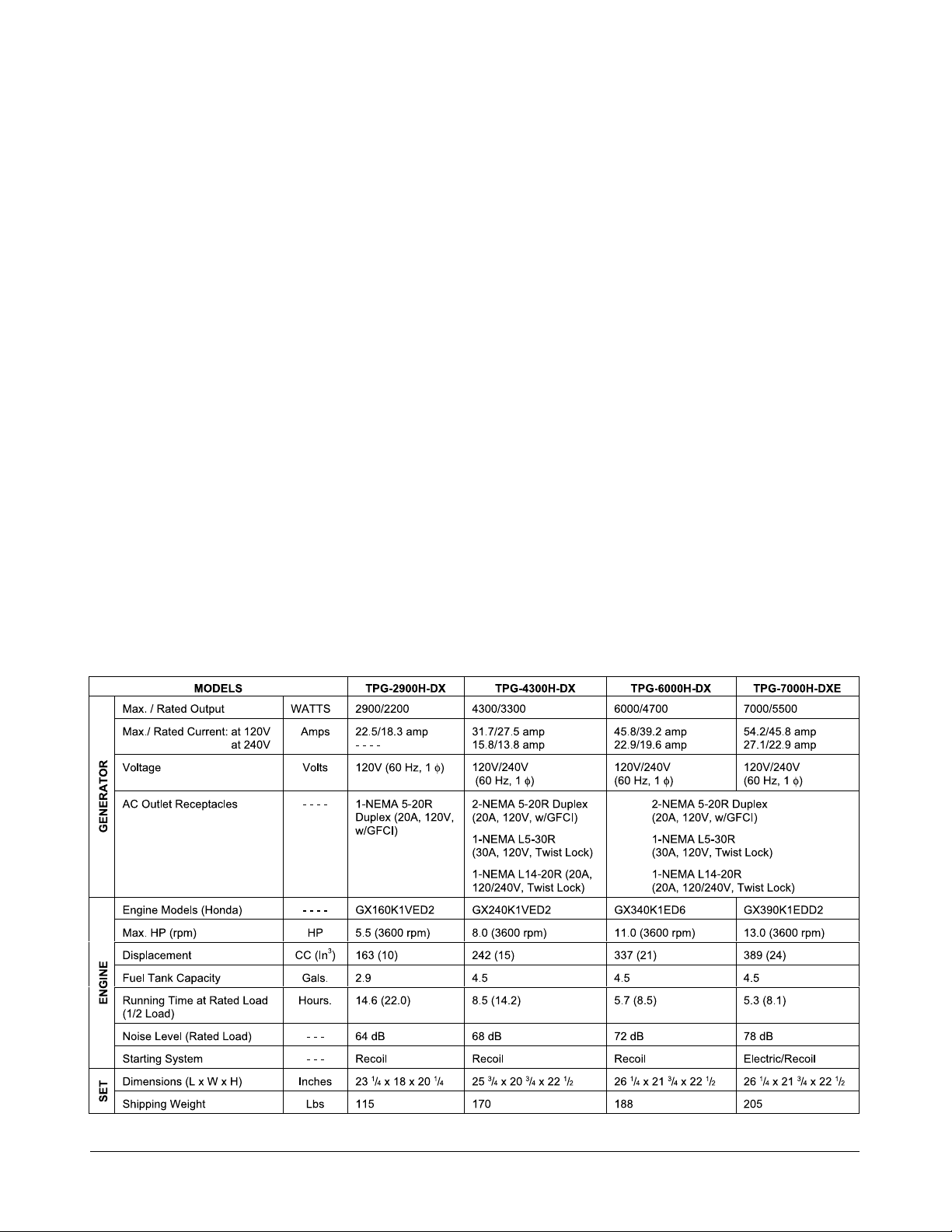

C. Specifications/Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Description and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

A. Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

B. Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

A. Operating Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

B. DC Circuit Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

C. Check the Engine Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

D. Check Engine Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

E. Pre-Start Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

F. Starting and Operating the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

G. Using the Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

H. AC Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

I. Stopping the Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

J. Oil Alert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

K. Idle Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

L. Stopping the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

M. Wattage Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

A. Changing Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

B. Air Cleaner Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

C. Sediment Cup Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

D. Cleaning and Adjusting Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

(Models TPG-4300H-DX, TPG-6000H-DX, TPG-7000H-DXE)

5. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

A. Isolating Fault to the Generator or to the Control Panel . . . . . . . . . . . . . . . . . . 27

B. Measuring Insulation Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

C. Electrical Limits Reference Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

D. Troubleshooting Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

E. Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6. Removal/Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

A. Replacement of Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

B. Removal/Installation of Battery Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

C. Replacement of Engine Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

(Models TPG-4300H-DX, TPG-6000H-DX, TPG-7000H-DXE)

D. Replacement of Engine Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

(Model TPG-2900H-DX)

E. Replacement of Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

F. Removal/Installation of Engine and Generator as a Unit . . . . . . . . . . . . . . . . . . 47

G. Replacement of Generator Stator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

H. Replacement of Rotor Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

I. Replacement of Rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

J. Replacement of Front Panel Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7. Storage Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8. Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

A. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

B. Ordering Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Appendix A – Battery Enclosure Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B – Wheel Kit Model PGWK-100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Appendix C – Wheel Kit Model PGWK-200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

1. INTRODUCTION

We thank you for purchasing a Tsurumi Generator. We are sure that the generator you have selected

will meet all your portable electric power needs.

This manual applies to the Tsurumi Generators listed below. Specifications for the generators are provided in the SPECIFICATIONS section. Key features of the generator are shown in the DESCRIPTION

section.

TPG-2900H-DX

TPG-4300H-DX

TPG-6000H-DX

TPG-7000H-DXE

This manual provides instructions for operation, service, and repair of your generator. We strongly recommend that those who operate the generator become familiar with the generator’s features and controls, and read the operating instructions before using the generator.

The Operation, Repair, and Service Manual also provides instructions to service, checkout, and repair

the generator. This manual also provides replacement parts information.

Repair and service information for the Honda engine is provided in the Owner’s Manual for Models

GX160, GX240, GX340, and GX390. A copy of the Owner’s Manual has been provided in the generator’s literature package. Parts information for the Honda Engine is available in Honda’s Parts

Catalogs.

When there are differences between generator models, separate instructions are provided. The separate instructions are provided to make sure the correct procedures are used on the affected generators.

All information in the Tsurumi manuals is based upon the latest production configuration of the generator at the time of approval for printing.

If you have a problem with your generator that cannot be resolved using the Operation, Repair, and

Service Manual, or if you have questions about the operation, service, repair, or maintenance of your

generator, contact your local Tsurumi generator dealer.

Page 1 Introduction

Tsurumi’s Operation, Service, and Repair Manual

A. PRECAUTIONS AND PLACARDS

Pay special attention to precautionary notes preceded by the words WARNING, CAUTION, and

NOTE

.

W

ARNINGS indicate that there is a strong possibility of personal injury or loss of life if the procedure

is not followed, or if cleaning, lubricating, adhesives, and other materials are not used properly.

CAUTIONS

indicate that there is a possibility of equipment damage if instructions are not followed.

NOTES

are used in procedures to provide additional or supplemental information to make the proce-

dure easier or more efficient.

W

ARNING:

• THE GENERATOR IS DESIGNED TO GIVE SAFE AND DEPENDABLE SERVICE WHEN OPER-

ATED ACCORDING TO THE INSTRUCTIONS IN THE TECHNICAL MANUAL PROVIDED WITH

THE GENERATOR.

• DO NOT OPERATE THE GENERATOR BEFORE YOU HAVE READ AND UNDERSTAND THE

INSTRUCTIONS AND THE ENGINE MANUFACTURER’S MANUAL. FAILURE TO DO SO

COULD RESULT IN PERSONAL INJURY OR EQUIPMENT DAMAGE.

Introduction Page 2

Tsurumi’s Operation, Service, and Repair Manual

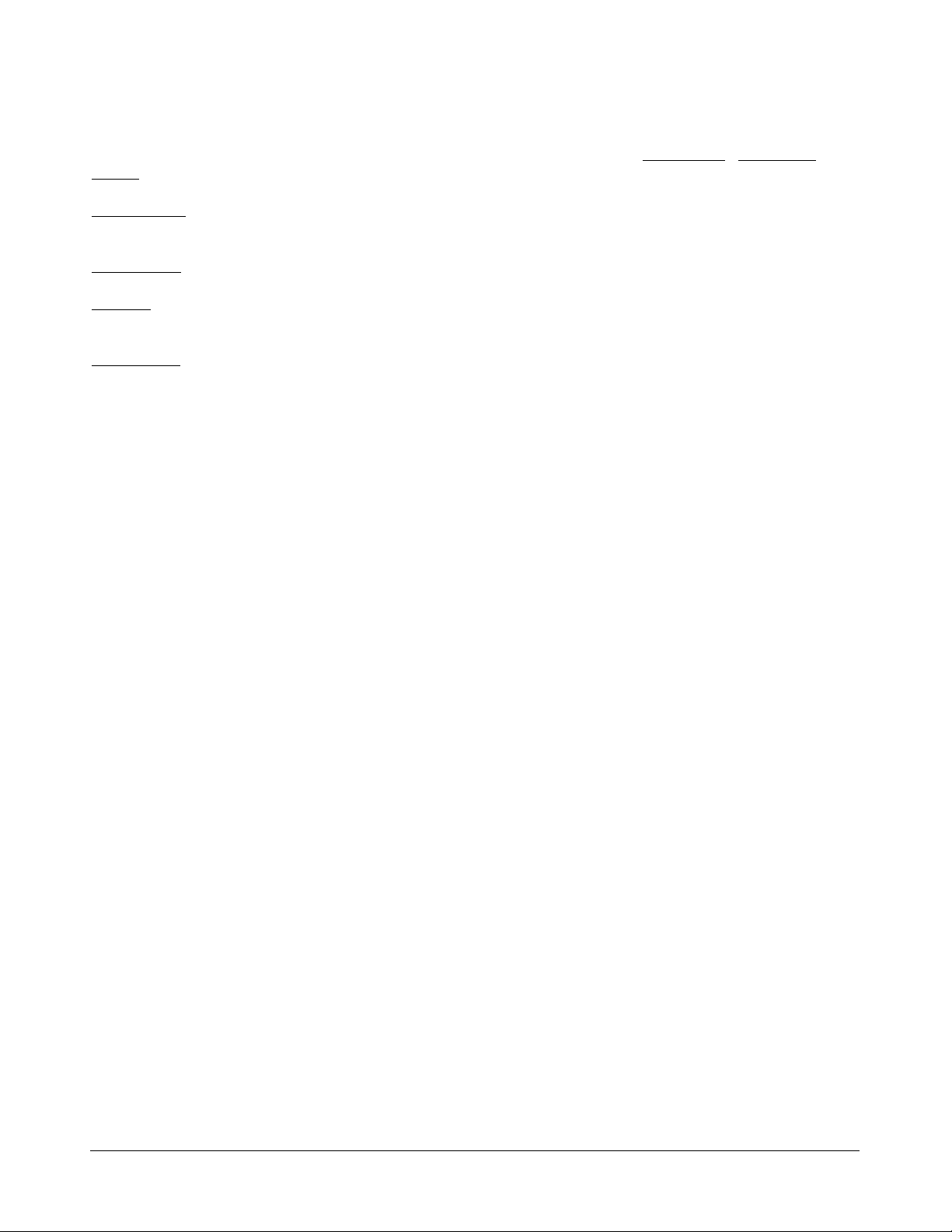

Placards, shown below, are provided on the portable generator to warn operating and maintenance personnel of potential hazards, to provide maintenance information, and to provide generator rating and

capabilities. The large label below is located on the front panel of the portable generator. The label presents operational Warnings and Cautions for generator users.

DATA PLATE

FUEL WARNING

PLACARD

AIR CLEANER

MAINTENANCE

HOT MUFFLER &

EXHAUST PLACARD

Page 3 Introduction

Tsurumi’s Operation, Service, and Repair Manual

OUTPUT

T

SURUMI A.C. GENERATOR

VOLTAGE

FREQUENCY

MAX

RATED

2900W

2400W

120V

60Hz

MODEL

SER.NO.

TSURUMI MANUFACTURING CO., LTD.

OSAKA, JAPAN

CHECK FOR SPILLED FUEL OR FUEL LEAKS .

STOP ENGINE BEFORE REFUELING .

CONTROLER QU ’ IL N ’ Y A NI FUITE NI ESSENCE

INSPECCIONAR PARA COMBUSTIBLE DERRAMADO

REPANSUE SUR L ’ APPAREIL .

ARRETER LE MOTEUR AVANT DE REFAIRE LE PLEIN .

O ESCAPE .

PARAR MOTOR ANTES DE ECHAR .

HOT EXHAUST

ECHAPPEMENT

CHAUD

DO NOT USE INDOORS. EXHAUST

GAS CONTAINS POISONOUS

CARBON MONOXIDE.

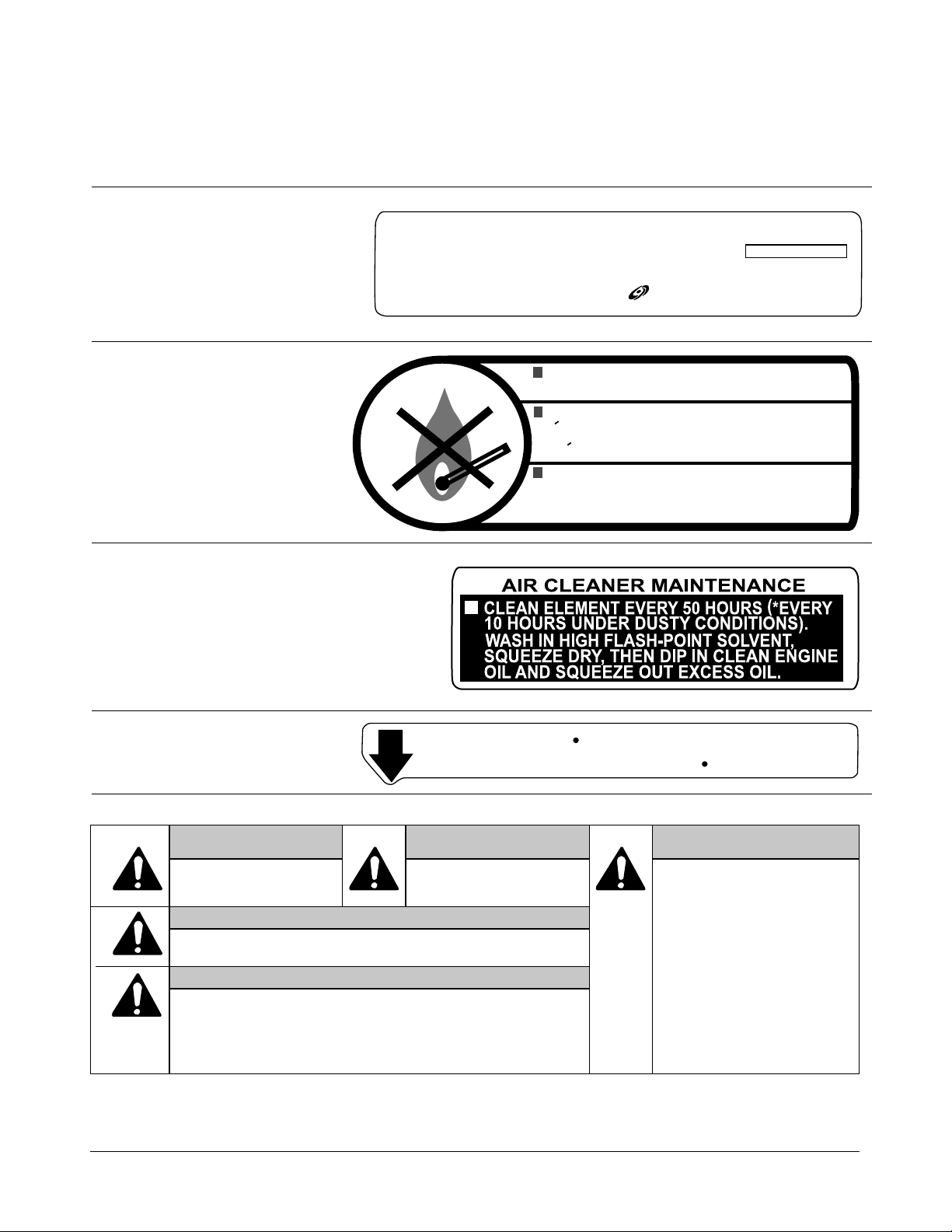

WARNING

USING THE GENERATOR IN RAIN, SNOW OR NEAR WATER CAN LEAD TO

DEATH FROM ELECTRIC SHOCK. KEEP GENERATOR DRY.

WARNING

ATENCION

NO LO USE EN LUGARES CERRADOS

PORQUE EL MONOXIDE DE CARBONO

ES VENENOSO

WARNING

ELECTROCUTION OR PROPERTY DAMAGE CAN OCCUR. DO NOT CONNECT

THIS GENERATOR TO ANY BUILDING’S ELECTRICAL SYSTEM UNLESS AN

ISOLATION SWITCH HAS BEEN INSTALLED BY A LICENSED ELECTRICIAN.

READ OWNER’S MANUAL CAREFULLY.

NOT RESPONSIBLE WHEN

EXCEEDING GENERATORS

WATTAGE/AMPERAGE CAPACITY

CAN DAMAGE GENERATOR

AND/OR ELECTRICAL DEVICES

CONNECTED TO IT.

• START GENERATOR AND LET ENGINE

STABILIZE BEFORE CONNECTING

ELECTRICAL LOADS.

• NO SENSITIVE EQUIPMENT LIKE

COMPUTERS, STEREOS, TVS, OR ANY

PRODUCTS THAT CONSUME CLEAN

POWER. (CHECK MANUFACTURER’S

PRODUCT MANUAL.)

CAUTION

B. SAFETY PRECAUTIONS

WARNING:

• IN ORDER TO ASSURE SAFE AND EFFICIENT OPERATION OF THE GENERATOR, OPERA-

TOR’S SHOULD READ AND COMPLY WITH THE FOLLOWING SAFETY PRECAUTIONS.

• Do not operate the generator near gasoline or gaseous fuels because of the potential danger from explosion or fire. Do not fill the fuel tank with fuel while the engine is running. Do not

smoke or use open flame near the fuel tank. Be careful not to spill fuel during refueling. If fuel is

spilled, wipe it off and let it dry before starting the engine.

• Do not place flammable materials near the generator. Be careful not to place fuel, matches,

gunpowder, oily cloths, straw, trash, or any other combustibles near the generator.

• Do not operate the generator inside a room, cave, tunnel, or other insufficiently ventilated

area. Always operate the generator in a well-ventilated area. The engine may become overheat-

ed, and the poisonous carbon monoxide gas contained in the exhaust gases will endanger human

lives.

• Keep the generator at least 1 meter (3 feet) away from any structure or building during use.

When a generator is located close to a building or nearby equipment, heat and exhaust from the

engine will cause the surrounding temperature to rise. This will degrade the engines cooling efficiency, causing overheating.

• Do not enclose the generator nor cover it with a box. The generator has a built-in, forced-air

cooling system, and may become overheated if it is enclosed.

• Operate the generator on a level surface. It is not necessary to prepare a special foundation for

the generator. However, the generator will vibrate on an irregular surface. Therefore, choose a

level place without surface irregularities.

• Shutoff the generator when moving the generator to another work site. It the generator is tilt-

ed or moved during operation, fuel may spill and/or the generator may tip over, causing a hazardous situation. Proper lubrication cannot be expected if the generator is operated on a steep

incline or slope. In such a case, the piston may seize; it may seize even if the oil is above the upper

level.

• Do not operate in rain or with wet hands. The operator may suffer severe electric shock, if the

generator is wet due to rain or snow. If wet, wipe dry well before starting. Do not pour water directly over the generator, nor wash it with water.

• Do not connect the generator to a commercial power line. Connection to a commercial power

line may result in short circuit and damage the generator. When connecting to domestic circuits,

install only approved transfer switches and make sure power and control circuitry meet local electrical code requirements.

• Do not smoke or use other smoking materials (pipes, cigars, etc.) while handling the battery. The battery emits flammable hydrogen gas, which can explode if exposed to electric arcing

or open flame. Keep the work area well ventilated and keep the battery away from open

flames/sparks.

Introduction Page 4

Tsurumi’s Operation, Service, and Repair Manual

C. SPECIFICATIONS/KEY FEATURES

• Honda Powered…proven reliability…quiet operation…efficient fuel consumption

• Automatic Idle Control…reduces fuel consumption, noise, and engine wear (this feature is not

available on Model TPG-2900H-DX).

• Large, Silent Muffler (with USDA qualified spark arrestor) to significantly reduce noise. The

spark arrestor is designed to screen out hot sparks.

• Large Air Filter…for superior emission control.

• Large Capacity Fuel Tank with Fuel Gauge…for extended run time.

• Rubber Vibration Pads…isolates generator/engine vibration from the frame for maximum pro-

tection and noise reduction.

• Ground Fault Circuit Interrupter (GFCI)…on 120V duplex receptacle protects operator from

shock.

• Full Power Switch…allows voltage selection; either full-rated output from 120V receptacle or halfrated output from 120V receptacle and full-rated output from 240V receptacles (this feature is not

available on Model TPG-2900H-DX).

• Circuit Breaker…protects generator from overload damage; can be reset with the flip of a switch

(no fuse to replace).

• 100% Copper Windings…for long life.

Page 5 Introduction

Tsurumi’s Operation, Service, and Repair Manual

2. DESCRIPTION AND OPERATION

A. PHYSICAL DESCRIPTION

(1) Description of the Portable Generator

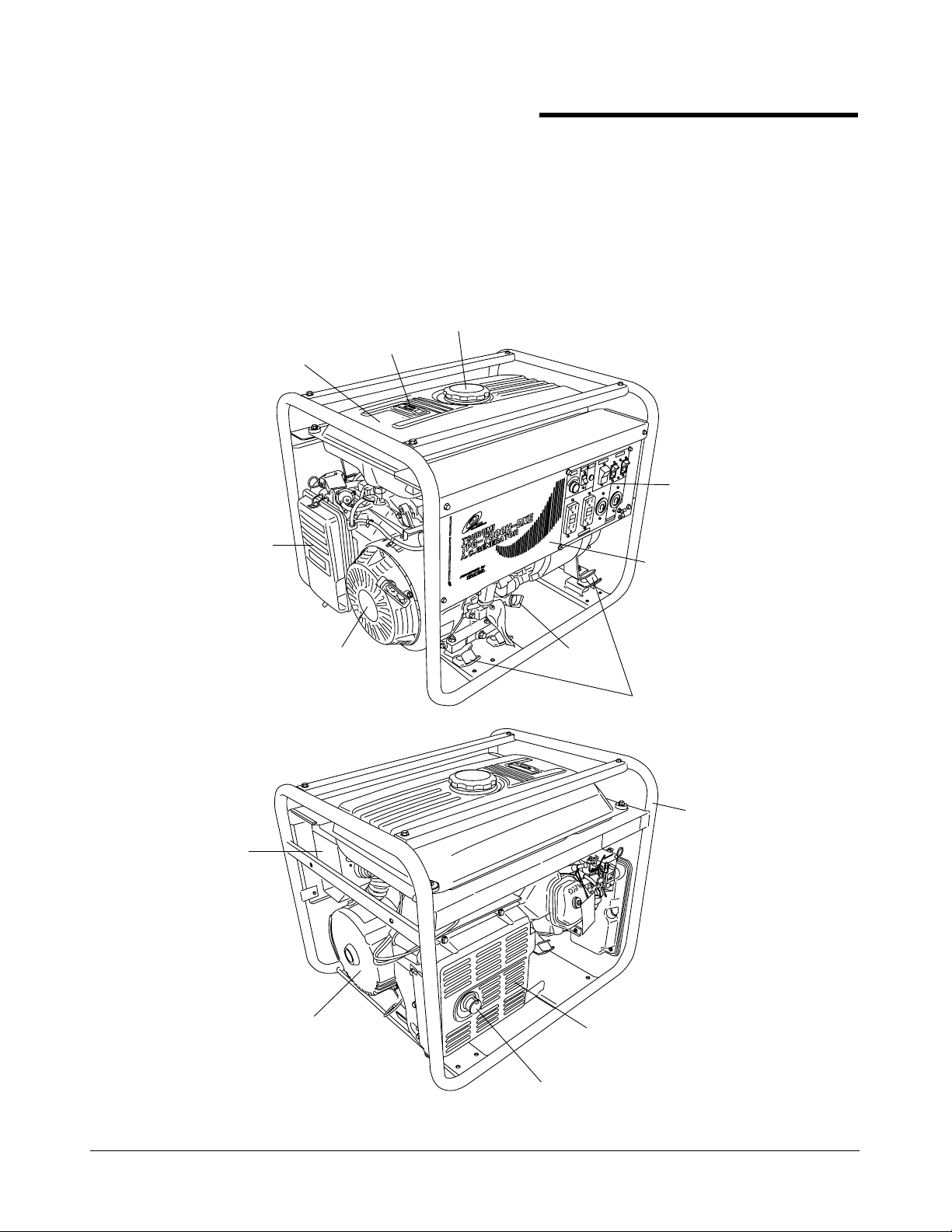

(a) The key features of the portable generator are shown in Figure 1. A cutaway view of

the generator is provided in Figure 2.

Figure 1: Key Features of Generator (Model TPG-7000H-DXE Shown)

Description and Operation Page 6

Tsurumi’s Operation, Service, and Repair Manual

Filler Cap

Fuel Gauge

Fuel Tank

Air Filter

Engine

Controls

Front Panel

Oil

Filler

Plug

Vibration Mounts

Control Box

Generator

Tubular Frame

Muffler

Spark Arrestor

(b) The generator consists of a tubular frame onto which is installed the generator,

engine, front panel, control box and fuel tank.

(c) The generator and engine are installed on crossover plates that form the base of the

tubular frame. Vibration isolators support the generator and engine unit. The isolators

are fitted with threaded studs that secure the generator and engine unit to the frame.

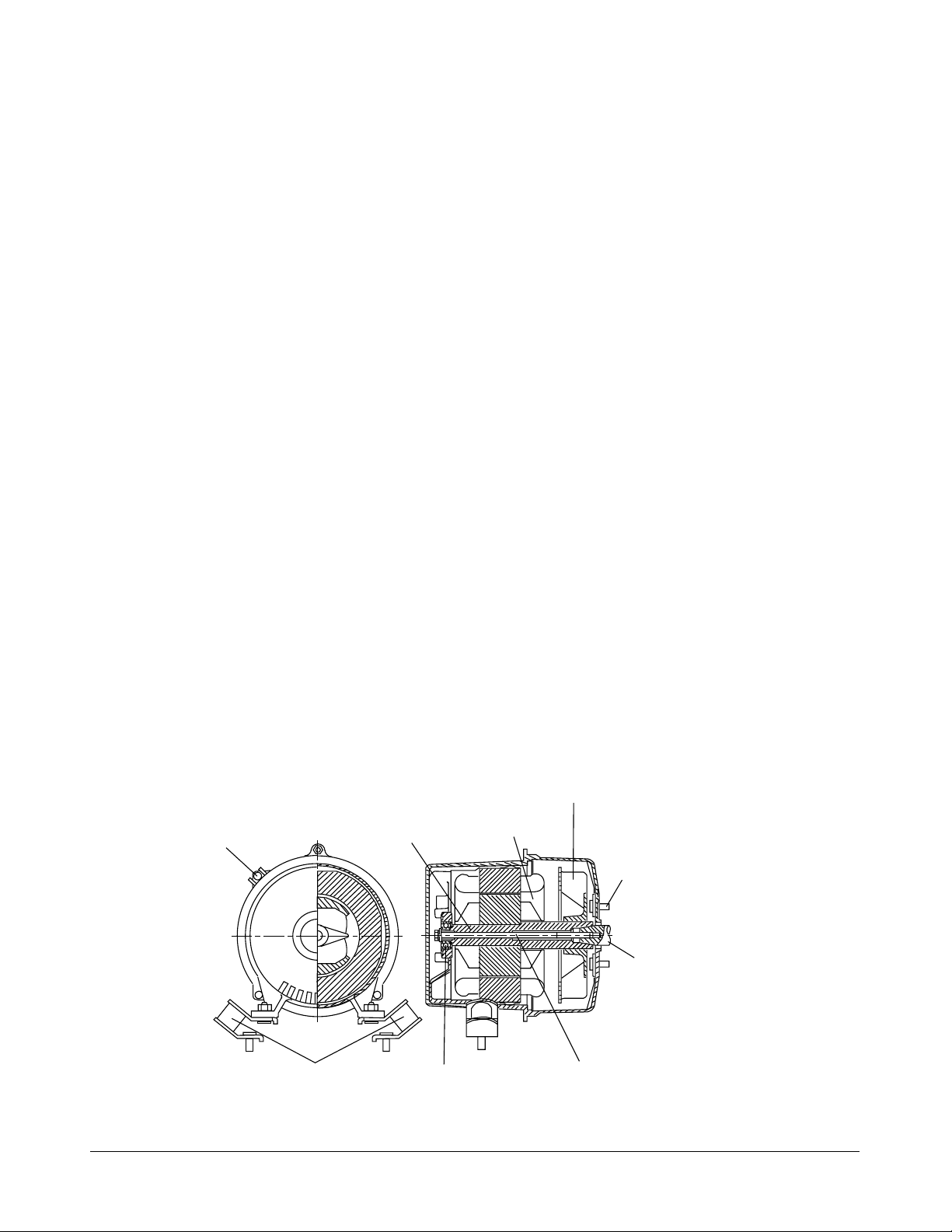

(2) Description of Generator

(a) The generator consists of a rear cover, stator cover, stator, rotor, and front cover.

(b) The front cover of the generator attaches to the engine and forms the generator-to-

engine interface.

(c) The front cover has a series of slots that allow entry of cooling air into the generator.

A fan on the rotor circulates air through the generator.

(d) The rear cover has mounting lugs that are the generator-to-frame attachment points.

The rear cover supports a ball bearing at the back end of the generator rotor.

(e) The rear cover has a removable access plate to provide access to the stator wiring

(an access plate is not used on Model TPG-2900H-DX.)

(f) The rotor consists of a shaft, a stack of steel laminations, and copper wire windings.

Components mounted on the rotor include a diode, a surge absorber, two permanent

magnets, and a cooling air fan.

(g) The windings and the laminated steel core form the field coil. The permanent mag-

nets are used to induce voltage in the main coil of the stator. The diode and the surge

absorber are located under the rotor windings at the bearing end of the rotor shaft.

(h) The rotor is attached to the engine crankshaft with a through bolt (tie-bolt). The

engine crankshaft is tapered and mates with a tapered bore in the rotor shaft. The

clamping force applied to the through bolt ties the rotor shaft to the engine crankshaft.

Figure 2: Cutaway of Generator (Model TPG-2900H-DX Shown)

Page 7 Description and Operation

Tsurumi’s Operation, Service, and Repair Manual

Tie-Bolts (3)

Rotor

Vibration Mounts

Ball Bearing

Through-Bolt

Stator

Cooling Fan

Generator-To-Engine-Bolts

Tapered Shaft

(3) Description of the Engine

NOTE:

• Refer to the Honda engine Owner’s Manual for Models GX160, GX240, GX340, and GX390 for addi-

tional coverage of the engine.

(a) The TPG-7000H-DXE generator has an electric starter and a recoil starter. All other

generators are equipped with a recoil starter.

(b) The engine is equipped with an air filter to remove airborne contaminants from the

engine inlet air.

(c) The engine is fitted with a muffler that provides quiet operation and controls the flow

of engine exhaust gases. The muffler is attached to the rear generator cover using a

mounting bracket.

(d) The muffler for Models TPG-4300H-DX, TPG-6000H-DX, and TPG-7000-DX expels

exhaust gases through a port in the side of the muffler. The muffler for Model TPG2900H-DX has a smaller muffler that expels gases through a curved tube on the bottom of the muffler.

(e) The muffler is fitted with a spark arrestor to screen-out sparks ejected in the exhaust

gases. The spark arrestor for Models TPG-4300H-DX, TPG-6000H-DX, and TPG7000-DX is installed in the exhaust port of the muffler. The spark arrestor for Model

TPG-2900H-DX is installed in the inlet side of the muffler.

(f) The engine has an oil filler plug that is used to check engine oil level. Engine oil is

added through the same filler plug port. The engine oil drain plug is installed in the

engine casing adjacent to the oil filler plug.

(g) The engine has a carburetor choke control for starting the engine during cold weath-

er operation. (Models TPG-4300H-DX, TPG-6000H-DX, and TPG-7000H-DXE have

a ring-type choke control; Model TPG-2900H-DX has a choke lever.)

(4) Description of the Fuel Tank

(a) The fuel tank is attached to one side of the frame by two cushioned mounts. The tank

is supported on the opposite side by cushioned pads that fit into a channel on the

backside of the front panel.

(b) A screen is provided under the filler cap to prevent entry of large contaminants.

(c) The tank has a fuel shutoff valve that is used to prevent fuel spillage when the gen-

erator is not in use. The fuel shutoff valve is used to drain fuel from the tank if need-

ed for replacement of generator components. The fuel shutoff valve should be closed

during transport to prevent fuel spillage.

(d) The fuel shutoff valve has a sediment bowl to capture heavier contaminants that may

have passed through the fuel tank filler screen.

(5) Description of the Front Panel

NOTE:

• Refer to Figure 7 through Figure 10 for illustrations of the generator front panels. Familiarize yourself with the layout of the front panel for your generator before operating the generator.

(a) The operating controls, switches, lights, electrical receptacles, and circuit breakers for

the generator are mounted on the front panel.

(b) A control box is mounted on the back of the front panel. The control box contains the

idle control unit, diode, condensers, and dc reset pushbutton switch (refer to Figure 11).

Description and Operation Page 8

Tsurumi’s Operation, Service, and Repair Manual

(c) The engine, starter, and control wiring exits through a hole in the side of the control box.

The diode and fuse that are part of the DC circuit are located inside the control box.

(d) The generator leads and control wiring are connected inside the control box. A flexible

rubber sleeve provides protection for the generator wiring.

B. FUNCTIONAL DESCRIPTION

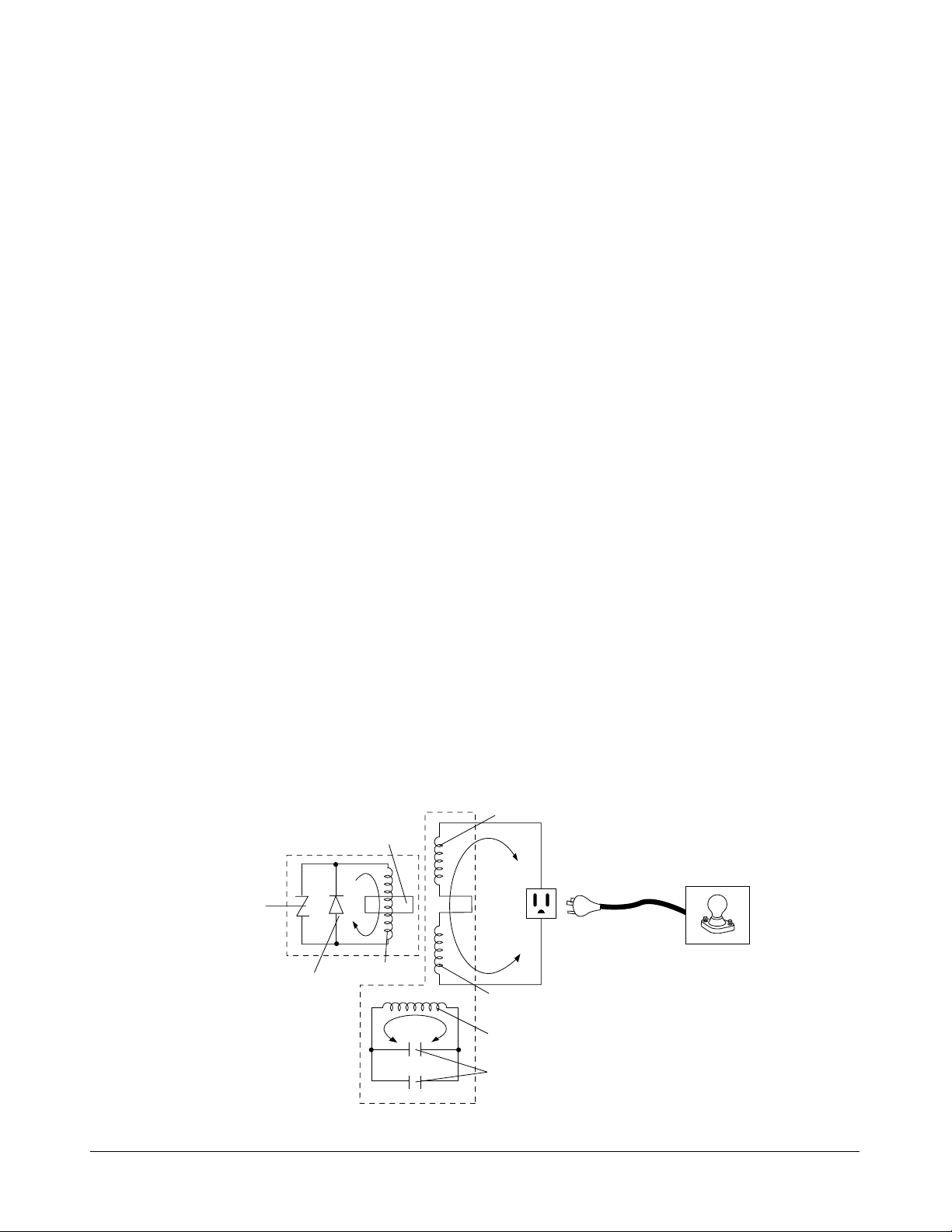

(1) Generation of No-Load Voltage (refer to Figure 3)

(a) When the generator rotor begins to rotate, the permanent magnet in the rotor gener-

ates 3 to 6 volts alternating current in the main coil and in the condenser coil windings.

(b) The low voltage generated in the condenser coil also generates minute current flow (a)

through the condenser coil. At the same time, low-level magnetic flux intensifies at the

rotor’s magnetic pole. As the magnetic force intensifies, voltage increases in the main

coil and in the condenser coil. As current (a) increases, magnetic flux also increases at

the rotor’s magnetic pole, and continues to increase as generator speed increases.

(c) As AC current flows through the condenser coil, the density of the magnetic flux in the

rotor changes. The change in magnetic flux density induces AC voltage in the field coil,

and the diode rectifier in the field coil circuit rectifies the AC voltage into DC voltage.

The resultant DC current flows (b) through the field coil and magnetizes the rotor core

to generate output voltage in the main coil.

(d) When the generator speed reaches 3000 to 3300 rpm (60 Hz generators), the current

in the condenser coil increases rapidly. This acts to stabilize the output voltage of each

coil. When the generator speed reaches its rated speed, the generator output will be

at its rated value.

(2) Voltage Fluctuations Under Load (refer to Figure 3)

(a) When output current (c) flows through the main coil to the appliance being used, a

magnetic flux is produced and serves to increase current (a) in the condenser coil. As

a result, the current flowing in the field coil increases and the generator output voltage

is prevented from decreasing.

Figure 3: Generation of No-Load Voltage

Page 9 Description and Operation

Tsurumi’s Operation, Service, and Repair Manual

Permanent magnet

for initial excitation

Stator

Main coil

Appliance

Receptacle

Main coil

Condenser coil

Condenser

Field coil

Diode

Surge

absorber

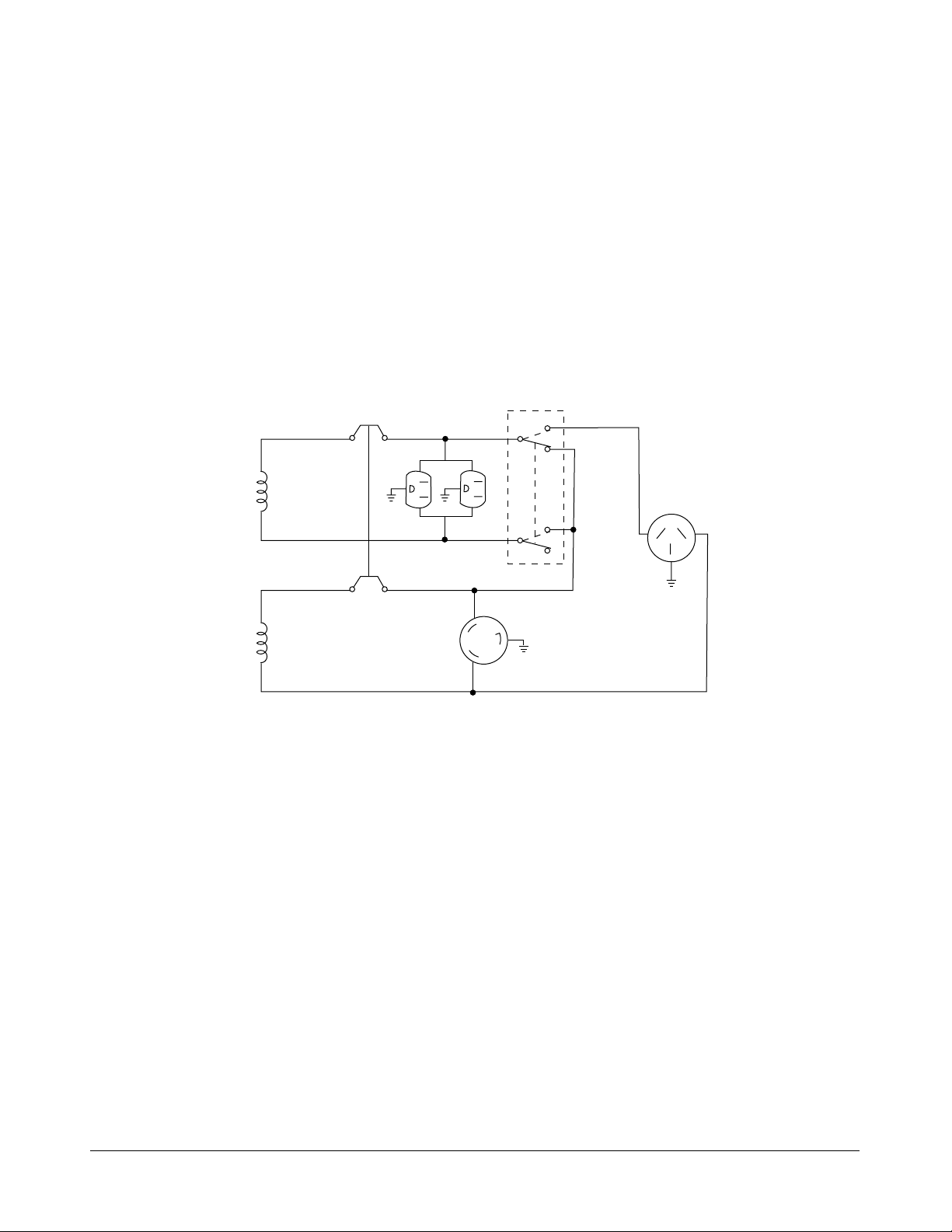

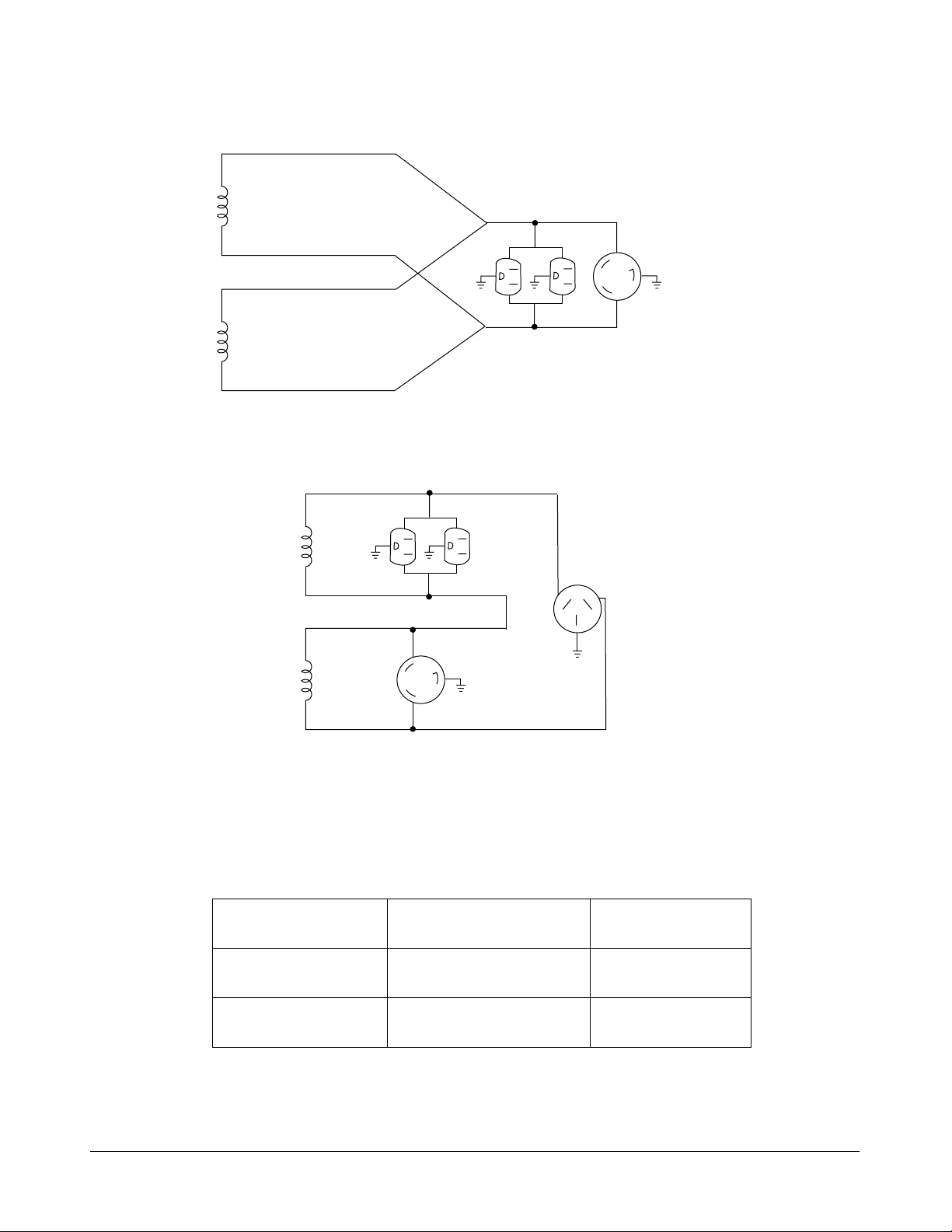

(3) Full Power Switch (Dual Voltage Type) (refer to Figure 4)

(a) The full power switch provides both 120V and 240V dual voltages at full rated power.

The full rated power will be available from one 120V receptacle and one 240V receptacle.

(b) Two main coils are wound over core of the stator. Each main coil outputs half the

rated power at the lower voltage (110V or 120V). These main coils are wound so they

are in the same phase. The full power switch reconnects these main coils in parallel

or in series.

(c) Refer to the circuit diagram in Figure 4. When the full power switch is set for single

lower voltage indication (110V or 120V), the switch position will be as indicated by the

lower coils line in the diagram.

Figure 4: Full Power Switch Circuit Diagram

(d) Refer to Figure 5 for a simplified diagram of the circuit. The two main coils are shown

in parallel. In this case, the higher voltage (220V or 240V) at Receptacle (Rec.) 3 is

not available. Rec. 2 for the lower voltage is available up to the rated power (up to

30A if the rated current is over 30A), and Rec. 1 is available up to 15A. When the full

power switch is set for double voltage indication (110V/220V or 120V/240V), the

switch position is indicated by the upper dotted line in Figure 8.

(e) Refer to Figure 6 for a simplified diagram of the circuit. The two main coils are shown

connected in series. In this example, power is simultaneously available from the

receptacles for both voltages. Higher voltage receptacle, Rec. 3, has power available

up to rated power, however, Rec. 1 and Rec. 2 for the lower voltage can output only

up to the rated power of each receptacle.

(f) Table 1 summarizes in tabular form the power available, or not available, depending

upon the position of the full power switch.

Description and Operation Page 10

Tsurumi’s Operation, Service, and Repair Manual

MC

1

MC

2

Rec. 1

120V

(or 110V)

120V

(or 110V)

120V/240V (or 110V/220V)

240V (or 220V)

Rec. 3

Rec. 2

120V (or 110V)

Figure 5: Full Power Switch Set for Single-Voltage Output

Figure 6: Full Power Switch Set for Dual-Voltage Output

Page 11 Description and Operation

Tsurumi’s Operation, Service, and Repair Manual

MC

1

MC

2

Rec. 2

120V

(or 110V)

120V (or 110V)

MC

1

MC

2

Rec. 1

120V

(110V)

Rec. 3

240V

(220V)

Rec. 2

Table 1: Full Power Switch – Switch Setting Versus Output Available

Switch

Position

Lower Voltage

Receptacle

Higher Voltage

Receptacles

110V

or 120V

Rated

Output

No Output

Can Be Taken

110V /120V

or 120V / 240V

Half of Rated

Output

Rated

Output

3. OPERATING INSTRUCTIONS

A. OPERATING CONTROLS

(1) The main operating controls for the generator are, with a few exceptions, mounted on the

front panel of the generator.

(2) The controls consist of an ENGINE switch, an IDLE switch, a FULL POWER switch, a

PILOT light, circuit BREAKER(s), a ground (or earth) post, and electrical receptacles. The

specific controls used in each model are shown in Figures 7 through 10.

(3) The Model TPG-7000H-DXE generator is equipped with a electric starter motor. The

ENGINE switch in this model is a key-operated, STOP/RUN/START switch. The springloaded switch is turned to the right to start the engine, and to the left to shut off the engine.

(4) The IDLE switch allows the generator speed to drop to idle speed if there is no electrical

load demand on the generator. When an electrical load is sensed, the idle control increases the speed of the generator up to operating speed level. When there is no load, the

engine speed returns to idle.

(5) The FULL POWER switch allows the generator to provide full rated power for the loading

appliances and/or tools. When the FULL POWER switch is set to on, power will be provided to only one 120 Vac receptacle and one 240 Vac receptacle.

(6) The PILOT light provides an indication to the operator that the generator is generating elec-

tricity.

(7) Circuit breakers are provided to protect the generator in the event of a short circuit. The

breakers will trip when the circuit load exceeds the breaker’s rated value.

(8) The ground post is used to provide a positive ground for the generator. The post has a

wing-nut to quickly connect a ground wire to the generator.

(9) There are three types of receptacles: one 120 Vac, GFI-protected receptacles (two on most

models), one twist-type, 120 Vac receptacle, and one 120 Vac / 240 Vac, combination

receptacle.

B. DC CIRCUIT CONTROLS

(1) The circuitry for DC circuit consists of a 10 Amp fuse, an overload protector, and a re-set

switch.

(2) In the event of an overload, the overload protector will trip the reset switch (refer to Figure 11).

Operating Instructions Page 12

Tsurumi’s Operation, Service, and Repair Manual

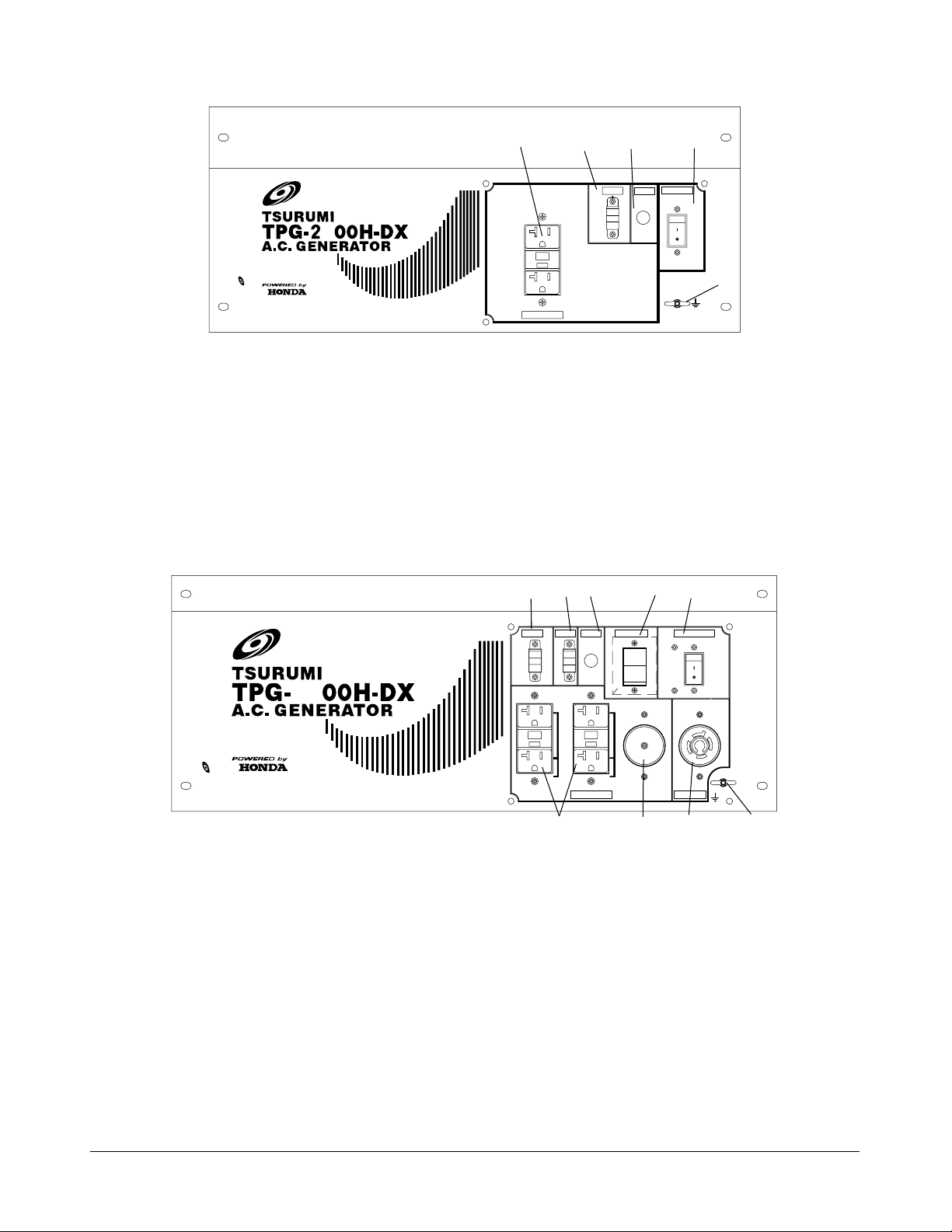

LEGEND

1 120 Vac Receptacle 4 18 Amp Circuit Breaker

2 Engine Switch 5 Ground Post

3 Pilot Light

Figure 7: Model TPG-2900H-DX

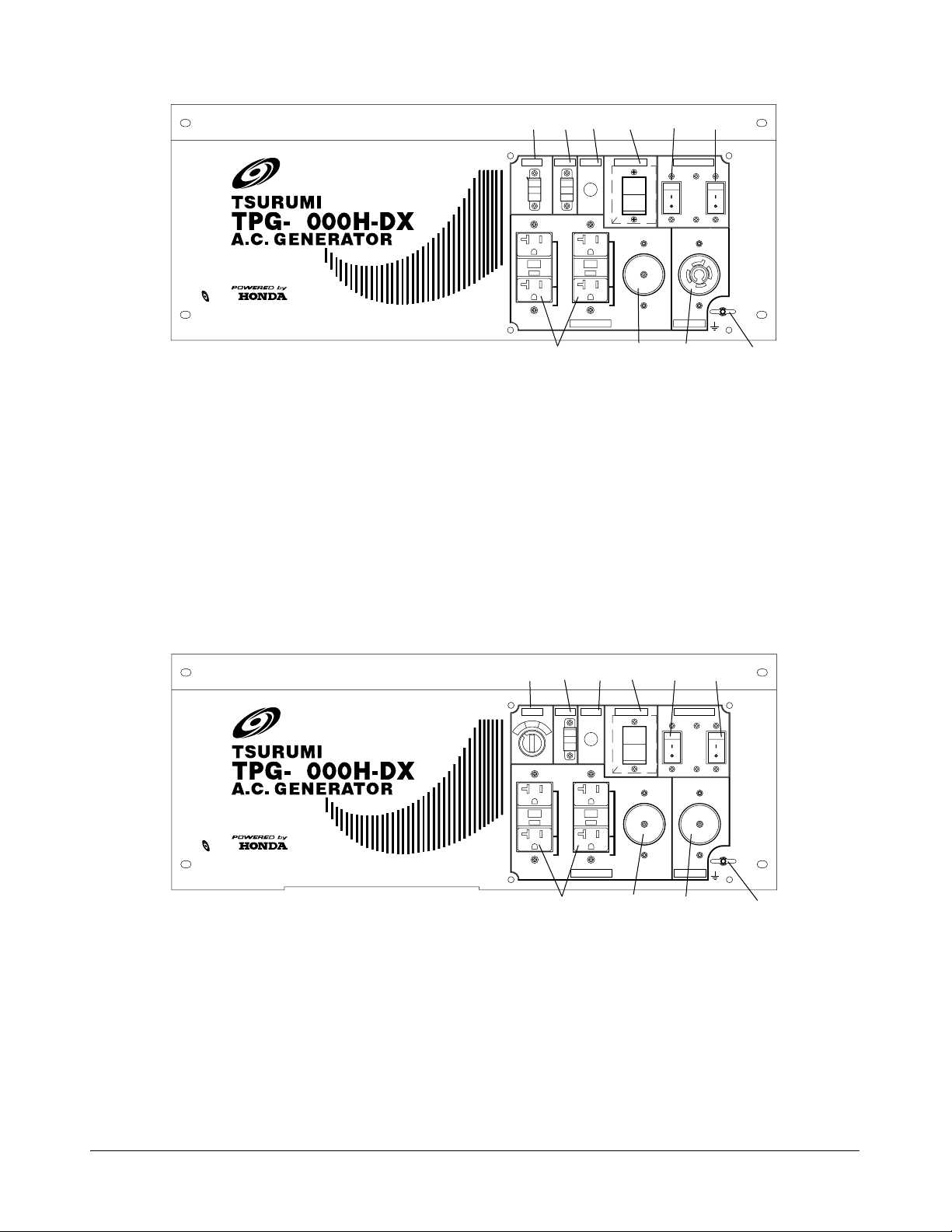

LEGEND

1 Engine Switch 6 Ground Post

2 Idle Switch 7 Receptacle 120Vac / 240Vac

3 Pilot Light 8 Receptacle 120Vac

4 Full Power Switch 9 Receptacle 120Vac, GFI (2)

5 14 Amp Circuit Breaker

Figure 8: Model TPG-4300H-DX

Page 13 Operating Instructions

Tsurumi’s Operation, Service, and Repair Manual

TSURUMI

MANUFACTURING CO.,LTD.

TSURUMI MANUFACTURING CO., LTD. MADE IN JAPAN

RUN

STOP

OFF

ON

BREAKER

ENGINE

PILOT

AC 120V

9

1

2

3

4

5

ON

OFF

BREAKERFULL

120

240

120

IDLEENGINE

PILOT

TSURUMI

MANUFACTURING CO., LTD.

TSURUMI MANUFACTURING CO., LTD. MADE IN JAPAN

4

RUN

STOPONOFF

3

MAX20MAX20

AC120V/240V

AC 120V

1

23

4

5

6

7

8

9

LEGEND

1 Engine Switch 6 20 Amp Circuit Breaker

2 Idle Switch 7 Ground Post

3 Pilot Light 8 Receptacle 120Vac / 240Vac

4 Full Power Switch 9 Receptacle 120Vac

5 30 Amp Circuit Breaker 10 Receptacle 120Vac, GFI (2)

Figure 9: Model TPG-6000H-DX

LEGEND

1 Engine Switch 6 22 Amp Circuit Breaker

2 Idle Switch 7 Ground Post

3 Pilot Light 8 Receptacle 120Vac / 240Vac

4 Full Power Switch 9 Receptacle 120Vac

5. 30 Amp Circuit Breaker 10 Receptacle 120Vac, GFI (2)

Figure 10: Model TPG-7000H-DX

Operating Instructions Page 14

Tsurumi’s Operation, Service, and Repair Manual

OFF

ON ON

OFF

BREAKER

FULL

120

240

120

IDLE

ENGINE

PILOT

TSURUMI

MANUFACTURING CO., LTD.

TSURUMI MANUFACTURING CO., LTD. MADE IN JAPAN

ON

OFF

7

E

MAX20 MAX20

AC120V/240V

AC 120V

1

234

5

6

7

8

9

10

TSURUMI MANUFACTURING CO., LTD. MADE IN JAPAN

TSURUMI

MANUFACTURING CO., LTD.

1

ENGINE

RU

STOOOF

6

MAX20 MAX20

10

3

2

IDLE

PILOT

120

AC 120V

45

FULL

120

O O

240

OF

9

BREAKER

AC120V/240V

8

6

OF

7

Figure 11: DC Circuit Reset Pushbutton

C. CHECK THE ENGINE OIL LEVEL

CAUTION:

• Engine oil is a major factor affecting performance and service life. Non-detergent oils and

2-stroke oils are not recommended because they have inadequate lubricating characteristics

• Check the oil level with the engine on a level surface and the engine stopped.

(1) Use Honda 4-stroke oil, or use an equivalent high detergent, premium quality motor oil cer-

tified to meet or exceed U.S. automobile manufacturer’s requirements for Service

Classification SG, SF. Motor oils classified SG, SF will show this designation on the container.

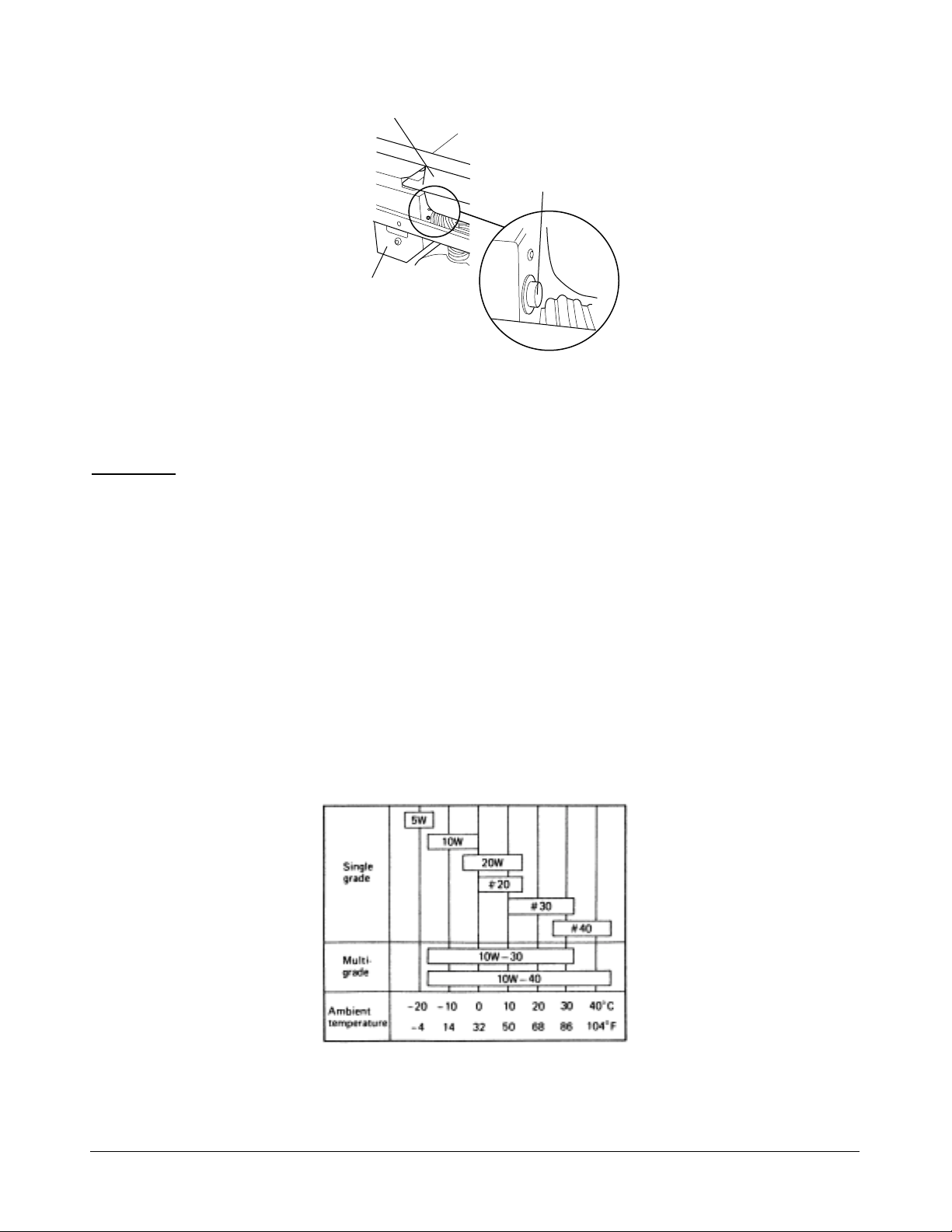

(2) SAE 10W/30 is recommended for general, all-temperature use.

(3) Other viscosity grades shown in Figure 12 may be used when the average temperature in

your area is within the indicated range.

Figure 12: Oil Viscosity Grade-to-Temperature Recommendations

Page 15 Operating Instructions

Tsurumi’s Operation, Service, and Repair Manual

T

O

F

R

A

M

E

Fuel Tank

Control Box

Reset Button

When checking oil, observe the following (refer to Figure 13):

(1) Make sure the engine is in a level position.

(2) Remove the oil filler cap/dipstick and wipe it clean.

(3) Insert the filler cap/dipstick into the oil filler neck, but do not screw it in.

(4) Remove the filler cap/dipstick and check the oil level.

(5) If the level is low, fill to the top of the oil filler neck with the recommended oil.

(6) Reinstall the oil filler cap/dipstick.

Figure 13: Checking Oil Level

D. CHECK ENGINE FUEL

W

ARNING:

• MAKE SURE YOU REVIEW EACH WARNING IN ORDER TO PREVENT FIRE HAZARD.

• DO NOT REFILL TANK WHILE ENGINE IS RUNNING OR HOT.

• CLOSE FUEL SHUT OFF VALVE BEFORE REFUELING WITH FUEL.

• BE CAREFUL NOT TO GET DUST, DIRT, WATER OR OTHER FOREIGN OBJECTS INTO FUEL.

• WIPE OFF SPILLED FUEL THOROUGHLY BEFORE STARTING ENGINE.

• KEEP AWAY FROM OPEN FLAMES.

• DO NOT USE SMOKING MATERIALS WHEN FILLING THE FUEL TANK.

• DO NOT REFUEL WHILE SMOKING OR NEAR OPEN FLAME OR OTHER SUCH POTENTIAL

FIRE HAZARDS. OTHERWISE FIRE ACCIDENT MAY OCCUR.

• AVOID REPEATED OR PROLONGED CONTACT WITH SKIN OR BREATHING OF VAPOR.

• KEEP OUT OF REACH OF CHILDREN.

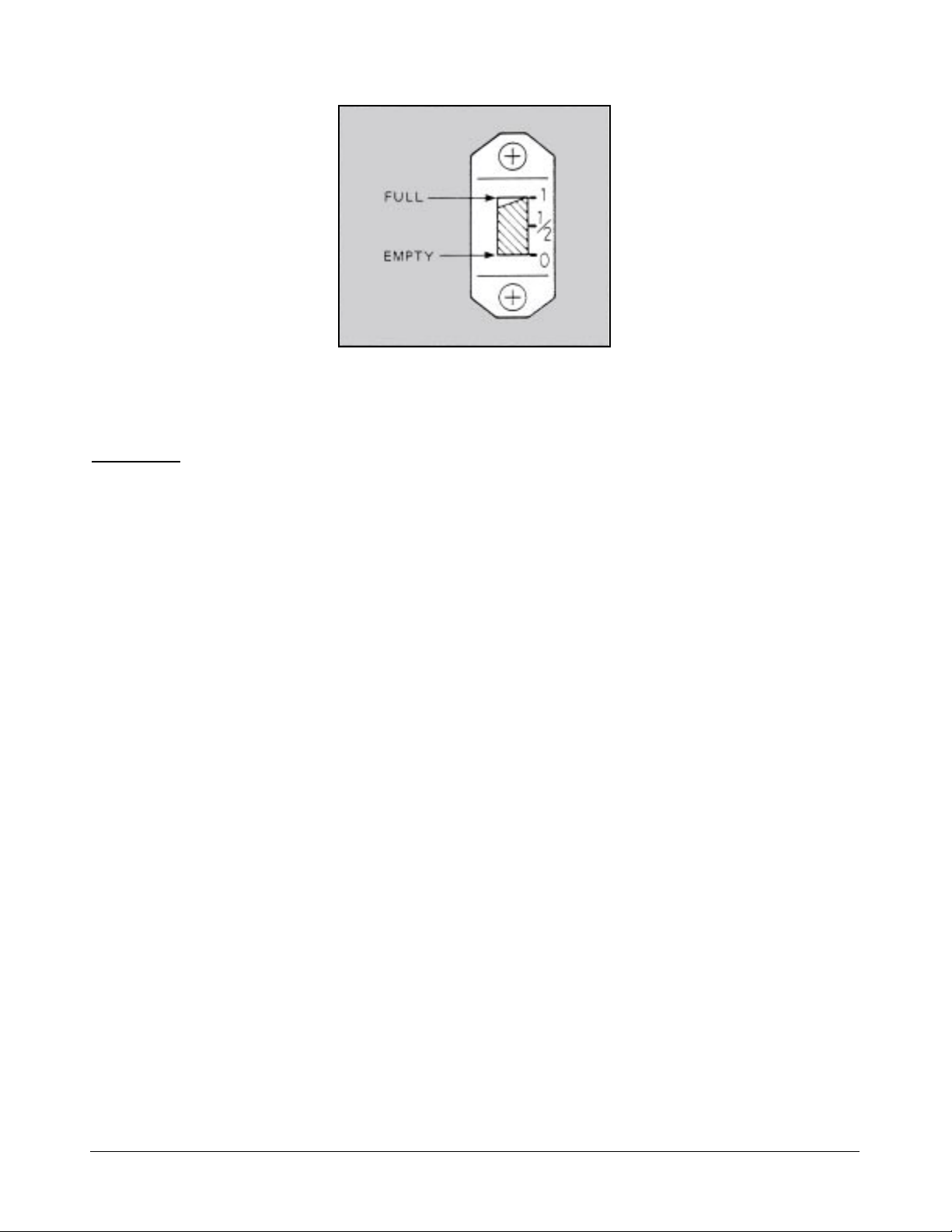

(1) Check fuel level at fuel level gauge (refer to Figure 14).

(2) If fuel level is low, refill with unleaded automotive gasoline.

(3) Fuel tank capacity TPG-2900H-DX (2.9 gal.)

TPG-4300H-DX (4.5 gal.)

TPG-6000H-DX (4.5 gal.)

TPG-7000H-DXE (4.5 gal.)

Operating Instructions Page 16

Tsurumi’s Operation, Service, and Repair Manual

Figure 14: Fuel Gauge Indications

E. PRE-START CHECKS

W

ARNING:

• MAKE SURE YOU REVIEW EACH WARNING IN ORDER TO PREVENT FIRE HAZARD.

• KEEP AREA CLEAR OF FLAMMABLES OR OTHER HAZARDOUS MATERIALS.

(1) Check the following items before starting the engine.

(a) Fuel leakage from fuel hose, etc.

(b) Bolts and nuts for looseness.

(c) Components for damage or breakage.

(2) Check generator surroundings.

(a) Keep generator at least 3 feet (1 meter) away from buildings or other structures.

(b) Only operate generator in a dry, well-ventilated area.

(c) Keep exhaust pipe clear of foreign objects.

(d) Keep generator away from open flame.

(e) Keep generator on a stable and level surface.

(f) Do not block generator air vents with paper or other material.

F. STARTING & OPERATING THE ENGINE

(1) Before starting the engine, set AC circuit breakers to OFF.

(2) Refer to the Honda engine owner’s manual.

(a) Turn the fuel valve to the ON position.

(b) Move the choke lever to the CLOSE position.

Page 17 Operating Instructions

Tsurumi’s Operation, Service, and Repair Manual

NOTE:

• The choke may not be needed if the engine is warm or the air temperature is high.

(3) Move the throttle lever slightly to the left.

(4) (MODEL TPG-7000H-DXE ONLY): To start the engine using the electric starter, proceed as

follows:

(a) Turn key in engine START/STOP switch.

(b) Turn key fully right to START position. Hold in START position until engine starts.

(c) Release key; the key is spring-loaded to the RUN position.

(d) As the engine warms up, gradually move the choke lever to the OPEN position.

(e) Position the throttle lever at the desired engine speed.

(5) (ALL MODELS): When starting the engine using recoil starter, proceed as follows:

(a) Turn the engine switch to the ON position.

(b) Pull the starter grip lightly until resistance is felt, then pull briskly.

NOTE:

• When using the recoil starter, do not allow the starter grip to snap back against the engine. Return

it gently to prevent damage to the starter.

(c) As the engine warms up, gradually move the choke lever to the OPEN position.

(d) Position the throttle lever at the desired engine speed.

G. USING THE GENERATOR

W

ARNING:

• TO PREVENT ELECTRICAL SHOCK FROM FAULTY APPLIANCES, THE GENERATOR

SHOULD BE GROUNDED. CONNECT A LENGTH OF HEAVY WIRE BETWEEN THE GENERATOR’S GROUND TERMINAL AND EXTERNAL GROUND SOURCE.

• CONNECTIONS FOR STANDBY POWER TO A BUILDING’S ELECTRICAL SYSTEM MUST BE

MADE BY A QUALIFIED ELECTRICIAN AND MUST COMPLY WITH ALL APPLICABLE LAWS

AND ELECTRICAL CODES. IMPROPER CONNECTIONS CAN ALLOW ELECTRICAL CURRENT FROM THE GENERATOR TO BACK-FEED INTO THE UTILITY LINES. SUCH BACKFEED MAY ELECTROCUTE UTILITY COMPANY WORKERS OR OTHERS WHO CONTACT

THE LINES DURING A POWER OUTAGE, AND WHEN UTILITY POWER IS RESTORED, THE

GENERATOR MAY EXPLODE, BURN, OR CAUSE FIRES IN THE BUILDING’S ELECTRICAL

SYSTEM.

H. AC APPLICATION

A Single Voltage Type

(1) Check the pilot lamp for proper voltage.

NOTE:

• The generator is thoroughly tested and adjusted in the factory. If the generator does not produce

the specific voltage, consult your nearest Tsurumi Generator dealer.

(2) Set switches on the electrical appliances to OFF before connecting to the generator.

(3) Insert the plug of the electrical appliance into the appropriate receptacle.

Operating Instructions Page 18

Tsurumi’s Operation, Service, and Repair Manual

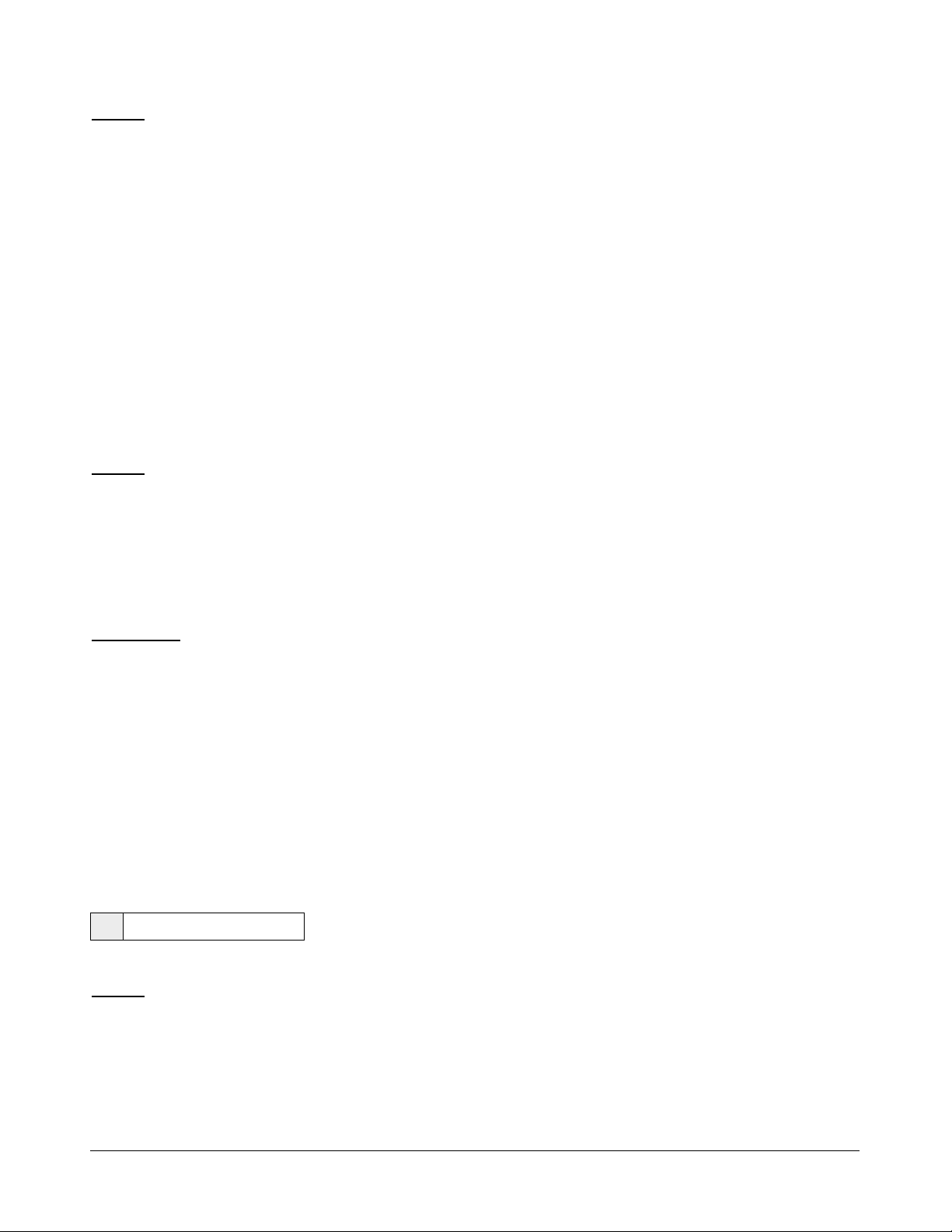

NOTE:

• Check the amperage of the receptacles used referring to Table 2, and be sure not to take a current

exceeding the specified amperage.

• Be sure that the total wattage of all appliances does not exceed the rated output of the generator.

W

ARNING:

• TO CONNECT AND LOCK A PLUG IN A TWIST LOCK RECEPTACLE, INSERT THE PLUG INTO

RECEPTACLE AND TURN CLOCKWISE.

• BE SURE TO GROUND THE GENERATOR IF THE CONNECTED ELECTRICAL EQUIPMENT IS

GROUNDED.

NOTE:

• When the circuit breaker trips off during operation, the generator is overloaded or the appliance is

defective.

• When the circuit breaker trips, stop the generator immediately. Check the appliance and/or gener-

ator for an overload or defect and repair as necessary.

CAUTION:

• The 120V duplex receptacle is protected by a GFCI (Ground Fault Circuit Interrupter). The

GFCI shuts off the output current from the 120V duplex receptacle when a ground fault

occurs in the generator or the appliance.

• Please note that other receptacles are not protected by a GFCI.

B Dual Voltage Type

(1) Select the voltage using the FULL POWER switch in accordance with the electrical appli-

ance. Refer to Table 3.

(2) Operate the generator in the same way as step (a) through step (c) of single voltage type.

Page 19 Operating Instructions

Tsurumi’s Operation, Service, and Repair Manual

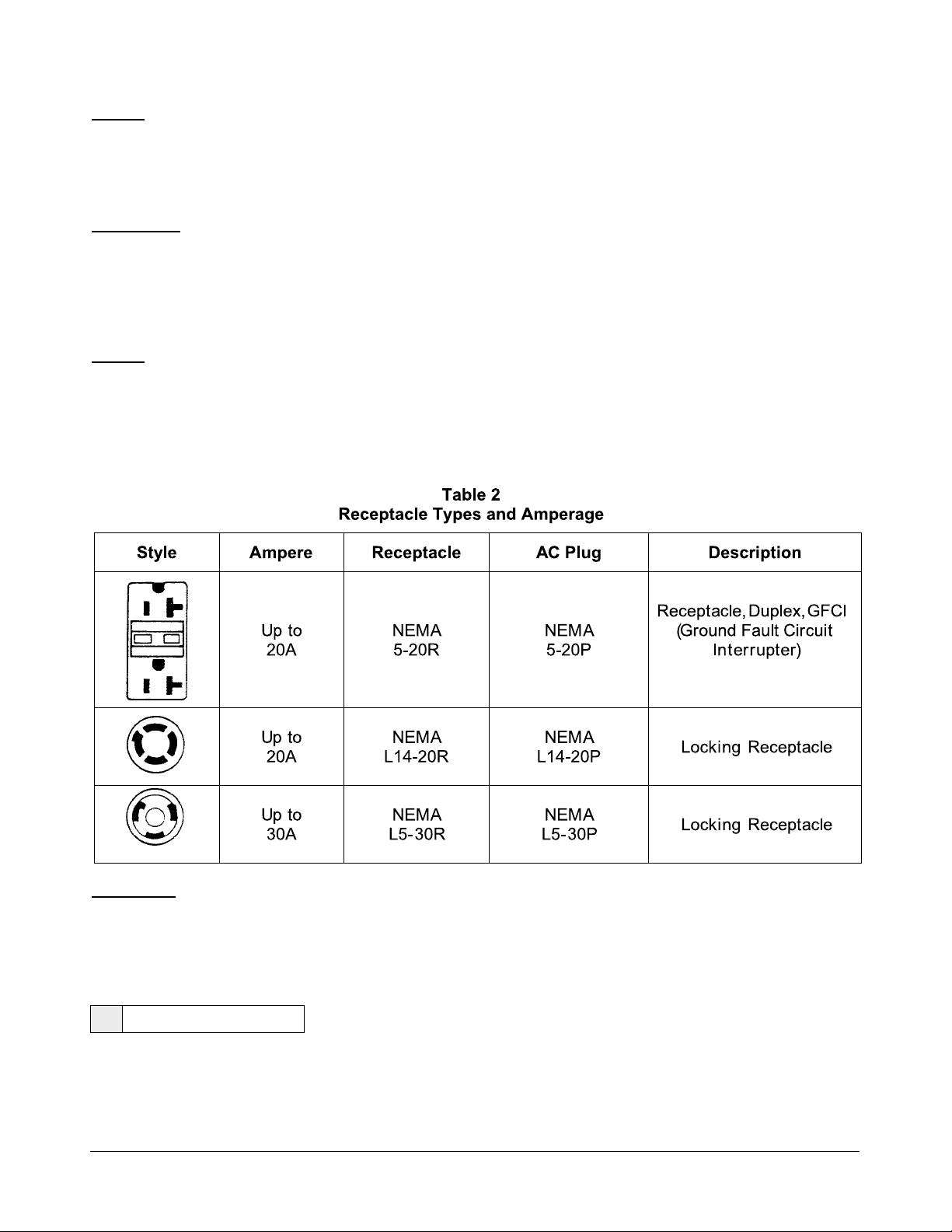

Table 3

Available Receptacles With Full Power Switch On

Switch Setting Lower Voltage Receptacle Higher Voltage Receptacle

120V Rated Output is Available Unavailable

120V/240V Half of Rate Output is Available Rated Output is Available

W

ARNING:

• TO TAKE OUT POWER FROM TWIST LOCK RECEPTACLE, INSERT THE PLUG INTO RECEP-

TACLE AND TURN CLOCKWISE TO LOCK IT.

• BE SURE TO GROUND THE GENERATOR IF THE CONNECTED ELECTRICAL EQUIPMENT IS

GROUNDED.

NOTE:

• When the circuit breaker turns off during operation, the generator is overloaded or the appliance is

defective.

• Stop the generator immediately, check the appliance and/or generator for overloading or defect and

repair as necessary.

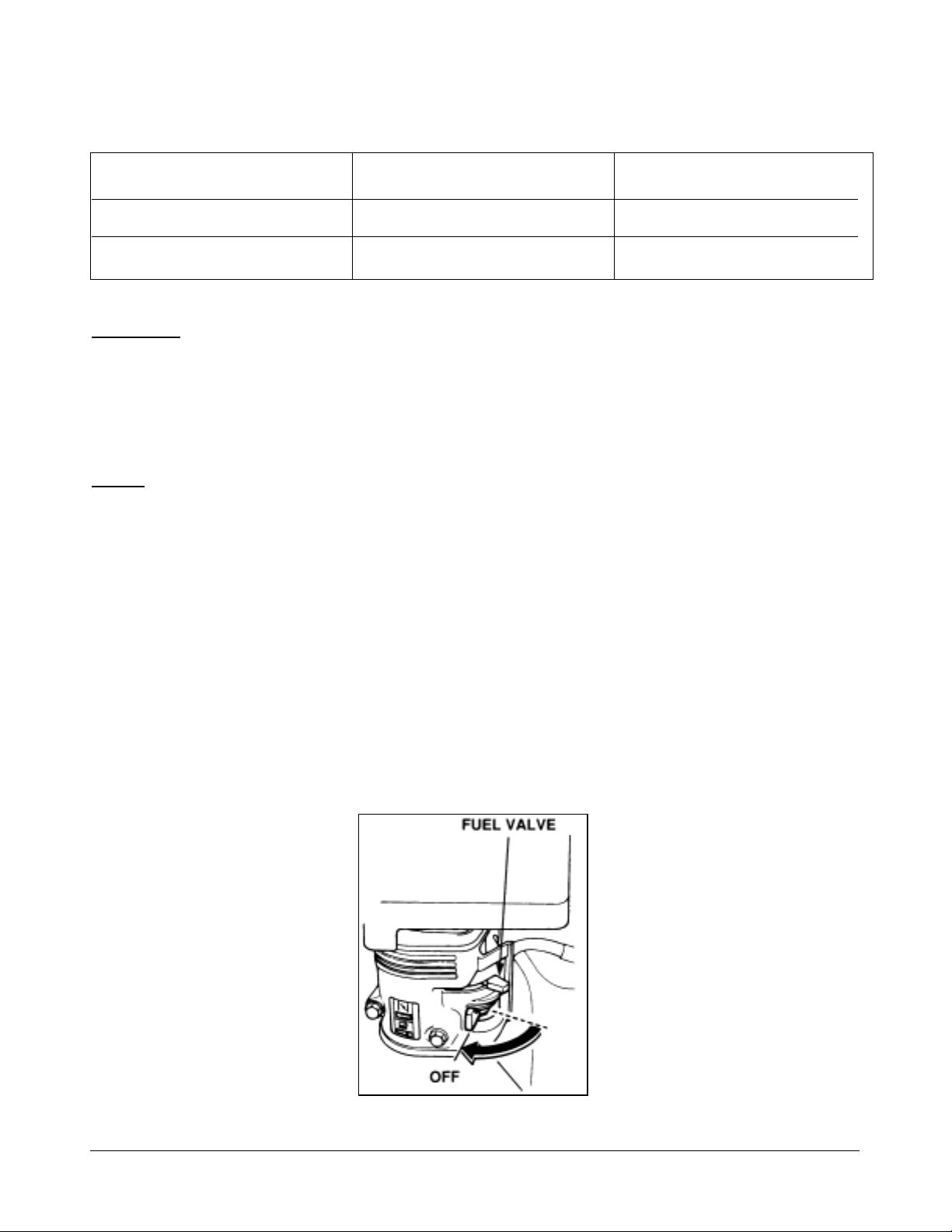

I. STOPPING THE GENERATOR

(1) Set the power switch to OFF or unplug the cord from the receptacle.

(2) Move the throttle lever fully to the right.

(3) Turn the engine switch to the OFF position.

(4) Turn the fuel valve to the OFF position.

Figure 15: Fuel Valve

Operating Instructions Page 20

Tsurumi’s Operation, Service, and Repair Manual

J. OIL ALERT

(1) The oil alert detects the fall in oil level in the crankcase and automatically stops the engine

when the oil level falls down below the predetermined level.

(2) When the engine has stopped automatically, check the oil level. Refill engine oil to the

upper level and restart the engine.

(3) If the engine does not start by usual starting procedures, check the oil level.

K. IDLE CONTROL (TPG-4300H-DX, TPG-6000H-DX, AND TPG-7000H-DXE)

The idle control feature automatically reduces engine speed when there is no load on the generator

and automatically increases engine speed up to rated speed when load is applied.

The idle control feature provides fuel economy and low noise operation at no-load running.

(1) How To Use Idle Control

(a) Start the engine with IDLE switch set to OFF.

NOTE:

• Warm up the engine without a load for a few minutes.

(b) Set IDLE switch to the ON position.

(2) Checking Idle Function

(a) When the idle function does not operate normally, please check the following:

NOTE:

• Most induction loads, such as an electric motor, require wattage three to five times larger than their

rating at starting. This starting wattage should not exceed the rated output of the generator.

(b) Is the generator overloaded? Make sure that the generator is not overloaded.

(c) Turn the IDLE switch off when the idle control does not work normally under the rated

output.

L. STOPPING THE ENGINE

(1) Turn off the switch of load or disconnect the load.

(2) Turn the IDLE switch off.

(3) Push ENGINE to stop.

NOTE:

• Allow the engine about 3 minutes to cool down at no-load before stopping.

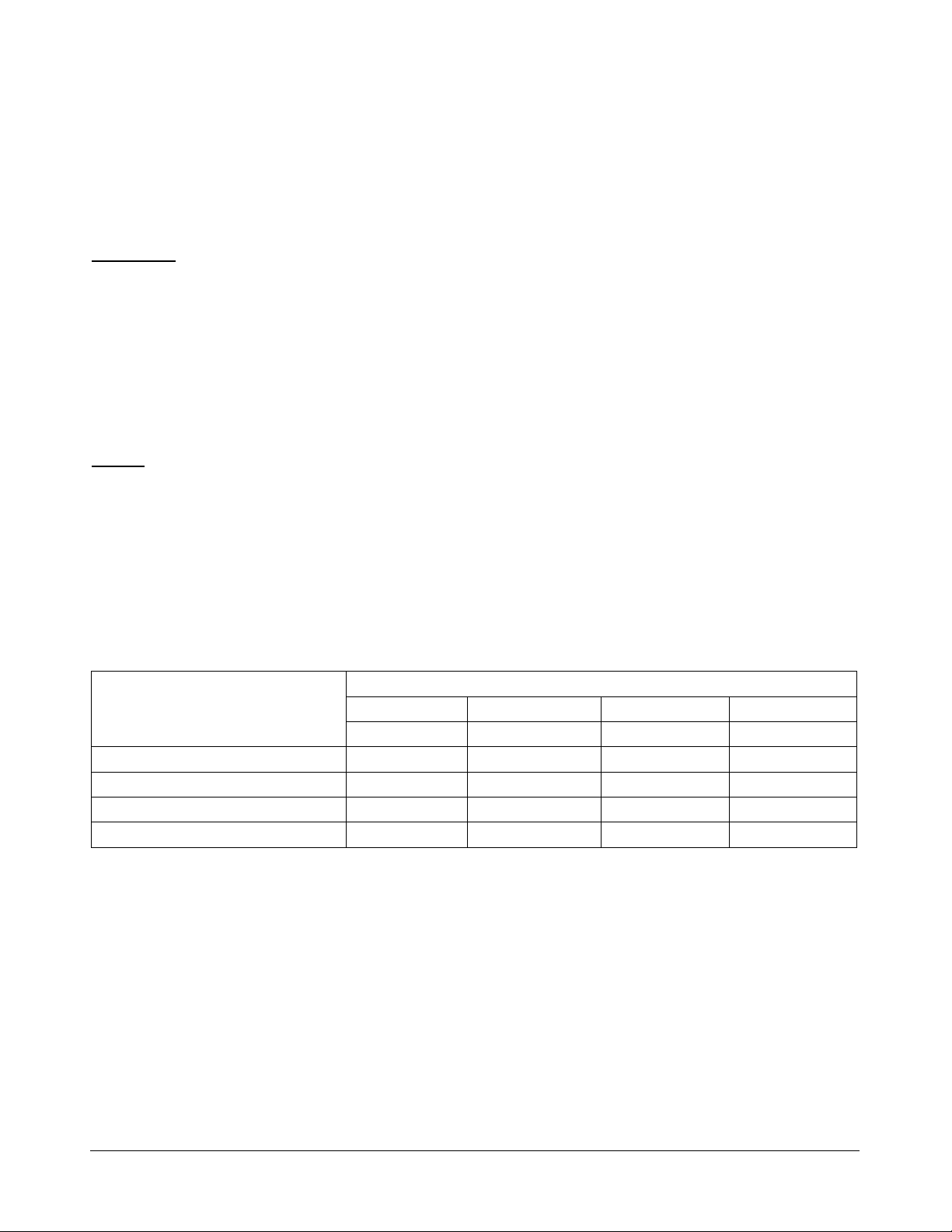

M. WATTAGE INFORMATION

When starting some appliances, a “surge” of energy occurs. Depending upon the nature of the electrical load, the amount of electrical power needed to start the appliance may exceed the amount needed to maintain its use. See Table 4 for appliances you may use with this generator.

Electrical appliances and tools normally come with a label indicating voltage, cycles/Hz, amperage

(amps) and electrical power needed to run the appliance or tool. Check with your nearest dealer with

questions regarding power surge of certain appliances or power tools.

Page 21 Operating Instructions

Tsurumi’s Operation, Service, and Repair Manual

Electrical loads such as incandescent lamps and hot plates require the same wattage to start as needed to maintain use.

Loads such as fluorescent and mercury lamps require 1.2 to 2 times the indicated wattage to start.

Electric motors require a large starting current. Power requirements depend on the type of motor and

its use. Once enough “surge” is attained to start the motor, the appliance will require only 50% to 30%

of the wattage to continue running.

CAUTION:

• Check motor starting current and power factor carefully.

Most electrical tools require 1.2 to 3 times their wattage for running. For example, the 5,000 watts generated could power an 1800-watt to a 4000-watt electric drill.

Loads such as submersible pumps and air compressors require a very large force to start. They need

3 to 5 times the wattage needed to maintain the tool in order to start. For example, a 5,000 watt generator would only be able to drive a 1,000 watt to 1,700 watt pump.

NOTE:

The wattage chart (Table 4) is a guide only. Refer to your specific appliance for correct wattage.

To determine the total wattage required for operating a particular electrical appliance or tool, multiply

the wattage figure of the appliance/tool by the tool’s amperage (amps). The voltage and amperage

(amps) information can usually be found on a data plate or label, which is normally attached to electric appliances and tools.

Operating Instructions Page 22

Tsurumi’s Operation, Service, and Repair Manual

Table 4

Wattage Chart

Applicable Wattage (w)

TPG-2900H-DX TPG-4300H-DX TPG-6000H-DX TPG-7000H-DXE

Applicable Wattage (W)

60 Hz 60 Hz 60 Hz 60 Hz

Incandescent Lamp, Heater 2000 3300 4500 5300

Fluorescent Lamp, Mercury Lamp 1200 1900 2800 3100

Electric Tool 1200 2800

Pump, Compressor 500 700 1000 1500

1900 3100

4. MAINTENANCE

To maintain the generator in peak operating condition, observe and implement the maintenance and

adjustment schedule in Table 5. Inspect and/or service the generator as scheduled in Table 5.

W

ARNING:

• SHUT OFF THE ENGINE BEFORE PERFORMING ANY MAINTENANCE. IF OPERATION OF

THE ENGINE IS REQUIRED, MAKE SURE THE AREA IS WELL VENTILATED; THE ENGINE

EXHAUST CONTAINS POISONOUS CARBON MONOXIDE GAS.

CAUTION:

• Refer to the Honda engine owner’s manual for other maintenance requirements.

An initial oil change should be performed after the first twenty (20) hours of use. Thereafter, change

oil every 100 hours.

Before changing the oil, check for a suitable way to dispose of the used oil. Do not pour it down sewer

drains, onto garden soil or into open streams. Refer to your local zoning and environmental regulations for disposal and handling requirements.

Page 23 Maintenance

Tsurumi’s Operation, Service, and Repair Manual

Table 5: Maintenance Schedule

Daily

•

Check oil level.

•

Check all components according to the PRE-OPERATIONAL CHECKS section.

50 Hours

•

Wash cleaner element.

•

Check spark plug and clean if necessary.

100 Hours

•

Change engine oil.

200 Hours

•

Adjust spark plug gap.

•

Clean fuel strainer.

500 Hours

(12 Months)

•Replace spark plug and cleaner element.

•

Clean and adjust carburetor, valve clearance, and valve seat along with

cylinder head.

1,000 Hours

(24 Months)

•

Inspect control panel parts.

•

Check rotor and stator.

•

Replace engine mount rubber.

•

Overhaul engine.

•

Change fuel lines.

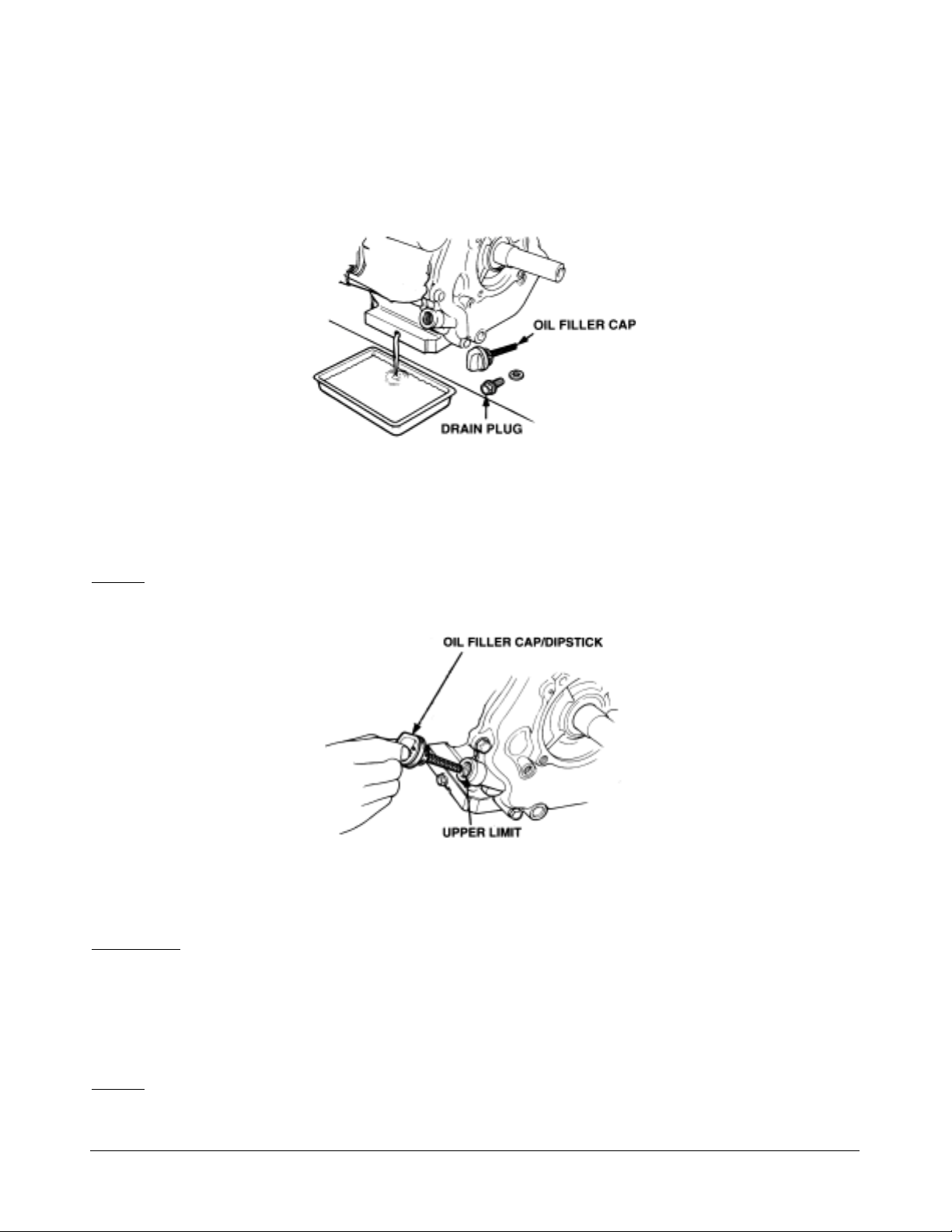

A. CHANGING ENGINE OIL

(1) Drain the oil while the engine is still warm to assure rapid and complete draining.

(2) Remove the oil filler dipstick/cap and drain plug.

(3) Allow oil to drain from the engine (Figure 16).

Figure 16: Draining Engine Oil

(4) Install the drain plug, and tighten it securely.

(5) Refill with the recommended oil (Figure 12). Check the oil level. Install the oil filler dip-

stick/cap (Figure 17).

NOTE:

• Engine oil capacity: 1.1 liters (1.16 U.S. Quart)

Figure 17: Checking Oil Level

B. AIR CLEANER SERVICE

W

ARNING:

• NEVER USE GASOLINE OR LOW FLASH POINT SOLVENTS FOR CLEANING THE AIR

CLEANER ELEMENT. A FIRE OR EXPLOSION COULD RESULT.

(1) A dirty air cleaner will restrict airflow to the carburetor. To prevent carburetor malfunction,

service the air cleaner regularly. Service more frequently when operating the engine in

extremely dusty areas.

NOTE:

• Never run the engine without the air cleaner. Rapid engine wear will result from contaminants, such

as dust and dirt, being drawn through the carburetor, into the engine.

Maintenance Page 24

Tsurumi’s Operation, Service, and Repair Manual

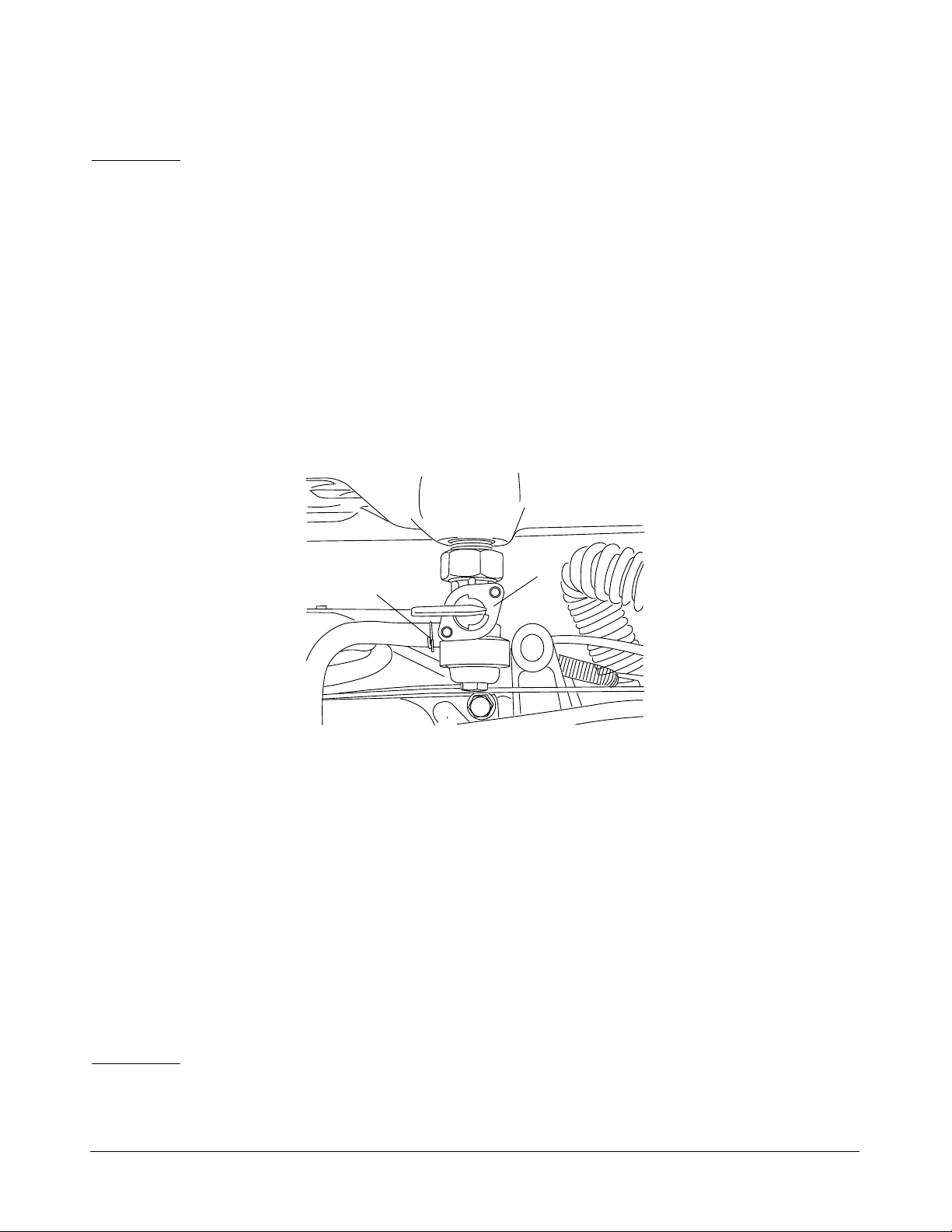

C. SEDIMENT CUP CLEANING

WARNING:

• GASOLINE IS EXTREMELY FLAMMABLE AND IS EXPLOSIVE UNDER CERTAIN CONDI-

TIONS. DO NOT SMOKE OR ALLOW FLAMES OR SPARKS IN THE AREA.

• AFTER INSTALLING THE SEDIMENT CUP, CHECK FOR LEAKS, AND MAKE SURE THE AREA

IS FREE OF RESIDUAL FUEL SPILLS OR SEEPAGE BEFORE STARTING THE ENGINE.

(1) Turn the fuel valve to OFF.

(2) Remove (turn clockwise) the sediment cup and O-ring. Wash both parts in nonflammable

or high flash point solvent.

(3) Wipe the sediment cup and O-ring dry, then reinstall.

(4) Set the fuel shutoff valve (Figure 18) to ON. Check for leaks.

Figure 18: Fuel Shutoff Valve

D. CLEANING AND ADJUSTING SPARK PLUG

Recommended spark plugs: BPR6ES (NGK)

W20EPR-U (NIPPONDENSO)

To ensure proper engine operation, the spark plug must be properly gapped and free of deposits.

(1) Remove the spark plug cap.

(2) Clean any dirt from around the spark plug base.

(3) Use the proper size spark plug wrench to remove the spark plug.

W

ARNING:

• THE MUFFLER BECOMES VERY HOT DURING OPERATION AND REMAINS HOT FOR A

WHILE AFTER STOPPING THE ENGINE. BE CAREFUL NOT TO TOUCH THE MUFFLER

WHILE IT IS HOT.

Page 25 Maintenance

Tsurumi’s Operation, Service, and Repair Manual

H-2

H-13

Loading...

Loading...