Honda Power Equipment MM60 User Manual

INTRODUCTION

TO

THE

OWNER

Read this manual before operating your mower. The information presented

and safer job, Keep this manual handy for ready reference.

The mower you .have purchased has been carefully engineered and manufactured

-

and satisfactory use, Like all mechanical products, it

will

require cleaning and upkeep. Lubricate the

mower as specified. Observe all safety information in this manual and safety decals on the mower and

tractor.

For

service, your authorized dealer has trained mechanics, genuine service parts, and the necessary tools

and equipment to handle all your needs.

will

prepare you to do a better

to

provide dependable

Use only genuine service

parts.

Substitute parts may not meet standards required for safe and satisfactory

operation.

Model

"60 Rotary Mower

Record the serial number of your mower:

Serial Number (see Safety Decal page for location)

Provide this information to your dealer

Throughout this manual, the term NOTICE

to

obtain correct repair parts.

is

used to indicate that failure to observe this instruction can

cause damage to equipment. The terms CAUTION, WARNING and DANGER are used in conjunction with

the Safety

-

Alert Symbol, (a triangle with an exclamation mark), to indicate the degree of hazard for items of

personal safety.

The Safety

YOUR

-

Alert Symbol means ATTENTION! BECOME ALERT!

SAFETY

IS

INVOLVED!

Denotes a reminder of safety practices or directs attention to unsafe practices

which could result

!

1-

Denotes a hazard exists which can result

in

personal injury if proper precautions are not taken.

are not taken.

#.

Denotes an extreme intrinsic hazard exists which would result

of death or irreparable injury

in

injury or death if proper precautions

if

proper precautions are not taken.

in

high probability

1

INTRODUCTION

I

GENERAL

The purpose of this manual is to assist the opera

tor in maintaining and operating this mower. Read

it carefully. It furnishes information and instructions

that will help you achieve years

performance. These operating and maintenance

instructions have been compiled from extensive

field experience and engineering data. Some

information may be general in nature due to

unknown and varying conditions. However, you

should be able to develop operating procedures

suitable to your particular situation.

The illustrations and data used in this manual were

current at the time of printing, but due to possible

in

-

line production changes, your machine may

vary slightly in detail. We reserve the right

redesign and change the machine as may be

necessary without notification.

1-

show the mower with safety shields removed

to provide a better view. The mower should

never be operated with any safety shielding

removed.

INFORMATlON

of

dependable

to

Some illustrations in this manual

-

,

Throughout this manual, references are made

right and left directions. These are determined by

standing behind the equipment and facing the

direction of forward travel. Blade rotation

wise as viewed from the top of the mower.

is

to

clock

-

CONTENTS

INTRODUCTION

TO THE OWNER

GENERAL INFORMATION

SAFETY INFORMATION

SAFETY RULES

SET-UP AND ASSEMBLY

DEALER SET-UP INSTRUCTIONS

UNPACKING AND CHECKING PARTS

MOUNTING MOWER LIFT SYSTEM

ASSEMBLING MOWER

INSTALLING MOWER

INSTALLING MOWER TO TRACTOR

DETACHING MOWER FROM TRACTOR

OPERATION

ADJUSTING CUlllNG HEIGHT

PRE-OPERATION CHECK LIST

OPERATING TECHNIQUE

CUlllNG PATTERNS

OPERATING YOUR MOWER WITH OTHER EQUIPMENT

...........................................................................................................................

............................................................................................................

.............................................................................................................................

.............................................................................................

........................................................................................

..........................................................................................

..............................................................................................................

.........................................................................................

...................................................................................

.................................................................................................

.................................................................................................

..........................................................................................................

.................................................................................................................

........................................................

1

1

2

4

4

8

-8

8

11

17

18

21

25

28

29

30

31

32

33

MAINTENANCE

OWNER SERVICE

LUBRICATION INFORMAllON

BLADE INSPECTION

BLADE SERVlClNG

REPLACING BELTS

DEALER LEVEL MAINTENANCE

SPINDLE REPAIR

UNIVERSAL JOINT REPAIR

GEARBOX MAINTENANCE

STORAGE

TROUBLESHOOTING

SPECIFICATIONS

WARRANTY SERVICE

.......................................................................................................................

.....................................................................................................................

....................................................................................................................

.......................................................................................................................

36

36

.................................................................

..................................................................................................................

...................................................................................

.......................................................................................................

........................................................................................................

.............:.....

...............

.............

37

38

39

41

42

43

47

49

52

53

55

56

3

SAFETY INFORMATION

Safety

manufacture of our products. Unfortunately,

our efforts to provide safe equipment

wiped out by a single careless act of an

operator.

In addition to the design

equipment, hazard

prevention are dependent upon the aware

ness, concern, prudence and proper training

of personnel involved in the operation, trans

port, maintenance and storage of equipment.

It has been said, "The best safety device is

an informed, careful operator.

be that kind of an operator.

is

a primary concern in the design and

can

and configuration of

control and accident

"

We ask you to

be

-

-

SAFETY RULES

ATTENTION! BECOME ALERT!

IS

YOUR SAFETY

The designed and tested safety of this equipment

depends on it being operated within the limitations

explained in this manual.

INVOLVED!

Training

Safety instructions are important! Read this

manual, the tractor manual and

Know your controls and how to stop tractor

engine and mower quickly in an emergency.

Operators .must be instructed in and be ca

pable of the safe operation

attachments and all controls.

anyone

proper instructions,

Keep hands and body away from pressurized

lines. Use paper

to check for leaks. Hydraulic fluid (oil) under

pressure will penetrate skin causing serious

injury.

Make sure that all operating and service per

sonnel know that in the event hydraulic fluid

penetrates skin, it must be surgically removed

within a few hours by a doctor familiar with this

form of injury,

Do

operate equipment.

not

to

operate this equipment without

or

cardboard, not body parts

or

gangrene may result.

allow

children

or

unqualified persons

all

safety rules.

of

the equipment, its

Do

not allow

-

-

to

4

SAFETY

INFORMATION

Preparation

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough

equipment

Ensure that mower is properly mounted, ad

justed and in good, operating Condition.

Make sure mower driveline spring-activated

locking collar slides freely and the balls are

seated in mid

Remove accumulated debris from mower to

avoid

fire

Ensure all safety decals are installed and in

good condition. (See Safety Decals section for

location drawing.)

:

Ensure shields and guards are properly in

stalled and in good condition.

A

minimum

weight must be on tractor front wheels with

mower in transport position. Without this

weight, tractor could tip over causing personal

injury

or

front wheel weights,

tractor weights. When attaining the minimum

20%

weight on the front wheels, you must not

exceed the

(ROPS)

and equipment.

Inspect area to be cut and remove stones,

branches

thrown, causing injury

-

soled work shoes and protective

for,eyes, hands, hearing and head.

-

PTO shaft groove.

hazard.

20%

of tractor and equipment

death. The weight may be attained with

ballast.in tires

Roll

Over Protection Structure

weight certification. Weigh the tractor

Do

not estimate.

or

other hard objects that might be

or

damage.

or

front

Operational Safety

You may not be able to stop the tractor safely

the clutch or brake pedal mechanisms are

improperly adjusted, allowing them to contact

mower components.

-

-

When the mower

instructed in this manual, .properly adjusted

clutch and brake pedal mechanisms

contact mower components. You should

frequently check that the tractor clutch and

brake pedal mechanisms are in adjustment.

If

the clutch

contact mower components, do not operate

until properly adjusted.

Do

not operate mower unless discharge chute

is

installed.

Keep bystanders away from equipment while it

is

in operation.

Never direct discharge toward anyone.

Operate only in daylight or good artificial light.

Keep hands and feet away from mower while

tractor engine is running.

Stay clear of all moving parts.

If

your tractor is equipped with a

must wear your seat belt.

No

riders are allowed on tractor

Start engine from operator's seat after disen

gaging tractor PTO and placing transmission in

neutral.

Always sit in tractor seat when starting the

engine or operating controls.

Disengage power-take-off , shift tractor into

neutral, and place all controls in neutral before

starting tractor engine.

Operate tractor mid-PTO at no more than

RPM

(maximum governed engine

Make sure area behind'you

operating in reverse.

Do

not operate on steep slopes.

Do

not stop, start or change directions sud

denly on slopes.

Use extreme care and reduce ground speed

on slopes and rough terrain.

Watch for hidden hazards on the terrain during

operation.

lift

stops are installed as

will

or

brake pedal mechanisms can

ROPS,

or

mower.

RPM).

is

clear before

if

not

you

-

2400

-

5

SAFETY INFORMATION

1

Stop mower and tractor immediately upon

off

striking an obstruction. Turn

key, inspect and repair any damage before

resuming operation.

Before working underneath, raise mower, install

transport lock and block mower securely.

Hydraulic system leak down and failure of

mechanical or hydraulic system can cause

equipment to drop.

Disengage power to mower, lower mower to

ground, stop engine, set parking brake

remove key before dismounting tractor.

Maintenance Safety

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough

equipment for eyes, hands, hearing and head.

Lower mower to ground or block securely, turn

tractor engine

mower

performing any service or maintenance.

Never perform service or maintenance with

tractor engine running.

Before working underneath, raise mower, install

transport lock and block mower securely.

Hydraulic system leak down and failure of

mechanical or hydraulic system can cause

equipment to drop.

Keep

area while performing adjustments, service

maintenance.

Frequently check blades. They should be

sharp, free of nicks and cracks and securely

fastened.

Use a new Nylok blade bolt when you replace

the blade. Do not substitute any bolt for the

special blade bolt. It is self

non

tion.

Your dealer

blades. Substitute blades may not meet original

equipment specifications and may

ous.

Tighten all bolts, nuts and screws, and check

that all cotter pins are installed securely

ensure mower is in a safe condition before

operating.

U-joint driveline from tractor

all

-

loosening requirements for this applica

-

soled work shoes and protective

off

,

remove key and disconnect

persons away from operator control

can

supply genuine replacement

engine, remove

and

PTO

before

-

locking, meeting the

be

danger

to

or

-

Ensure all safety decals are installed and in

..good condition. (See Safety Decals section for

location drawing.)

Ensure shields and guards are properly in

stalled and in good condition.

-

Storage

Block mower securely for storage.

-

6

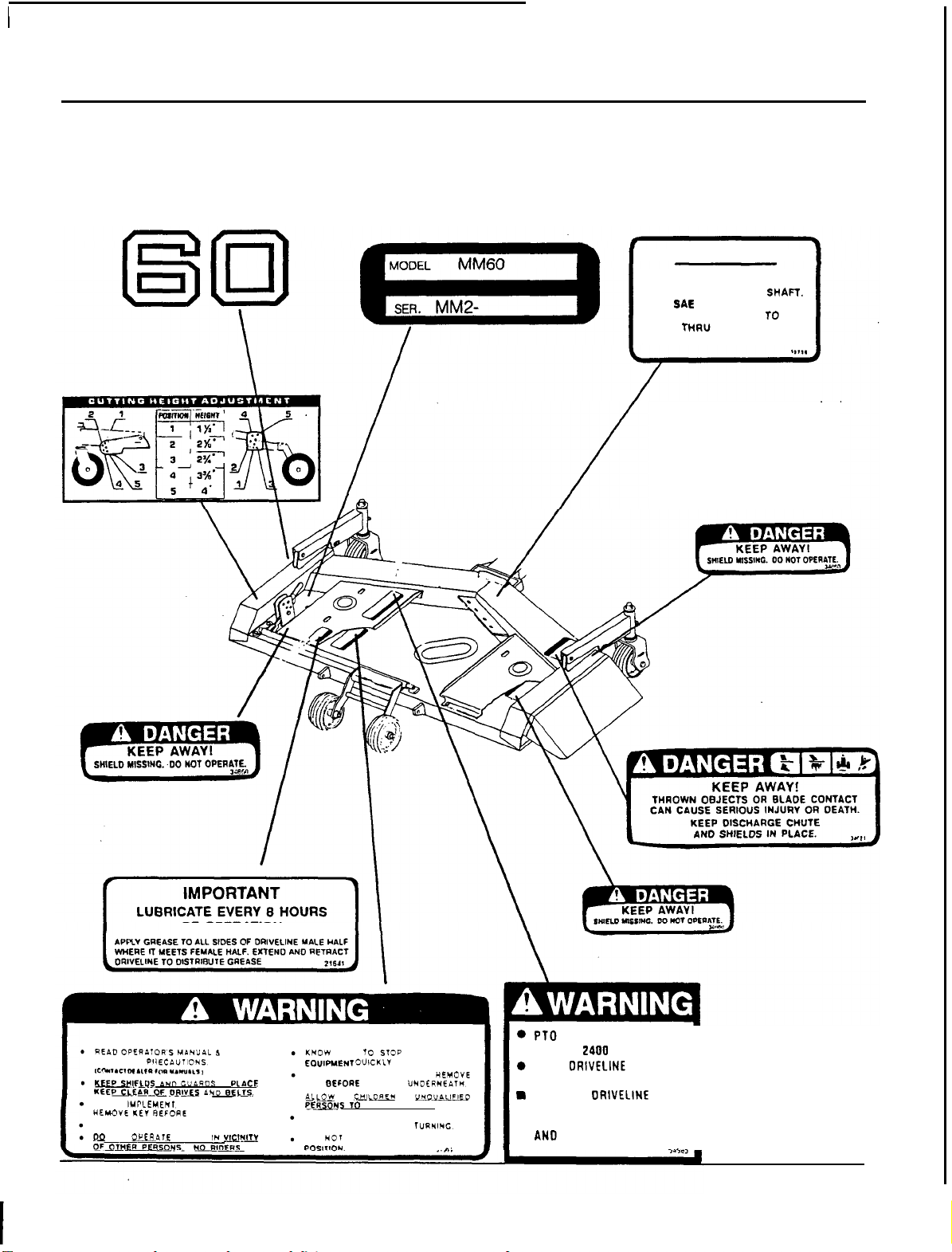

SAFETY INFORMATION

Safety

Decals

Replace immediately

if

damaged.

IMPORTANT

FILL GEAR BOX

LINE

OF

HORIZONTAL SHAFT.

USE SA€

ALLOW

FLOW

THEN RECHECK.

90

TIME

THRU

GEAR LUBE.

FOR

BEARINGS.

TO

OIL

CENTER

TO

..

OF

OPERATION

TO

AVOID

READOPERATORSMANUALS FOLLOW KHOW

ALL SAFETY PI4ECAUTIONS.

ICII.CI

w.LtPr(rn*.IY.,,I

W.ELW!FLQS

UEEP_UELR-W.D_RIVU AH0 9CLIS:

LOWER

I(LM0VE UEV

CLEAR MOWING AREA

Pa

NOT

AND GUARDS

IUPLEMENL

REFORE

OPERaTE

MOWER

SERIOUS

m

STOP ENGINE AND

DISMOUNTING.

OF

DEBRIS. DECREASE SPEED WNEN WRNING.

IN

VICW~

INJURY

EOUIPMENT

PLACE KEY

BLOCK UP

ALLOW

CEiNZ

BE

DO

OR

DEATH!

now

TO

STOP

TRACTOR

OUICKLV IN AH EMERGENCY.

IMPLEMENT

DEFORE

WORKING UHOERNEATN.

NO WLDREN

10

CAREFUL ON UNEVEN TERRAIN.

NOT OPERATE IN TRANSPORT

RUN

OH

EOUIPMENT.

AND

AND HEMOVE

UNOUALIFIED

...

".

PTO

SPEEO

EXCEED

LOCK

DRIVRINE ON

TRACTOR PTO.

.i

A

LOOSE

HIGHER

CAUSE PERSONAL INJURV

AN0 EQUIPMENT FAILURE.

MUST

2400

RPM.

DRlVELlNE

PTO RPM CAN

N

O

T

OR

A

I

7

c

SET-UP

DEALER SET-UP INSTRUCTIONS

Assembly of this mower

dealer. The mower should be delivered to the

owner completely assembled, lubricated and

adjusted for normal mowing conditions.

Using these instructions, set mower up as re

ceived from the factory. Complete Check Lists

Page

You may install the

sub frame installed. The front loader must be

removed from the sub frame.

BH6575

frame must be removed. The adjustment of the

rod is different from the standard installation.

These differences are explained in the appropriate

sections. Follow these procedures to avoid

damage to deck and linkage.

The mower is shipped partially assembled.

Assembly will

and loosely assembled before tightening hard

ware. Recommended torque values for hardware,

are included in the assembly instructions.

AND

10

when set-up is complete.

Back Hoe, both the back hoe and its sub

ASSEMBLY

is

the responsibility of the

"60 mower with the FL6555

If

you also have

be

easier

if

cqmponents are aligned

-

on

a

lift

-

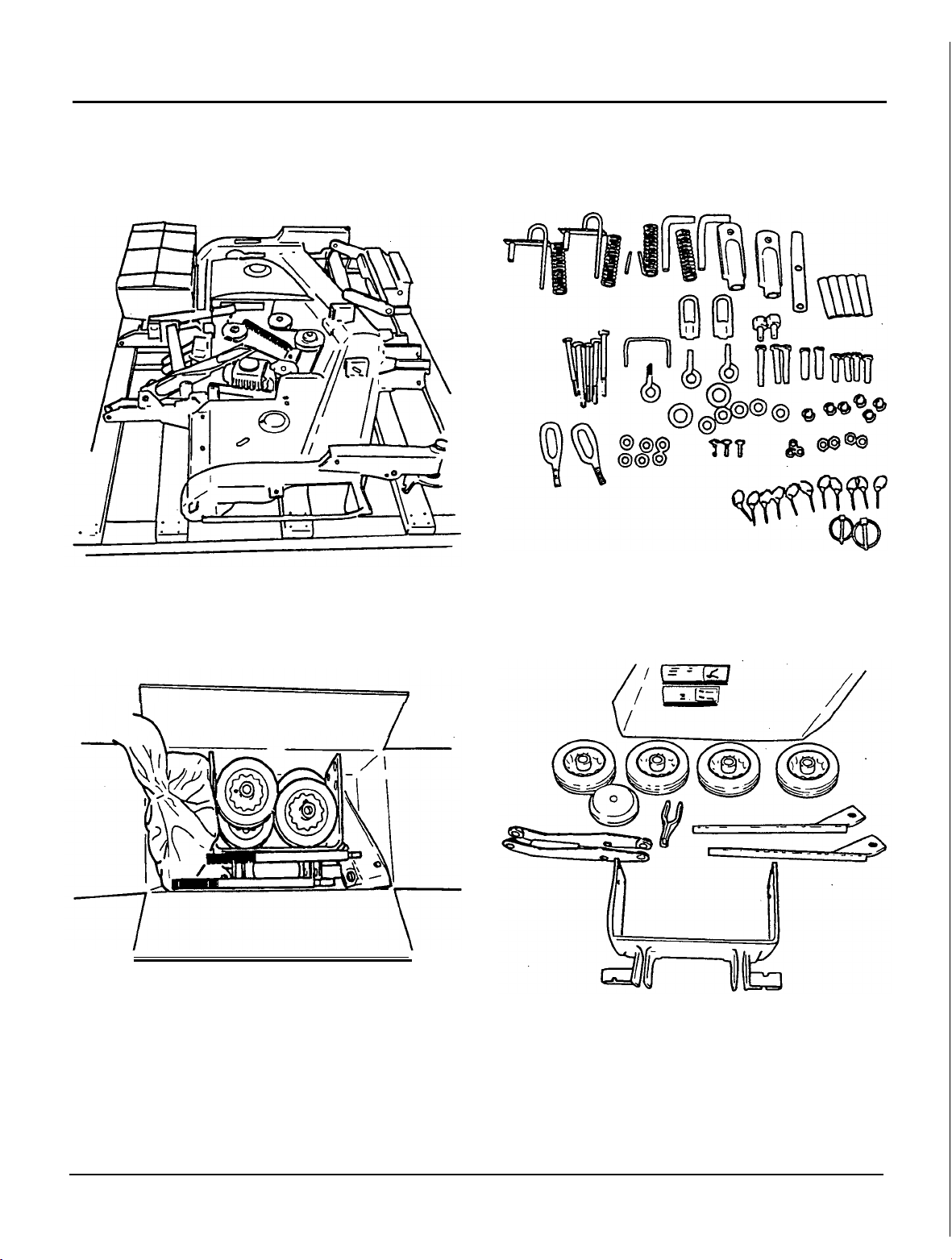

UNPACKING ANDCHECKING PARTS

The mower assembly kit contains the following

parts:

Mower deck with rear linkage installed

Lift plate assembly

.

Box containing

Unbolt the mower deck, and the lift plate

and cut the packing straps holding

linkage and mower driie shaft. Packing list is

contained in both the crate holding the mower,

and in the parts box in the crate. Before assem

bling check for missing

lift

linkage and hardware

down

or

damaged parts.

assembl!

the rear

-

Select a suitable working area. Open parts boxes

and lay

easy. Refer to illustrations, accompanying text,

parts lists and exploded view drawings.

For

lubricate bearing area with a lithium based grease

of

disulfide) additive before installing. The manual

will also indicate when grease is necessary.

belted clothing to avoid entanglement

moving parts. Wear sturdy, rough-soled

work shoes and protective equipment for

eyes, hands, hearing and head.

out

parts and hardware to make location

all pins, shafts and other bearing surfaces,

#2

consistency with a MOLY (molybdenum

.

Always wear relatively tight and

in

Before working underneath, raise mower,

install transport lock and block mower

securely. Hydraulic system leak down and

failure of mechanical or hydraulic system

can cause equipment to drop.

Keep all persons away from operator

control area while performing adjust

ments, service or maintenance.

-

--

.

8

SET-UP

AND

ASSEMBLY

Mower Assembly.

Parts Box

Kit

in

Crate

/

Parts

Parts

in

Burlap Bag

in

Parts

Box

9

SET-UP AND ASSEMBLY

Pre-Delivery Check List

(Dealer Responsibility)

1.

Inspect the mower thoroughly after assembly to

ensure

it

is

set up properly before delivering it to

the customer. The following check lists are a

reminder of points to inspect. Check

item as it

is

found satisfactory

or

off

each

after proper

adjustment is made.

2.

Check

all

bolts to be sure they are correctly

torqued.

3,

Check that all linchpins

4.

Lubricate all grease fittings; check to make sure

a

small amount of grease comes out of seal.

5.

Check that gearbox is serviced and that vent

..

are properly installed.

plug is properly installed and seals are not leak

ing.

6.

Check that blades have been properly installed.

Delivery Check List

(Dealer Responsibility)

1.

Check mower attitude and belt alignment.

2.

Check that mower lift is properly adjusted. (See

Assembly instructions.)

3.

Show customer how to make adjustments.

4.

Explain importance of lubrication to customer

and point out lubrication points on mower.

5.

Point out safety features, shielding and options.

6.

Present the Operator's Manual, and ask cus

-

tomer to become familiar with all sections.

7.

Explain to customer that when mower

-

ported on a road

or

highway, safety devices

is

trans

-

should be used for adequate warning to

operators of other vehicles.

SET-UP

AND

ASSEMBLY

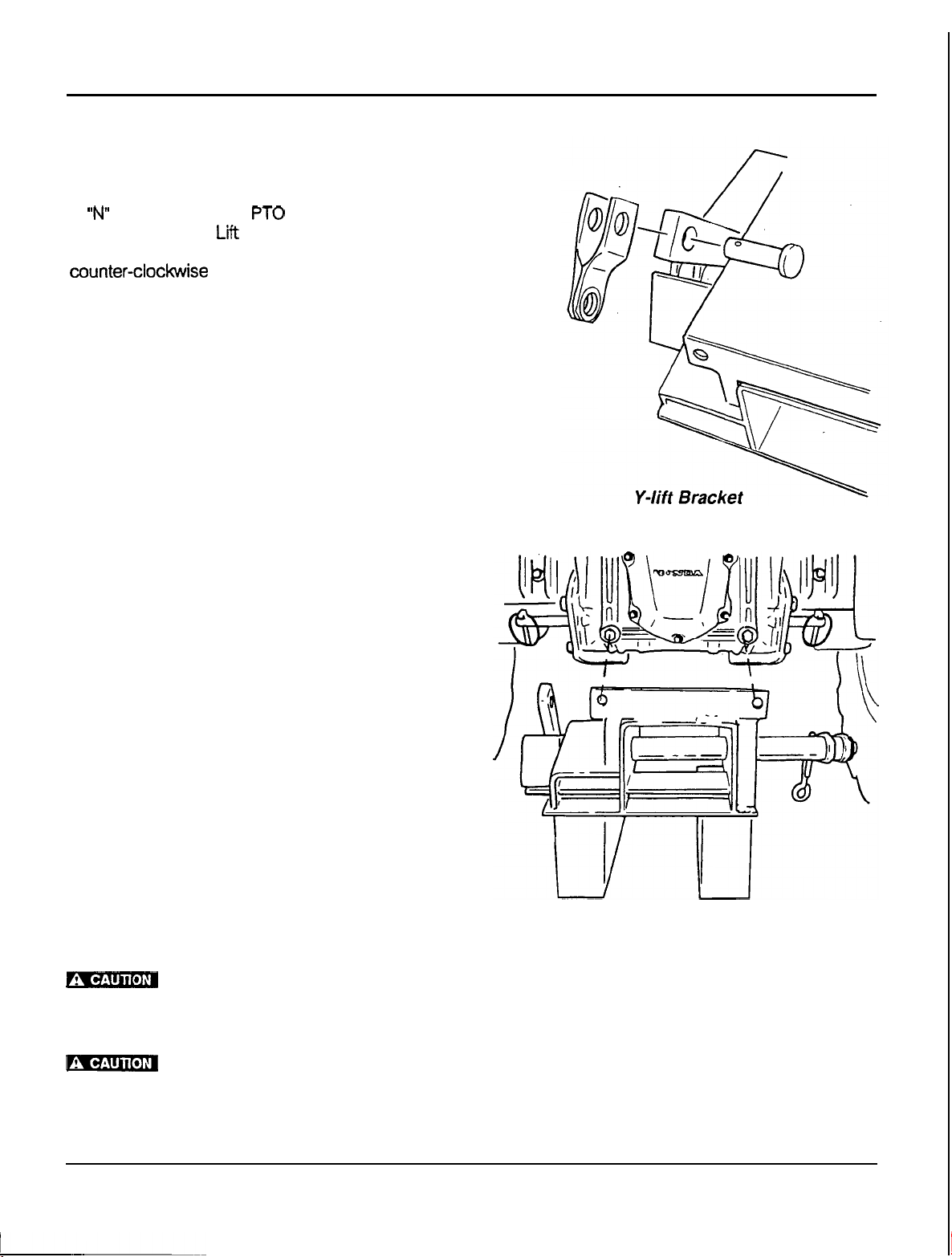

MOUNTING MOWER

Install with the tractor on level ground.

Lock the parking brake, set the transmission lever

in

"N"

(Neutral) and the

"

OFF

"

position. Set

and turn Lowering Speed Control knob fully

counter-clockwise

the rear

bly easier.

Installing Mower Lift Plate to Tractor

1.

2.

lift

arms down by hand and makes assem

Remove drawbar assembly; this is bolted onto

the transmission housing below the Rear PTO.

Retain bolts, nuts and spacers for installation of

lift

plate assembly. Remove any dirt and debris

from bottom of transmission housing and make

sure bolt holes and screw threads are clean.

Assemble

Raised flange on

of tractor. Insert

faces front of tractor.

Y-lift

("FAST").

bracket to

Y-lift

LIFT

SYSTEM

Pi0

clutch lever in the

Lift

Control lever to

This allows you to pull

lift

plate assembly.

lift

plate assembly will face rear

bracket

so

"

DOWN

that fork

"

of

Y

-

3.

Attach mower

passing the

transmission housing through the holes in the

plate flange. Slide on 2 spacers previously

removed and hand tighten both

locknuts.

4.

Reach beneath the mower

and carefully insert the four

bolts through holes in

into threaded holes on bottom of transmission

housing. Housing

bolts by hand to guard against cross threading.

Tighten to

5.

Finish by tightening

on projecting studs to

your hands when installing lift link kit and

mower deck.

and hands,

lift

arms when operating.

lift

plate assembly to tractor,

two

projecting stud bolts on the

26

mm flange

lift

plate assembly

12

mm

x

32

mm

lift

plate assembly and

is

made of aluminum,

7

kg-m

(50

ft-lb).

two

26

mm flange locknuts

7

kg-m

(50

ft-lb).

Wear heavy gloves to protect

Lifting system can crush fingers

so

keep them clear of links and

so

lift

start

Mower

Lift

Plate

11

SET-UP

Lift Unk

\

AND

ASSEMBLY

Lower Link Shaft

Y

-

bracket

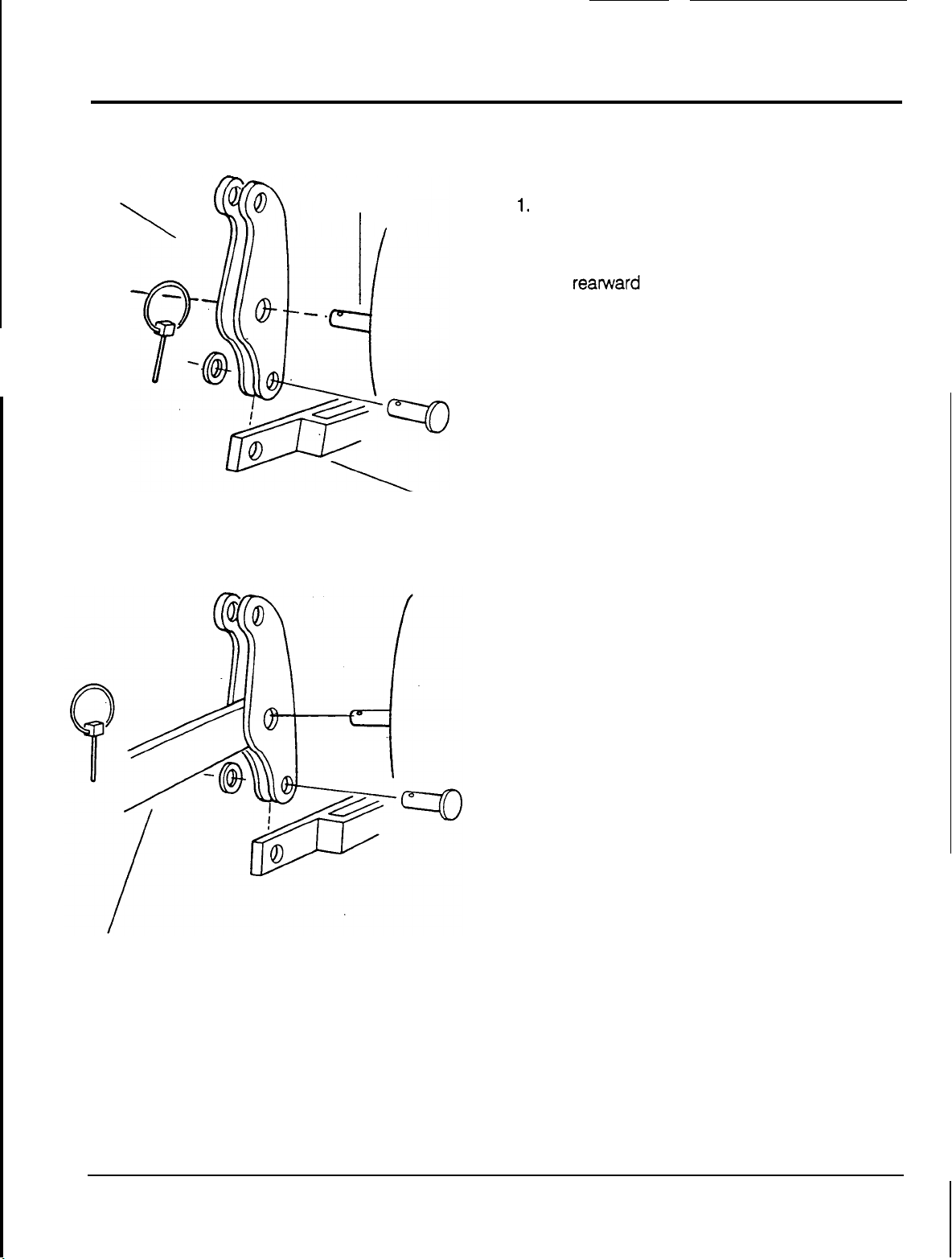

Attaching Lift Link to Lift Plate Assembly

(For Tractors Without Rear Three Point Hitch)

1.

Slide middle hole in

hand lower link shaft which comes installed on

the tractor. Install

the end with

face

reaward

grease to shaft. Secure with linchpin.

2.

Use a block of wood to raise left arm of lift plate

assembly about

ing the Y-bracket and the bottom hole of the

link easier. Line up hole in Y-bracket with lower

hole in

align. Insert greased

and secure with cotter pin, passing pin from

top to bottom. Head on clevis pin faces in.

Attaching Lift Link to Lift Plate Assembly

(For Tractors With Rear Three Point Hitch)

1.

Remove left hand three point hitch lower link

from lower link shaft.

two

lift

link moving arm and

lift

link onto greased left

lift

link

so

that it

is

vertical and

holes is down. Lift link should

as

illustrated. Be sure to apply

150

mm

(6

in) to make attach

lift

link until they

22

mm

x

76

mm clevis pin

-

lift

Lower Link

2.

Mount

shaft by lining up middle hole in

in lower link. Pass greased lower link shaft

through both as illustrated. Secure with linchpin,

passing pin from top to bottom.

3.

Support

wood as described above. Move lift link and

bracket

Y

Insert greased

head facing in and secure with cotter pin,

passing pin from top to bottom.

lift

link and-lower link back on lower link

lift

plate assembly arms on block of

on

lower lift plate assembly until hole in

-

bracket and bottom hole in

22

mm

x

57

lift

link and hole

lift

link line up.

mm clevis pin with

Y

-

12

SET-UP

AND

ASSEMBLY

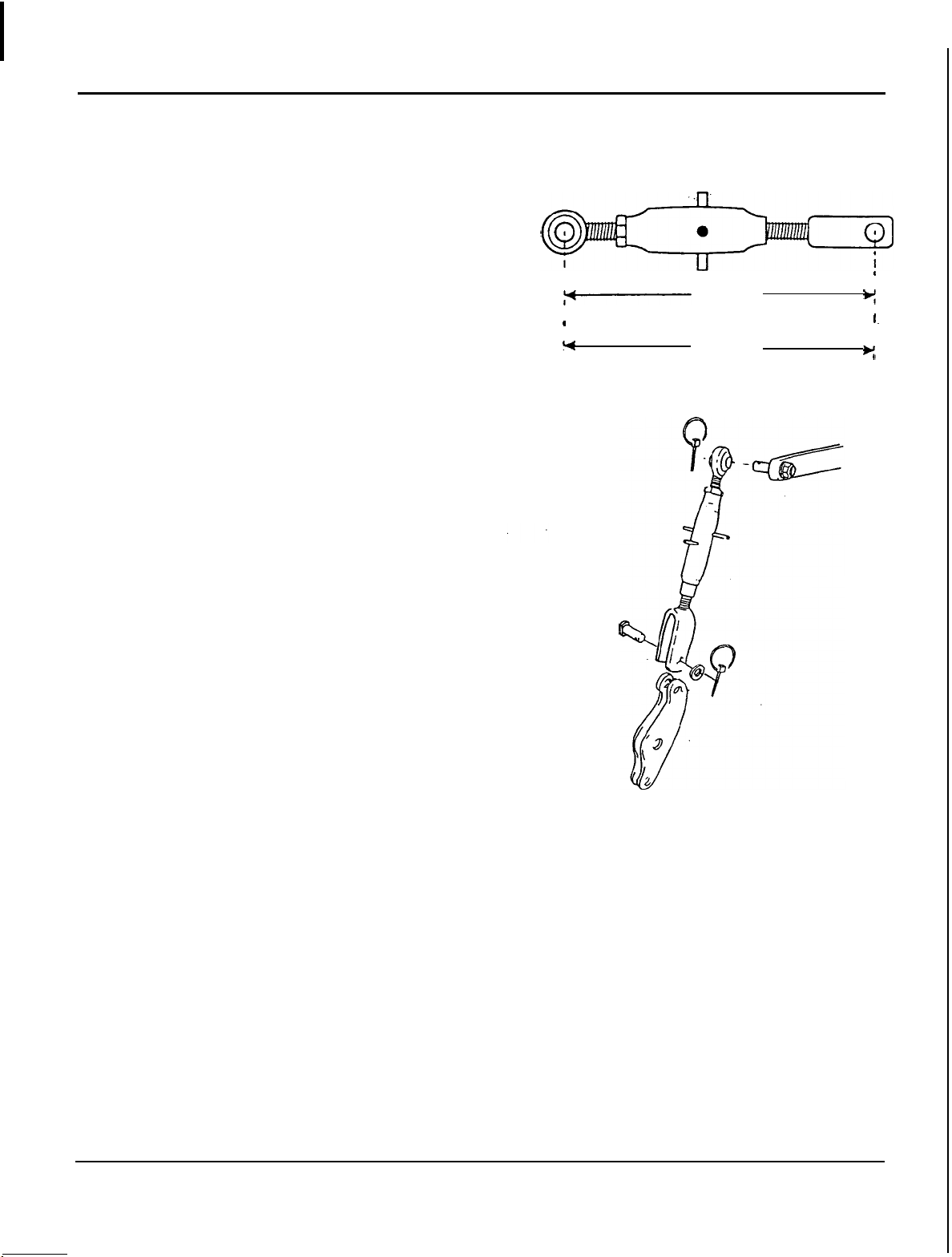

Installing

(For

1.

Adjust the

from

made by turning barrel

Lift

Rods

Tractors Without Rear Three Point Hitch)

lift

rod to 365 mm

(1

4.4

in) measured

eye to eye as illustrated. Adjustment is

of

rod, then secured by

tightening nut. Be sure that an equal length

threads shows on either end

2.

Slide eye

Position clevis

of

lift

rod over pin on tractor lift arm.

of

lift

rod between brackets on

link. Note that outside leg

side

of

lift link as illustrated. Install with greased

22

x

76

mm clevis pin with head on left side as

shown. Secure both ends with

of

,of

lift

22

barrel.

rod goes out

rnrn

and linchpins.

of

-

washers

lift

I

I

I'c--------

I

I

I

Y

(with loader subframe)

365 mm

14.4

in.

375

mm

14.8

in.

y

y

I

I

I.

I

NOTE: The eye

of

the lift rod is not straight. The

curve should point to the inside

when properly installed.

of

the tractor

i3

SET-UP

AND

ASSEMBLY

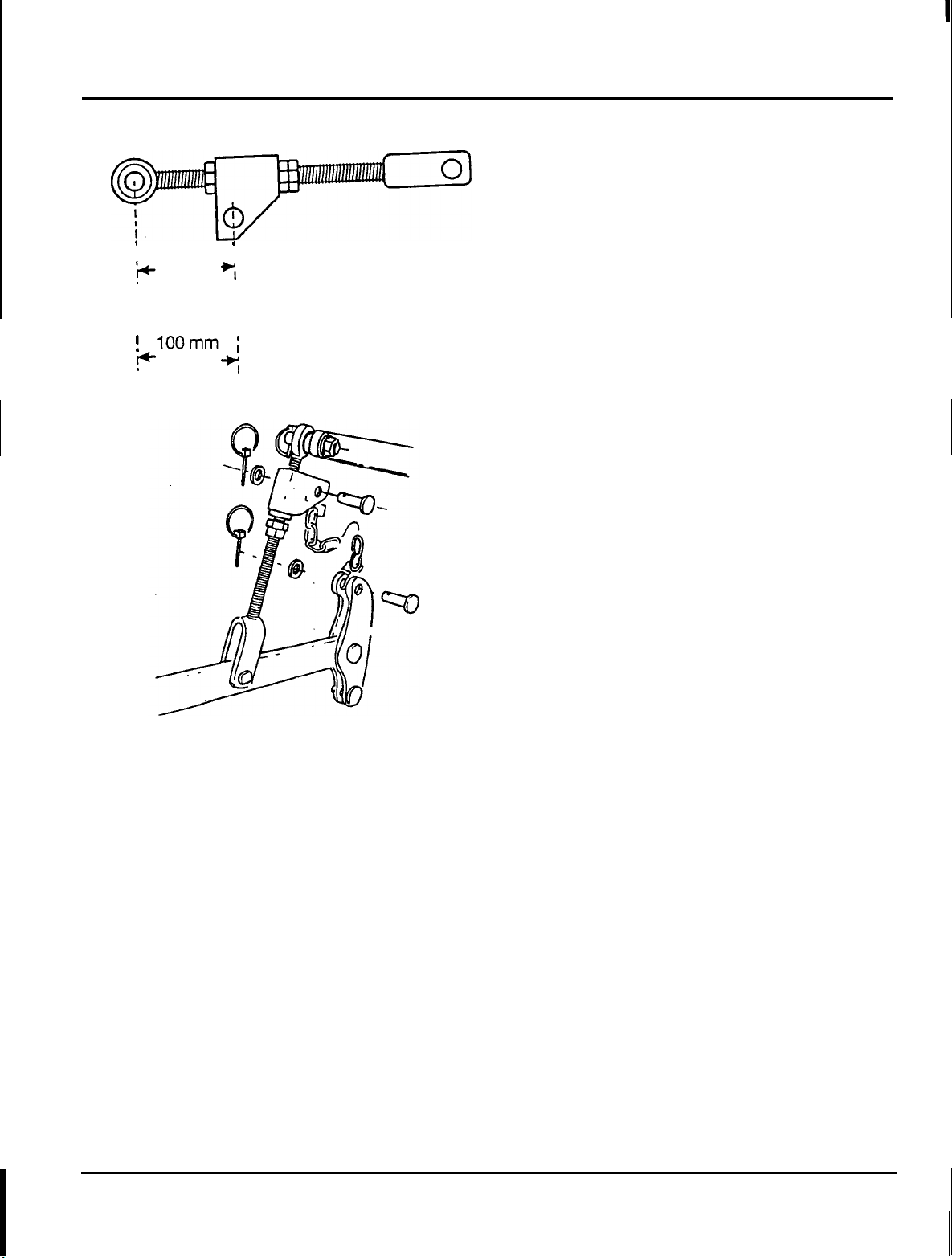

I

I

‘y

85

3.4

(with loader subframe)

100mm

4.0

mm

in.

in.

I

I

7

;

-y

Installing Lift

(For Tractors With a Rear Three Point Hitch)

1.

Replace the existing left hitch rod with the unit

provided with the mower.

2.

Loosen the locknut and the adjusting nuts and

turn them to position the bracket hole

(3.4

in) from the

measurement). The bracket must face forward.

3.

Tighten the adjusting nuts and secure with the

locknut.

4.

Couple

16

mm lift pin. Head of pin faces inward. Secure

with washer and cotter pin. Attach upper end

lift

link chain to bracket on

16

mm

with washer and linchpin.

Rods

on Lower Link Lift

85

mm

lift

rod eye (center-to-center

lift

link chain and

lift

pin. Head of pin faces inward. Secure

lift

link with greased

lift

rod, with greased

of

14

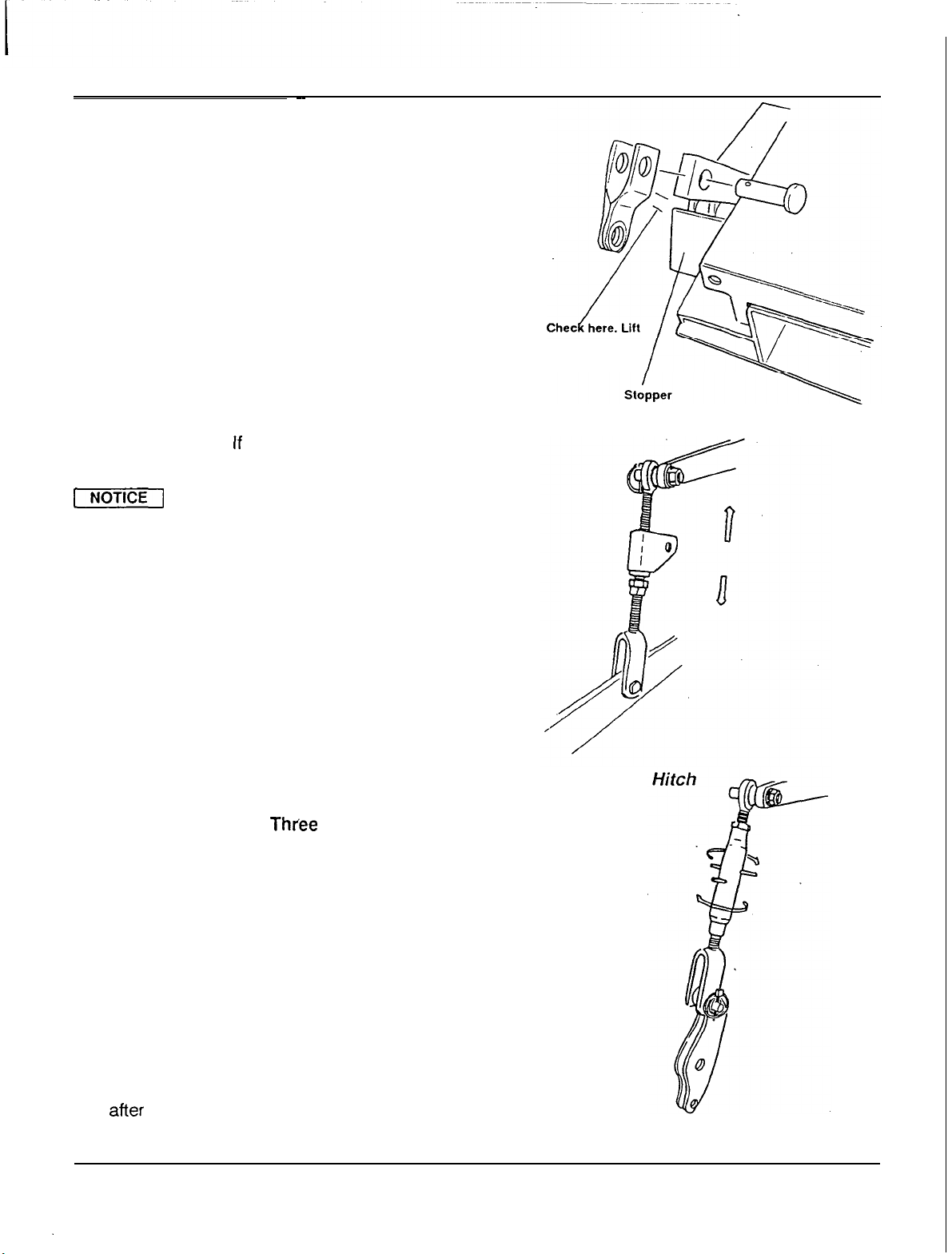

Adjusting Lift Rod

(For Tractors With and Without Rear Three

Point Hitch)

SET-UP

AND

ASSEMBLY

Follow this procedure

if

you do not have a loader

subframe installed.

Adjust the lift rod clearance by starting the engine,

and shifting the Lift Control lever

sure hands are clear of

lift

to

"UP"

.

Make

arms before starting.

Engine will not start unless operator is seated.

Raise until

encountered.

Turn Lowering Speed control fully clockwise

arms up. Turn engine

check them for slack. They should be able

slightly on their pins.

lift

arm reaches top or until resistance is

If

resistance

is

encountered, stop.

off.

Grasp

If

there is no-slack in the

lift

rods and

to

to

slide

lift

lock

rods, increase clearance as illustrated.

Lifting system can be seriously

damaged if arm presses against stop.

Adjusting Lift

Rod

(Tractors With Rear Three Point Hitch)

on

To increase clearance turn bottom nut

counterclockwise

then snug

top

to

loosen, slide down flange and

nut.

To

decrease clearance, slide

adjuster

adjuster up as shown.

arm

should

not

contact stopper

Adjusting Lift

Rod

(Tractors Without Rear Thtee Point Hitch)

Turn the barrel of the

to

shorten or lengthen the rod. Move adjuster as

required. The projecting pins must point side

side (transversely) when you are finished.

don't, turn the barrel in the direction

lift

rod by the projecting pins

If

to

increase

to

they

clearance until they do.

Restart engine, move Lift Selector lever

When

lift

arms reach top position, stop engine,

apply brakes and re

and fingers clear of

-

check clearance. Keep hands

lift

system when operating to

to

"

UP.

avoid injury. There should be slack in the linkage.

there is

nuts after adjusting both types

not,

readjust as necessary. Tighten lock

of

lift

rods.

-

With

Three

If

Point

Without Three Point Hitch

15

SET-UP

AND

ASSEMBLY

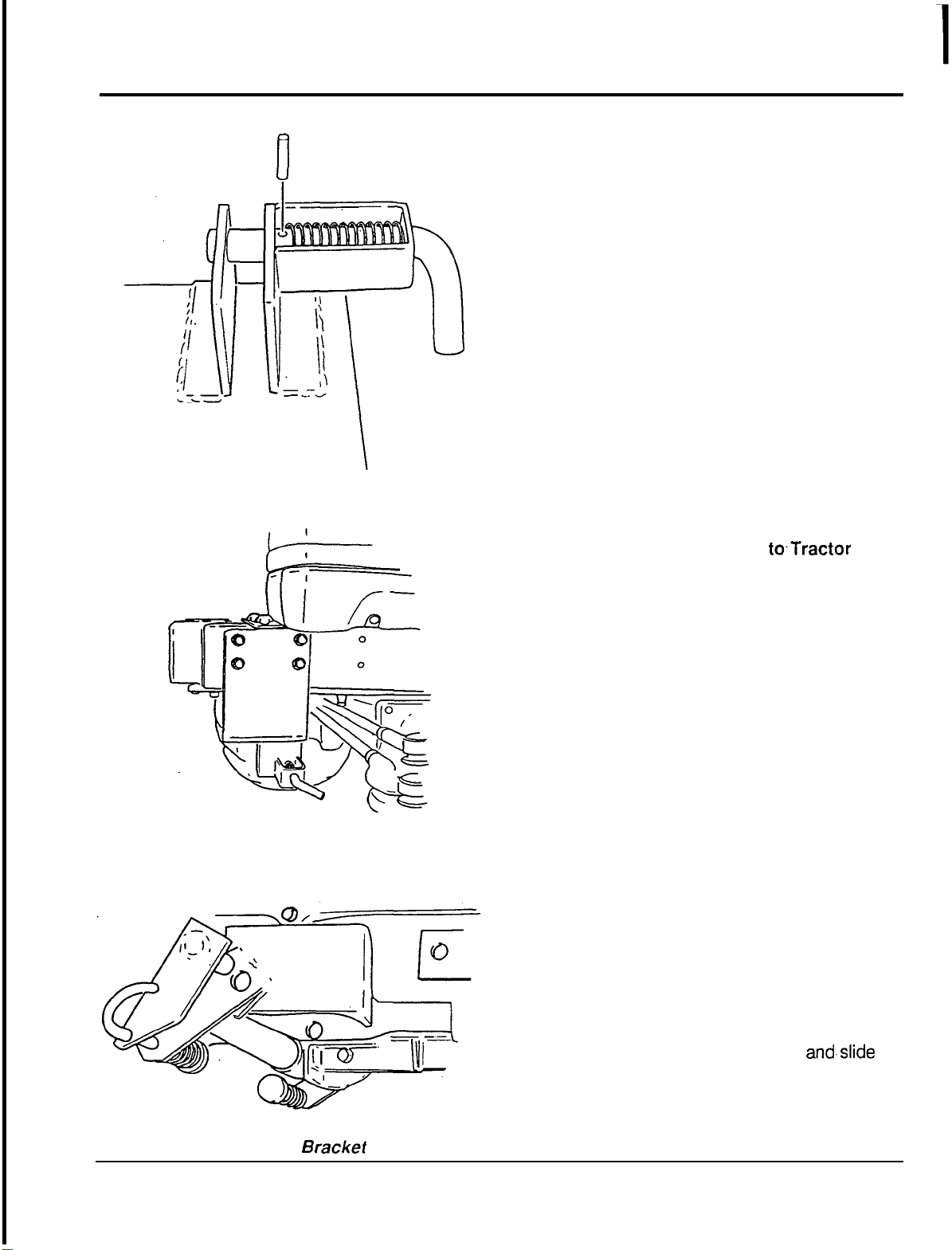

Subassembling Front Link Brackets

Assemble by compressing the front spring and

it

inserting

front quick release pin through hole in the front

bracket and spring. Pull back spring slightly to

uncover hole in quick release pin. Use hammer

tap in spring pin until

sides of quick release pin.

in the front bracket slot. Pass greased

it

is equidistant from both

to

Front Link Bracket

NOTE: Hold back bottom of spring

clears it.

Assemble both right and left brackets.

Mounting Front Link Bracket to.Tractor

1.

From bottom, slip the assembled front mount

ing bracket

2.

Insert 8 flange bolts

6

kg-m

to

NOTE:

face rearward and downward when front link

bracket

up

onto the front frame rails.

12

mm

(43

ft-lb).

With

pins correctly installed, they

is

installed on the tractor.

so

that pin

x

30

mm. Tighten all

-

will

16

Front

Rear

Link Bracket

Link Brackef

Assembling Rear Link Bracket

Insert the greased rear quick release pin in the

mounting bracket attached to the tractor frame. It

is

located beneath the tractor along the mid-line

as illustrated. Pass the long arm

release pin through the lower hole in the bracket

and the spring. Compress the spring

washer over hole in arm. Secure with split pin,

spreading legs

and left brackets.

of

split pin. Assemble both right

of

the quick

and.slide

Loading...

Loading...