Owner's Manual

Includes Remote Control

Supplement

Outboard Motor

BF9.9A/15A

©1999 Honda Motor Co., Ltd.—All Rights Reserved

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

Keep this owner’s manual handy, so you can refer to it at any time.

I

This owner’s manual is considered a permanent part of the outboard motor

and should remain with the outboard motor if resold.

The information and specifications included in this publication were in effect

at the time of approval for printing. Honda Motor Co., Ltd. reserves the right,

however, to discontinue or change specifications or design at any time without

notice and without incurring any obligation whatever. No part of this publication may be reproduced without written permission.

INTRODUCTION

Congratulations on your selection of a Honda outboard motor. We are certain

you will be pleased with your purchase of one of the finest outboard motors on

the market.

We want to help you get the best results from your new outboard motor and

to operate it safely. This manual contains the information on how to do that;

please read it carefully.

As you read this manual, you will find information preceded by a m

symbol. That information is intended to help you avoid damage to your

outboard motor, other property, or the environment.

We suggest you read the warranty policy to fully understand its coverage and

your responsibilities of ownership. The warranty policy is a separate document

that should have been given to you by your dealer.

When your outboard motor needs scheduled maintenance, keep in mind that

your Honda servicing dealer is specially trained in servicing Honda outboard

motors. Your Honda servicing dealer is dedicated to your satisfaction and will

be pleased to answer your questions and concerns.

Best Wishes,

Honda Motor Co., Ltd.

1

INTRODUCTION

A FEW WORDS ABOUT SAFETY

Your safety and the safety of others are very important. And using this

outboard motor safely is an important responsibility.

To help you make informed decisions about safety, we have provided

operating procedures and other information on labels and in this manual. This

information alerts you to potential hazards that could hurt you or others.

Of course, it is not practical or possible to warn you about all the hazards

associated with operating or maintaining a outboard motor. You must use your

own good judgment.

You will find important safety information in a variety of forms, including:

l

Safety Labels - on the outboard motor.

l

Safety Messages- preceded by a safety alert symbol A and one of three

signal words, DANGER, WARNING, or CAUTION.

These signal words mean:

You WILL be KILLED or SERIOUSLY HURT if you

don’t follow instructions.

You CAN be KILLED or SERIOUSLY HURT if you

don’t follow instructions.

You CAN be HURT if you don’t follow instructions.

l

Safety Headings - such as IMPORTANT SAFETY INFORMATION.

l

Safety Section - such as OUTBOARD MOTOR SAFETY.

l

Instructions - how to use this outboard motor correctly and safely.

This entire book is filled with important safety information - please read it

carefully.

2

CONTENTS

OUTBOARD MOTOR SAFETY

IMPORTANT SAFETY INFORMATION

Operator Responsibility

Refuel With Care

Carbon Monoxide Hazard

SAFETY LABEL LOCATIONS

CONTROLS & FEATURES

COMPONENT & CONTROL LOCATIONS

CONTROLS

Engine Stop Switch

Choke Knob

Throttle Grip

Throttle Friction Knob

Gearshift Lever ................................................................................ 14

Recoil Starter Grip ........................................................................... 14

Electric Starter Button

Steering Friction Bolt ....................................................................... 15

Tilt Lever ..........................................................................................

Transom Angle Adjusting Rod ......................................................... 16

Engine Cover Lock Lever ................................................................ 16

Fuel Priming Bulb ............................................................................ 17

Fuel Cap Vent Knob ....................................................................... .17

FEATURES .......................................................................................... 17

Fuel Gauge ...................................................................................... 17

Oil Pressure Indicator Light ............................................................. 17

Water Check Hole.. .......................................................................... 17

Anode

Overrev Limiter ................................................................................ 18

.........................................................................................

..............................................................................................

...............................................................................

..........................................................................

.....................................................................................

.....................................................................................

..................................................................

.................................................

.....................................................................

..................................................................

...............................................................

...................................................................... 10

..........................................

...................................................................... 13

......................................................................

7

7

7

8

8

9

10

12

12

12

13

14

15

18

3

CONTENTS

INSTALLATION

INSTALLATION POSITION .................................................................

INSTALLATION HEIGHT

OUTBOARD MOTOR ATTACHMENT..

MOTOR ANGLE FOR CRUISING

MOTOR ANGLE ADJUSTMENT

BATTERY CONNECTIONS

Models With Electric Starter

Models Without Electric Starter

Battery Installation

EMERGENCY PROCEDURES..

Connections to the Battery ............................................................. .24

BEFORE OPERATION

ARE YOU READY TO GET UNDER WAY?

Knowledge

Safety Apparel

IS YOUR OUTBOARD MOTOR

Safety Inspection

Maintenance Inspection

OPERATION

SAFE OPERATING PRECAUTIONS..

BREAK-IN PROCEDURE

PORTABLE FUEL TANK PLACEMENT AND CONNECTIONS..

Fuel Tank Placement

Fuel Hose Connections

Fuel Priming

STARTING THE ENGINE

EMERGENCY STARTING

........................................................................................

.....................................................................

..............................................

.......................................................

.........................................................

.................................................................

............................................................

......................................................

...........................................................................

.........................................................

.............................................................................

........................................ 25

.......................................................................................

................................................................................

READY TO GO?.

............................................................................

.................................................................. .26

.............................................................................................

................................................

...................................................................

.......................................................................

...................................................................

.................................................................................... .28

...................................................................

...................................................................

.............................

.......

19

19

19

.20

21

21

22

22

.22

23

.23

25

25

.25

.25

.26

27

.27

.27

.27

27

28

.29

33

CONTENTS

5

STOPPING THE ENGINE

Emergency Engine Stopping

Normal Engine Stopping

GEAR SHIFTING

STEERING

CRUISING

TILTING THE OUTBOARD MOTOR

SERVICING YOUR HONDA OUTBOARD MOTOR

THE IMPORTANCE OF

MAINTENANCE

Safety

TOOL KIT AND SPARE PARTS

MAINTENANCE

REFUELING

FUEL

COOLING

Cleaning and

Cleaning and Flushing Without the

ENGINE OIL LEVEL CHECK

ENGINE OIL CHANGE

ENGINE

GEAR OIL LEVEL CHECK

GEAR OIL CHANGE

LUBRICATION

SPARK PLUG SERVICE

FUEL FILTER REPLACEMENT

RECOIL STARTER ROPE INSPECTION

ANODE

PROPELLER REPLACEMENT

..........................................................................................

...........................................................................................

Precautions..

RECOMMENDATIONS..

SYSTEM

OIL RECOMMENDATIONS

REPLACEMENT

................................................................................

SAFETY

SCHEDULE

........................................................................................

Flushing With the

....................................................................................

...................................................................

..........................................................

.................................................................

..................................................

MAINTENANCE..

...................................................................

........................................................................

........ .

.............................................................

...........................................................

CLEANING AND

Flush

..............................................................

........................................................................

..................................................................

...........................................................................

....................................................................

..........................................................

...................................................................

...........................................................

.........................................

................................................

FLUSHING..

Kit..

.....................................

Flush

Kit..

.................................................

................ i..

................................

...........................

................................

........................

.34

.34

.34

.35

.36

.37

.38

40

.40

.41

.41

.42

.43

.44

.45

.45

.46

.46

.47

48

.49

49

.50

.51

.52

.53

.55

.55

.56

CONTENTS

6

HELPFUL TIPS & SUGGESTIONS

STORING

Storage Preparation

Storage

Removal From Storage

TRANSPORTING

TAKING CARE OF UNEXPECTED PROBLEMS

ENGINE WILL

ENGINE OVERHEATS

BATTERY DOES NOT CHARGE AND ELECTRIC STARTER

(applicable

Fuse Replacement

SUBMERGED MOTOR

TECHNICAL & CONSUMER INFORMATION

TECHNICAL INFORMATION

Serial Number

Carburetor Modification for High Altitude Operation

Oxygenated Fuels

Emission Control System Information

Specifications

WIRING

CONSUMER INFORMATION

Honda Publications

Warranty Service Information

YOUR OUTBOARD

.........................................................................

Precautions

NOT

models)

.................................................................................. .71

DIAGRAMS..

........................................................................

....................................................................

................................................................................ .60

START..

........................................................................

DOES

...........................................................................

.......................................................................

Locations

...........................................................................

..........................................................................

..........................................................................

.........................................................

MOTOR..

..............................................................

NOT OPERATE

...............................................................

................................................................

..............................................................

..........................................................

...........................................

....................................

........................................

.........................................

..............................................

.......................

57

.57

57

59

60

61

.61

62

.63

63

.64

66

66

.66

.67

.68

69

74

76

76

77

INDEX

QUICK REFERENCE INFORMATION

.......................................................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . .

78

Inside back cover

OUTBOARD MOTOR SAFETY

IMPORTANT SAFETY INFORMATION

Honda BF9.9A and BF15A outboard motors are designed for use with boats

that have a suitable manufacturer’s power recommendation, and other uses

can result in injury to the operator or damage to the outboard motor and other

property.

Most accidents can be prevented if you follow all instructions in this manual

and on the outboard motor. The most common hazards are discussed below,

along with the best way to protect yourself and others.

Operator Responsibility

It is the operator’s responsbility to provide the necessary safeguards to

protect people and property. Know how to stop the engine quickly in case

of emergency. Understand the use of all controls.

Stop the engine immediately if anyone falls overboard, and do not run the

engine while the boat is near anyone in the water.

Always stop the engine if you must leave the controls for any reason.

Attach the emergency stop switch lanyard securely to the operator.

Always wear a PERSONAL FLOTATION DEVICE (PFD) while on the boat.

Familiarize yourself with all laws and regulations relating to the boating and

the use of outboard motors.

Be sure that anyone who operates the outboard motor receives proper

instruction.

Be sure the outboard motor is properly mounted on the boat.

Do not remove the engine cover while the engine is running.

Do not attempt to modify the outboard motor.

Do not remove any labels, covers, or safety devices; they are installed for

your safety.

7

OUTBOARD MOTOR SAFETY

8

Refuel With Care

Gasoline is extremely flammable, and gasoline vapor can explode. Refuel

outdoors, in a well-ventilaed area, with the engine stopped. Never smoke

near gasoline, and keep other flames and sparks away.

Remove any portable fuel tank from the boat for refueling. Keep the

portable fuel tank away from the battery or other potential spark sources.

Refuel carefully to avoid spilling fuel. Avoid overfilling the fuel tank.

After refueling, tighten the filler cap securely. If any fuel is spilled, make sure

the area is dry before starting the engine.

Carbon Monoxide Hazard

Exhaust gas contains poisonous carbon monoxide. Avoid inhalation of

exhaust gas. Never run the engine in a closed garage or confined area.

OUTBOARD MOTOR SAFETY

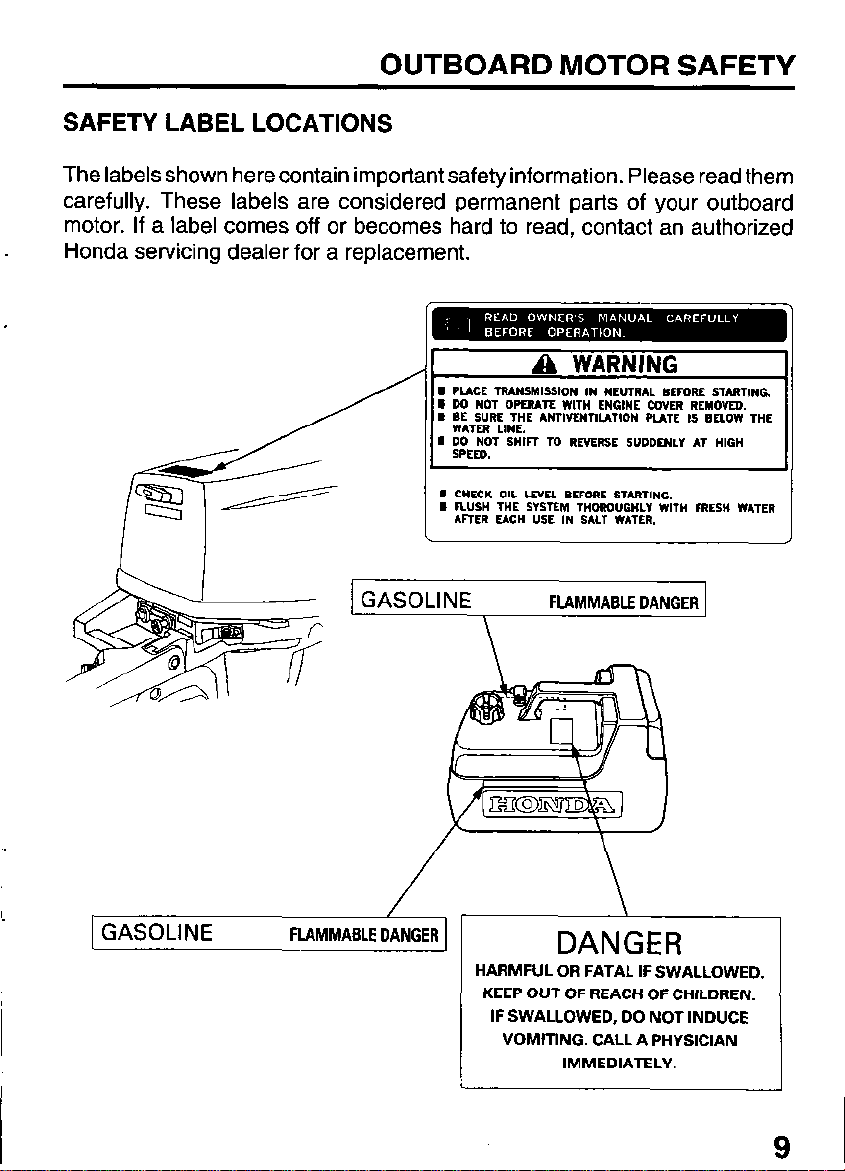

SAFETY LABEL LOCATIONS

The labels shown here contain important safety information. Please read them

carefully. These labels are considered permanent parts of your outboard

motor. If a label comes off or becomes hard to read, contact an authorized

Honda servicing dealer for a replacement.

I DO NOT OPERATE WITH

I CHECK OIL LEVEL BEFORE STARTING.

I FLUSH THE SYSTEM THOROUGHLY WITH FRESH WATER

AITER EACH USE IN SALT WATER.

ENGINE COVER REMOVED.

CONTROLS & FEATURES

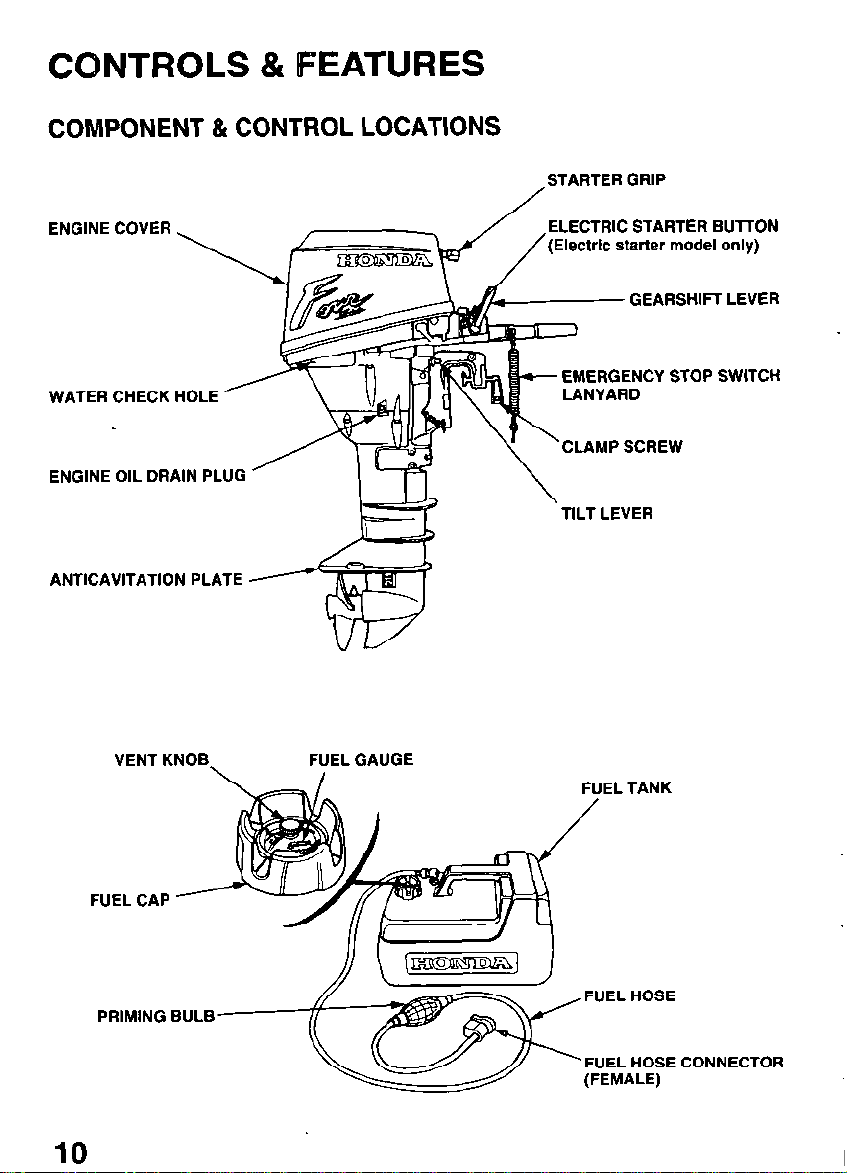

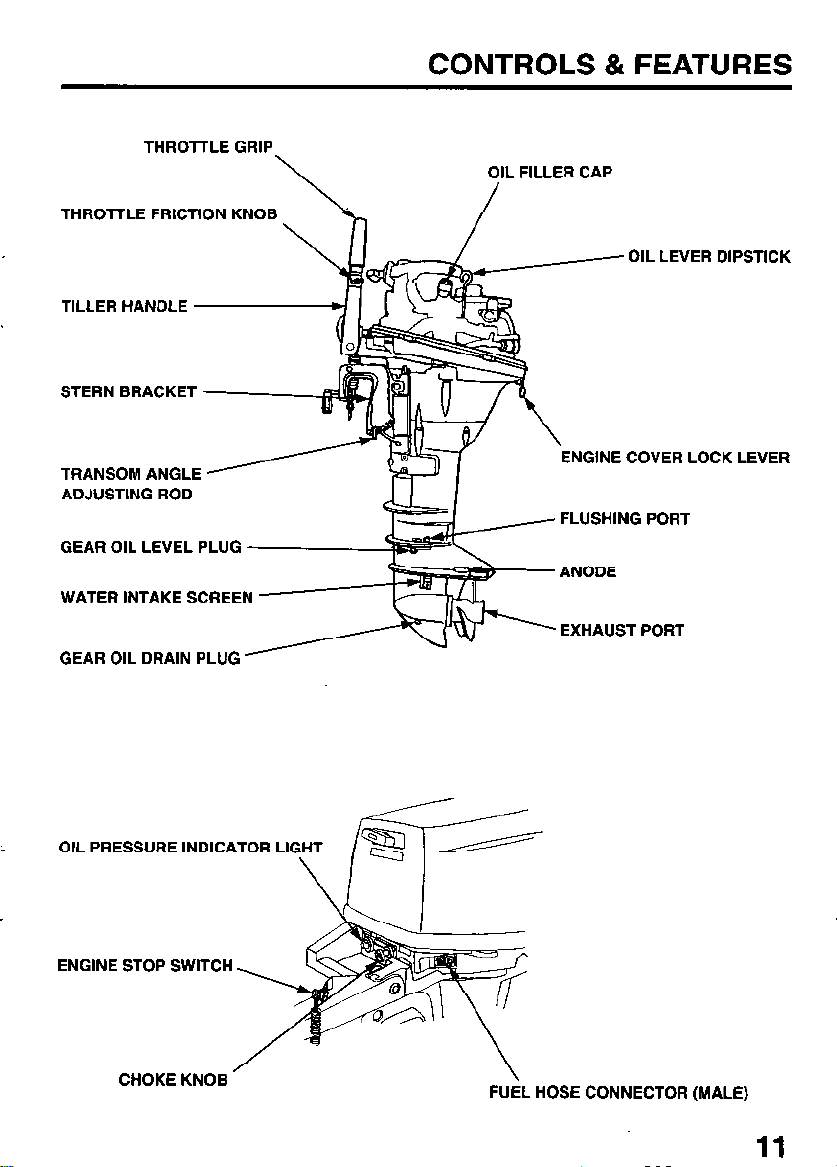

COMPONENT & CONTROL LOCATIONS

ENGINE COVER

WATER CHECK HOLE

ENGINE OIL DRAIN PLUG

ANTICAVITATION PLATE

‘Tq

?!i@

STARTER GRIP

/

EMERGENCY STOP SWITCH

LANYARD

I

‘CLAMP SCREW

\

TlLT LEVER

VENT KNOB

FUEL CAP

PRIMING BULB

10

FUEL GAUGE

FUEL HOSE CONNECTOR

THROlTLE GRIP

THROlTLE FRICTION KNOB

TILLER HANDLE

STERN BRACKET

CONTROLS & FEATURES

OIL FILLER CAP

OIL LEVER DIPSTICK

TRANSOM ANGLE

ADJUSTING ROD

GEAR OIL LEVEL PLUG

WATER INTAKE SCREEN

GEAR OIL DRAIN PLUG

OIL PRESSURE INDICATOR LIGHT

ENGINE STOP SWITCH

ENGINE COVER LOCK LEVER

FLUSHING PORT

EXHAUST PORT

CHOKE KNOB

FUEL HOSE CONNECTOR (MALE)

11

CONTROLS & FEATURES

CONTROLS

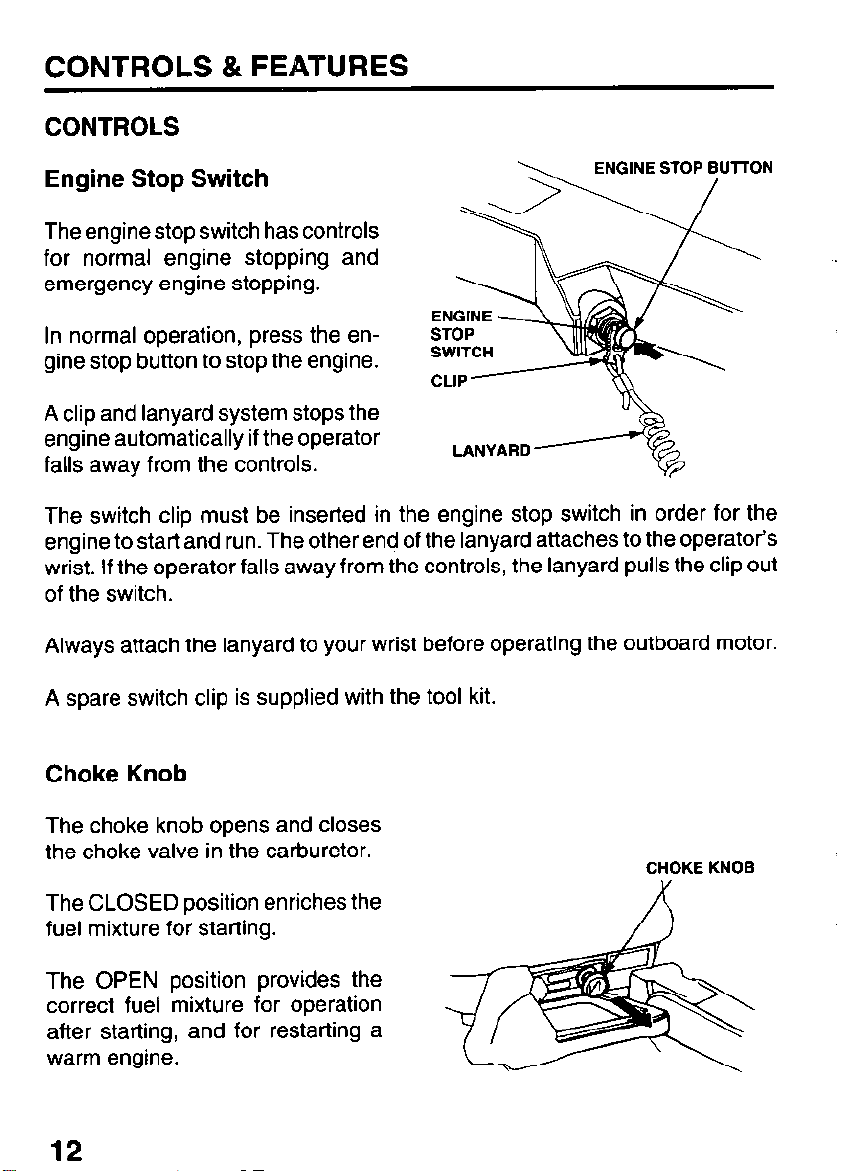

Engine Stop Switch

The engine stop switch has controls

for normal engine stopping and

emergency engine stopping.

In normal operation, press the engine stop button to stop the engine.

A clip and lanyard system stops the

engine automatically if the operator

falls away from the controls.

The switch clip must be inserted in the engine stop switch in order for the

engine to start and run. The other end of the lanyard attaches to the operator’s

wrist. If the operator falls away from the controls, the lanyard pulls the clip out

of the switch.

Always attach the lanyard to your wrist before operating the outboard motor.

A spare switch clip is supplied with the tool kit.

Choke Knob

Thechokeknobopensandcloses

the choke valve in the carburetor.

The CLOSED position enriches the

fuel mixture for starting.

The OPEN position provides the

correct fuel mixture for operation

after starting, and for restarting a

warm engine.

12

CHOKE KNOB

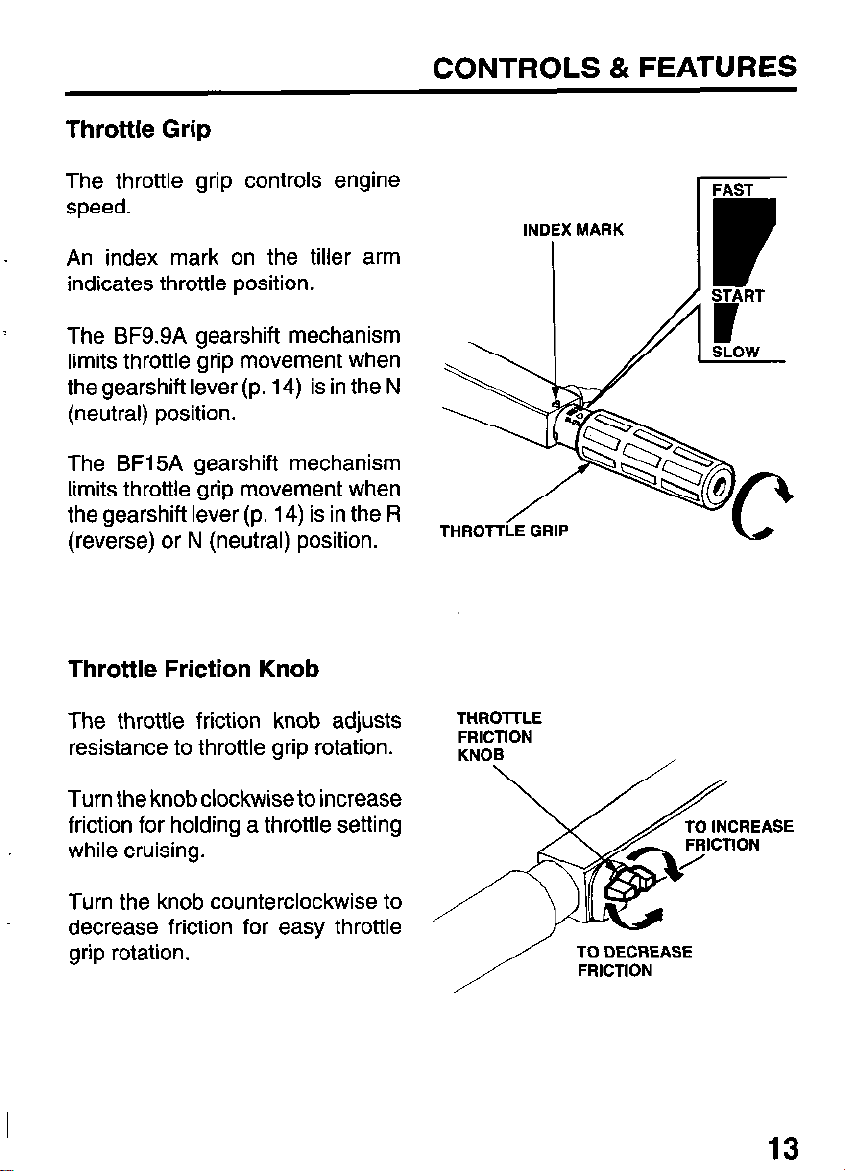

Throttle Grip

The throttle grip controls engine

speed.

An index mark on the tiller arm

indicates throttle position.

The BF9.9A gearshift mechanism

limits throttle grip movement when

the gearshift lever (p. 14) is in the N

(neutral) position.

The BF15A gearshift mechanism

limits throttle grip movement when

the gearshift lever (p. 14) is in the R

(reverse) or N (neutral) position.

CONTROLS & FEATURES

INDEX MARK

Throttle Friction Knob

The throttle friction knob adjusts

resistance to throttle grip rotation.

Turn the knob clockwise to increase

friction for holding a throttle setting

while cruising.

Turn the knob counterclockwise to

decrease friction for easy throttle

grip rotation.

THROlTLE

FRICTION

KNOB

,

TO INCREASE

TODECREASE

FRICTION

13

CONTROLS & FEATURES

.

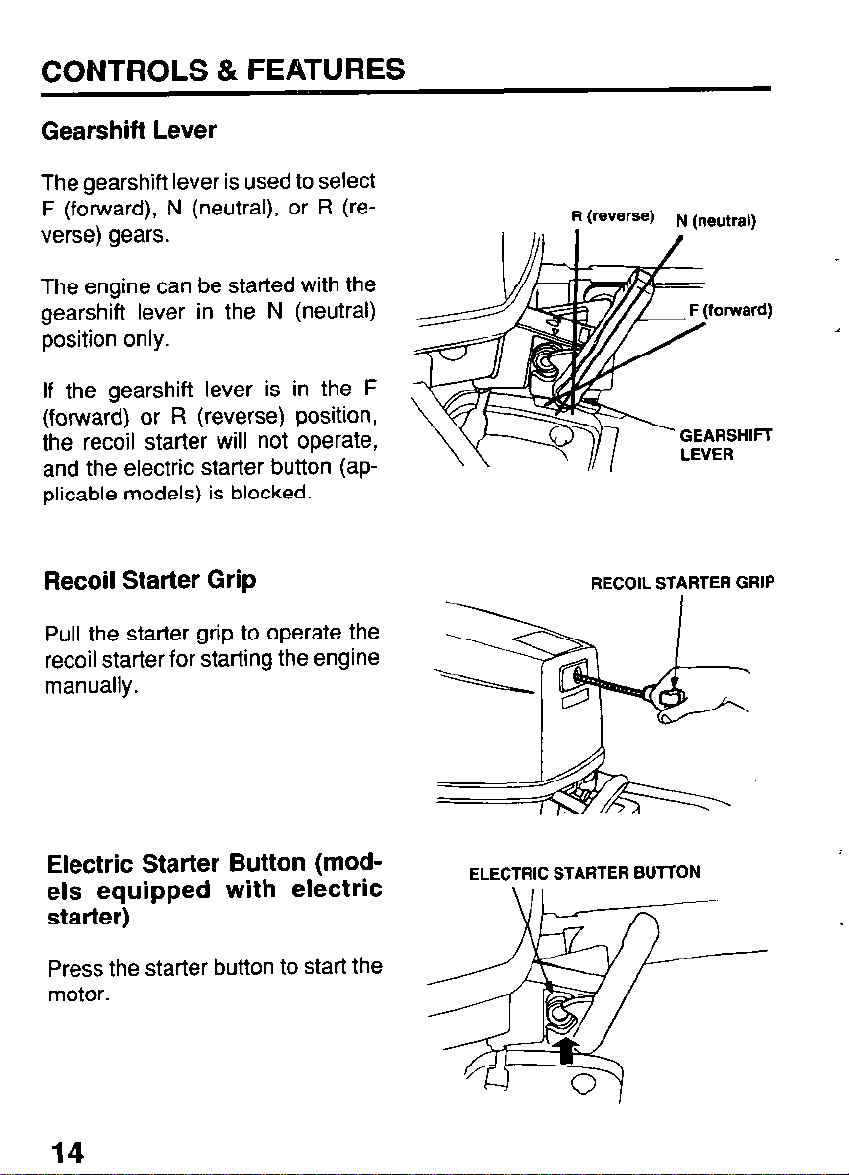

Gearshift Lever

The gearshift lever is used to select

F (forward), N (neutral), or R (reverse) gears.

The engine can be started with the

gearshift lever in the N (neutral)

position only.

If the gearshift lever is in the F

(forward) or R (reverse) position,

the recoil starter will not operate,

and the electric starter button (ap-

plicable models) is blocked.

R @ever@

N (neutral)

Recoil Starter Grip

Pull the starter grip to operate the

recoil starter for starting the engine

manually.

Electric Starter Button (models equipped with electric

starter)

Press the starter button to start the

motor.

14

RECOIL STARTER GRIP

ELECTRIC STARTER BUllON

k

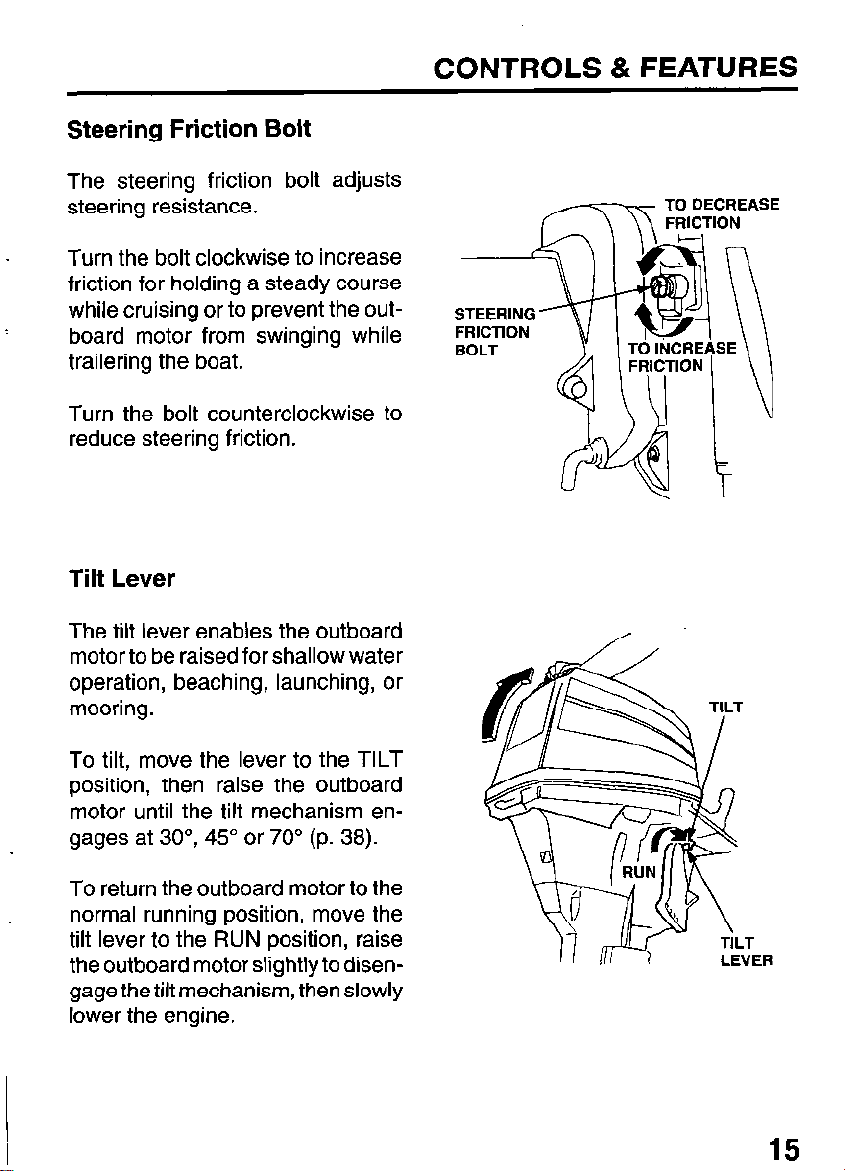

Steering Friction Bolt

The steering friction bolt adjusts

steering resistance.

Turn the bolt clockwise to increase

friction for holding a steady course

while cruising or to prevent the out-

board motor from swinging while

trailering the boat.

Turn the bolt counterclockwise to

reduce steering friction.

Tilt Lever

The tilt lever enables the outboard

motor to be raised for shallow water

operation, beaching, launching, or

mooring.

CONTROLS & FEATURES

TODECREASE

m FRICTION

To tilt, move the lever to the TILT

position, then raise the outboard

motor until the tilt mechanism engages at 30”, 45” or 70” (p. 38).

To return the outboard motor to the

normal running position, move the

tilt lever to the RUN position, raise

the outboard motor slightly to disengage the tilt mechanism, then slowly

lower the engine.

15

CONTROLS & FEATURES

16

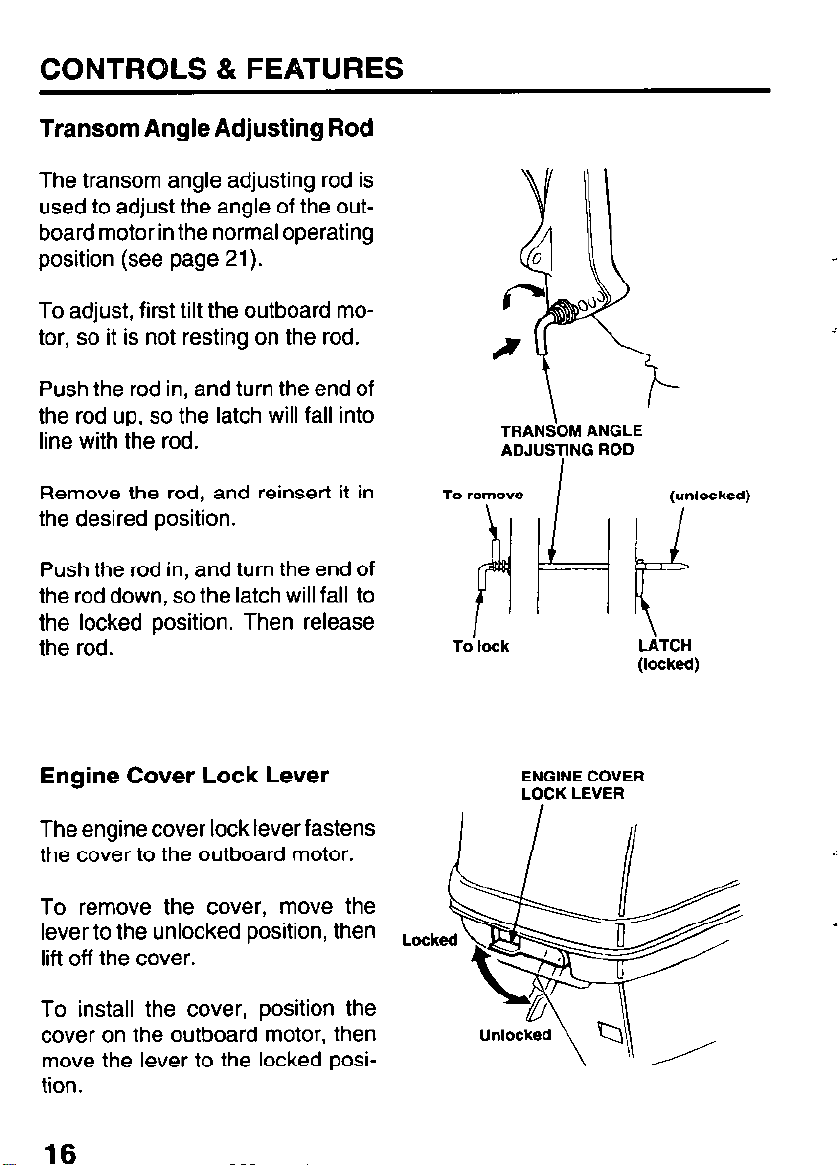

Transom Angle Adjusting Rod

The transom angle adjusting rod is

used to adjust the angle of the outboard motor in the normal operating

position (see page 21).

To adjust, first tilt the outboard motor, so it is not resting on the rod.

Push the rod in, and turn the end of

the rod up, so the latch will fall into

line with the rod.

\ ’

TRANSOM ANGLE ADJUSTING ROD

Remove the rod, and reinsert it in

the desired position.

Push the rod in, and turn the end of

the rod down, so the latch will fall to

the locked position. Then release

the rod.

Engine Cover Lock Lever

The engine cover lock lever fastens

the cover to the outboard motor.

To remove the cover, move the

lever to the unlocked position, then

lift off the cover.

To install the cover, position the

cover on the outboard motor, then

move the lever to the locked posi-

tion.

To remove

?‘k

To lock

(unlocked)

.

LATCH

(locked)

ENGINE COVER LOCK LEVER

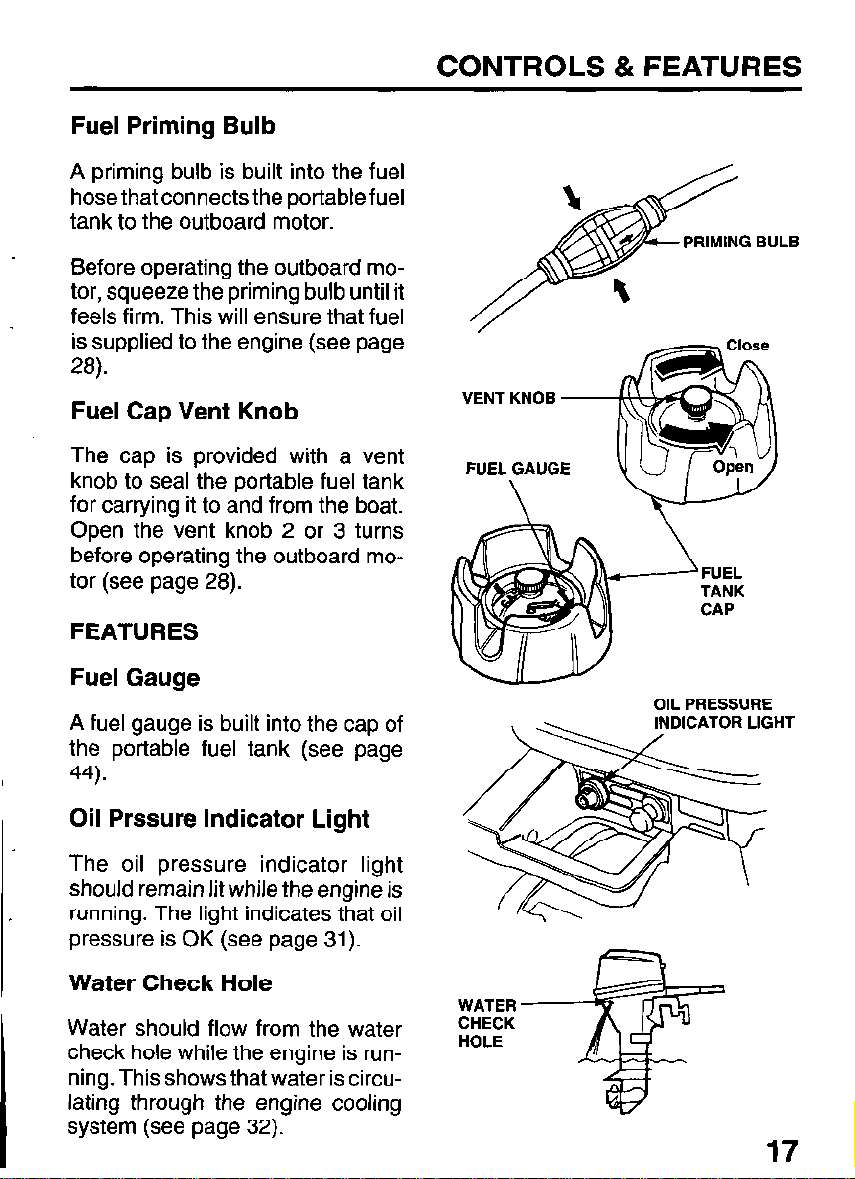

Fuel Priming Bulb

A priming bulb is built into the fuel

hose that connects the portable fuel

tank to the outboard motor.

Before operating the outboard motor, squeeze the priming bulb until it

feels firm. This will ensure that fuel

is supplied to the engine (see page

28).

Fuel Cap Vent Knob

CONTROLS & FEATURES

RIMING BULB

VENT KNOB

The cap is provided with a vent

knob to seal the portable fuel tank

for carrying it to and from the boat.

Open the vent knob 2 or 3 turns

before operating the outboard mo-

tor (see page 28).

FEATURES

Fuel Gauge

A fuel gauge is built into the cap of

the portable fuel tank (see page

44).

Oil Prssure Indicator Light

The oil pressure indicator light

should remain lit while the engine is

running. The light indicates that oil

pressure is OK (see page 31).

Water Check Hole

Water should flow from the water

check hole while the engine is run-

ning. This shows that water is circulating through the engine cooling

system (see page 32).

FUEL GAUGE

\

FUEL

TANK

CAP

OIL PRESSURE INDICATOR LIGHT

WATER

CHECK

HOLE

17

CONTROLS & FEATURES

18

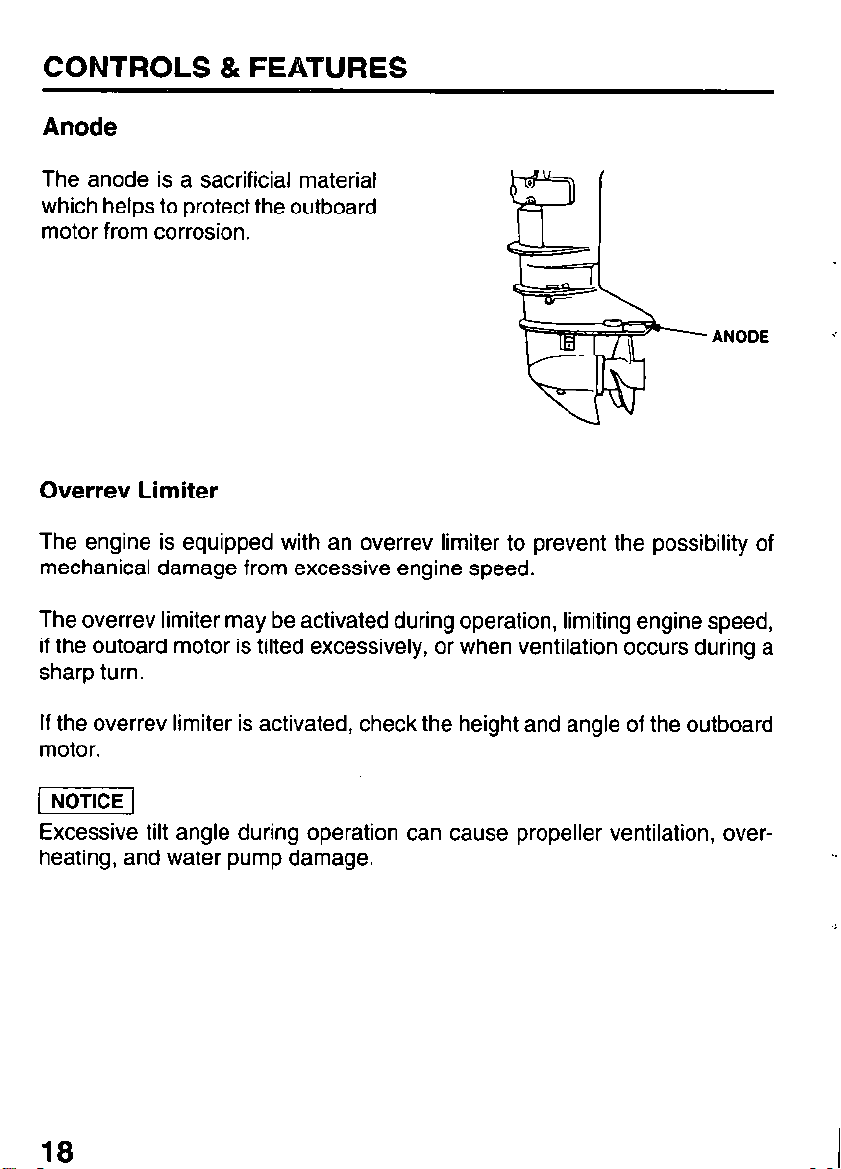

Anode

The anode is a sacrificial material

which helps to protect the outboard

motor from corrosion.

Overrev Limiter

The engine is equipped with an overrev limiter to prevent the possibility of

mechanical damage from excessive engine speed.

The overrev limiter may be activated during operation, limiting engine speed,

if the outoard motor is tilted excessively, or when ventilation occurs during a

sharp turn.

If the overrev limiter is activated, check the height and angle of the outboard

motor.

Excessive tilt angle during operation can cause propeller ventilation, over-

heating, and water pump damage.

INSTALLATION

It is your responsibility to choose a boat suitable for the outboard motor.

Do not exceed the boat manu-

facturer’s power recommendation.

Damage and injury may result.

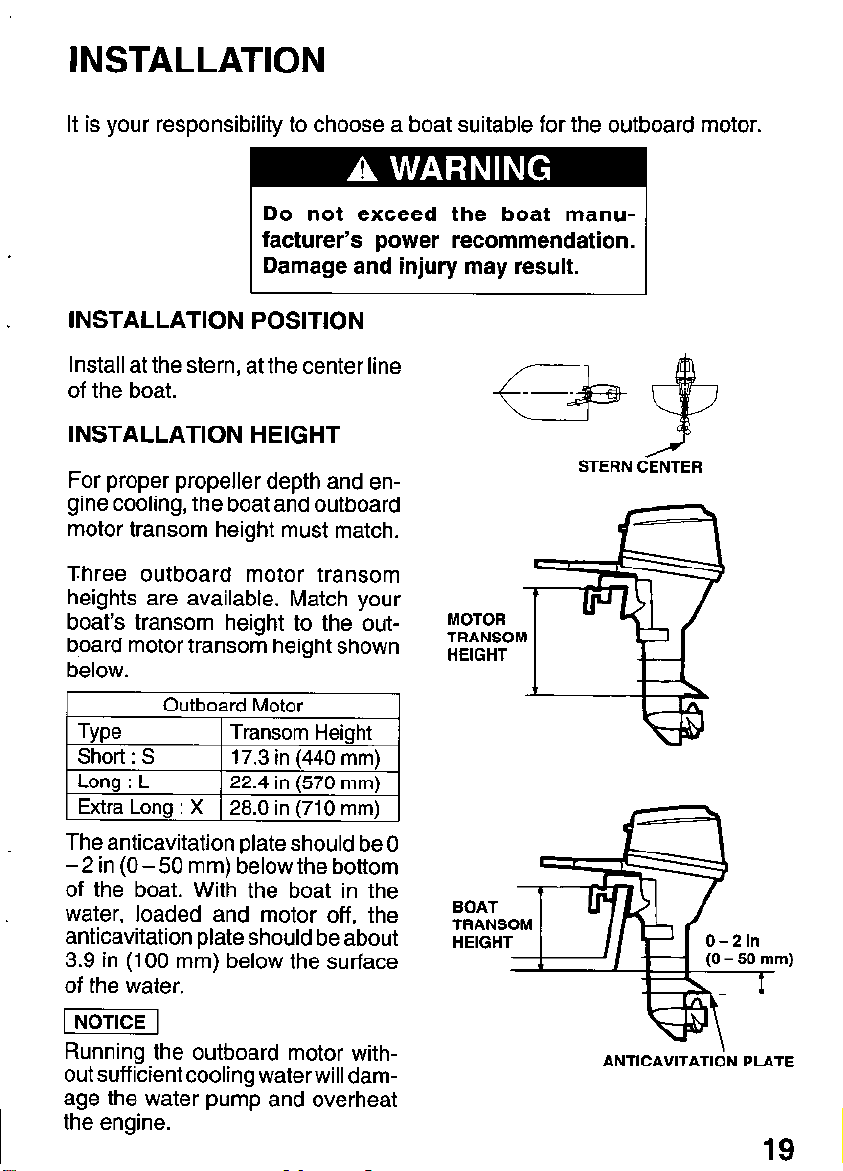

INSTALLATION POSITION

Install at the stern, at the center line

of the boat.

INSTALLATION HEIGHT

For proper propeller depth and engine cooling, the boat and outboard

motor transom height must match.

Three outboard motor transom

heights are available. Match your

boat’s transom height to the outboard motor transom height shown

below.

STERNCENTER

The anticavitation plate should be 0

- 2 in (0 - 50 mm) below the bottom

of the boat. With the boat in the

water, loaded and motor off, the

anticavitation plate should be about

3.9 in (100 mm) below the surface

of the water.

Running the outboard motor with-

out suff icient cooling water will damage the water pump and overheat

the engine.

ANTlCAVlTATldN PLATE

19

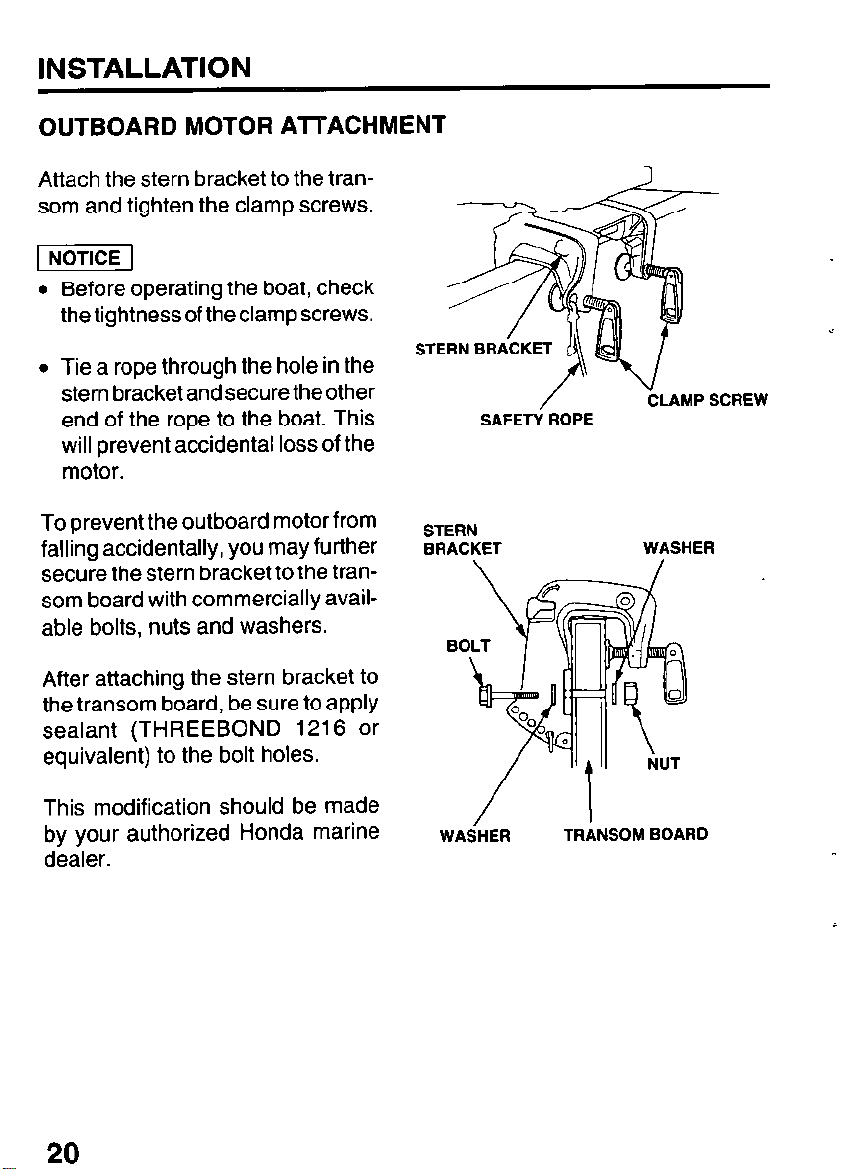

OUTBOARD MOTOR AlTACHMENT

20

Attach the stern bracket to the transom and tighten the clamp screws.

l

Before operating the boat, check

the tightness of the clamp screws.

l

Tie a rope through the hole in the

stem bracket and secure the other

end of the rope to the boat. This

will prevent accidental loss of the

motor.

/

SAFETY ROPE

& SCREW

To prevent the outboard motor from

falling accidentally, you may further

secure the stern bracket to the transom board with commercially available bolts, nuts and washers.

After attaching the stern bracket to

the transom board, be sure to apply

sealant (THREEBOND 1216 or

equivalent) to the bolt holes.

This modification should be made

by your authorized Honda marine

dealer.

STERN

BRACKET WASHER

WAgHER

TRANSOM BOARD

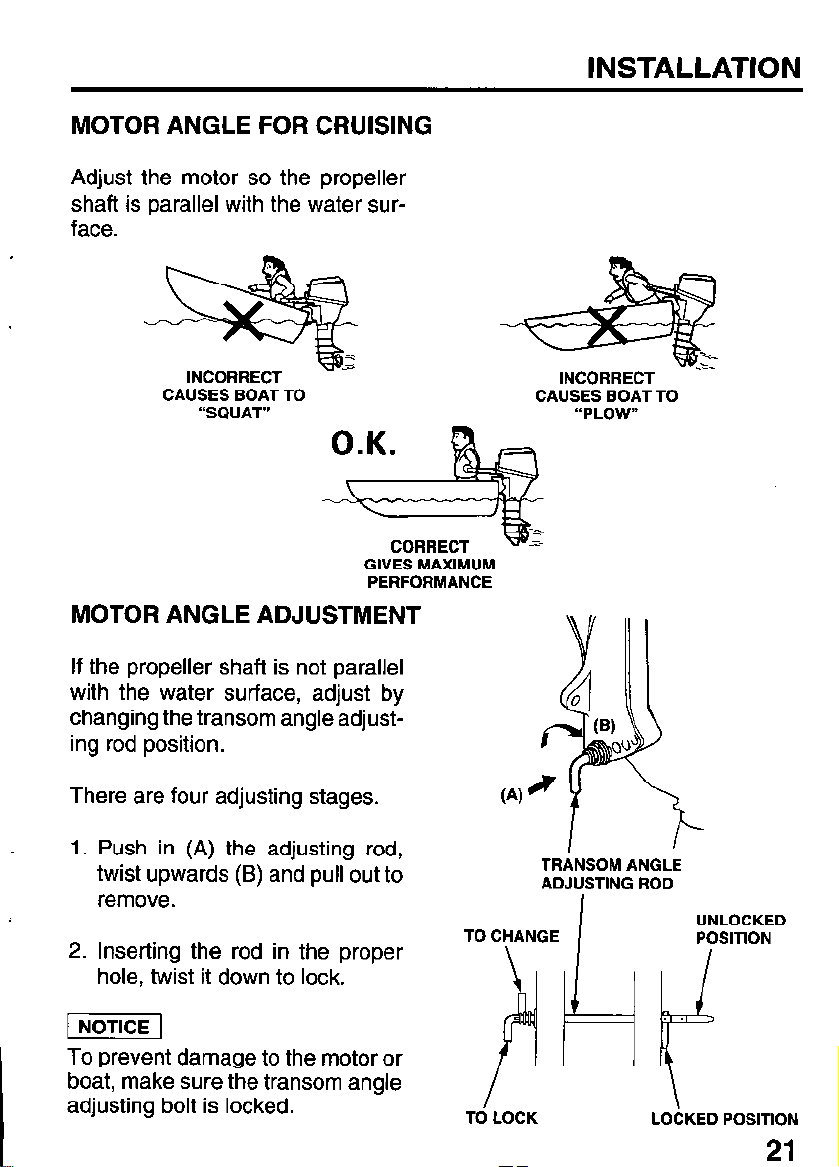

MOTOR ANGLE FOR CRUISING

21

Adjust the motor so the propeller

shaft is parallel with the water surface.

INSTALLATION

INCORRECT -

CAUSES BOAT TO

“SQUAT”

GIVES MAXIMUM

PERFORMANCE

MOTOR ANGLE ADJUSTMENT

If the propeller shaft is not parallel

with the water surface, adjust by

changing the transom angle adjust-

ing rod position.

There are four adjusting stages.

1. Push in (A) the adjusting rod,

twist upwards (B) and pull out to

remove.

2. Inserting the rod in the proper

hole, twist it down to lock.

CAUSES BOAT TO

TRANSOM ANGLE

ADJUSTING ROD

TO CHANGE

INCORRECT ---

“PLOW”

UNLOCKED

POSITION

) NOTICE 1

To prevent damage to the motor or

boat, make sure the transom angle

adjusting bolt is locked.

):I:

TO LOCK

.

LOCKED POSITION

INSTALLATION

22

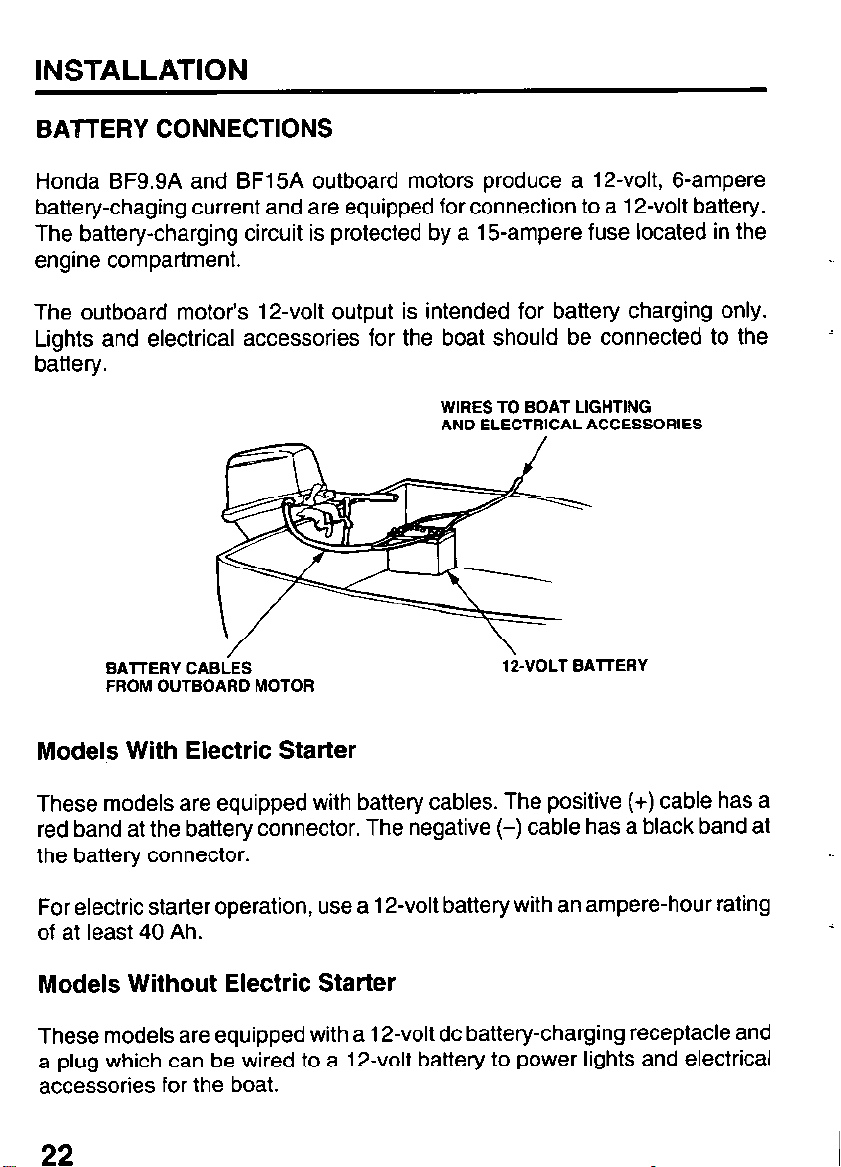

BATTERY CONNECTIONS

Honda BF9.9A and BF15A outboard motors produce a 12-volt, 6-ampere

battery-chaging current and are equipped for connection to a 12-volt battery.

The battery-charging circuit is protected by a 15-ampere fuse located in the

engine compartment.

The outboard motor’s 12-volt output is intended for battery charging only.

Lights and electrical accessories for the boat should be connected to the

battery.

WIRES TO BOAT LIGHTING

AND ELECTRICAL ACCESSORIES

BAlTERY CABLES

FROM OUTBOARD MOTOR

1 P-VOLT BAlTERY

Models With Electric Starter

These models are equipped with battery cables. The positive (+) cable has a

red band at the battery connector. The negative (-) cable has a black band at

the battery connector.

For electric starter operation, use a 12-volt battery with an ampere-hour rating

of at least 40 Ah.

Models Without Electric Starter

These models are equipped with a 12-volt dc battery-charging receptacle and

a plug which can be wired to a 12-volt battery to power lights and electrical

accessories for the boat.

INSTALLATION

23

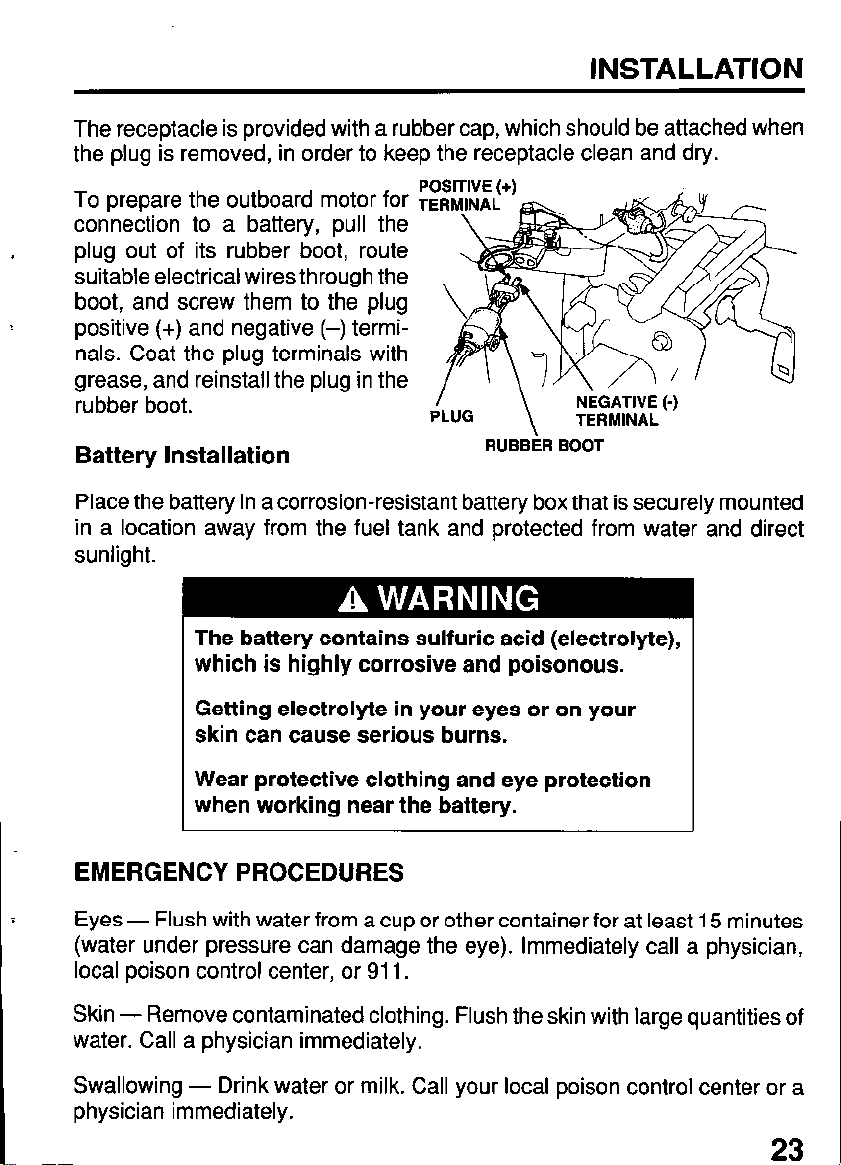

The receptacle is provided with a rubber cap, which should be attached when

the plug is removed, in order to keep the receptacle clean and dry.

To prepare the outboard motor for

connection to a battery, pull the

.

plug out of its rubber boot, route

suitable electrical wires through the

boot, and screw them to the plug

positive (+) and negative (-) termi-

nals. Coat the plug terminals with

grease, and reinstall the plug in the

rubber boot.

Battery Installation

/

PLUG

RUBBER BOOT

\

NEGATIVE (-)

TERMINAL

Place the battery in a corrosion-resistant battery box that is securely mounted

in a location away from the fuel tank and protected from water and direct

sunlight.

The battery contains sulfuric acid (electrolyte),

which is highly corrosive and poisonous.

Getting electrolyte in your eyes or on your

skin can cause serious burns.

Wear protective clothing and eye protection

when working near the battery.

EMERGENCY PROCEDURES

Eyes - Flush with water from a cup or other container for at least 15 minutes

(water under pressure can damage the eye). Immediately call a physician,

local poison control center, or 911.

Skin

- Remove contaminated clothing. Flush the skin with large quantities of

water. Call a physician immediately.

Swallowing - Drink water or milk. Call your local poison control center or a

physician immediately.

INSTALLATION

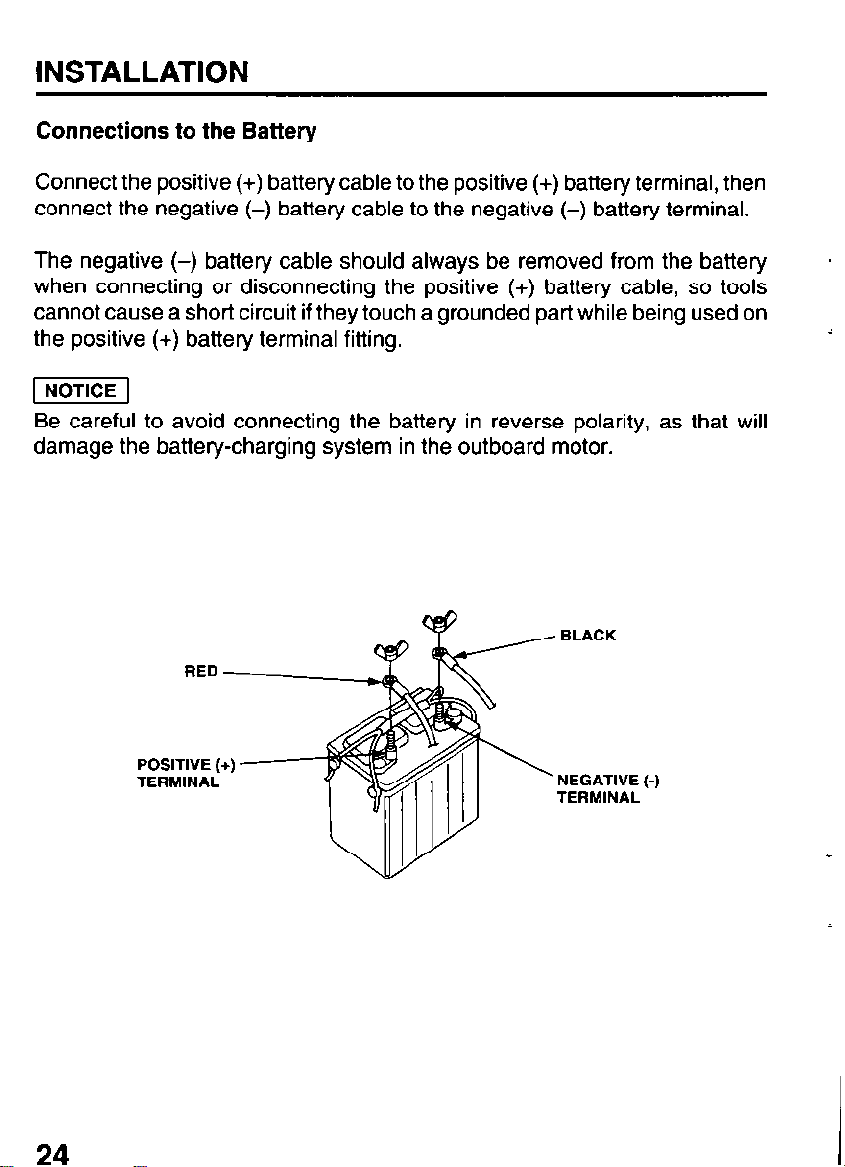

Connections to the Battery

Connect the positive (+) battery cable to the positive (+) battery terminal, then

connect the negative (-) battery cable to the negative (-) battery terminal.

The negative (-) battery cable should always be removed from the battery

when connecting or disconnecting the positive (+) battery cable, so tools

cannot cause a short circuit if they touch a grounded part while being used on

the positive (+) battery terminal fitting.

Be careful to avoid connecting the battery in reverse polarity, as that will

damage the battery-charging system in the outboard motor.

. BLACK

NEGATIVE (-)

TERMINAL

BEFORE OPERATION

ARE YOU READY TO GET UNDERWAY?

Your safety is your responsibility. A little time spent in preparation will

significantly reduce your risk of injury.

Knowledge

Read and understand this manual. Know what the controls do and how to

operate them.

Familiarize yourself with the outboard motor and its operation before you get

underway. Know what to do in case of emergencies.

Familiarize yourself with all laws and regulations relating to boating and the

use of outboard motors.

Safety Apparel

Always wear a PFD while on the boat. Attach the emergency stop switch

lanyard securely to your PFD or your wrist.

IS YOUR OUTBOARD MOTOR READY TO GO?

For your safety, and to maximize the service life of your equipment, it is very

important to take a few moments before you operate the outboard motor to

check its condition. Be sure to take care of any problem you find, or have your

servicing dealer correct it, before you operate the outboard motor.

Improperly maintaining this outboard motor, or failing to correct a

problem before operation, could

cause a malfunction in which you

could be seriously injured.

Always perform a preoperation

inspection before each operation,

and correct any problem.

BEFORE OPERATION

26

Safety Inspection

l

Look around for signs of oil or gasoline leaks. Make sure the fuel tank is in

good condition and properly secured in the,boat (see page 27). Check that

the fuel hose is undamaged and properly connected (see page 28). Wipe

up any spills before starting the engine.

l

Check the stern bracket to be sure the outboard motor is securely installed.

l

Check that all controls are operating properly.

l

Replace any damaged parts.

l

Check that all fasteners are in place and securely tightened.

Maintenance Inspection

Check the engine oil level (see page 47). Running the engine with a low oil

level can cause engine damage.

Check to be sure the propeller is undamaged, and the retaining nut is

secured with a cotter pin (see page 56).

Check that the anode is securely attached to the anticavitation plate and is

not excessively worn (see page 55). The anode helps to protect the

outboard motor from corrosion.

Make sure the tool kit and spare parts are onboard (see page 42).

Replace any missing items.

Check the fuel level in the fuel tank (see page 44).

OPERATION

SAFE OPERATING PRECAUTIONS

To safely realize the full potential of this outboard motor, you need a complete

understanding of its operation and a certain amount of practice with its

controls.

Before operating the outboard motor for the first time, please review the

MPORTANT SAFETY /NFORMAT/ON on page 7 and the chapter titled

BEFORE OPERATION.

For your safety, avoid starting or operating the engine in an enclosed area.

Your engine’s exhaust contains poisonous carbon monoxide gas which can

collect rapidly in an enclosed area and cause illness or death.

BREAK-IN PROCEDURE

Proper break-in procedure allows the moving parts to wear in smoothly for best

performance and long service life.

For the first 10 hours, run the outboard motor at low speed, and avoid fullthrottle operation.

PORTABLE FUEL TANK PLACEMENT AND CONNECTIONS

Fuel Tank Placement

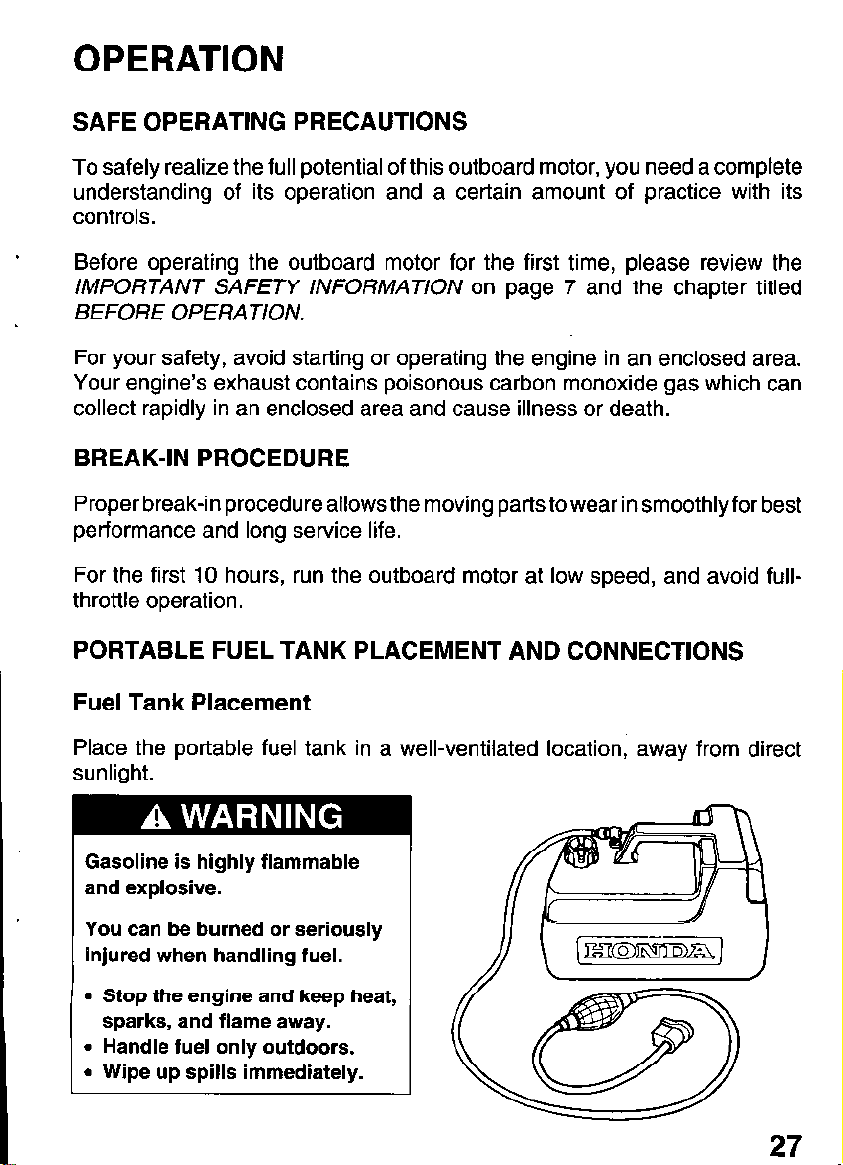

Place the portable fuel tank in a well-ventilated location, away from direct

sunlight.

Gasoline is highly flammable

and explosive.

You can be burned or seriously

injured when handling fuel.

l Stop the engine and keep heat,

sparks, and flame away.

l Handle fuel only outdoors.

l Wipe up spills immediately.

27

OPERATION

28

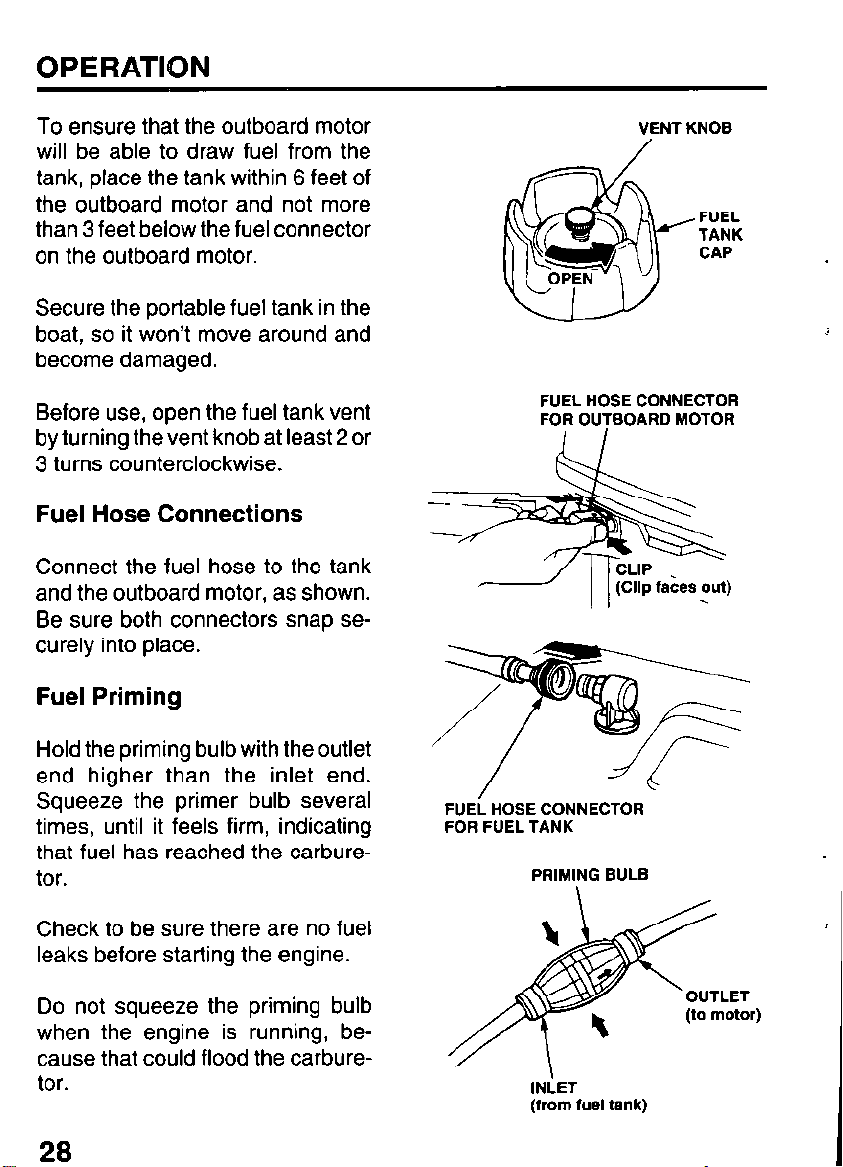

To ensure that the outboard motor

will be able to draw fuel from the

tank, place the tank within 6 feet of

the outboard motor and not more

than 3 feet below the fuel connector

on the outboard motor.

Secure the portable fuel tank in the

boat, so it won’t move around and

become damaged.

Before use, open the fuel tank vent

by turning the vent knob at least 2 or

3 turns counterclockwise.

Fuel Hose Connections

Connect the fuel hose to the tank

and the outboard motor, as shown.

Be sure both connectors snap securely into place.

Fuel Priming

VENT KNOB

FUEL

TANK

CAP

FUEL HOSE CONNECTOR

FOR OUTBOARD MOTOR

Hold the priming bulb with the outlet

end higher than the inlet end.

Squeeze the primer bulb several

times, until it feels firm, indicating

that fuel has reached the carburetor.

Check to be sure there are no fuel

leaks before starting the engine.

Do not squeeze the priming bulb

when the engine is running, be-

cause that could flood the carbure-

tor.

FUEi HOSE CONNECTOR

FOR FUEL TANK

PRIMING BULB

INiET

(from fuel tank)

Loading...

Loading...