Honda Power Equipment BF75D, BF90D User Manual

The engine exhaust from this

product contains chemicals

known to the State of California to

cause cancer, birth defects, or

other reproductive harm.

Keep this owner’s manual handy, so you can refer to it at any time. This owner’s

manual is considered a permanent part of the outboard motor and should remain with

the outboard motor if resold.

2008 Honda Motor Co., Ltd. All Rights Reserved

The information and specifications included in this publication were in effect at the

time of approval for printing. Honda Motor Co., Ltd. reserves the right, however, to

discontinue or change specifications or design at any time without notice and without

incurring any obligation whatever. No part of this publication may be reproduced

without written permission.

−

INTRODUCTION

Congratulations on your selection of

a Honda outboard motor. We are

certain you will be pleased with your

purchase of one of the finest

outboard motors on the market.

We want to help you get the best

results from your new outboard

motor and to operate it safely. This

manual contains information on how

to do that; please read it carefully.

As you read this manual you will

find information preceded by a

symbol. That information

is intended to help you avoid damage

to your outboard motor, other

property, or the environment.

We suggest you read the warranty

policy to fully understand its

coverage and your responsibilities of

ownership.

When your outboard motor needs

scheduled maintenance, keep in mind

that your Honda Marine dealer is

specially trained in servicing Honda

outboard motors. Your Honda

Marine dealer is dedicated to your

satisfaction and will be pleased to

answer your questions and concerns.

Best Wishes,

Honda Motor Co., Ltd.

1

INTRODUCTION

A FEW WORDS ABOUT SAFETY

Your safety and the safety of others

are very important. And using this

outboard motor safely is an important

responsibility.

To help you make informed

decisions about safety, we have

provided operating procedures and

other information on labels and in

this manual. This information alerts

you to potential hazards that could

hurt you or others.

Of course, it is not practical or

possible to warn you about all the

hazards associated with operating or

maintaining an outboard motor. You

must use your own good judgment.

You will find important safety information in a variety of forms, including:

Safety Labels

Safety Messages

three signal words, DANGER, WARNING, or CAUTION.

These signal words mean:

Safety Headings

Safety Section

Instructions

This entire book is filled with important safety information please read it

carefully.

−

on the outboard motor.

−

preceded by a safety alert symbol and one of

You WILL be KILLED or SERIOUSLY

HURT if you don’t follow instructions.

You CAN be KILLED or SERIOUSLY

HURT if you don’t follow instructions.

You CAN be HURT if you don’t follow

instructions.

−

such as

−

such as

−

how to use this outboard motor correctly and safely.

IMPORTANT SAFETY INFORMAT ION.

OUTBOARD MOTOR SAFETY.

−

2

CONTENTS

...................................OUTBOARD MOTOR SAFETY . 7

................IMPORTANT SAFETY INFORMATION . 7

..................................SAFETY LABEL LOCATION . 9

..................................CONTROLS AND FEATURES . 10

CONTROL AND FEATURE IDENTIFICATION

..................................................................CODES . 10

..............................................................CONTROLS . 19

LHT Type (tiller handle)

......................................................Ignition Switch . 19

Emergency Stop Switch Clip and Emergency

.......................................................Stop Switch . 19

..........................................................Throttle Grip . 20

.....................................Throttle Friction Adjuster . 21

.....................................................Gearshift Lever . 21

..........................................Steering Friction Knob . 21

LRT and XRT Types (remote control)

Side-Mount Type

..................................................Ignition Switch . 22

Emergency Stop Switch Clip and Emergency

...................................................Stop Switch . 22

......................Gearshift/Throttle Control Lever . 23

...................................................Fast Idle Lever . 24

....COMPONENT AND CONTROL LOCATIONS . 11

Panel-Mount Type

..................................................Ignition Switch . 25

Emergency Stop Switch Clip and Emergency

...................................................Stop Switch . 26

......................Gearshift/Throttle Control Lever . 27

.................................................Fast Idle Button . 28

Top-Mount Type

..................................................Ignition Switch . 29

Emergency Stop Switch Clip and Emergency

...................................................Stop Switch . 29

......................Gearshift/Throttle Control Lever . 30

.................................................Fast Idle Button . 32

Common Controls

........................................Power Trim/Tilt Switch . 33

..................................................Power Tilt Switch . 34

.............................................Manual Relief Valve . 34

.....................................................Tilt Lock Lever . 35

...........................Engine Cover Latch (front/rear) . 35

................................................................Trim Tab . 35

.......................................................INSTRUMENTS . 36

.........................Trim Meter (optional equipment) . 36

.........................Tachometer (optional equipment) . 36

.............Digital Tachometer (optional equipment) . 36

...........Digital Speedometer (optional equipment) . 37

.........................Fuel Gauge (optional equipment) . 37

3

CONTENTS

...........................................................INDICATORS . 38

...................................Alternator (ACG) Indicator . 38

............................................Oil Pressure Indicator . 39

.................................................Overheat Indicator . 40

.....................................Cooling System Indicator . 41

................................................OTHER FEATURES . 42

........................................Water Separator Buzzer . 42

.....................................................Overrev Limiter . 42

...................................................................Anodes . 44

................................................BEFORE OPERATION . 45

IS YOUR OUTBOARD MOTOR

..............................................READY TO GO? . 45

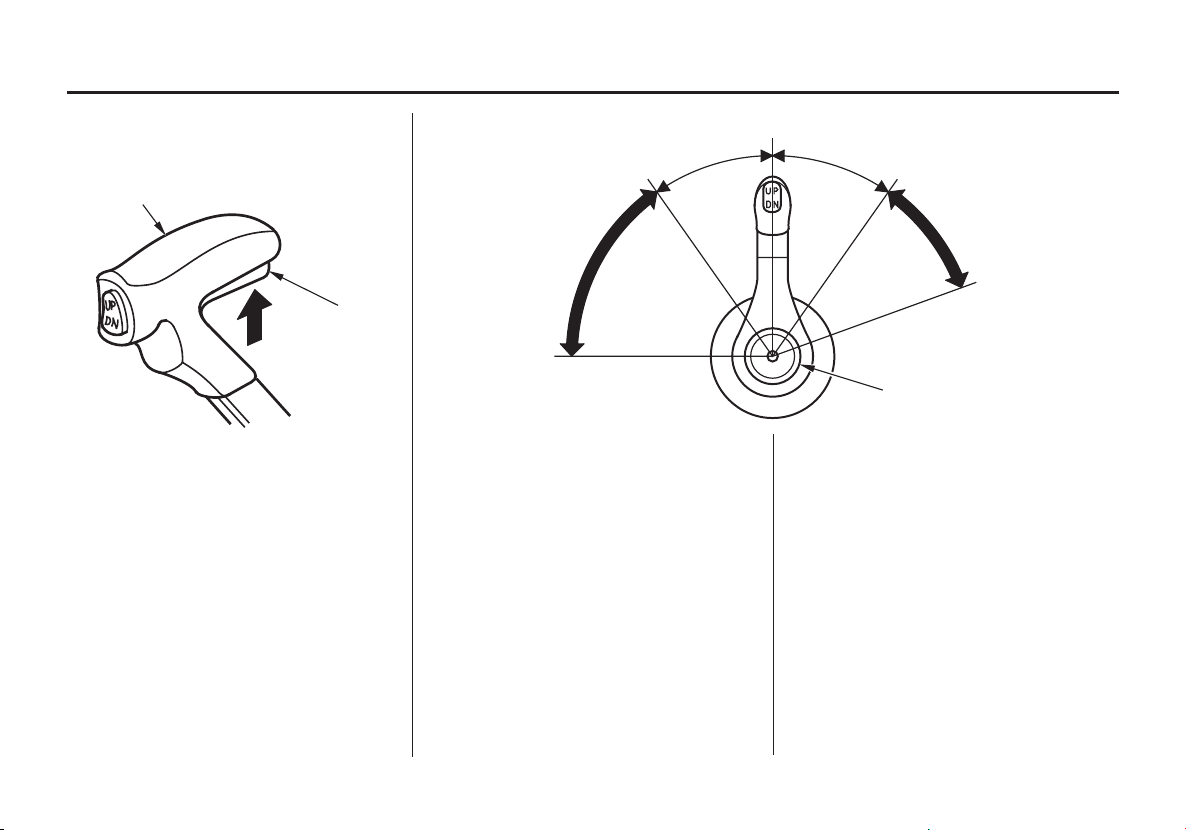

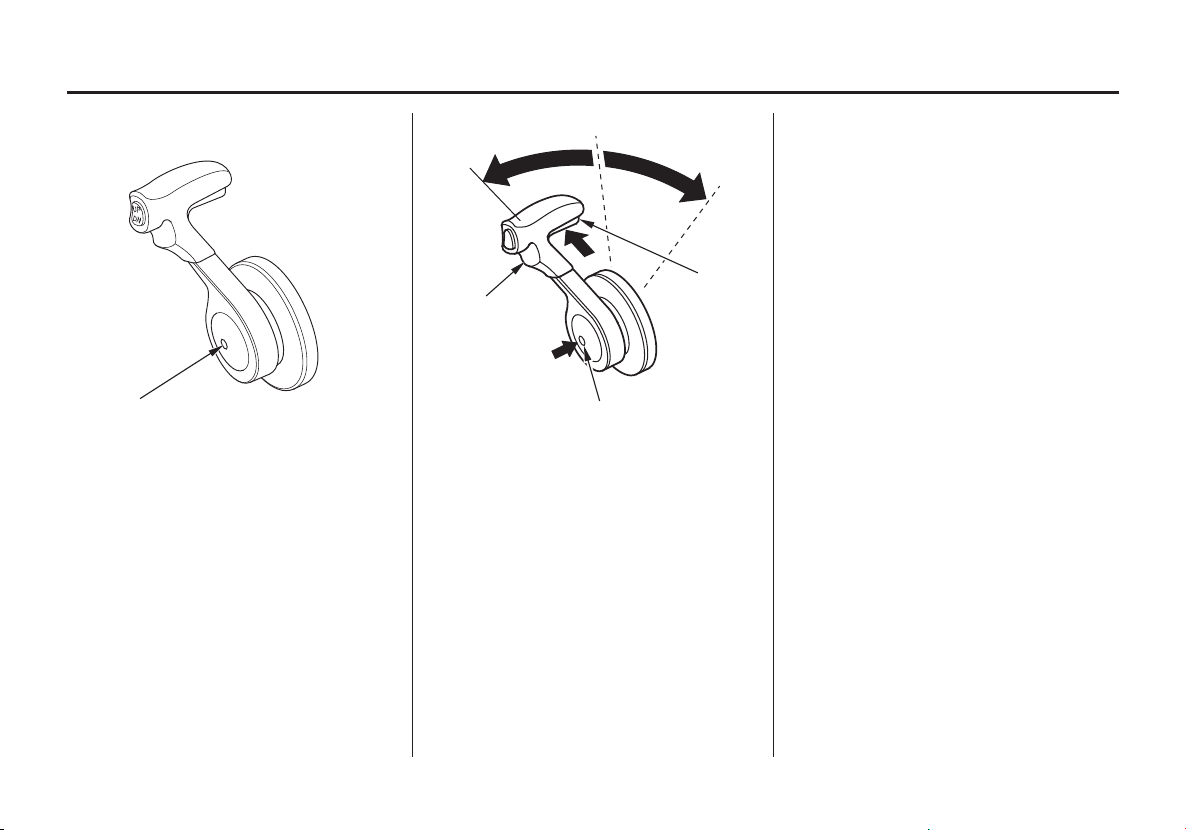

Tiller Handle Height/Angle Adjustment

........................................................(LHT type) . 47

..Programmed Fuel Injection (PGM-FI) Indicator . 38

.............Portable Fuel Tank (optional equipment) . 42

.Fuel Filler Cap Vent Knob (optional equipment) . 43

..............Fuel Priming Bulb (optional equipment) . 43

.........ARE YOU READY TO GET UNDERWAY? . 45

................................................................OPERATION . 48

....................SAFE OPERATING PRECAUTIONS . 48

.......................................BREAK-IN PROCEDURE . 48

....PORTABLE FUEL TANK (optional equipment) . 49

................................FUEL HOSE CONNECTIONS . 50

.......................................................FUEL PRIMING . 51

......................................STARTING THE ENGINE . 52

.......................................LHT Type (tiller handle) . 52

.................LRT and XRT Types (remote control) . 55

..............................................Side-Mount Type . 55

............................................Panel-Mount Type . 58

...............................................Top-Mount Type . 60

.....................................EMERGENCY STARTING . 63

.......................................STOPPING THE ENGINE . 66

................................Emergency Engine Stopping . 66

.......................................Normal Engine Stopping . 67

.....GEARSHIFT AND THROTTLE OPERATION . 69

...............................................................STEERING . 72

................................................................CRUISING . 73

........................SHALLOW WATER OPERATION . 75

...............MOORING, BEACHING, LAUNCHING . 76

4

CONTENTS

.....................................MAINTENANCE SAFETY . 79

...........................EMERGENCY STARTER ROPE . 80

...............................MAINTENANCE SCHEDULE . 81

....................................TRIM TAB ADJUSTMENT . 83

....................................MANUAL RELIEF VALVE . 84

ENGINE COVER REMOVAL AND

..................................................INSTALLATION . 84

........................................Engine Oil Level Check . 85

................................................Engine Oil Change . 86

...................................................Oil Filter Change . 87

..............................Engine Oil Recommendations . 88

................................................Spark Plug Service . 89

.................................................Lubrication Points . 92

..............SERVICING YOUR OUTBOARD MOTOR . 78

...........THE IMPORTANCE OF MAINTENANCE . 78

...................TOOL KIT and OWNER’S MANUAL . 80

.............................................................REFUELING . 94

...............................FUEL RECOMMENDATIONS . 95

...............Water Separator Inspection and Service . 96

...............Fuel Filter Inspection and Replacement . 99

Portable Fuel Tank and Tank Filter Cleaning

.......................................(optional equipment) . 102

............................................Anode Replacement . 103

........................................Propeller Replacement . 103

..................................................................STORAGE . 105

.................................STORAGE PREPARATION . 105

........................................Cleaning and Flushing . 105

......................................................................Fuel . 107

...........................................................Engine Oil . 109

..............HOISTING THE OUTBOARD MOTOR . 109

.................................STORAGE PRECAUTIONS . 109

.............................REMOVAL FROM STORAGE . 110

5

CONTENTS

......................................................TRANSPORTING . 111

WITH OUTBOARD MOTOR

....................................INSTALLED ON BOAT . 111

WITH OUTBOARD MOTOR

................................REMOVED FROM BOAT . 111

................................ENGINE WILL NOT START . 112

HARD STARTING OR STALLS AFTER

.........................................................STARTING . 115

.........................................ENGINE OVERHEATS . 116

.....................................................................FUSES . 117

........................Electric Starter Will Not Operate . 117

.....................................Battery Will Not Charge . 117

...............................................Fuse Replacement . 117

OIL PRESSURE INDICATOR GOES OFF AND

..........................ENGINE SPEED IS LIMITED . 119

OVERHEAT INDICATOR COMES ON AND

..........................ENGINE SPEED IS LIMITED . 120

........WATER SEPARATOR BUZZER SOUNDS . 122

...................WATER SEPARATOR INDICATOR . 122

........................................SUBMERGED MOTOR . 123

..TAKING CARE OF UNEXPECTED PROBLEMS . 112

TECHNICAL AND CONSUMER

.................................................INFORMATION . 125

.............................TECHNICAL INFORMATION . 125

....................................Serial Number Locations . 125

.................................................................Battery . 126

...............Emission Control System Information . 126

............................................................Star Label . 129

......................................................Specifications . 131

.............................CONSUMER INFORMATION . 134

.............................................Honda Publications . 134

............................Customer Service Information . 134

..........................Distributor’s Limited Warranty . 137

...................Emission Control System Warranty . 141

.........................................................................INDEX . 145

6

OUTBOARD MOTOR SAFETY

IMPORTANT SAFETY INFORMATION

The Honda BF75D/BF90D outboard

motors are designed for use with

boats that have a suitable

manufacturer’s power

recommendation. Other uses can

result in injury to the operator or

damage to the outboard motor and

other property.

Most accidents can be prevented if

you follow all instructions in this

manual and on the outboard motor.

The most common hazards are

discussed in this chapter, along with

the best way to protect yourself and

others.

Operator Responsibility

It is the operator’s responsibility to

provide the necessary safeguards

to protect people and property.

Know how to stop the engine

quickly in case of emergency.

Understand the use of all controls.

Stop the engine immediately if

anyone falls overboard, and do not

run the engine while the boat is

near anyone in the water.

Always stop the engine if you

must leave the controls for any

reason.

Attach the emergency stop switch

lanyard securely to the operator.

Always wear a PFD (Personal

Flotation Device) while on the

boat.

Familiarize yourself with all laws

and regulations relating to boating

and the use of outboard motors.

Be sure that anyone who operates

the outboard motor receives proper

instruction.

Be sure the outboard motor is

properly mounted on the boat.

Do not remove the engine cover

while the engine is running.

7

OUTBOARD MOTOR SAFETY

Carbon Monoxide HazardRefuel With Care

Gasoline is extremely flammable,

and gasoline vapor can explode.

Refuel outdoors, in a wellventilated area, with the engine

stopped. Never smoke near

gasoline, and keep other flames

and sparks away.

Refuel carefully to avoid spilling

fuel. Avoid overfilling the fuel

tank.

After refueling, tighten the filler

cap securely. If any fuel is spilled,

make sure the area is dry before

starting the engine.

Exhaust gas contains poisonous

carbon monoxide. Do not inhale

exhaust gas. Never run the engine in

a closed garage or confined area.

8

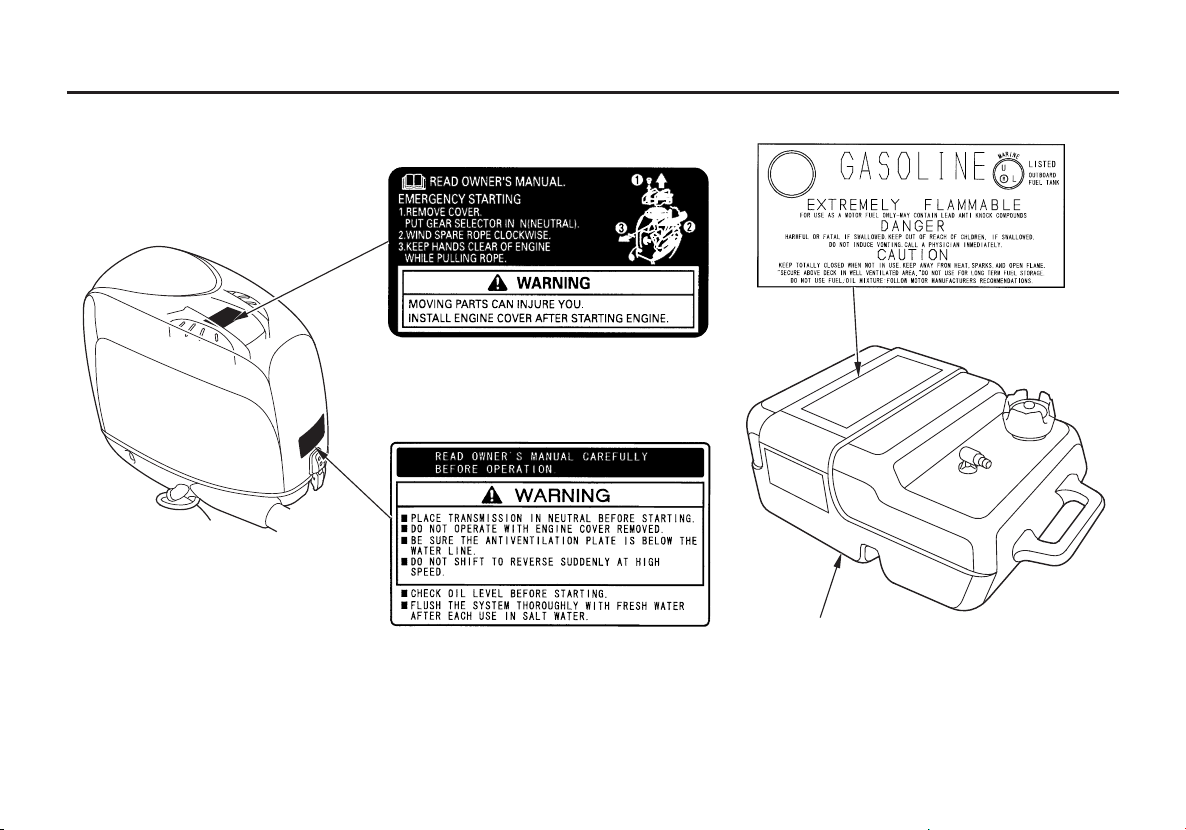

SAFETY LABEL LOCATION

OUTBOARD MOTOR SAFETY

FUEL TANK

[optional equipment (LHT type)]

The label shown here contains important safety information. Please read it carefully. This label is considered a

permanent part of your outboard motor. If the label comes off or becomes hard to read, contact an authorized Honda

Marine dealer for a replacement.

9

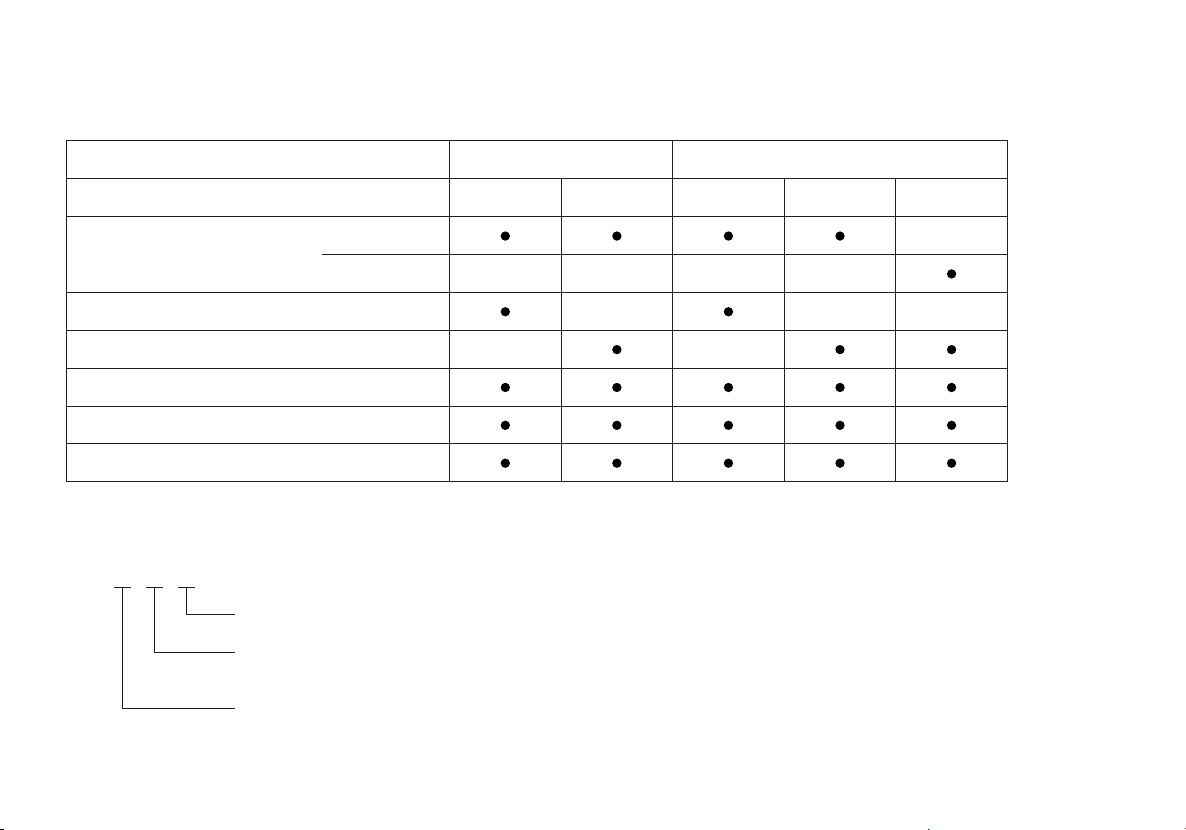

CONTROLS AND FEATURES

CONTROL AND FEATURE IDENTIFICATION CODES

Model BF75D BF90D

Type

Transom Height

(Shaft Length)

Tiller Handle

Remote Control

Power Trim/Tilt

Trim Meter (optional equipment)

Tachometer (optional equipment)

Refer to this chart for an explanation of the Type Codes used in this manual to identify control and feature applications.

TYPE CODE (example)

LRT

Tilt System

T = Power Trim/Tilt

Control System

H = Tiller Handle

R = Remote Control

Transom Height (Shaft Length)

L = 21.1 in (537 mm)

X = 26.1 in (664 mm)

21.1 in (537 mm)

26.1 in (664 mm)

LHT LHT XRTLRT LRT

10

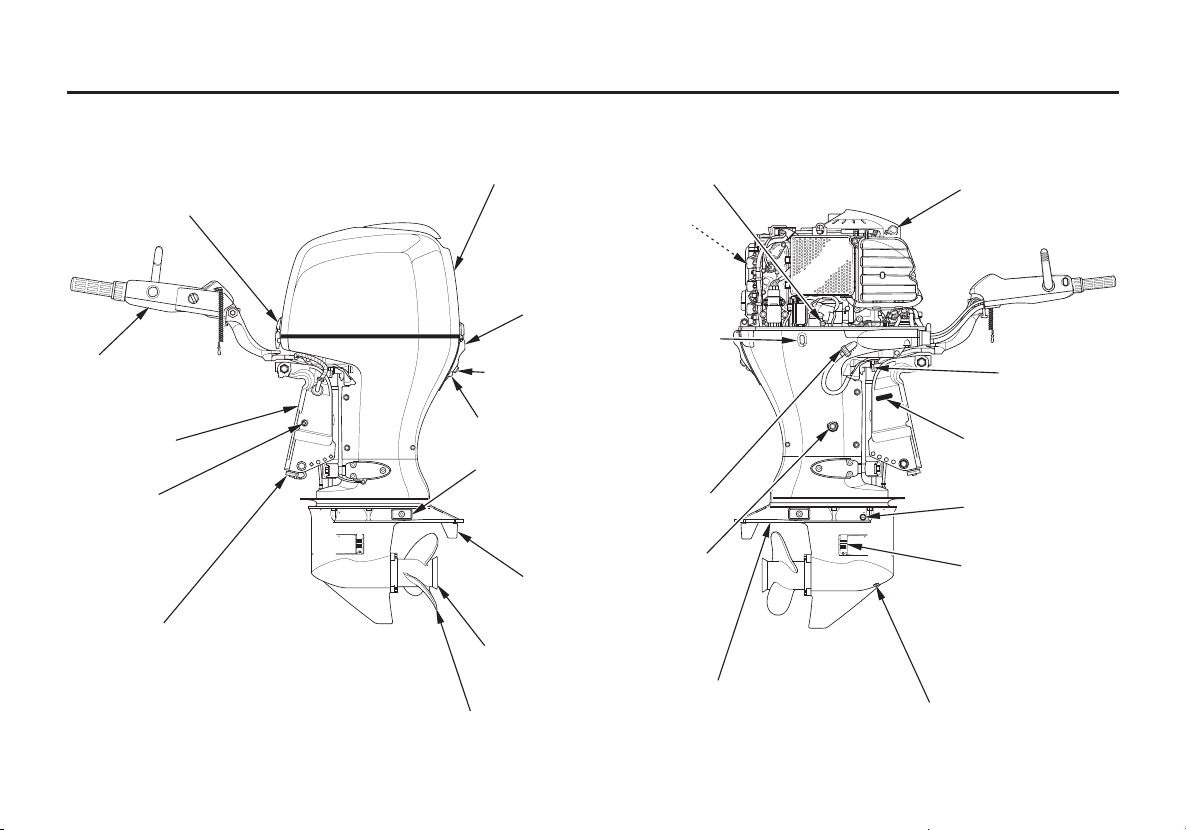

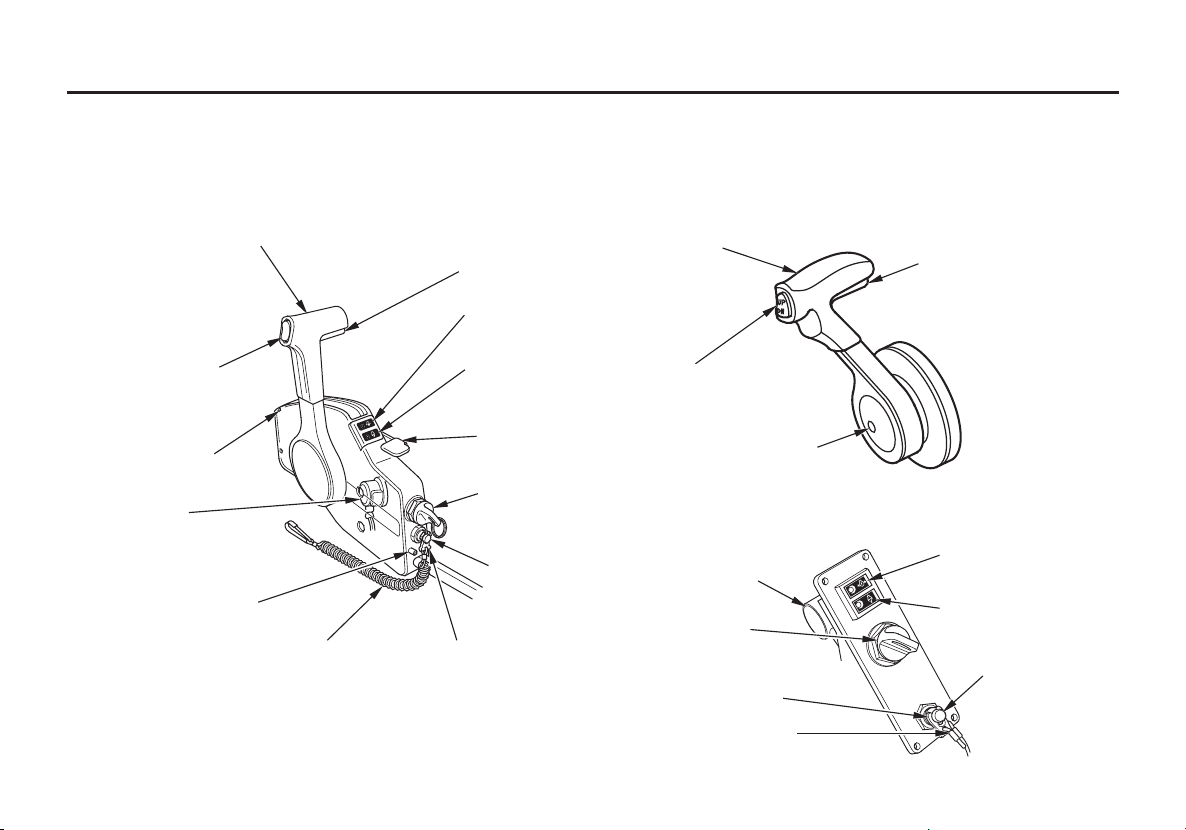

COMPONENT AND CONTROL LOCATIONS

LHT Type (tiller handle)

ENGINE COVER

ENGINE COVER

LATCH (front)

ENGINE COVER

LATCH (rear)

TILLER

HANDLE

STERN

BRACKET

MANUAL

RELIEF VALVE

ANODE

IDLE PORT

COOLING SYSTEM

INDICATOR

ANODE

(each side)

TRIM TAB

EXHAUST PORT/WATER

OUTLET PORT

PROPELLER

(optional equipment)

OIL LEVEL DIPSTICK

SPARK PLUG

(under coil)

POWER TILT

SWITCH

FLUSH PORT

CONNECTOR

ENGINE OIL

DRAIN BOLT

ANTIVENTILATION

PLATE

CONTROLS AND FEATURES

OIL FILLER CAP

TILT LOCK

LEVER

PRODUCT

IDENTIFICATION

NUMBER

GEAR OIL

LEVEL SCREW

COOLING WATER

INTAKE PORT

(each side)

GEAR OIL DRAIN SCREW

11

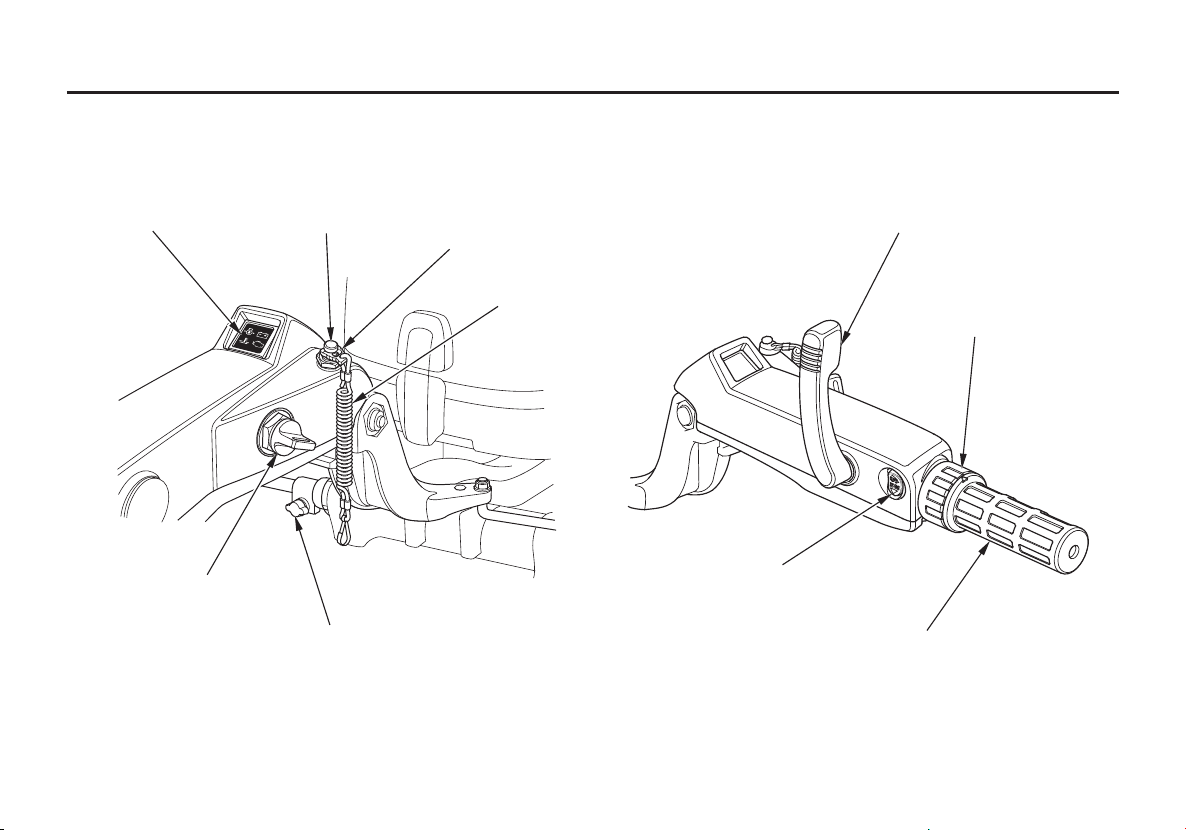

CONTROLS AND FEATURES

INDICATORS

(Oil pressure, Overheat,

Alternator, PGM-FI)

EMERGENCY STOP

SWITCH

GEARSHIFT LEVER

EMERGENCY STOP

SWITCH CLIP

IGNITION SWITCH

12

STEERING FRICTION

KNOB

EMERGENCY STOP

SWITCH LANYARD

THROTTLE FRICTION

ADJUSTER

POWER TRIM/TILT

SWITCH

THROTTLE GRIP

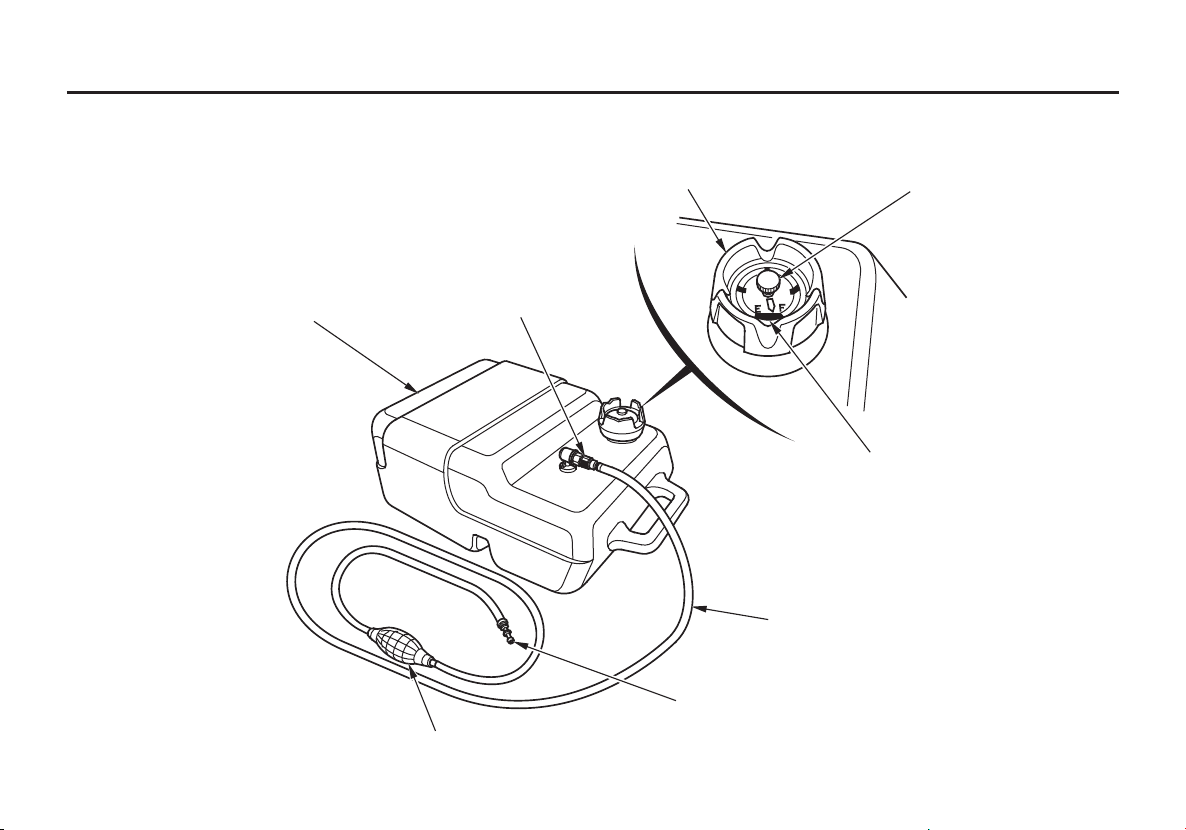

Portable Fuel Tank and Fuel Tank Hose Assembly

(optional equipment)

CONTROLS AND FEATURES

FUEL TANK

FUEL HOSE

CONNECTOR

FUEL PRIMING BULB

FUEL FILLER CAP

FUEL HOSE JOINT

(motor side)

VENT KNOB

FUEL GAUGE

FUEL TANK HOSE

ASSEMBLY

13

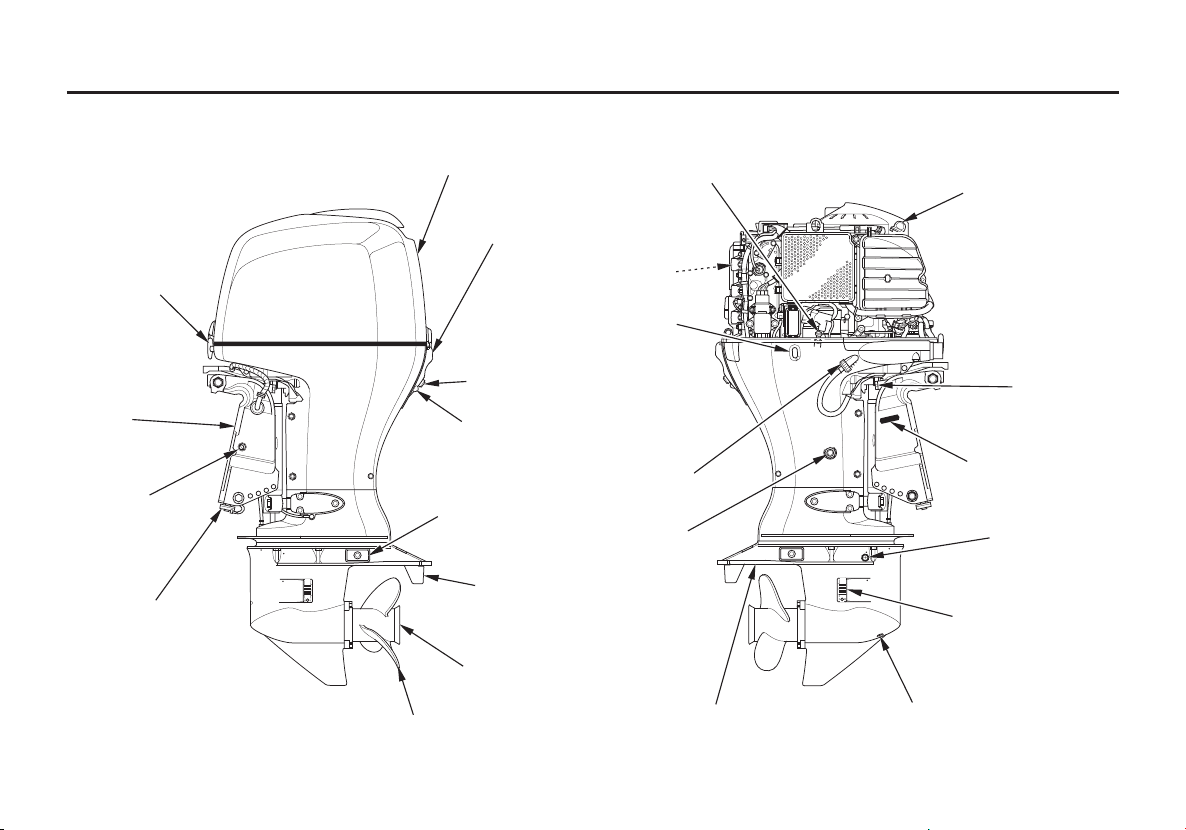

CONTROLS AND FEATURES

LRT and XRT Types (remote control)

ENGINE COVER

LATCH (front)

STERN

BRACKET

MANUAL

RELIEF VALVE

ANODE

ENGINE COVER

ENGINE COVER

LATCH (rear)

IDLE PORT

COOLING SYSTEM

INDICATOR

ANODE

(each side)

TRIM TAB

EXHAUST PORT/WATER

OUTLET PORT

PROPELLER

(optional equipment)

OIL LEVEL DIPSTICK

SPARK PLUG

(under coil)

POWER TILT

SWITCH

FLUSH PORT

CONNECTOR

ENGINE OIL

DRAIN BOLT

ANTIVENTILATION

PLATE

OIL FILLER CAP

TILT LOCK

LEVER

PRODUCT

IDENTIFICATION

NUMBER

GEAR OIL

LEVEL SCREW

COOLING WATER

INTAKE PORT

(each side)

GEAR OIL DRAIN SCREW

14

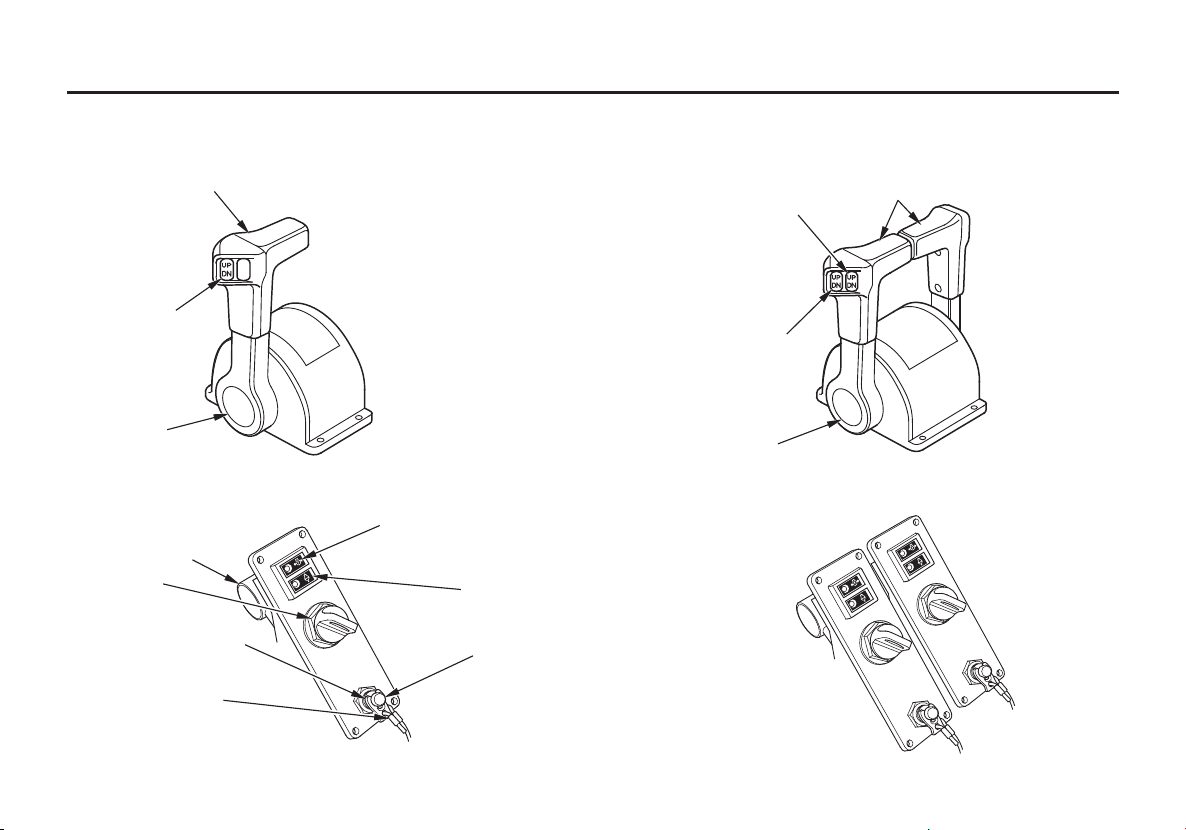

Remote Controls (optional equipment)

CONTROLS AND FEATURES

(SIDE-MOUNT REMOTE CONTROL)

GEARSHIFT/THROTTLE

CONTROL LEVER

POWER TRIM/TILT

SWITCH

SPARE SWITCH

CLIP

BUZZER

(inside)

CONTROL LEVER

FRICTION ADJUSTER

LANYARD

NEUTRAL RELEASE

LEVER

OIL PRESSURE

INDICATOR

OVERHEAT

INDICATOR

FAST IDLE

LEVER

IGNITION

SWITCH

EMERGENCY

STOP SWITCH

SWITCH CLIP

(PANEL-MOUNT REMOTE CONTROL)

GEARSHIFT/THROTTLE

CONTROL LEVER

NEUTRAL RELEASE

LEVER

POWER TRIM/TILT

SWITCH

FAST IDLE BUTTON

CONTROL PANEL

(for PANEL-MOUNT type)

BUZZER

IGNITION

SWITCH

EMERGENCY STOP

SWITCH CLIP

LANYARD

OIL PRESSURE

INDICATOR

OVERHEAT

INDICATOR

EMERGENCY

STOP SWITCH

15

CONTROLS AND FEATURES

(SINGLE TOP-MOUNT REMOTE CONTROL) (DUAL TOP-MOUNT REMOTE CONTROL)

GEARSHIFT/THROTTLE

CONTROL LEVER

POWER

TRIM/TILT

SWITCH

FAST IDLE

BUTTON

CONTROL PANEL

(for TOP-MOUNT SINGLE type)

BUZZER

IGNITION

SWITCH

EMERGENCY STOP

SWITCH CLIP

LANYARD

GEARSHIFT/THROTTLE

CONTROL LEVERS

POWER TRIM/TILT

SWITCH (RIGHT)

POWER TRIM/TILT

SWITCH (LEFT)

FAST IDLE

BUTTON

(for TOP-MOUNT DUAL type)

OIL PRESSURE

INDICATOR

OVERHEAT

INDICATOR

EMERGENCY

STOP SWITCH

16

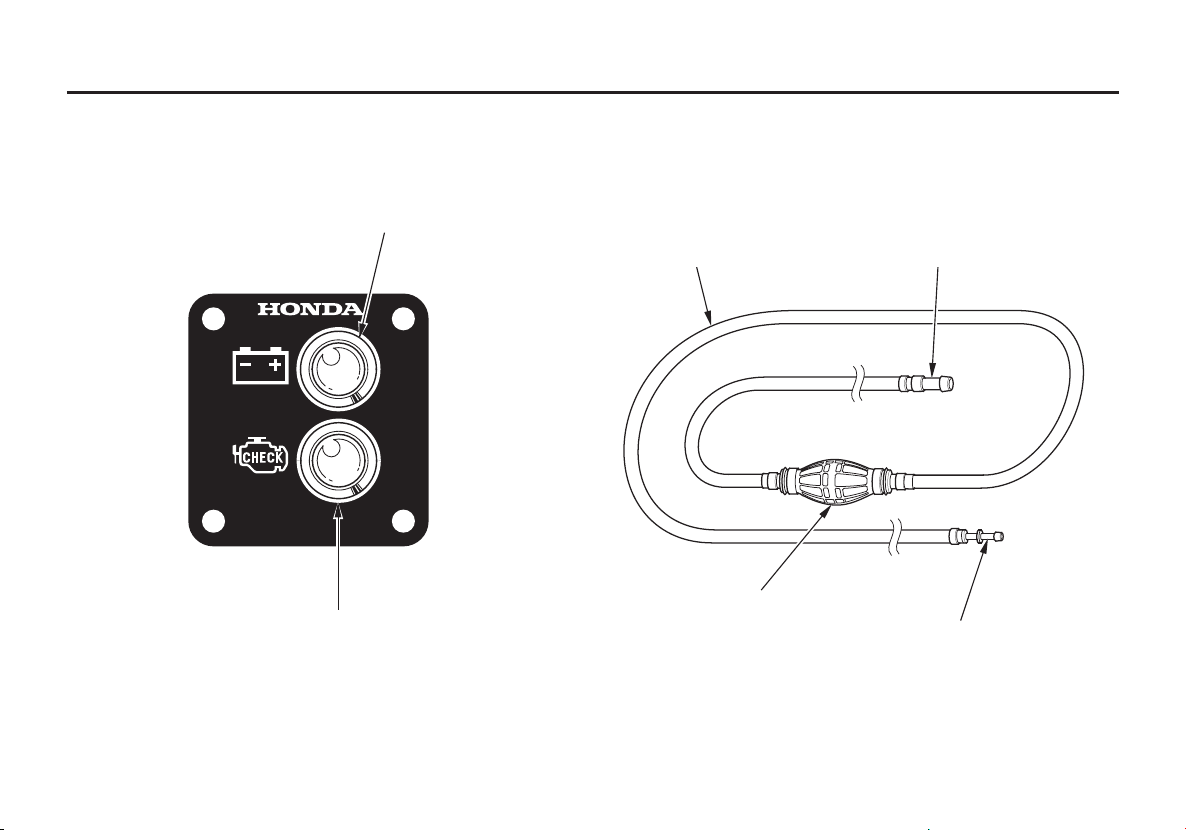

CONTROLS AND FEATURES

Indicator Panel (standard equipment)

PROGRAMMED FUEL

INJECTION (PGM-FI)

INDICATOR

ALTERNATOR (ACG)

INDICATOR

Fuel Hose Assembly (optional equipment)

FUEL HOSE

ASSEMBLY

FUEL PRIMING BULB

FUEL HOSE JOINT

(fuel tank side)

FUEL HOSE JOINT

(motor side)

17

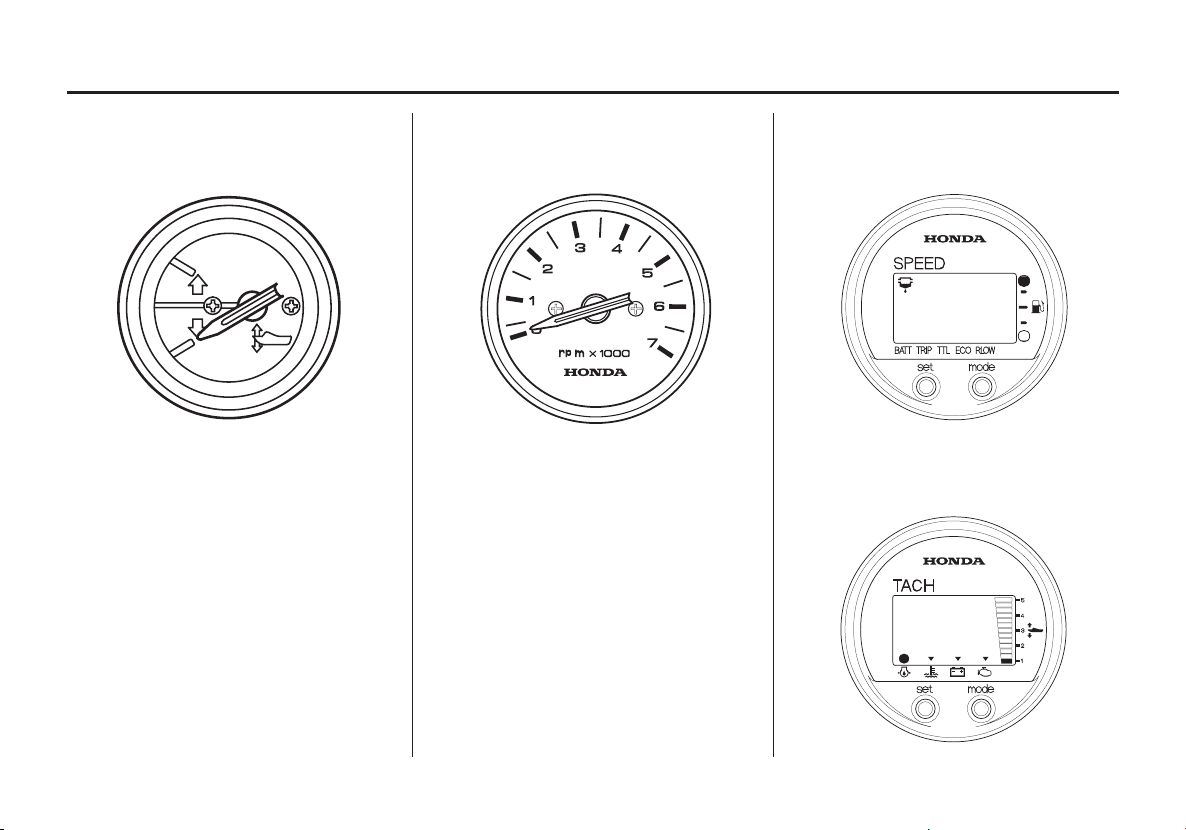

CONTROLS AND FEATURES

Trim Meter (optional equipment)

Tachometer (optional equipment)

Digital Speedometer (optional equipment)

Digital Tachometer (optional equipment)

18

CONTROLS AND FEATURES

CONTROLS

LHT Type (tiller handle)

Ignition Switch

OONN

OOFFFF

IGNITION SWITCH

The ignition switch controls the

ignition system and the starter motor.

START

Turning the ignition switch key to the

START position operates the starter

motor. The key automatically returns

to the ON position when released

from the START position.

The engine will not start unless the

gearshift lever is in the N (neutral)

position (p. ) and the emergency

52

stop switch clip is in the emergency

stop switch.

Turning the ignition switch to the

OFF position stops the engine.

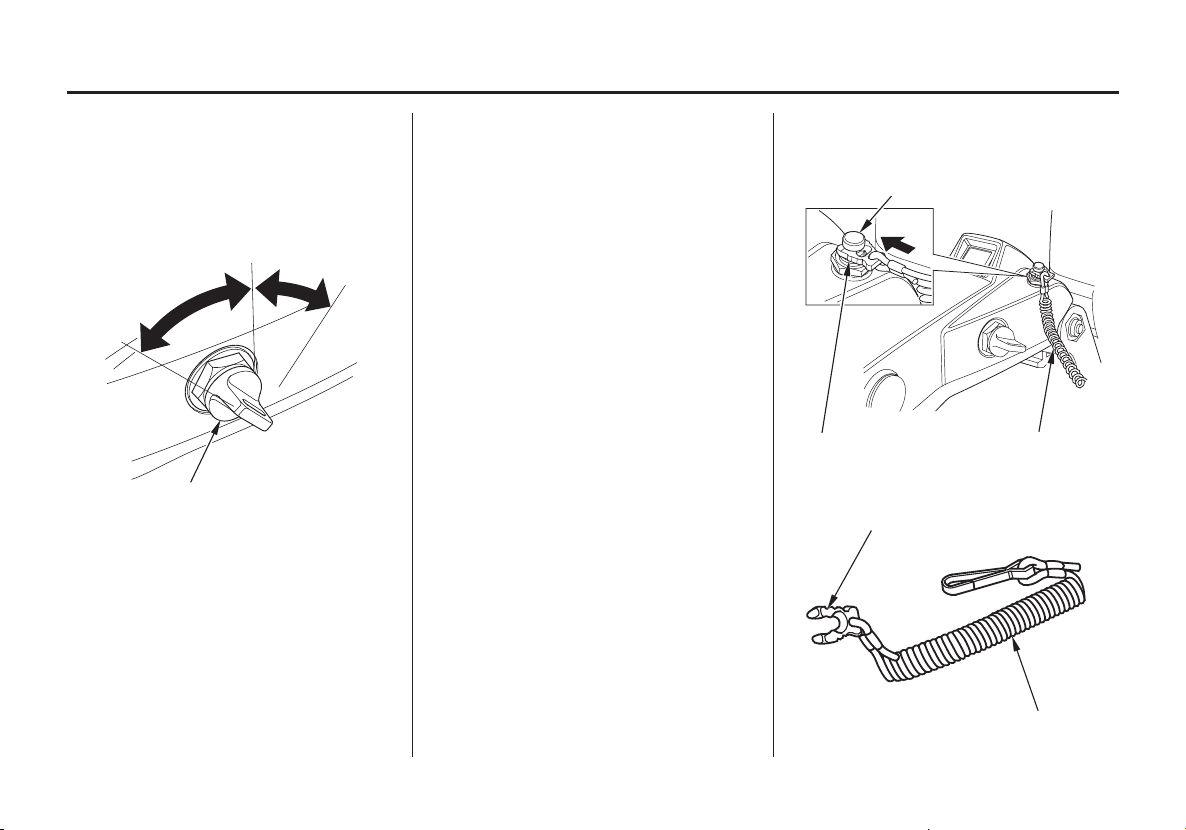

Emergency Stop Switch Clip and

Emergency Stop Switch

EMERGENCY STOP SWITCH

EMERGENCY STOP

SWITCH CLIP

EMERGENCY STOP SWITCH CLIP

LANYARD

LANYARD

19

CONTROLS AND FEATURES

The emergency stop switch clip must

be inserted in the emergency stop

switch in order for the engine to start

and run. The emergency stop switch

lanyard must be attached securely to

the operator or to the operator’s PFD

(Personal Flotation Device).

When used as described, the

emergencystopswitchand

emergency stop switch lanyard

system stops the engine if the

operator falls away from the controls.

A spare switch clip is provided in the

tool bag (p. ).

80

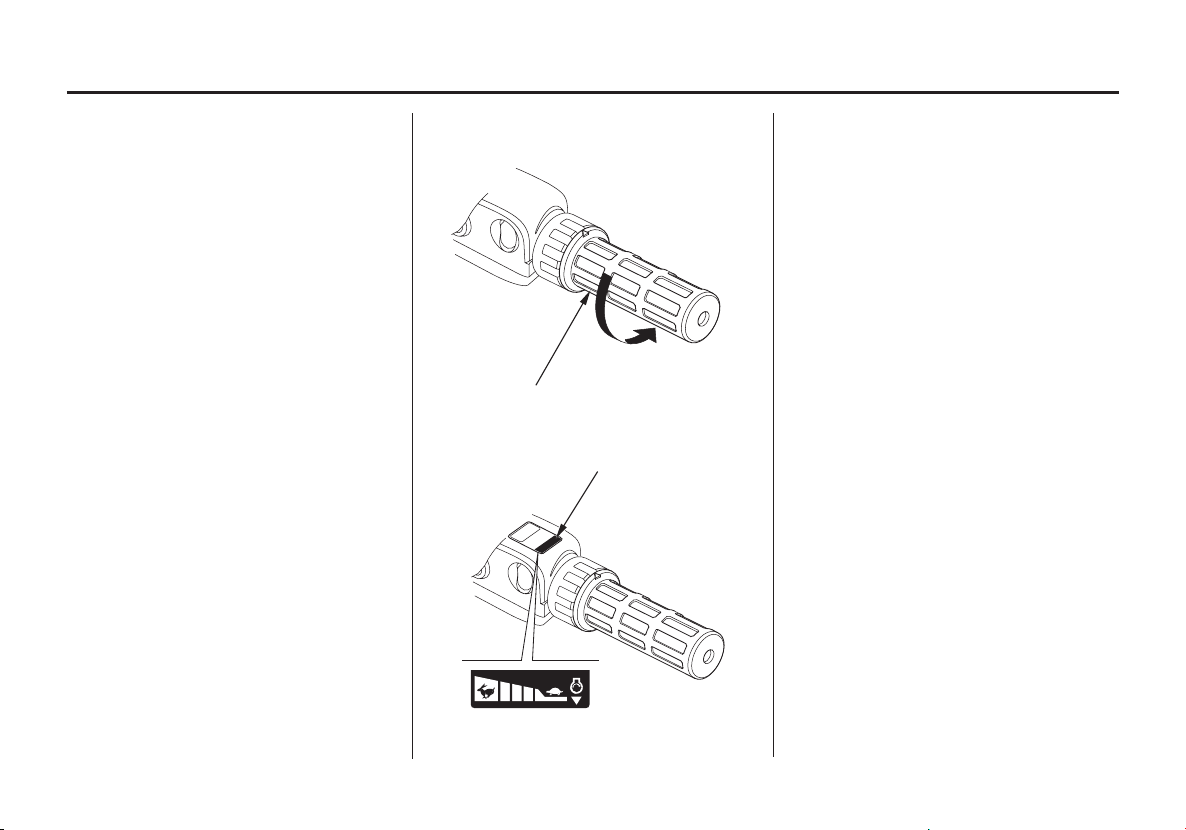

Throttle Grip

THROTTLE GRIP

THROTTLE INDEX MARK

INCREASE

The throttle grip controls engine

speed.

An index mark on the tiller arm

shows throttle position and is helpful

for setting the throttle correctly when

starting (p. ).

69

20

CONTROLS AND FEATURES

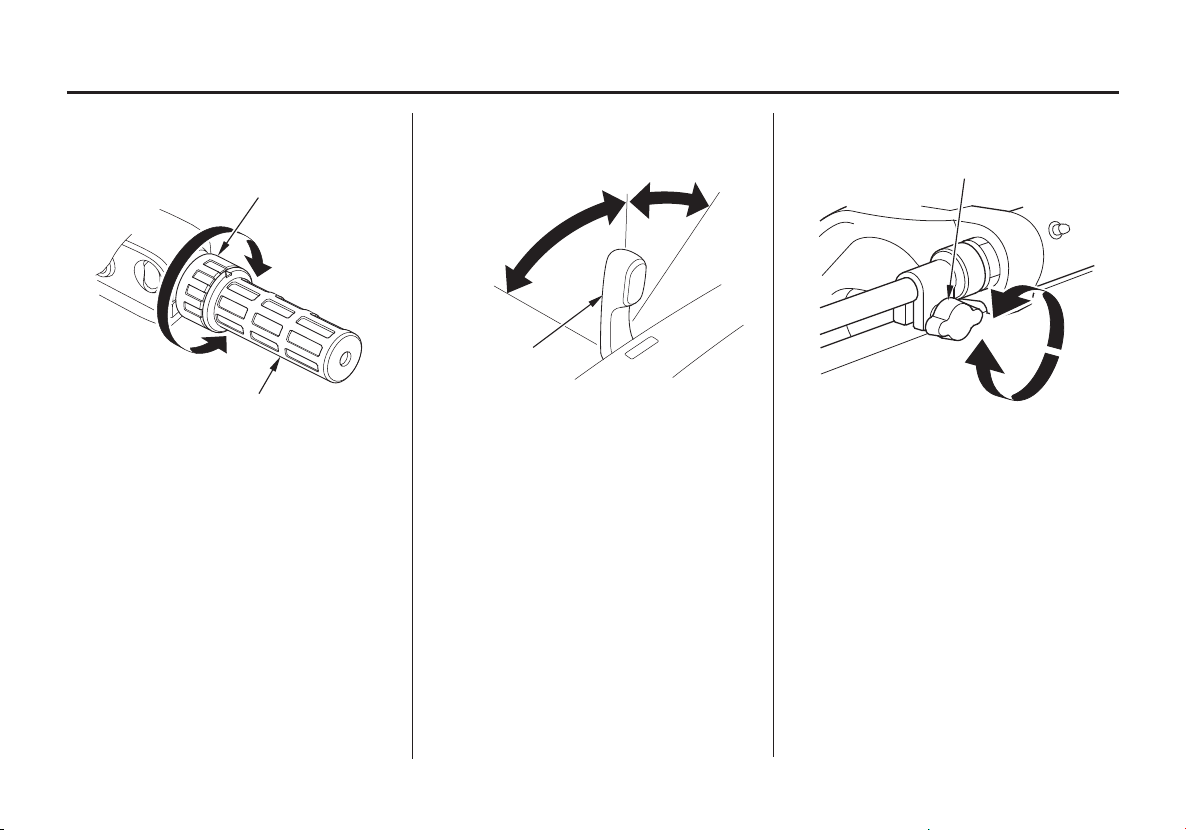

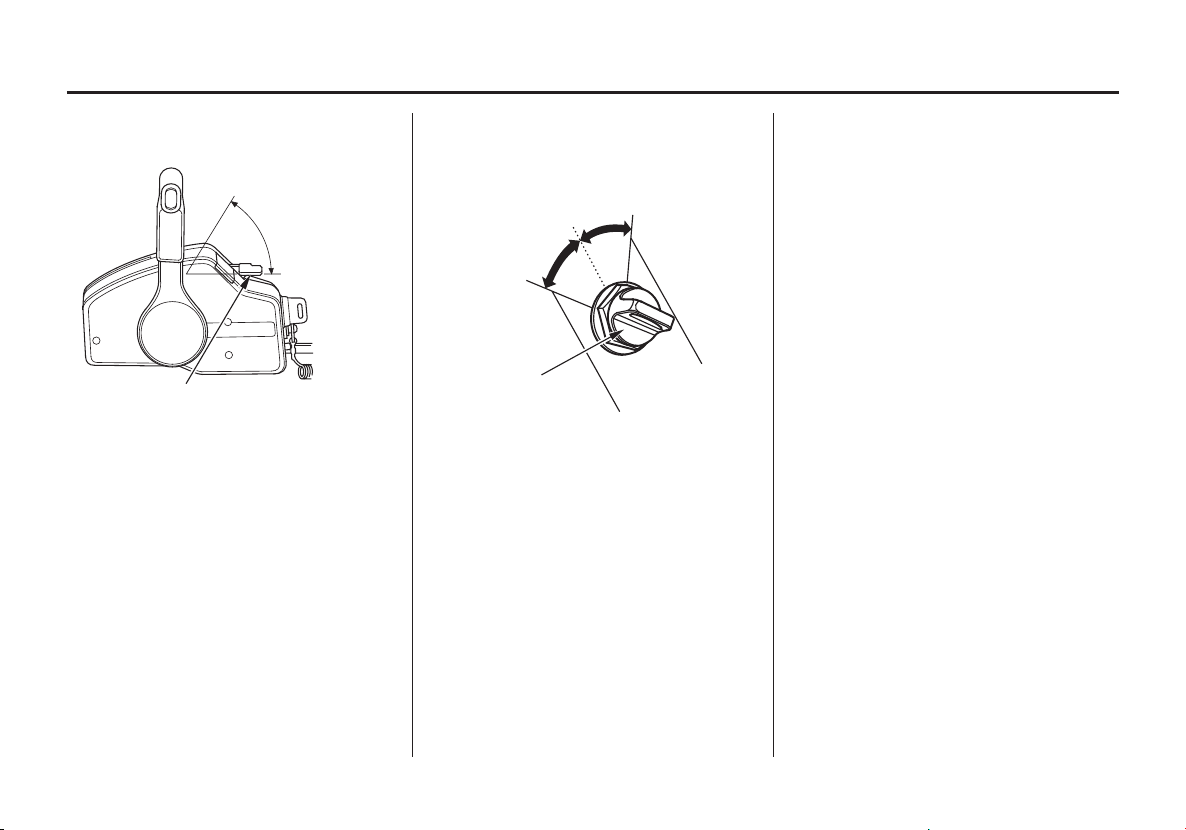

Gearshif t LeverThrottle Friction Adjuster Steering Friction Knob

THROTTLE FRICTION ADJUSTER

FIX

RELEASE

THROTTLE GRIP

The throttle friction adjuster adjusts

resistance to throttle grip rotation.

Turn the adjuster clockwise to

increase friction for holding a throttle

setting while cruising.

Turn the adjuster counterclockwise to

decrease friction for easy throttle grip

rotation.

N (neutral)

F

(forward)

GEARSHIFT LEVER

R (reverse)

The gearshift lever is used to select F

(forward), N (neutral), or R (reverse)

gears.

The engine can be started with the

gearshift lever in the N (neutral)

position only.

STEERING FRICTION KNOB

RREELLEEAASSEE

FIX

The steering friction adjuster adjusts

steering resistance.

Less friction allows the outboard

motor to turn more easily. More

friction helps to hold a steady course

while cruising or to prevent the

outboard motor from swinging while

trailering the boat.

21

CONTROLS AND FEATURES

LRT and XRT Types (remote control)

Side-Mount Type

Ignition Switch

OONN

OOFFFF

IGNITION

SWITCH

The ignition switch controls the

ignition system and the starter motor.

START

Turning the ignition switch key to the

START position operates the starter

motor. The key automatically returns

to the ON position when released

from the START position.

The ignition switch can be used to

start the engine only when the control

lever is in the N (neutral) position (p.

) and the emergency stop switch

55

clip is in the emergency stop switch.

Turning the ignition switch to the

OFF position stops the engine.

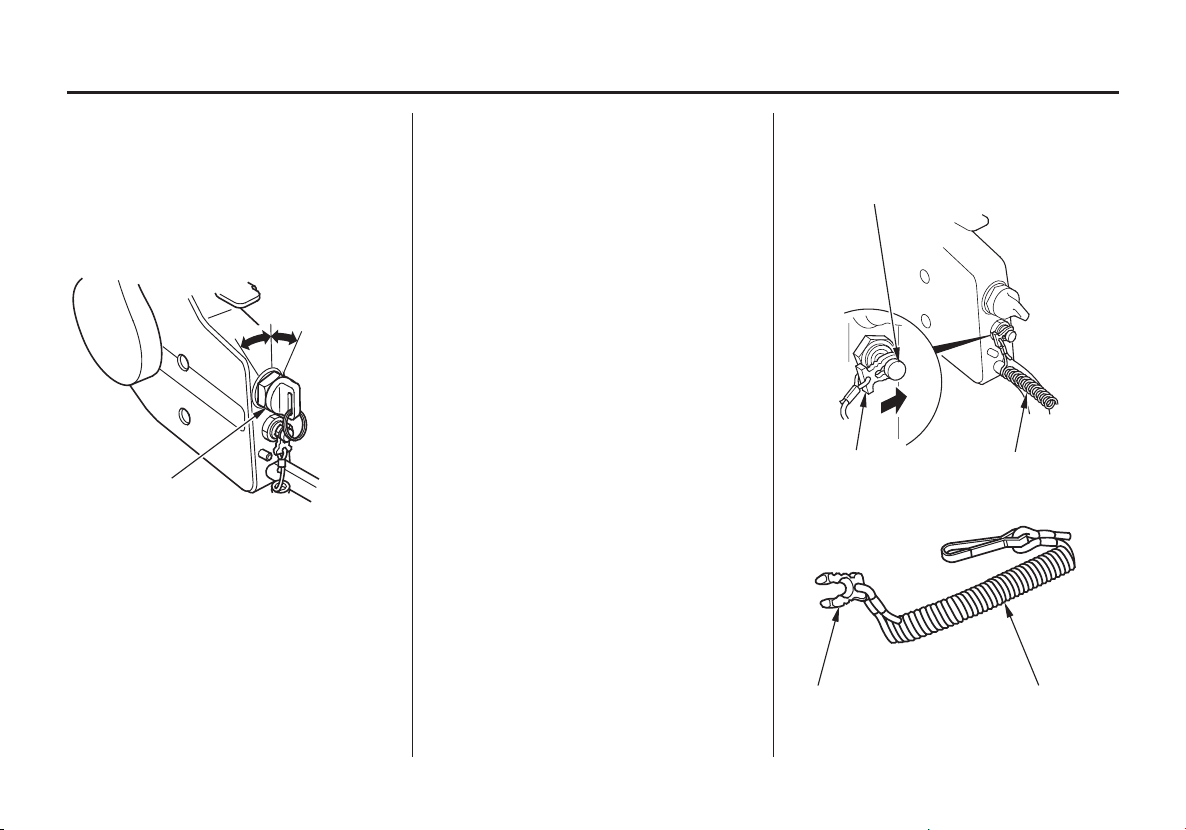

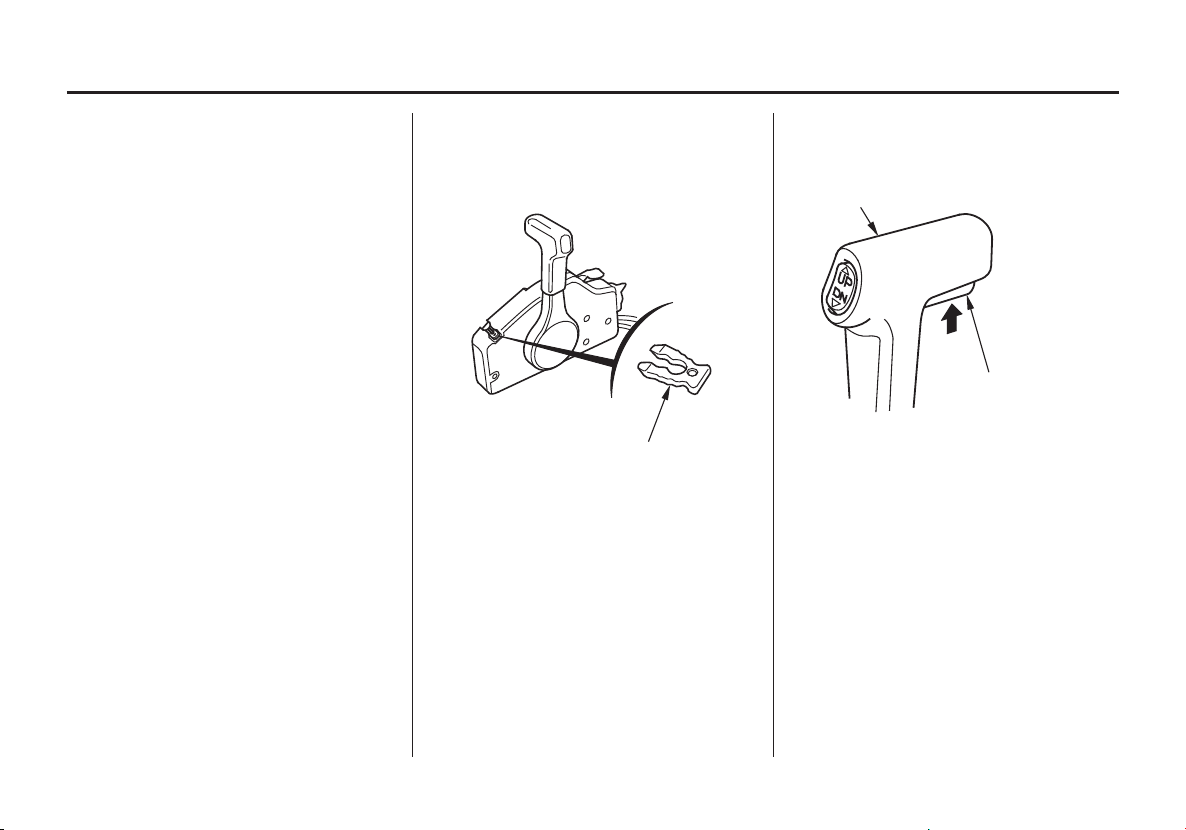

Emergency Stop Switch Clip and

Emergency Stop Switch

EMERGENCY STOP SWITCH

EMERGENCY STOP

SWITCH CLIP

EMERGENCY STOP

SWITCH CLIP

LANYARD

LANYARD

22

CONTROLS AND FEATURES

The emergency stop switch clip must

be inserted in the emergency stop

switch in order for the engine to start

and run. The emergency stop switch

lanyard must be attached to the

operator’s PFD (Personal Flotation

Device) or to the operator securely.

When used as described, the

emergency stop switch clip and

emergency stop switch lanyard

system stops the engine if the

operator falls away from the controls.

A spare switch clip is stored in a slot

in the control housing and is

provided in the tool bag (p. ).

SPARE SWITCH CLIP

80

Gearshift/Throttle Control Lever

GEARSHIFT/THROTTLE

CONTROL LEVER

NEUTRAL RELEASE

LEVER

The gearshift/throttle control lever

controls engine speed and selects F

(forward), N (neutral), or R (reverse)

gears.

23

CONTROLS AND FEATURES

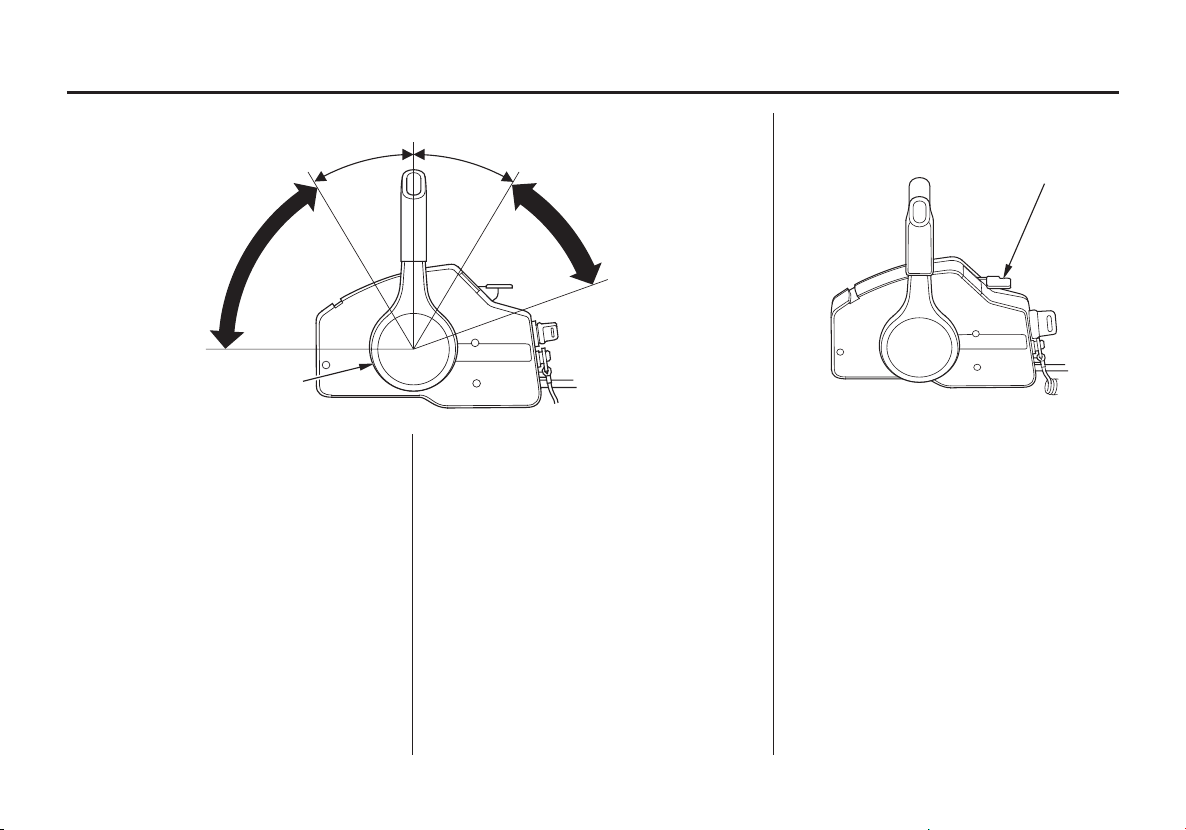

N (NEUTRAL)

F (FORWARD)

TTHHRROOTTTTLLEE OOPPEENNIINNGG

MAXIMUM

GEARSHIFT/THROTTLE

CONTROL LEVER

30°

SHIFT

MMIINNIIMMUUMM

Moving the control lever 30° from N

(neutral) selects the gear, and further

movement increases engine speed.

The control lever automatically locks

itself in the N (neutral) position. To

move the lever out of the N (neutral)

position, you must squeeze the

neutral release lever on the underside

of the lever handle.

30°

R (REVERSE)

SHIFT

MMIINNIIMMUUMM

TTHHRROOTTTTLLEE OOPPEENNIINNGG

MAXIMUM

A friction adjuster near the base of

the control lever(s) adjusts the

operating resistance of the control

lever(s). Refer to p. .

71

Less friction allows easier control

lever movement. More friction helps

to hold a steady throttle setting while

cruising.

Fast Idle Lever

FAST IDLE LEVER

Use the fast idle lever to accelerate

engine warm-up after starting the

engine. Do not use the fast idle lever

when starting the engine.

See page for engine warm-up

instructions.

57

24

CONTROLS AND FEATURES

N (neutral)

MAXIMUM FAST IDLE

LOWEST

POSITION

FAST IDLE LEVER

The fast idle lever allows you to

increase the idle speed only when the

control lever is in the N (neutral)

position. Place the fast idle lever in

its lowest position to cancel the f ast

idle and return the control lever to

normal operation.

Panel-Mount Type

Ignition Switch

ON

OFF

IGNITION

SWITCH

The ignition switch controls the

ignition system and the starter motor.

START

Turning the ignition switch key to the

START position operates the starter

motor. The key automatically returns

to the ON position when released

from the START position.

The ignition switch can be used to

start the engine only when the control

lever is in the N (neutral) position (p.

) and the emergency stop switch

58

clip is in the emergency stop switch.

Turning the ignition switch to the

OFF position stops the engine.

25

CONTROLS AND FEATURES

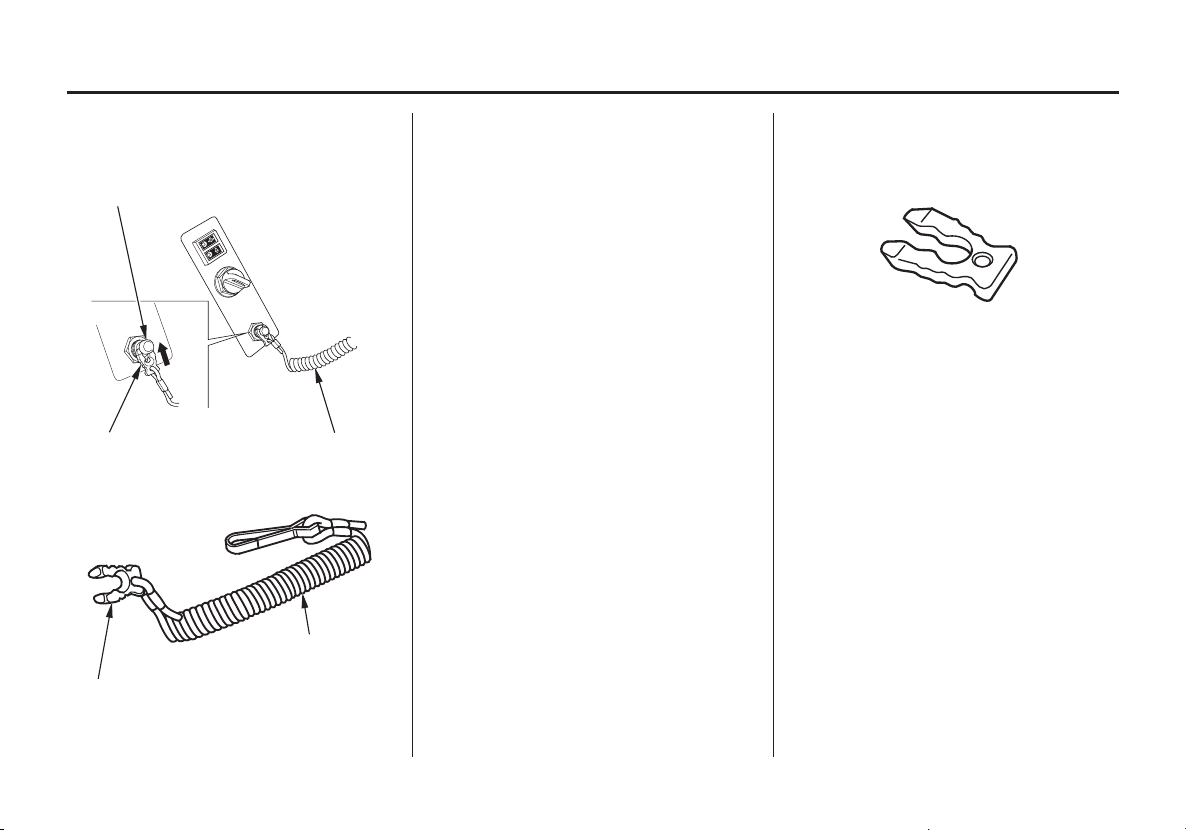

Emergency Stop Switch Clip and

Emergency Stop Switch

EMERGENCY STOP SWITCH

EMERGENCY STOP

SWITCH CLIP

EMERGENCY STOP

SWITCH CLIP

LANYARD

LANYARD

The emergency stop switch clip must

be inserted in the emergency stop

switch in order for the engine to start

and run. The emergency stop switch

lanyard must be attached securely to

the operator or to the operator’s PFD

(Personal Flotation Device).

When used as described, the

emergency stop switch clip and

emergency stop switch lanyard

system stops the engine if the

operator falls away from the controls.

A spare switch clip is provided in the

tool bag (p. ).

80

SPARE SWITCH CLIP

26

CONTROLS AND FEATURES

Gearshift/Throttle Control Lever

GEARSHIFT/THROTTLE

CONTROL LEVER

TTHHRROOTTTTLLEE OOPPEENNIINNGG

NEUTRAL

RELEASE

LEVER

The gearshift/throttle control lever

controls engine speed and selects F

(forward), N (neutral), or R (reverse)

MAXIMUM

Moving the control lever 35° from N

(neutral) selects the gear, and further

movement increases engine speed.

gears. 71

F (FORWARD)

MMIINNIIMMUUMM

N (NEUTRAL)

35°

SHIFT

35°

SHIFT

MMIINNIIMMUUMM

A friction adjuster near the base of

the control lever adjusts the operating

resistance of the control lever. Refer

to p. .

The control lever automatically locks

itself in the N (neutral) position. To

move the lever out of the N (neutral)

position, you must squeeze the

neutral release lever on the underside

Less friction allows easier control

lever movement. More friction helps

to hold a steady throttle setting while

cruising.

of the lever handle.

R (REVERSE)

TTHHRROOTTTTLLEE OOPPEENNIINNGG

MAXIMUM

GEARSHIFT/THROTTLE

CONTROL LEVER

27

CONTROLS AND FEATURES

Fast Idle Button

FAST IDLE BUTTON

Use the fast idle button to accelerate

engine warm-up after starting the

engine. Do not use the fast idle

button when starting the engine.

See page for engine warm-up

instructions.

59

F(forward)

CONTROL

LEVER

N (neutral)

PPuullll uupp

Push

FAST IDLE BUTTON

R (reverse)

NEUTRAL

RELEASE

LEVER

The fast idle button allows you to

increase the idle speed without

engaging the drive gears. Move the

control lever forward or reverse after

pushing in the fast idle button to

increase the idle speed.

It is necessary to position the control

leverinN(neutral)topushinthefast

idle button.

Return the control lever to N position

to cancel the fast idle operation.

28

Loading...

Loading...