Honda Power Equipment BF75A, BF90A User Manual

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

Thank you for purchasing a Honda

Outboard Motor.

This manual describes the operation

and maintenance of the Honda

BF 75A and BF 90A Outboard

Motors.

All information in this publication is

based on the latest product information available at the time of printing.

Honda Motor Co., Ltd. reserves the

right to make changes at any time

without notice and without incurring

any obligation.

No part of this publication may be

reproduced without written

permission.

This manual should

permanent part of the Outboard

and it must stay with the Outboard

Motor if resold.

be considered a

Motor

SAFETY MESSAGES

Your safety and the safety of others is

very important. We have provided

important safety messages in this

manual and on the outboard motor.

Please read these messages carefully.

A safety message alerts you to poten-

tial hazards that can hurt you and

others. Each safety message is preceded

by a safety alert symbol A and one of

three words: DANGER, WARNING,

or CAUTION.

These mean:

m You WILL be

KILLED or SERIOUSLY HURT

if you don’t follow instructions.

B You CAN be

KILLED or SERIOUSLY HURT

if you don’t follow instructions.

pxfl You CAN be HURT

if you don’t follow instructions.

Each message tells you what the

hazard is, what can happen, and what

can happen, and what you can do to

avoid or reduce injury.

DAMAGE PREVENTION

MESSAGES

You will also see other important

messages that are preceded by the

word NOTICE.’

This word means:

NOTICE ] Your outboard motor

or other property can be damaged

if you don’t follow instructions.

The purpose of these messages is to

help prevent damage to your outboard

motor, other property, or the

environment.

“-

HONDA MOTOR CO., LTD. 1995

ALL RIGHTS RESERVED

1

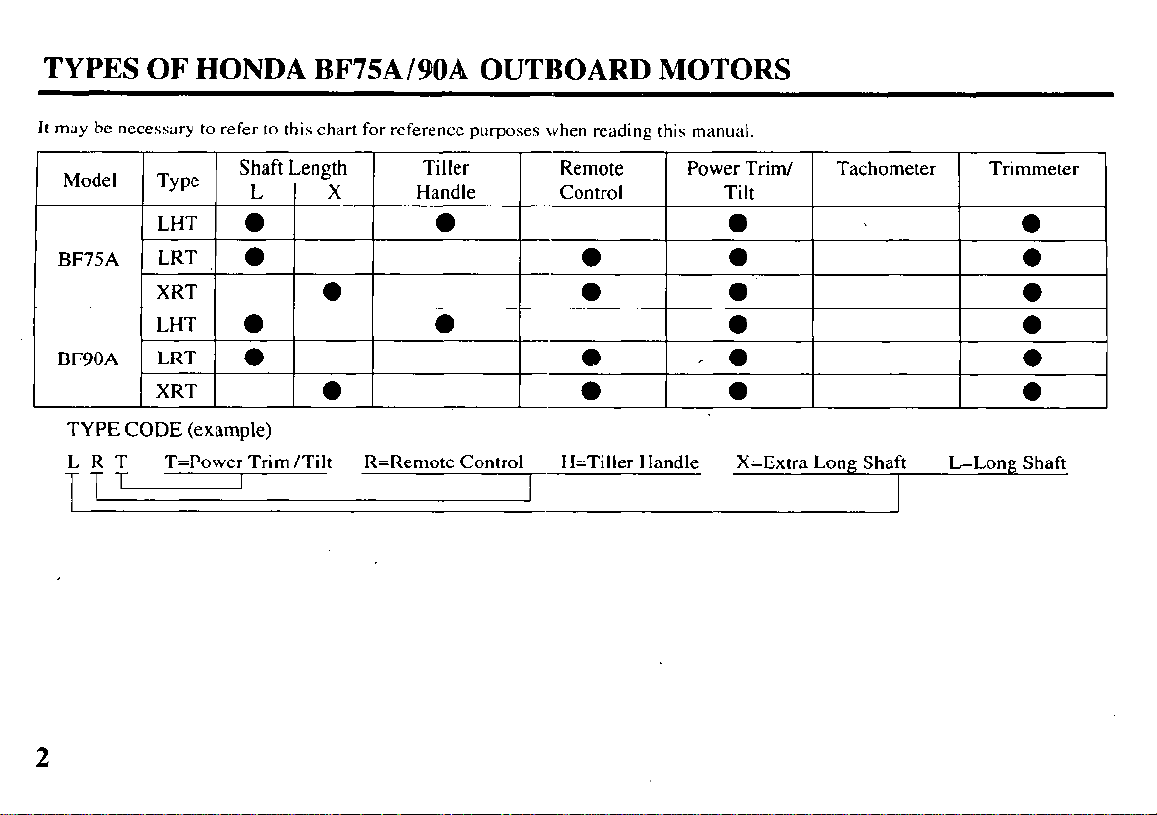

TYPES OF HONDA BF75A/90A OUTBOARD MOTORS

It may bc necessary to refer to this chart for reference purposes when reading this manual.

TYPE CODE (example)

LRT T=Power Trim /Tilt

Remote

Control Tilt

0 0 0

0 a 0

a ro 0

0 0 0

Power Trim/

R=Remote Control H=Tiller Handle

Tachometer Trimmeter

0 0

0 0

X=Extra Long Shaft L=Long Shaft

2

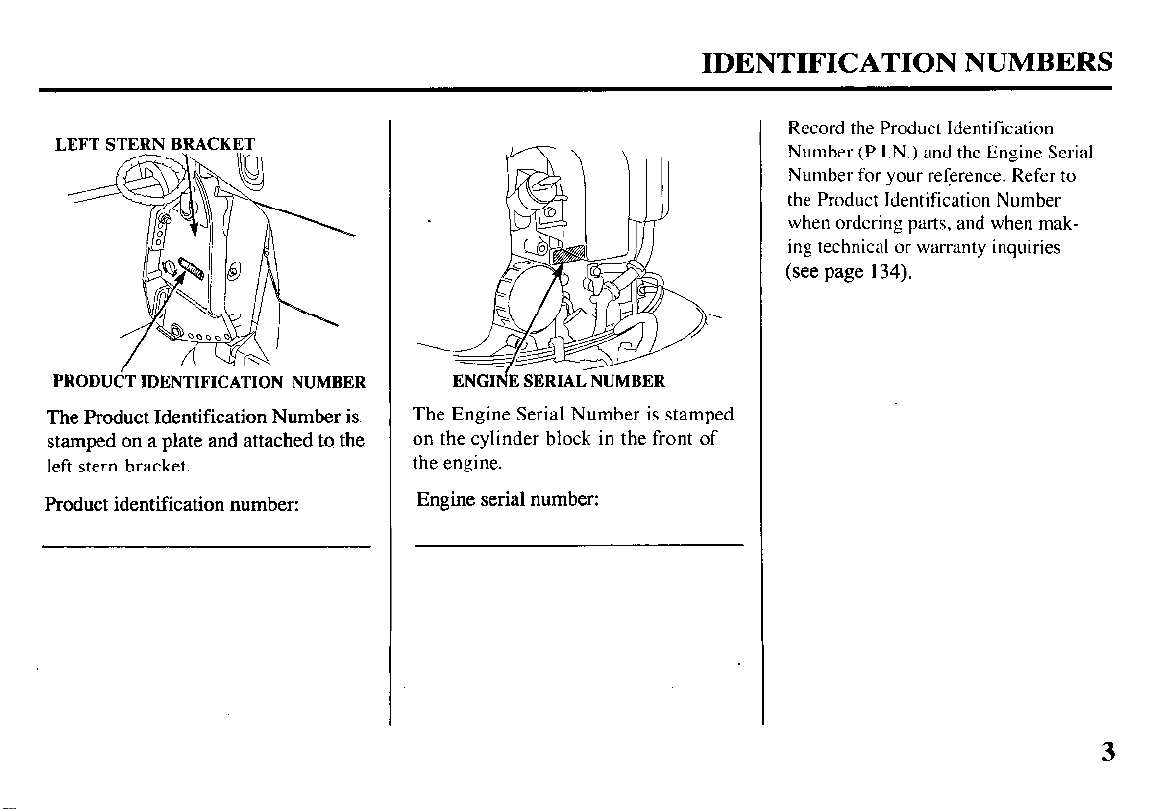

IDENTIFICATION NUMBERS

LEFT STERN BRACKET

PRODUdT IDENTIFICATION NUMBER

The Product Identification Number is.

stamped on a plate and attached to the

left stern bracket.

Product identification number:

Record the Product Identification

Number (P.I.N.) and the Engine Serial

Number for your reference. Refer to

the Product Identification Number

when ordering parts, and when mak-

ing technical or warranty inquiries

(see page 134).

ENGINE SERIAL NUMBER

The Engine Serial Number is stamped

on the cylinder block in the front of

the engine.

Engine serial number:

3

CONTENTS

I. SAFETY

SAFETY LABELS

SAFETY INFORMATION..

.....................

...... 7

2. COMPONENT IDENTIFICATION

3. CONTROLS & INSTRUMENTS

TILLER HANDLE TYPE

Ignition Switch

Gear Shift Lever

........................... I4

......................... 14

Choke Knob.. ..............................

Throttle Grip..

Throttle Opening Indicator..

Throttle Friction Knob

Engine Stop Switch

............................. I5

....... 15

............... 15

.................... 16

Emergency Stop Switch Lanyard . .

Oil Pressure Indicator Light..

Overheat Indicator Light

Power Trim/Tilt Switch..

Steering Friction Adjuster

..... 17

............ I7

............ 18

.......... 18

REMOTE CONTROL TYPE

(SIDE-MOUNT TYPE)

Remote Control Lever ................

Neutral Release Lever

Ignition Switch

................ 20

........................... 20

Emergency Stop Switch Lanyard . .

Choke/Fast Idele Lever

Manual Choke Knob

.............. 22

.................. ,22

Oil Prcssurc Indicator Light/Buzzer..

Overheat Indicator Light/Buzzer.. .

Power Trim/Tilt Switch..

............ 24

6

... 8

14

16

19

21

.. 23

23

(PANEL-MOUNT TYPE)

Remote Control Lever . . . . . . . . . . . . . . . .

Ncrtral Release Lever . . . . . . . . . . . . . . . . .

Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emergency Stop Switch Lnayard 27

Throttle Button . . . . . . . . . . . . . . . . . . . . . . . . . . .

Choke Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Choke Knob . . . . . . . . . . . . . . . . . .

Oil Pressure Indicator Light/Buzzer . . . .

Overheat Indicator Light/Buzzer . . . . . .

Power Trim/Tilt Switch . . . . . . . . . . . . . .

(TOP-MOUNT TYPE)

Remote Control Lever . . . . . . . . . . . . . . . .

Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emergency Stop Switch Lanyard 33

Throttle Button . . . . . . . . . . . . . . . . . . . . . . . . . . .

Choke Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Choke Knob . . . . . . . . . . . . . . . . . .

Oil Pressure Indicator Light/Buzzer . . . .

Overheat Indicator Light/Buzzer . . .

Power Trim/Tilt Switch

(remote control lever) . .

Power Trim/Tilt Switch

(control box console) . . .

COMMON

Power Tilt Switch (engine pan) . .

Trim Meter

..*.** . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Tachometer (optional equipment) ., 37

Manual Relief Valve . . . . . . . . . . . . . . . . . .

Tilt Lock Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Trim Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

26

26

Anode Metal

Cooling System Indicator . . . . . . . . . . .

Water Intakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transom Angle Adjusting Rod . .

28

28

28

29

29

30

Fuel Cap/Gauge/Vent Knob

(optional fuel tank) . .

Over-Rev Limiter

Engine Cover Lock Lever . . . . . . . . . .

Fuel Hose Connector . . . . . . . . . . . . . . . . . .

4. PRE-OPERATION CHECKS

Engine Cover RcmovaVInstallation . .

3 I

32

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Level (optional fuel tank) . . .

Fuel Recommendations

34

34

34

35

35

Oxygenated Fuels

Propeller and

Steering Friction Adjustment

(TILLER HANDLE TYPE) . .

Remote Control Friction

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36

36

37

Engine Cover Lock Lever

Other Checks

l

Stem bracket

l

Tool Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l

Anodes . . . . . . . . . . . . .._......................

5. STARTING THE ENGINE

38

Optional Fuel

Fuel Line Connection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

Tab Washer . . . . . . . . . . .

Adjustment . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tank . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

39

40

40

40

41

42

42

43

43

44

45

46

47

48

49 ’

50

50

51

52

52

52

53

53

4

CONTENTS

STARTING THE ENGINE

(TILLER HANDLE TYPE) . . . .

STARTING THE ENGINE

(REMOTE CONTROL TYPE) .a.

(SIDE-MOUNT TYPE) . . . . . . . . . .

(PANEL-MOUNT TYPE) . . . . . .

(TOP-MOUNT TYPE) . . . . . . . . . . . .

STARTING THE ENGINE

(EMERGENCY STARTING).

Troubleshooting Starting Problems . .

6. OPERATION

Break-in Procedure . . . . . . . . . . . . . . . . . . . . .

TILLER HANDLE TYPE

Gear Shifting . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOTE CONTROL TYPE

(SIDE-MOUNT TYPE)

Gear Shifting . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruising . . . . . . . . . . . . . . ~ . . . . . . . . . . . . . . . . . . . .

(PANEL-MOUNT TYPE)

Gear Shifting . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(TOP-MOUNT TYPE)

Gear Shifting . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POWER TRIM/TILT

Power Trim/Tilt System . . . . . . . .

Trim Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Tilt Switch (engine pan) . . .

Manual Relief Valve ............... 87

55

60

E

66

69

74

75

76

76

77

78

79

84

86

87

Tilt Lock Lever.. ...................... 88

Trim Tab Adjustment .................. 89

MOTOR PROTECTION SYSTEM

Engine Oil Pressure and

Overheat Warning System ...... 90

Over-Rev Limiter .................... 92

Anodes.. ................................... 92

Shallow Water Operation ........... 93

High Altitude Operation.. ........... 94

7. STOPPING THE ENGINE

TILLER HANDLE TYPE .......... 95

REMOTE CONTROL TYPE

(SIDE-MOUNT TYPE) ............. 96

(PANEL-MOUNT TYPE) ......... 97

(TOP-MOUNT TYPE). .............. 98

8. TRANSPORTING ...................... 99

9. CLEANING AND FLUSHING . 102

10. MAINTENANCE ....................... 104

THE IMPORTANCE OF

MAINTENANCE .................... 104

MAINTENANCE SAFETY ....... 104

Tool Kit and Spare Parts ......... 105

MAINTENANCE SCHEDULE.. . .106

Engine Oil ............................... 108

Gear Oil ................................... 110

Spark Plugs.. ............................ 1 I2

Battery (not included). ............. 1 13

Lubrication .............................. 1 16

Engine Fuel Filter .................... 1 19

Fuel Tank and Filter ................ 12 1

Fuse Replacement ................... 122

Propeller .................................. 123

Submerged Motor.. .................. 124

11. STORAGE.. ................................ 126

12. TROUBLESHOOTING ............. 130

13. SPECIFICATIONS .................... I32

14. WARRANTY SERVICE ........... 134

15. INDEX.. ...................................... 135

16. WIRING DIAGRAM ................. 139

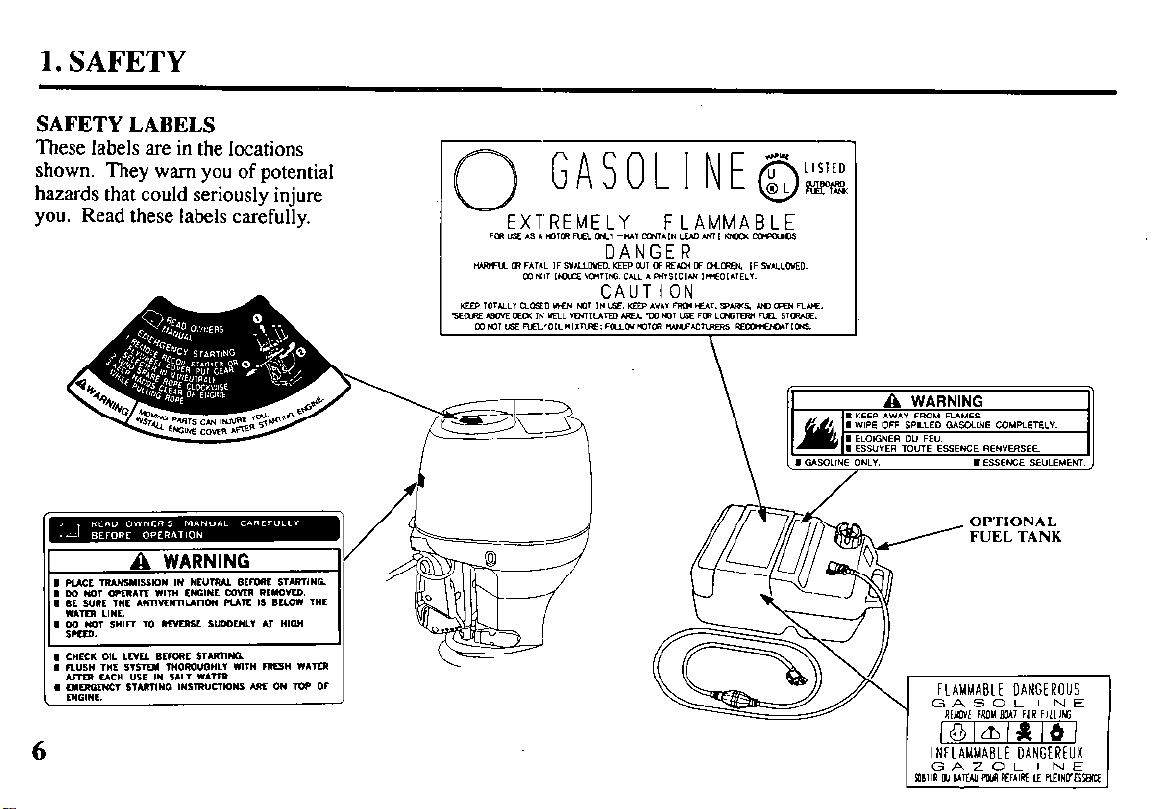

1. SAFETY

SAFETY LABELS

These labels are in the locations

shown. They warn you of potential

hazards that could seriously injure

you. Read these labels carefully.

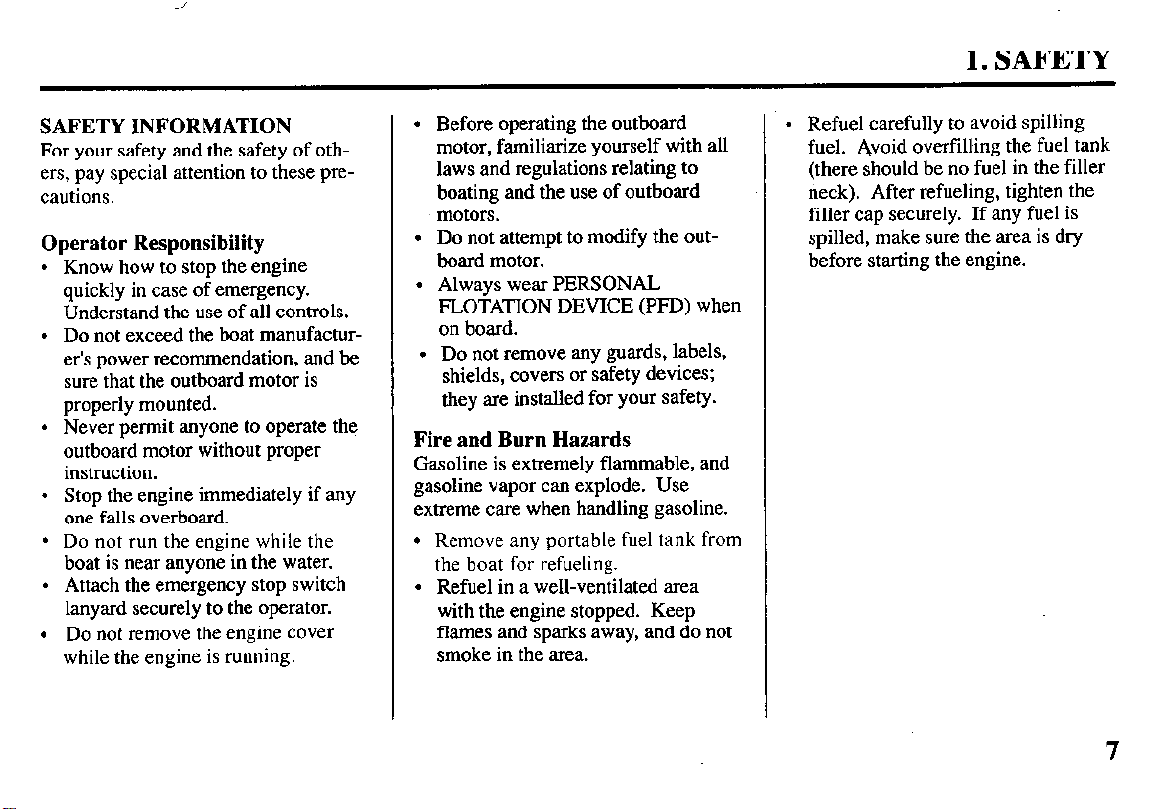

SAFETY INFORMATION

For your safety and the safety of others, pay special attention to these precautions.

Operator Responsibility

l

Know how to stop the engine

quickly in case of emergency.

Understand the use of all controls.

l

Do not exceed the boat manufacturer’s power recommendation, and be

sure that the outboard motor is

properly mounted.

l

Never permit anyone to operate the

outboard motor without proper

instruction.

l

Stop the engine immediately if any

one falls overboard.

l

Do not run the engine

while the

boat is near anyone in the water.

l

Attach the emergency stop switch

lanyard securely to the operator.

l

Do not remove the engine cover

while the engine is running.

l

Before operating the outboard

motor, familiarize yourself with all

laws and regulations relating to

boating and the use of outboard

motors.

l

Do not attempt to modify the outboard motor.

l

Always wear PERSONAL

FLOTATION DEVICE (PFD) when

on board.

l

Do not remove any guards, labels,

shields, covers or safety devices;

they are installed for your safety.

Fire and Burn Hazards

Gasoline is extremely flammable, and

gasoline vapor can explode. Use

extreme care when handling gasoline.

l

Remove any portable fuel tank from

the boat for refueling.

l

Refuel in a well-ventilated area

with the engine stopped. Keep

flames and sparks away, and do not

smoke in the area.

1. SAFETY

l

Refuel carefully to avoid spilling

fuel. Avoid overfilling the fuel tank

(there should be no fuel in the filler

neck). After refueling, tighten the

filler cap securely. If any fuel is

spilled, make sure the area is dry

before starting the engine.

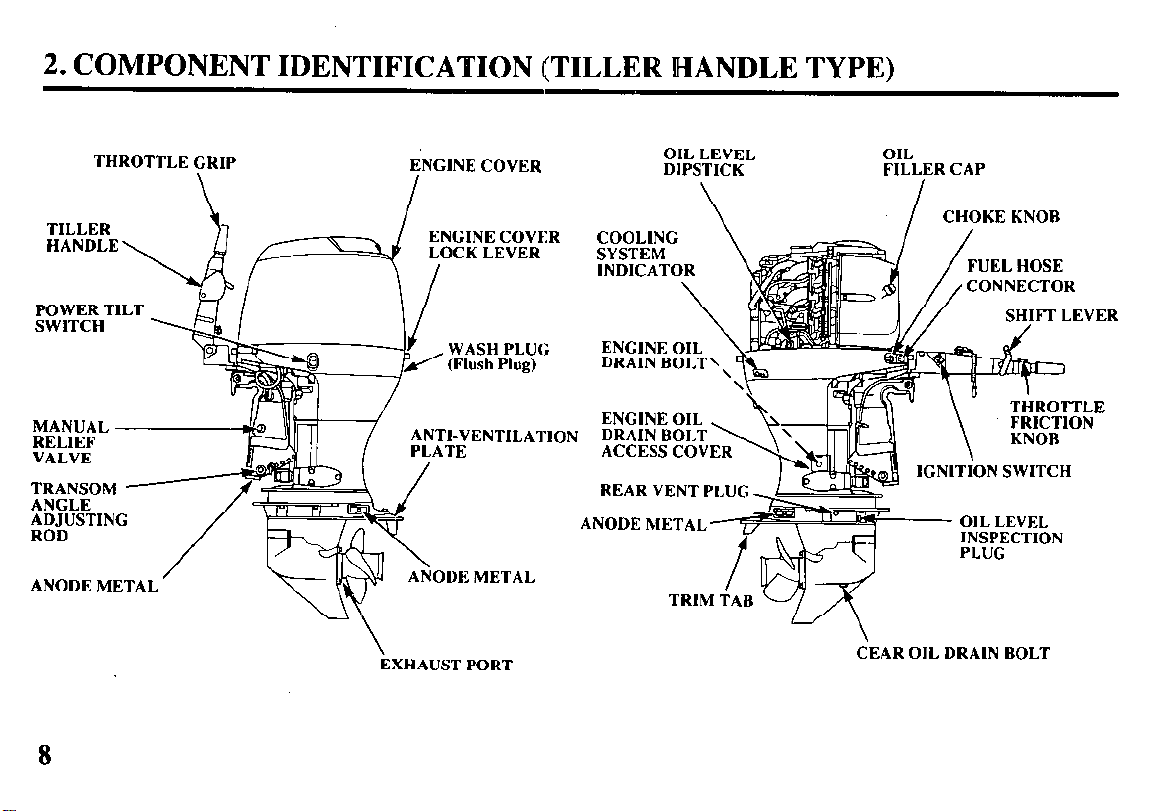

2. COMPONENT IDENTIFICATION (TILLER IHANDLE TYPE)

THROTTLE GRIP

ANGLE

ADJUSTING

ROD

ANODE METAL

ENGINE COVER

\

I

OIL LEVEL

DIPSTICK

\

ENGINE OIL

ANTI-VENTILATION

/

ODE METAL

\

EXHAUST PORT

DRAIN BOLT

ACCESS COV

REAR VENT PLUG

A

LNODE METAL

OIL

FILLER CAP

CHOKE KNOB

CONNECTOR

THROTTLE

FRICTION

\

KNOR

IGNITION SWITCH

INSPECTION

C‘EAR OIL DRAIN BOLT

8

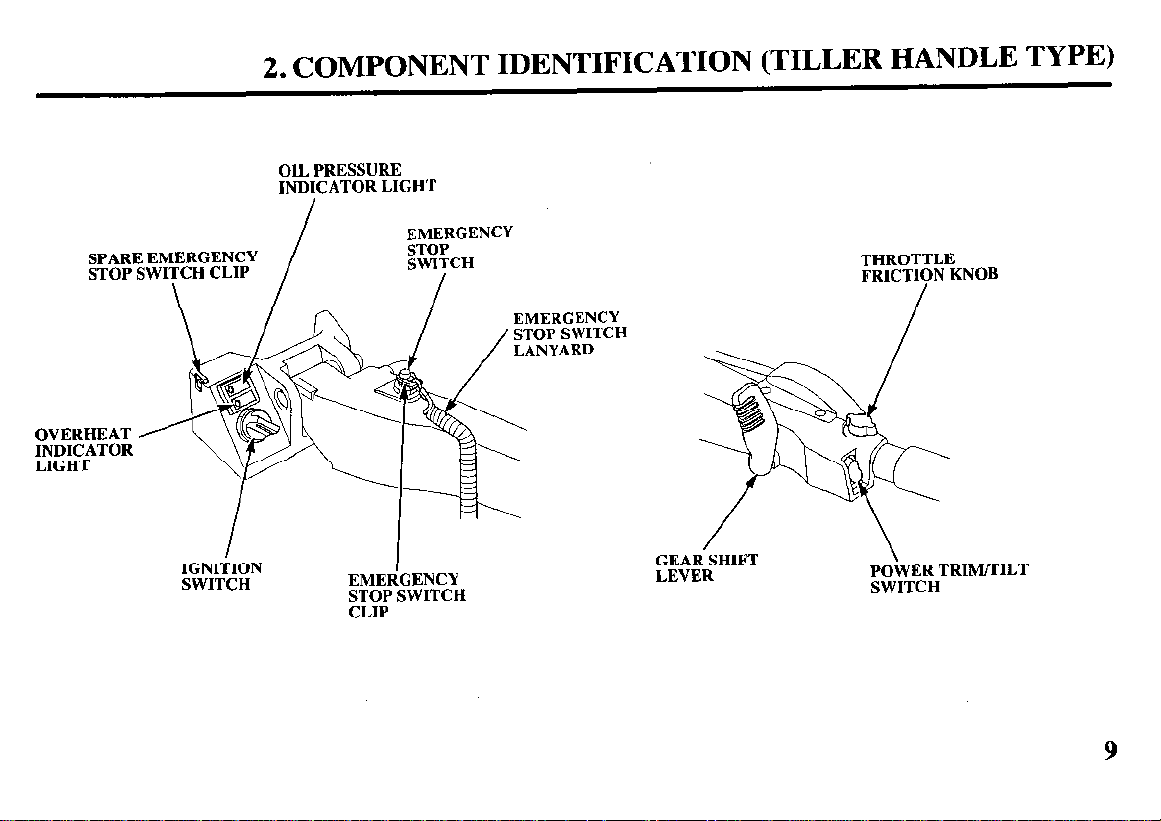

SPARE EMERGENCY

STOP SWITCH CLIP

OVERHEAT

;mIDI$TOR

2. COMPONENT IDENTIFICATION (TILLER HANDLE TYPE)

OIL PRESSURE

INDICATOR LIGHT

EMERGENCY

STOP

SWITCH

\

THROTTLE

FRICTION KNOB

/

IGNIiION

SWITCH

I

EMERGENCY

;a?; SWITCH

GEAIi SHIFT

LEVER

\

;gyT%RHTRIMfTILT

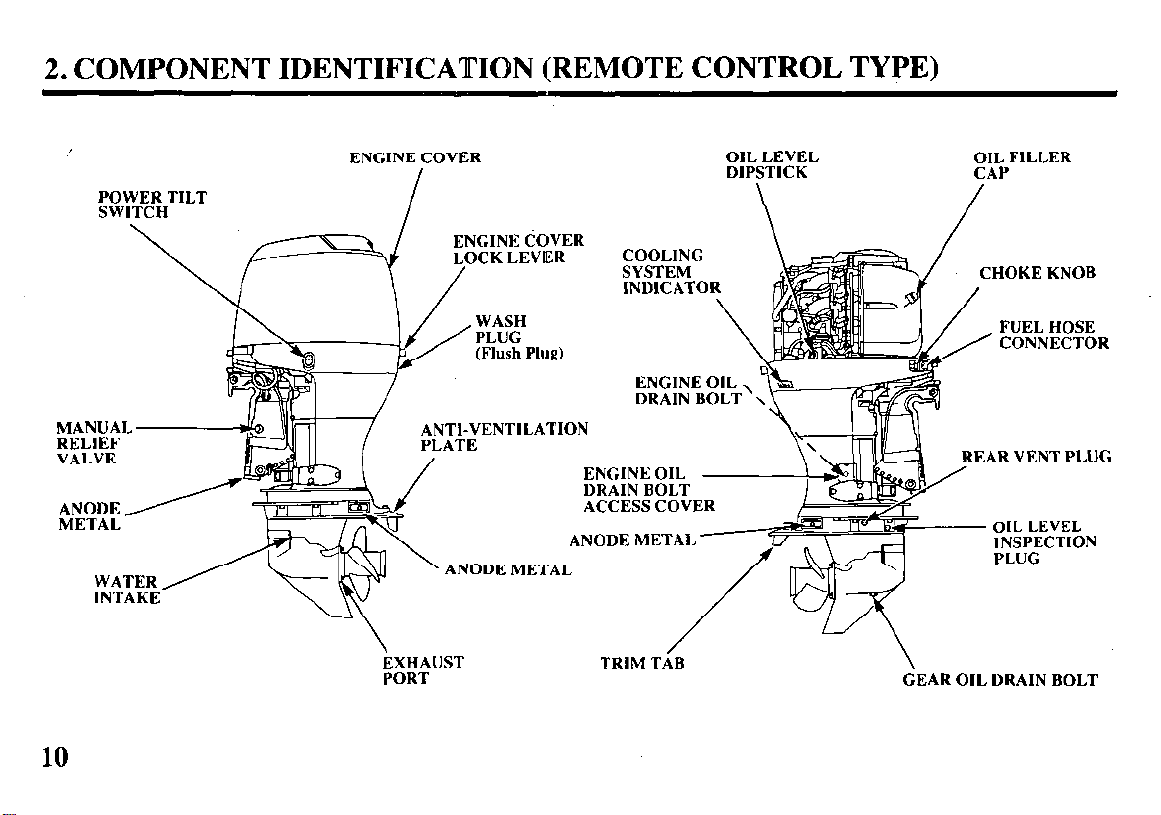

2. COMPONENT IDENTIFICATION (REMOTE CONTROL TYPE)

POWER TILT

SWITCH

ENGINE COVER

I

ANODE METAL

\

EEUST

OIL LEVEL

DIPSTICK

COOLING

ENGINE OIL

ENGINE OIL

DRAIN BOLT

ACCESS COVER

ANODE METAL

TRIM TA/B \

CHOKE KNOB

FUEL HOSE

CONNECTOR

EAR VENT PLUG

OIL LEVEL

INSPECTION

PLUG

GEAR OIL DRAIN BOLT

10

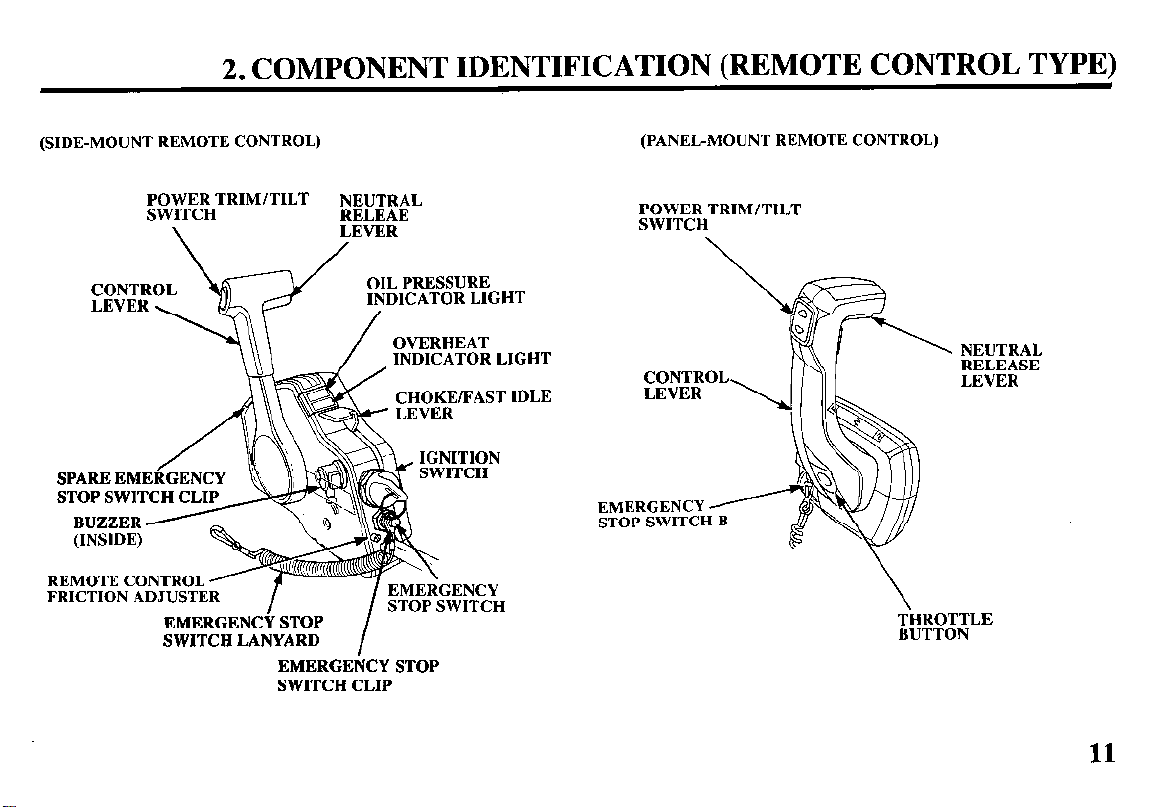

2. COMPONENT IDENTIFICATION (REMOTE CONTROL TYPE)

(SIDE-MOUNT REMOTE CONTROL)

;$yT:RHTRIM/TILT

\

SPARE EMERGENCY

STOP SWITCH CLIP

BUZZER H

(INSIDE)

REMOTE CONTROL ’

FRICTION ADJUSTER

/

Q

/

EMERGENCY STOP

SWITCH LANYARD

EMERGENCY STOP

SWITCH CLIP

NEUTRAL

RELEAE

LEVER

OIL PRESSURE

INDICATOR LIGHT

OVERHEAT

INDICATOR LIGHT

/ STOP SWITCH

I

IDLE

(PANEL-MOUNT REMOTE CONTROL)

EMERGENCY

STOP SWITCH B

11

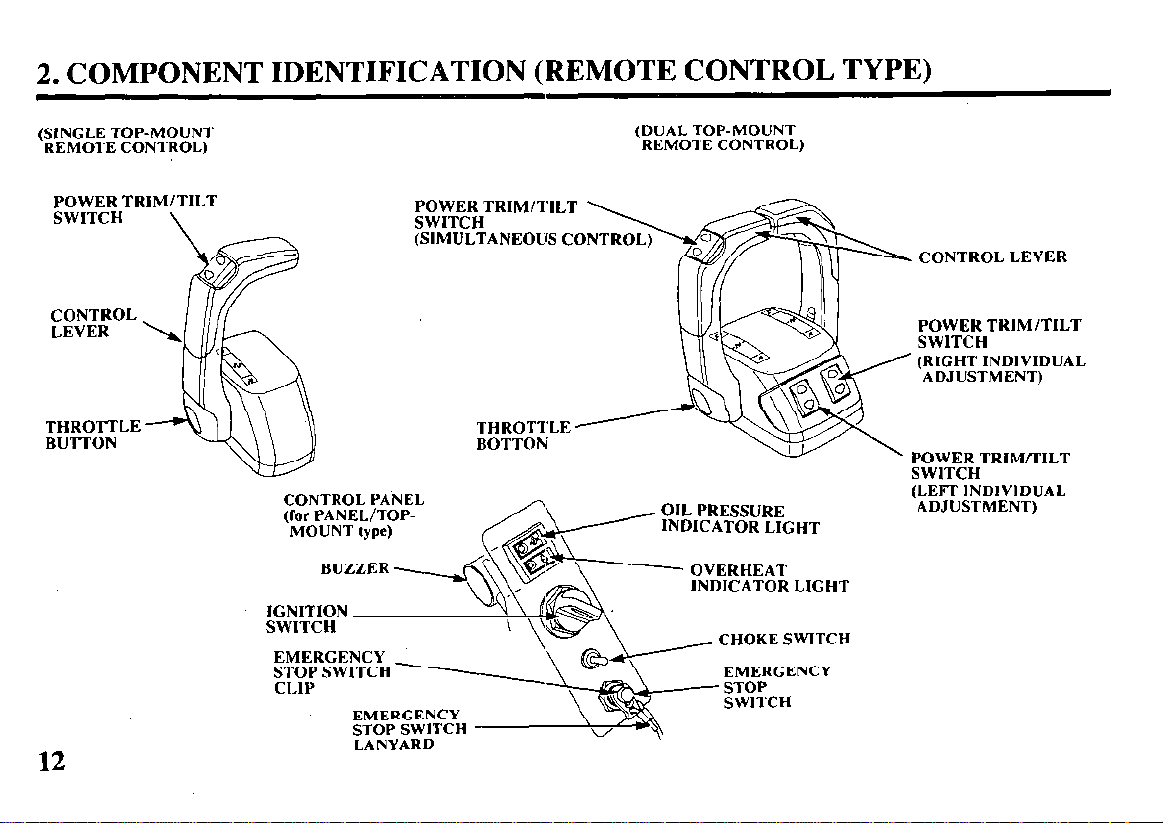

2. COMPONENT IDENTIFICATION (REMOTE CONTROL TYPE)

(SINGLE TOP-MOUNI

REMOTE CONTROL)

~~~T~HTRIM/TILT

I

f

\/-----l

THRO’Ill

BU’ITON

AEw

CONTROL PANEL

(for PANEL/TOP-

MOUNT

SWITCH

type)

POWER TRIM/TILT

SWITCH

(SIMULTANEOUS CO

(DUAL TOP-MOUNT

REMOTE CONTROL)

OIL PRESSURE

INDICATOR LIGHT

- OVERHEAT

INDICATOR LIGHT

/ CHOKE SWITCH

CONTROL LEVER

POWER TRIM/TILT

SWITCH

(RIGHT INDIVIDUAL

ADJUSTMENT)

’ POWER TRIMmILT

SWITCH

nlVlDUAL

12

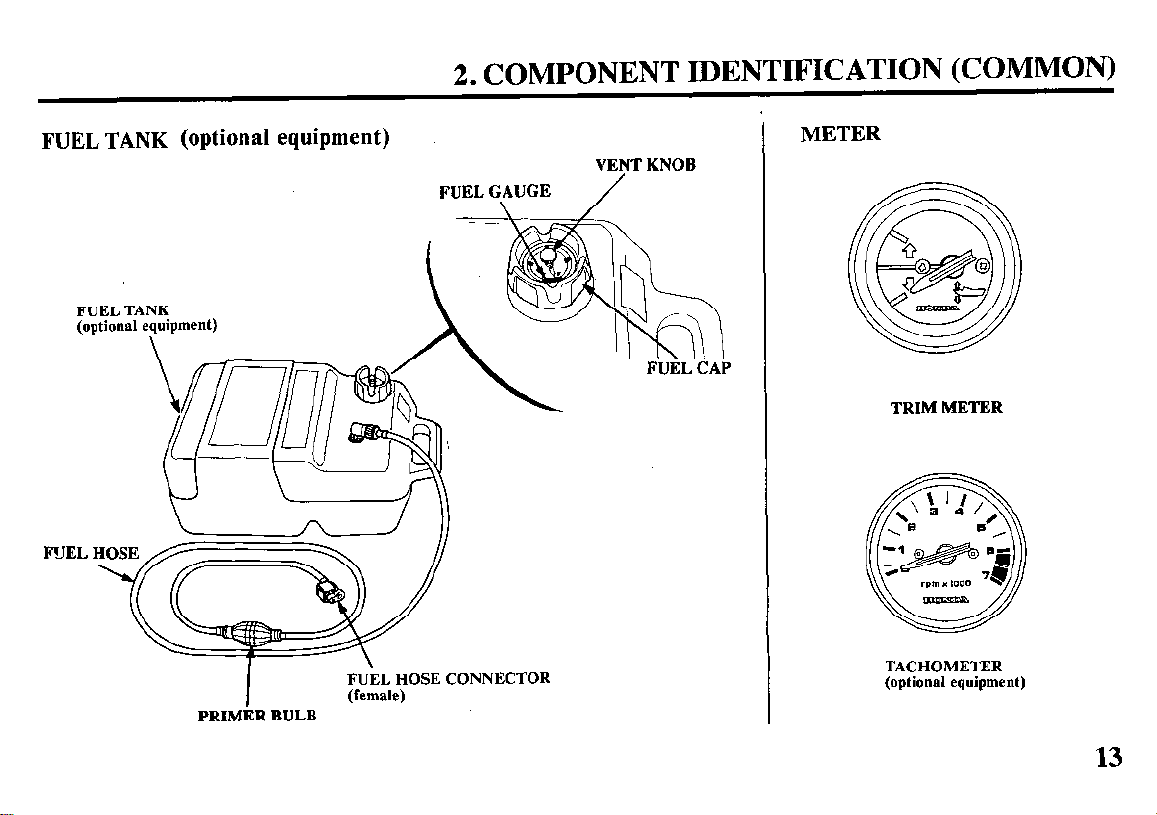

2. COMPONENT IDENTIFICATION (COMMON)

FUEL TANK (optional equipment)

FUEL

(option

FUEL

F&L L HOSE CONNECTOR

I

PRIMER BULB PRIMER BULB

(female)

FUEL G>AUGE

HOSE CONNECTOR

VENT KNOB

/

METER

TRIM METER

TACHOMETER

(optional equipment)

13

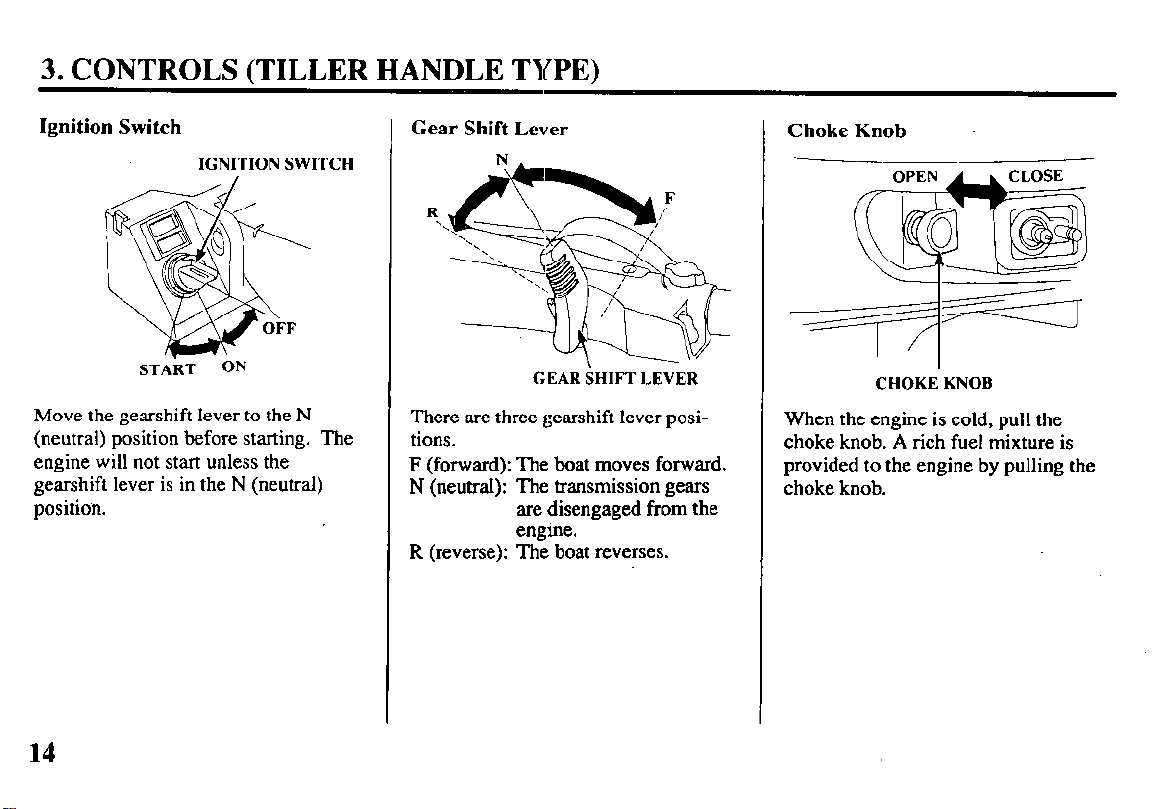

3. CONTROLS (TILLER HANDLE TYPE)

Ignition Switch

IGNITION SWITCH

START ON

Move the gearshift lever to the N

(neutral) position before starting. The

engine will not start unless the

gearshift lever is in the N (neutral)

position.

Gear Shift Lever

GEAR SHIFT LEVER

There are three gearshift lever positions.

F (forward): The boat moves forward.

N (neutral): The transmission gears

are disengaged from the

engine.

R (reverse): The boat reverses.

Choke Knob

CHOKE KNOB

When the engine is cold, pull the

choke knob. A rich fuel mixture is

provided to the engine by pulling the

choke knob.

14

3. CONTROLS

(TILLER HANDLE TYPE)

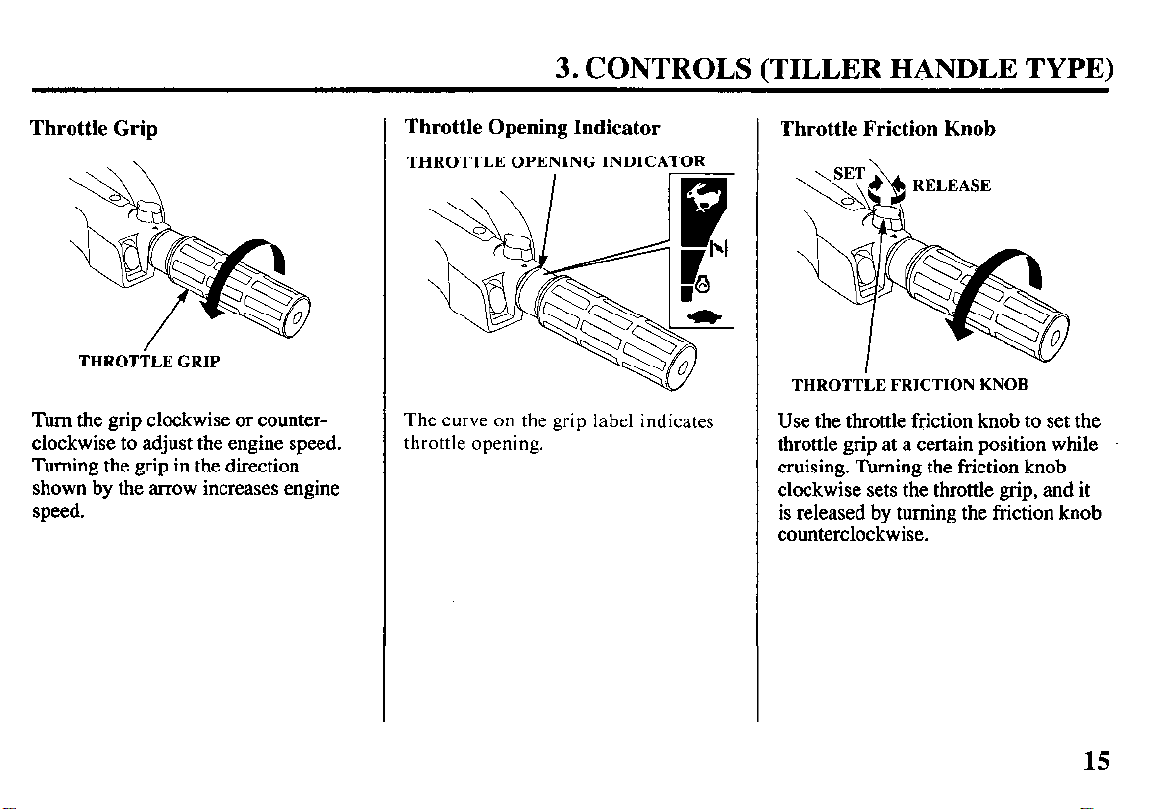

Throttle Grip

THROTTLE GRIP

Turn the grip clockwise or counterclockwise to adjust the engine speed.

Turning the grip in the direction

shown by the arrow increases engine

speed.

Throttle Opening Indicator

THROTTLE OPENING INDICATOR

The curve on the grip label indicates

throttle opening.

Throttle Friction Knob

THROTTLE FRICTION KNOB

Use the throttle friction knob to set the

throttle grip at a certain position while

cruising. Turning the friction knob

clockwise sets the throttle grip, and it

is released by turning the friction knob

counterclockwise.

15

3. CONTROLS (TILLER HANDLE TYPE)

Emergency Stop Switch

STOF

LANYARD -‘.

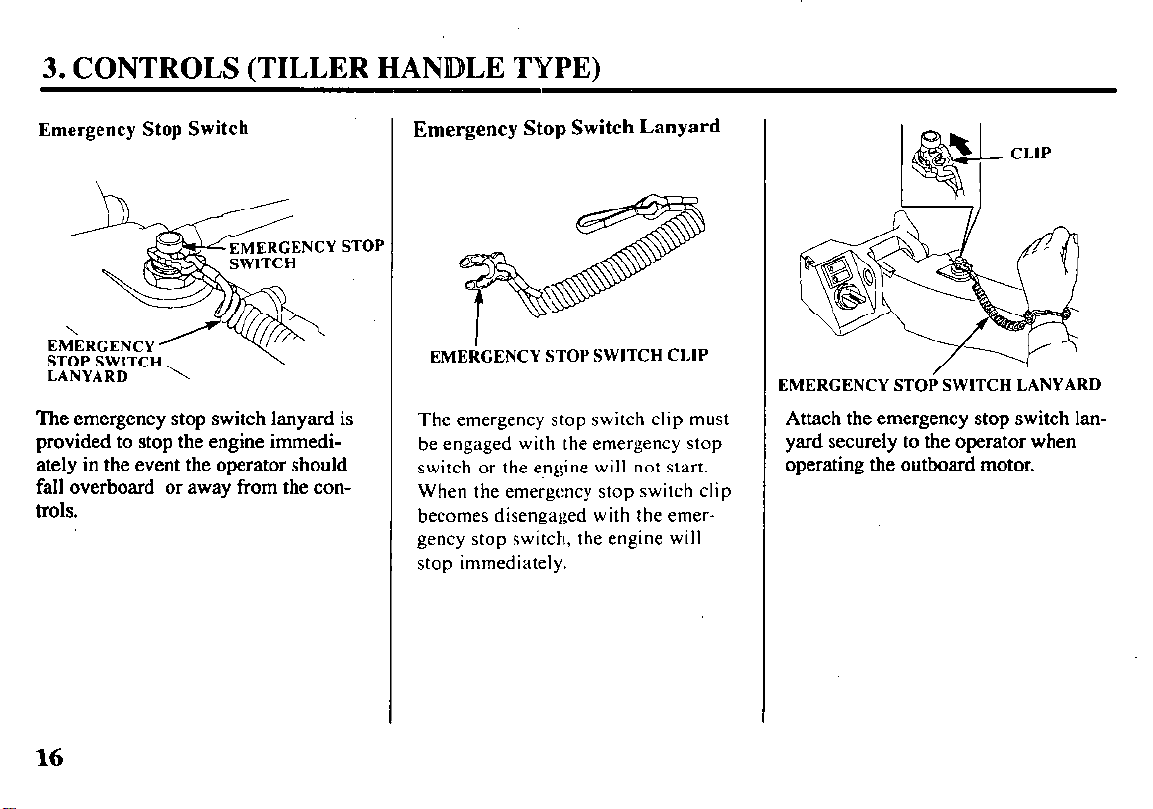

The emergency stop switch lanyard is

provided to stop the engine immediately in the event the operator should

fall overboard or away from the controls.

Emergency Stop Switch Lanyard

I

EMERGENCY STOP SWITCH CLIP

The emergency stop switch clip must

be engaged with the emergency stop

switch or the engine will not start.

When the emergency stop switch clip

becomes disengaged with the emergency stop switch, the engine will

stop immediately.

CLIP

EMERGENCY STOi SWITCH LANYARD

Attach the

emergency

stop switch lanyard securely to the operator when

operating the outboard motor.

16

3. CONTROLS (TILLER HANDLE TYPE)

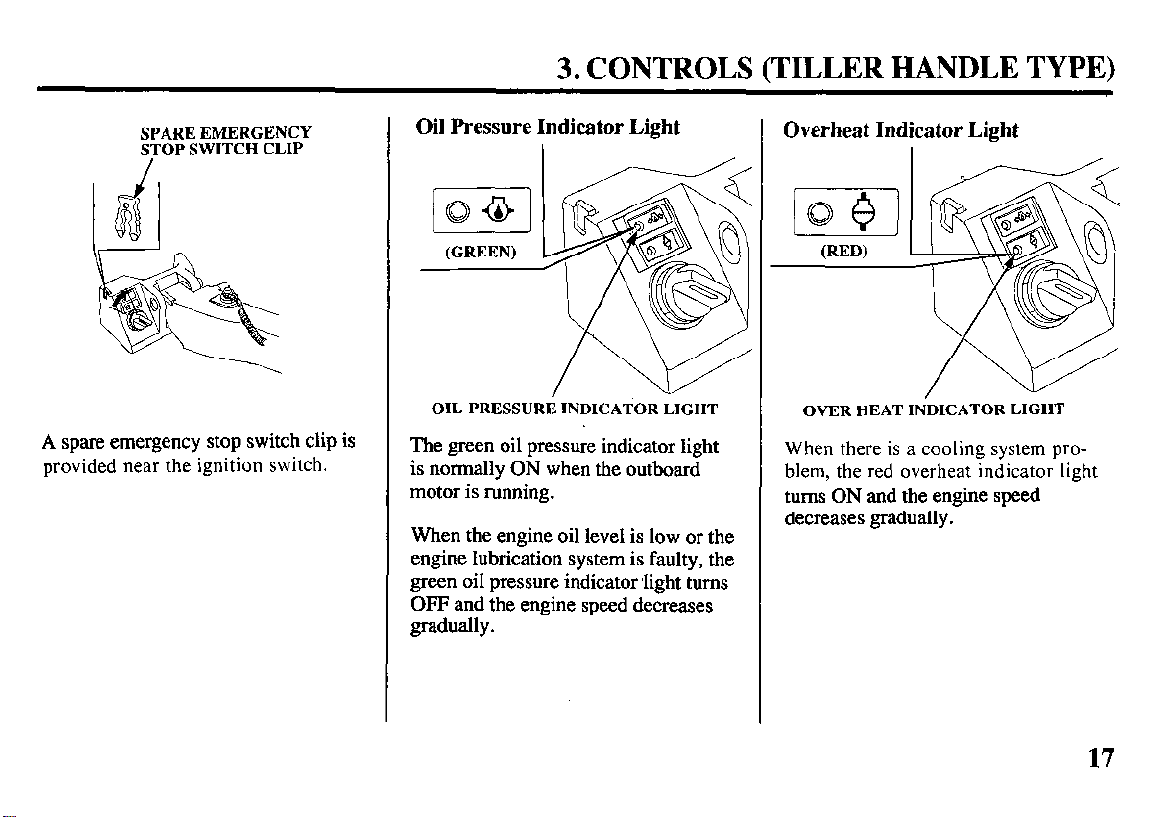

SPARE EMERGENCY

STOP SWITCH CLIP

A spare emergency stop switch clip is

provided near the ignition switch.

Oil Pressure Indicator Light

(GREEN)

OIL PRESSURE INDICATOR LIGHT

The green oil pressure indicator light

is normally ON when the outboard

motor is running.

When the engine oil level is low or the

engine lubrication system is faulty, the

green oil pressure indicator #light turns

OFF and the engine speed decreases

gradually.

Overheat Indicator Light

[-G-J

(RED)

OVER HEAT INDICATOR LIGHT

When there is a cooling system pro-

blem, the red overheat indicator light

turns ON and the engine speed

decreases gradually.

17

3. CONTROLS (TILLER HANDLE TYPE)

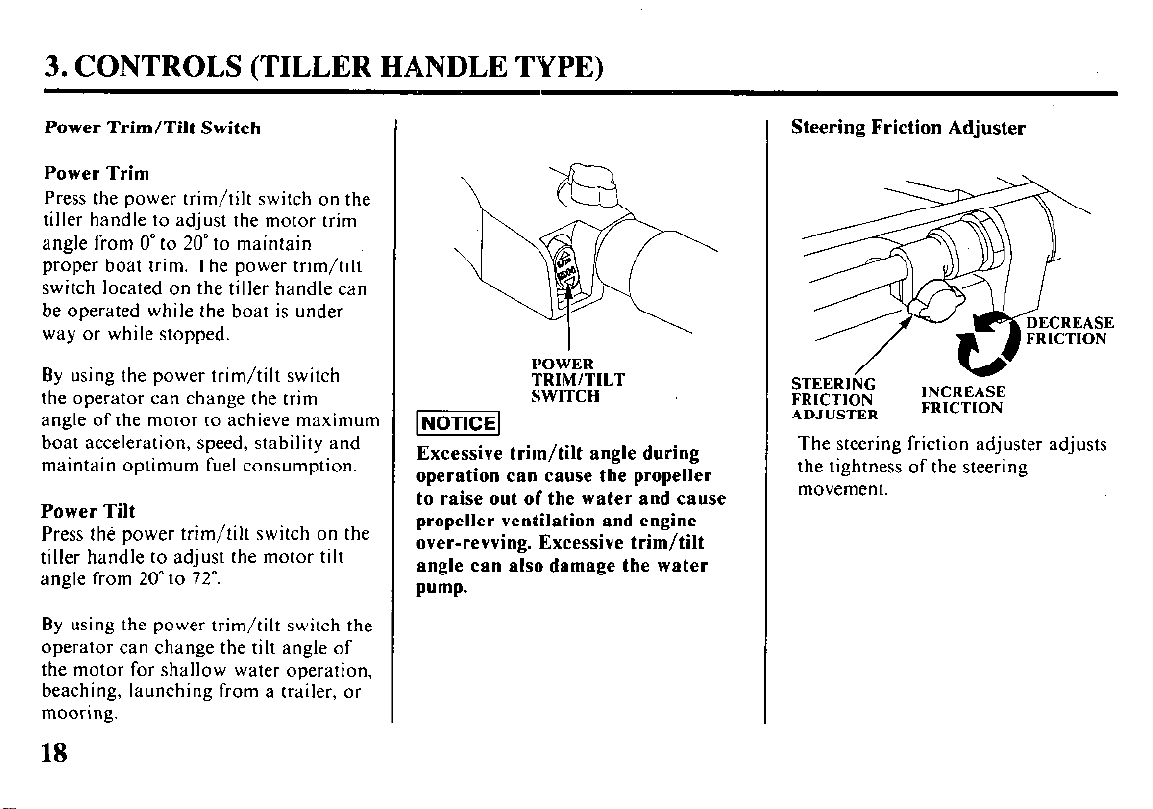

Power Trim/Tilt Switch

Power Trim

Press the power trim/tilt switch on the

tiller handle to adjust the motor trim

angle from 0” to 20” to maintain

proper boat trim. The power trim/tilt

switch located on the tiller handle can

be operated while the boat is under

way or while stopped.

By using the power trim/tilt switch

the operator can change the trim

angle of the motor to achieve maximum

boat acceleration, speed, stability and

maintain optimum fuel consumption.

Power Tilt

Press the power trim/tilt switch on the

tiller handle to adjust the motor tilt

angle from 20” to 72”.

By using the power trim/tilt switch the

operator can change the tilt angle of

the motor for shallow water operation,

beaching, launching from a trailer, or

mooring.

POWER TRIM/TILT SWITCH

Excessive trim/tilt angle during

operation can cause the propeller

to raise out of the water and cause

propeller ventilation and engine

over-revving. Excessive trim/tilt

angle can also damage the water

pump-

Steering Friction Adjuster

The steering friction adjuster adjusts

the tightness of the steering

movement.

18

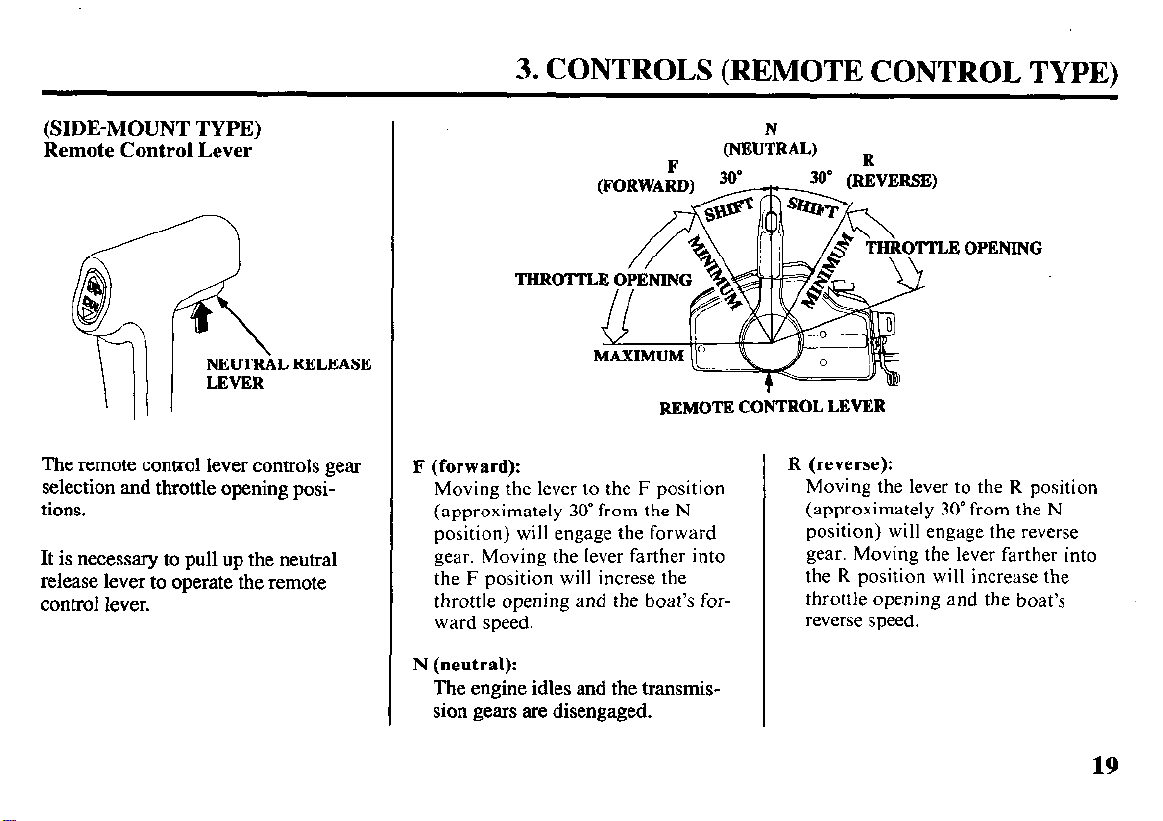

(SIDE-MOUNT TYPE)

Remote Control Lever

3. CONTROLS (REMOTE CONTROL TYPE)

OPENING

REMOTE CONTROL LEVER

The remote control lever controls gear

selection and throttle opening posi-

tions.

It is necessary to pull up the neutral

release lever to operate the remote

control lever.

F (forward):

Moving the lever to the F position

(approximately 30” from the N

position) will engage the forward

gear. Moving the lever farther into

the F position will increse the

throttle opening and the boat’s forward speed.

N (neutral):

The engine idles and the transmission gears are disengaged.

R (reverse):

Moving the lever to the R position

(approximately 30” from the N

position) will engage the reverse

gear. Moving the lever farther into

the R position will increase the

throttle opening and the boat’s

reverse speed.

19

3. CONTROLS (REMOTE CONTROL TYPE)

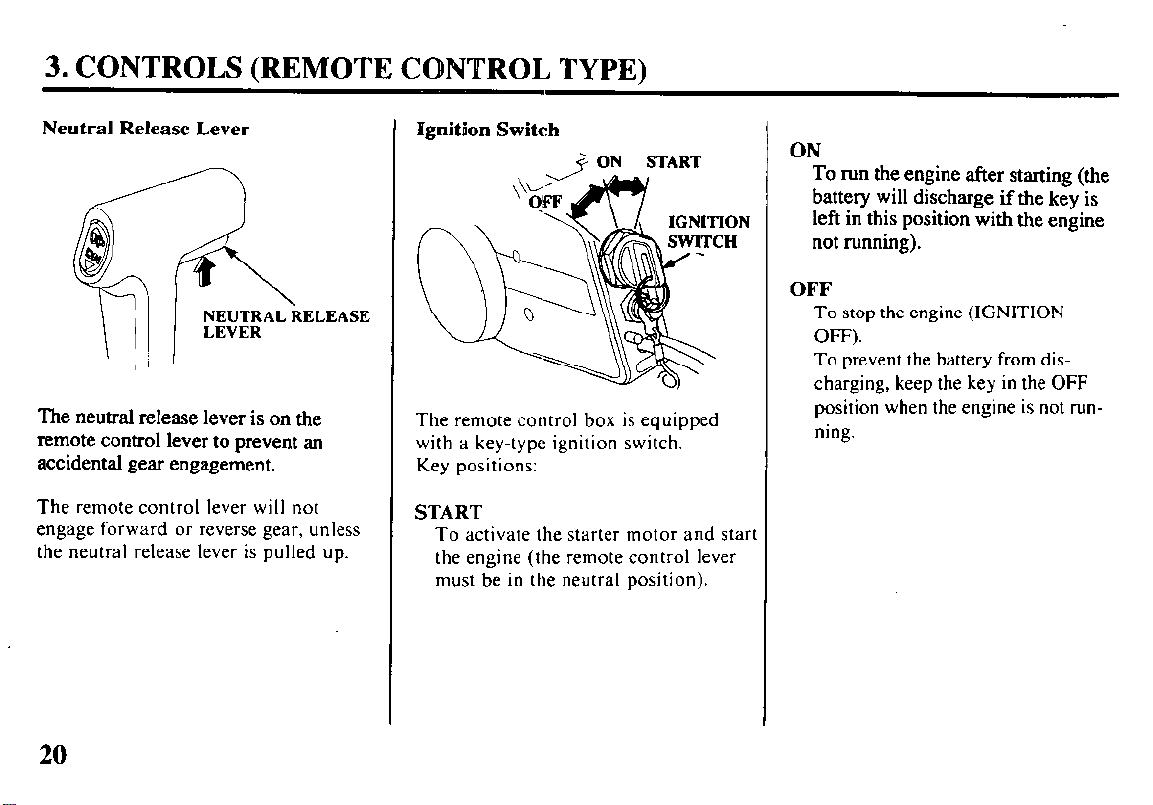

Neutral Release Lever

The neutral release lever is on the

remote control lever to prevent an

accidental gear engagement.

The

remote control lever will not

engage forward or reverse gear, unless

the neutral release lever is pulled up.

Ignition

The remote control box is equipped

with a key-type ignition switch.

Key positions:

START

To activate the starter motor and start

the engine (the remote control lever

must be in the neutral position).

Switch

START

ON

To run the engine after starting (the

battery will discharge if the key

left in this position with the engine

not running).

OFF

To stop the engine (IGNITION

OFF).

To prevent the battery from discharging, keep the key in the

position when the engine is not running.

OFF

is

20

3. CONTROLS (REMOTE CONTROL TYPE)

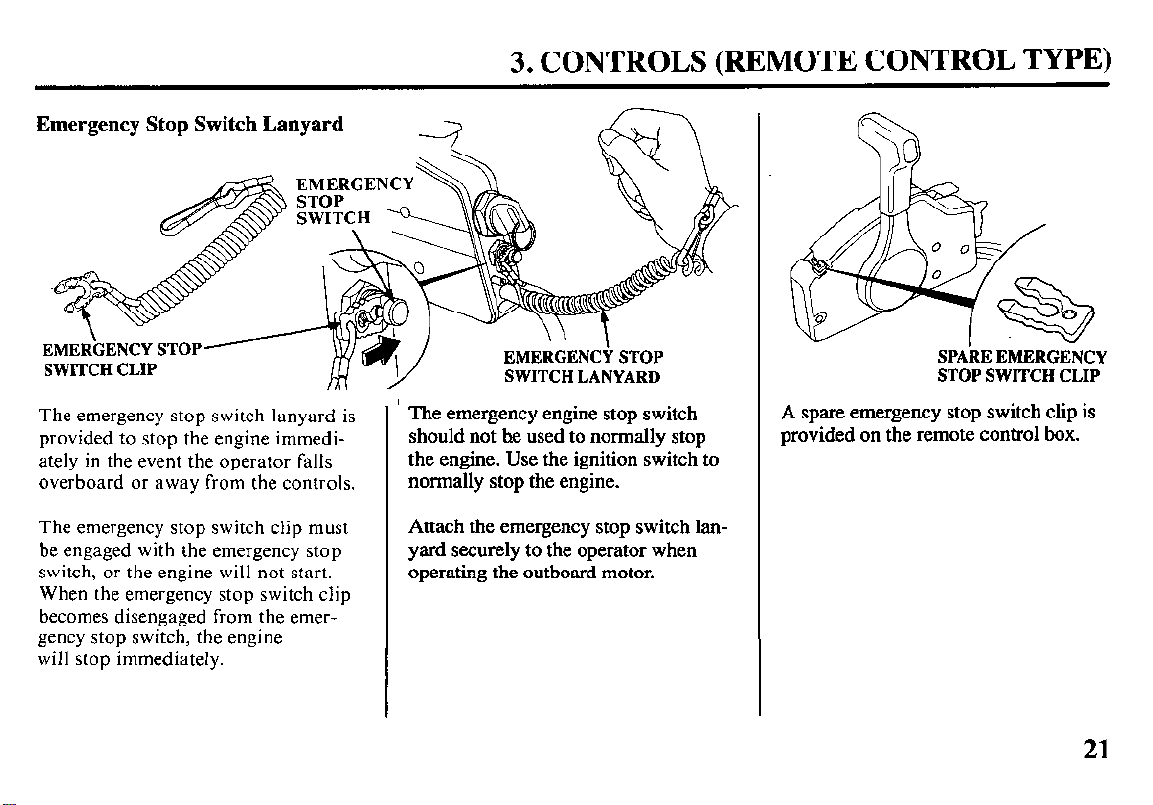

Emergency Stop Switch Lanyard

The emergency stop switch lanyard is

provided to stop the engine immediately in the event the operator falls

overboard or away from the controls.

The emergency stop switch clip must

be engaged with the emergency stop

switch, or the engine will not start.

When the emergency stop switch clip

becomes disengaged from the emergency stop switch, the engine

will stop immediately.

-7

SWITCH LANYARD

’ The emergency engine stop switch

should not be used to normally stop

the engine. Use the ignition switch to

normally stop the engine.

Attach the emergency stop switch lanyard securely to the operator when

operating the outboard motor.

SPAkE EMERGENCY

STOP SWITCH CLIP

A spare emergency stop switch clip is

provided on the remote control box.

21

3. CONTROLS (REMOTE CONTROL TYPE)

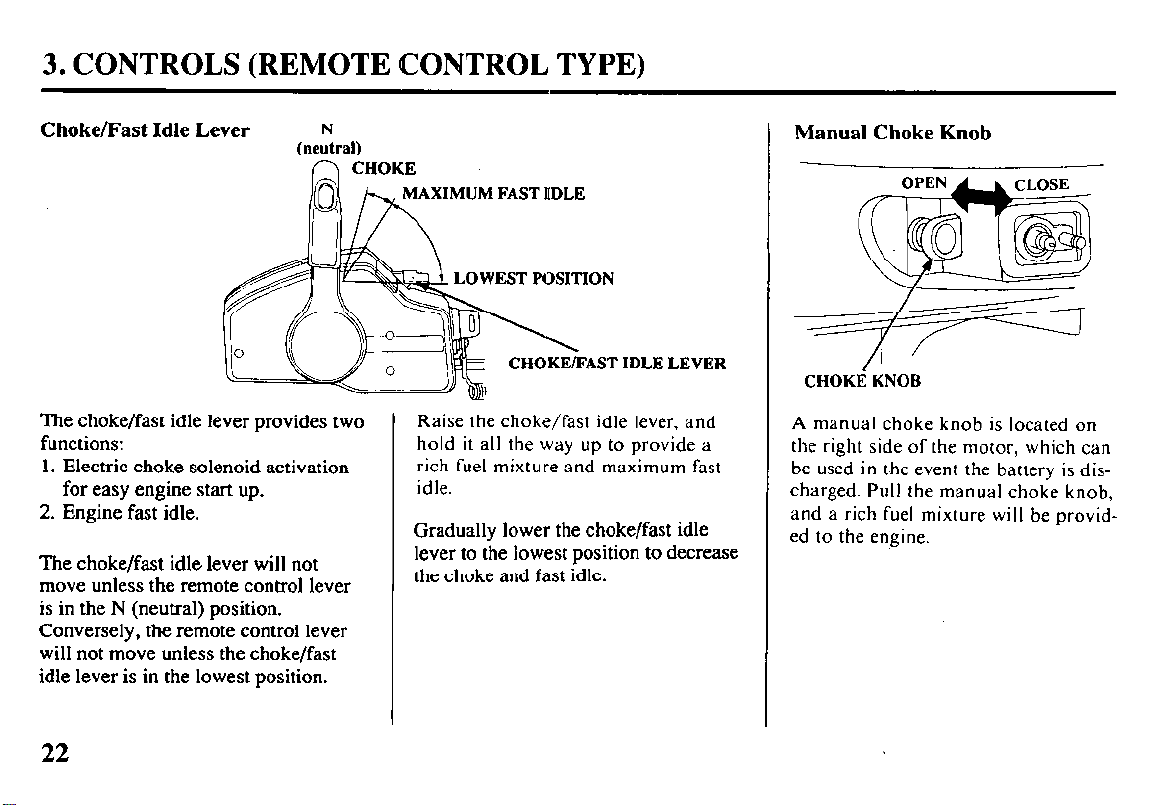

Choke/Fast Idle Lever

N

(neutral)

f-’ CHOKE

/((=j MAXIMUM FAST IDLE

The choke/fast idle lever provides two

functions:

1. Electric choke solenoid activation

for easy engine start up.

2. Engine fast idle.

The choke/fast idle lever will not

move unless the remote control lever

is in the N (neutral) position.

Conversely, the remote control ,lever

will not move unless the choke/fast

idle lever is in the lowest position.

WEST POSITION

ST IDLE LEVER

Raise

the choke/fast idle lever, and

hold it all the way up to provide a

rich fuel mixture and maximum fast

idle.

Gradually lower the choke/fast idle

lever to the lowest position to decrease

the choke and fast idle.

Manual Choke Knob

I /

/

CHOKE KNOB

A

manual choke knob is located on

the right side of the motor, which can

be used in the event the battery is discharged.

and a rich fuel mixture will be provided to the engine.

Pull

the manual choke knob,

22

3. CONTROLS (REMOTE CONTROL TYPE)

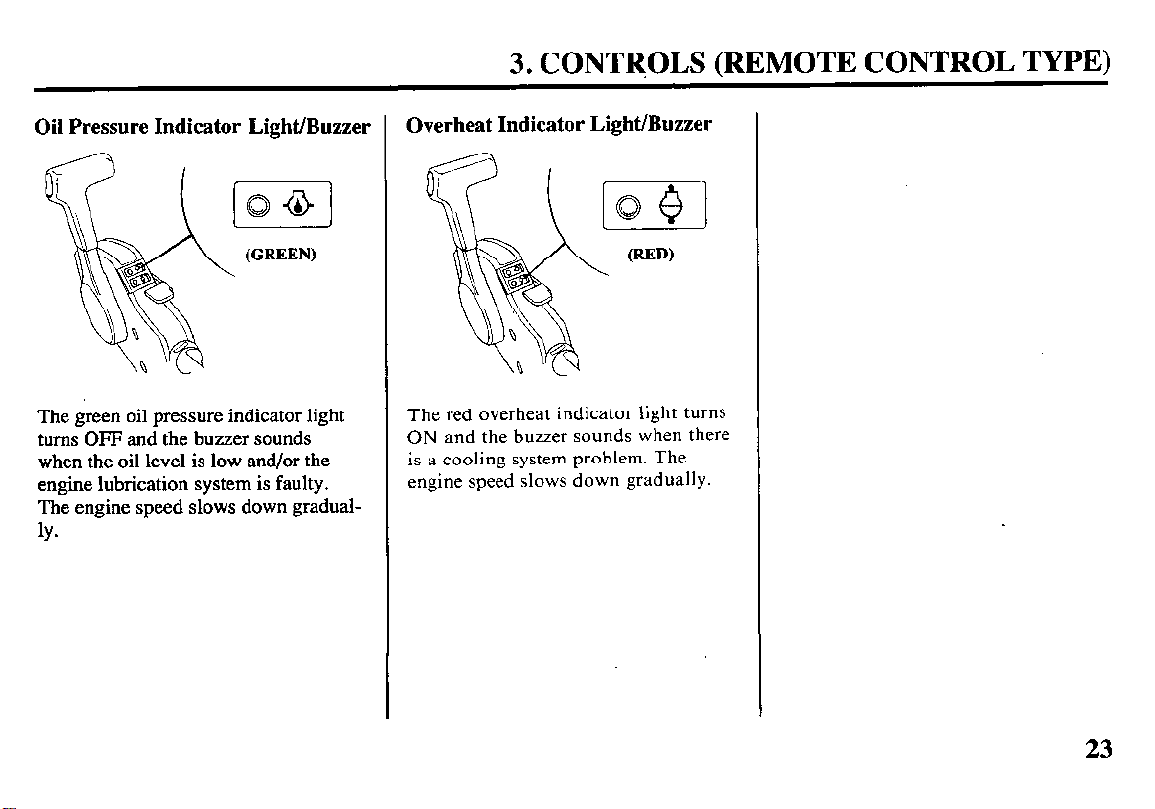

Oil Pressure Indicator Light/Buzzer

The green oil pressure indicator light

turns OFF and the buzzer sounds

when the oil level is low and/or the

engine lubrication system is faulty.

The engine speed slows down gradual-

ly*

Overheat Indicator Light/Buzzer

The red overheat indicator light turns

ON and the buzzer sounds when there

is a cooling system problem. The

engine speed slows down gradually.

23

3. CONTROLS (REMOTE CONTROL TYPE)

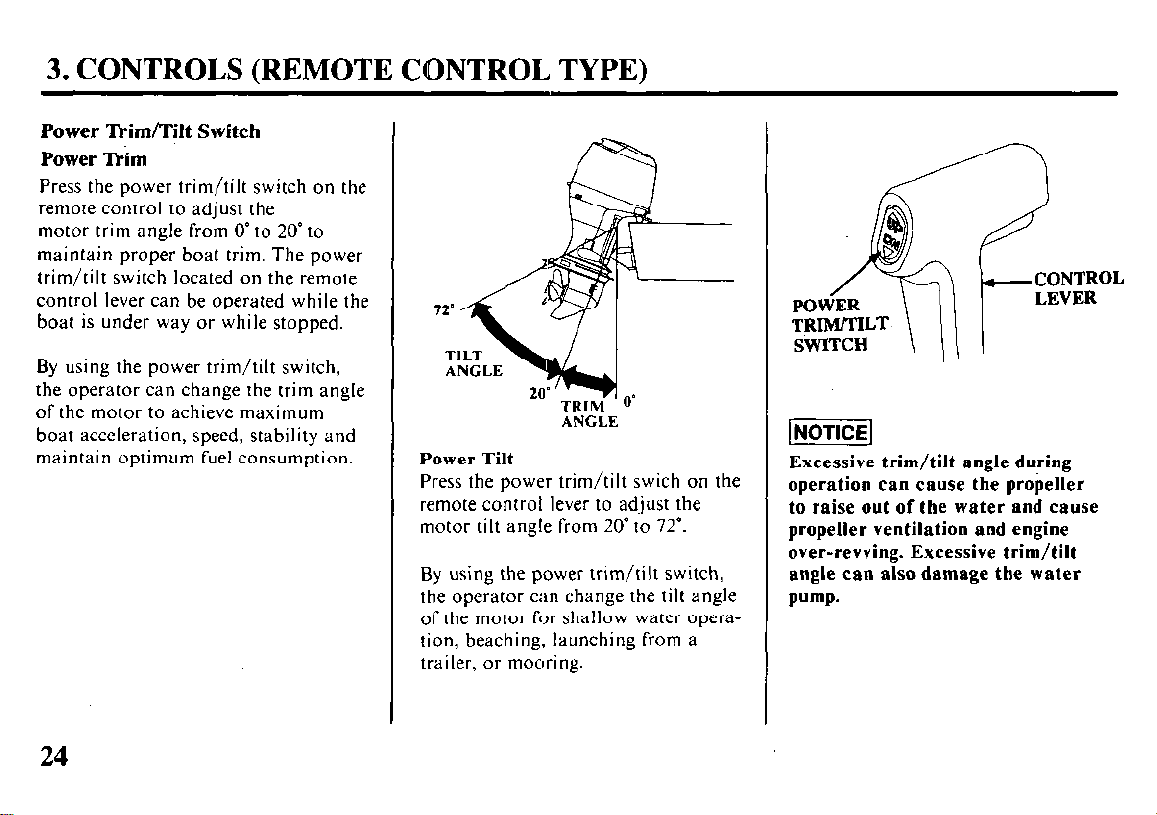

Power ‘Mm/Tilt Switch

Power Grn

Press the power trim/tilt switch on the

remote control to adjust the

motor trim angle from 0” to 20” to

maintain proper boat trim. The power

trim/tilt switch located on the remote

control lever can be operated while the

boat is under way or while stopped.

By using the power trim/tilt switch,

the operator can change the trim angle

of the motor to achieve maximum

boat acceleration, speed, stability and

maintain optimum fuel consumption.

Power Tilt

Press the power trim/tilt swich on the

remote control lever to adjust the

motor tilt angle from 20” to 72”.

By using the power trim/tilt switch,

the operator can change the tilt angle

of the motor for shallow water operation, beaching, launching from a

trailer, or mooring.

ANGLE

Excessive trim/tilt angle during

operation can cause the propeller

to raise out of the water and cause

propeller ventilation and engine

over-revving. Excessive trim/tilt

angle can also damage the water

pump.

24

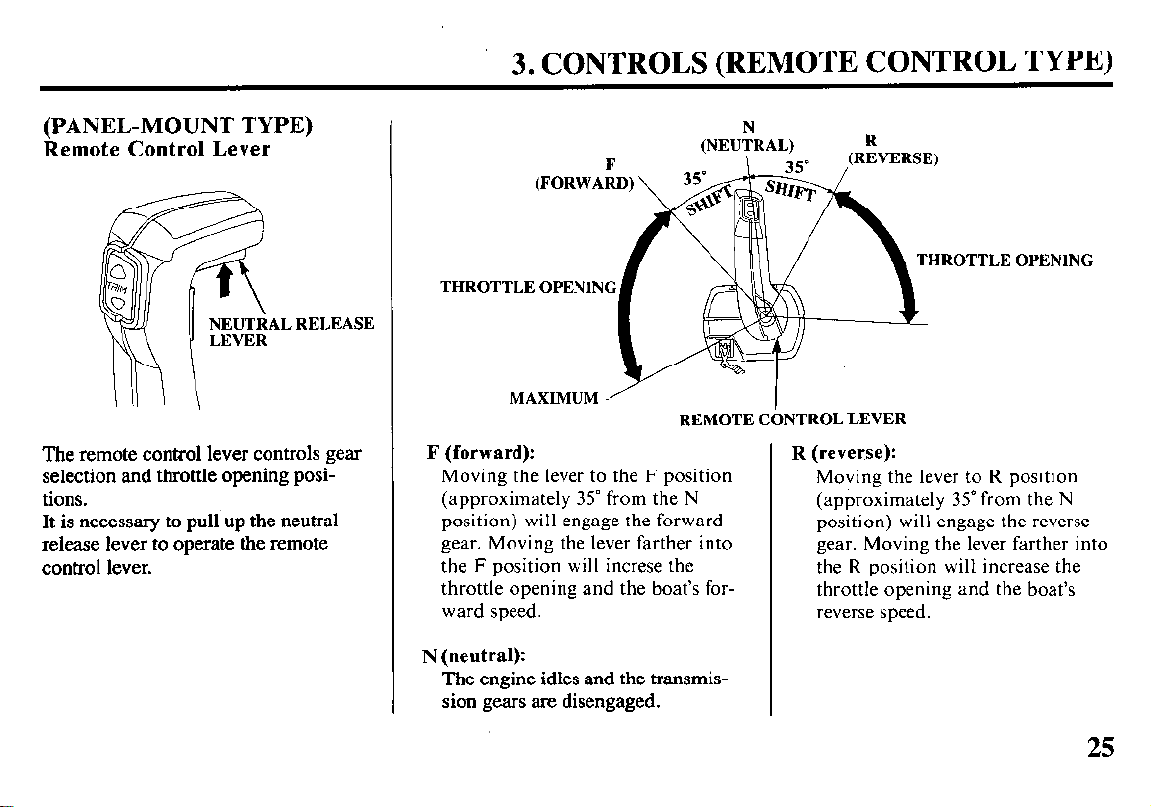

(PANEL-MOUNT TYPE)

Remote Control Lever

3. CONTROLS (REMOTE CONTROL TYPE)

The remote control lever controls gear

selection and throttle

tions.

opening posi-

It is necessary to pull’up the neutral

release lever to operate the remote

control lever.

THROTTI

.E OPENING

MAXIMUM -’

REMOTE CONTROL LEVER

F (forward):

Moving the lever to the F position

(approximately 35” from the N

position) will engage the forward

gear. Moving the lever farther into

the F position will increse the

throttle opening and the boat’s for-

ward speed.

N (neutral):

The engine idles and the transmis-

sion gears are disengaged.

THROTTLE

I

R (reverse):

Moving the lever to R position

(approximately 35” from the N

position) will engage the reverse

gear. Moving the lever farther into

the R position will increase the

throttle opening and the boat’s

reverse speed.

OPENING

3. CONTROLS (REMOTE CONTROL TYPE)

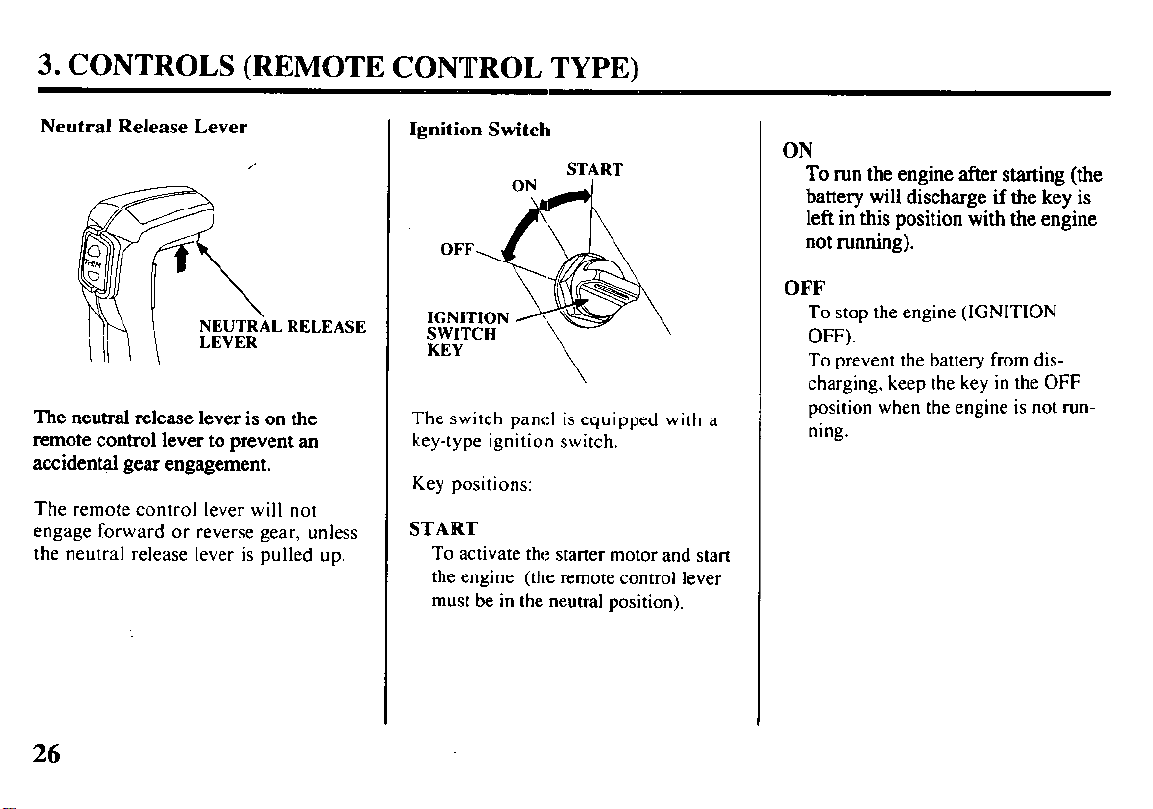

Neutral Release Lever

The neutral release lever is on the

remote control lever to prevent an

accidental gear engagement.

The remote control lever will not

engage forward or reverse gear, unless

the neutral release lever is pulled up.

Ignition Switch

START

The switch panel is equipped with a

key-type ignition switch.

Key positions:

START

To activate the starter motor

the engine (the remote control lever

must be in the neutral position).

and start

ON

To run the engine after starting (the

battery will discharge if the key is

left in this position with the engine

not running).

OFF

To stop the engine (IGNITION

OFF).

To prevent the battery from discharging, keep the key in the

position when the engine is not run-

ning.

OFF

26

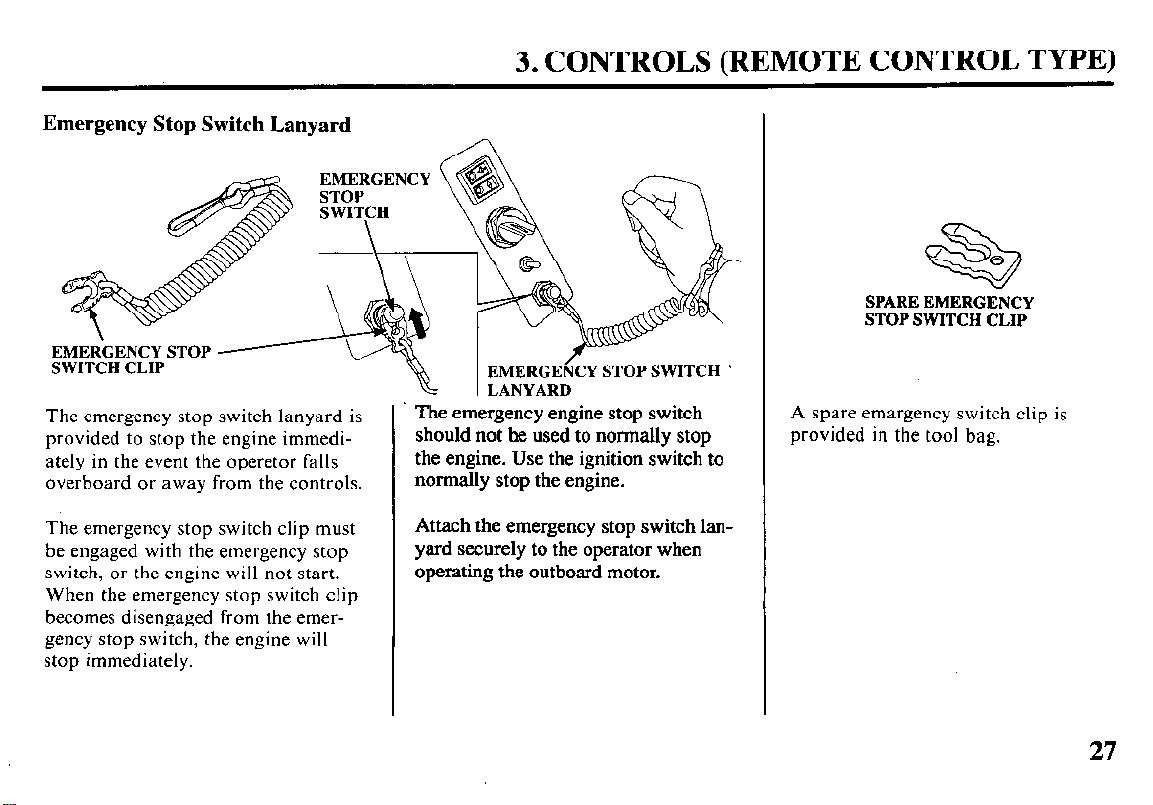

Emergency Stop Switch Lanyard

EMERGENCY

STOP

SWITCH

The emergency stop switch lanyard is

provided to stop the engine immediately in the event the operetor falls

overboard or away from the controls.

3. CONTROLS (REMOTE CONTROL TYPE)

\

EMERGEkCY STOP SWITCH ’

LANYARD

The emergency engine stop switch

should not he used to normally stop

the engine. Use the ignition switch to

normally stop the engine.

SPARE EMERGENCY

STOP SWITCH CLIP

A spare emargency switch clip is

provided in the tool bag.

The emergency stop switch clip must

be engaged with the emergency stop

switch, or the engine will not start.

When the emergency stop switch clip

becomes disengaged from the emergency stop switch, the engine will

stop immediately.

Attach the emergency stop switch lanyard securely to the operator when

operating the outboard motor.

27

3. CONTROLS (REMOTE CONTROL TYPE)

Throttle Button

(NC&l)

l ..*q;,:ckword

,’

,

NEUTRAL

RELEASE

LEVER

THROTTLE

BUTTON

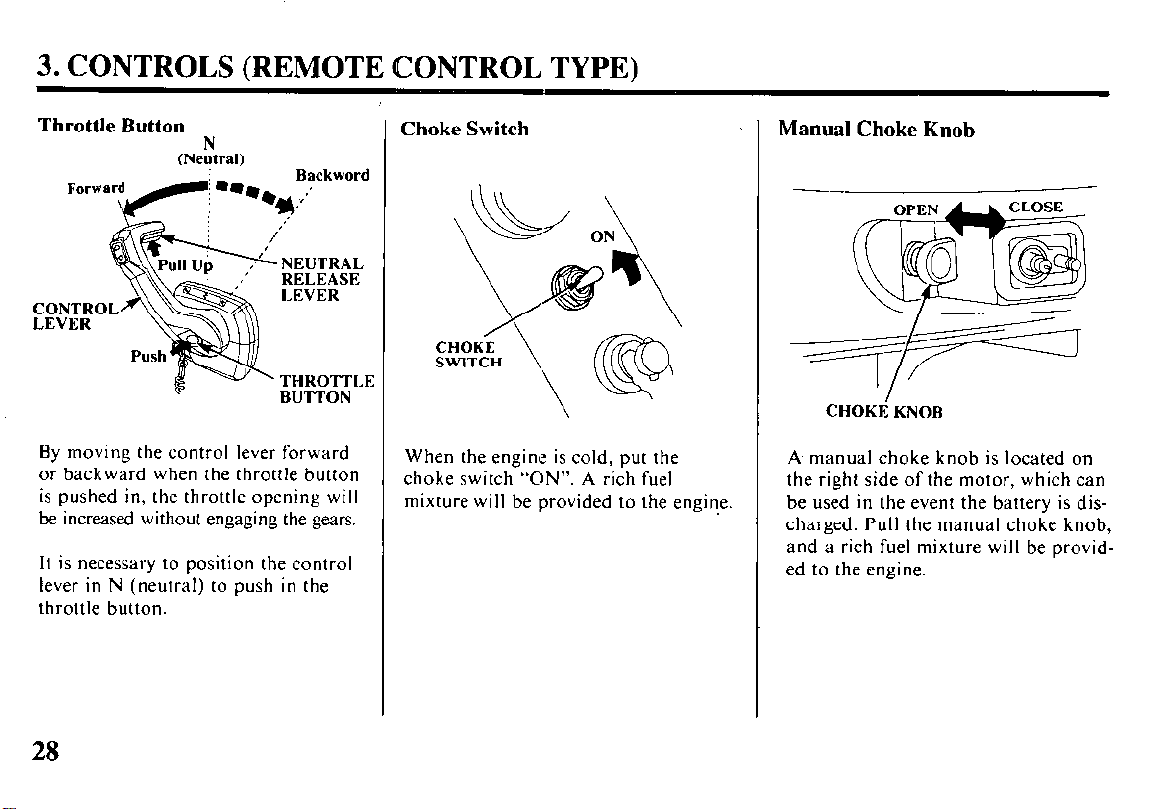

By moving the control lever forward

or backward when the throttle button

is pushed in, the throttle opening will

be increased without engaging the gears.

It is necessary to position the control

lever in N (neutral) to push in the

throttle button.

Choke Switch

When the engine is cold, put the

choke switch “ON”. A rich fuel

mixture will be provided to the engine.

Manual Choke Knob

CHOKE! KNOB

A manual choke knob is located on

the right side of the motor, which can

be used in the event the battery is discharged. Pull the manual choke knob,

and a rich fuel mixture will be provided to the engine.

28

Loading...

Loading...