Honda Power Equipment BF2D User Manual

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

I.

Keep this owner’s manual

This owner’s manual is considered a permanent part of the outboard motor

and should remain with the outboard motor if resold.

The information and specifications included in this publication were in

at the time of approval for printing. Honda Motor Co., Ltd. reserves the right,

however, to discontinue or change specifications or design at any time without

notice and without incurring any obligation whatever. No part of this publication may be reproduced without written permission.

handy, so you can refer to it at any time.

effect

INTRODUCTION

Congratulations on your selection of a Honda outboard motor. We are certain

you will be pleased with your purchase of one of the finest outboard motors on

the market.

We want to help you get the best results from your new outboard motor and

to operate it safely. This manual contains the information on how to do that;

please read it carefully.

As you read this manual, you will find information preceded by a [

symbol. That information is intended to help you avoid damage to your

outboard motor, other property, or the environment.

We suggest you read the warranty policy to fully understand its coverage and

your responsibilities of ownership. The warranty policy is a separate document

that should have been given to you by your dealer.

When your outboard motor needs scheduled maintenance, keep in mind that

your Honda servicing dealer is specially trained in servicing Honda outboard

motors. Your Honda servicing dealer is dedicated to your satisfaction and will

be pleased to answer your questions and concerns.

Best Wishes,

Honda Motor Co., Ltd.

NOTICE 1

1

INTRODUCTION

A FEW WORDS ABOUT SAFETY

Your safety and the safety of others are very important. And using this

outboard motor safely is an important responsibility.

To help you make informed decisions about safety, we have provided

operating procedures and other information on labels and in this manual. This

information alerts you to potential hazards that could hurt you or others.

Of course, it is not practical or possible to warn you about all the hazards

associated with operating or maintaining an outboard motor. You must use

your own good judgment.

You will find important safety information in a variety of forms, including:

l

Safety Labels - on the outboard motor.

l

Safety Messages- preceded by a safety alert symbol A and one of three

signal words, DANGER, WARNING, or CAUTION.

These signal words mean:

You WILL be KILLED or SERIOUSLY HURT if you

don’t follow instructions.

You CAN be KILLED or SERIOUSLY HURT if you

don’t follow instructions.

l

Safety Headings - such as IMPORTANT SAFETY INFORMATION.

l

Safety Section - such as OUTBOARD MOTOR SAFETY.

l

Instructions - how to use this outboard motor correctly and safely.

This entire book is filled with important safety information - please read it

carefully.

2

CONTENTS

OUTBOARD MOTOR SAFETY

IMPORTANT SAFETY INFORMATION

Operator Responsibility

Refuel With Care

Carbon Monoxide

SAFETY LABEL LOCATIONS

CONTROLS & FEATURES

COMPONENT & CONTROL LOCATIONS

CONTROLS

Engine Stop Switch

Choke Knob

Throttle Lever..

Throttle Grip

Throttle Grip Friction

Fuel Valve Lever

Recoil Starter Grip

Steering Friction Bolt

Tilt Lever

Transom Angle Adjusting Bolt

Fuel Cap Vent Knob

Engine Cover Retaining Strap

Clamp Screws

FEATURES

Centrifugal Clutch

Oil Level Inspection

Anode ..............................................................................................

.........................................................................................

..........................................................................................

..........................................................................................

................................................................................

Hazard

.....................................................................................

................................................................................

....................................................................................

.............................................................................

..........................................................................

.................................................................................

............................................................................

..............................................

.....................................................................

.................................................................

...............................................................

.....................................

..........................................................................

Knob

..............................................................

........................................................................

..........................................................

........................................................................

.........................................................

Window

...........................................................

.

...................

.................................................

.

................................

..........................................

7

7

7

8

.8

9

10

10

12

12

12

.13

.13

.13

.14

.14

15

15

16

16

17

.17

18

18

.18

18

3

CONTENTS

INSTALLATION ........................................................................................ 19

INSTALLATION

INSTALLATION

OUTBOARD

MOTOR

MOTOR

ANGLE FOR CRUISING

ANGLE ADJUSTMENT

POSITION ................................................................. 19

HEIGHT

MOTOR ATTACHMENT ................................................

.....................................................................

......................................................

........................................................

19

.20

.20

.21

BEFORE OPERATION

ARE YOU

Knowledge

Safety Apparel

IS YOUR OUTBOARD MOTOR

Safety Inspection ............................................................................

Maintenance Inspection ..................................................................

OPERATION .............................................................................................

SAFE

BREAK-IN PROCEDURE

STARTING

EMERGENCY

STOPPING

Emergency Engine Stopping

Normal Engine Stopping

STEERING

CRUISING ...........................................................................................

REVERSING THE OUTBOARD

TILTING THE OUTBOARD

READY TO GET UNDER WAY? .......................................

......................................................................................

OPERATING PRECAUTIONS.. ................................................

THE ENGINE ...................................................................

THE ENGINE..

..........................................................................................

.............................................................................

................................................................................

READY TO GO?. ............................. .22

...................................................................

STARTING ..................................................................

.................................................................

..........................................................

.................................................................

MOTOR

MOTOR

...........................................

..................................................

22

.22

.22

.22

.23

.23

24

.24

.24

.25

.28

.29

.29

.29

.31

.32

.33

.34

4

CONTENTS

5

SERVICING YOUR HONDA OUTBOARD MOTOR

THE IMPORTANCE OF MAINTENANCE ...........................................

MAINTENANCE SAFETY

Safety Precautions

TOOL KIT AND SPARE PARTS

MAINTENANCE SCHEDULE .............................................................

REFUELING

FUEL RECOMMENDATIONS.. ...........................................................

CLEANING ..........................................................................................

ENGINE OIL LEVEL CHECK ..............................................................

ENGINE OIL CHANGE

ENGINE OIL RECOMMENDATIONS .................................................

GEAR OIL LEVEL CHECK

GEAR OIL CHANGE

LUBRICATION

SPARK PLUG SERVICE

RECOIL STARTER ROPE

ANODE REPLACEMENT

SHEAR PIN REPLACEMENT

.........................................................................................

.....................................................................................

....................................................................

...........................................................................

..........................................................

........................................................................

..................................................................

............................................................................

.....................................................................

INSPECTION

...................................................................

..............................................................

...........................................

................................. 36

.36

37

37

38

.39

40

.41

.42

.43

44

.45

46

47

48

49

.51

.51

52

HELPFUL TIPS & SUGGESTIONS

STORING YOUR OUTBOARD

Storage Preparation

Storage Precautions .......................................................................

Removal From Storage

TRANSPORTING..

........................................................................

....................................................................

..............................................................................

.......................................................... 53

MOTOR.. ........................................... .53

.53

.56

57

.57

CONTENTS

TAKING CARE OF UNEXPECTED PROBLEMS

ENGINE WILL NOT START

SUBMERGED MOTOR

TECHNICAL & CONSUMER INFORMATION

TECHNICAL INFORMATION

Serial Number Locations

Carburetor Modification for High Altitude Operation .......................

Oxygenated Fuels

Emission Control System Information

Specifications

WIRING DIAGRAMS

CONSUMER INFORMATION

Honda Publications

Warranty Service Information .......................................................... 71

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

...........................................................................

..................................................................................

...........................................................................

................................................................

.......................................................................

..............................................................

.................................................................

.............................................

.............................................................

.........................................................................

....................................

.........................................

59

.59

.60

62

.62

.62

.63

.64

.65

.67

.69

.70

.70

QUICK REFERENCE INFORMATION

6

. . . . . . . . . . . . . . . . . . . . . . . . . . Inside back cover

OUTBOARD MOTOR SAFETY

IMPORTANT SAFETY INFORMATION

Honda BF2D outboard motors are designed for use with boats that have a

suitable manufacturer’s power recommendation, and other uses can result in

injury to the operator or damage to the outboard motor and other property.

Most accidents can be prevented if you follow all instructions in this manual

and on the outboard motor. The most common hazards are discussed below,

along with the best way to protect yourself and others.

Operator Responsibility

l

It is the operator’s responsibility to provide the necessary safeguards to

protect people and property. Know how to stop the engine quickly in case

of emergency. Understand the use of all controls.

l

Stop the engine immediately if anyone falls overboard, and do not run the

engine while the boat is near anyone in the water.

l

Always stop the engine if you must leave the controls for any reason.

l

Attach the emergency stop switch lanyard securely to the operator.

l

Always wear a PERSONAL FLOTATION DEVICE (PFD) while on the boat.

l

Familiarize yourself with all laws and regulations relating to boating and the

use of outboard motors.

l

Be sure that anyone who operates the outboard motor receives proper

instruction.

l

Be sure the outboard motor is properly mounted on the boat.

l

Do not remove the engine cover while the engine is running.

l

I

Do not attempt to modify the outboard motor.

l

Do not remove any labels, covers, or safety devices; they are installed for

your safety.

7

OUTBOARD MOTOR SAFETY

8

Refuel With Care

l

Gasoline is extremely flammable, and gasoline vapor can explode. Refuel

outdoors, in a well-ventilated area, with the engine stopped. Never smoke

near gasoline, and keep other flames and sparks away.

l

Refuel carefully to avoid spilling fuel. Avoid overfilling the fuel tank.

l

After refueling, tighten the filler cap securely. If any fuel is spilled, make sure

the area is dry before starting the engine.

Carbon Monoxide Hazard

Exhaust gas contains poisonous carbon monoxide. Avoid inhalation of

exhaust gas. Never run the engine in a closed garage or confined area.

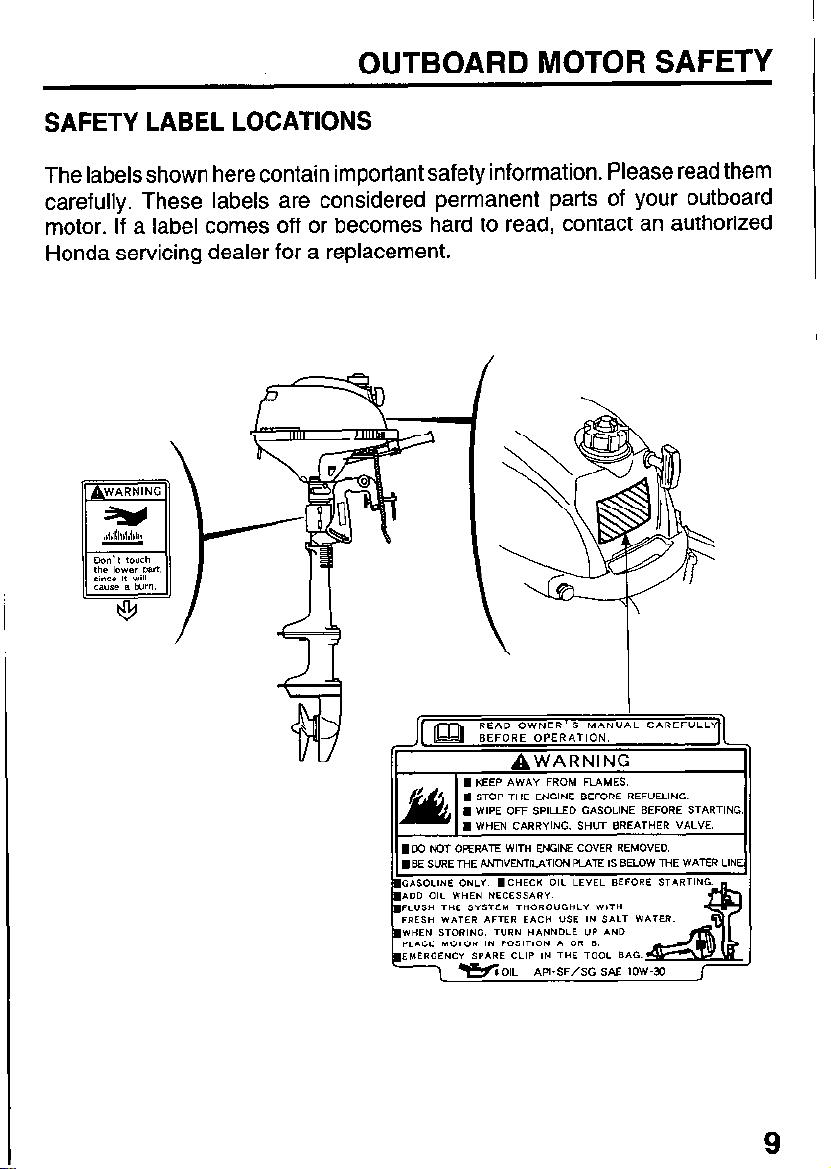

OUTBOARD MOTOR SAFETY

SAFETY LABEL LOCATIONS

The labels shown here contain important safety information. Please read them

carefully. These labels are considered permanent parts of your outboard

motor. If a label comes off or becomes hard to read, contact an authorized

Honda servicing dealer for a replacement.

lo0 NOT OPERATE WITH ENGINE COVER REMOVED.

n BE SURE THE ANnVENTtLATlC+d PLATE IS BELOW THE WATER LIN

TER AFTER EACH “SE IN SALT WATER.

RING. T”RN HANNOLE VP AND

OR IN POSITION A OR 8.

CY SPARE CLIP IN THE TOOL BAG.

+&OIL API-SF/X SAE low-33

9

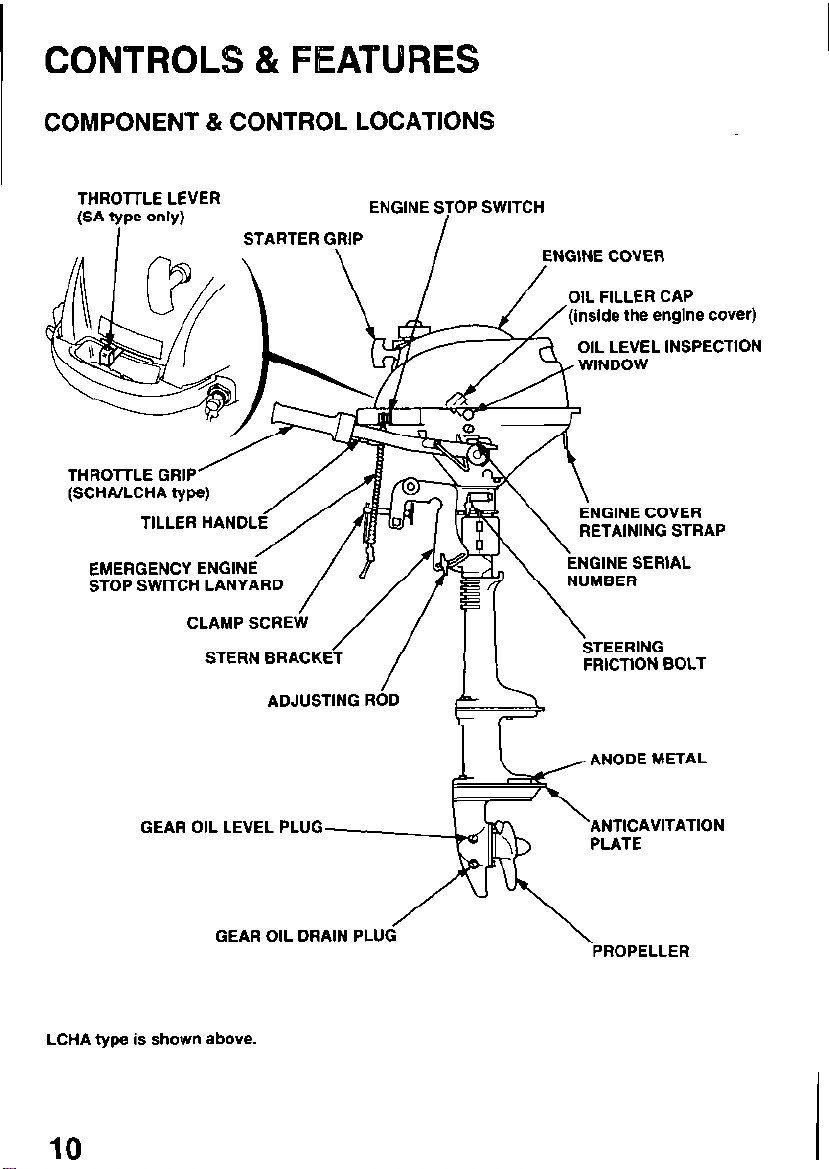

CONTROLS & FEATURES

10

COMPONENT & CONTROL LOCATIONS

THROllLE LEVER

PA type only)

THROlTLE GRI

(SCHAILCHA ty

TILLER HANDL

EMERGENCY ENGIN

CTnD CWlTfSl

. -. . _..._ .%RD

CLAMP SCREW

I ANV

STERN BRACKEC

ADJUSTING ROD

ENGINE SJOP SWITCH

RETAINING STRAP

NGINE SERIAL

FRICTION BOLT

/

ANODE METAL

GEAR OIL LEVEL PLUG

GEAR OIL DRAIN PLU

LCHA type is shown above.

ANTICAVITATION

PROPELLER

CASE PROTECTOR

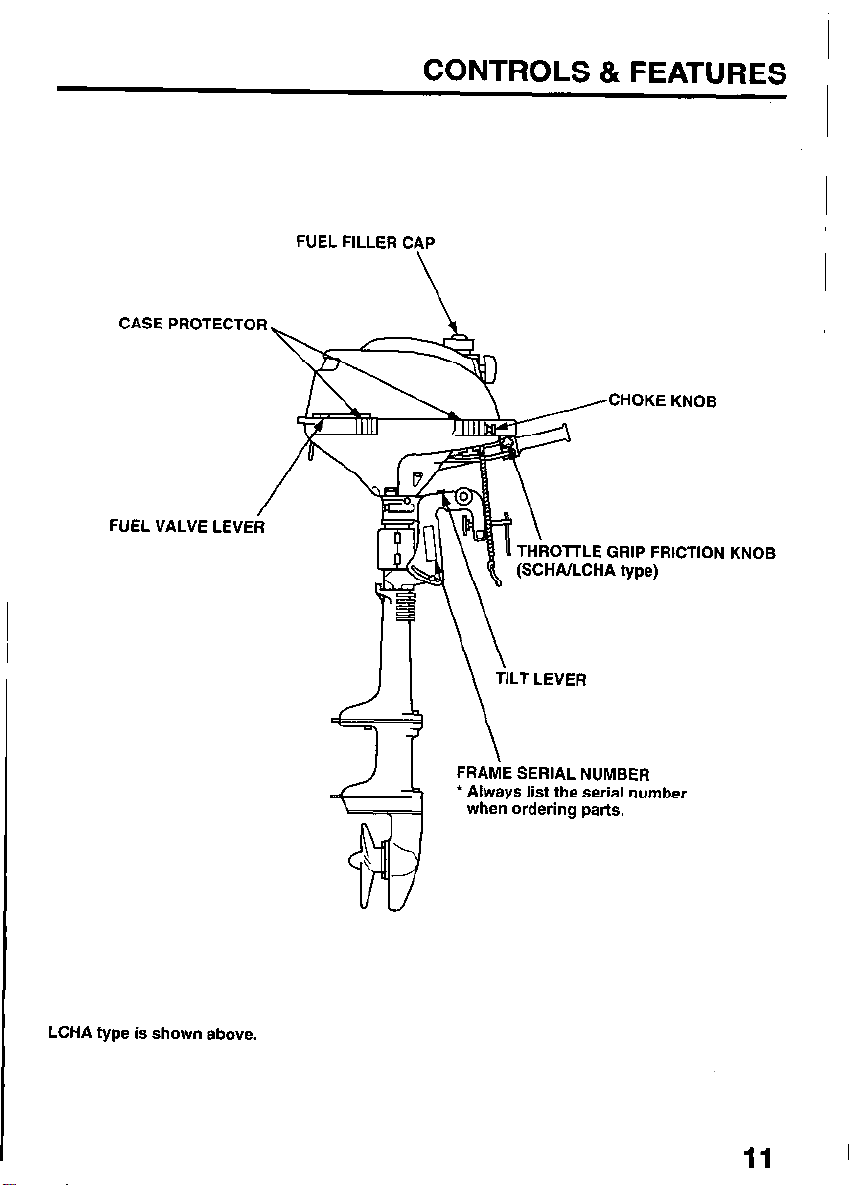

CONTROLS & FEATURES

FUEL FILLER CAP

~>J/CH~KE KNOB

FUEL VALVE LEVE

LCHA type is shown above.

THkOlTLE GRIP FRICTION

(SCHAILCHA type)

\ TILT LEVER

=!5=+ \

FRAME SERIAL NUMBER

l

Always list the serial number

when ordering parts.

KNOB

11

CONTROLS & FEAUURES

12

CONTROLS

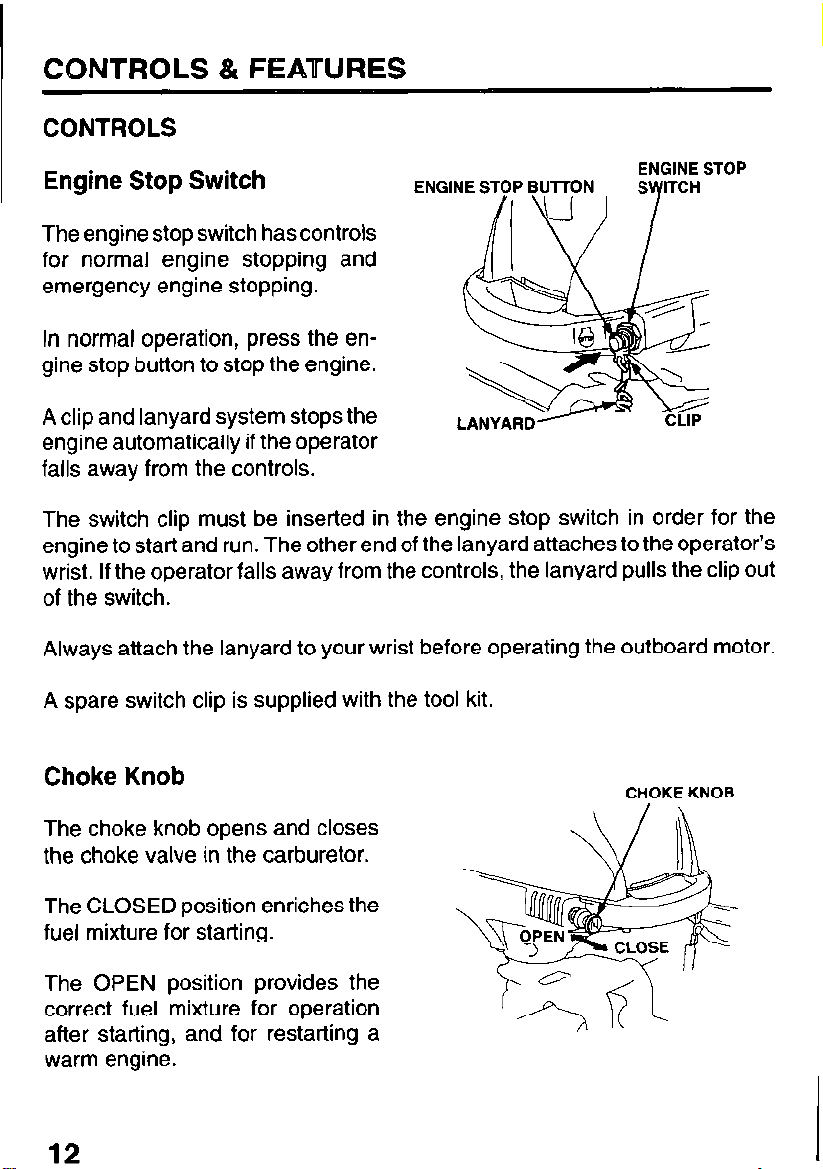

Engine Stop Switch

The engine stop switch has controls

for normal engine stopping and

emergency engine stopping.

In normal operation, press the engine stop button to stop the engine.

A clip and lanyard system stops the

engine automatically if the operator

falls away from the controls.

The switch clip must be inserted in the engine stop switch in order for the

engine to start and run. The other end of the lanyard attaches to the operator’s

wrist. If the operator falls away from the controls, the lanyard pulls the clip out

of the switch.

Always attach the lanyard to your wrist before operating the outboard motor.

A spare switch clip is supplied with the tool kit.

ENGINE STOP

Choke Knob

Thechoke knobopensand closes

the choke valve in the carburetor.

The CLOSED position enriches the

fuel mixture for starting.

The OPEN position provides the

correct fuel mixture for operation

after starting, and for restarting a

warm engine.

CHOKE KNOB

CONTROLS & FEATURES

1

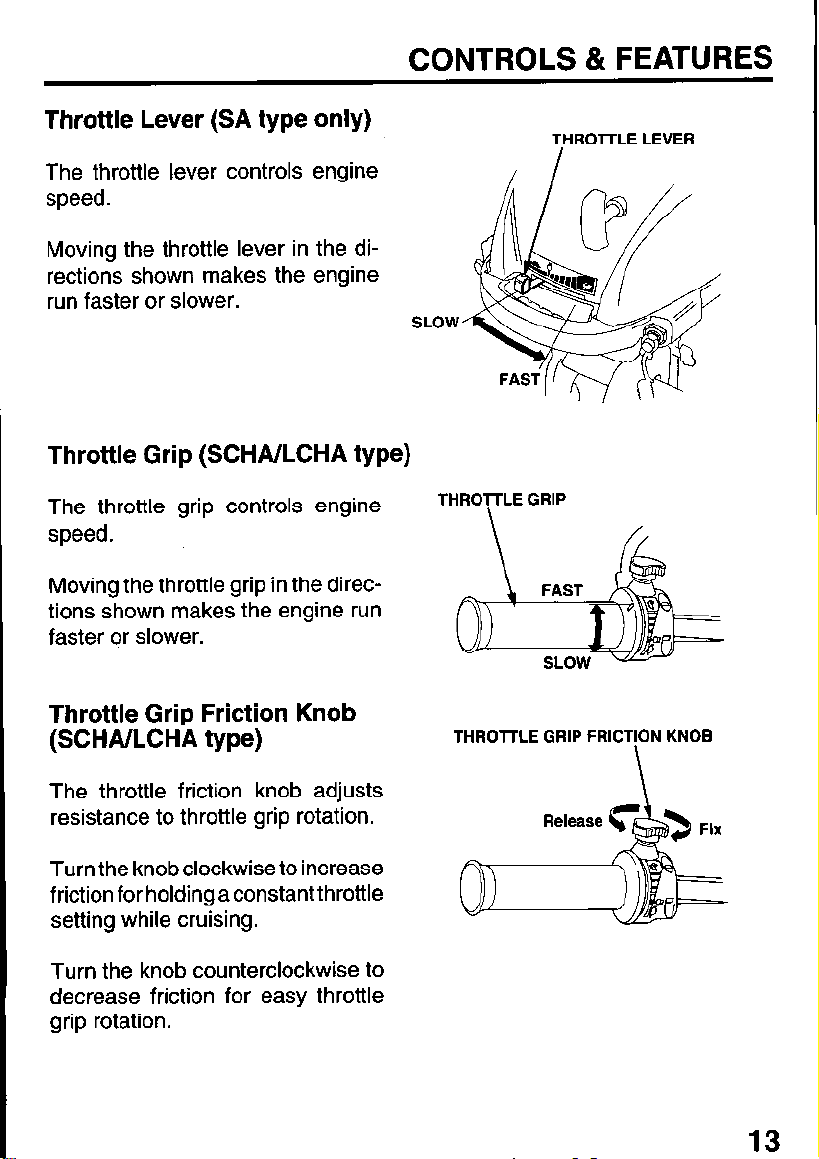

Throttle Lever (SA type only)

The throttle lever controls engine

speed.

Moving the throttle lever in the di-

rections shown makes the engine

run faster or slower.

Throttle Grip (SCHAILCHA type)

The throttle grip controls engine

speed.

Moving the throttle grip in the directions shown makes the engine run

faster or slower.

THROlTLE LEVER

SLOW

THROlTLE GRIP

\

Throttle Grip Friction Knob

(SCHA/LCHA type)

The throttle friction knob adjusts

resistance to throttle grip rotation.

Turn the knob clockwise to increase

friction for holding a constant throttle

setting while cruising.

Turn the knob counterclockwise to

decrease friction for easy throttle

grip rotation.

THRO-ITLE GRIP FRICTION KNOB

13

CONTROLS & FEATURES

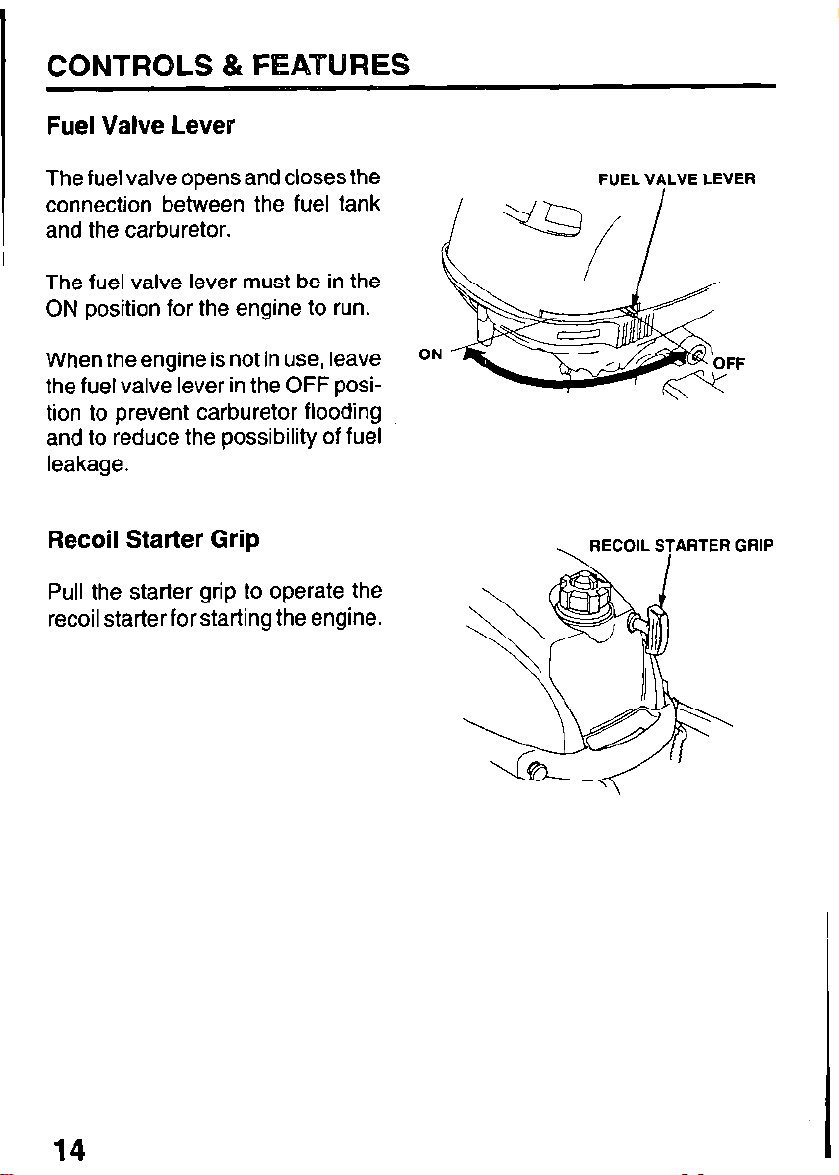

Fuel Valve Lever

The fuel valve opens and closes the

connection between the fuel tank

and the carburetor.

The fuel valve lever must be in the

ON position for the engine to run.

When the engine is not in use, leave

the fuel valve lever in the OFF position to prevent carburetor flooding

and to reduce the possibility of fuel

leakage.

Recoil Starter Grip

Pull the starter grip to operate the

recoil starter for starting the engine.

ON

FUEL VALVE LEVER

RECOIL STARTER

FF

GRIP

14

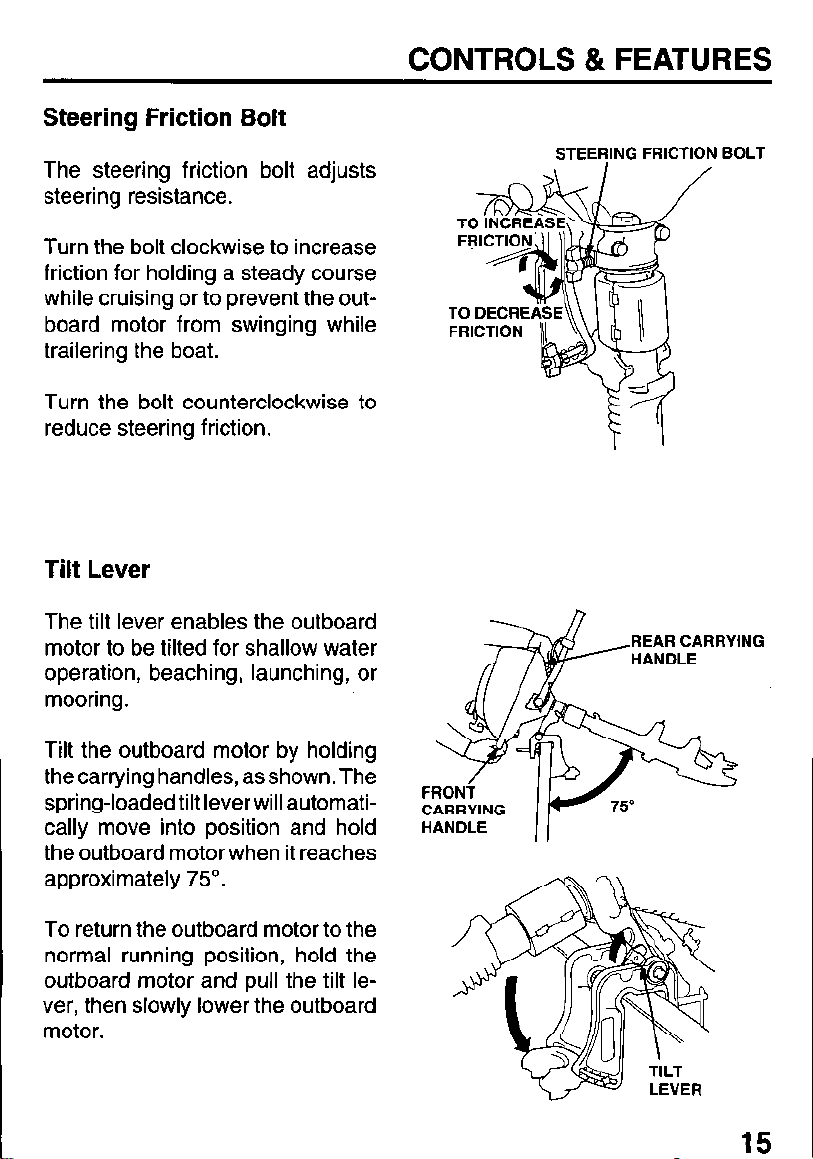

Steering Friction Bolt

15

The steering friction bolt adjusts

steering resistance.

Turn the bolt clockwise to increase

friction for holding a steady course

while cruising or to prevent the outboard motor from swinging while

trailering the boat.

Turn the bolt counterclockwise to

reduce steering friction.

Tilt Lever

CONTROLS & FEATURES

STEERING FRICTION BOLT

The tilt lever enables the outboard

motor to be tilted for shallow water

operation, beaching, launching, or

mooring.

Tilt the outboard motor by holding

the carrying handles, as shown. The

spring-loaded tilt lever will automatitally move into position and hold

the outboard motor when it reaches

approximately 75”.

To return the outboard motor to the

normal running position, hold the

outboard motor and pull the tilt lever, then slowly lower the outboard

motor.

REAR CARRYING

CARRYING

CONTROLS & FEAlJURES

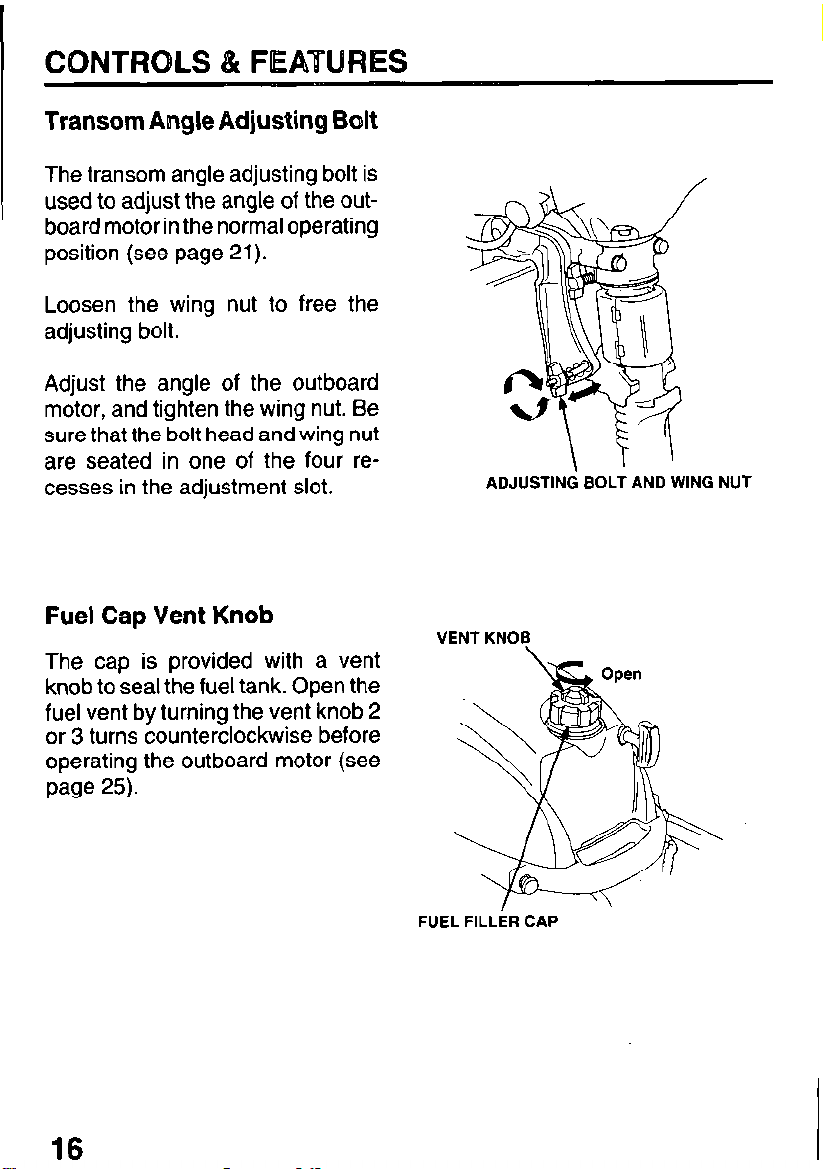

Transom Angle Adjusting Bolt

The transom angle adjusting bolt is

used to adjust the angle of the out-

board motor in the normal operating

position (see page 21).

Loosen the wing nut to free the

adjusting bolt.

Adjust the angle of the outboard

motor, and tighten the wing nut. Be

sure that the bolt head and wing nut

are seated in one of the four re-

cesses in the adjustment slot.

ADJlJSTlNd BOLT AND WING NUT

Fuel Cap Vent Knob

The cap is provided with a vent

knob to seal the fuel tank. Open the

fuel vent by turning the vent knob 2

or 3 turns counterclockwise before

operating the outboard motor (see

page 25).

76

VENT KNOB

FUEL FILLER CAP

\

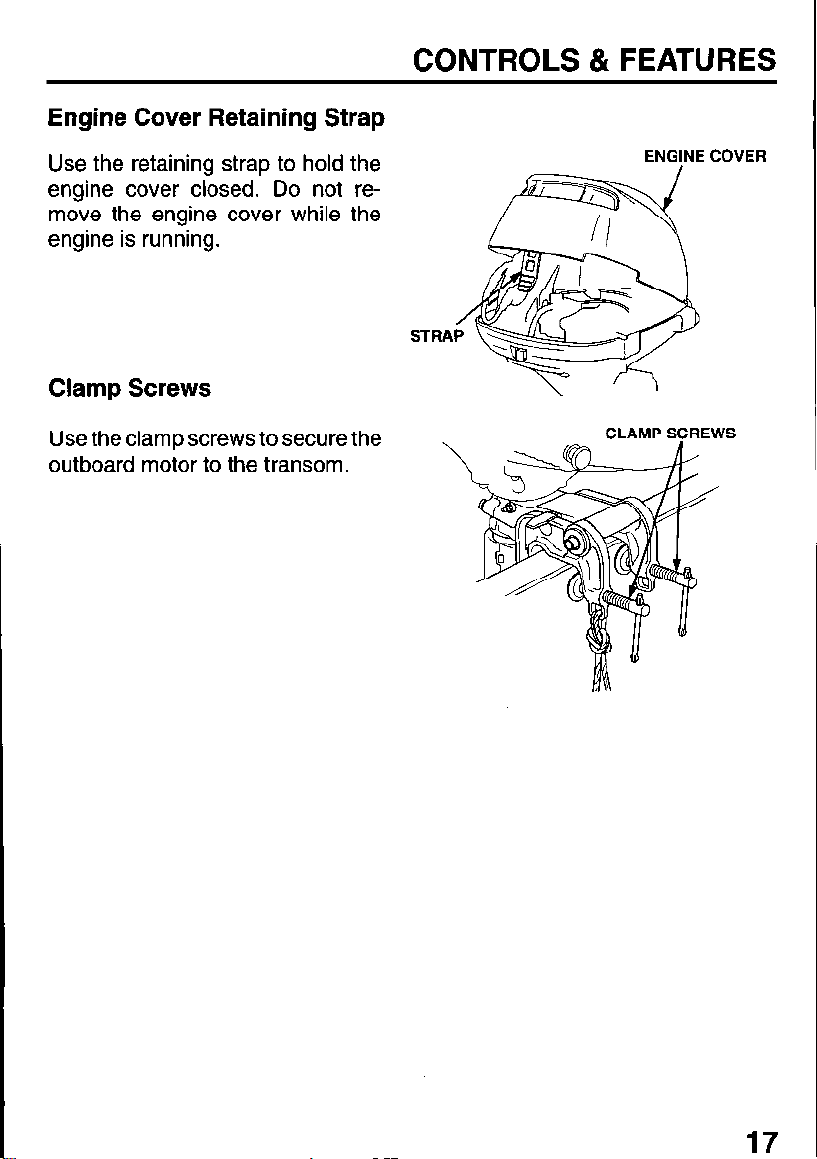

Engine Cover Retaining Strap

CONTROLS & FEATURES

Use the retaining strap to hold the

engine cover closed. Do not remove the engine cover while the

engine is running.

Clamp Screws

Use the clamp screws to secure the

outboard motor to the transom.

ENGINE COVER

CLAMP SCREWS

77

CONTROLS & FEATURES

78

FEATURES

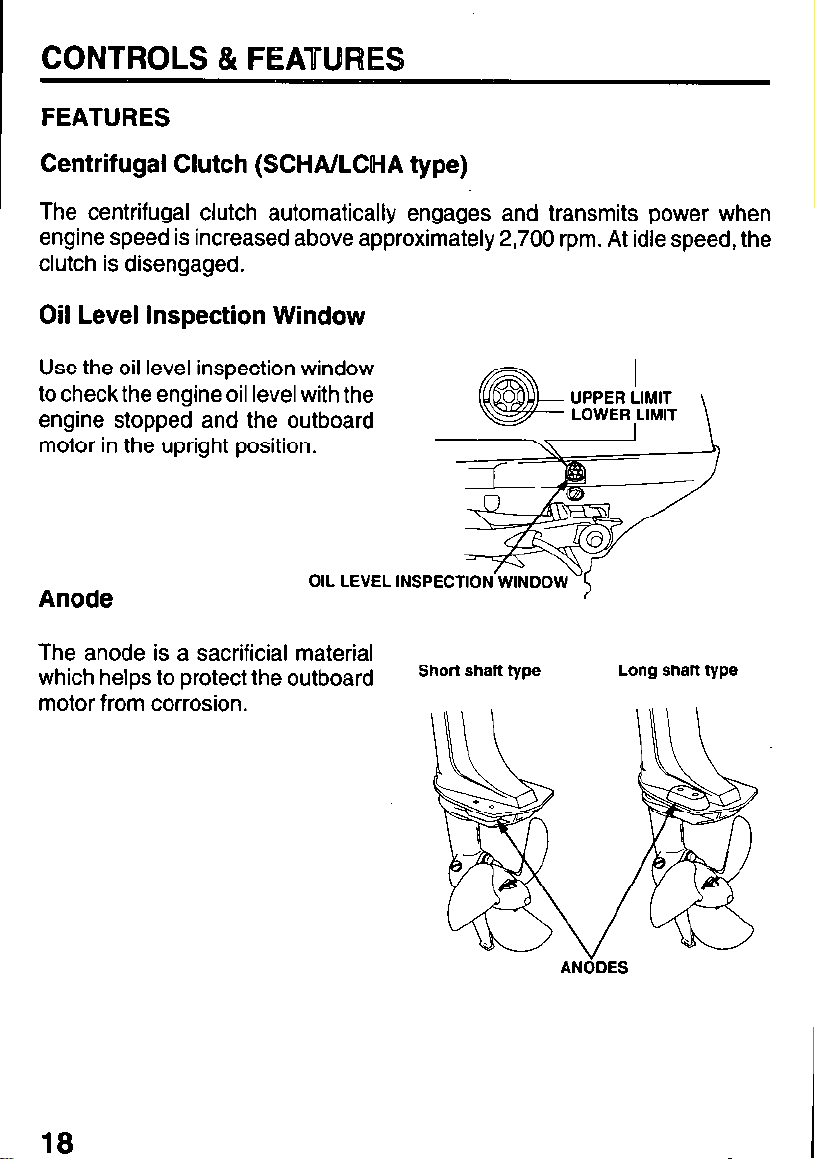

Centrifugal Clutch (SCHA/LCHA type)

The centrifugal clutch automatically engages and transmits power when

engine speed is increased above approximately 2,700 rpm. At idle speed, the

clutch is disengaged.

Oil Level Inspection Window

Use the oil level inspection window

to check the engine oil level with the

engine stopped and the outboard

motor in the upright position.

OIL LEVEL INSPEC

Anode

The anode is a sacrificial material

which helps to protect the outboard

motor from corrosion.

INSTALLATION

79

It is your responsibility to choose a boat suitable for the engine.

Do not exceed the boat manufacturer’s power recommendation.

Damage and injury may result.

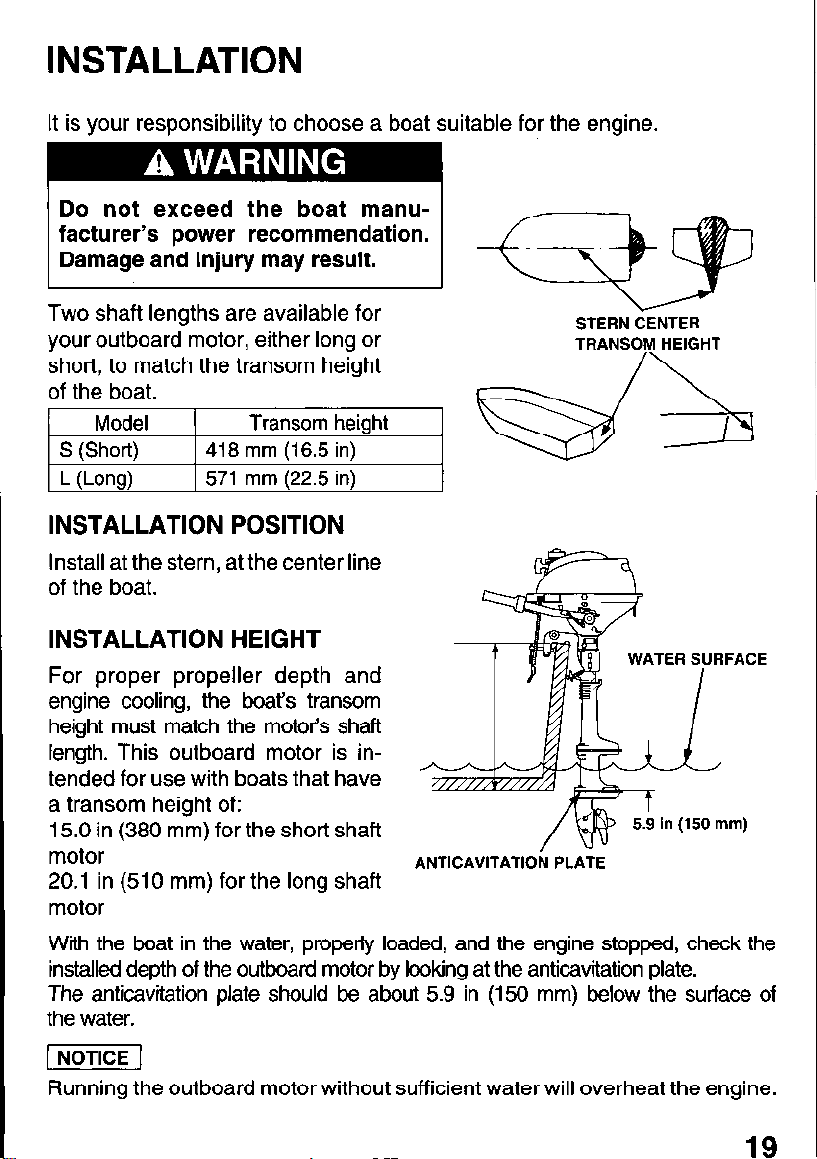

Two shaft lengths are available for

your outboard motor, either long or

short, to match the transom height

of the boat.

I

Model 1 Transom heiaht 1

S (Short)

L (Long)

418 mm (16.5 in)

571 mm (22.5 in)

INSTALLATION POSITION

Install at the stern, at the center line

of the boat.

INSTALLATION HEIGHT

For proper propeller depth and

engine cooling, the boat’s transom

height must match the motors shaft

length. This outboard motor is intended for use with boats that have

a transom height of:

15.0 in (380 mm) for the short shaft

motor

20.1 in (510 mm) for the long shaft

motor

STERNdENTER

TRANSOM HEIGHT

ANTICAVITATION PLATE

/ Y”

With the boat in the water, properly loaded, and the engine stopped, check the

installed depth of the outboard motor by looking at the anticavitation plate.

The anticavitation plate should be about 5.9 in (150 mm) below the surface of

the water.

Running the outboard motor without sufficient water will overheat the engine.

INSTALLATION

20

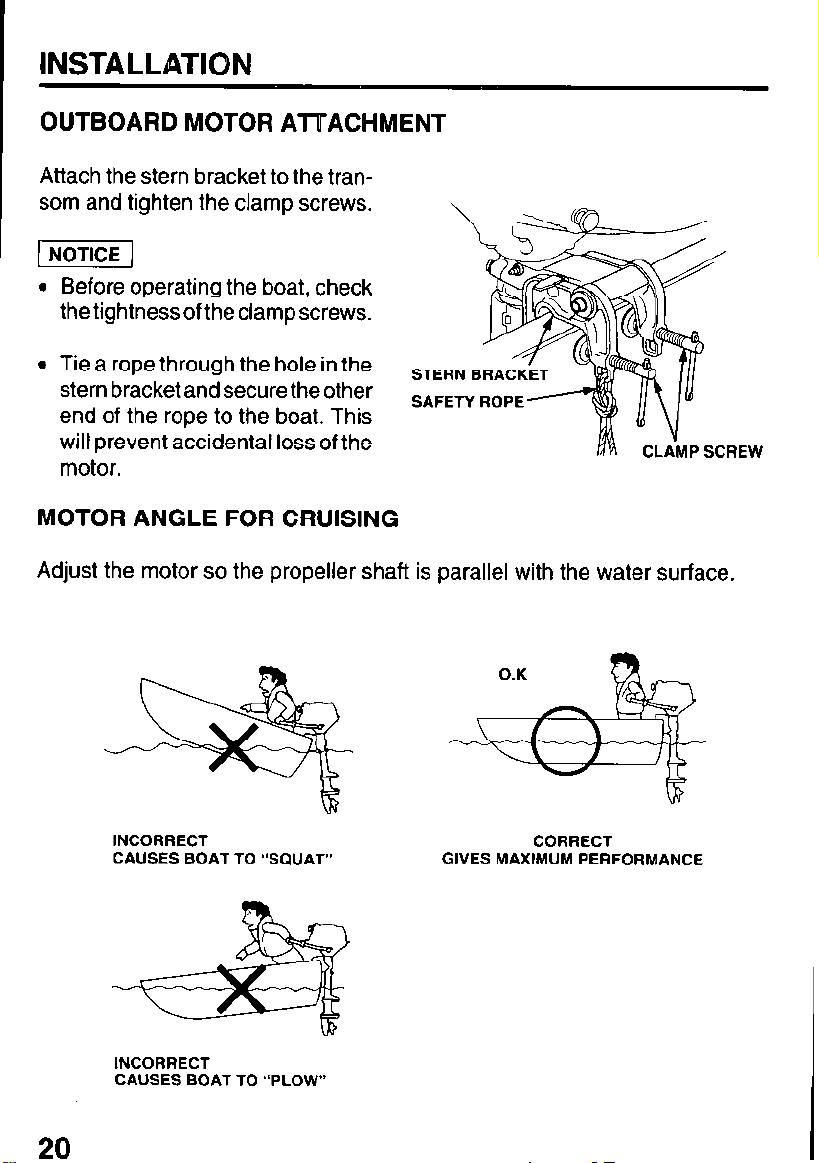

OUTBOARD MOTOR AlTACHMENT

Attach the stern bracket to the transom and tighten the clamp screws.

( NOTICE 1

l

Before operating the boat, check

the tightness of the clamp screws.

l

Tie a rope through the hole in the

stern bracket and secure the other

end of the rope to the boat. This

will prevent accidental loss of the

motor.

MOTOR ANGLE FOR CRUISING

Adjust the motor so the propeller shaft is parallel with the water surface.

INCORRECT

CAUSES BOAT TO “SQUAT”

INCORRECT

CAUSES BOAT TO “PLOW”

GIVES MAXIMUM PERFORMANCE

CORRECT

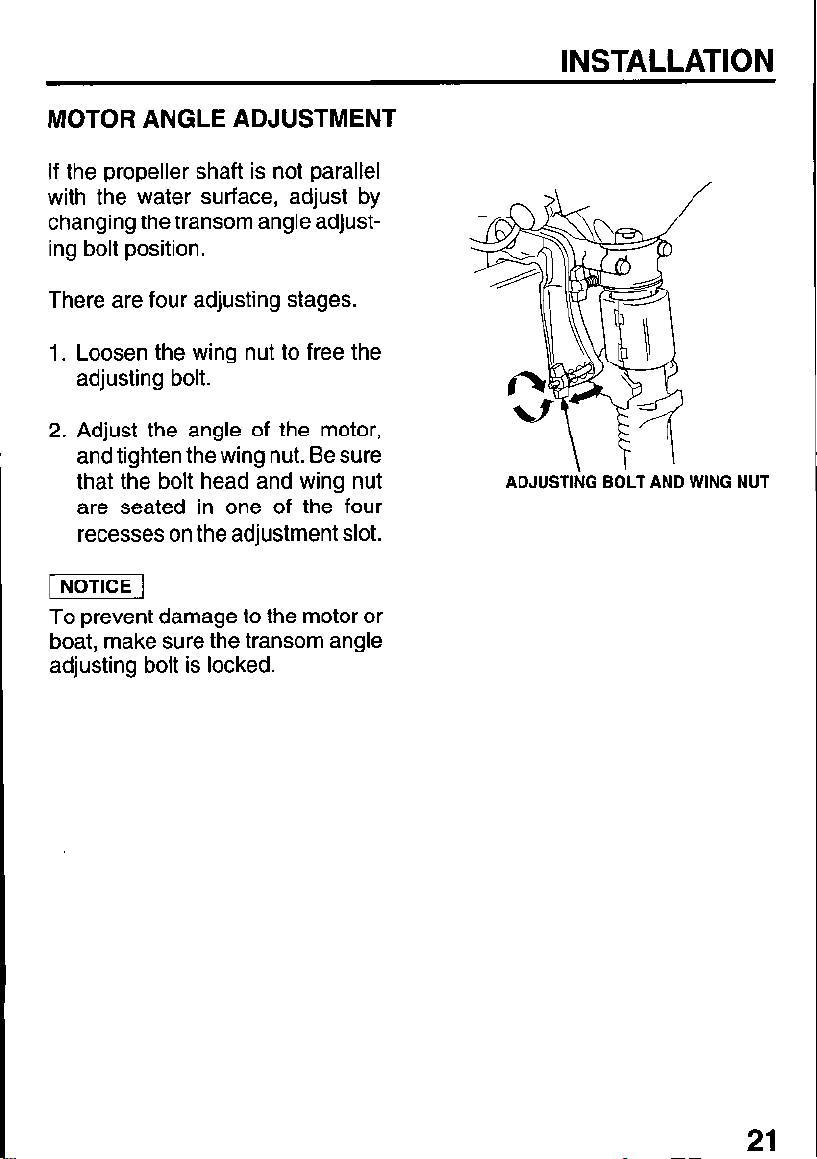

MOTOR ANGLE ADJUSTMENT

If the propeller shaft is not parallel

with the water surface, adjust by

changing the transom angle adjusting bolt position.

There are four adjusting stages.

1. Loosen the wing nut to free the

adjusting bolt.

2. Adjust the angle of the motor,

and tighten the wing nut. Be sure

that the bolt head

are seated in one of the four

and wing nut

recesses on the adjustment slot.

To prevent damage to the motor or

boat, make sure the transom angle

adjusting bolt is locked.

INSTALLATION

27

BEFORE CWERATION

ARE YOU READY TO GET UNDERWAY?

Your safety is your responsibility. A little time spent in preparation will

significantly reduce your risk of injury.

Knowledge

Read and understand this manual. Know what the controls do and how to

operate them.

Familiarize yourself with the outboard motor and its operation before you get

underway. Know what to do in case of emergencies.

Familiarize yourself with all laws and regulations relating to boating and the

use of outboard motors.

Safety Apparel

Always wear a PERSONAL FLOTATION DEVICE (PFD) while on the boat.

IS YOUR OUTBOARD MOTOR READY TO GO?

For your safety, and to maximize the service life of your equipment, it is very

important to take a few moments before you operate the outboard motor to

check its condition. Be sure to take care of any problem you find, or have your

servicing dealer correct it, before you operate the outboard motor.

Improperly maintaining this outboard motor,

or failing to correct a problem before opera-

tion, could cause a malfunction in which you

could be seriously injured.

Always perform a preoperation inspection

before each operation, and correct any

problem.

22

BEFORE OPERATION

23

Safety Inspection

l

Look around for signs of oil or gasoline leaks. Make sure the fuel filler cap

and cap gasket are in good condition. Wipe up any spills before starting the

engine.

l

Check the stern bracket to be sure the outboard motor is securely installed.

l

Check that all controls are operating properly

l

Replace any damaged parts.

l

Check that all fasteners are in place and securely tightened.

Maintenance Inspection

l

Check the engine oil level (see page 43). Running the engine with a low oil

level can cause engine damage.

l

Check to be sure the propeller is undamaged, and secured with a cotter pin

(see page 52).

l

Check that the anode is securely attached to the anticavitation plate and is

not excessively worn (see page 51). The anode helps to protect the

outboard motor from corrosion.

l

Make sure the tool kit and spare parts are onboard (see page 38).

Replace any missing items.

l

Check the fuel level in the fuel tank (see page 40).

Loading...

Loading...