Honda Power Equipment BF2A User Manual

Thank you for purchasing a Honda Outboard Motor.

This manual covers operation and maintenance of the Honda BF2A

Outboard Motor. All information in this publication is based on the latest

product information available at the time of approval for printing.

Honda Motor Co., Ltd. reserves the right to make changes at any time

without notice and without incurring any obligation.

No part of this publication may be reproduced without written permission.

This manual should be considered a permanent part of the Outboard Motor

and should remain with the Outboard Motor when it is sold.

Pay special attention to statements preceded by the following words:

ADANGER: Indicates severe personal injury or death will result if instructions are not followed.

m Indicates a strong possibility of severe personal injury or death

if instructions are not followed.

CAUTION: Indicates a possibility of personal injury or equipment damage

if instructions are not followed.

NOTE: Gives helpful information.

If a problem should arise, or if you have any questions about the Outboard

Motor, consult an authorized Honda dealer.

1

CONTENTS

1. SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. COMPONENT IDENTIFICATION

3. INSTALLATION

4. PRE-OPERATION CHECKS

5. STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. OPERATION

7. STOPPING THE ENGINE

8. MAINTENANCE

9. TRANSPORTING/STORAGE

10. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. SPECIFICATIONS

12. OPTIONAL PART

13. WARRANTY SERVICE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . : . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

5

7

9

13

18

24

‘26

35

37

38

40

2

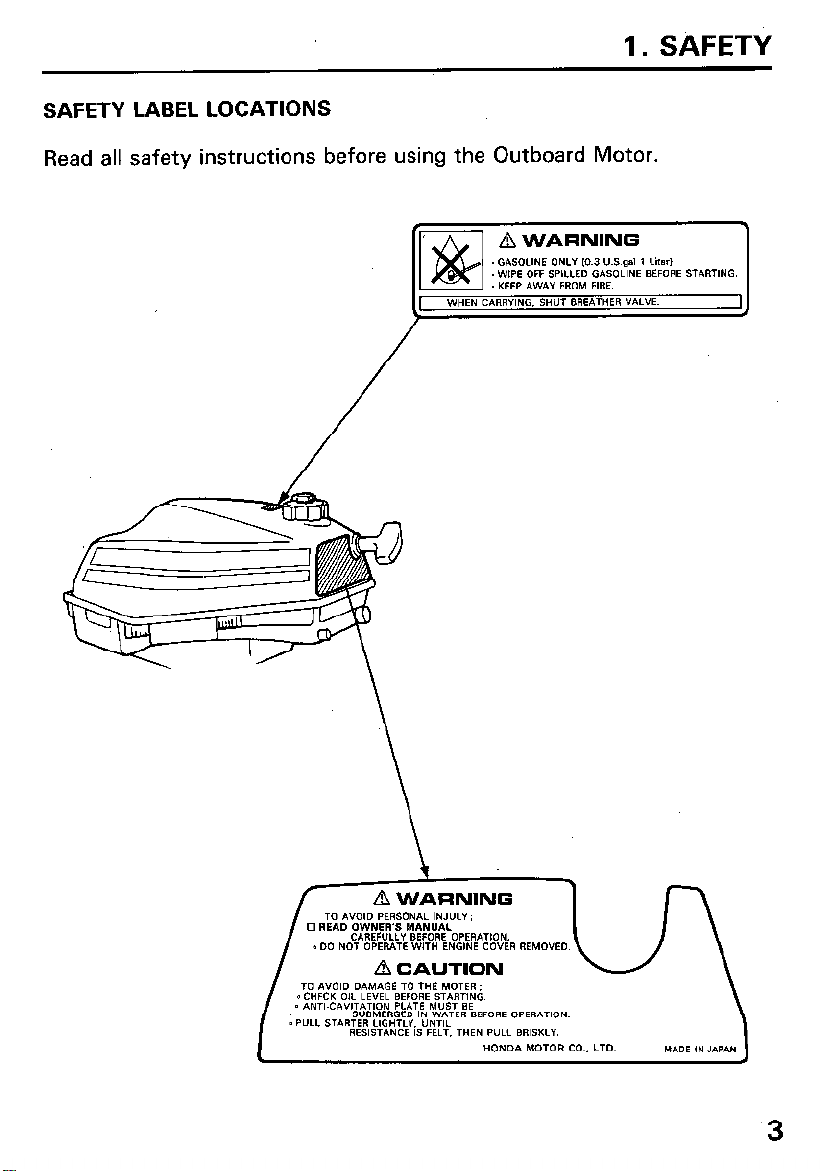

1. SAFETY

SAFETY LABEL LOCATIONS

Read all safety instructions before using the Outboard Motor.

WARNING

. GASOLINE ONLY 10.3 U.S.gal 1

. WPE OFF SPlLLED GASOLINE BEFORE STARTING.

. KEEP AWAY FROM FIRE.

Liter)

L% WARNING

TO AWlD PERSONAL INJULY;

Cl READ OWNER’S MANVAL

CAREFULLY BEFORE OPERATION.

0 DO NOT OPERATE WITH ENGINE COVER

TO A”OlD DAMAGE TO THE MOTER ;

0 CHFCK OIL LEVEL BEFORE STARTING.

0 ANTI-CAYITATKJN PLATE MVST BE

D PULL STARTER LIGHTLY. “NTIL

Ld CAUTION

SVBMERGED IN WATER BEFORE OPERATION.

RESISTANCE IS FELT. THEN PULL BRISKLY.

REMOVED.

HONDA MOTOR CO., LTD.

MADE IN JAPAN

3

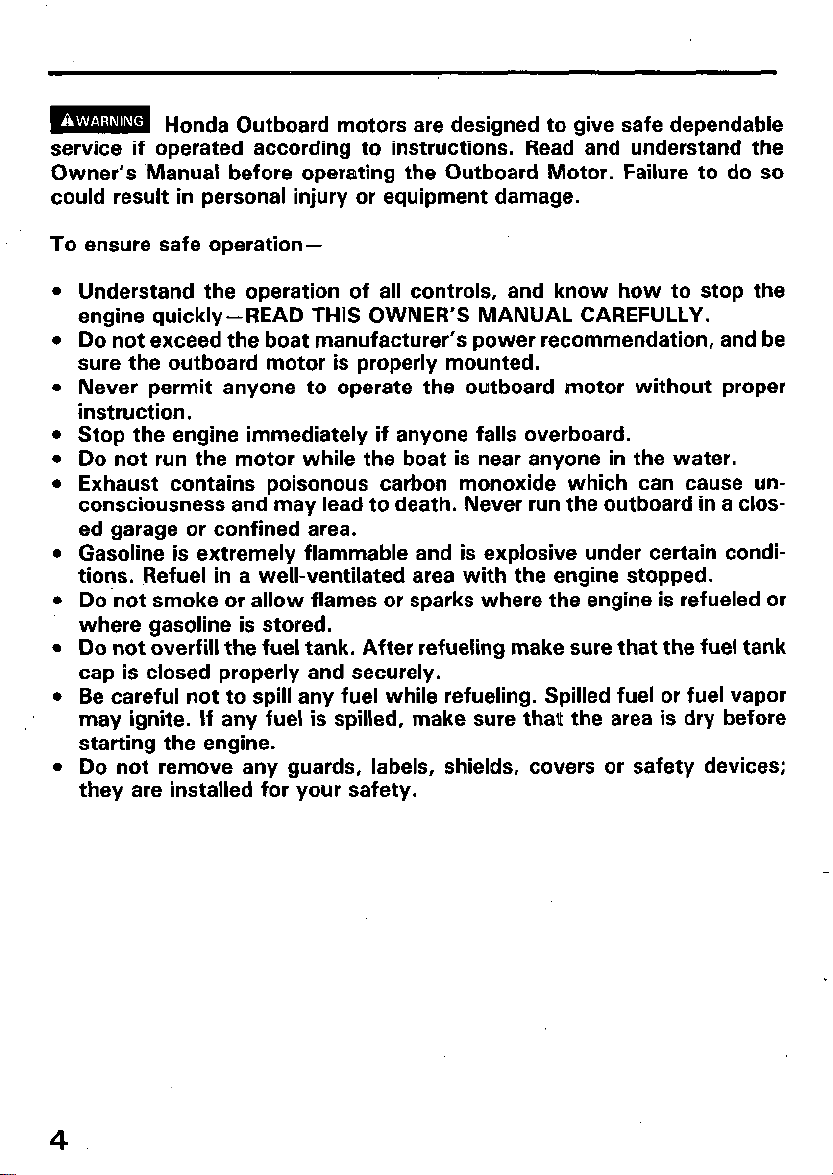

m

service if operated according to instructions. Read-and understand the

Owner’s ‘Manual before operating the Outboard Motor. Failure to do so

could result in personal injury or equipment damage.

To ensure safe operation-

Understand the operation of all controls, and know how to stop the

engine quickly- READ THlS OWNER’S MANUAL CAREFULLY.

Do not exceed the boat manufacturer’s power recommendation, and be

sure the outboard motor is properly mounted.

Never permit anyone to operate the outboard motor without proper

instruction.

Stop the engine immediately if anyone falls overboard.

Do not run the motor while the boat is near anyone in the water.

Exhaust contains poisonous carbon monoxide which can cause unconsciousness and may lead to death. Never run the outboard in a closed garage or confined area.

Gasoline is extremely flammable and is explosive under certain conditions. Refuel in a well-ventilated area with the engine stopped.

Do not smoke or allow flames or sparks where the engine is refueled or

where gasoline is stored.

Do not overfill the fuel tank. After refueling make sure that the fuel tank

cap is closed properly and securely.

Be careful not to spill any fuel while refueling. Spilled fuel or fuel vapor

may ignite. If any fuel is spilled, make sure that the area is dry before

starting the engine.

Do not remove any guards, labels, shields, covers or safety devices;

they are installed for your safety.

Honda Outboard motors are designed to give safe dependable

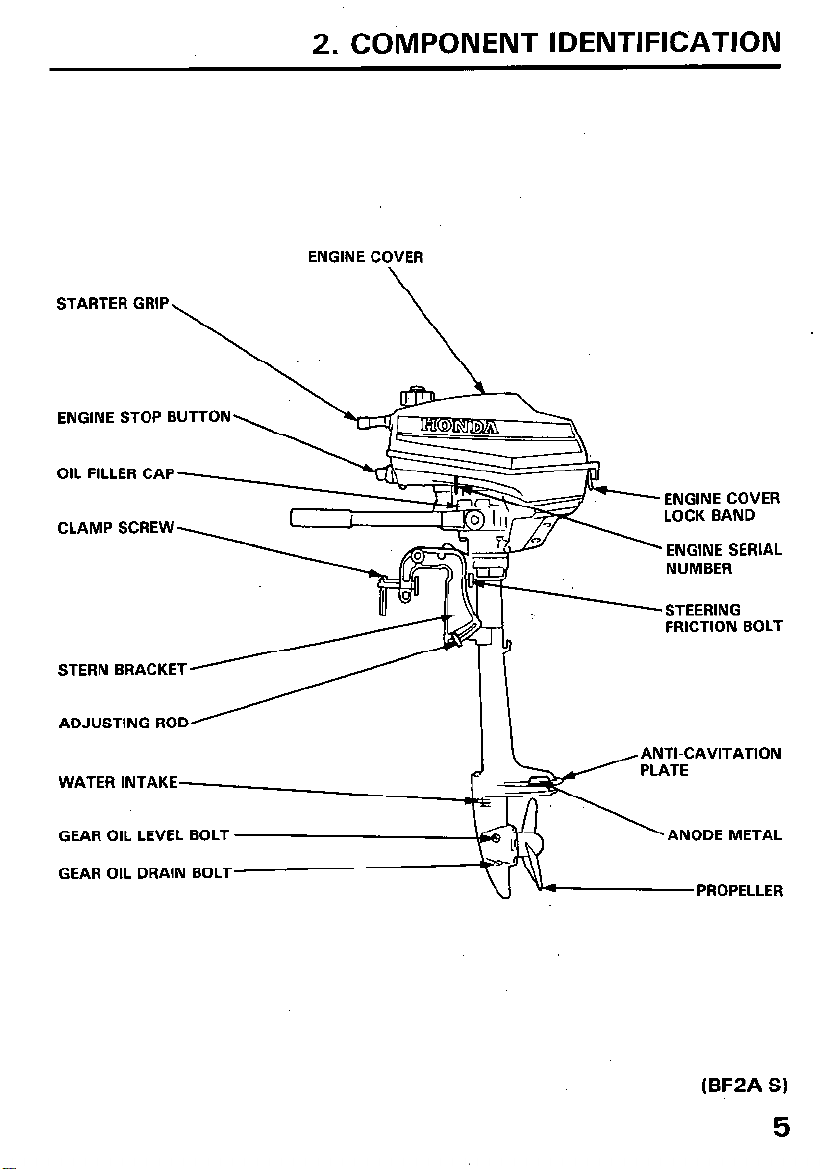

STARTER GRIP

ENGINE STOP BUTTON

OIL FILLER CAP

CLAMP SCREW

2. COMPONENT IDENTIFICATION

ENGINE COVER

ENGINE COVER

LOCK BAND

’ ENGINE SERIAL

NUMBER

STERN BRACKET

ADJUSTING ROD/

WATER INTAKE

GEAR OIL LEVEL BOLT

GEAR OIL DRAIN BOLT

+ STEERING

FRICTION BOLT

ANODE METAL

(BFZA S)

5

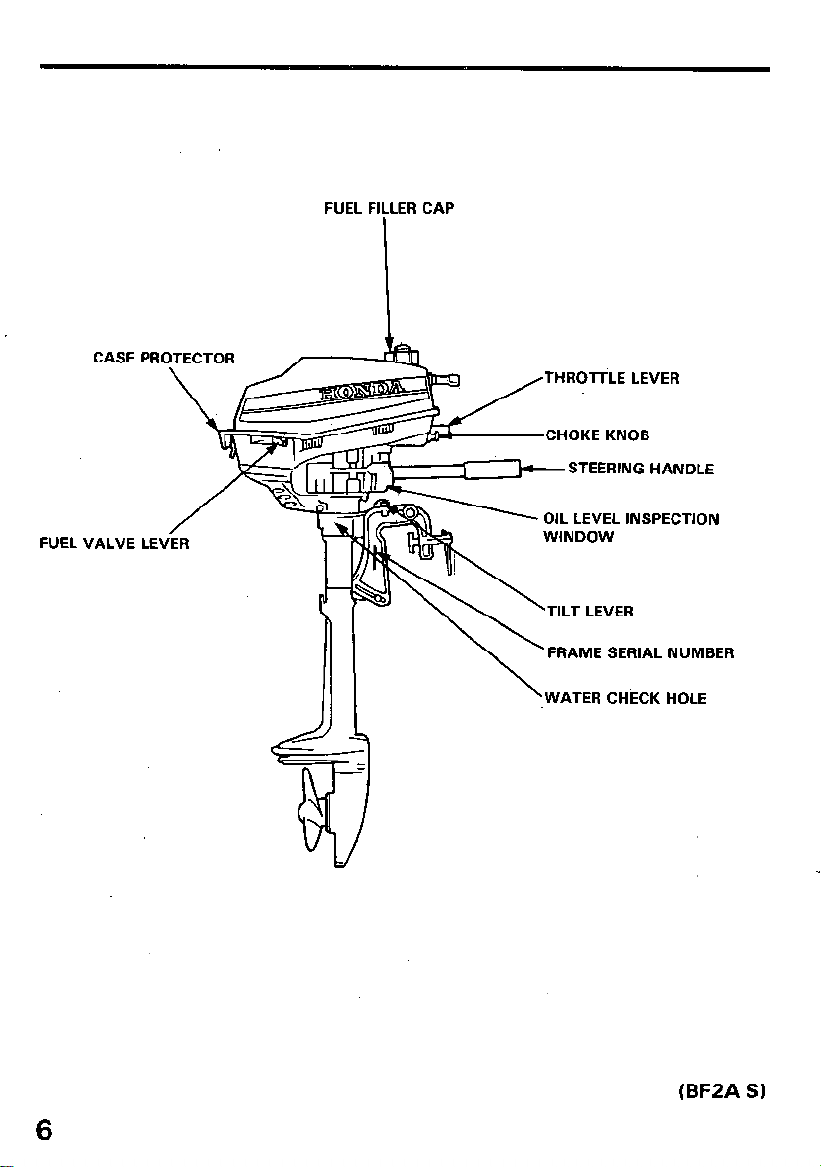

CASE

FUEL VALVE

PROTECTOR

LE&R

FUEL FILLER CAP

L

II I

THROTTLE LEVER

OKE KNOB

STEERING HANDLE

LEVEL INSPECTION

WINDOW

FRAME SERIAL NUMBER

\

WATER CHECK HOLE

6

(BFZA S)

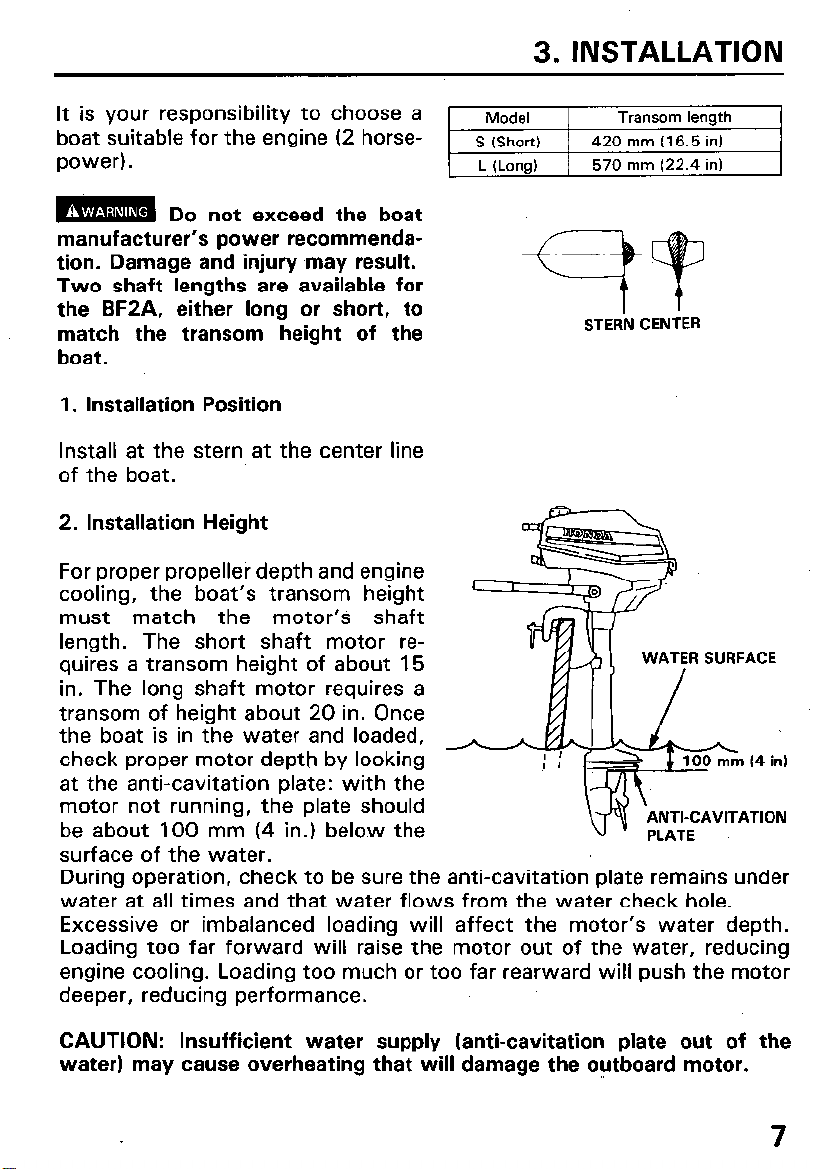

3. INSTALLATION

It is your responsibility to choose a

boat suitable for the engine (2 horse-

power).

manufacturer’s power recommenda-

tion. Damage and injury may result.

Two shaft lengths are available for

the BF2A, either long or short, to

match the transom height of the

boat.

1. Installation Position

Install at the stern at the center line

of the boat.

2. Installation Height

For proper propellei depth and engine

cooling, the boat’s transom height

must match the motor’s shaft

length. The short shaft motor re-

quires a transom height of about 15

in. The long shaft motor requires a

transom of height about 20 in. Once

the boat is in the water and loaded,

check proper motor depth by looking

at the anti-cavitation plate: with the

motor not running, the plate should

be about 100 mm (4 in.) below the

surface of the water.

During operation, check to be sure the anti-cavitation plate remains under

water at all times and that water flows from the water check hole.

Excessive or imbalanced loading will affect the motor’s water depth.

Loading too far forward will raise the motor out df the water, reducing

engine cooling. Loading too much or too far rearward will push the motor

deeper, reducing performance.

STERN CENTER

CAVITATION

CAUTION: Insufficient water supply (anti-cavitation plate out of the

water) may cause overheating that will damage the outboard motor.

7

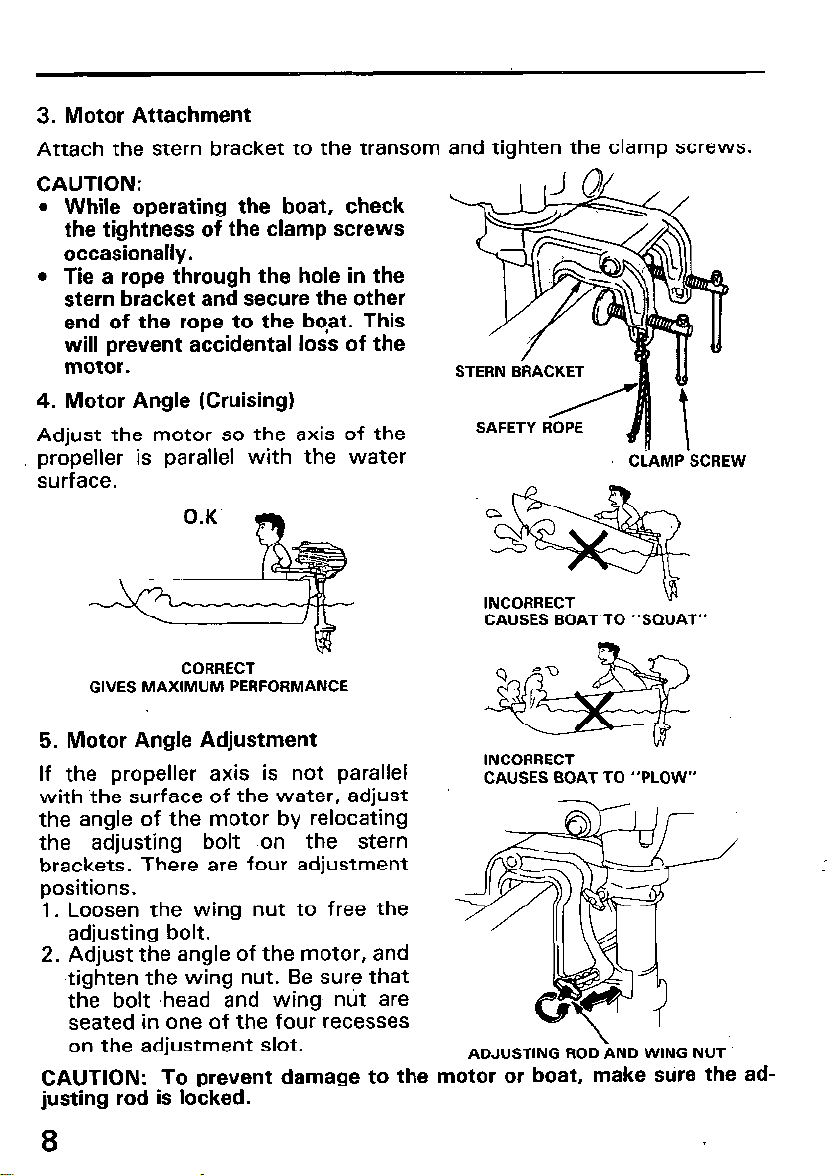

3. Motor Attachment

Attach the stern bracket to the transom and tighten the clamp screws.

CAUTION:

l

While operating the boat, check

the tightness of the clamp screws

occasionally.

l

Tie a rope through the hole in the

stern bracket and secure the other

end of the rope to the bo,at. This

will prevent accidental loss of the

motor.

4.

Motor Angle (Cruising)

Adjust the motor so the axis of the

propeller is parallel with the water

CCAMP‘SCREW

surface.

INCORRECT

CAUSES BOAT.TO “SQUAT”

GIVES MAXIMUM PERFORMANCE

CORRECT

5. Motor Angle Adjustment

If the propeller axis is not parallel

INCORRECT

CAUSES BOAT TO “PLOW”

with the surface of the water, adjust

the angle of the motor by relocating

the adjusting bolt on the stern

brackets. There are four adjustment

positions.

1. Loosen the wing nut to free the

adjusting bolt.

2. Adjust the angle of the motor, and

tighten the wing nut. Be sure that

the bolt .head and wing ntit are

seated in one of the four recesses

on the adjustment slot.

CAUTION: To prevent damage to the motor or boat, make slire the ad-

justing rod is locked.

ADJUSTING ROD \AND WING NUT

8

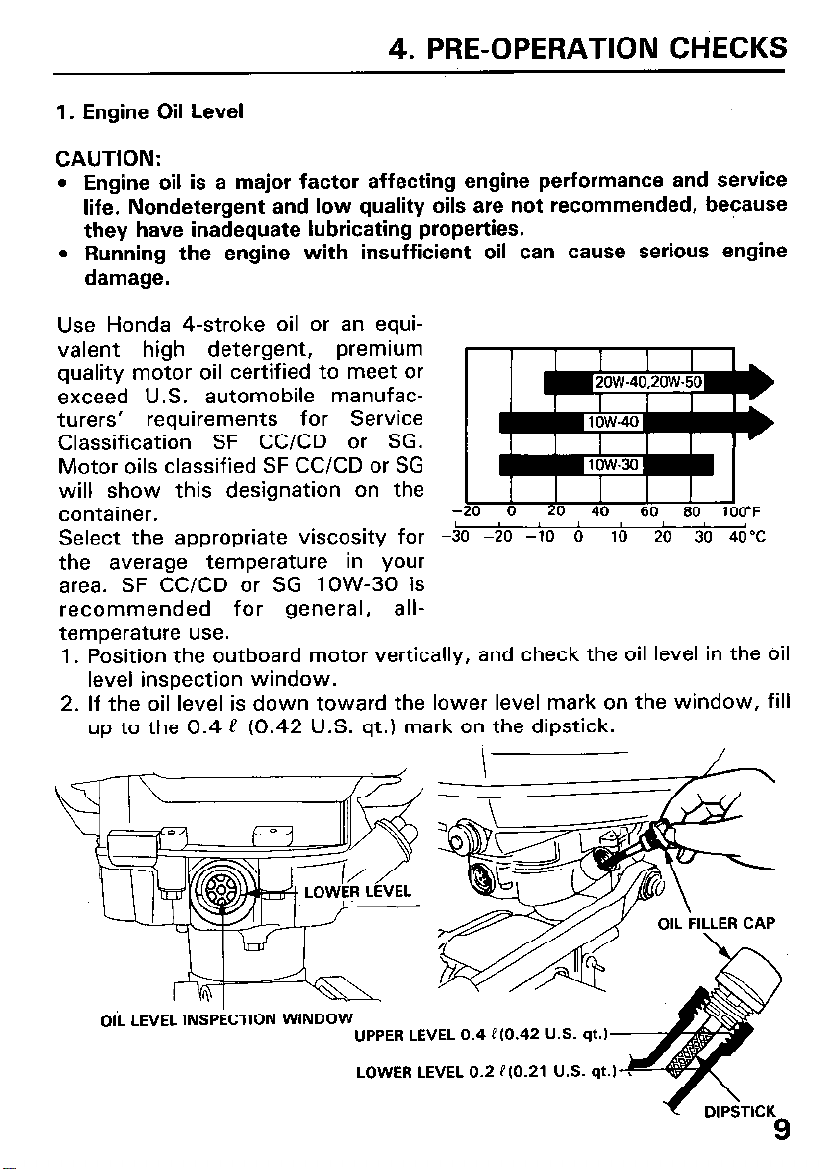

4. PRE-OPERATION CHECKS

1. Engine Oil Level

CAUTION:

l

Engine oil is a major factor affecting engine performance and service

life. Nondetergent and low quality oils are not recommended, because

they have inadequate lubricating properties.

l

Running the engine with insufficient oil can cause serious engine

damage.

Use Honda 4-stroke oil or an equivalent high detergent, premium

quality motor oil certified to meet or

exceed U.S. automobile manufacturers’

Classification SF CC/CD or SG.

Motor oils classified SF CC/CD or SG

will show this designation on the

container.

Select the appropriate viscosity for

the average temperature in your

area. SF CC/CD or SG low-30 is

recommended for general, all-

temperature use.

1. Position the outboard motor vertically, and check the oil level in the oil

2. If the oil level is down toward the lower level mark on the window, fill

requirements for Service

-20

0

,

-30 -20

20 40

-10 o IO

level inspection window.

up to the 0.4 e (0.42 U.S. qt.) mark on the dipstick.

60 80

20 30 40"~

100°F

,

l--b WA.-

OIL LEVEL INSPECTION WINDOW

I

UPPER LEVEL 0.4 P(0.42 U.S. qt.)

LOWER LEVEL 0.2 P(0.21 U.S. qt.)

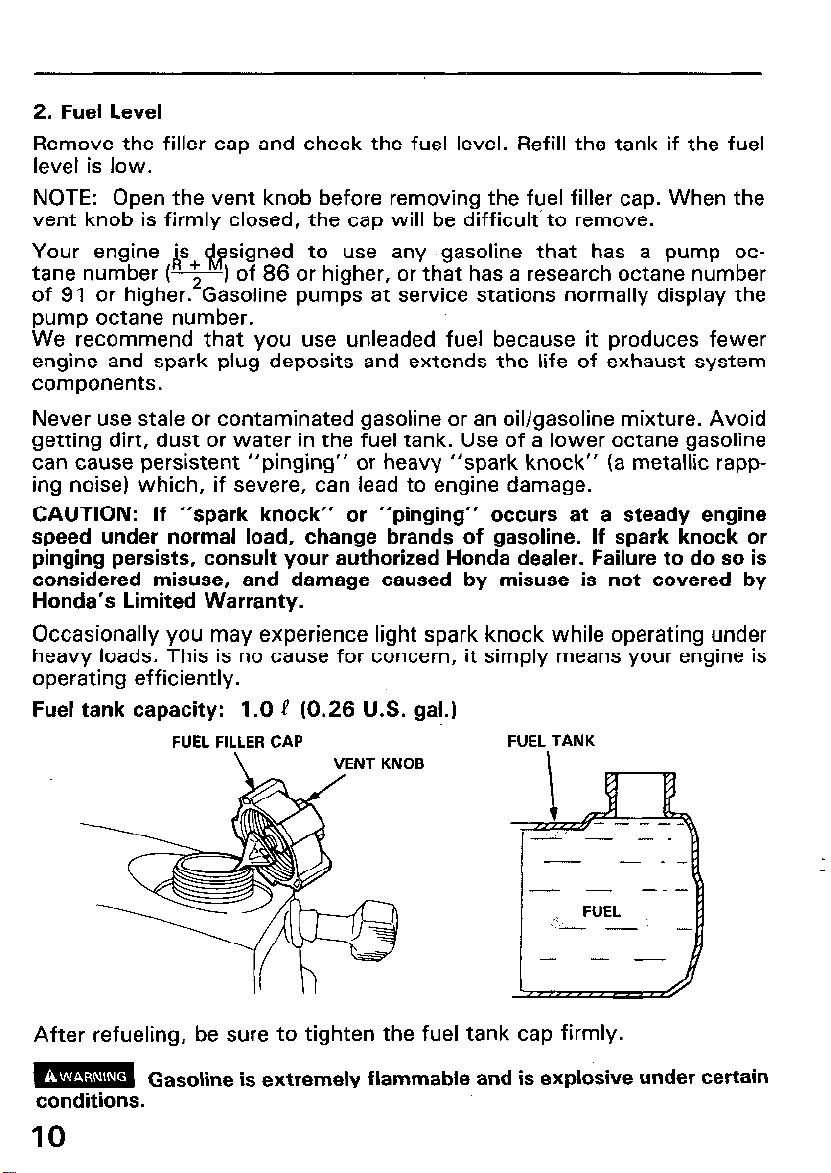

2. Fuel Level

Remove the filler cap and check the fuel level. Refill the tank if the fuel

level is low.

NOTE: Open the vent knob before removing the fuel filler cap. When the

vent knob is firmly closed, the cap will be difficult’to remove.

Your engine ‘s

tane number (-

R +esigned to use any gasoline that has a pump oc-

) of 86 or higher, or that has a research octane number

of 91 or higher.2Gasoline pumps at service stations normally display the

pump octane number.

We recommend that you use unleaded fuel because it produces fewer

engine and spark plug deposits and extends the life of exhaust system

components.

Never use stale or contaminated gasoline or an oil/gasoline mixture. Avoid

getting dirt, dust or water in the fuel tank. Use of a lower octane gasoline

can cause persistent “pinging” or heavy “spark knock” (a metallic rapping noise) which, if severe, can lead to engine damage.

CAUTION: If “spark knock” or “pinging” occurs at a steady engine

speed under normal load, change brands of gasoline. If spark knock or

pinging persists, consult your authorized Honda dealer. Failure to do so is

considered misuse, and damage caused by misuse is not covered by

Honda’s Limited Warranty.

Occasionally you may experience light spark knock while operating under

heavy loads. This is no cause for concern, it simply means your engine is

operating efficiently.

Fuel tank capacity: 1.0 P (0.26 U.S. gal.)

FUEL FILLER CAP

FUEL TANK

After refueling, be sure to tighten the fuel tank cap firmly.

w

conditions.

Gasoline is extremely flammable and is explosive under certain

10

l

Refuel in a well-ventilated area with the engine stopped. Do not smoke

or allow flames or sparks in the area where the engine is refueled or

where gasoline is stored.

l

Do not overfill the tank (there should be no fuel in the filler neck). After

refueling, make sure the tank cap is closed properly and securely.

l

Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor may

ignite. If any fuel is spilled, make sure the area is dry before starting the

engine.

l

Avoid repeated or prolonged contact with skin or breathing of vapor.

KEEP OUT OF REACH OF CHILDREN.

GASOLINES CONTAINING ALCOHOL

If you decide to use a gasoline containing alcohol (gasohol), be sure its octane rating is at least as high as that recommended by Honda. There are

two types of “gasohol”:

one containing ethanol, and the other containing

methanol. Do not use gasohol that contains more than 10% ethanol. Do

not use gasoline containing methanol (methyl or wood alcohol) that does

not also contain cosolvents and corrosion inhibitors for methanol. Never

use gasoline containing more than 5% methanol, even if it has cosolvents

and corrosion inhibitors.

NOTE:

l

Fuel system damage or engine performance problems resulting from the

use of fuels that contain alcohol is not covered under the warranty.

Honda cannot endorse the use of fuels containing methanol since

evidence of their suitability is as yet incomplete.

l

Before buying fuel from an unfamiliar station, try to find out if the fuel

contains alcohol; if it does, confirm the type and percentage of alcohol

used. If you notice any undesirable operating symptoms while using a

gasoline that contains alcohol, or one that you think contains alcohol,

switch to a gasoline that you know does not contain alcohol.

II

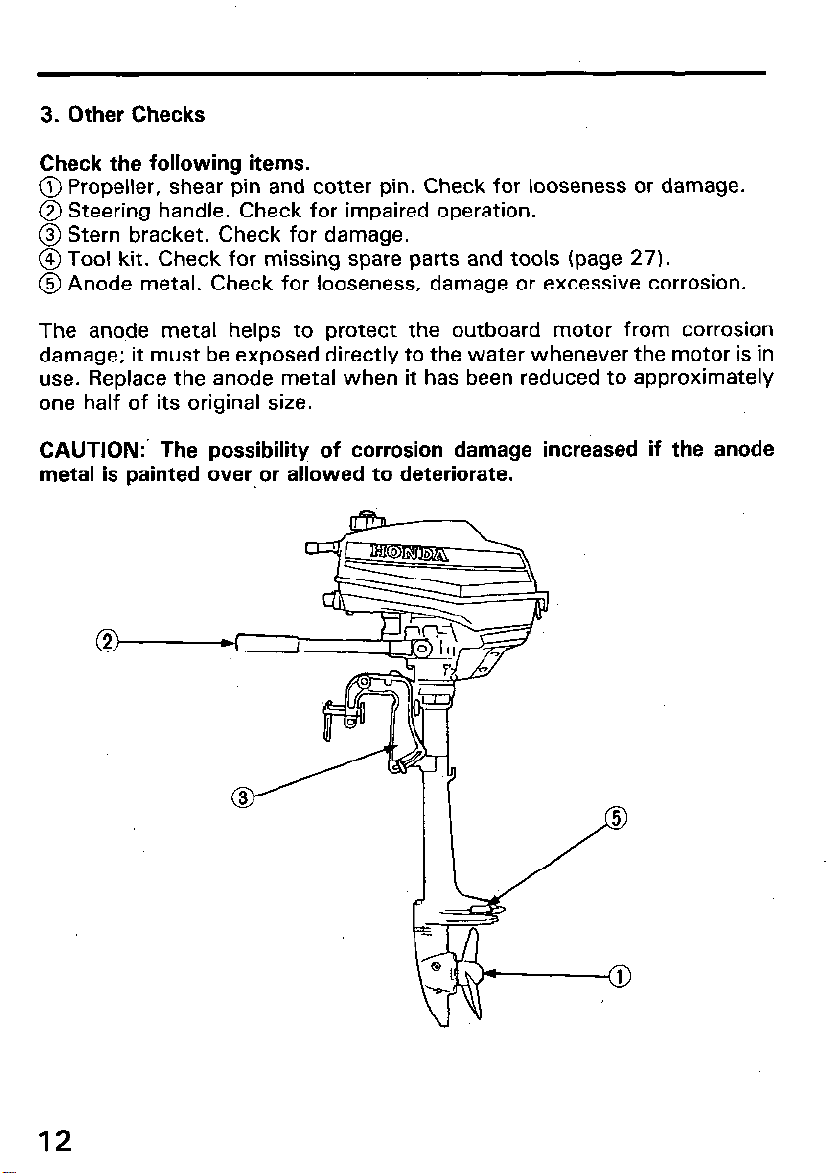

3. Other Checks

Check the following items.

@ Propeller, shear pin and cotter pin. Check for looseness or damage.

@ Steering handle. Check for impaired operation.

@ Stern bracket. Check for damage.

@Tool kit. Check for missing spare parts and tools (page 27).

@ Anode metal. Check for looseness, damage or excessive corrosion.

The anode metal helps to protect the outboard motor from corrosion

damage; it must be exposed directly to the water whenever the motor is in

use. Replace the anode metal when it has been reduced to approximately

one half of its original size.

CAUTION:’ The possibility of corrosion damage increased if the anode

metal is painted over or allowed to deteriorate.

12

Loading...

Loading...