Honda Power Equipment BF75, BF100 User Manual

Thank you for purchasing a Honda Outboard Motor.

This manual covers operation and maintenance of the Honda .Outboard

Motor. All information in this publication is based on the latest product

information available at the time of approval for printing.

Honda Motor Co., Ltd. reserves the right to make changes at any time without

notice and without incurring any obligation.

No part of this publication may be reproduced without written permission.

This manual should, be considered a permanent part of the Outboard Motor

and should remain with the Outboard Motor when it is sold.

Pay special attention to statements preceded by the following words:

B Indicates a strong possibility of severe personal injury or loss of

life if instructions are not followed.

CAUTION: Indicates a possibility of personal injury or equipment damage if

instructions are not followed.

NOTE: Gives helpful information.

If a problem should arise, or if you have any questions about the Outboard

Motor, consult an authorized Honda dealer.

m Honda Outboard Motors are designed to give safe and dependable

service if operated according to instructions. Read and understand the

Owner’s Manual before operating the Outboard Motor. Failure to do so could

result in personal injury or equipment damage

2

CONTENTS

1. SAFETY INSTRUCTIONS

...........................................................

2. WARNING LABELS ...................................................................

3. COMPONENT IDENTIFICATION

..................................................

4. INSTALLATION .......................................................................

5. PRE-OPERATION CHECK

6. STARTING THE ENGINE

...........................................................

............................................................

7. OPERATION ............................................................................

8. STOPPING THE ENGINE

.

High altitude operation

9. MAINTENANCE

.......................................................................

.......................... .

............................................................

10. TRANSPORTING/STORAGE

.......................................................

.................................

11. TROUBLESHOOTING ................................................................

12. SPECIFICATIONS

13. WIRING DIAGRAM

14. OPTIONAL PARTS

15. WARRANTY SERVICE

.....................................................................

...................................................................

....................................................................

...............................................................

.

4

5

6

8

10

13

18

24

24

25

36

38

39

40

41

42

.I. SAFETY lNSTF?UCTUONS

To ensure safe operation-

0 Understand the operation of all controls, and know how to stop the

engine quickly -READ THIS OWNER’S MANUAL CAREFULLY.

0 Do not exceed the boat manufacturer’s power recommendation, and be

sure the outboard motor is properly mounted.

0 Never permit anyone to operate the outboard motor without proper

instruction.

0 Stop the engine immediately if any passenger falls overboard.

0 Do not run the motor while the boat is near any person in the water.

0 Exhaust gas contains poisonous carbon monoxide. Never run the out-

board motor in a closed garage or confined area.

0 Gasoline is extremely flammable and is explosive under certain condi-

tions. Refuel in a well ventilated area with the engine stopped.

0 Do not smoke or allow flames or sparks where the engine is refueled or

where gasoline is stored.

0 Do not overfill the fuel tank, and make sure the fuel tank cap is securely

closed after refueling.

0 Be careful not to spill fuel when refueling. Fuel vapor or spilled fuel may

ignite. If any fuel is spilled, make sure the area is dry before starting the

engine.

4

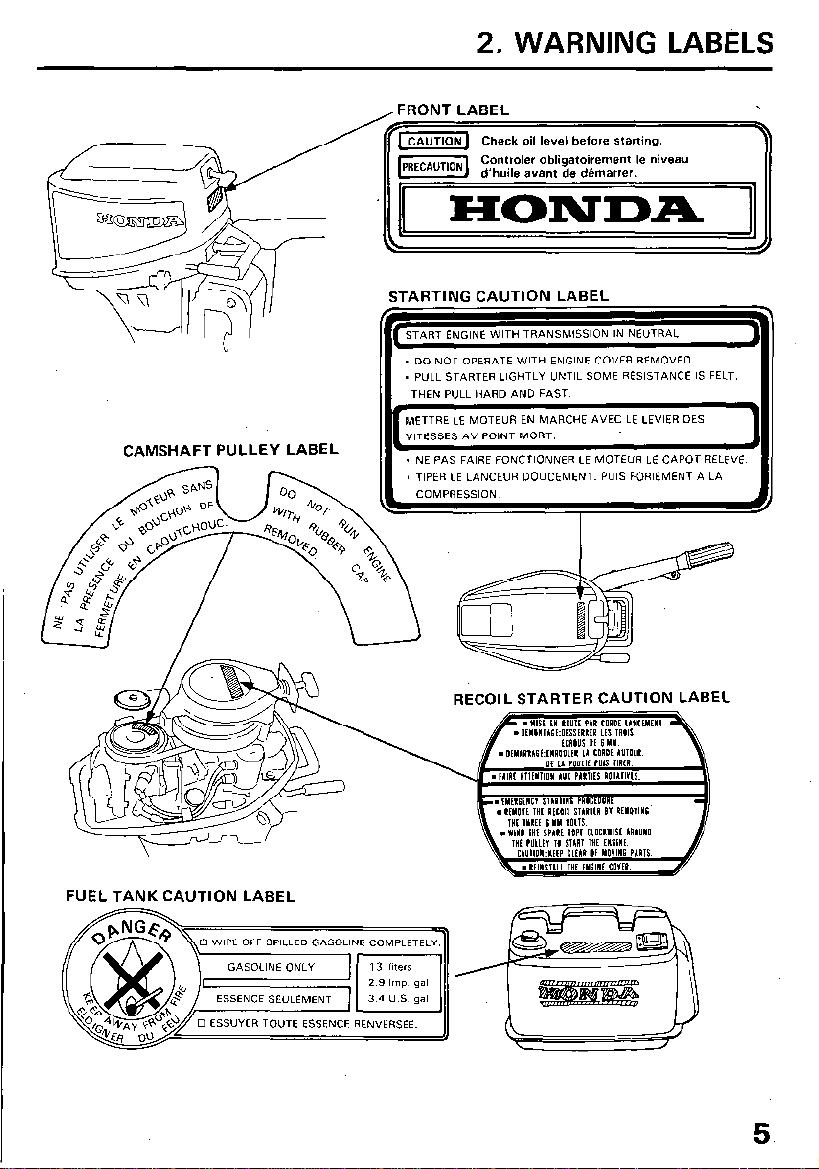

CAMSHAFT PULLEY LABEL

2. WARNING LABELS

FRONT LABEL

Check oil level before starting.

B d’huile avant de d8marrer.

Controler obligatoirement le niveau

I

STARTING CAUTION LABEL

. DO NOT OPERATE WITH ENGINE COVER REMOVED

. PULL STARTER LIGHTLY UNTIL SOME RESISTANCE IS FELT.

II

THEN PULL k

. OTEUR EN MARCHE AVEC LE LEVIER DES

VlTESSES AV POINT MORT.

. NE PAS FAIRE FONCTIONNER LE MOTEUR LE CAPOT RELEVE

* TIPER LE LANCEUR DOUCEMENT. PUIS FORIEMENT A LA

II

lARD AND FAST.

9

1

II

1

II

FUEL TANK CAUTION LABEL

0 ESSUYER TOUTE ESSENCE RENVERSEE.

RECOIL STARTER CAUTION LABEL

5.

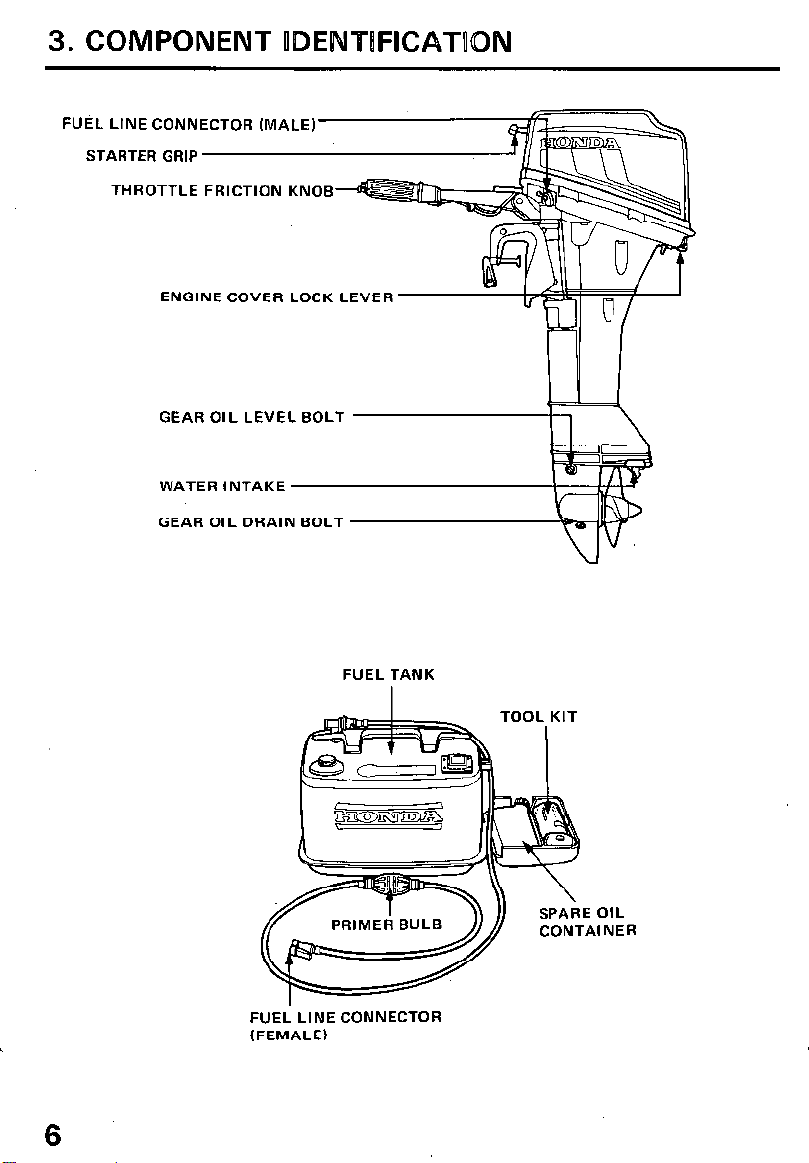

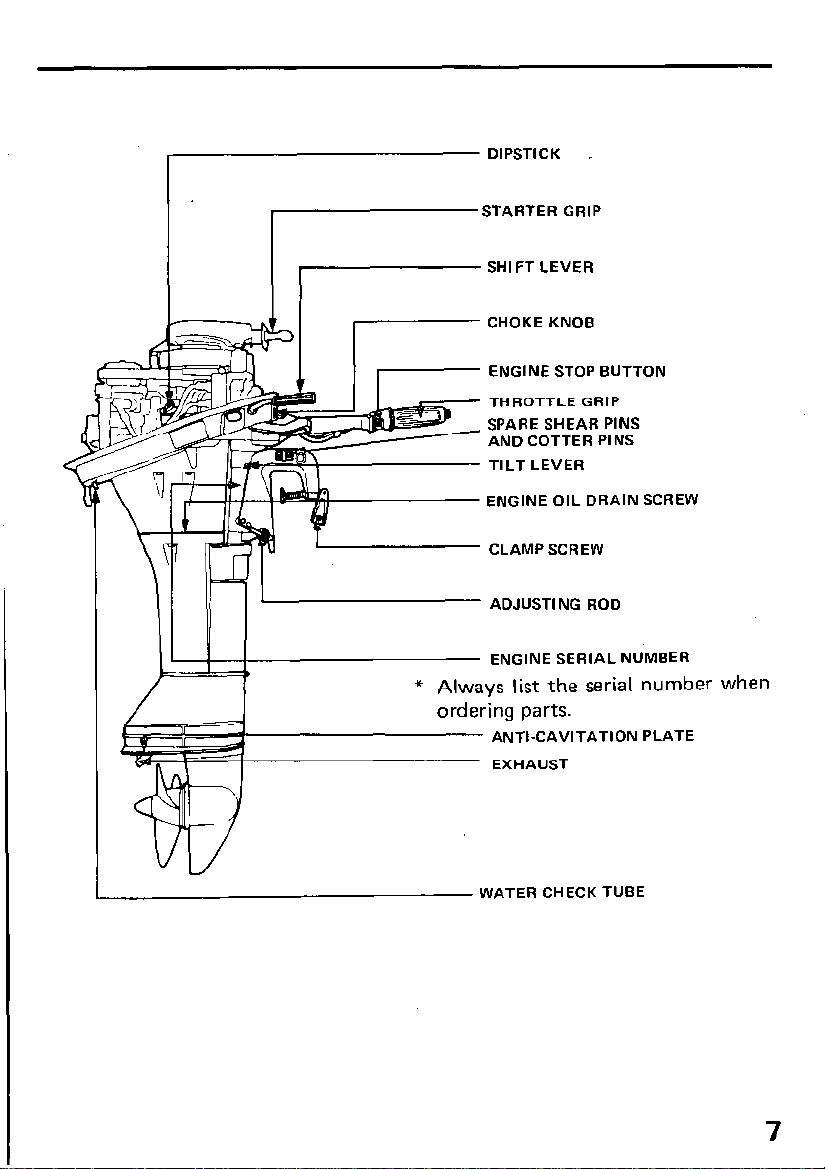

3. COMPONENT ODENTUFICATOON

FUEL LINE CONN

STARTER GRIP

THROTTLE FRICTION KNOB

ENGINE COVER LOCK LEVER

GEAR OIL LEVEL BOLT

WATER INTAKE

GEAR OIL DRAIN BOLT

6

FUEL TANK

PRIMER BULB

FUEL LINE CONNECTOR

(FEMALE)

TOOL KIT

\

SPARE OIL

CONTAINER

DIPSTICK _

c ;;;;;r;-;TTON

SPARE SHEAR PINS

AND COTTER PINS

TILT LEVER

ENGINE OIL DRAIN SCREW

CLAMP SCREW

ENGINE SERIAL NUMBER

* Always list the serial number when

ordering parts.

ANTI-CAVITATION PLATE

EXHAUST

WATER CHECK TUBE

7

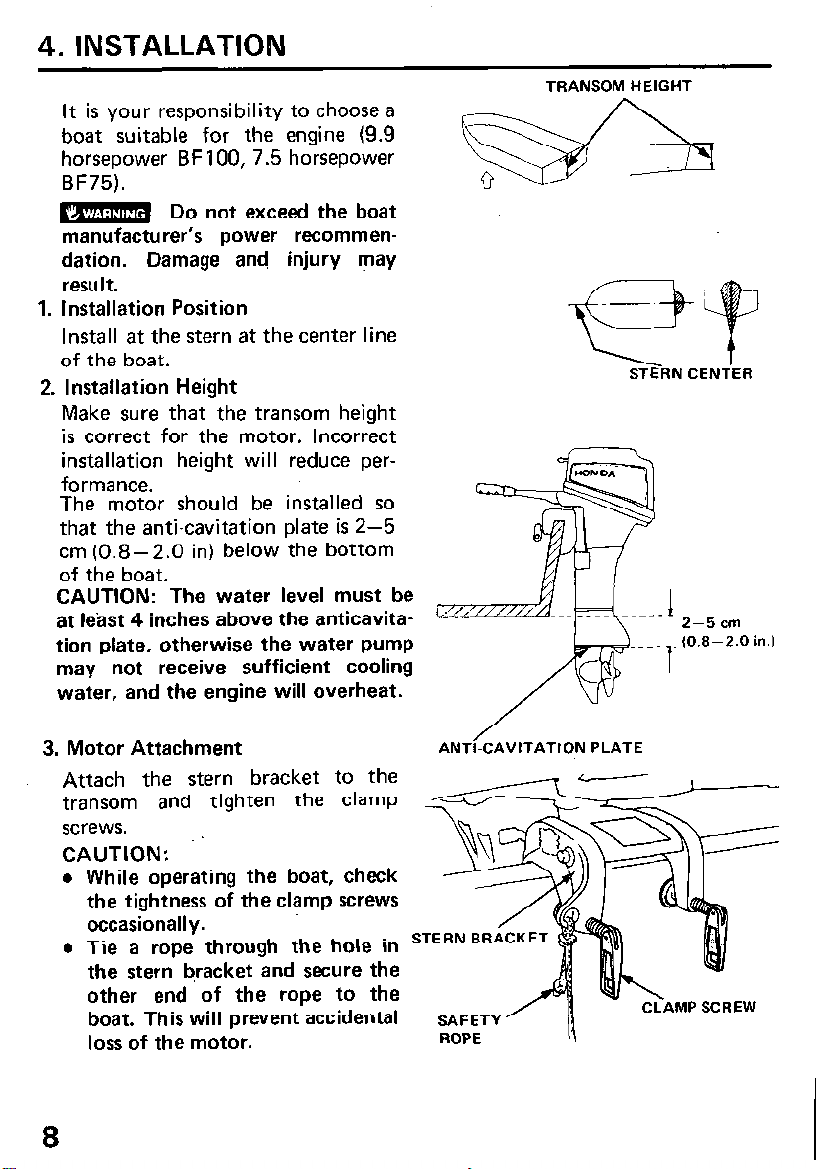

4. INSTALLATION

It is your responsibility to choose a

boat suitable for the engine (9.9

horsepower BFlOO, 7.5 horsepower

BF75).

M Do not exceed the boat

manufacturer’s power recommendation. Damage and injury may

result.

1. Installation Position

Install at the stern at the center line

of the boat.

2. Installation Height

Make sure that the transom height

is correct for the motor. Incorrect

installation height will reduce per-

formance.

The motor should be installed so

that the anti-cavitation plate is 2-5

cm (0.8-2.0 in) below the bottom

of the boat.

CAUTION: The water level must be

at least 4 inches above the anticavita-

tion plate, otherwise the water pump

may not receive sufficient cooling

water, and the engine will overheat.

TRANSOM HEIGHT

\ t

STERN CENTER

I

2-5 cm

lO.8-2.0 in.)

3. Motor Attachment

Attach the stern bracket to the

transom and tighten the clamp

screws.

CAUTION: -.

While operating the boat, check

the tightness of the clamp screws

occasionally.

Tie a rope through the hole in

the stern bracket and secure the

other end of the rope to the

boat. This will orevent accidental

loss of the motor.

ANTI-CAVITATION PLATE

ROPE

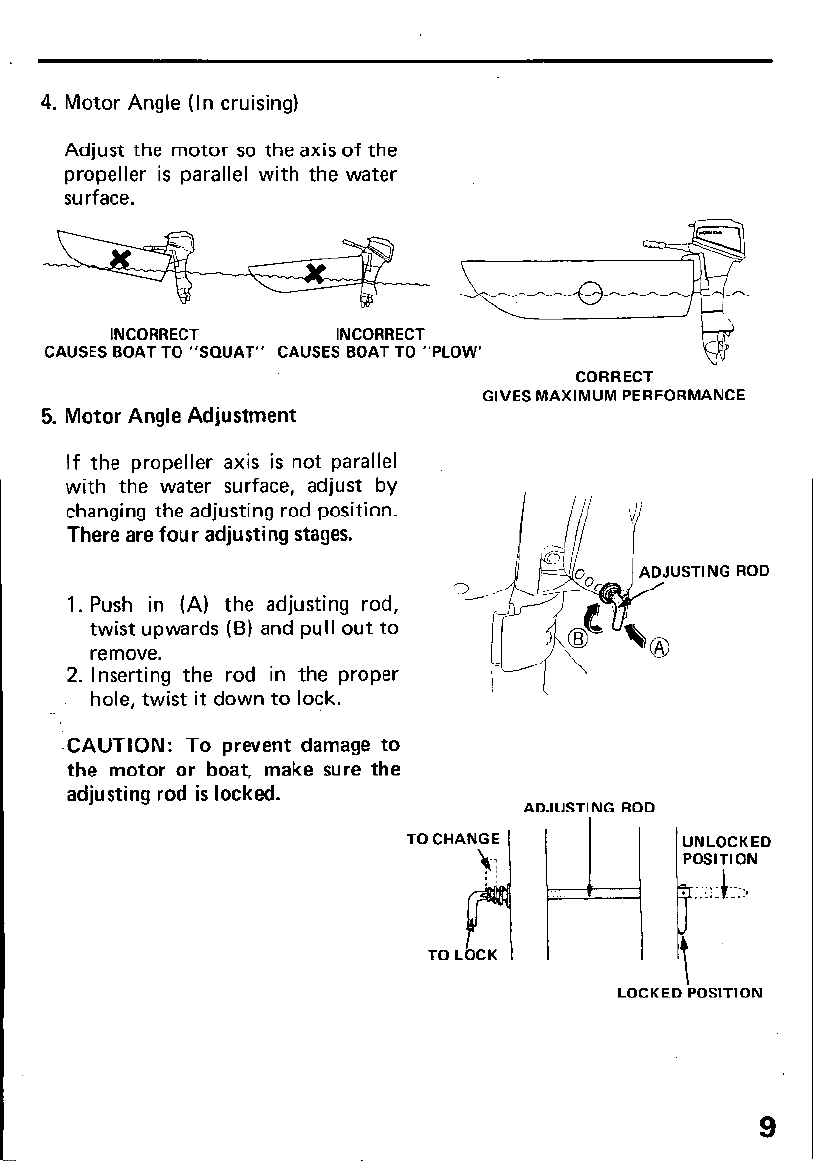

4. Motor Angle (In cruising)

Adjust the motor so the axis of the

propeller is parallel with the water

surface.

CAUSES BOAT TO “SQUAT” CAUSES BOAT TO “PLOW’

INCORRECT INCORRECT

5. Motor Angle Adjustment

If the propeller axis is not parallel

with the water surface, adjust by

changing the adjusting rod position.

There are four adjusting stages.

1. Push in (A) the adjusting rod,

twist upwards (B) and pull out to

remove.

2. Inserting the rod in the proper

hole, twist it down to lock.

-CAUTION: To prevent damage to

the motor or boat, make sure the

adjusting rod is locked.

TO CHANGE

GIVES MAXIMUM PERFORMANCE

3

.A.

CORRECT

ADJUSTING ROD

USTING ROD

UNLOCKED

POSITION

. .

.A..~

TO L

Hi

LOCKED POSITION

\

9

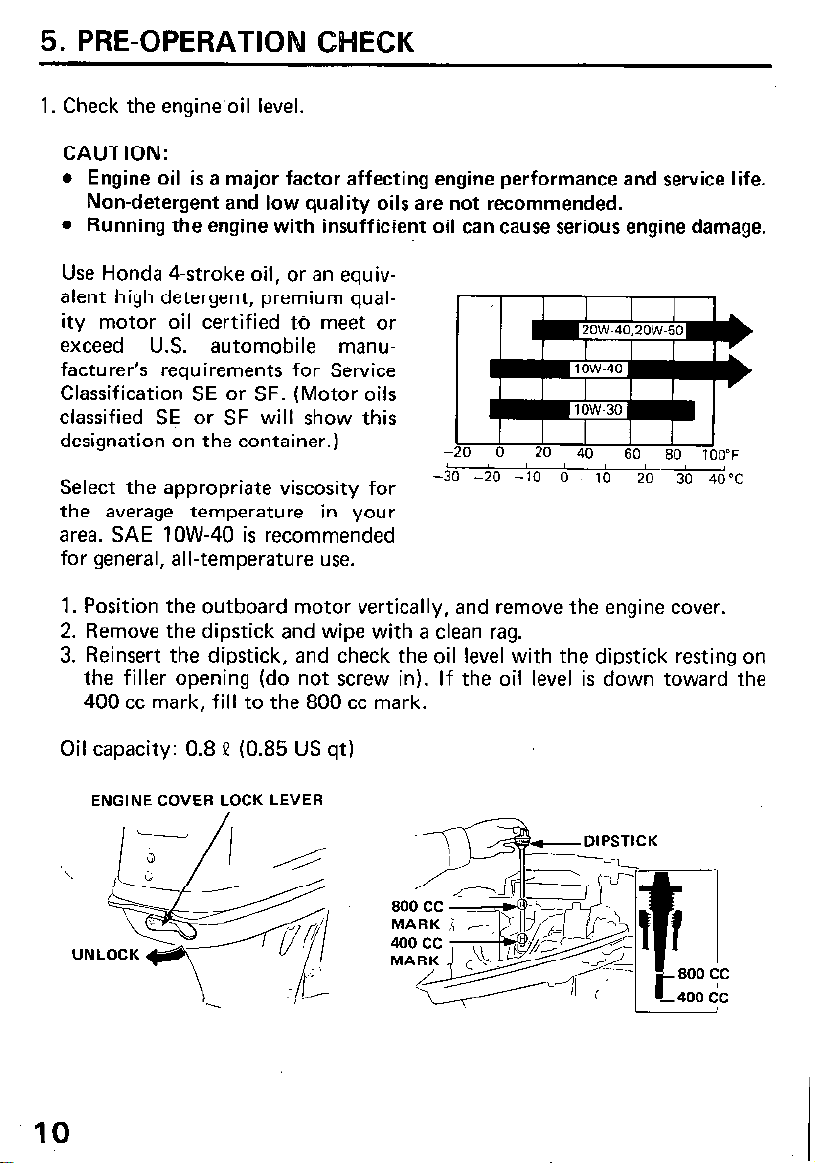

5. PRE-OPERATION CHECK

1. Check the engine’oil level.

CAUTION:

l

Engine oil is a major factor affecting engine performance and service life.

Non-detergent and low quality oils are not recommended.

l

Running the engine with insufficient oil can cause serious engine damage.

Use Honda 4-stroke oil, or an equiv-

alent high detergent, premium qual-

ity motor oil certified t0 meet or

exceed U.S. automobile manufacturer’s requirements for Service

Classification SE or SF. (Motor oils

classified SE or SF will show this

designation on the container.)

Select the appropriate viscosity for

the average temperature in your

area. SAE low-40 is recommended

for general, all-temperature use.

1. Position the outboard motor vertically, and remove the engine cover.

2. Remove the dipstick and wipe with a clean rag.

3. Reinsert the dipstick, and check the oil level with the dipstick resting on

the filler opening (do not screw in). If the oil level is down toward the

400 cc mark, fill to the 800 cc mark.

1

-30 -20 -10 0 10

20 30 40°C

Oil capacity: 0.8 II (0.85 US qt)

ENGINE COVER LOCK LEVER

10

*DIPSTICK

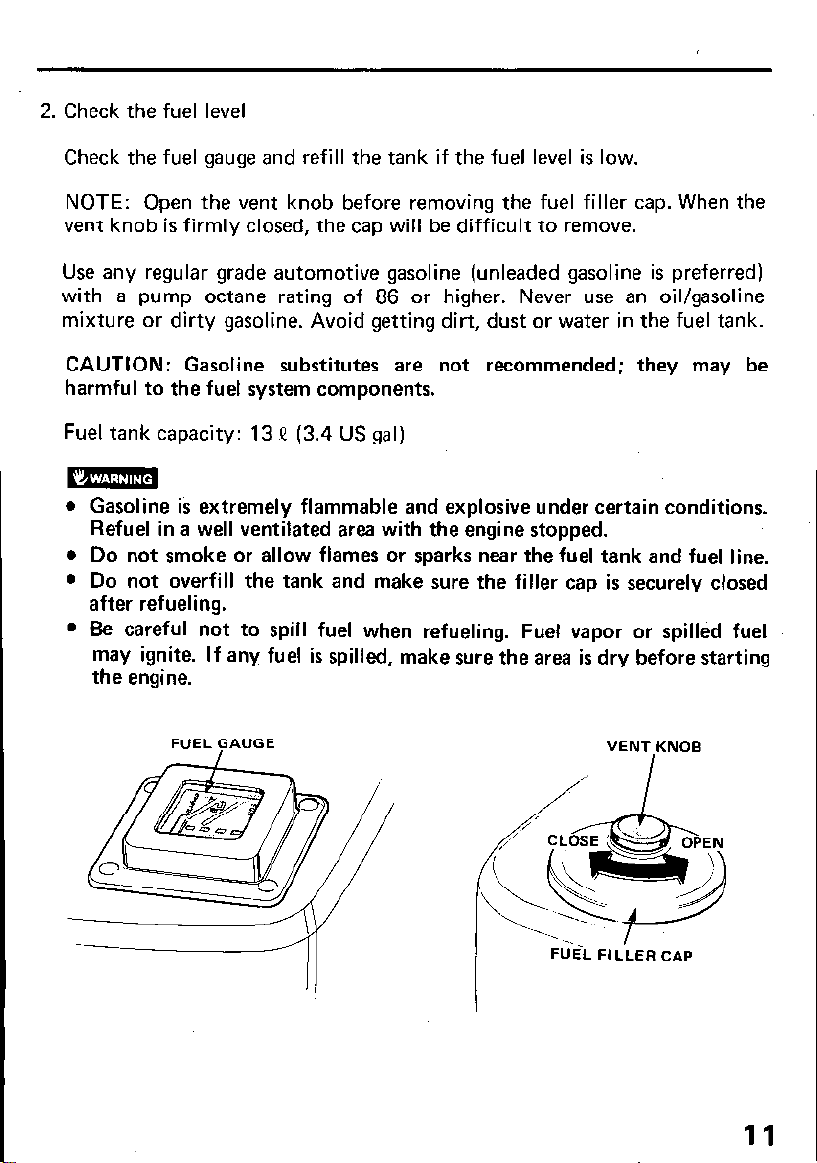

2. Check the fuel level

Check the fuel gauge and refill the tank if the fuel level is low.

NOTE: Open the vent knob before removing the fuel filler cap. When the

vent knob is firmly closed, the cap will be difficult to remove.

Use any regular grade automotive gasoline (unleaded gasoline is preferred)

with a pump octane rating of 86 or higher. Never use an oil/gasoline

mixture or dirty gasoline. Avoid getting dirt, dust or water in the fuel tank.

CAUTION: Gasoline substitutes are not recommended; they may be

harmful to the fuel system components.

Fuel tank capacity: 13 II (3.4 US gal)

l

Gasoline is extremely flammable and explosive under certain conditions.

Refuel in a well ventilated area with the engine stopped.

l

Do not smoke or allow flames or sparks near the fuel tank and fuel line.

l

Do not overfill the tank and make sure the filler cap is securely closed

after refueling.

l

Be careful not to spill fuel when refueling. Fuel vapor or spilled fuel

may ignite. If any fuel is spilled, make sure the area is dry before starting

the engine.

FUEL S;AUGE

VENT KNOB

11

3. Check the following items.

l

Check the propeller, the shear pin, and the cotter pin to be sure they are

secure and undamaged.

l

Check the stern bracket to be sure the motor is securely installed.

l

Check steering handle operation.

l

Make sure you have the tool kit and spare parts with you (P. 26).

12

6. STARTING THE ENGINE

CAUTION: Damage to the water pump, engine components and exhaust

system may occur if the motor is operated while the propeller is out the

water.

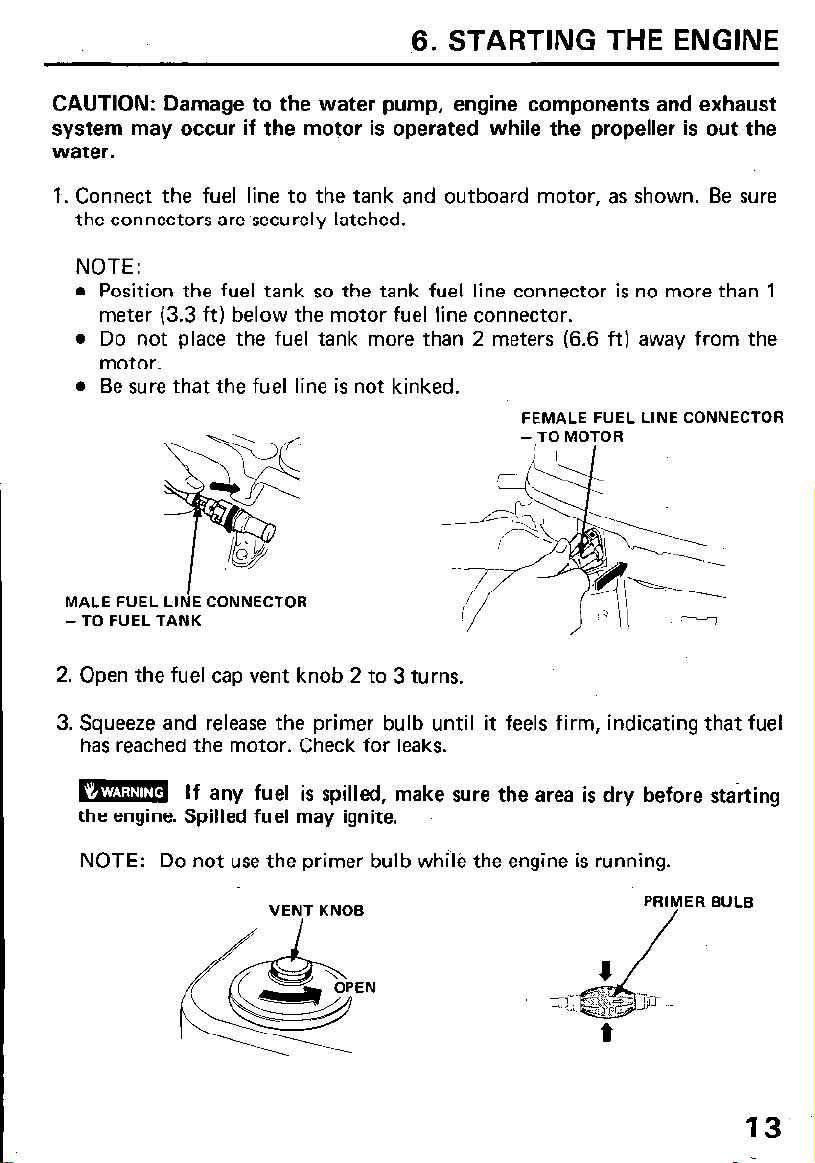

1. Connect the fuel line to the tank and outboard motor, as shown. Be sure

the connectors are securely latched.

NOTE:

l

Position the fuel tank so the tank fuel line connector is no more than 1

meter (3.3 ft) below the motor fuel line connector.

l

Do not place the fuel tank more than 2 meters (6.6 ft) away from the

motor.

l

Be sure that the fuel line is not kinked.

FEMALE FUEL LINE CONNECTOR

- TO MOTOR

MALE FUEL LI CONNECTOR

-TO FUEL TANK

2. Open the fuel cap vent knob 2 to 3 turns.

3. Squeeze and release the primer bulb until it feels firm, indicating that fuel

has reached the motor. Check for leaks.

w If any fuel is spilled, make sure the area is dry before starting

the engine. Spilled fuel may ignite.

NOTE: Do not use the primer bulb whiie the engine is running.

PRIMER BULB

13

Loading...

Loading...