Honda Power Equipment 3755790, PL752A User Manual

WARRANTY

SERVICE

Your satisfaction and goodwill

warranty

this booklet.

your dealer's'

details

Normally,

service

are

explained in the Distributor's Limited

any

dpeartment.

are

important to your dealer and to us.

problems concerning the product

If

you have

a

warranty

problem

Warranty

will

been handled to your satisfaction, we suggest you take the following action:

Discuss your problem with a member

complaints

reviewed with the

can

be quickly resolved at that level.

Service

Manager, contact the owner

of

dealership management. Often

If

the problem has already

of

the dealership or the

General Manager.

If

your problem

.

.

Customer Relations Department

We

will

need the following information in order to

-

Your name, address, and telephone number

-

Product model and serial number

-

Date of purchase

-

Dealer name and address

-

Nature of the problem

still

has not

been

of

AMERI%A2II

PYlwgR

4475

DUL;UTB,

CUS!,#MER

(404) 497-6400

EOlDDA

EQUEUEAP

m'

GEORGIA

SERVICE

resolved to your satisfaction, contact the

American Honda Motor

MOTOR

DIVISION

G%EEN

CO.

PA.RKMAp

30136

DEP-NT

assist

llC.

you:

Co.,

Inc.:

be

handled

that

All

Honda

at

the back of

has

not

been

by

After reviewing

taken. Please

dealership, using

important that your initial

Your purchase

all

the facts involved. you

bear

in mind that your problem

the

dealer's facilities. equipment, and personnel,

contact

of

a Honda product

be

with

is

greatly

will

be advised

will

likely be resolved at the

of

what action

so

it

can

is

the dealer.

appreciated by both your dealer and

be

very

American Honda Motor Company. We want to assist you in every way possible to

assure your complete satisfaction with your purchase.

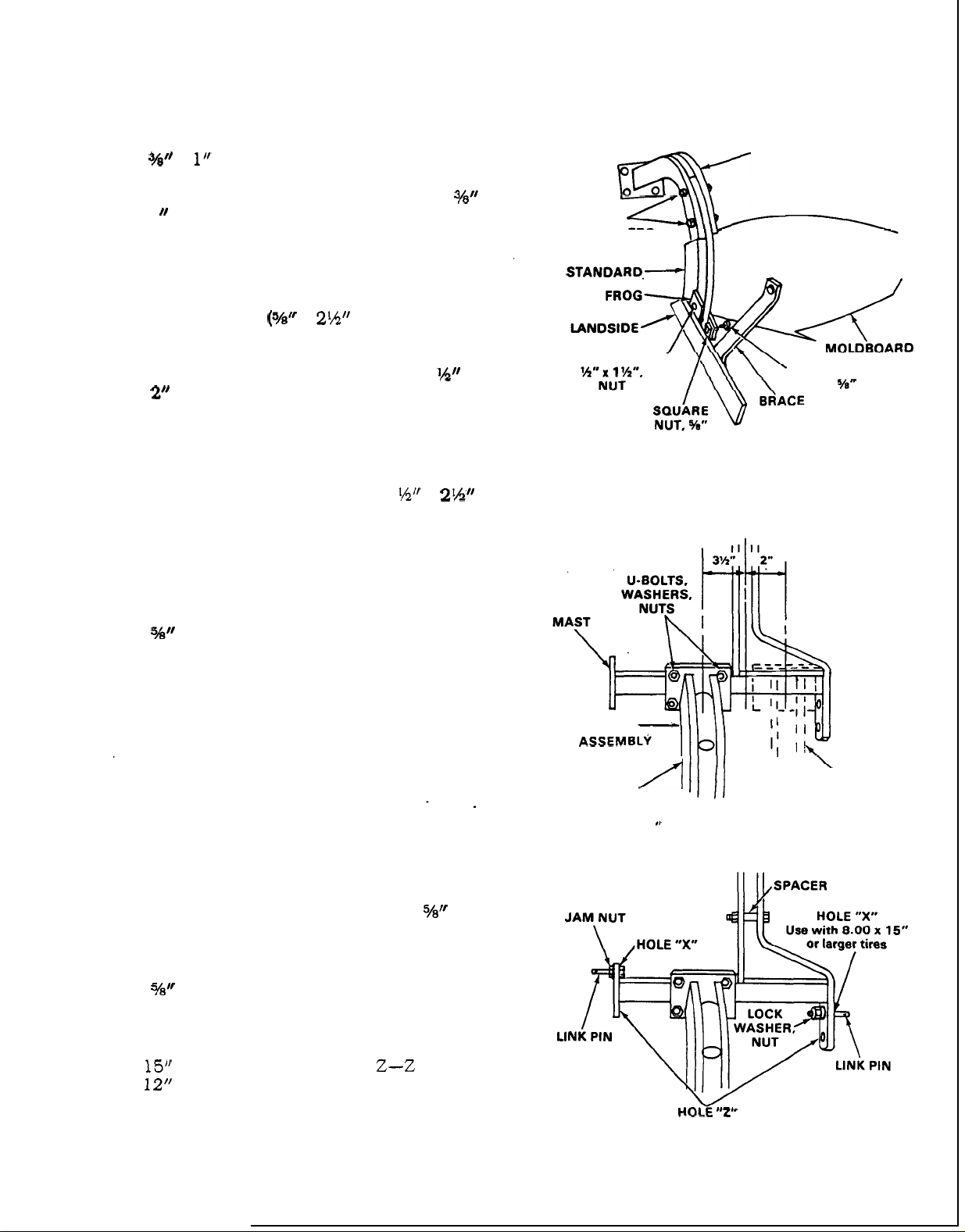

ASSEMBLY

1.

Secure

%If

tighten.

the landside to the frog with

x

1"

plow bolts and square nuts; finger

Next,

mount the brace between

the moldboard and the landside with

1

If

plow bolts and square nuts. Tighten

bolts securely.

2.

Assemble the standard to the landside

assembly after inserting the land

adjusting bolt

tab

on

the standard and into the square

(94" x 2%"

hex) through the

nut. Then install the carriage bolt and

square nut

2"

plow bolt and square nut (not shown)

at

the remaining hole in the landside,

at

the top hole, and the

and standard. Tighten the bolts securely.

3.

Position the beam assembly over the

standard and secure with

two

1/13''

hex bolts, lock washers, and hex nuts;

tighten securely.

'Aff

x

two

%It

x

frog,

2*h"

x

all

.

BOLTS.

LOCK

WASHERS,

NUTS

CARRIAGE BOLT,

BEAM ASSEMBLY

LAND ADJUSTING

BOLT,

Ye"

X

2%

"

4.

Install the beam assembly on the mast

using

9@,lr

NOTE:

two

U-bolts

lock

washers,

If

the tractor rear wheels

(saddled

and

from the front),

hex

nuts.

are

in narrow tread position, position the

as

shown.

beam

-

'OPERATION

5.

Install the spacer

If

as

outlined.

wheels

section.)

are

set wide. locate the

(See

Width

between

of

the mast

Cut

at the bottom hole. Secure with a

21/13

"

hex bolt, lock washer. and hex hut.

6.

Install the link pins and secure them with

%If

hex

jam

nuts, lock washers. and hex

nuts.

NOTE:

x

x

Use holes

15"

or larger tires: use holes

12"

tires.

X-X

for

tractors with

2-2

set

beam

in

arms

%If

with

x

8.00

8.00

BEAM

-

ASSEMBLV

Beam position

with rear wheels

set

for narrow

tread; approx.

between tires.

/I

21

Use

"

with

HOLIE

8.00

T

x

12

"

Beam position

with rear wheels

set

tread; approx.

between tires.

tires

\

for wide tread;

30

"

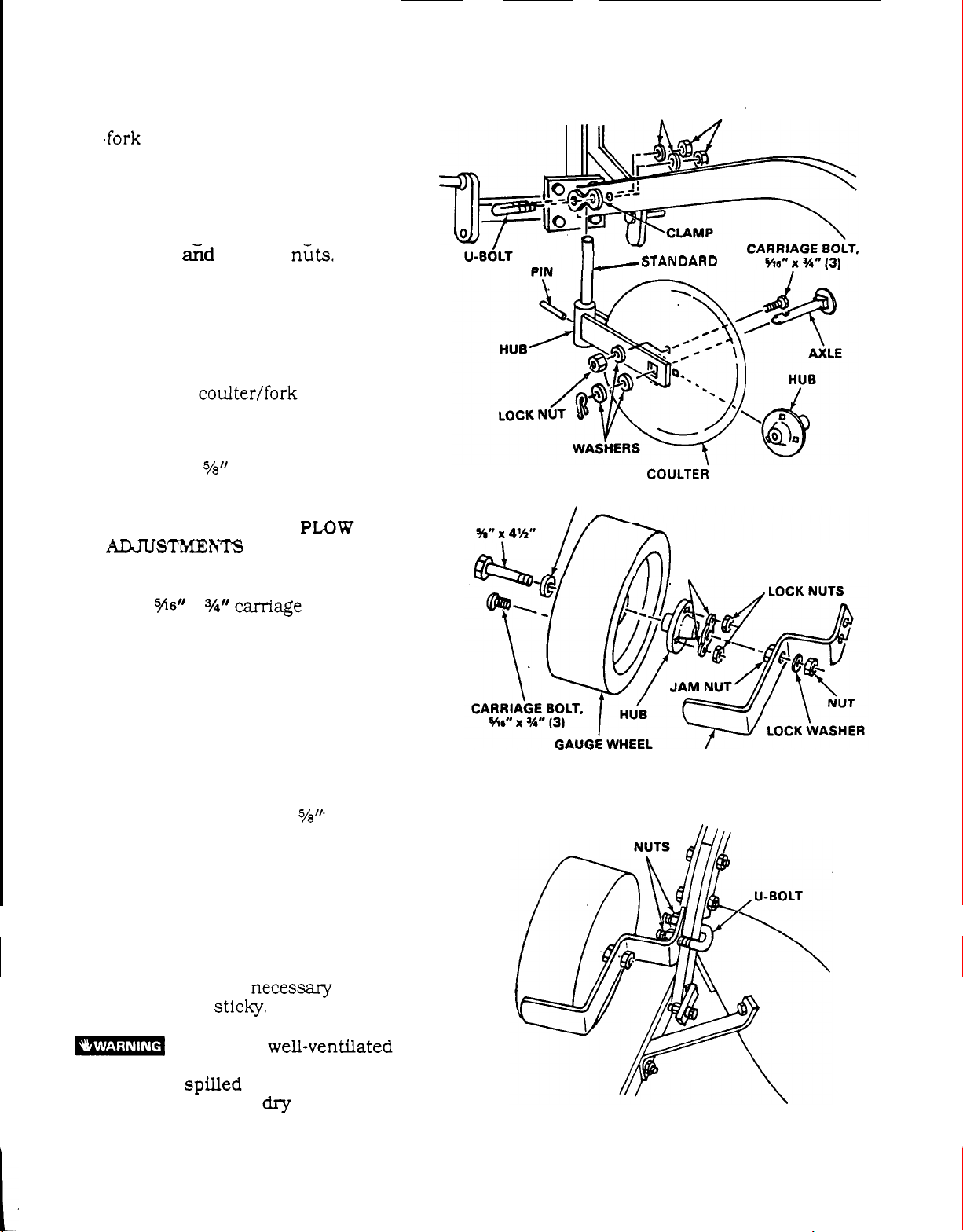

7.

Insert the standard into the hub on the

.fork and secure it with the pin.

Leave

equal amount of the pin extending on

each side

8.

Assemble the coulter blade hub to the

of

the hub.

blade using three carriage bolts,

washers, hex lock nuts.

9.

Assemble the fork and coulter with the

axle, aligning the squares. Install two

washers. and secure with the cotter pin.

Bend the legs of the pin over the axle.

10.

Mount the coulter/fork assembly on the

left side of the plow beam using the

clamp and U

between the beam

U

-

bolt with

-

bolt. Insert two spacers

arms,

94"

hex nuts: tighten the nuts

then secure the

securely.

After assembly, refer to

ADJUSTMENTS

1 1.

Install the hub on the gauge wheel using

three

!%//

x

to set the coulter.

3/4't

carriage bolts, plain

PLOW

washers, and hex lock nuts.

flat

an

flat

HEX BOLT

-STANDARD

-STANDARD

WASHER

SPACERS NUTS

SPACERS NUTS

COULTE~

h

BLADE

1

WASHERS

'

12.

Install the

flat

washer on the hex bolt,

insert the bolt through the hub. then add

a

second flat washer

and

the hex

jam

nut.

Secure with the lock washer and hex nut

on the inside of the bracket

13.

Mount the gauge wheel assembly on the

as

shown.

plow beam standard using the short

U

-

bolt and secure with

and

hex

nuts.

Preparing

Plow

for

Use

After assembly, clean the moldboard with

rag

soaked in turpentine, kerosene or

naphtha

so

that

dirt

will

be

94"

less

lock washers

a

likely to stick

to the protective coating. The coating can be

removed with an old brick or

but this usually isn't

soil

is

too wet or stice.

b-

and

handle

Wipe

up any spilled liquid immediately

make

sure

Work

cleaning materials

the

area

necessaq unless the

in a well-ventilated

is

dry

a

pumice stone,

with

before

starting

area

care.

and

the

tractor.

LOCK WASHERS,

BRACKET

If

//I

Loading...

Loading...