Page 1

Page 2

INTRODUCTION

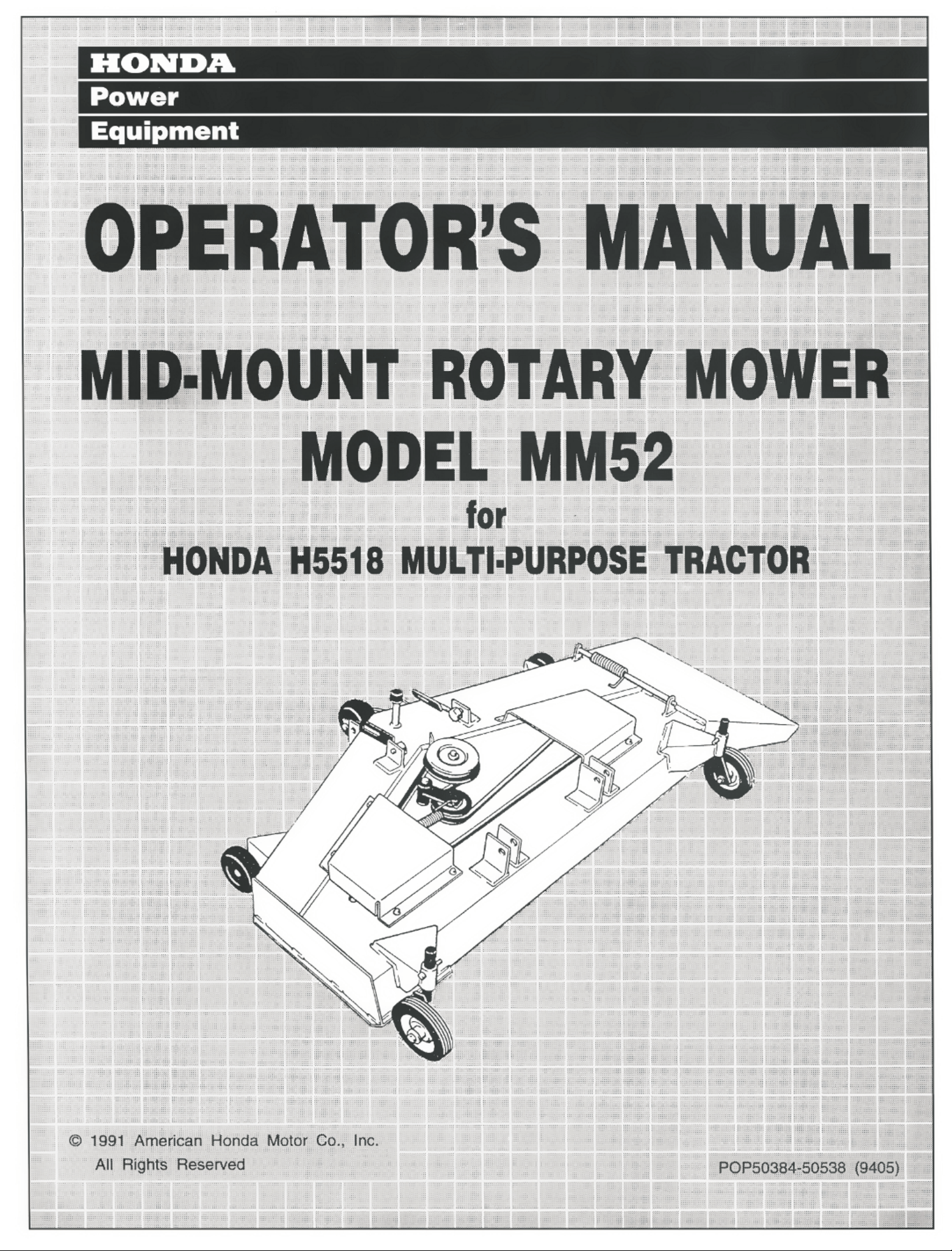

TO THE OWNER

Read this manual before operating your mower. The information presented will prepare you to do a better

and safer job. Keep this manual handy for ready reference.

The mower you have purchased has been carefully engineered and manufactured to provide dependable

and satisfactory use. Like all mechanical products, it will require cleaning and upkeep. Lubricate the

mower as specified. Observe all safety information in this manual and safety decals on the mower and

tractor.

For service, your authorized dealer has trained mechanics, genuine service parts, and the necessary tools

and equipment to handle all your needs.

Use only genuine service parts. Substitute parts may not meet standards required for safe and satisfac-

tory operation. Record the serial number of your mower:

Model MM52 Rotary Mower

Serial Number

(see Safety Decal page for location)

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term NOTICE is used to indicate that failure to observe this instruction can

cause damage to equipment. The terms CAUTION, WARNING and DANGER are used in conjunction with

the Safety-Alert Symbol, (a triangle with an exclamation mark), to indicate the degree of hazard for items of

personal safety.

The Safety-Alert Symbol means ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

! ’

m Denotes a reminder of safety practices or directs attention to unsafe practices

l

which could result in personal injury if proper precautions are not taken.

! I-

C Denotes a hazard exists which can result in injury or death if proper precautions

are not taken.

D*

m Denotes an extreme intrinsic hazard exists which would result in high probability

of death or irreparable injury if proper precautions are not taken.

1

Page 3

INTRODUCTION

GENERAL INFORMATION

The purpose of this manual is to assist the operator in maintaining and operating this mower. Read

it carefully. It furnishes information and instructions

that will help you achieve years of dependable

performance. These operating and maintenance

instructions have been compiled from extensive

field experience and engineering data. Some

information may be general in nature due to

unknown and varying conditions. However, you

should be able to develop operating procedures

suitable to your particular situation.

The illustrations and data used in this manual were

current at the time of printing, but due to possible

in-line production changes, your machine may

vary slightly in detail. We reserve the right to

redesign and change the machine as may be

necessary without notification.

*

1.

m Some Illustrations In this manual

show the mower with safety shields removed

to provide a better view. The mower should

never be operated with any safety shielding

removed.

Throughout this manual, references are made to

right and left directions. These are determined by

standing behind the equipment and facing the

direction of forward travel. Blade rotation is clock-

wise as viewed from the top of the mower.

2

Page 4

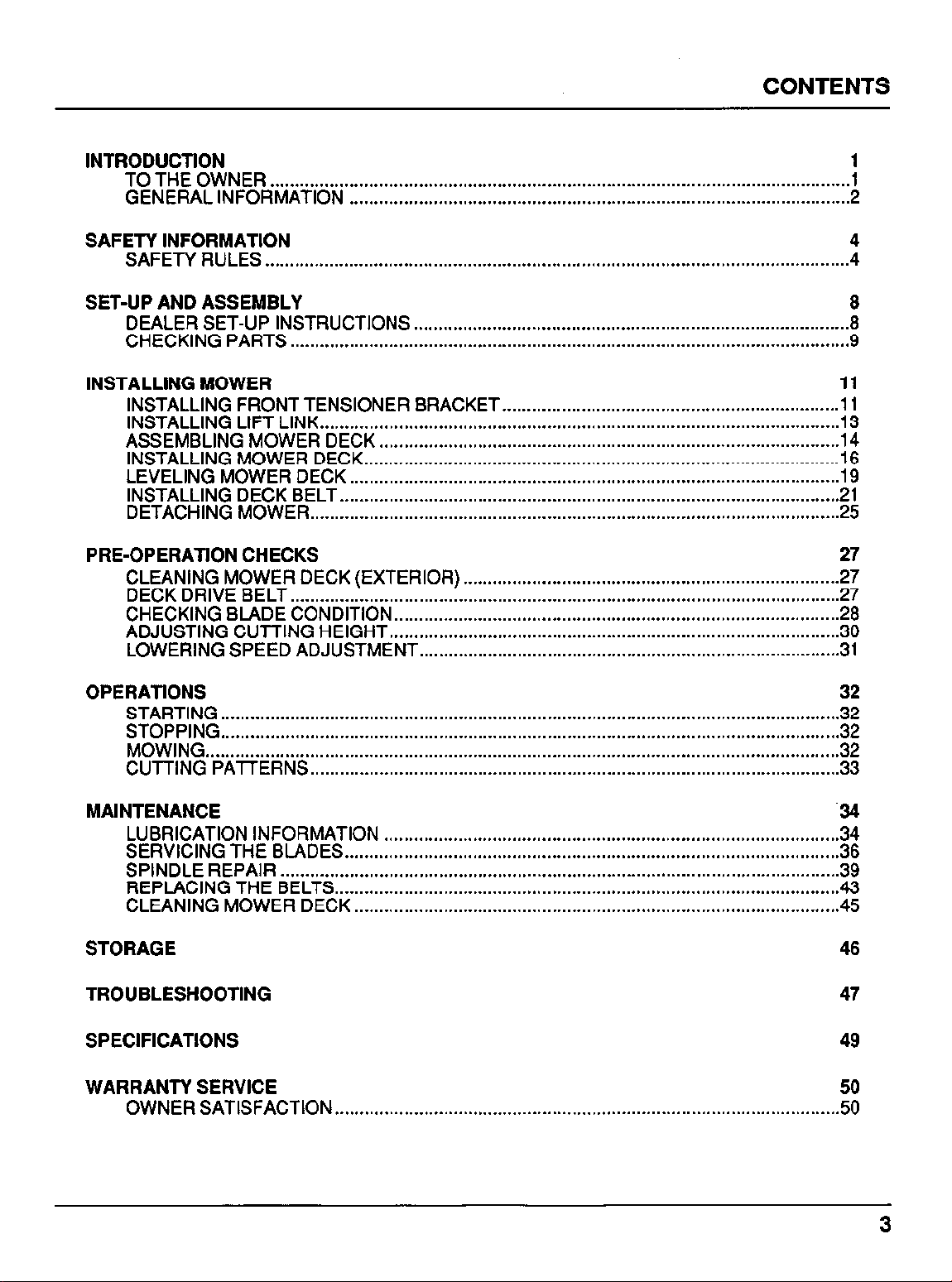

CONTENTS

...................................................................................................................................................................................

INTRODUCTION

TO THE OWNER

GENERAL INFORMATION

SAFETY INFORMATION

SAFETY RULES

SET-UP AND ASSEMBLY

DEALER SET-UP INSTRUCTIONS

CHECKING

INSTALLING MOWER

INSTALLING FRONT TENSIONER BRACKET

INSTALLING LIFT LINK

ASSEMBLING MOWER DECK

INSTALLING

LEVELING MOWER DECK

INSTALLING

DETACHING MOWER

PRE-OPERATION CHECKS

CLEANING MOWER DECK (EXTERIOR)

DECK DRIVE BELT

CHECKING

ADJUSTING CUTTING HEIGHT

LOWERING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.........................................................................................................

.............................................................................................

MOWER DECK..

DECK BELT.. ...................................................................................................

...........................................................................................................

...............................................................................................................

BLADE CONDITION..

SPEED ADJUSTMENT.. ..................................................................................

..............................................................................................

...................................................................................................

1

:

4

4

8

. . . . . . . . . . . . . . . . . . . . . . . . . ..*............................................................

i

11

....................................................................

1:

i:

i:

25

27

............................................................................

:5

;;

.31

OPERATIONS

STARTING

STOPPING

MOWING ................................................................................................................................

CUTTING PATTERNS

MAINTENANCE

LUBRICATION INFORMATION

SERVICING THE BLADES

SPINDLE REPAIR

REPLACING THE BELTS

CLEANING

STORAGE

TROUBLESHOOTING

SPECIFICATIONS

WARRANTY SERVICE

OWNER SATISFACTION

.............................................................................................................................

.............................................................................................................................

...........................................................................................................

............................................................................................

....................................................................................................

.................................................................................................................

......................................................................................................

MOWER DECK ..................................................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32

z

::

‘34

::

39

z

47

50

50

3

Page 5

SAFETY INFORMATION

Safety is a primary concern in the design and

manufacture of our products. Unfortunately,

our efforts to provide safe equipment can be

wiped out by a single careless act of an

operator.

In addition to the design and configuration of

equipment, hazard control and accident

prevention are dependent upon the awareness, concern, prudence and proper training

of personnel involved in the operation, transport, maintenance and storage of equipment.

It has been said ‘The best safety device is an

informed, careful operator.’ We ask you to be

that kind of an operator.

SAFETY RULES

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The designed and tested safety of this equipment

depends on it being operated within the limitations

explained in this manual.

Training

l Safety instructions are important! Read this

manual, the tractor manual and all safety rules.

l Know your controls and how to stop tractor

engine and mower quickly in an emergency.

l Operators must be instructed in and be ca-

pable of the safe operation of the equipment, its

attachments and all controls. Do not allow

anyone to operate this equipment without

proper instructions,

l Keep hands and body away from pressurized

lines. Use paper or cardboard, not body parts

to check for leaks. Hydraulic fluid (oil) under

pressure will penetrate skin causing serious

injury.

l Make sure that all operating and service per-

sonnel know that in the event hydraulic fluid

penetrates skin, it must be surgically removed

within a few hours by a doctor familiar with this

form of injury, or gangrene may result.

l Do not allow children or unqualified persons to

operate equipment.

Page 6

SAFETY INFORMATION

Preparation

l Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hands, hearing and head.

l Ensure that mower is properly mounted, ad-

justed and in good operating condition.

l Remove accumulated debris from mower to

avoid fire hazard.

l Ensure all safety decals are installed and in

good condition. (See Safety Decals section for

location drawing.)

l Ensure shields and guards are properly in-

stalled and in good condition.

l Inspect area to be cut and remove stones,

branches or other hard objects that might be

thrown, causing injury or damage.

Operational Safety

l You may not be able to stop the tractor safely if

the clutch or brake pedal mechanisms are

improperly adjusted, allowing them to contact

mower components.

l When the mower lift stops are installed as

instructed in this manual, properly adjusted

clutch and brake pedal mechanisms will not

contact mower components. You should

frequently check that the tractor clutch and

brake pedal mechanisms are in adjustment.

l If the clutch or brake pedal mechanisms can

contact mower components, do not operate

until properly adjusted.

Do not operate mower unless discharge chute

is installed.

Keep bystanders away from equipment while it

is in operation.

Never direct discharge toward anyone.

Operate only in daylight or good artificial light.

Keep hands and feet away from mower while

tractor engine is running.

l Stay clear of all moving parts.

l If your tractor is equipped with a ROPS, you

must wear your seat belt.

l No riders are allowed on tractor or mower.

l Start engine from operator’s seat after disen-

gaging tractor PTO and placing transmission in

neutral.

l Always sit in tractor seat when starting the

engine or operating controls.

l Disengage power-takeoff, shift tractor into

neutral, and place all controls in neutral before

starting tractor engine.

Make sure area behind you is clear before

operating in reverse.

Do not operate on steep slopes,

Do not stop, start or change directions suddenly on slopes.

Use extreme care and reduce ground speed

on slopes and rough terrain,

l Watch for hidden hazards on the terrain during

operation.

l Stop mower and tractor immediately upon

striking an obstruction. Turn off engine, remove

key, inspect and repair any damage before

resuming operation.

l Before working underneath, raise mower, and

block securely. Hydraulic system leak down

and failure of mechanical or hydraulic system

can cause equipment to drop.

l Disengage power to mower, lower mower to

ground, stop engine, set parking brake and

remove key before dismounting tractor.

5

Page 7

SAFETY INFORMATION

Maintenance Safety

l Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hands, hearing and head.

l Lower mower to ground or block securely, turn

tractor engine off, before performing any

service or maintenance.

l Never perform service or maintenance with

tractor engine running.

l Before working underneath, raise mower, and

block securely. Hydraulic system leak down

and failure of mechanical or hydraulic system

can cause equipment to drop.

l Keep all persons away from operator control

area while performing adjustments, service or

maintenance.

l Frequently check blades. They should be

sharp, free of nicks and cracks and securely

fastened.

l Use a new Nylok blade bolt when you replace

the blade. Do not substitute any bolt for the

special blade bolt. It is self-locking, meeting the

non-loosening requirements for this applica-

tion.

l Your dealer can supply genuine replacement

blades. Substitute blades may not meet original

equipment specifications and may be dangerous.

l Tighten all bolts, nuts and screws, and check

that all cotter pins are installed securely to

ensure mower is in a safe condition before

operating.

l Ensure all safety decals are installed and in

good condition. (See Safety Decals section for

location drawing.)

l Ensure shields and guards are properly in-

stalled and in good condition,

Storage

Block mower securely for storage.

6

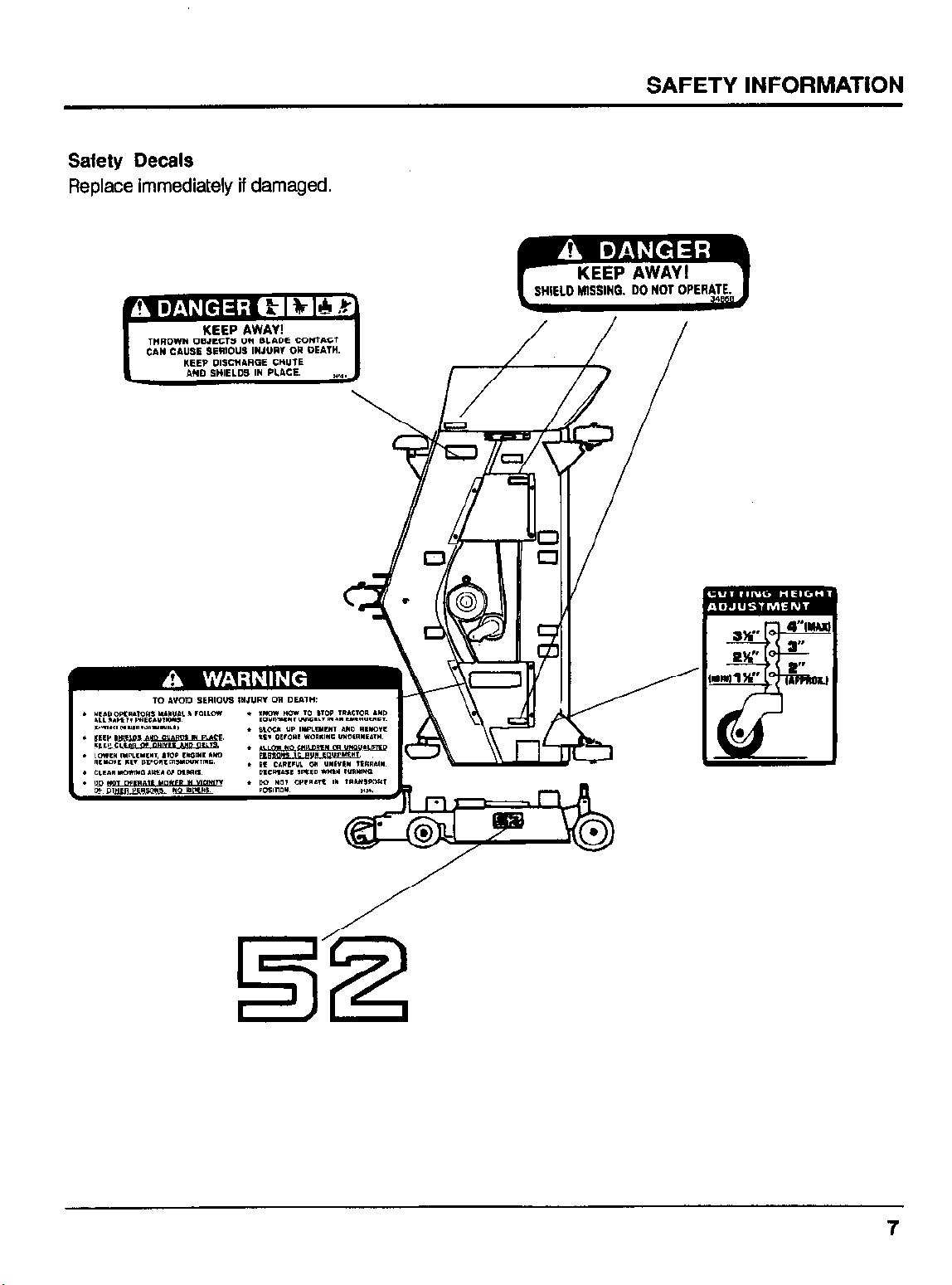

Page 8

Safety Decals

Replace immediately if damaged.

SAFETY INFORMATION

THROWN OBJECTS OR BLADE CONTACT

CAN CAUSE SERIOUS INJURY OR DEATH.

*

KEEP AWAY!

KEEP DISCIIARQE CHUTE

AND SHIELDS IN PLACE.

,“~,

7

Page 9

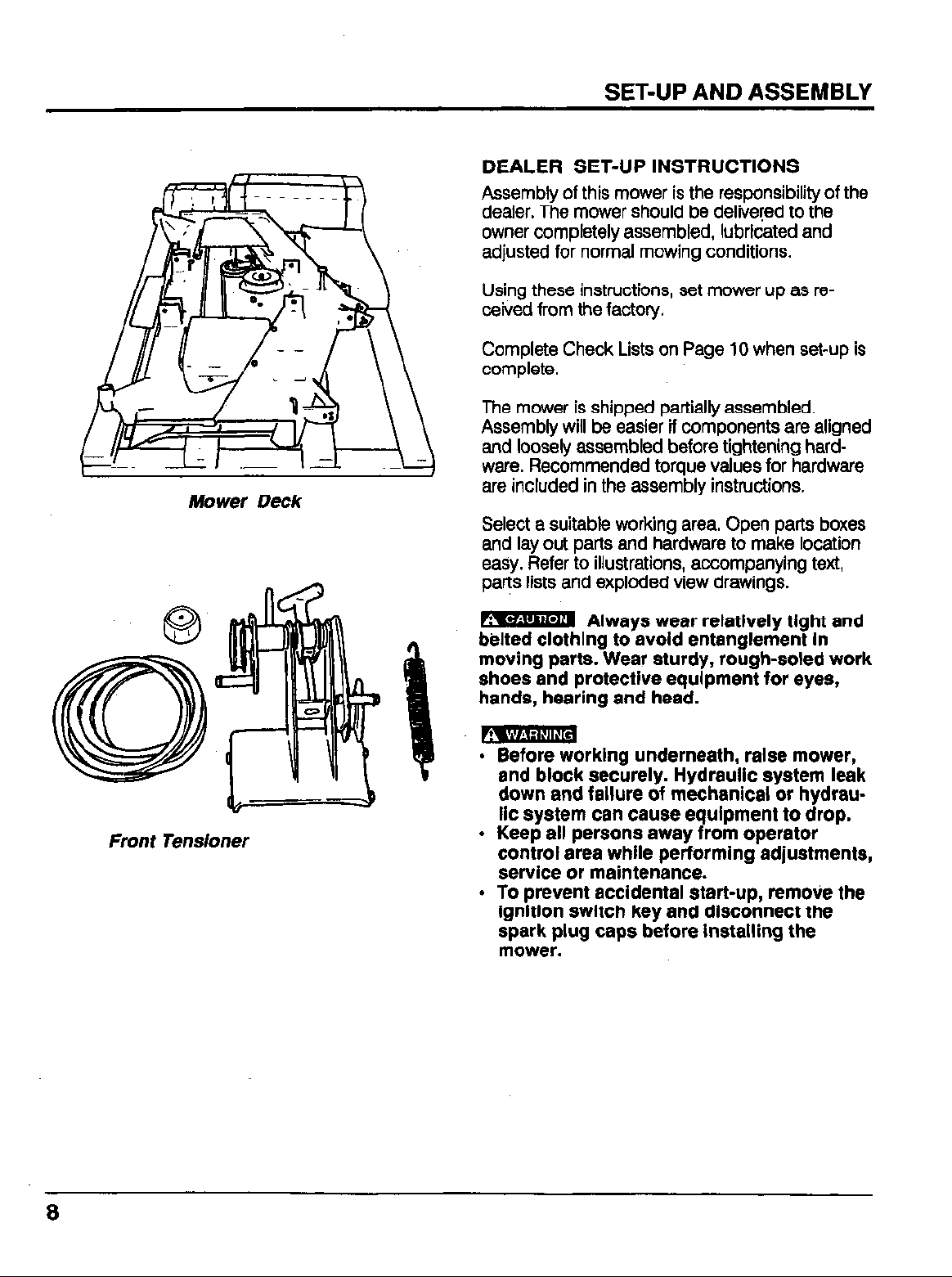

Mower Deck

SET-UP AND ASSEMBLY

DEALER SET-UP INSTRUCTIONS

Assembly of this mower is the responsibility of the

dealer. The mower should be delivered to the

owner completely assembled, lubricated and

adjusted for normal mowing conditions.

Using these instructions, set mower up as re-

ceived from the factory.

Complete Check Lists on Page 10 when set-up is

complete.

The mower is shipped partially assembled.

Assembly will be easier if components are aligned

and loosely assembled before tightening hardware. Recommended torque values for hardware

are included in the assembly instructions.

Select a suitable working area. Open parts boxes

and lay out parts and hardware to make location

easy. Refer to illustrations, accompanying text,

parts lists and exploded view drawings.

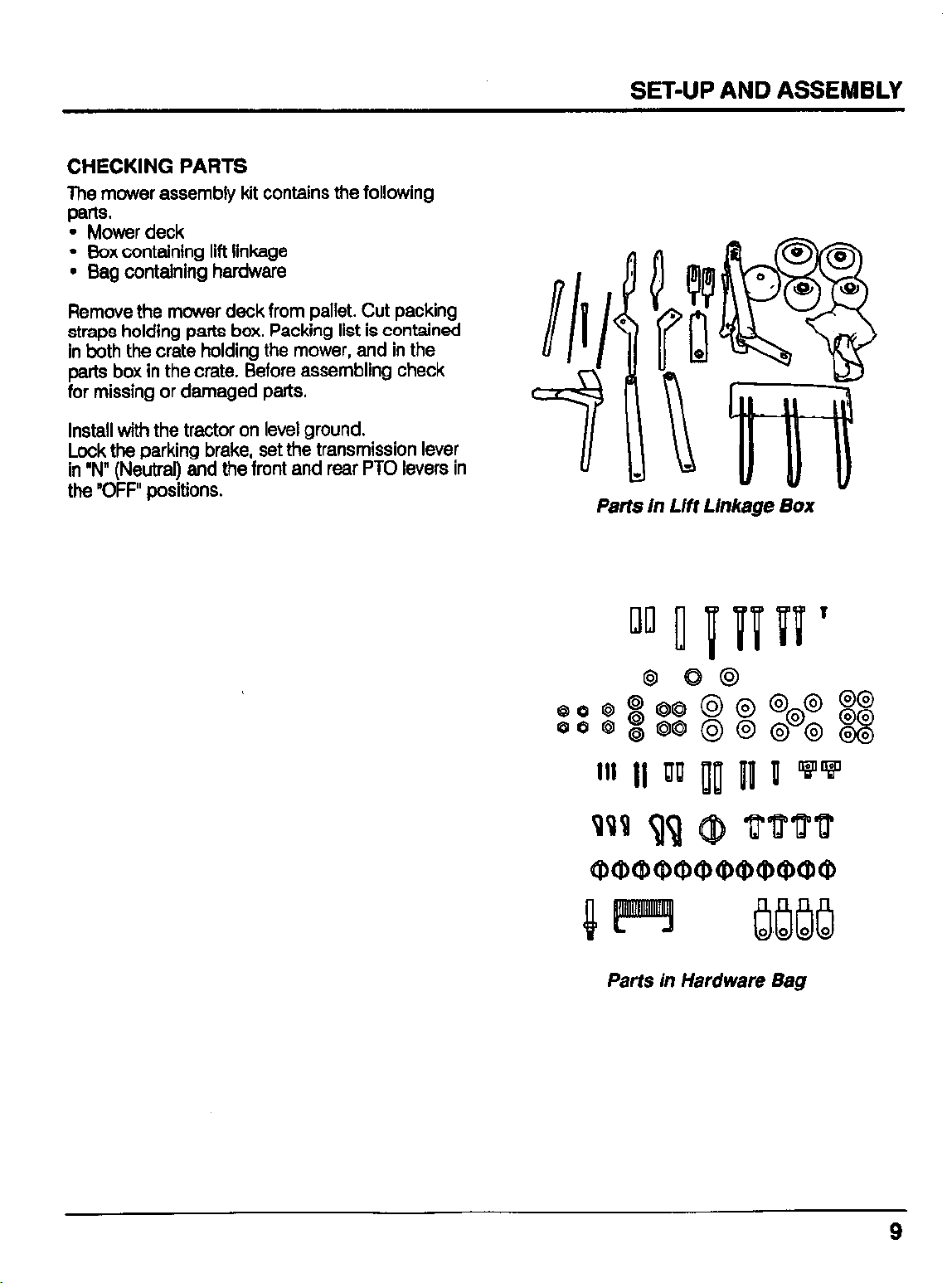

Front Tensioner

m Always wear relatively tight and

b$lted ckthlng to avoid entanglement In

moving parts. Wear sturdy, rough-soled work

shoes and protective equipment for eyes,

hands, hearing and head.

rklng underneath, raise mower,

and block securely. Hydraulic system leak

down and failure of mechanical or hydraulic system can cause equipment to drop.

l Keep all persons away from operator

control area while performing adjustments,

service or maintenance.

l To prevent accidental start-up, remove the

ignition switch key and disconnect the

spark plug caps before installing the

mower.

8

Page 10

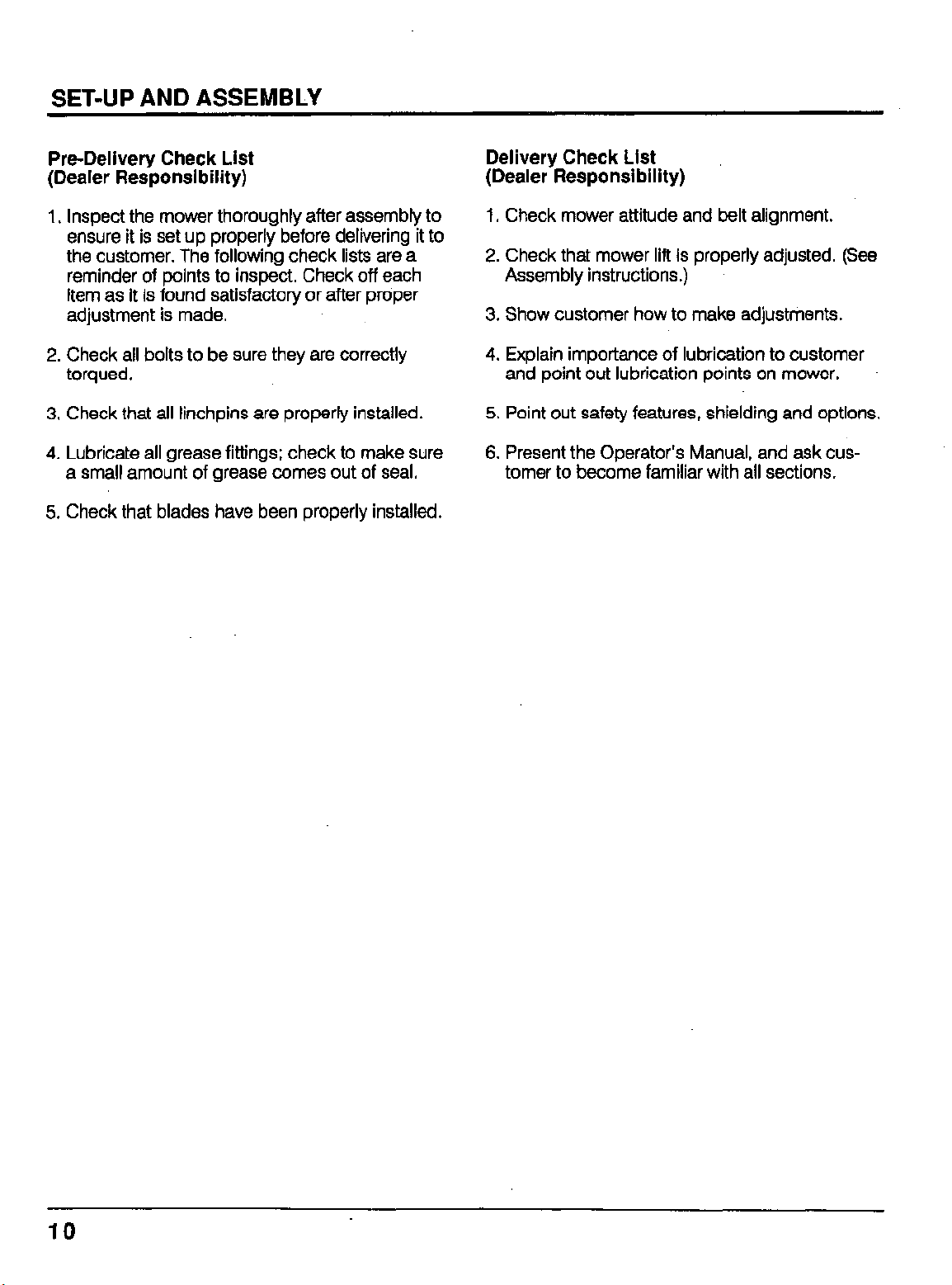

CHECKING PARTS

The mower assembly kit contains the following

p&S.

l Mower deck

l Box containing lift linkage

l Bag containing hardware

Remove the mower deck from pallet. Cut packing

straps holding parts box. Packing list is contained

in both the crate holding the mower, and in the

parts box in the crate. Before assembling check

for missing or damaged parts.

Install with the tractor on level ground.

Lock the parking brake, set the transmission lever

in “N” (Neutral) and the front and rear PTO levers in

the “OFF” positions.

Parts in Lift Linkage Box

Parts in Hardware Bag

9

Page 11

SET-UP AND ASSEMBLY

Pre-Delivery Check List

(Dealer Responsibility)

1. Inspect the mower thoroughly after assembly to

ensure it is set up properly before delivering it to

the customer. The following check lists are a

reminder of points to inspect. Check off each

item as it is found satisfactory or after proper

adjustment is made.

2. Check all bolts to be sure they are correctly

torqued .

3. Check that all linchpins are properly installed.

4. Lubricate all grease fittings; check to make sure

a small amount of grease comes out of seal.

5. Check that blades have been properly installed.

Delivery Check List

(Dealer Responsibility)

1. Check mower attitude and belt alignment.

2. Check that mower lift is properly adjusted. (See

Assembly instructions.)

3. Show customer how to make adjustments.

4. Explain importance of lubrication to customer

and point out lubrication points on mower.

5. Point out safety features, shielding and options.

6. Present the Operator’s Manual, and ask customer to become familiar with all sections.

Page 12

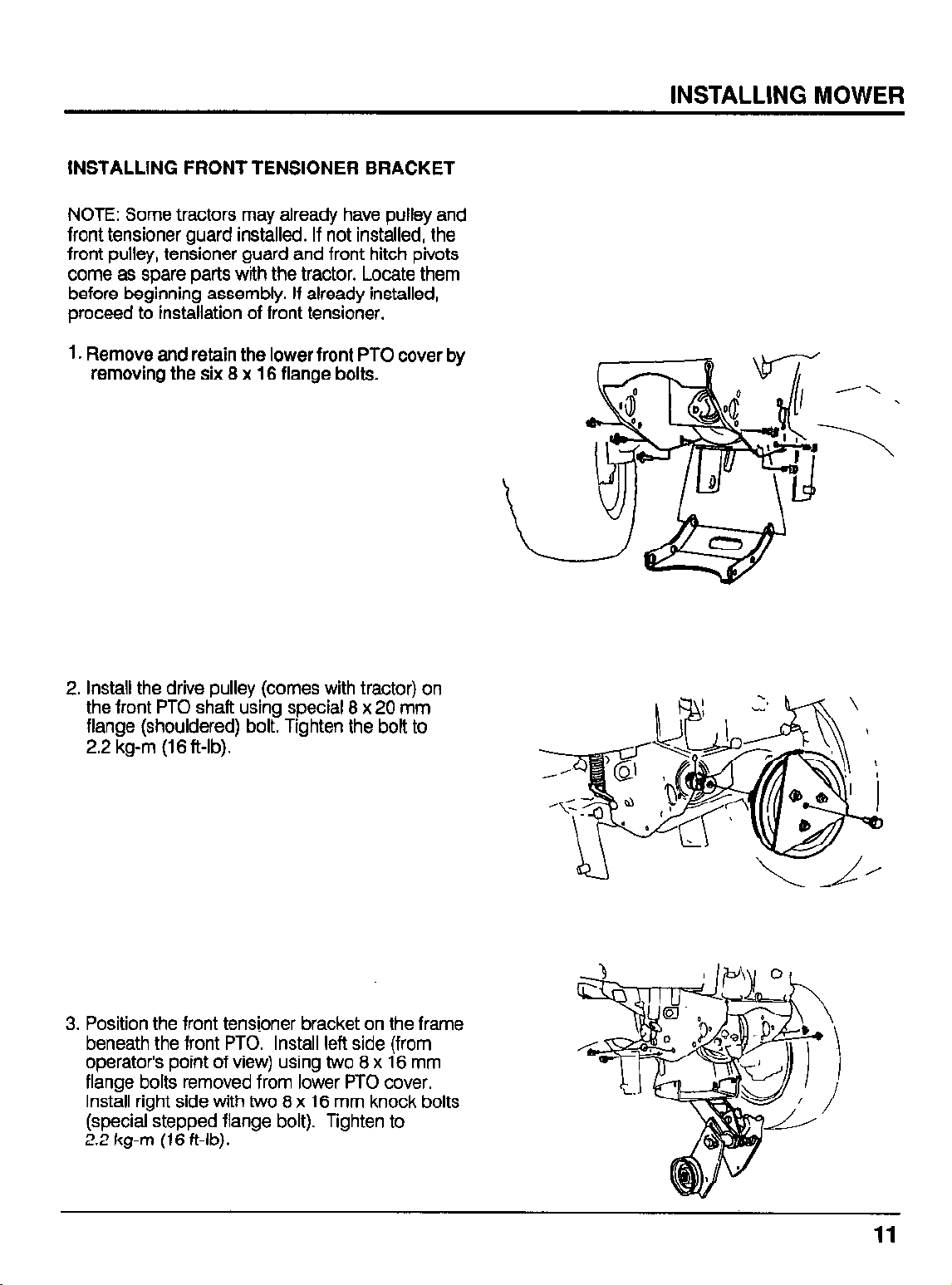

INSTALLING FRONT TENSIONER BRACKET

NOTE: Some tractors may already have pulley and

front tensioner guard installed. If not installed, the

front pulley, tensioner guard and front hitch pivots

come as spare parts with the tractor. Locate them

before beginning assembly. if already installed,

proceed to installation of front tensioner.

1. Remove and retain the lower front PTO cover by

removing the six 8 x 16 flange bolts.

2. Install the drive pulley (comes with tractor) on

the front PTO shaft using special 8 x 20 mm

flange (shouldered) bolt. Tighten the bolt to

2.2 kg-m (16 &lb).

3. Position the front tensloner bracket on the frame

beneath the front PTO. Install left side (from

operator’s point of view) using two 8 x 16 mm

flange bolts removed from lower PTO cover.

Install right side with two 8 x 16 mm knock bolts

(special stepped flange bolt). Tighten to

2.2 kg-m (16 ft-lb).

Page 13

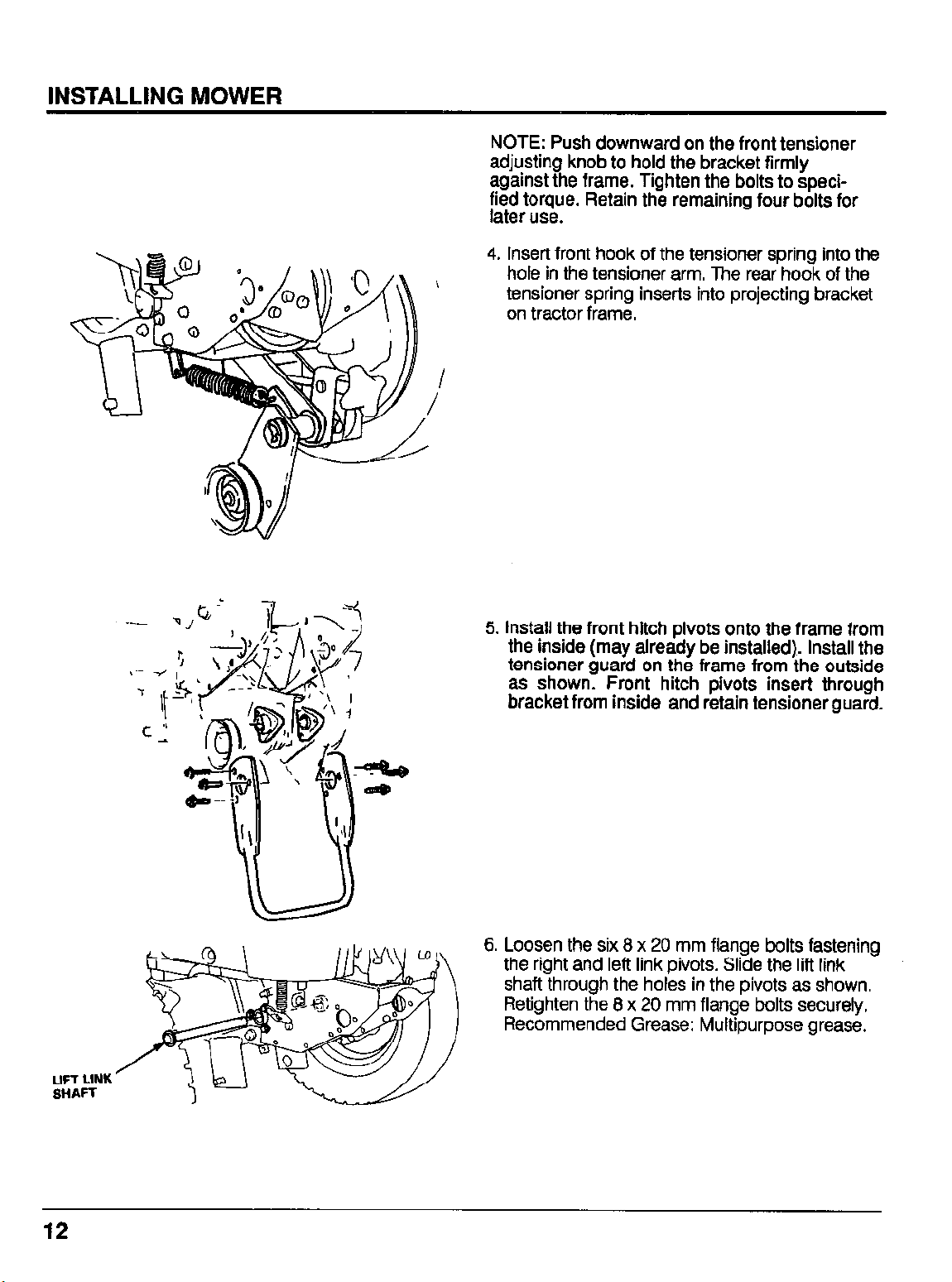

NOTE: Push downward on the front tensioner

adjusting knob to hold the bracket firmly

against the frame. Tighten the bolts to specified torque. Retain the remaining four bolts for

later use.

4. Insert front hook of the tensioner spring into the

hole in the tensioner arm. The rear hook of the

tensioner spring inserts into projecting bracket

on tractor frame.

LIFT LINK

SHAFT

5. install the front hitch pivots onto the frame from

the inside (may already be installed). install the

tensioner guard on the frame from the outside

as shown. Front hitch pivots insert through

bracket from inside and retain tensioner guard.

6. Loosen the six 8 x 20 mm flange bolts fastening

the right and left link pivots. Slide the lift link

shaft through the holes in the pivots as shown.

Retighten the 8 x 20 mm flange bolts securely.

Recommended Grease: Multipurpose grease.

12

Page 14

INSTALLING LIFT LINK

m Wear heavy gloves to protect

ybur’haids when installing lift link kit and

mower deck.

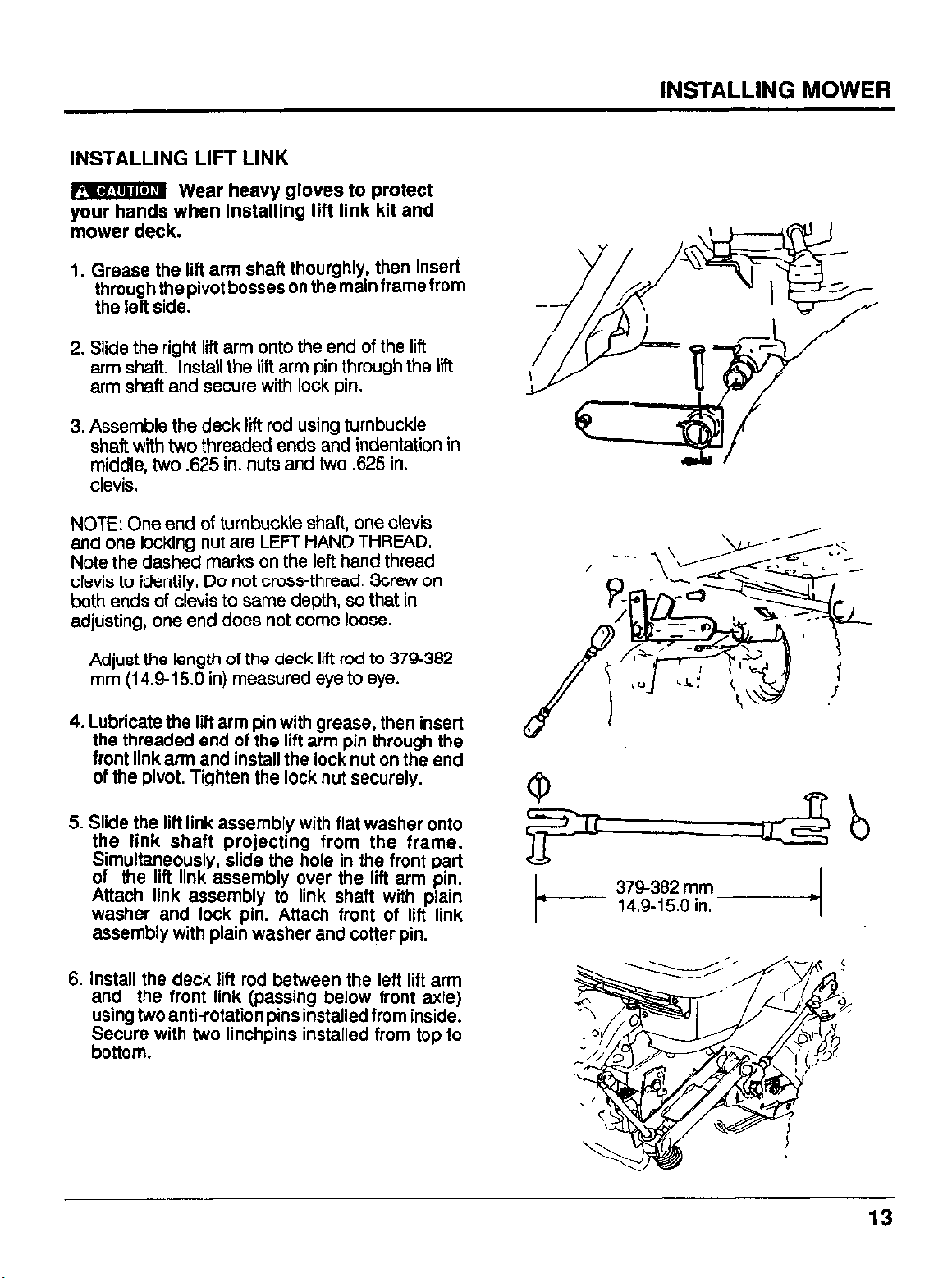

1, Grease the lift arm shaft thourghiy, then insert

through the pivot bosses on the main frame from

the left side.

2. Slide the right lift arm onto the end of the lift

arm shaft, Install the lift arm pin through the lift

arm shaft and secure with lock pin.

3. Assemble the deck lift rod using turnbuckle

shaft with two threaded ends and indentation in

middle, two ,625 in. nuts and two .625 in.

clevis.

NOTE: One end of turnbuckle shaft, one clevis

and one locking nut are LEFT HAND THREAD.

Note the dashed marks on the left hand thread

clevis to identify. Do not cross-thread. Screw on

both ends of cievis to same depth, so that in

adjusting, one end does not come loose.

INSTALLING MOWER

Adjust the length of the deck lift rod to 379-382

mm (149-l 5.0 in) measured eye to eye.

4. Lubricate the lift arm pin with grease, then insert

the threaded end of the lift arm pin through the

front link arm and install the lock nut on the end

of the pivot. Tighten the lock nut securely.

Slide the lift link assembly with flat washer onto

5.

the link shaft projecting from the frame.

Simultaneously, slide the hole in the front part

of the lift link assembly over the lift arm pin.

Attach link assembly to link shaft with plain

washer and lock pin. Attach front of lift link

assembly with plain washer and cotter pin.

6.

install the deck lift rod between the left lift arm

and the front link (passing below front axle)

using two anti-rotation pins installed from inside.

Et;:: with two linchpins installed from top to

.

Page 15

INSTALLING MOWER

ASSEMBLING MOWER DECK

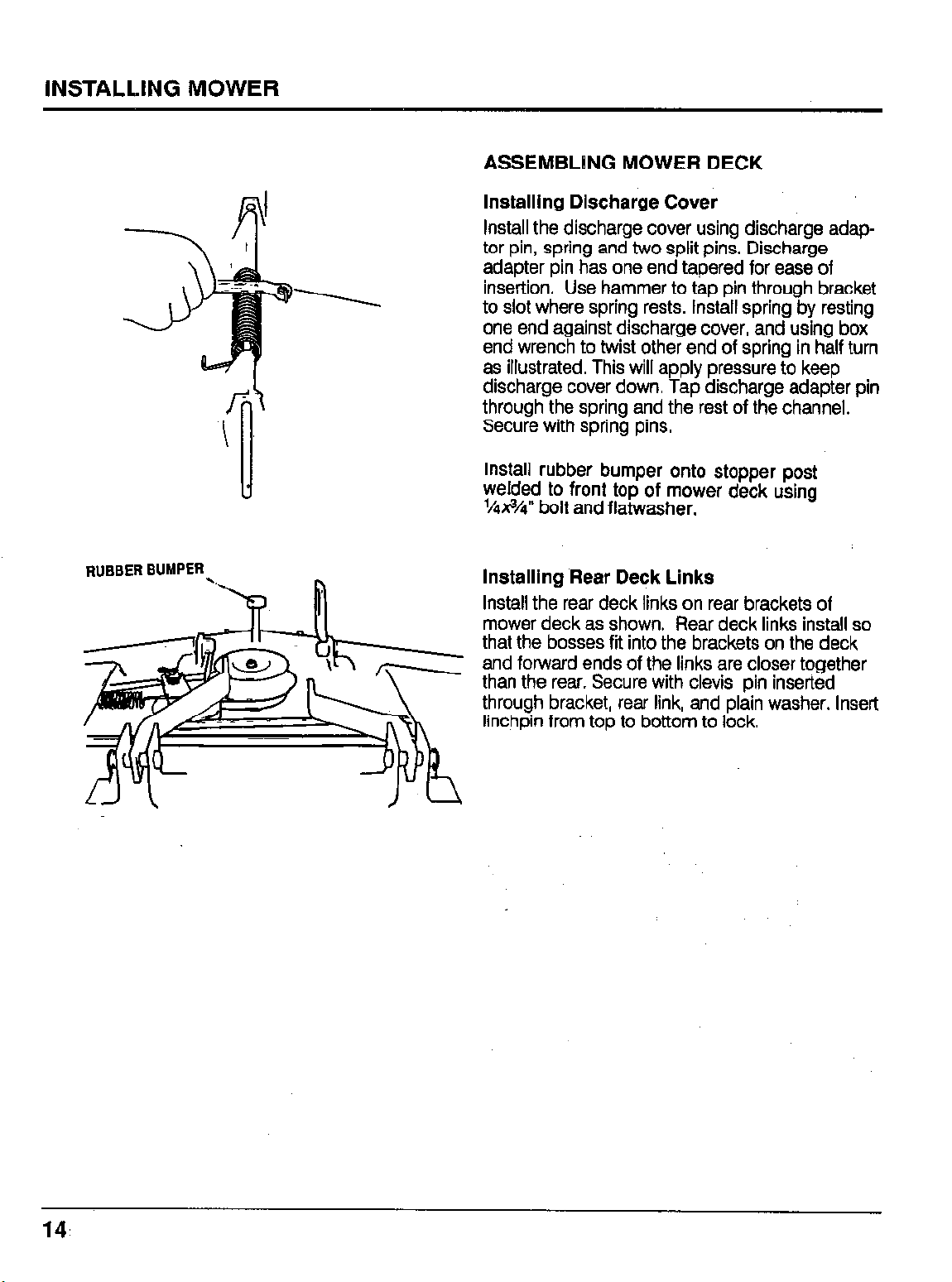

InstaDiing Discharge Cover

Install the discharge cover using discharge adaptor pin, spring and two split pins. Discharge

adapter pin has one end tapered for ease of

insertion. Use hammer to tao oin throuah bracket

to slot where spring rests. Install spring‘iby resting

one end against discharge cover, and using box

end wrench to twist other end of spring in half turn

as illustrated. This will apply pressure to keep

discharge cover down. Tap discharge adapter pin

through the spring and the rest of the channel.

Secure with spring pins.

install rubber bumper onto stopper post

welded to front top of mower deck using

1/4x3/4” bolt and fiatwasher.

RUBBER BUMPER

.,

installing Rear Deck Links

Install the rear deck links on rear brackets of

k

mower deck as shown. Rear deck links install so

that the bosses fit into the brackets on the deck

and forward ends of the links are closer together

than the rear. Secure with clevis pin inserted

through bracket, rear link, and plain washer. Insert

linchpin from top to bottom to lock.

14.

Page 16

installing Wheels On Mower

, -

t

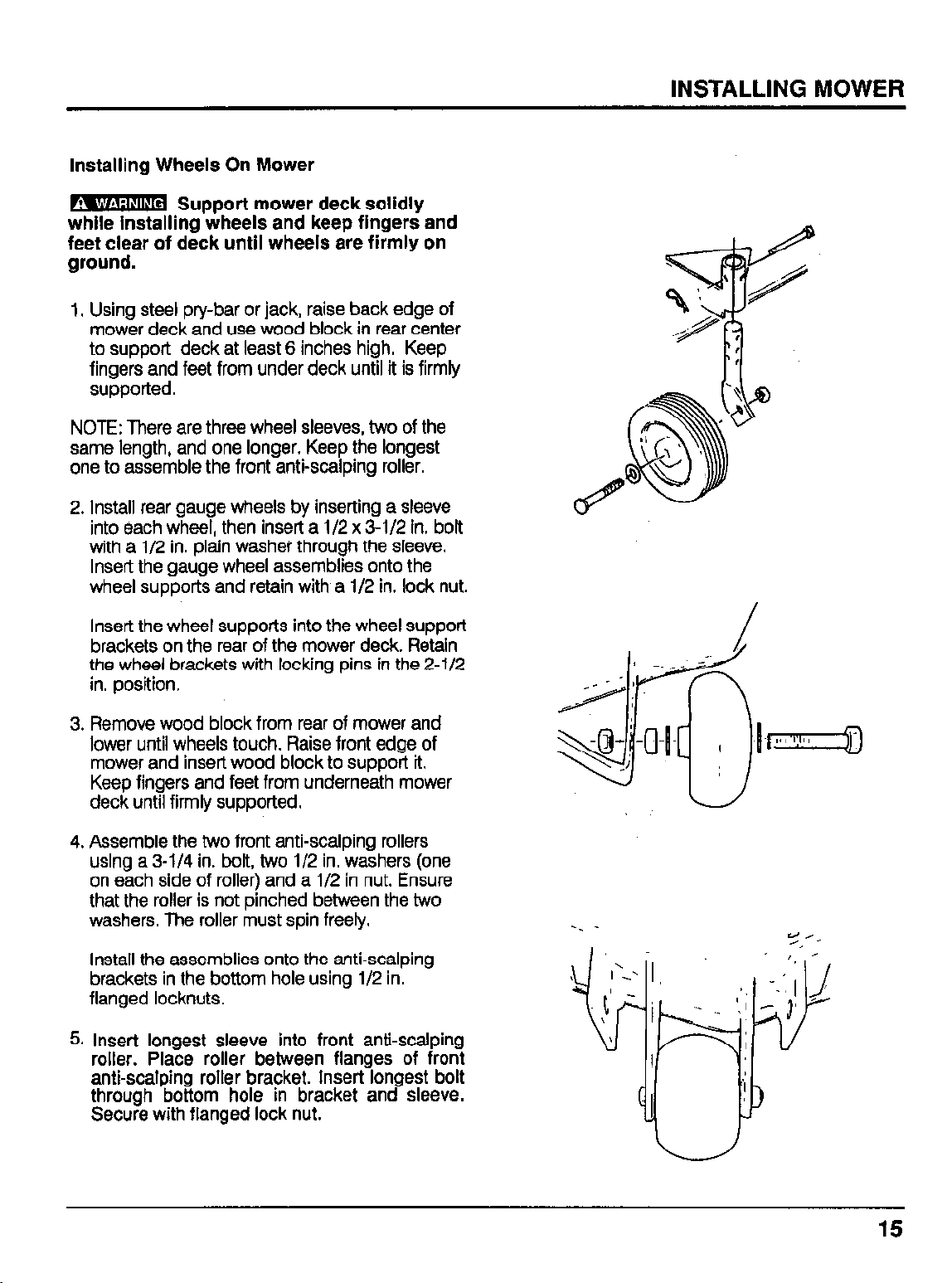

m Support mower deck solidly

while installing wheels and keep fingers and

feet clear of deck until wheels are firmly on

ground.

1, Using steel pry-bar or jack, raise back edge of

mower deck and use wood block in rear center

to support deck at least 6 inches high. Keep

fingers and feet from under deck until it is firmly

supported.

NOTE: There are three wheel sleeves, two of the

same length, and one longer. Keep the longest

one to assemble the front anti-scalping roller.

2. Install rear gauge wheels by inserting a sleeve

into each wheel, then insert a 112 x 3-l/2 in. bolt

with a 112 in. plain washei through the sleeve.

Insert the gauge wheel assemblies onto the

wheel supports and retain with a 112 in. lock nut.

INSTALLING MOWER

Insert the wheel supports into the wheel support

brackets on the rear of the mower deck. Retain

the wheel brackets with locking pins in the 2-112

in. position,

3. Remove wood block from rear of mower and

lower until wheels touch. Raise front edge of

mower and insert wood block to support it.

Keep fingers and feet from underneath mower

deck until firmly supported.

4. Assemble the two front anti-scalping rollers

using a 3-l/4 in. bolt, two l/2 in. washers (one

on each side of roller) and a l/2 in nut. Ensure

that the roller is not pinched between the two

washers. The roller must spin freely.

Install the assemblies onto the anti-scalping

brackets in the bottom hole using 112 in.

flanged locknuts.

5. insert longest sleeve into front anti-scalping

roller. Place roller between flanges of front

anti-scalping roller bracket. Insert longest bolt

through bottom hole in bracket and sleeve.

Secure with flanged lock nut.

15

Page 17

INSTALLING MOWER DECK

Positioning Mower Under Tractor

1. Connect the spark plug caps to the spark plugs

(if removed) and insert the ignition key in the

ignition switch. Check that the hydraulic ilft lever

is in NEUTRAL. Start the engine and move the

hydraulic cylinder selector lever (if installed) to

the FRONT position. Raise the lift arm fully with

the Lii Selector Lever.

2, Turn the Lowering Speed Adjusting knob fully

clockwise to lock the lift arm up. Stop the

engine. Remove the key from the engine switch

and disconnect the spark plug caps.

3.

Turn the steering wheel to the extreme left to

allow clearance for the mower deck. To avoid

obstructions, make sure rear deck links are I

forward, towards front of mower. Roil and push

the mower deck under the tractor from the right

side; return the steering wheel to the straightahead position.

4.

Return lift arms to down position to complete

hookup of mower. Turn the Lowering Speed

Adjusting knob fully counter-clockwise (“FAST

direction). Move the Lii Selector Lever to

“DOW, and push the front lift arm completely

down by hand.

NOTE: If arm does not move, Lowering Speed

Adjusting knob is not fully counter-clockwise. Turn

to release, then push down on lift arms as iilustrated.

16

Page 18

Attaching Rear Mower Deck Links

mm

1. Roil mower forward or backward or tug from

side to side as necessary to line up holes in rear

mower deck link with holes in bracket under

tractor. Bracket is difficult to recognize at first,

look for hole just behind the main mounting

bracket along centerline of tractor.

2. Grease the rear link shaft (long shaft with two

holes in either end for linchpins) then slide it

horizontally through the holes in rear deck links

and holes in the bracket as shown. Start by

hand, but it may be necessary to tap with

hammer to complete. Secure both sides with

iinchpins.

Attaching Front Deck Links To Mower

1. Turn the two clevis to adjust the length of the

front deck links to 280-282 mm (11.0-l 1 .l in)

measured from eye to eye, then tighten the lock

nut securely.

Ins&t Rear Link Shaft

2. Raise the front of the mower deck a few inches

with steel pry bar, block of wood or jack to align

the holes in the links and brackets.

3. Fasten front link to mower deck by inserting

cievis on projecting bracket on front of mower.

Secure by passing anti-rotation pin through

cievis and bracket and insert linchpin.

4. Fasten other end of front link to projecting

bracket on front of tractor, fiiing upper hole in

deck link over projecting stud on bracket.

Secure with iinchpin. Repeat for other side.

Remove support from front of mower deck.

(11.0-l 1 .l in)

:,

J

1’

r

Page 19

150-l 52 mm

5.9 - 6.0 in

Attaching Lift Plates

Screw mower deck lift plates into adjustable

pins as illustrated. Turn to adjust the length of

the-mower deck lift plates to 150-152 mm (5.9-

6.0 in), then tighten the nuts securely. Install the

mower deck lift plates on the mower deck with

5/8 in. plain washers and lock pins.

2.

Raise the right mower deck lift plate to the lift

arms installed earlier on the lift arm shaft assembly. Lift arms will be directly above the lift

plate. Maneuver the mower deck lift plate over

the projecting stud on the lift arm. Secure with

5/8 in. plain washer and lock pin. install the left

mower deck lift plate the same way.

18

Attaching Front Link Protector

Position the front link protector on link arms. Insert

clevis pin through hole in front link protector

bracket and front link from the inside. Secure with

l/2 in. plain washer and lock pin. Repeat for other

side.

Page 20

LEVELING MOWER DECK

1. Place the tractor on a firm, level surface and set

the parking brake. Make certain that tractor tires

are inflated to proper pressure. See Tractor

Owners Manual for information on inflation.

2. Check that the gauge rollers and front antiscalping rollers are set on 2.5 in. position (one

hole showing on wheel support). If not, raise the

mower deck with the Lift Selector lever set to

“UP”.

3. When lift arms are fully raised, turn the Lowering Speed Adjusting knob fully clockwise to lock

the deck in position.

4. Stop the engine and remove the key; adjust

wheels to the 2.5 in. position.

5. Return the Lowering Speed Adjusting knob to its

original position; lower the mower deck fully.

INSTALLING MOWER

m if the Lift Selector Lever is set to

“&VN’:the mower deck will automatically

lower to the ground as the Lowering Speed

Adjusting knob is turned counter-clockwise.

Keep clear of the deck.

19

Page 21

Front to Back Leveling

1. Set the left and right mower blades so that they

face front and rear. Measure the distance to the

ground from front and rear of blades.

NOTE: This measurement can be made with a

steel tape or by using the Blade Height Gauge, an

optional HONDA part (#07JPJ-75OOlOA) available at your HONDA Multipurpose Tractor Dealer.

With the gauge wheels set at the 2%”

position, and the two outside blades

positioned as shown, the blade height at

points A and B should be 64 - 70 mm (2.52 -

2.76 in). The blade height at points C and D

should be slightly higher by about 3 mm (.l

in). The blade height should be the same for

left and right blades.

2. If distance at front of blade tip is too great or

too small, adjust as follows: (Perform this

before connecting drive belt). Tip up front of

deck with steel pry bar and support front of

deck with wooden block.

3. Remove the linchpin and clevis pin from the

right and left front links. Loosen the nuts which

hold the clevis tight. Turn both cievis an equal

number of full turns so that both will be set at

same length.

NOTE: Turning the clevis “OUT” lowers the front

clearance; “IN” raises the clearance Each turn

changes height by just over 1 mm (l/32 in).

4. If right and left blade heights are not equal, add

or subtract turns to make equal.

5. After completing adjustment, tighten nut holding

clevis in place, reinsert clevis pin and secure

with linchpin

Page 22

INSTALLING DECK BELT

! .-

m Never attempt to than e drive

belts while the engine is running.

I?

emove

the ignition switch key from the ignition and

disconnect the spark plug caps to prevent

accidental start up.

Loosen the Belt Tension Adjusting knob fully.

1.

Place the V-belt on the PTO drive pulley, then

on the mower drive pulley as illustrated.

Push up on drive belt tensioner to ease instal-

2.

lation, then place the belt on the pulley on the

tensioner side (right). Next, place belt on the

pulley on the left side.

3. Position the V-belt drive stopper (comes

with tractor) onto the frame as shown using

one 10 x 20 flange bolt and one 8 x 16

flange bolt. Tighten bolts to 2.2 Kg-m (16

ft-lb).

INSTALLING MOWER

4. install the belt stopper collars on each side

of the tensioner frame using 8 x 45 mm

flange bolts. Tighten bolts to 2.2 Kg-m (16

ft-lb).

NOTE: Check that the belt is properly installed on

the pulley with a 90” twist between the drive

pulley and the idler pulley. Be sure the “V” of the

belt goes in the “V” of the pulley.

5. Reconnect spark plugs. Start the engine, move

the hydraulic cylinder selector lever (if so

equipped) to “FRONT’. Move Lift Sector lever

to “UP” and raise the mower deck fully.

NOTE: Deck must be in fully raised position to

properly set belt tension.

Turn the Lowering Speed Adjusting knob fully

6,

clockwise to prevent the deck from lowering.

7.

Stop the engine and remove the key from the

engine switch.

Adjust the Belt Tension Knob until the

8.

BELT ADJUST ST0

stopper of the tension arm just contacts the

frame as illustrated.

BELT STOPPER COLLAR

Return the Lowering Speed Adjusting knob

9.

the original position.

to

Page 23

INSTALLING MOWER

Adjusting Lifting Height With Lift Plate

1, Place the tractor on a firm, level surface. Apply

and lock the parking brake.

2. Start the engine, move the Hydraulic Cylinder

Selector Lever (if installed) to FRONT. Set Lift

Selector lever to “UP” and raise the mower deck

fully.

3. When mower is fully raised, turn the Lowering

Speed Adjusting knob fully clockwise to lock

hydraulic system.

4. Stop the engine and remove the key from the

ignition switch.

If the Lift Selector Lever is set to

“DOWN” the mower deck will automatically

lower to the ground as the Lowering Speed

Adjusting knob is turned counterclockwise.

Keep clear of the deck.

Set a wood block under the deck to hold it 4 or

5.

more inches off the ground, if it should descend. Measure from mower deck to ground. If

measurement is less than 109 mm (4.3 in)

shorten the mower deck lift plates to raise the

deck higher. When raised to the maximum

position, the mower should be 109-l 13 mm

(4.3-4.5 in) off the ground. Measure both sides

to be sure they are equal.

If shortening the mower deck lift plates is

6.

necessary, lower deck by moving Lift Selector

Lever to “DOWN”. Mower will descend as the

Lowering Speed Adjusting knob is turned

counterclockwise.

Remove lock pin holding lift plate onto stud on

7.

lift arm. Pull the lift plate towards you. This will

free lift plate so that it can turn to adjust. Screw

the lift plate in to shorten it, which will increase

the mower deck lift height. [Each turn will

shorten by about 3 mm]. Shorten or lengthen

the plates as necessary to make both sides

equal.

22

6.

After adjusting length of lift plates, replace plate

on stud, and lock with lock pin. Start engine,

raise mower, turn Lowering Speed Adjusting

knob fully clockwise to lock and repeat adjust-

ment. If deck cannot be raised to 109 mm, see

next section on adjusting lift rod.

Page 24

Mower Deck Lift Rod

1, If the height of the mower deck is less than 109

mm (4.3 in), adjust the mower deck lift rod until

the height is between 109 to 113 mm (4.3 to 4.5

in). The mower deck lift rod is adjusted as

follows: With deck in the lowered position, back

off on lock nuts on lift rod. Rod is designed as a

turnbuckle. Use a wrench on the flats of the rod

to turn it.

2. Turn the rod clockwise to tighten, thus increasing the lift height of the deck. Turn it counter-

clockwise to loosen. After adjustment, tighten

the lock nuts securely.

3. Do not shorten the mower deck lift rod to less

than 379 mm (14.9 in) when first adjusting deck.

If the height of the mower blade is below

109 mm (4.3 in) when the mower deck lift rod is

379 mm (14.9 in) long, first use the mower deck

lift plates to adjust the deck height.

INSTALLING MOWER

4. If the mower cannot be raised to 109 mm (4.3

in) using the deck lift plates, then adjust the

length of the mower deck lift rod.

23

Page 25

INSTALLING MOWER

Lift Link Rod

1. Check that the distance between the end of the

rod and the bottom washer is 27-29 mm

(1.0-l .l in).

2. To adjust, loosen the lock nut and turn the

adjusting nut. After adjustment, retighten the

lock nut securely.

24

Page 26

DETACHING MOWER

1. Start the engine and move the Hydraulic Cylinder Control lever (if installed) to “FRONT’. Move

Lii Selector Lever to “UP”. Stop engine and

remove key and disconnect spark plugs.

2. Set gauge wheel at rear to l-1/2 in. and lower

the deck.

3. Start engine and lower deck. Stop engine,

remove key, disconnect spark plugs.

4. Remove mower deck drive belt from driven

pulley on deck by removing front tensioner belt

stopper, belt stopper collar, and loosening

front tensioner adjusting knob. Remove belt

from front tensioner to create slack for driven

pulley. (Sea Maintenance section for detailed

description.)

5. Remove lock pins holding front deck lift plates

and slip lift plates off projecting stud on tractor

frame.

6. Remove belt guard.

Removb lock pins

25

Page 27

7. Use steel pry bar or jack to raise front of deck

slightly. Pull linchpins holding front deck links to

projecting bracket on deck. Lower deck to

ground..

8. Pull lock pin holding rear deck links to rear deck

link shaft. Use drift pin to tap out rear deck link

shaft. Lower rear deck links to deck as shaft is

withdrawn.

26

Remove linchpins and link shaft

9. Turn steering wheel to extreme left. Pull mower

deck from right side of tractor.

Page 28

For safe and efficient mowing, always make a pre-

operation inspection before starting:

Inspect the tractor on level ground.

Set the parking brake, put the transmission lever in

“N” (NEUTRAL) and PTO clutch lever in the “OFF”

and the lift lever in the center (NEUTRAL) positions. Disconnect the spark plug cap and remove

the key to prevent accidental engine start-up.

Never run the engine in an

enclosed area. Be sure to provide adequate

ventilation. Exhaust contains poisonous

carbon monoxide gas that may cause loss of

consciousness and lead to death.

CLEANING MOWER DECK (EXTERIOR)

1, Check that the mower deck is lowered fully.

2. Remove grass and other foreign matter from the

mower deck.

DECK DRIVE BELT

Lower the mower deck fully, remove the ignition

key and disconnect the spark plug caps. Visually

inspect the drive belt for wear, cracks or other

faults, if the drive belt is faulty, follow the replacement procedure described on Page 39.

27

Page 29

PRE-OPERATION CHECKS

CHECKING BLADE CONDITION

Before each use, check each mower blade for

damage or abnormal wear.

1. Stan the engine and set Hydraulic Cylinder

Selector lever (ii installed) to “FRONT”. Raise the

mower deck fully with the Lii Selector lever.

Turn the Lowering Speed Control knob fully

clockwise to prevent descent. Do not over-

tighten the knob.

9 1.

m Severe personal injury can

result if a piece of blade breaks off and is

thrown from under the mower deck.

.

Never operate the tractor with a worn or

damaged blade.

.

Never operate the tractor with a blade that

is cracked or notched at the base of its

upturned edge.

Push the Lii Selector lever toward “DOWN” to

2,

be sure that the mower deck is locked in the

fully raised position. Mower should not descend.

3. Set Lii Selector lever back to “NEUTRAL”.

9 a-

m To avoid personal injury:

l Remove the ignition key to prevent acci-

dental starting.

l Wear heavy gloves to protect your hands

from the mower blades.

l Place a block under the mower deck to

prevent it from lowering unexpectedly.

l Stop the engine, remove the ignition key

and disconnect the spark plug caps.

4. inspect each of the blades for cracks, bending

or signs of wear. The right and center blades

can be seen from under the right side of the

mower deck . The left blade can be seen from

under the left front edge of the mower deck.

Turn the blades 180” to inspect the opposite

side.

28

Page 30

If any of the blades show signs of damage or

excessive wear, a more thorough inspection is

necessary (see Page 25 for Mower Deck Removal). A dull blade can be sharpened, but a

blade that is worn out, bent, cracked or otherwise

damaged must be replaced. If a blade needs

sharpening or replacement, take the mower deck

to your authorized HONDA Multipurpose tractor

dealer. Or if you have the proper tools, you can

remove and install the blade yourself.

Use a genuine HONDA replacement blade

or equivalent.

To reduce the possibiiity of weakening the

blade or causing imbalance or poor cutting

performance, sharpening should be per-

formed by an authorized HONDA Muiti-

purpose Tractor dealer.

5. When you have completed the blade inspection, return the Lowering Speed Adjust knob to

its original position.

PRE-OPERATION CHECKS

NORMAL

EXCESSIVELY

WORN

CRACKED

m if the Lift Selector Lever is set to

**LO\;JN*‘the mower deck will automatically

lower to the ground as the Lowering Speed

Adjusting knob is turned counterclockwise.

Keep clear of the deck.

29

Page 31

ADJUSTING CUTTING HEIGHT

1. Park the tractor on a level surface and set the

parking brake.

2. Make sure the Main Transmission Lever is in

“NEUTRAL” and the PTO levers are “OFF” and

the lift lever is in the center (NEUTRAL) position.

3. Start the engine, move the hydraulic cylinder

selector lever (if installed) to “FRONT” and raise

the mower deck fully with the Lift Selector lever.

4. Turn the Lowering Speed Adjust knob fully

clockwise to lock the hydraulic system.

5. Set the Lift Selector lever to “DOWN” to be sure

the mower deck is locked in the fully raised

position. Deck should not descend. Return the

lift lever to “NEUTRAL” and then stop the engine

and remove the ignition key.

A -

t

m Be sure all moving parts have

stopped before adjusting cutting height.

Contacting moving parts can cause injury.

6. Remove the locking ,pin from the gauge wheel

and set the wheel for the desired cutting height.

7. Repeat the adjustment procedure for the other

gauge wheel.

NOTE: Both gauge wheels must be set to the

same height.

8. If necessary, remove the nut and bolt from left,

right and center anti-scalping rollers, and set

the anti-scalp rollers for the desired cutting

height. This height is determined by which hole

is used in anti-scalping wheel brackets. As

illustrated, top hole sets height of 1.5 in, middle

hole 2 in and bottom hole 2 l/2 in. Make sure to

set all anti-scalping rollers to same height.

9. Insert the bolt into the anti-scalp roller bracket

and secure it with the nut.

30

Page 32

LOWERING SPEED ADJUSTMENT

1. Adjust how quickly the deck descends by

turning the Lowering Speed Adjusting knob.

Adjustment is normal if it takes l-2 seconds for

the mower deck to lower from the highest

position to the ground.

2, Turning the knob clockwise toward “SLOW’ will

decrease the speed, and turning it counterclockwise toward “FAST” will increase the

speed.

NOTE: Uneven mowing may result if the descent

speed is too slow.

OPERATION

31

Page 33

OPERATION

STARTING

1. Start the engine. With parking brake set,

depress the clutch pedal and place the main

and auxiliary transmission levers in the desired

gear range for mowing.

2. Lower the mower deck and advance throttle to

increase engine speed. Always mow at full

throttle for best Ft quality.

3. Depress the brake pedal and release the

parking brake lock lever.

4. Slowly move the front PTO lever to “ON”

position. The mower blades will start to

rotate.

STOPPING

in An Emergency

1, Turn the engine switch to “OFF”.

2. Depress clutch and brake pedal.

In Normal Use

I. Move throttle to “SLOW”.

Depress clutch and brake pedals

simultaneously

Move Main Transmission lever to

“NEUTRAL”.

2. Shift PTO lever to “OFF” position.

3. Turn engine switch to “OFF”. Remove key from

ignition.

4. Press down on Parking Brake Lock Lever while

depressing brake pedal to set parking brake.

MOWING

Before operating this tractor you should read and

understand the Safety Information on Pages 4-6.

When mowing tall grass, make a first pass with the

deck fully raised. This will help to expose any

hidden obstacles. When you are sure that the area

is completely cleared, mow again at the desired

height.

m] if the tractor should accidentally

get caught on an unseen object (rock, root,

hole, etc.), do not attempt to ride over the

obstruction or turn the steering wheel to free

the mower. These actions can damage the

steering mechanism or the deck.

Mowing Tips

1. Mow at full throttle for best cut quality. The lawn

may not be trimmed uniformly at medium or low

engine speeds.

2. Observe the following when mowing:

4th gear

5/6th gear Normal cutting

7th gear Light cutting or transporting

8th gear

3. If grass is exceptionally tall, set deck to highest

position on first pass, then mow again with

deck set to desired height. Also allow the lawn

to dry thoroughly before you use the mower. To

cut a thick or lush lawn, mow in a lower gear or

cut twice.

4. Always turn counter-clockwise at low ground

speed when cutting close to trees, posts,

sprinklers, wails, etc.

5. Y&J may cut the lawn too short when the lawn is

thick or wet, and/or the ground is soft as the

gauge wheels may sink into soft ground.

Heavy cutting or trimming

Use only for transporting

32

6. Increase the cutting height if the lawn is spindly

and the surface is uneven.

Page 34

CUTTING PATTERNS

These cutting patterns are only recommended for

a flat, level lawn surface.

In a small area

First make 2 or 3 turns in a clockwise direction.

Then turn around and continue cutting in the

reverse direction.

In a large area

The first round of cuts is the key to making a neat

finish. First, make 2 or 3 turns in a clockwise

direction, As you reach the center of the area, turn

to the right and continue cutting in the reversa

direction until you have finished the upper half of

the area. Cut the grass in the remaining half in a

counter-clockwise direction.

OPERATION

Small Area Cuffing Pattern

Mowing unsquars areas

If your mowing area is not square or four-sided,

divide the area into several blocks so you can

mow In a neat mowing pattern.

Overlapping on straightaways

Be sure that each mowing lane overlaps sufficiently. The recommended overlap width is between 4-6 inches or approximately the width of

one of the mower’s front tires.

Overlapping in curves and turns

When cutting in curves and turns, shift to a slower

speed and be sure to overlap the previous cut by

20-50% or approximately half the width of the

mower.

Large Area Cutting Pattern

33

Page 35

LUBRICATION INFOFiMATlON

1. Do not let grease or oil collect on or around

parts, particularly when operating in sandy

areas.

2 The accompanying illustration shows lubrication

points. The’chart gives the frequency of lubrica-

tion in ‘operating hours, based on normal

operating conditions. Severe or unusual conditions may require more frequent lubrication.

Some reference numbers have more than one

location; be sure you lubricate all locations,

3. In addition to the lubrication points shown, at

least once a year, oil the mower lift pivot points,

Lubrication Points

Ref. No. Item Description Frequency

1. Rear Gauge Wheel Shaft

8 hrs

Item Operation

Each Use First 20 Hrs Every 50 Hrs Refer To Page

4. Use a good quality SAE Multipurpose grade

grease at grease fiiing locations. Be sure to

clean fiiings thoroughly before attaching

grease gun.

5. Use SAE 30W oil in areas without grease

fiiings.

Maintenance Schedule

Periodic maintenance and adjustment are necessary to keep the tractor in good operating condition. Service and inspect according to the Maintenance Schedule.

Service Period

Mower Deck Exterior

Deck Drive Belt

Blade Condition

Blade Bolt Tightness

Blade Belt

Mower Deck (inside)

34

Clean

Check

Check

Check

Check

Clean

ii

X

X,

27,41

27,39

28,36

38

ii

X

40

Ad

Page 36

Weekly Check

1. Check all nuts and fasteners for tightness.

2. Note any joints or lubrication points needing

grease. Pay special attention to blade spindles,

the rear deck lift joints and the rear gauge

wheels. Use SAE Multi-purpose grade grease.

m To avoid carbon monoxide

pbisdning , shut off the engine before performing any maintenance. If you run the

engine in an area that is confined, or even

partially enclosed, the air you breathe will

contain a dangerous amount of exhaust gas.

If the engine must be run for any reason, be

sure the area is well ventilated.

l To avoid serious burns, allow engine to

cool before performing maintenance

MAINTENANCE

l Shut off engine and set the parking brake

before performing any maintenance.

. To prevent accidental start-up, remove the

ignition switch key and disconnect the

spark plug caps.

l The tractor and mower should be serviced

by an authorized HONDA multipurpose

tractor dealer unless the owner has proper

tools, service data and is mechanically

inclined.

35

Page 37

MAINTENANCE

BLADE SERVICING

Inspect blades for condition and proper installa-

tion.each time before operation. Replace any

blade that is bent, excessively nicked, worn or

has any other damage. Small nicks can be

ground out when sharpening.

Blade Removal

1.

Always wear heavy gloves when working near

the blade. Secure the movement of the blade

with a block of wood.

2.

Remove the special Nylock blade bolt (RIGHT

HAND THREADS). Remove the cup washers,

5/8” flat washer and blade. The shoulder washer

normally does not come off unless intentionally

removed.

1. Blade

2. Shoulder washer

3. Left belt shield

4. S/8” Standard flat washer

5. Cup washers

6. Blade bolt, special Nylock (right hand threads)

Blade Assembly

&

6

Blade Installation

1. Install the shoulder washer (if removed).

Check the orientation of the blade and make

2.

sure the cutting edge is positioned to lead in a

clockwise rotation, as viewed from the top of the

mower.

Inspect the condition of the cup washers.

3.

Replace the cup washers if they appeared

burned or flat.

v *

m Use a new Nylok blade bolt

when you replace the blade. Do not substitute any other bolt for the special blade bolt.

It Is self-locking, meeting the non-loosening

requirements for this application.

4. Install two cup washers on bolt. Install washer

and blade on bolt. Remember bolt has right

hand threads; install bolt and blade assembly

into spindle. Torque bolt to 23.5 kg/m (170 ft/

Ibs).

.

36

Page 38

Sharpening Blades

1, Remove blades.

MAINTENANCE

MAINTAIN CORNER

2. Always sharpen both ends equally to maintain

balance. Follow original sharpening pattern. Do

not sharpen blade to a razor edge. Leave from

l/32 in. to l/16 in. blunt edge. Do not sharpen

back side.

-1 When sharpening blades be sure

to balance them. Unbalanced blades will

cause excessive vibration which can damage

blade spindle bearings. Vibration may also

cause structural cracks in mower compo-

nents.

1, Test balance by placing the clean, sharpened

blade on a screwdriver. A balanced blade will

stay horizontal. If one end of the blade dips,

grind or file the heavy end until good balance is

achieved.

BLADE INSPECTION

Before each use, check each mower blade for

damage or abnormal wear.

1. Start the engine and raise the mower deck fully

with the Lii Control Lever set to “UP”. Turn the

Lowering Speed Control knob fully clockwise to

prevent descent. Do not overtighten the knob.

FOLLOW ORIGINAL

Blade Sharpening

NORMAL ‘Ty

BENT D

2. Stop the engine and remove the ignition key.

Block deck with wood block to prevent lowering.

3. Inspect each of the blades for cracks, bending

or signs of wear. The right and center blades

can be seen under the right side of the mower

deck, The left blade can be seen from under

the left front edge of the mower deck. Turn the

blades 180“ to inspect the opposite side.

.

Severe personal injury can result if a piece

of blade breaks off and is thrown from

under the mower deck.

l Never operate the tractor with a worn or

damaged blade.

.

Never operate the tractor with a blade that

is cracked or notched at the base of its

upturned edge.

x CRACKEO

Blade Condition

37

Page 39

MAINTENANCE

1.

2. Shoulder washer -’ 6

3. Left belt shield

4. 5/8 in. standard flat washer

5. Cup washers

6. Blade bolt, special Nylok (right hand threads)

&

Blade Installation

1.

Install shoulder washer (if removed) small end

up. Make sure blade cutting edge is positioned

to lead in clockwise rotation, as viewed from top

of mower.

2.

Excessive blade slippage can cause cup

washers to burn and lose their clamping force.

Inspect cup washers to determine if they are

burned or have lost their clamping force. Replace as necessary.

mend you install a new Nylok

blade bolt when you replace the blade.

. Do not substitute just any bolt for the

special blade bolt. It is self-locking, meet-

ing the non-loosening requirements for

this application.

3. Install two cup washers on bolt,

4. Install washer and blade on bolt.

5. Install bolt and blade assembly in to spindle.

Blade Assembly

, ,

m Your dealer can supply genuine

HONDA replacement blades. They are made

of special steel alloys and subjected to rigid

heat-treat and inspection requirements.

Substitute blades may not meet these rigid

specifications and MAY BE ,DANGEROUS.

6. Torque bolt to 23.4 kg-m (170 ft-lbs).

0

38

Page 40

SPINDLE REPAIR

Blade Spindle Removal

1. Remove blade from spindle.

2. Remove belt shield.

MAINTENANCE

3. Remove belt from pulleys.

4. Remove bolt and flat washer from top of spindle

shaft.

5. Disassemble split taper bushing (located on top

of pulley) by removing the two bolts and inserting them into the threaded holes in bushing

flange. Tighten bolts alternately to remove split

taper bushing. Remove pulley.

6. Remove three bolts attaching spindle to mower

frame and remove spindle.

Spindle Repair Tips

1. As a reference point, the top of spindle housing

is the short portion.

2. To minimize wear, bearing cups, cones and

sleeves are press fit to shaft and will require a

press or similar device for removal.

3. When disassembling, support housing casting

to prevent damage.

4. Remove bearing cups by placing a punch in

housing slots and drive cup out. Alternate

punch positions from side to side. Use care to

prevent housing damage.

5. Bore-tite” sealant is used on the outer diameter

of the seals, Substitute seals may not meet

original equipment specifications and could

cause leakage.

Bore-Me Is a registered trademark of Chicago Rawhide Industries.

1. Spindle assembly

2. Seal

3. Sleeve

4. Bearing

5. Housing and cups

6. Cup

7. Shaft

cone

Spindle Assembly

I

c 1

39

Page 41

MAINTENANCE

Blade Spindle Disassembly

1. Support spindle in a press and push shaft

down through housing.

2. Remove seals from housing.

3. Remove bearing cups from housing as described in Spindle Repair Tips section.

4. Remove bearing cone from shaft.

5-

1. Spindle

2. Seal

3. Sleeve

4. Bearing

5. Housing and cups

6. Cup

7. Shaft

assembly

cone

-1

40

Spindle Assembly

Page 42

Blade Spindle Assembly

1, Bearing cups and cones are designed to work

together. It is important to position them so

bearing cone taper mates with bearing cup

taper.

2. Lubricate new cups with a light oil. Place them

in spindle housing so they will mate with cones.

Seat cups against machined shoulder of housing with a press or by placing a large drift on the

flat lip and driving them into housing.

3. Place bottom bearing cone onto spindle shaft

with taper up, Seat on bottom shoulder of shaft

with a press.

4. Insert shaft and bearing cone assembly through

bottom of housing. Fill housing cavity with a

lithium grease of #2 consistency with a MOLY

(molybdenum disulfide) additive.

5. Place top bearing cone on shaft to mate with

top bearing cup.

MAINTENANCE

7

I

5

1-1 Bearing adjustment is set by

pressing sleeve against bearing cone until

proper adjustment is attained.

6. Install sleeve on shaft and press sleeve and

bearing cone onto shaft until all bearing free

play is removed and there is a slight drag

(similar to adjusting the front wheel bearings on

an automobile). Check by spinning spindle. It

should turn freely.

6. Be careful not to over-tighten bearings. Proper

bearing adjustment is essential to good bearing

life.

7. Should you over-tighten bearings, hold spindle

housing and rap spindle shaft with a lead

hammer to loosen bearings, Readjust bearings

until proper setting is obtained.

-1 Improper positioning of seals

can cause seal failure.

8. Proper seal installation is important. An improp-

erly installed seal will leak and could cause

bearing failure.

@

1. Soindle assemblv e.

2. seal

3. Sleeve

4. Bearing cone

5. Housing and cups

6. Cup

7. Shaft

Spindle Assembly

s

1’

9.Pull the rubber portion of seal back and locate

spring.

41

Page 43

MAINTENANCE

I

2-

49 -3

----+\

lO.Apply a thin coat of lubricant to bottom seal (2)

and install with spring up toward center of

housing.

11 *Place bottom seal, squarely on housing. Select

a piece of pipe or tubing with an OD that will set

on outside edge of seal. A tube that is too small

will bow seal cage.

12Carefully press seal into housing, preventing

distortion to ‘metal seal cage. Seal should seat

firmly and squarely against machined shoulder

in housing.

13.Make sure seal lip did not roll under. Distortion

to seal cage or damage to seal lip will cause

seal. to leak. Damaged seals must be replaced.

14.Apply a thin coat of lubricant to top seal (2) and

install with spring up away from center of

housing. Top seal should be flush with top of

housing.

1, Spindle assembly

2. Seal

3. Sleeve

4. Bearing cone

5. Housing and cups

6. Cup

7. Shaft

Spindle Assembly

15Lubricate spindle with a lithium grease of #2

consistency with a MOLY (molybdenum disulfide) additive. Vent top seal with a blunt edged

tool such as a letter opener while filling with

grease. Rotate housing on spindle shaft,

checking for free movement.

Blade Spindle Installation

1. Insert spindle through bottom of mower deck

and install three mounting bolts, Be sure to

position grease fittings toward lubrication

access areas. Refer to lubrication chart.

I Pullev installation seauence is

very important fof bearing life. Follow the

sequence exactly.

2. Install pulley and split taper bushing with integral key on spindle shaft. Install bolt and flat

washer in top of spindle shaft. Torque this bolt

to 1.7 kg/cm (12 ft/lbs), then alternately tighten

split taper bushing bolts to 1.7 kg/cm (12 ft/lbs).

42

Page 44

REPLACING THE BELTS

One of the major causes of belt failure is improper

installation. Before a new belt is installed, check

pulley shafts and bearings for wear. Check pulley

grooves for cleanliness. Make sure spindles turn

freely and without wobble. If grooves require

cleaning, moisten a cloth with a non-flammable,

non-toxic degreasing agent or commercial detergent and water.

Avoid excessive force during installation. Do not

use tools to pry belt into pulley groove. Do not roll

belt over pulleys to install. This can cause hidden

damage and premature belt failure.

Drive Belt Replacement

1, Set the rear gauge wheel to 1 -l/2 in. position

(see Wheel Adjustments). Turn Lowering Speed

Adjusting knob counter-clockwise towards

“FAST’ and lower deck.

t accidental start-up, remove the

ignition switch key and disconnect the

spark plug caps before installing the

mower.

Wear gloves when installing belt. Be care-

ful. Do not allow your fingers to be caught

between belt and pulley.

Use care when installing or removing belt

from spring-loaded idler. Springs store

energy when extended and, if released

suddenly, can cause personal injury.

I. Remove belt stopper from front tensioning

guide, and belt stopper collars and two bolts

10 mm x 20 mm and 8 x 16 mm flange bolt

3. Turning counterclockwise, loosen the belt

tension adjust knob fully. Push up on the left

tensioner pulley to gain some slack in the belt.

Pull belt off left side pulley and remove it from

remaining pulleys starting with the one on the

opposite side.

4. Installation sequence is the reverse of disas-

sembly. After installing, check that belt is fully

seated in V-groves of pulley.

5. Adjust the amount of slack in the belt as described on Page 21 I

43

Page 45

MAINTENANCE

Pulley covera

siomr srm Idler pulley

Blade Belt Replacement

1.

Remove the mower deck from the tractor.

2.

Remove the four 5/16 in. nuts holding down the

left and right mower pulley covers. Clean out

any grass or debris.

3.

Check the belt for wear or cracks.

4.

If necessary to replace the belt, grasp it midway

between the right and left deck pulleys. As you

face the deck from the REAR, pull the belt

towards you and to the left. This will create

slack in the belt as the tensioner pulley moves.

With the slack you have created, slip the belt off

the left deck pulley. Next remove belt from right

pulley.

5.

Pull back on tensioner arm to release pressure

on tensioner arm spring. Unhook and remove

tensioner arm spring. Remove the spring pin

holding the tensioner arm to mower deck. Lii

arm and remove, allowing belt to slip free.

Pull here

6; Slip V-belt off remaining pulleys.

7. Install new V-belt in the reverse order of removal. Start with the driven pulley in center of

deck, then install tensioner arm, washer, felt

seal and spring pin. install tensioner arm spring,

then pass V-belt over left pulley and right pulley.

*

m If the belt Is not released slowly,

the ic&r pulley will move suddenly and could

injure your hand. Be sure to reinstall right

and left pulley covers after changing belt.

Failure to use pulley covers can cause serl-

ous personal injury.

8. Reinstall mower pulley covers using the four

5/l 6 in. nuts removed earlier.

44

Page 46

CLEANING MOWER DECK

1. Remove the mower from the tractor.

2. Remove the four 5/16 in. nuts holding down the

pulley covers and remove the left and right

pulley covers.

3. Remove grass and other foreign matter from

inside the covers.

4. Using a jack or other lifting mechanism, raise

deck a foot or more off the ground. Place two

wooden blocks in front and support deck firmly.

Clean off accumulated grass and other debris,

making sure to keep fingers away from blades.

NOTICE Do not use water or hose to clean

!iGJ

blade spindle bearings will cause premature

wear. Wait until bearings have cooled.

5. Install the mower back on the tractor.

NOTE: After pushing deck under tractor and

before installing, make sure that lift arms are all the

way down. Put Lift Selector Lever in Down position

and turn Lowering speed Adjustment Knob to

“FAST”, then pull arms down by hand to test.

ck just after mowing. Water on hot

45

Page 47

STORAGE

STORAGE

1, Remove the mower deck from the tractor.

2. Turn the mower deck upside down. Clean the

underside of the deck with water and dry

thoroughly.

3. For longer service and greater efficiency, keep

the underside of the mower housing clean and

free of accumulated grass clippings by washing

it down with a hose after use and/or cleaning it

with a wire brush and scraper, Remove any rust

and apply a rust-resistant paint. Cleaning and

rust prevention are especially important before

seasonal storage.

m Washing the deck directly after

use can cause premature bearing wear.

Allow the deck to cool before washing, then

run the deck to remove any excess moisture.

46

Page 48

TROUBLESHOOTING

PROBLEM

1. Mower overloading; material too tall or heavy

2. Oil on belt from over-lubrication

3. Belt hung up or rubbing

4. Belt or pulleys worn out

1. Belt misaligned or rubbing guide

1. Damaged belt

2. Worn pulley groove

SOLUTION

1. Reduce tractor speed but operate at full throttle.

Cut material twice: one high pass, then mow at

desired height, Cut a partial swath.

2. Be careful not to over-lubricate. Clean lubricant

from belt and pulleys with clean rag. Replace

oil-soaked belt.

3. Check belt for free travel in pulleys and belt

guides. Check under mower and around blade

spindle shafts for wire, rags or other foreign material. Clean all material from under mower.

4. If belt rides in bottom of pulley groove, either

belt or pulley is worn and must be replaced.

1. Re-align belt or guide. Be sure belt doesn’t rub

any other part while running.

1. Lay belt flat on floor. If belt does not lie flat (has

humps or twists), indicating broken or stretched

cords, it must be replaced.

2. Replace pulley.

1. Roll-over, high shock loads or installation

damage

1. High shock loads

2. Belt came off drive

1. Replace belt.

1. Avoid abusive mowing. Avoid hitting the ground

or obstructions.

2. Check drive alignment for foreign material in

grooves. Avoid hitting solid objects or ground.

47

Page 49

TROUBLESHOOTING

PROBLEM

1. Tractor speed too fast

2. Grass accumulation inside deck

3. Dull Blade

4. Tires improperly inflated

5. Mower not level

6. Wrong mower deck height

7. Engine speed too low

1. Blade drive belt worn or broken

2. PTO lever cable faulty or out of adjustment

3. Faulty PTO

1. Wrong blades

2. Deck too low

3. Engine overloaded

4. Lawn wet or watered

5. Lawn too tall

6. Engine speed too low

SOLUTlON

1. Shift to lower gear.

2. Clean deck underside.

3. Have the blades sharpened or replaced.

4. Check the tire inflation.

5. Level or see authorized HONDA Multi-purpose

Tractor dealer.

6. Change to proper height.

7. Run at full throttle.

1. Replace with new belt.

2. See your authorized HONDA multi-purpose

tractor dealer.

3. See your authorized HONDA multi-purpose

tractor dealer.

1. Use genuine HONDA blades or equivalent.

2. Raise deck and adjust deck height properly.

3. Operate at full throttle. Use lower speed range.

Set mower deck higher than desired height for

first pass, then cut to desired height on second

pass.

4. Allow to dry before cutting.

5. Set mower deck higher than desired height for

first pass, then cut to desired height on second

pass.

6. Run at full throttle.

1. Cutting height too low

2. Tractor speed too high

3. Uneven surface

4. Rough and uneven surface

1. Unbalanced blades

2. Drive/blade belt damaged

3. Pulley(s) damaged or out of alignment

1. Engine speed too low

2. Tractor speed too fast

3. Pebbles or other foreign matter are stuck

in mower deck

48

1. Increase to proper height.

2. Lower to proper speed.

3. Change cutting pattern.

4. Adjust with height adjuster.

1. Balance.

2. Replace.

3. See your authorized HONDA multi-purpose

tractor dealer.

1. Run at full throttle.

2. Shift to lower gear.

3. Remove.

Page 50

SPECIFICATIONS

1 Model

1 Overall length

verall width

ro---

Mowing width

Weight (including link)

Cutting height range

Number of blades

Blade length

Left and center blade speed

Right blade speed

Gauge wheels

Deck lifting/lowering

Deck mounting

MM52

1050 mm (41.3 in)

1675 mm (66 in)

1320 mm (52 in)

120 kg (266 Ibs)

1 -l/2 in. to 4 in.

3

456 mm (18 in)

3355 t-pm

3700 rpm

(2) 152.4 mm (6 in) diameter

Hydraulic

4 point linkage

I

49

Page 51

WARRANTY SERVICE

OWNER SATISFACTION

Your satisfaction and goodwill are important to your dealer and to us. All HONDA warranty details are

explained in the Distributor’s Limited Warranty. Normally, any problems concerning the product will be

handled by your dealer’s service department. If you have a warranty problem that has not been handled to

your satisfaction, we suggest you take the following action:

l Discuss your problem with a member of dealership management. Often complaints can be quickly

resolved at that level. If the problem has already been reviewed with the Service Manager, contact the

owner of the dealership or the General Manager.

l If your problem still has not been resolved to your satisfaction, contact the Power Equipment Customer

Service Department of American Honda Motor Co., Inc.

AMERICAN HONDA MOTOR CO., INC.

Power Equipment Customer Service Dept.

Duluth, Georgia30136-9421

Telephone: (404) 497-6400

We will need the following information in order to assist you:

- Your name, address and telephone number

- Product model and serial number

- Date of purchase

- Dealer name and address

- Nature of problem

After reviewing all the facts involved, you will be advised of what action can be taken. Please bear in mind

that your problem will likely be resolved at the dealership, using the dealer’s facilities, equipment and

personnel, so it is very important that your initial contacts be with the dealer.

Your purchase of a HONDA product is greatly appreciated by both your dealer and American Honda

Motor Co., Inc. We want to assist you in every way possible to assure your satisfaction with your purchase.

50

Page 52

Current customer service contact information:

United States, Puerto Rico, and U.S. Virgin Islands:

Honda Power Equipment dealership personnel are trained professionals. They should

be able to answer any question you may have. If you encounter a problem that your

dealer does not solve to your satisfaction, please discuss it with the dealership's

management. The Service Manager or General Manager can help. Almost all problems

are solved in this way.

If you are dissatisfied with the decision made by the dealership's management, contact

the Honda Power Equipment Customer Relations Office. You can write:

American Honda Motor Co., Inc.

Power Equipment Division

Customer Relations Office

4900 Marconi Drive

Alpharetta, GA 30005-8847

Or telephone: (770) 497-6400 M-F, 8:30 am - 5:00 pm EST

When you write or call, please provide the following information:

• Model and serial numbers

• Name of the dealer who sold the Honda power equipment to you

• Name and address of the dealer who services your equipment

• Date of purchase

• Your name, address, and telephone number

• A detailed description of the problem

Page 53

Loading...

Loading...