Page 1

Page 2

Page 3

The HRA-21 meets CPSC blade safety requirement for walkbehind rotary power mowers.

This manual covers operation and maintenance of the

All

information in this publication is based on the latest product information available at the time of approval for

HONDA ROTARY MOWER HRA2 1.

printing. Honda Motor Co., Ltd. reserves the right to make changes at any time without notice and without incurring any obligation.

Any powered product can be a potential source of danger if misused or improperly maintained.

Pay particular attention to statements preceded by the following words:

Indicates the possibility of personal injury or loss of life if instructions are not followed.

Indicates the possibility of equipment damage if instructions are not followed.

HONDA MOTOR CO., LTD 1982, ALL RIGHTS RESERVED

Page 4

Thank you for purchasing a Honda Lawn Mower.

If any problems occur, or if there are any questions concerning the mower, consult an authorized HONDA dealer.

No part of this publication may be reproduced without written permission.

The Honda rotary mower is designed to give safe and dependable service if operated according to instructions and

intended use: mowing (cutting) grass, and bagging cut grass when equipped with the grass bag. Any other use

could be dangerous.

Read and understand the Owner% Manual before operating the mower.

injury or equipment damage.

2

Failure to do so could result in personal

Page 5

CONTENTS..

............................................................

3

GENERAL SAFETY

COMPONENT IDENTIFICATION

THECONTROLS.. ........................................................

OPERATION

............................................................. 9

TRANSPORTING/STORAGE

MAINTENANCE

TROUBLESHOOTING .....................................................

............................... : ....................... 4

.............................................

................................................

..........................................................

5

7

18

21

33

SPECIFICATIONS ......................................................... 34

3

Page 6

GENERAL SAFETY

* Know how to stop the engine quickly and under-

stand operation

anyone to operate the mower without proper instrut tion.

* The rear shield is for your protection; keep it

in place at all times.

* The blade is sharp and dangerous. Never put your

hands or feet under the mower. Never tilt the

mower to expose the blade while the engine is run-

Fing.

or mower, stop the engine and remove the spark

plug cap.

* Never stand

when the engine is running. Someone may accidentally engage the drive clutch.

* Keep clear of the discharge opening when the bag

is not attached to avoid being hit by a flying objet t.

mowing. Mow only in cleared areas in daylight or

good artificial light.

If

you find it necessary to work on the blade

Clear the lawn of sticks, stones, or debris before

of

aN rhe controls. Never permit

in

front of self-propelled mowers

* Protect yourself by wearing long .trousers and ap-

propriate shoes. Don’t wear loose fitting clothing

or sandals when mowing.

* Keep children and pets away from the mower at all

times.

*

If

the blade strikes a stone, sprinkler head, etc., be

sure the blade, blade holder, woodruffkey, fasteners, crankshaft, etc. are in good condition before

continuing to mow.

Replace any damaged parts.

Page 7

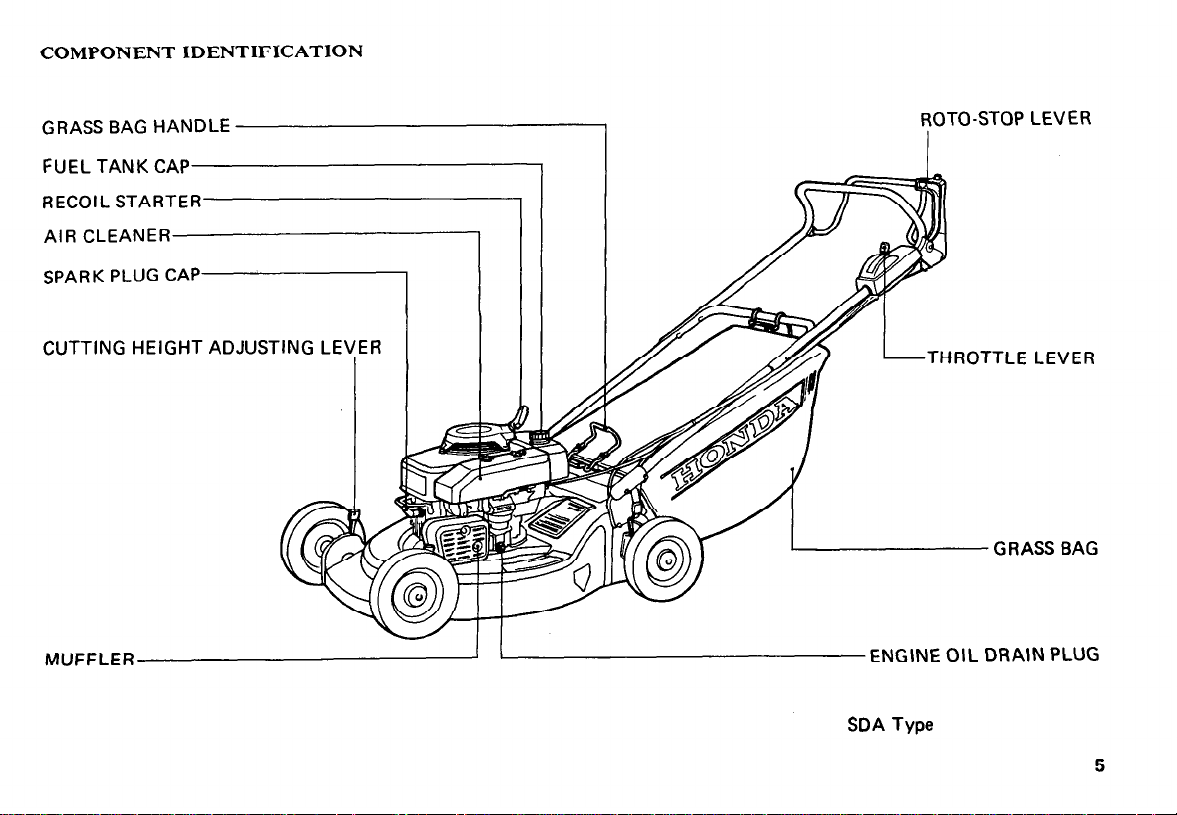

COMPONENT IDENTIFICATION

GRASS BAG HANDLE

FUEL TANK CAP

RECOIL STARTER

AIR CLEANER

SPARK

CUTTING HEIGHT ADJUSTING

MUFFLER

PLUG CAP

LEYER

ROTO-STOP LEVER

1

THROTTLE LEVER

GRASS BAG

ENGINE OIL DRAIN PLUG

SDA Type

5

Page 8

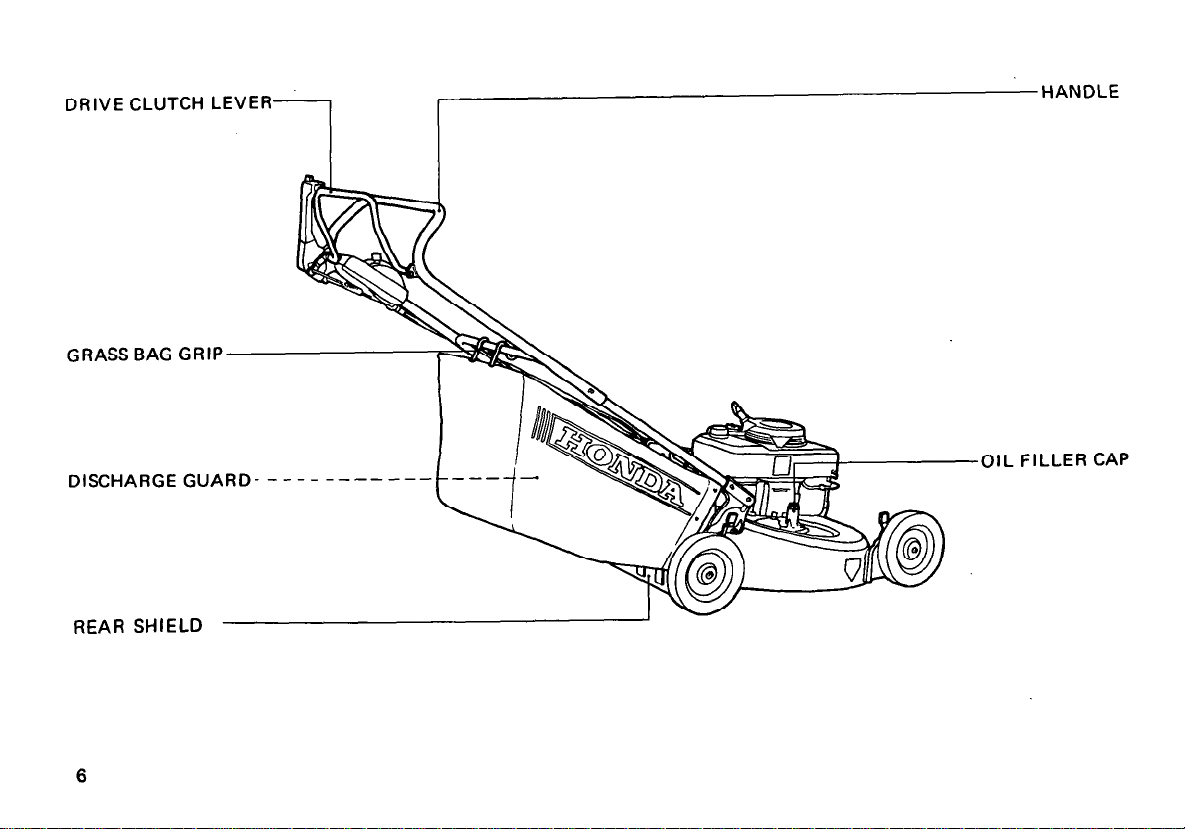

DRIVE CLUTCH LEVER

GRASS BAG GRIP

1 ~HANDLE

,,lSC..,ARGE G,,

REAR SHIELD

6

OIL FILLER CAP

Page 9

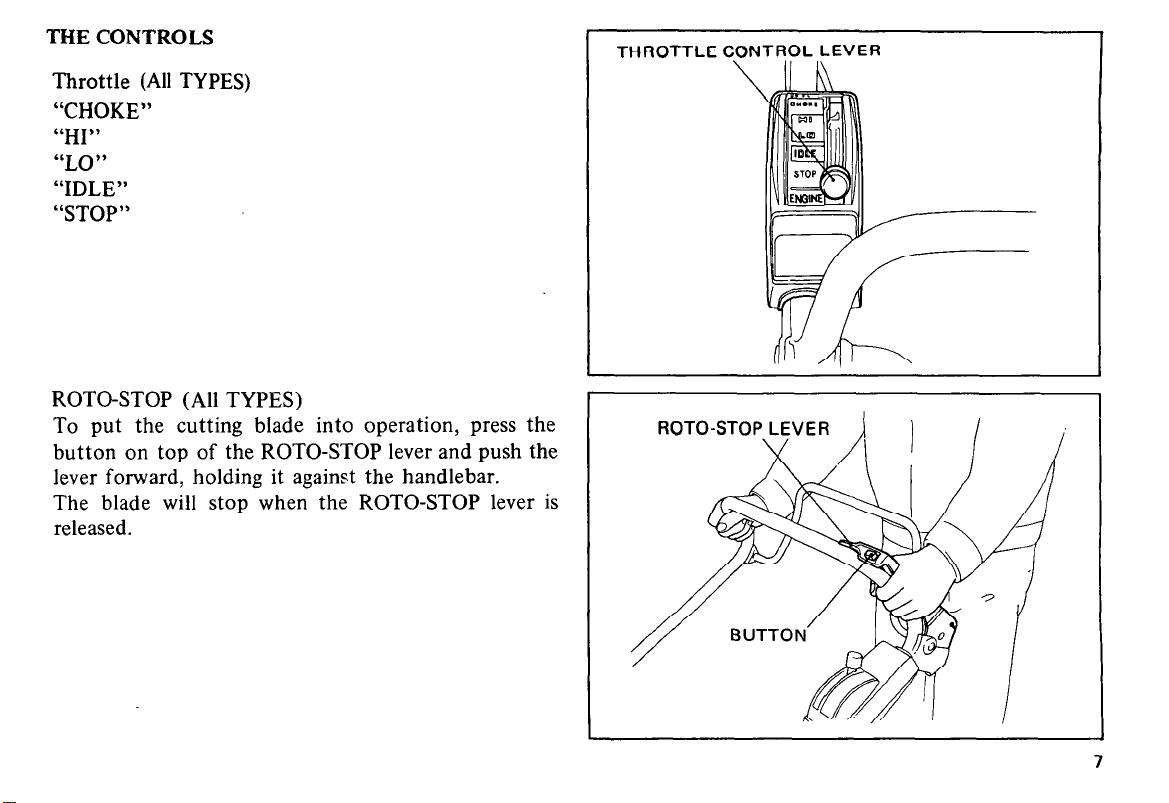

THE CONTROLS

Throttle (All TYPES)

“CHOKE”

“HI”

“LO”

“IDLE”

“STOP”

ROTO-STOP (All TYPES)

To put the cutting blade into operation, press the

button on top of the ROTO-STOP lever and push the

lever forward, holding it against the handlebar.

The blade will stop when the ROTO-STOP lever is

released.

THROTTLE CONTROL LEVER

ROTO-STOP LEVER

Page 10

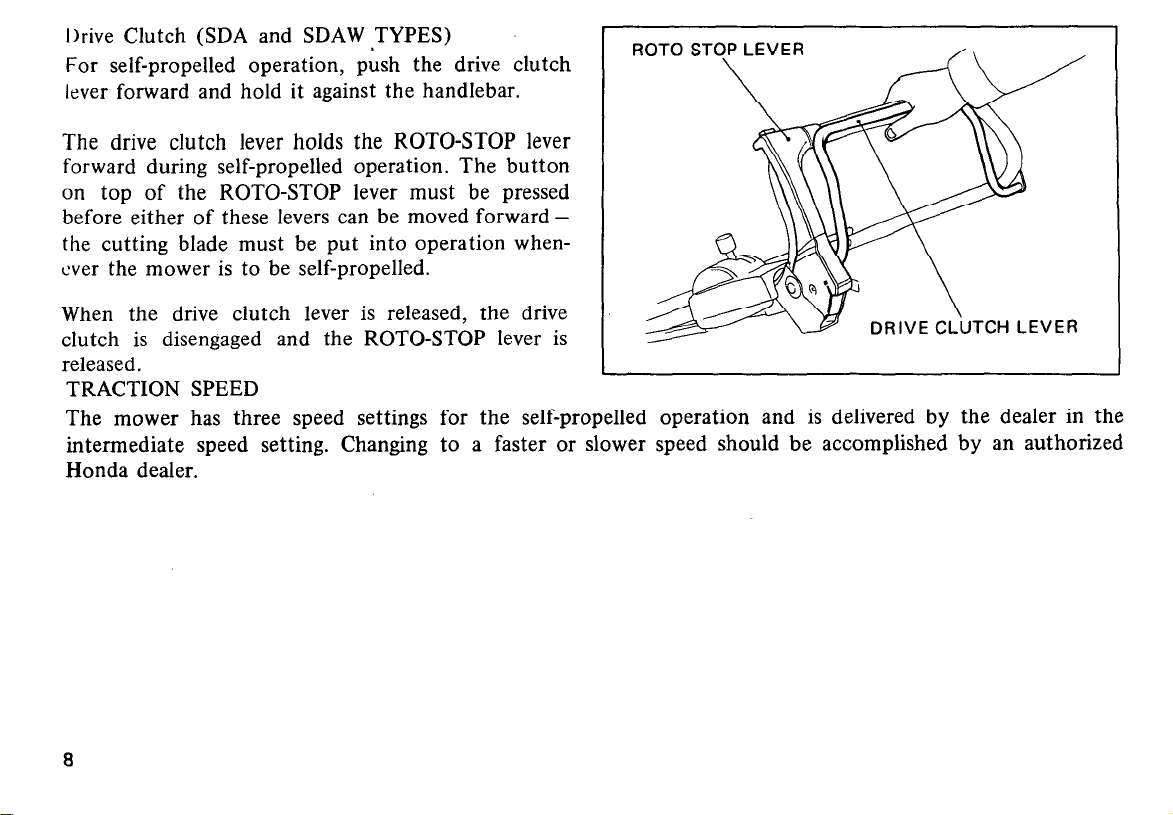

I)rive Clutch (SDA and SDAW ,TYPES)

For self-propelled operation, push the drive clutch

lever forward and hold it against the handlebar.

The drive clutch lever holds the ROTO-STOP lever

forward during self-propelled operation. The button

on top of the ROTO-STOP lever must be pressed

before either of these levers can be moved forward the cutting blade must be put into operation whenever the mower is to be self-propelled.

When the drive clutch lever is released, the drive

clutch is disengaged and the ROTO-STOP lever is

released.

TRACTION SPEED

The mower has three speed settings for the self-propelled operation and is delivered by the dealer in the

intermediate speed setting. Changing to a faster or slower speed should be accomplished by an authorized

Honda dealer.

Page 11

OPERATION

The HRA21 may be used with the grass bag or discharge adapter.

The following suggestions and rules are intended

to help you operate your Honda HRA21 under the

safest conditions possible. Be alert and exercise the

same care using the mower as you would using any

other power tool.

* Be especially careful when mowing uneven or rough

ground. The mower may tilt, exposing the blade,

and hidden objects could be thrown by the blade.

Keep all four wheels on the ground.

1

I

* Use extra care when mowing around objects to

keep the blade from striking them. Never delibera-

tely mow over any object.

* Stop the engine immediately if the blade hits an

object or the mower starts to vibrate. Remove the

spark plug cap (keep the wire away from the plug)

and inspect for damage.

NOTE:

Mow across slopes.

Do not mow excessively steep

slopes.

Always push, never pull, a mower with the engine

running.

Control direction by the handle, not by

foot pressure on the mower housing.

Keep a firm hold on the handle and walk, never

run, with the mower. Don’t lag behind the machine or let it pull you.

(SDA and SDAW TYPES) Do not use the drive

clutch when maneuvering around trees, etc. Release

the clutch and push the mower while using the

ROTO-STOP for better directional control.

Page 12

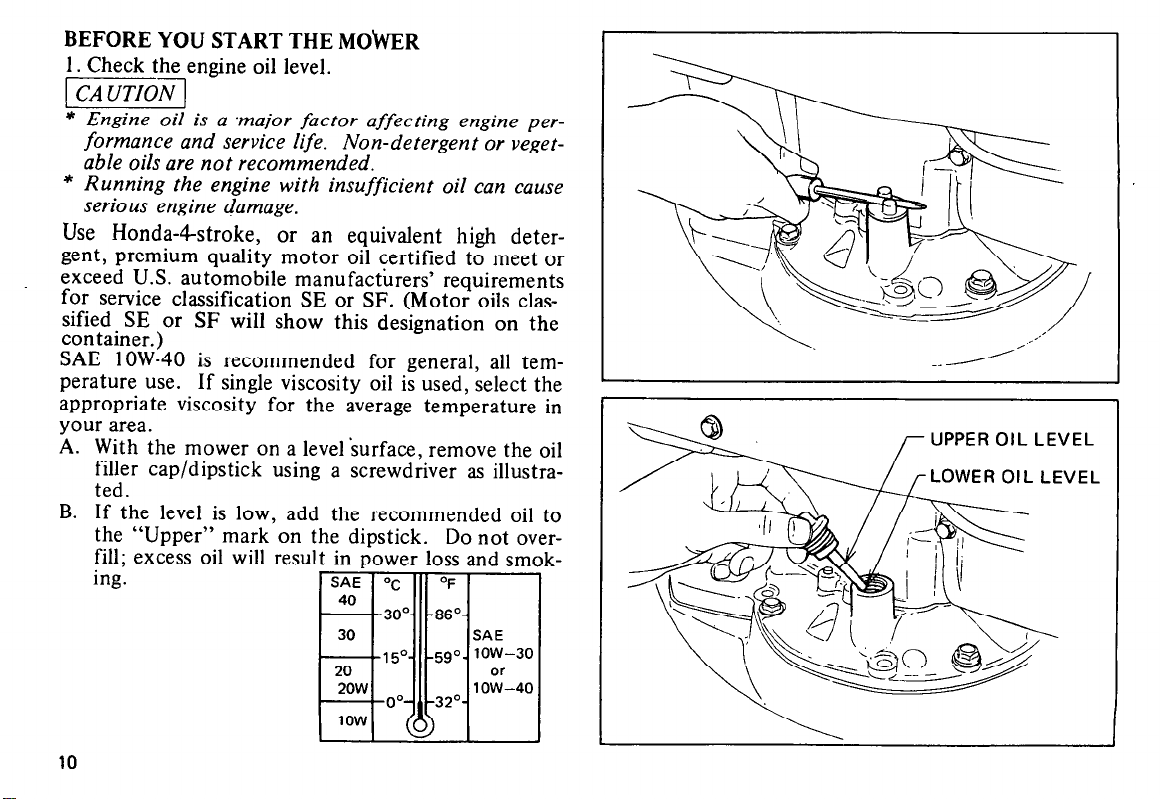

BEFORE YOU START THE MObVER

1. Check the engine oil level.

pY5V-l

* Engine oil is a .major factor affecting engine per-

formance and service life. Non-detergent or veget-

able oils are not recommended.

* Running the engine with insufficient oil can cause

serious engine damage.

Use Honda-&troke, or an equivalent high deter-

gent, premium quality motor oil certified to meet or

exceed U.S. automobile manufacturers’ requirements

for service classification SE or SF. (Motor oils classified SE or SF will show this designation on the

container.)

SAE low-40 is recommended for general, all temperature use. If single viscosity oil is used, select the

appropriate viscosity for the average temperature in

your area.

A. With the mower on a level ‘surface, remove the oil

filler cap/dipstick using a screwdriver as illustrated.

B. If the level is low, add the recommended oil to

the “Upper” mark on the dipstick. Do not overfill; excess oil will result in power loss and smok-

ing.

UPPER OIL LEVEL

LOWER OIL LEVEL

10

Page 13

2. Check the fuel level.

Use regular or unleaded automotive gasoline of 86

pump octane or higher.

Never use an oil/gasoline mixture or dirty gasoline.

Avoid getting dirt, dust or water in the fuel tank.

* Gasoline is extremely flammable and explosive un-

der certain conditions. Refuel in a well ventilated

area with the engine stopped.

* Do not smoke or allow flames or sparks in the area

where the mower is refueled or where gasoline is

stored.

* Be careful not to spill fuel when refueling. Fuel

vapor or spilled fuel may ignite. Make sure the

area is dry before starting the engine.

* Do not overfill the tank and make sure the filler

cap is securely closed after refueling.

* Refuel when the engine is cold.

-1 Gasoline substitutes, such as gasohol etc., are not

recommended, they may be harmful to the fuel system cov-

ponents.

11

Page 14

3. Check the grass bag for fraying, tears and clogged

mesh. Wash the bag with water if necessary, and

let it dry thoroughly. Grass will not chute properly without adequate ventilation through the bag.

Make sure the lock lever is latched securely.

4. Check the blade bolts for tightness.

Torque: 455.5 kg m ( 32.5-39.8 ft lb)

-

* To be certain that the engine will not start acciden-

tally, remove the spark plug cap before performing

this inspection.

5. Check and clean the air cleaner element if it is

dirty (p. 24).

12

Page 15

STARTING THE ENGINE

* Exhaust gas contains poisonous carbon monoxide.

Never run the mower in an enclosed area. Be sure

to provide adequate ventilation.

1. Move the throttle lever to “CHOKE”.

NOTE:

Do not use “CHOKE”

when the engine is warm or

the air temperature is high. Move the throttle to

“LO” instead.

2. Turn the fuel valve “ON”.

CHOKE

HROTTLE LEVER

Page 16

3. Place your foot on the “STEP” of the mower housing.

4. Pull the starter rope lightly until you feel compression,

then

pull

briskly.

NOTE:

Do not allow the rope to snap back; return it by hand.

5. After the engine warms up, move the throttle lever

to “HI”.

Squeeze the ROTO-STOP to start the

blade.

SDA and SDAW TYPES: Engage the drive clutch/

ROTO-STOP. Mower will move forward.

NOTE:

The throttle lever may be moved anywhere between

“HI” and “LO” to adjust engine speed during operation.

However the engine may stall if the lever is at “IDLE”

when the ROTO-STOP is engaged. *

’

Page 17

Flooded Engine

If the engine won’t start after several pulls on the

starter rope the engine is probably flooded.

To clear a flooded engine:

1. Move the throttle lever to “STOP” and turn off the

fuel valve.

2. Remove and dry the spark plug. When re-installing

the plug, thread it in by hand until it seats. Then

tighten it an additional l/8- l/4 turn with the spark

plug wrench to compress the washer.

3. Move the throttle to “HI”, turn on the fuel valve

and repeat steps 3-5 under “Starting the Engine”.

Stopping the Engine

1. Release the roto-stop lever.

SDA and SDAW TYPES: Release the drive clutch

lever.

2. Move the throttle lever to “STOP” and turn off

the fuel valve.

ROTTLE LEVER

Page 18

Cutting Height Adjustment

Six settings are available: S/8”, l”, l-1/2”,2”,2-1/2”,3”.

To change blade height:

1. Stop the engine.

2. Push the adjusting lever t&ward the wheel and

move it up or down to raise or lower the blade

height.

3. Release the lever in the appropriate notch.

4. Adjust the other three wheels. Make sure all four

wheels are at the same level.

* Be careful not to touch the muffler when adjust-

ing the right front wheel height.

The muffler wiN stay hot for a while after the en-

gine is stopped.

[CAUTION:

* Adiust all four wheels to the same level.

3”

lJ-===-F -w

ADJUSTING LEVER

16

Page 19

Grass Bag

The bag is subject to wear under normal usage; frequently check for fraying and tears. Replace deteriorated bags only with Honda replacement bags or

equivalent. When the bag needs cleaning, wash it

with water and make sure it is dry before using it.

Clogged mesh will result in poor grass chuting and a

wet bag will clog quickly.

Removale

q

Remove the grass bag grip from handle pipe.

a Push the door latch down.

q

Pull the grass bag rear ward while pushing the

door latch down.

Installation

‘$J Grab the grass bag handle, set the lower edge of

the bag onto the recess of the mower housing.

q

Push the grass bag handle forward until the forward end of the handle rests on the latch groove.

q

Hang the grass bag grip onto the lower handlebar.

Page 20

TRANSPORTING/STORAGE

Transporting

Turn

mower.

the fuel valve OFF when

transporting

the

* To avoid fuel and oil spillage do not tilt the unit;

spilled fuel may ignite.

Preparation for Storage

The following steps should be taken to protect the

mower whenever it will be stored for longer than 30

days.

1. Drain the fuel tank and carburetor into an approved gasoline container:

A. Remove the fuel tube and turn the fuel valve

ON to empty the fuel tank.

18

Page 21

B.

Loosen the carburetor drain bolt to drain the

carburetor.

C. Retighten the drain bolt, connect the fuel tube

and turn the fuel valve OFF.

* Gasoline is extremely flammable and explosive un-

der certain conditions. Do not smoke or allow

flames or sparks in the area.

2. Change the engine oil (p. 23).

NOTE :

If the mower will be stored for longer than a year,

remove

the spark plug and pour three tablespoonsful of clean motor oil into the cylinder. Pull

the starter rope slowly two or three times to distribute the oil.

Replace the plug.

I

DRAIN BOLT

1

I

19

Page 22

3. Pull the starter rope until resistance is felt. This

closes the valves and helps to protect the com-

bustion chamber from corrosion.

4. Remove dirt and debris from the underside of the

mower housing. Clean the mower thoroughly. Paint

areas that may rust with a rust-resistant paint, or

coat with a light film of oil.

5. Cover the mower and store it on a level surface

in a dry, dust-free area.

Removal From Storage

1. Remove the spark plug; check that it is clean and

properly gapped (p. 25). Pull the starter rope sev-

eral times.

2. Thread the spark plug in as far as possible by hand,

then use the plug wrench to tighten l/8 to l/4 turn

further.

3. Check the engine oil level and condition.

4. Fill the fuel tank and start the engine.,

NOTE:

If the cylinder was coated with oil, the engine will

smoke at start up; this is normal.

STARTER HANDLE

20

Page 23

MAINTENANCE

*

To

prevent accidental start-up, shut off the engine

and disconnect the spark plug cap before perform-

ing any maintenance.

* Use only genuine Honda parts or their equivalent

for maintenance or repair.

Replacement parts

which are not of equivalent quality may damage

the mower.

Periodic inspection and adjustment of the Honda

HRA2 1 are essential it high level performance is to be

maintained. Regular maintenance will also help to

extend service life. The required service intervals and

the kind of maintenance to be performed are des-

cribed in the chart on the following page.

For longer service and greater efficiency, keep the

underside of the mower housing clean and free of accumulated grass clippings by washing it down with a

hose after use and/or cleaning it with a wire brush

and scraper. Remove any rust and apply a rust-re-

sistant paint. Cleaning and rust prevention are especially important before seasonal storage.

21

Page 24

MAINTENANCESCHEDULE

Regular Service Period

Perform at every indicated month

or operating hour intervals,

whichever occurs first.

3ngine oil

4ir cleaner element

Check level

Change

Check

Check

Gel strainer Check

spark plug

31ade bolts (Tightness)

brass bag

Throttle cable

Clean-Adjust

Check

Check

Adjust

Drive belt Inspection

Drive clutch cable

XOTO-STOP cable

tOTO-STOP

__-

gnition timing

Valve clearance

Combustion chamber

?uel tank

Adjust

Adjust

Check

Check-Adjust

-__

Check-Adjust

C$fe;- Lap

--

Clean

Check

‘uel tube

(Replace, if

necessary)

l

Service the air cleaner more frequently when used in dusty areas.

,

Each

Use

0

0

0

0

First

1 month

20’irs.

-

0

I

I

Every

1 month

20°4rs.

0+

Every

6 months

1 OCGIrs.

0

0

0

I

,

-

0

0**

one year

3OCkS.

,

I

Every

0

0

0

0 **

0 **

0 +*

I

y

0

J

*+ These items should be serviced by an authorized Honda dealer, unless the owner has the proper tools and is mechanically proficient.

See the Honda Shop

Manual..

22

Page 25

ENGINE OIL CHANGE

Drain the oil while the engine is still warm to assure

rapid and complete draining.

1. Remove the tiller cap/dipstick using a screwdriver

as illustrated.

2. Remove the dram bolt, drain the oil, and retighten

the bolt securely.

3. Refill to the “Upper” level mark with the recommeded oil (see p. 10). Tighten-the cap securely to

prevent leakage.

I

\

II

- LOWER

OIL DdAlN

BOLT

Page 26

AIR CLEANER SERVICE

A dirty air cleaner will restrict air flow to the carbu-

retor. To prevent carburetor malfunction, service the

air cleaner frequently.

l.Remove the wing nuts and the air cleaner cover.

Remove the elements and separate them. Carefully

check both elements for holes or tears and replace

if damaged.

2.Foam element: Clean in warm soapy water, rinse

and allow to dry thoroughly. Or clean in high

flash-point solvent and allow to dry. Dip the element in clean engine oil and squeeze out all the

excess. The engine will smoke during initial startup if too much oil is left in the foam.

3. Paper element:

Tap the element lightly several

times on a hard surface to remove excess dirt, or

blow compressed air through the filter from the

inside out. Never try to brush the dirt off; brushing

will force dirt into the fibers, Clean in warm, soapy

water and rinse. Dry using compressed air blown

from the inside out, or shake the element and allow

it to air dry thoroughly. (Or clean in high flashpoint solvent, remove immediately, and allow to

dry.) Oil the outside of the paper with a light aerosol oil such as WD-40. The engine will smoke dur-

ing initial start-up if too much oil is used.

I

PAPER ELEMENT

I

WING NUTS

.---

:.

..:

I

F

FOAM ELEMENT

24

Page 27

SPARKPLUG

Standard Plugs: BMR-6A (NGK) or W20MR-U (ND)

1. Disconnect the cap and remove the spark plug.

2. Visually inspect the plug. Discard the plug if it is

heavily deposited or if the insulator is cracked or

chipped.

3. Measure the plug gap with a wire-type feeler gauge;

it should be 0.6-0.7 mm (0.024-0.028 in). If ad-

justment is necessary, bend the side electrode care-

fully.

4. Make sure the sealing washer is in good condition,

then thread the spark plug in by hand until it seats.

5. Use the wrench to tighten a new plug l/2 turn further to compress the washer. If you are reusing the

plug it should only take l/8 - l/4 turn after the

plug seats.

6. Replace the spark plug cap.

I

1

0.6-0.7

(0.024-0.028

mm

in)

25

Page 28

BLADE REMOVAL AND SHARPENING

* Wear heavy gloves CO protect your hands.

Before tilting the mower, remove the spark plug

cap.

1. Tilt the mower so the carburetor side is up.

Loosen the blade bolts to remove the blade.

* Never tilt the mower so the carburetor side is down.

It will result in hard starting.

2. Sharpen the blade cutting edges with a file. File

the top side only. Maintain the original bevel for a

fine cutting edge. File both ends evenly to maintain blade balance.

NOTE:

Use only a genuine HONDA replacement blade or

equivalent.

3. Clean away any dirt and grass from around the

blade shaft.

4. Install the blade so that the blade bolts are securely

tightened with specified torque.

Torque: 4.5 - 5.5 kg m (32.5 - 39.8 ft lb)

IJP

26

Page 29

THROTTLE CONTROL CABLE ADJUSTMENT

1. With the throttle lever in the “CHOKE” position,

the carburetor control lever should be pulled all

the way to the right. Push the control lever with

your finger to check whether it is all the way to

the right.

2. If adjustment is necessary, loosen the lock nuts and

turn them to run the adjuster up or down as required. Tighten the lock nuts and recheck the carburetor control lever position.

3. Start the engine and make sure the engine stops

when the throttle lever is moved to the “STOP”

position. Readjust the cable if necessary.

NUTS

CHOKE

OTTLE LEVER

I-

ADJUSTER

Page 30

ROTO-STOP LEVER FREE PLAY

(All TYPES)

1. Measure free play at the tip of the lever as shown;

it should be between 5 - 10 mm (3/ 16 - 3/8 in).

2. If adjustment is necessary, loosen the lock nuts and

turn them to run the adjuster up or down as re-

quired. Tighten the lock nuts and reckeck free

play.

3. Start the engine and operate the ROTO-STOP lever.

Check to be sure the blade stops when the lever

is released.

5-10mm (3/15-3/8 in)

I

I

-STOP LEVER

28

Page 31

DRIVE CLUTCH FREE PLAY

(SDA and SDAW TYPES)

1. Measure free play at the top of the lever as shown;

it should be between 7- 12 mm (9132-l 5132 in>.

2. If adjustment is necessary, loosen the lock nuts

and turn them to run the adjuster up or down as

required. Tighten the lock nuts and recheck free

play.

3. Start the engine and check to be sure the drive

clutch engages and releases properly.

7-12 mm (g/32-15/32 in)

L

Page 32

NOTE:

The following adjustments should be performed by

an authorized Honda dealer unless the owner has the

proper tools and is mechanically proficient.

1. Move the throttle lever to “IDLE” and start the

engine.

2. Turn the throttle stop screw either in or out as

required until the engine runs at 1,400 rpm.

THROTTLE STOP SCREW

30

Page 33

RASS BAG ASSEMBLY

2. Place the anti-sag rod in the bag as shown and

secure its upper sides to the upper frame with

two nuts.

,

3. Turn the bag upside down. Install the lower

frame with the lipped edge forward and secure

it with two screws as shown.

4. Insert the lower plate into the bag and secure

it to the lower frame with three bolts and

washers.

Page 34

GRA

5. Install the grass bag handle onto the upper frame

with two cap nuts as shown.

32

6. Install the grass bag grip by putting its ends in

the pivot hole on the rear end of the anti-sag rod.

Page 35

TROUBLESHOOTING CHART

Engine will not start

Hard starting or loss of power

Erratic operation

Engine overheats

I. No fuel.

2. Throttle lever in “STOP” position.

3. Spark plug wire loose or disconnected.

4. Spark plug faulty or improperly gapped (p. 25).

5. Engine flooded (p. 15).

6. Dirty air cleaner.

1. Dirt in gas tank.

2. Dirty air cleaner.

3. Water in gas tank.

4. Vent in gas cap and/or carburetor clogged.

I. Spark plug faulty or improperly gapped (p.25).

2. Dirty air cleaner.

1. Spark plug improperly gapped.

2. Dirty air cleaner.

3. Dirty cooling fins.

4. Low oil level.

5. Starter pulley clogged by grass, etc.

Excessive vibration

1. Loose blade or engine mounting hardware.

2. Blade unbalanced.

33

Page 36

SPECIFICATIONS

MODEL

ENGINE

Engine type

..................................

..................................

.............................

ROTARY MOWER HRA2

GVl50

Side valve, single-cylinder, forced air-cooled

four-stroke gasoline engine.

Displacement/Bore and stroke

Ignition timing

Ignition system

Engine oil capacity

Fuel tank capacity

Spark plug

FRAME

........................... 20” BTDC, Fixed

...........................

........................

........................

..............................

...............

Dimensions (Length x Width x Height)

. . . . . . . .

144 cc (8.8 cu in)/64 x 45 mm (2.52 x 1:77 in)

Flywheel magneto ignition

0.6 l(0.63 US qt)

1.0 1 (0.26 US gal)

BMRdA(NGK), WQOMR-U(ND)

1,585 x 540 x 975mm (62.4 x 21.3 x 38.4in)

Dry weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SDATYPE: 44.5 kg(98 lb)

SDAW TYPE: 43.5 kg (96 lb)

PDA TYPE: 41.5 kg(91 lb)

PDAW TYPE: 40.5 kg (89 lb)

Grass bag capacity . . . . . . . . . . . . . . . . . . . . . . . .

80Q

(2.2 bu)

Cutting width . . . . . . . . . . . . . . . . . . . . . . . . . . . . 540 mm (21 in)

1

34

Page 37

Page 38

Page 39

Page 40

Loading...

Loading...