Honda Automobiles FL5540KO, H5518A4 User Manual

MANUAL

Front Loader

Model

for

Multi-purpose Tractor

Honda H5518A4

FL5540KO

I

CONTENTS

TOPIC

1 .GENERAL ................................................................................................... 1

2 . INTRODUCTION ........................................................................................................ 3

Front loader safety ........................................................................................... 4

Maintenance safety ............................................................................................ 7

Safety label locations ......................................................................................... 8

3

.

PACKAGING INVENTORY ............................................................................ 9

4 . TRACTOR PREPARATION ............................................................................ 10

5 . LOADER SPECIFICATIONS ............................................................................. 11

6 .

ASSEMBLY INFORMATION ............................................................................. 12

Sub-frame installation/removal ........................................................................ 13

Front loader assembly ................................................................................... 19

Operational checks .......................................................................................... 25

PAGE

7 . OPERATING INSTRUCTIONS ............................................................................ 27

8 .

LOADER REMOVAL ................................................................................................ 31

Storage ............................................................................................................ 35

9

.

LOADER INSTALLATION ..................................................................................... 37

10 .TROUBLESHOOTING ........................................................................................ 41

11 . LUBRICATION and MAINTENANCE ................................................................. 43

Lubrication and maintenance chart .................................................................... 44

12 . PARTS ................................................................................................................ 45

13 . WARRANTY SERVICE ...................................................................................... 51

.

.

2

INTRODUCTION

INTRODUCTION

The purpose of this manual is to instruct you in maintaining and operating your HTA

Front Loader. Read it carefully; it furnishes information and instructions that will help you

achieve years

to unknown and varying conditions. However, through experience and these instructions, you

should be able to develop operating procedures suitable to your particular situation.

"

Right" and "Left

machine will travel when in use.

The illustrations and data used in this manual are current at time of printing, but due to possible

in

-

line production changes, your machine may vary slightly in detail. Extra equipment that may

be shown

redesign and change the machine as may be necessary without notification.

NOTE: Illustrations used in this manual may not show

to

ensure safe operation of tractor/loader. Refer to Safety Section of this manual and the Tractor

Owner's Manual for information concerning safety equipment. Consult your dealer for further

information.

of

dependable performance. Some information may be general in nature due

"

as

on

the machine

used throughout this manual are determined by facing the direction the

is

optional at extra cost. The manufacturer reserves the right to

all

safety equipment that is recommended

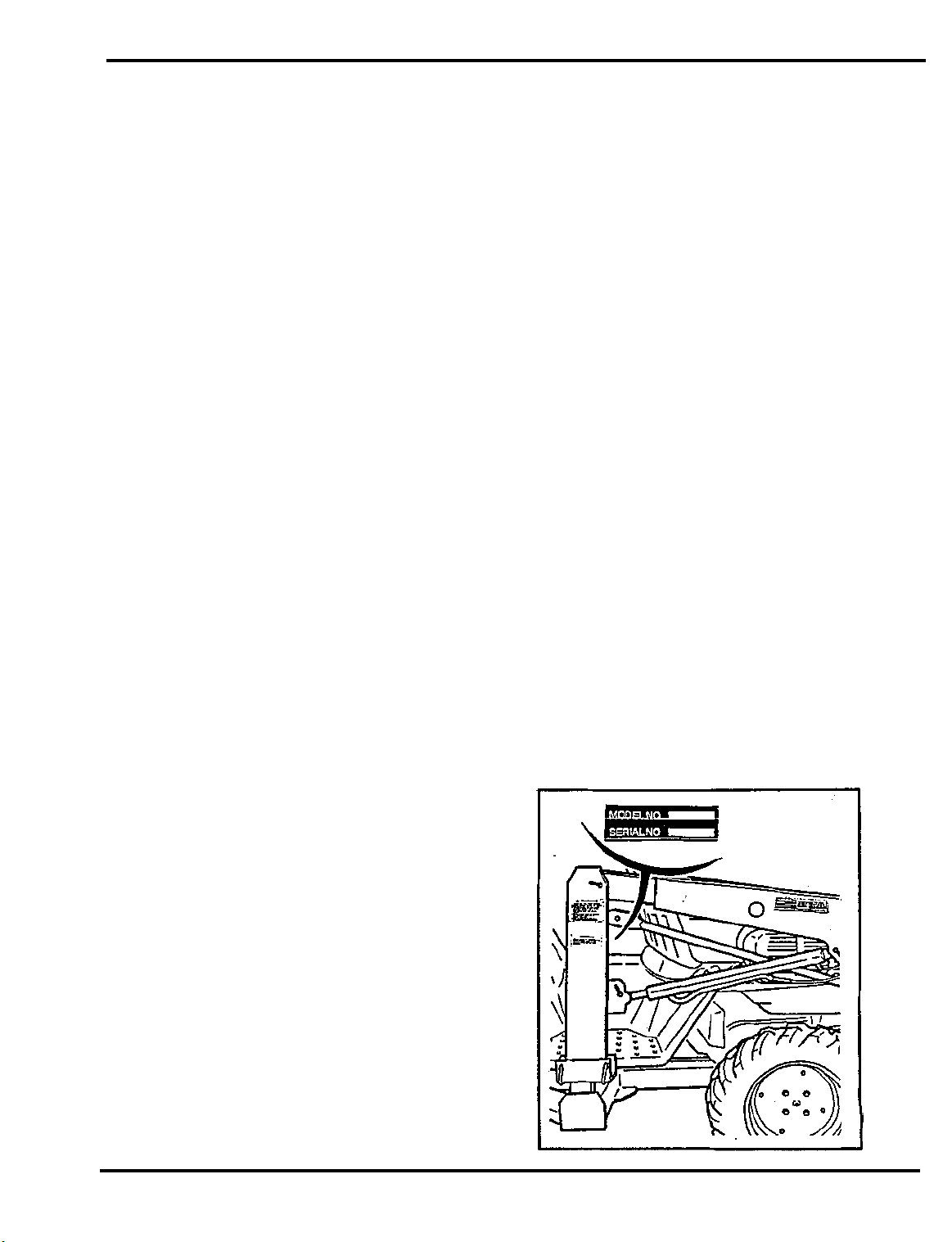

SERIAL NUMBER and LOCATION

The serial number is important information about the machine, and

it before obtaining the correct replacement parts. The serial number is located on the right side

mast as shown.

it

may be necessary to know

REPLACEMENT PARTS

Use only Genuine Honda Replacement parts to repair this machine. Honda replacement parts

-

are available from your Honda Multi

service, always remember to give the dealer the following information:

-

Correct part description or part number.

-

Model number

—

Serial number of your machine.

of

your machine.

purpose Tractor Dealer. To obtain prompt, efficient

3

FRONT

LOADER

SAFETY

FRONT LOADER SAFETY

Operating the tractor

and

the safety of others. Know these requirements before you operate the tractor

and

front loader requires

special efforts on your part to ensure your safety

loader.

SAFE

OPERATING RULES

Severe personal injury

(

pages

Always make pre

accident

To avoid severe personal injury

25

thru

30

or

equipment damage.

All parts, especially guards and shields, should be

place.

Be sure all nuts, bolts and screws are tight.

Do

not remove any guards, warning labels, shields or safety devices; they are installed for your

safety.

The tractor

-

you are also wearing the seat belt.

-

the

roll

ROPS

is securely attached and has not been modified

or

equipment damage may result

)

are not followed.

-

operation checks ( page

or

equipment damage, observe the following precautions.

over protective structure

if

the operating instructions on

25

)

before you start the engine. You may prevent an

in

good condition, and securely fastened in

(ROPS)

will only protect you from injury

or

structurally damaged.

if;

or

front

Know how to stop the engine quickly. Thoroughly understand operation of all controls.

or

Never permit anyone to operate the tractor

The tractor

loader.

Keep children and pets at a safe distance during operation.

Never allow anyone to get under the front loader bucket

bucket is raised or tractor engine

Always wear sturdy shoes

tractor

Be alert.

or

drugs.

Work with the equipment only in daylight or good artificial light.

Watch out for and avoid rocks, roots, holes and other objects.

If

you hit an object, stop and inspect for damage; repair any damage before you operate the

equipment again.

Replace damaged, worn or broken parts immediately.

is

an operator

or

the front loader.

Do

not operate the front loader when you are tired, ill or under the influence of alcohol

only

or

vehicle,

is

boots

do

running.

and avoid wearing bulky

front loader without proper instructions.

not allow passengers to ride on the tractor.or front

or

reach through the

or

loose clothing while operating the

lift

arms when the

The exhaust contains poisonous carbon monoxide gas that can cause

and may lead to death,

if

the front loader

is

operated in an enclosed place.

loss

of consciousness

FRONT LOADER SAFETY

Never operate the tractor or front loader when visibility is diminished by darkness or by bad

weather; your ability to see obstacles will become impaired.

Avoid loose

fill, rocks and holes. They may cause vehicle instability or cause the vehicle to

overturn.

The front loader is intended for relatively flat terrain useage.

Avoid overhead wires and obstacles when the front loader is in the raised position. Contacting

electric wires can cause electrocution.

Allow for the added length of the front loader attachment when making turns to prevent striking

people or objects.

When operating the front loader on a slope, always drive up and down the face of the grade.

Turning or driving across the face of the slope may cause the tractor to overturn.

Operate the front loader arms gradually by "feathering" the loader controls to prevent abrupt

movements that could cause damage to the front loader

Use added caution when working with shifting or loose loads

cause vehicle instability

To avoid

loss of control or overturning, always reduce speed and exercise extreme caution

or fall out of the bucket and cause personal injury.

and tractor.

in the.loader bucket. It could

when operating the front loader on sloping or uneven surfaces.

Operate loader controls only from the operator's seat to prevent possible severe personal injury.

Attempting to change gears while operating the front loader on a slope may adversely affect

vehicle stability and control and severe personal injury could result.

Do not back down, or rapidly accelerate up a sloping surface.

To avoid loss of control or overturning, do not stop or turn on sloping surfaces.

Do not operate the front loader near the edge of a ditch or an embankment. Slipping off the

edge could lead to severe personal injury or equipment damage.

When descending a slope, disengaging the clutch or shifting into neutral can cause

loss of

control that may result in severe personal injury.

Be sure to follow instructions below whenever applying the tractor differential lock during front

loader use.

-Do not apply the tractor differential lock while turning, use the differential lock only while driving

in

a straight line.

-Never apply the differential lock on paved surfaces.

To avoid injury to yourself and others; before leaving the front loader unattended, ALWAYS;

—park on level ground and lock the parking brake.

—lower the front bucket flat to the ground.

—disengage the front loader drive system.

—stop the engine and remove the key.

6

If you find it necessary to park on a grade, be sure to lock the parking brake and securely block

the wheels.

MAINTENANCE SAFETY

MAINTENANCE SAFETY

Maintenance of the tractor and front loader requires special efforts on your part to ensure your

safety

the tractor or front loader.

and the safety of others. Know these requirements before perfoming maintenance on

Before performing

Before cleaning, inspecting or servicing the loader be sure to;

- lower the front loader bucket flat to the ground.

- move the front PTO to the off position

- stop the engine and remove the key.

Always wear safety glasses when servicing or replacing the front loader cylinder pins. Use a

brass drift and hammer. Failure to do so could result in eye injuries from possible flying metal

objects.

Operating the front loader or the tractor with damaged, worn, or broken parts may result in

severe personal injury.

Before disconnecting any hydraulic lines, relieve all hydraulic pressure.

Keep hands and body from pressurized lines. Use paper ,or cardboard, not body parts, to check

for leaks. Hydraulic oil under pressure will penetrate the skin causing serious injury.

Make sure that all operating and service personnel know that in the event hydraulic fluid

penetrates the skin, it must be surgically removed within

this form

All nuts, bolts, and fasteners must be properly secured.

of injury, or gangrene may result.

maintenance/inspections,read the instructions thoroughly.

a few hours by a doctor familiar with

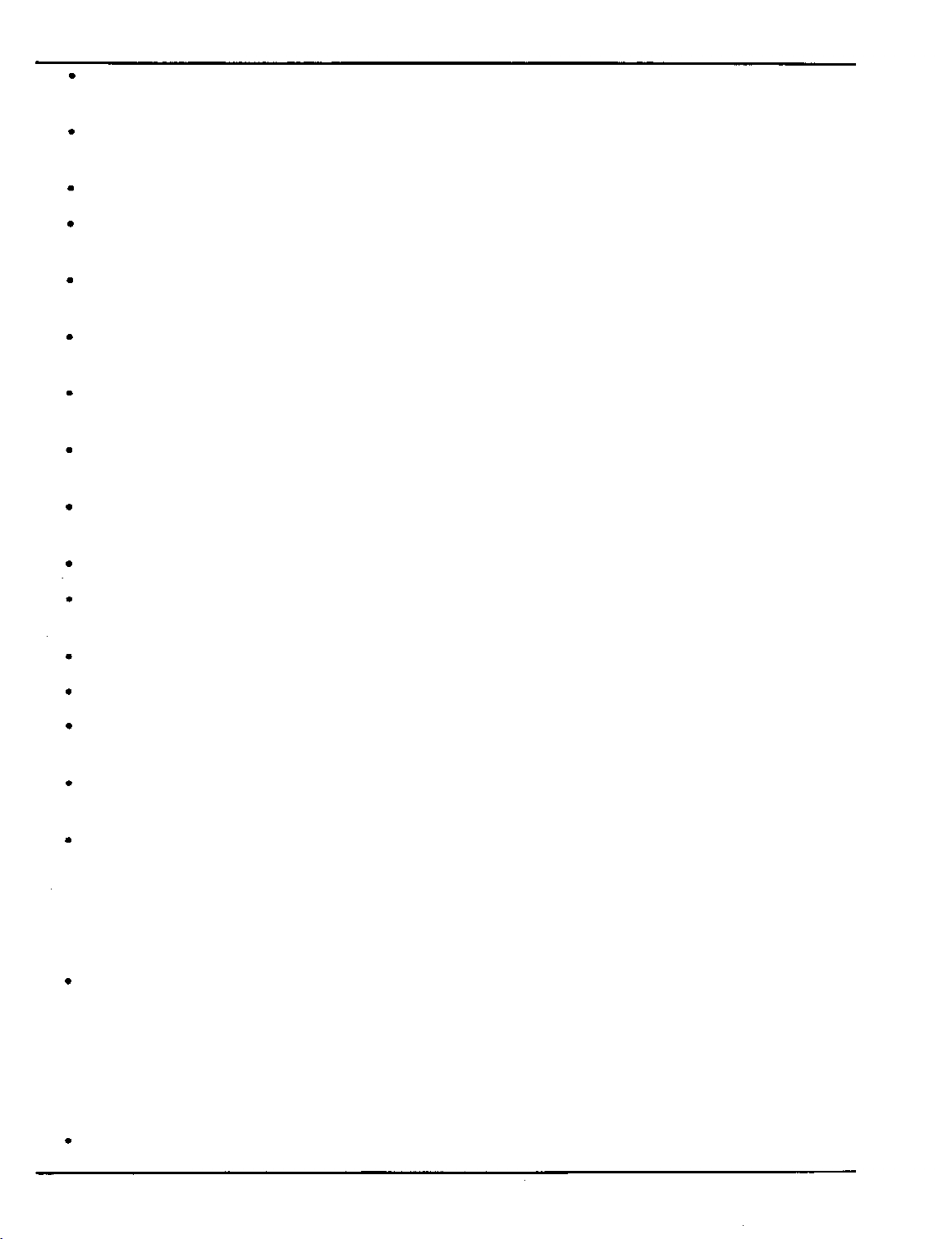

If you must work underneath a raised loader, make sure the arms are blocked in the raised

position with a safety bar. A suitable steel safety bar can be manufactured following the

dimensions as illustrated below.

-

AS REQUIRED

.\\

\

7

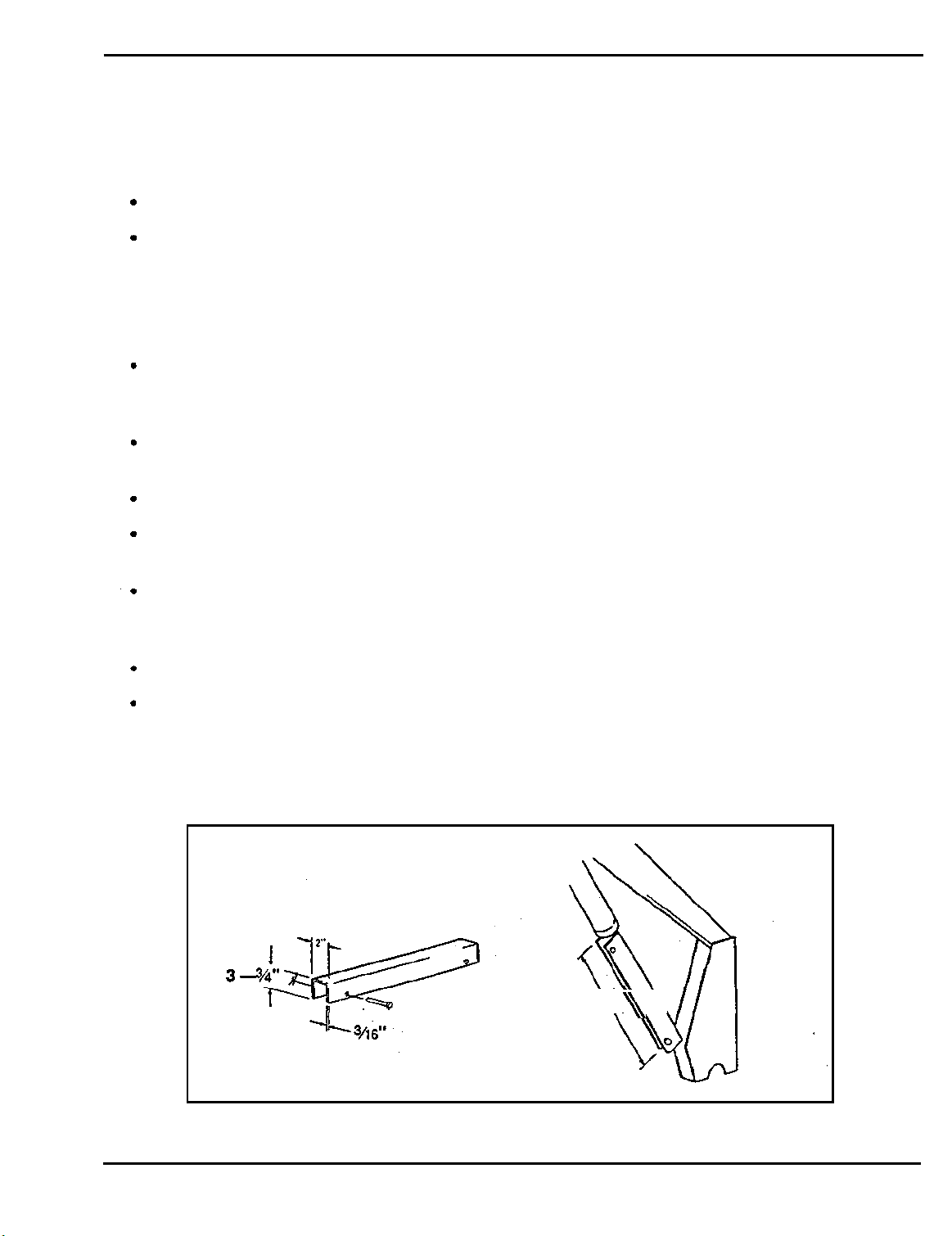

SAFETY LABEL LOCATIONS

SAFETY LABEL LOCATIONS

Read these

SAFETY

LABELS

IMPROPER

0

before

SERVICING

SERIOUS INJURY OR DEATH

Before

servicing

lower loader to the ground and

shut off engine.

Rolleve hydraulic

disconnecting oil lines.

you

or

pressure

operate the front loader.

CAN

CAUSE

adjustment

before

TRACTOR

CAUSE SERIOUS INJURY

OR DEATH

Add

•

wheel

counterweights

stability.

Drive

tractor at slow speed.

Place loader

transporting

especially on an incline

or

rough terrain.

e

Put loader

when parked.

Read

all instructlons in

operator's manual

before

TIP-OVER

recommended

ballast and/or

and turn

and understand

operation.

for

low when

loads,

on ground

CAN

FALL

FROM

LOADS CAN

CAUSING SERIOUS INJURY OR DEATH

BUCKET

INFORMATION

Special loader attachments

handling large objects are

available from agricultural

suppliers.

i

for

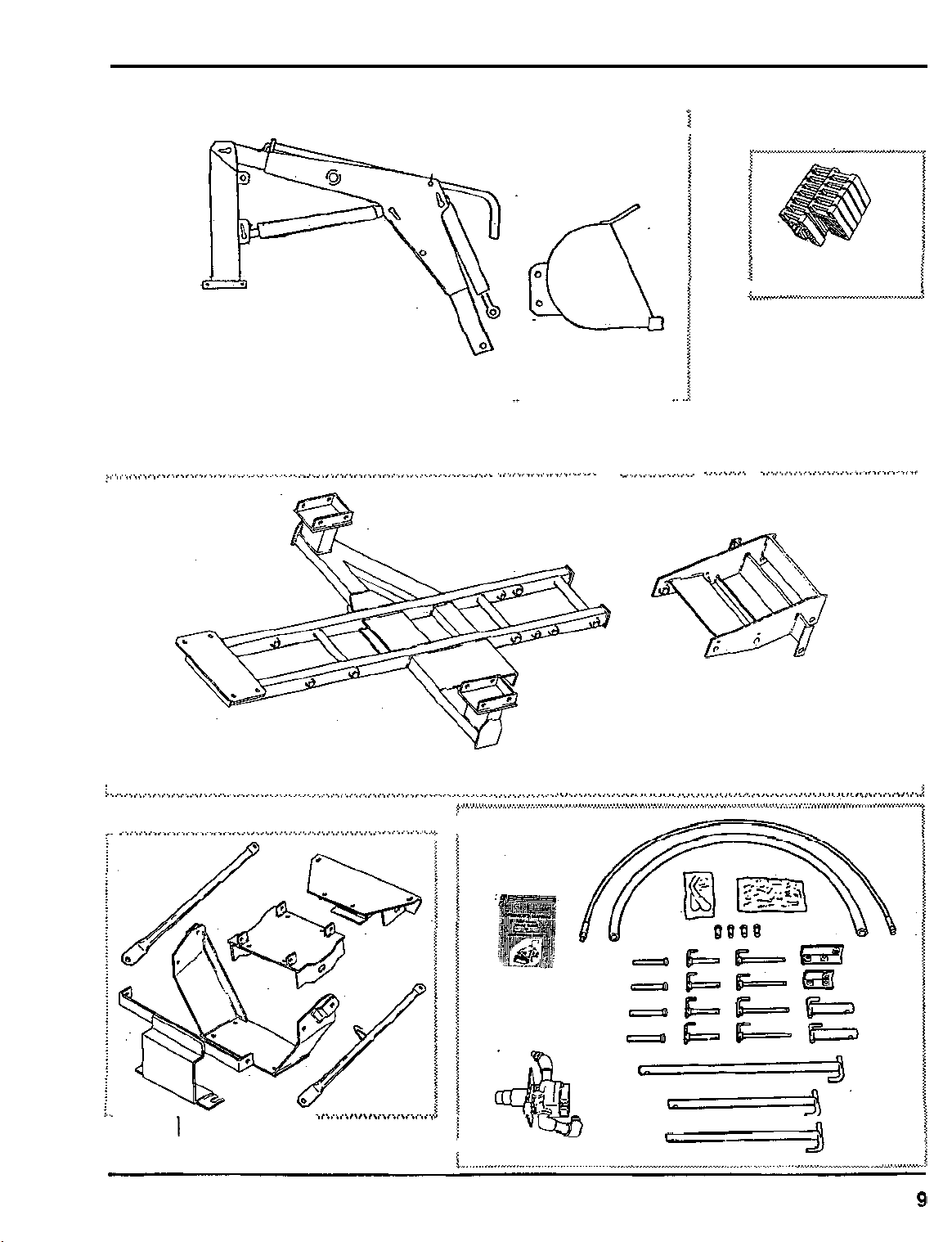

PACKAGING INVENTORY

.............................................................................................................................................

.................

................~....,..~.....................~...~..~~..............~...~....................................................,........,,..

....................................................................

SECURED

T

PACKAGING

I

O

C

RATE BOTTOM

I

.

INVENTORY

................................

..................,....CIC.......,,

........

\

.............,...,.....

12 Required

I

3

..

c,,..,,..,,

37.5 Ibs. each

j

1

WEIGHTS

...

.........,.....\,.....I..........

...l.l\>llll.i

.

..................................................................................................

...............................................

LARGE CARTON

1

SMALL CARTON—

..........................

..

TRACTOR PREPARATION

HARDWARE BAG CONTENTS

QNT'Y DESCRIPTION

5

2 10mm x 30mm hex hd capscrew

2

2 1/2-13x11/2" hex hd capscrew

16

12 3/4 x 11/4 x 10

2

2

2

7/16" lynchpin

12mm x 25mm

#11

clip pin

1/2-13x13/4" hex hd capscrew

3/8" flat washer

7/16-14x

11/4" hex hd capscrew

hex

hd

ga. machine bushing

capscrew

-

2

2

4

6

4

4

4

2

2

2

2

1

7/16"—14 hex nut

7/16"

lockwasher

1/2"—13

1/2"

1/2" lock

5/16"—18 x 1" hex hd capscrews

5/16

7/16" flatwasher

5/16"—18 13/4"

5/16" flatwasher

#

2

nylon

hex

flat washer

washer

"

lockwasher

hose clamp

tie

nut

hex

hd capscrew

TRACTOR PREPARATION

This loader is not intended to be used with any other attachments mounted on tractor.

REAR COUNTER WEIGHT

m-

The use of adequate rear counterweight is required for proper loader stability.

Refer to Tractor Owner's Manual for specific recommendations on counterweighting tractor.

1-

DO NOT EXCEED THE RATING

REFER TO OWNER'S MANUAL PROVIDED WITH TRACTOR.

FOR

MAXIMUM

GROSS

VEHICLE WEIGHT.

Weight added to the rear of the tractor provides better traction and easier, more efficient loader

operation. The tractor must be counterweighted by installation of rear weights.

Additional counterweight requirements will vary with loader attachments and equipment

applications.

--Certain

or may require more carefully restricted Operation at

ROLL-OVER PROTECTION STRUCTURE (ROPS) SYSTEM

The tractor ROPS system must be in place and used properly to ensure adequate operator

protection.

LOADER HYDRAULIC SYSTEM

Follow recommendations in this operator's manual for hydraulic fluid specifications.

TRACTOR

Selection of tires should be restricted to.tire recommendations as specified by your

Tractor owner's manual.

Ag tires are recommended when using the front loader

TIRE INFLATION

TIRES

specific conditions may not permit safe use of loader at loader rating

the rated load.

Front tires must be maintained at the maximum recommended inflation with the added weight

of loader and material.

Rear tires must be maintained at equal pressure within the recommended tire inflation range.

Ag Tire pressure

Ag Tire pressure 34 psi.

24 psi.

10

LOADER SPECIFICATIONS

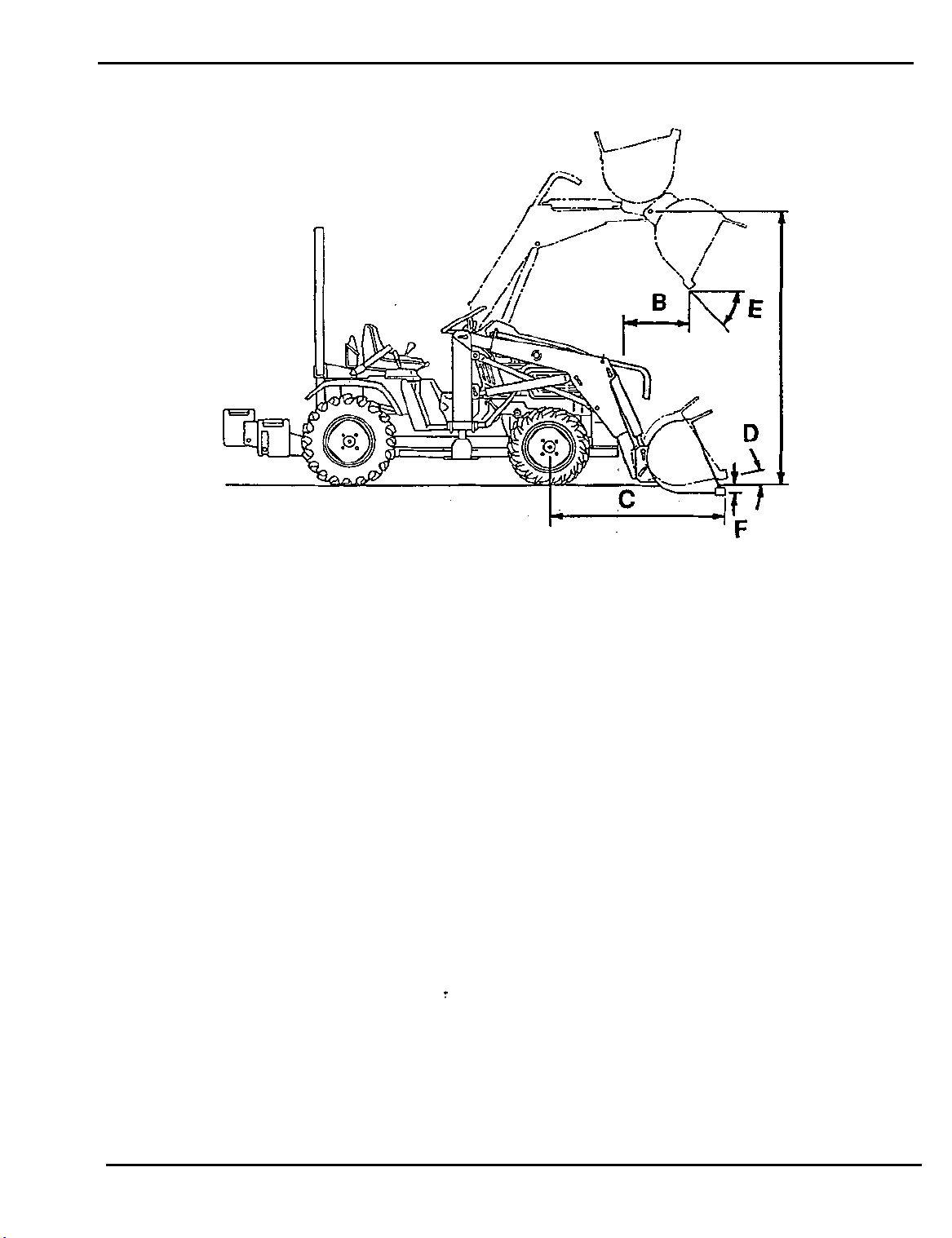

LOADER SPECIFICATIONS

A

-

-

LOADER SPECIFICATIONS

ITEM

Rated

Bucket Size (width)

Hydraulic cylinder

Counterweights

........................

Lift

Capacity

................

................

................

..................

...........................

Sub-frame

Hydraulic Pump Drive

Tractor Type

Weight w/ subframe

Maximum Lift Height

Reach @ Maximum Height.

Reach whucket

Bucket roll

Maximum Dump angle

Digging Depth Below Grade

.....................

...............

.................

................

................

............

on

ground

back angle

...............

............

...............

.....

......

........

........

........

.........

.........

........

........

.........

H55

18 A4 only

........

........

........

........

........

........

........

FL5540

400lb (180kg)

42in (1050mm

Double acting

Suit case type 37.5lb x 12

(17.0kg x 12)

Frame mount type

Front PTO coupled

-

Ag tires recommended

550lb (250kg)

'A'

72.1 in (1837mm)

'B' 16.4in (409.3mm)

'C' 47.9in (1195.2mm)

'D' 17o36'

'E'

47o31'

'F' 3.02in (80.5mm)

)

11

ASSEMBLY INFORMATION

ASSEMBLY INFORMATION

GENERAL

Read assembly instructions completely prior to installing loader to familiarize yourself with all

mounting and hydraulic system installation procedures.

The loader operates from its self contained hydraulic system with the pump driven from the

tractor front PTO.

A

pipe thread sealant must be used on all pipe threads.

All

hardware required for mounting loader is supplied.

Loader mount component hardware should be

left

loose until all mount components have been

installed.

Unless otherwise specified, refer to torque specification table for torque values

required for assembly.

Lay

out

and identify all components prior

to

installation.

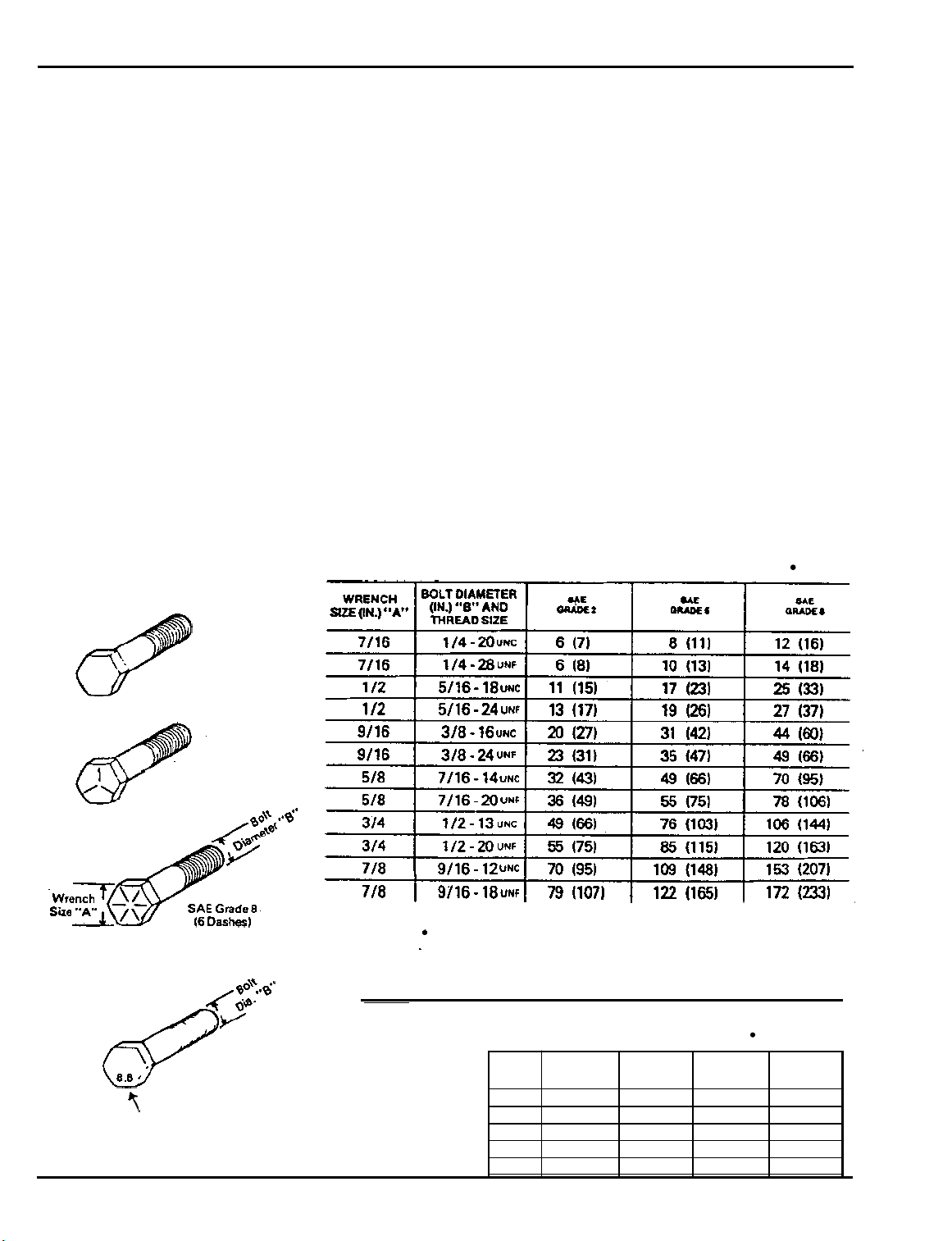

TORQUE SPECIFICATIONS

used

on Honda equipment

Pounds (Newton Meters).

AMERICAN

Bolt Head Markings

SAE

Grade

(No Dashes)

SAE

Grade 5

(3 Dashes)

Proper torque for American fasteners

in

Recommended Torque

2

Foot

of

hardware

METRIC

4;$d

6

Numbers appearing on bolt heads

indicate ASTM class.

12

2

Use

75%

'

fasteners. Use

for lubricated fasteners;

Proper torque for metric fasteners used on Honda equipment.

Recommended Torque

of the specified torque'value for plated

85%

of the specified torque values

in

Foot Pounds (Newton Meters).

BOLT

DIA.

(mm)

"B"

5

8

ASTM

CLASS

4.6

1.8 (2.4)

3 (4) 6

7.3 (10)

14.5 (20) 10

25 (34) 12

ASTM

8.8

74 (100)

ASTY

CLASS CLASS

9.8

5.1 (6.9)

8.7 (12)

21.1 (29)

42 (57)

73 (99)

ASTY

CLASS

10.9

6.5 (8.8)

11.1 (15)

27 (37)

53 (72)

93 (126)

I

FL5540

FL5540 SUB-FRAME

SUB-FRAME and COUNTERWEIGHT INSTALLATION/REMOVAL

and

COUNTERWEIGHT

INSTALLATION/REMOVAL

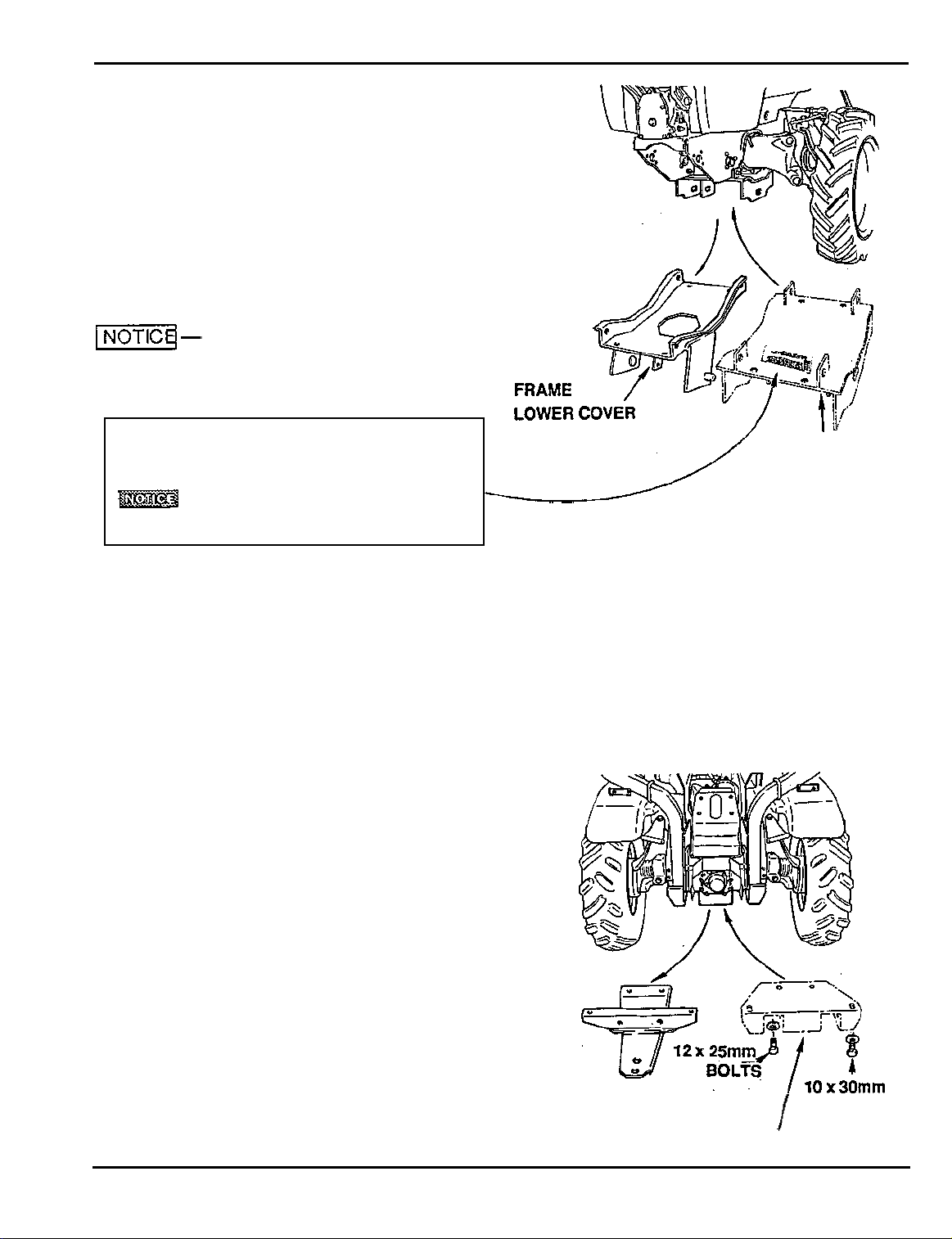

1. Remove the existing frame lower cover

and replace with the new lower cover

using existing mounting bolts and collar

washers.

--

1-d-

Never operate the tractor without

the lower cover.

INSTALLATION INSTRUCTIONS

1. CLEAN THE CONTACT SURFACES BETWEEN BRACKET AND FRAME.

2. MOUNT THE BRACKET BY INSTALLING THE (8) BOLTS FINGER TIGHT.

3. TIGHTEN UNDERSIDE MOUNTING BOLTS: 29 ft-lbs. (39 Nm TORQUE).

4. TIGHTEN SIDE MOUNTING BOLTS: 29 ft-lbs. (39 Nm TORQUE).

m

THE TRACTOR FRAME CAN BE DAMAGED IF THE TRACTOR

IS MOVED WHILE THIS COVER IS OFF OR BOLTS ARE

NOT TIGHTENED TO THE PROPER TORQUE.

Note: A second label is included with this

operator's manual. Install this label onto the

original

2.

frame lower cover.

Remove the drawbar and replace it with

the bottom bracket using the two

x 25 mm hex hd capscrews with 7/16"

12

washers and two 10 x 30mm hex hd

capscrews with

3/8" washers.

NEW LOWER

FRONT COVER

Torque front cover and rear bracket bolts as

follows:

10mm Bolts 29 ft-lbs. (29 Nm).

12mm Bolts 43 ft-lbs. (60 Nm).

DRAWBAR

/

BOTTOM BRACKET

BOLTS

13

FL5540 SUB-FRAME

forward from

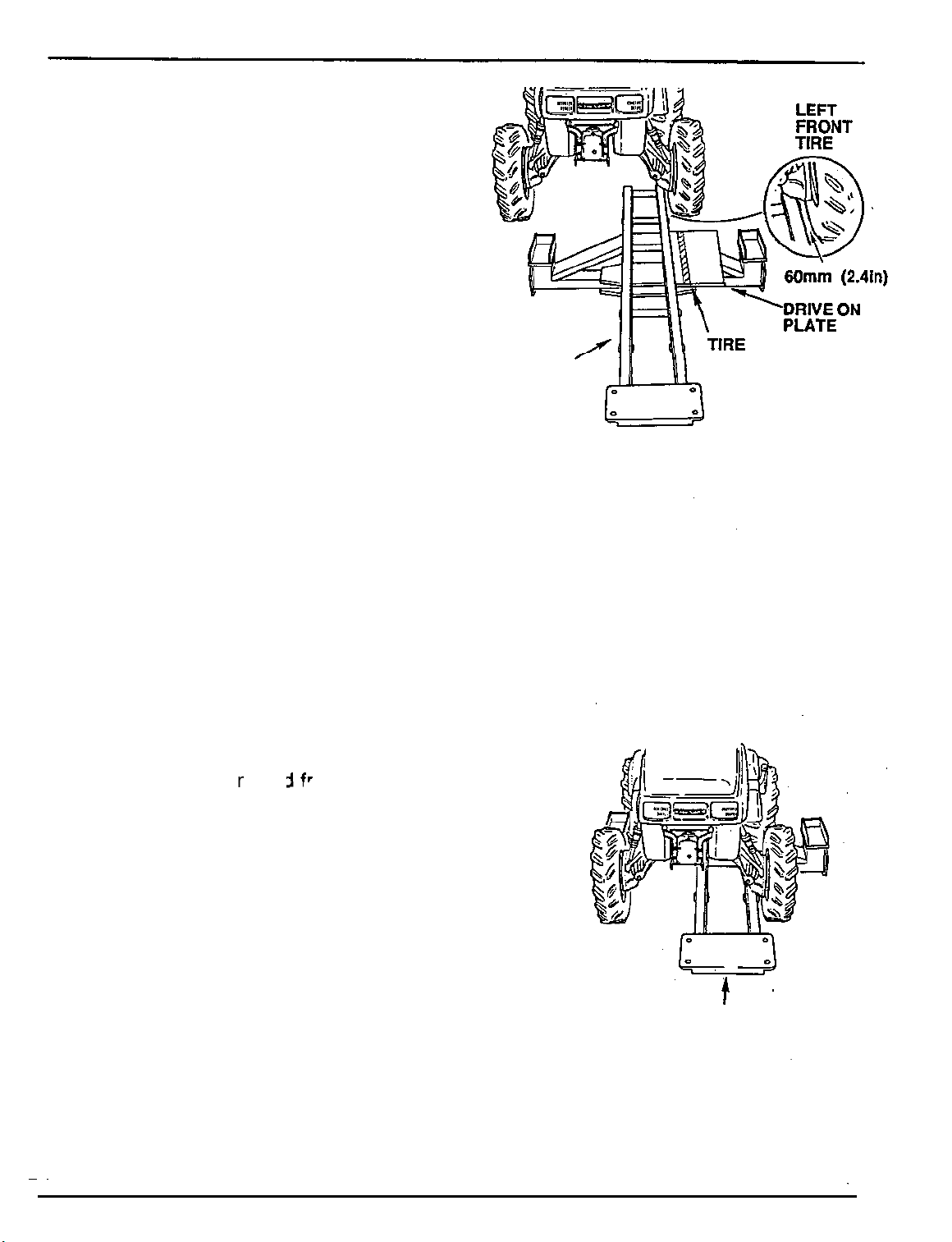

3. Lay the sub-frame on a level, solid area.

4. Position the tractor in line with the

sub-frame and tire guide on drive on plate,

allowing

a clearance of approximately

60mm (2.4in) between sub-frame and the

inner wall

of the left front tire.

and

COUNTERWEIGHT INSTALLATlON/REMOVAL

5. D

rive the tractor the rear of

the sub-frame, over the drive on plate

keeping it parallel with the sub-frame.

SUB-FRAME

GUIDE

Page 14

SUB

-

FRAME

Loading...

Loading...