Page 1

INTRODUCTION

Thank you for purchasing a Honda engine. We want to help you to get

the best results from your new engine and to operate it safely. This

manual contains information on how to do that; please read it carefully

before operating the engine. If a problem should arise, or if you have

any questions about your engine, consult an authorized Honda

servicing dealer.

All information in this publication is based on the latest product

information available at the time of printing. American Honda Motor

Co., Inc. reserves the right to make changes at any time without

notice and without incurring any obligation. No part of this publication

may be reproduced without written permission.

This manual should be considered a permanent part of the engine

and should remain with the engine if resold.

Review the instructions provided with the equipment powered by this

engine for any additional information regarding engine startup,

shutdown, operation, adjustments or any special maintenance

instructions.

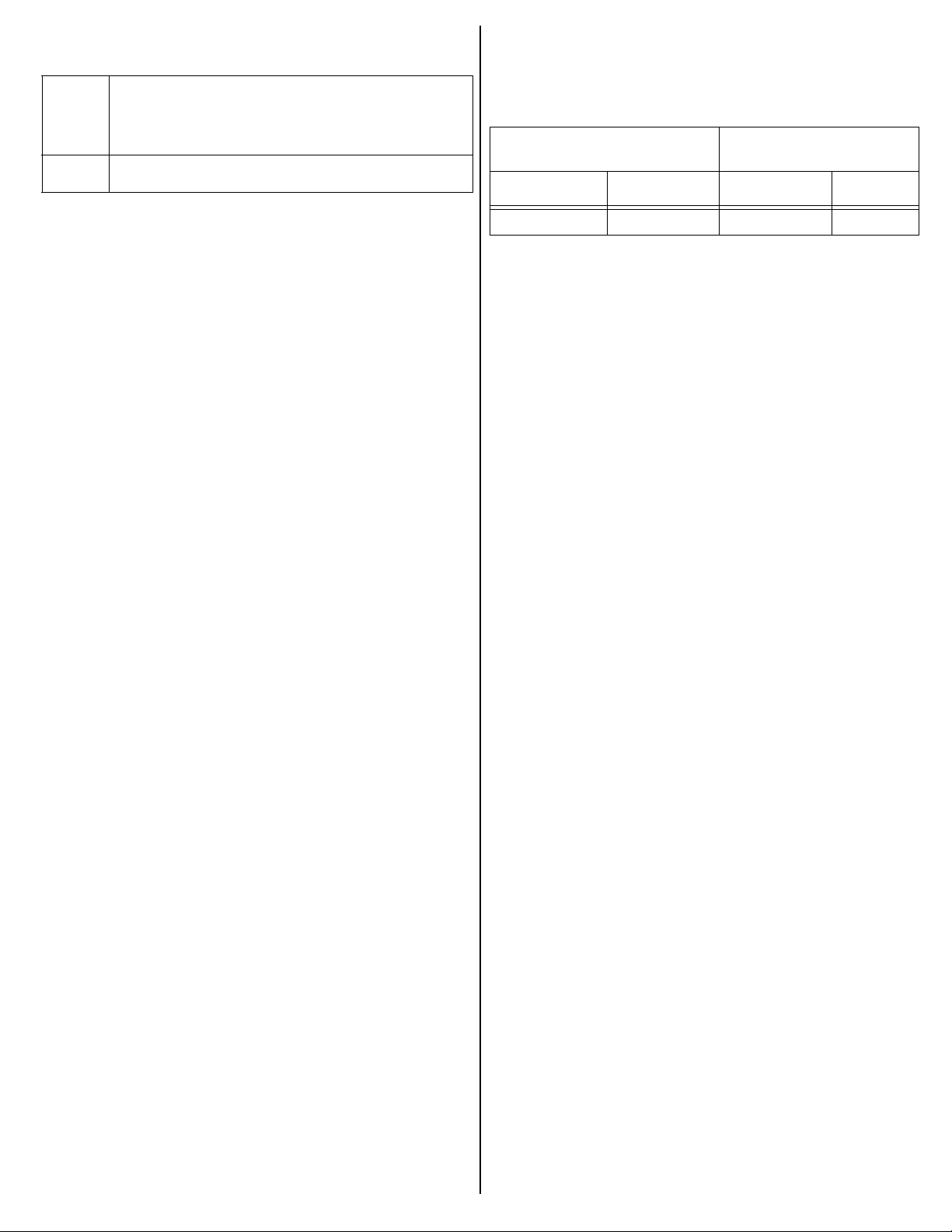

SAFETY MESSAGES

Your safety and the safety of others are very important. We have

provided important safety messages in this manual and on the

engine. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is preceded by a safety alert symbol

and one of three words, DANGER, WARNING, or CAUTION.

These signal words mean:

DANGER

WARNING

CAUTION

Each message tells you what the hazard is, what can happen, and

what you can do to avoid or reduce injury.

DAMAGE PREVENTION MESSAGES

You will also see other important messages that are preceded by the

word NOTICE.

This word means:

NOTICE

The purpose of these messages is to help prevent damage to your

engine, other property, or the environment.

SAFETY INFORMATION

• Understand the operation of all controls and learn how to stop the

engine quickly in case of emergency. Make sure the operator

receives adequate instruction before operating the equipment.

• Your engine’s exhaust contains poisonous carbon monoxide. Do

not run the engine without adequate ventilation, and never run the

engine indoors.

• The engine and exhaust become very hot during operation. Keep

the engine at least 3 feet (1 meter) away from buildings and other

equipment during operation. Keep flammable materials away, and

do not place anything on the engine while it is running.

© 2003–2007 American Honda Motor Co., Inc.—All Rights Reserved

31Z8B010

00X31-Z8B-0100

Your engine or other property can be

damaged if you don’t follow instructions.

You WILL be KILLED or SERIOUSLY

HURT if you don't follow instructions.

You CAN be KILLED or SERIOUSLY

HURT if you don't follow instructions.

You CAN be HURT if you don't follow

instructions.

IPC POM52684-L

EM5

XXX.2007.02

PRINTED IN U.S.A.

ENGLISH

OWNER’S MANUAL

MANUEL DE L’UTILISATUER

MANUAL DEL PROPIETARIO

GCV160 • GCV190

WARNING:

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects or

other reproductive harm.

CONTENTS

INTRODUCTION . . . . . . . . . . . 1

SAFETY MESSAGES. . . . . . . . 1

DAMAGE PREVENTION

MESSAGES . . . . . . . . . . . . . . 1

SAFETY INFORMATION . . . . 1

COMPONENT & CONTROL

LOCATION . . . . . . . . . . . . . . . . 2

BEFORE OPERATION CHECKS2

IS YOUR ENGINE READY TO

GO? . . . . . . . . . . . . . . . . . . . . 2

OPERATION. . . . . . . . . . . . . . . 2

SAFE OPERATING

PRECAUTIONS . . . . . . . . . . . 2

Type 1 Operation . . . . . . . . . 2

Type 2 Operation . . . . . . . . . 3

Type 3 Operation . . . . . . . . . 3

Type 4 Operation . . . . . . . . . . 4

Type 5 Operation . . . . . . . . . . 4

Type 6 Operation . . . . . . . . . . 4

Type 7 Operation . . . . . . . . . . 5

Type 8 Operation . . . . . . . . . . 5

SERVICING YOUR ENGINE . . 5

THE IMPORTANCE OF

MAINTENANCE . . . . . . . . . . . 5

MAINTENANCE SAFETY . . . 6

MAINTENANCE SCHEDULE. 6

REFUELING. . . . . . . . . . . . . . 6

ENGINE OIL. . . . . . . . . . . . . . 7

AIR CLEANER . . . . . . . . . . . . 7

SPARK PLUG . . . . . . . . . . . . 7

FLYWHEEL BRAKE

INSPECTION . . . . . . . . . . . . . 8

SPARK ARRESTER (optional

equipment) . . . . . . . . . . . . . . . 8

FRANÇAISESPAÑOL ENGLISH

HELPFUL TIPS &

SUGGESTIONS . . . . . . . . . . . . 8

STORING YOUR ENGINE. . . 8

ADDING A GASOLINE

STABILIZER TO EXTEND

FUEL STORAGE LIFE. . . . . . 9

DRAINING THE FUEL TANK

AND CARBURETOR . . . . . . . 9

TRANSPORTING. . . . . . . . . . 9

TAKING CARE OF

UNEXPECTED PROBLEMS . . 9

TECHNICAL INFORMATION . 10

SERIAL NUMBER AND TYPE

LOCATION. . . . . . . . . . . . . . 10

HIGH ALTITUDE

OPERATION . . . . . . . . . . . . 10

EMISSION CONTROL

SYSTEM INFORMATION . . 10

AIR INDEX . . . . . . . . . . . . . . 11

SPECIFICATIONS . . . . . . . . 11

BATTERY CONNECTIONS . 12

WIRING DIAGRAMS . . . . . . 12

CONSUMER INFORMATION. 13

HONDA PUBLICATIONS. . . 13

DISTRIBUTOR’S LIMITED

WARRANTIES . . . . . . . . . . . 13

EMISSION CONTROL

SYSTEM

WARRANTY. . . . . . . . . . . . . 14

DISTRIBUTOR/DEALER

LOCATOR INFORMATION . 13

CUSTOMER SERVICE

INFORMATION . . . . . . . . . . 13

INTERNATIONAL WARRANTY

INFORMATION . . . . . last page

1

Page 2

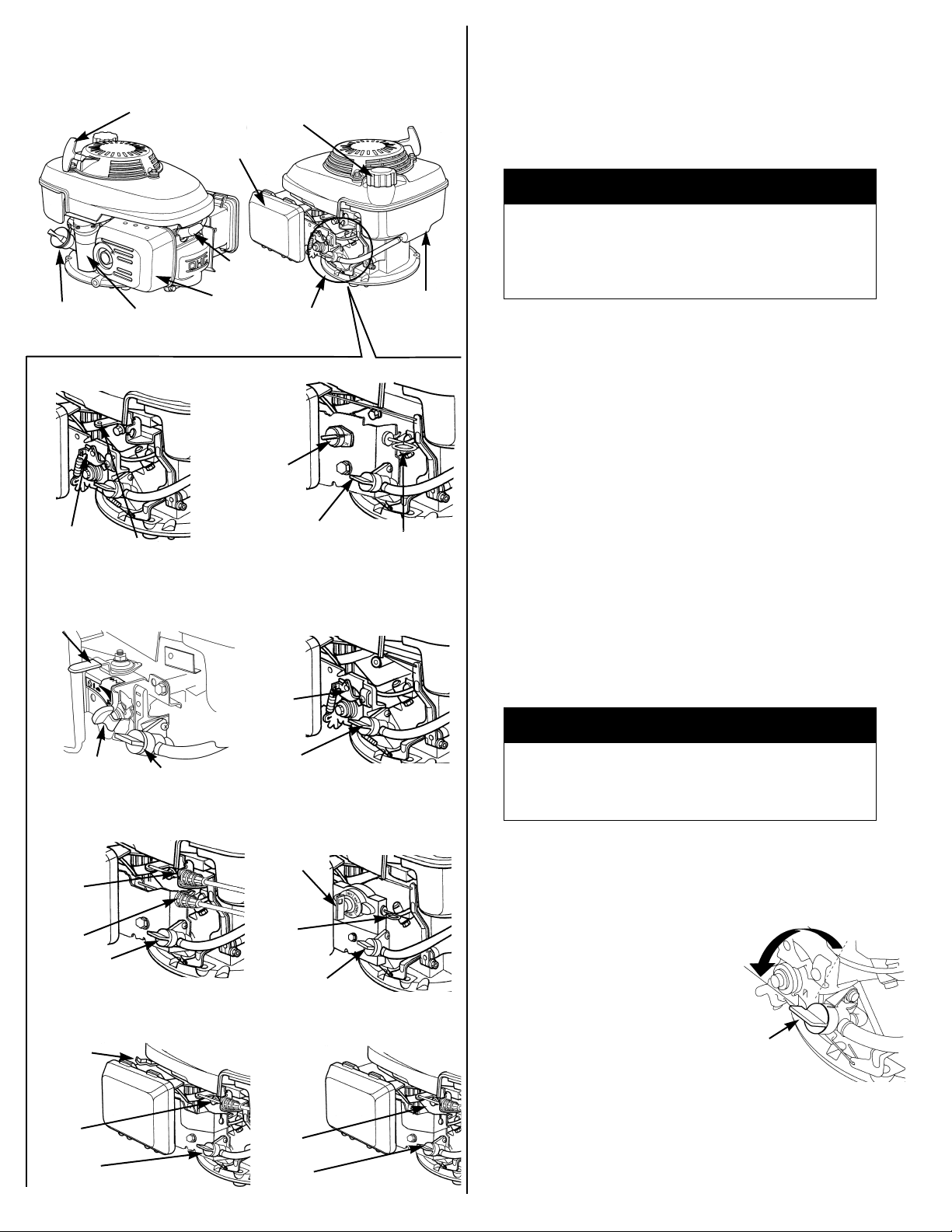

COMPONENT & CONTROL LOCATION

E

BEFORE OPERATION CHECKS

The engine control area differs based on the engine type. Refer to the

individual diagrams below to determine your engine control type when

reading the OPERATION section and other sections in this manual.

STARTER GRIP

OIL FILLER CAP/

DIPSTICK

ENGINE CONTROL TYPES

TYPE 1: FLYWHEEL BRAKE/

REMOTE THROTTLE

THROTTLE

LEVER

TYPE 2: MANUAL CHOKE/

TYPE 2: MANUAL CHOKE/

MANUAL

MANUAL THROTTLE

CHOKE LEVER

STARTER MOTOR

(if equipped)

FLYWHEEL BRAKE

CONTROL LEVER

FUEL FILLER CAP

AIR CLEANER

SPARK

PLUG

MUFFLER

ENGINE

CONTROL

AREA

TYPE 5: MANUAL CHOKE/FIXED THROTTL

ENGINE

STOP

SWITCH

FUEL VALVE

LEVER

TYPE 6: REMOTE THROTTLE/BLADE

BRAKE CLUTCH

(equipment control)

THROTTLE

LEVER

CHOKE ROD

FUEL TANK

IS YOUR ENGINE READY TO GO?

For your safety, and to maximize the service life of your equipment, it

is very important to take a few moments before you operate the

engine to check its condition. Be sure to take care of any problem you

find, or have your servicing dealer correct it, before you operate the

engine.

WARNING

Improperly maintaining this engine, or failure to correct a

problem before operation, can cause a malfunction in

which you can be seriously hurt or killed.

Always perform a pre-operation inspection before each

operation, and correct any problem.

Before beginning your pre-operation checks, be sure the engine is

level and the flywheel brake lever (TYPE 2: throttle lever, TYPE 5:

engine stop switch) is in the STOP or OFF position.

Always check the following items before you start the engine:

1. Fuel level (see page 6).

2. Oil level (see page 7).

3. Air cleaner (see page 7).

4. General inspection: Check for fluid leaks and loose or damaged

parts.

5. Check the equipment powered by this engine.

Review the instructions provided with the equipment powered by

this engine for any precautions and procedures that should be

followed before engine startup.

OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the engine for the first time, please review the

SAFETY INFORMATION section on page 1 and the BEFORE

OPERATION CHECKS above.

THROTTLE

LEVER

TYPE 3: FLYWHEEL BRAKE/REMOTE

FLYWHEEL

BRAKE

CONTROL

CABLE

CHOKE

CONTROL

CABLE

FUEL VALVE

LEVER

TYPE 4: AUTOMATIC CHOKE RETURN/

CHOKE

LEVER

FLYWHEEL

BRAKE

CONTROL

CABLE

FUEL VALVE

LEVER

FUEL VALVE LEVER

CHOKE/FIXED THROTTLE

FIXED THROTTLE

FUEL VALVE

LEVER

TYPE 7: ELECTRIC START (WITH

ENGINE-MOUNTED STARTER SWITCH)/

MANUAL CHOKE/PRESET THROTTLE

STARTER

SWITCH

CHOKE

ROD

FUEL VALVE

LEVER

TYPE 8: AUTOMATIC CHOKE/

FIXED THROTTLE

FLYWHEEL

BRAKE

CONTROL

CABLE

FUEL VALVE

LEVER

WARNING

Carbon monoxide gas is toxic. Breathing it can cause

unconsciousness and even kill you.

Avoid any areas or actions that expose you to carbon

monoxide.

Review the instructions provided with the equipment powered by this

engine for any safety precautions that should be observed with

engine startup, shutdown, or operation.

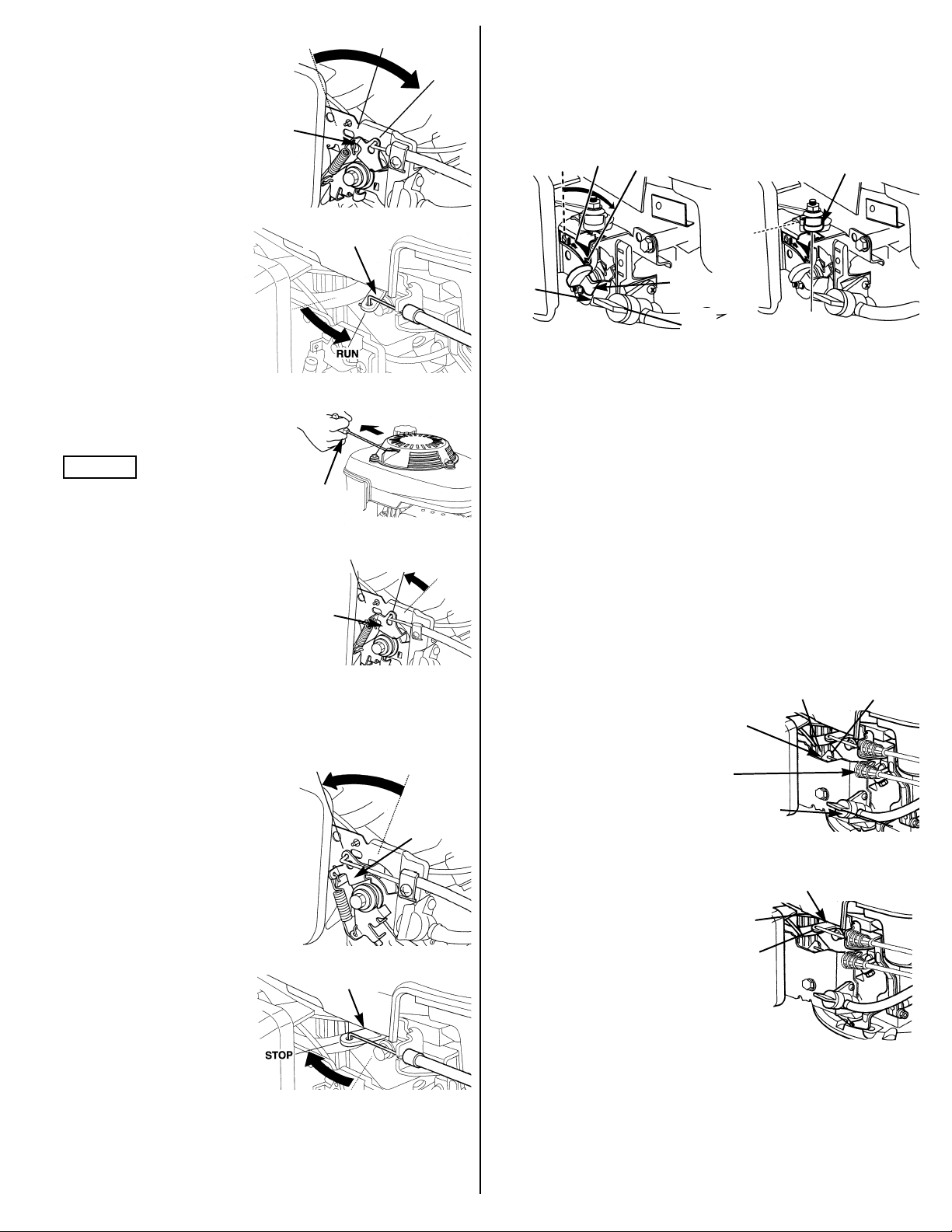

TYPE 1: FLYWHEEL BRAKE/REMOTE THROTTLE

Starting The Engine

1. Turn the fuel valve to the ON

position.

ON

FUEL

VALVE

OFF

2

ENGLISH

Page 3

2. See equipment manual and

position the throttle control

so the choke/throttle lever

moves to the CHOKE

position (cold engine).

SLOW

CHOKE/

THROTTLE

LEVER

FAST

CHOKE

TYPE 2: MANUAL CHOKE/MANUAL THROTTLE

Starting The Engine

1. Turn the fuel valve to the ON position (see TYPE 1 Step 1 on

page 2).

2. Move the choke lever to the ON position (cold engine).

3. Move the throttle lever to the FAST position.

SLOW

STOP

FAST

CHOKE LEVER

3. See equipment manual

and position the flywheel

FLYWHEEL

BRAKE LEVER

brake control so the

flywheel brake lever is in

the RUN position.

4. Pull the starter grip lightly until

resistance is felt, then pull briskly.

NOTICE

Do not allow the starter grip to snap

back against the engine. Return it

STARTER

GRIP

gently to prevent damage to the

starter.

5. If the choke was used to start the

engine, move the choke/throttle

lever to the FAST (or high) position

as soon as the engine warms up

CHOKE/

THROTTLE

LEVER

FAST

CHOKE

enough to run smoothly without

use of the choke.

Throttle Setting

Position the throttle control for the desired engine speed. For best

engine performance, it is recommended the engine be operated with

the throttle in the FAST (or high) position.

Stopping The Engine

1. Move the choke/throttle control to

SLOW

FAST

the SLOW position.

THROTTLE

LEVER

2. Release the flywheel

brake lever to stop the

engine.

FLYWHEEL

BRAKE LEVER

3. Turn the fuel valve to

the OFF position (see

TYPE 1 Step 1 on

page 2).

ENGLISH

OFF

FUEL

VALVE

THROTTLE

LEVER

ON

ON

4. Pull the starter grip lightly until resistance is felt, then pull briskly

(see TYPE 1 Step 4 on page 3).

5. If the choke was used to start the engine, move the choke lever to

the OFF position as soon as the engine warms up enough to run

smoothly without use of the choke.

6. Position the throttle lever for the desired engine speed. For best

engine performance, it is recommended the engine be operated

with the throttle in the FAST (or high) position.

Stopping The Engine

1. Move the throttle lever to the SLOW position and allow the engine

to idle for a few seconds.

2. Move the throttle lever to the STOP position.

3. Turn the fuel valve to the OFF position (see TYPE 1 Step 1 on

page 2).

TYPE 3: FLYWHEEL BRAKE/REMOTE CHOKE/FIXED

THROTTLE

Starting The Engine

1. Turn the fuel valve to the

ON position (see TYPE 1

CHOKE

ARM

OFF

Step 1 on page 2).

2. Move the choke control

cable (see equipment

manual) so that the choke

arm moves to the choke

CHOKE CONTROL

CABLE

FUEL VALVE

ON position (cold engine).

3. Move the flywheel brake lever

to the RUN position.

FLYWHEEL BRAKE LEVER

4. Pull the starter grip lightly until

resistance is felt, then pull

STOP

briskly (see TYPE 1 Step 4 on

page 3).

RUN

5. If the choke was used to start

the engine, move the choke

control cable so that the choke

arm moves to the OFF position

as soon as the engine warms

up enough to run smoothly without use of the choke.

The engine speed is preset on this type.

Stopping The Engine

1. Release the flywheel brake lever to stop the engine.

2. Turn the fuel valve to the OFF position (see TYPE 1 Step 1 on

page 2).

ON

ON

3

Page 4

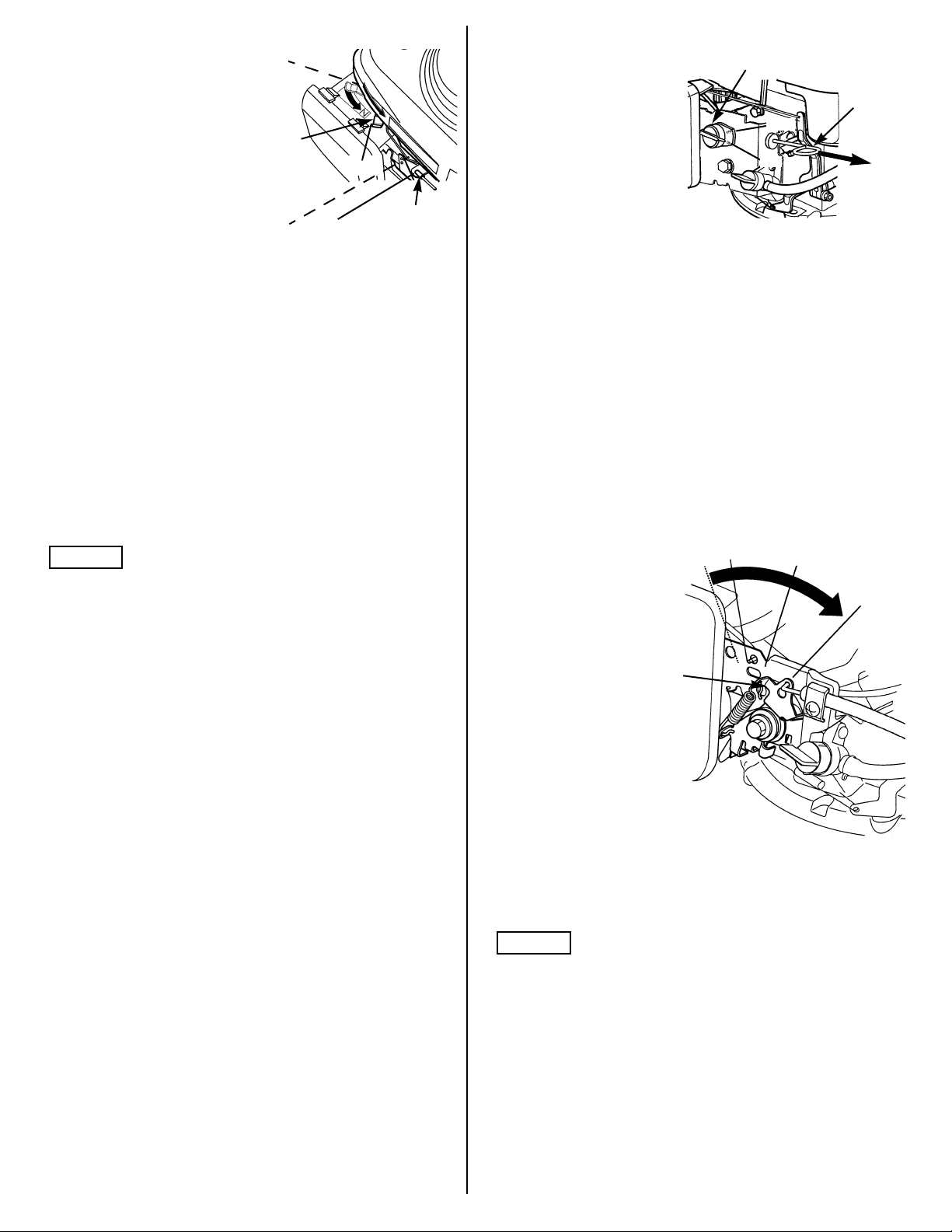

TYPE 4: AUTOMATIC CHOKE RETURN/FIXED THROTTLE

Starting The Engine

1. Turn the fuel valve to the ON

position (see TYPE 1

Step 1 on page 2).

2. Move the choke lever to the

choke position () (cold

engine).

3. Move the flywheel brake

lever to the RUN position.

The choke lever

automatically begins moving

to the OFF position when the flywheel brake lever is moved to the

RUN position.

4. Start the engine.

Recoil Starter Types

Pull the starter grip lightly until resistance is felt, then pull briskly

(see TYPE 1 Step 4 on page 3). Begin pulling the starter grip as

soon as you move the flywheel brake lever to the RUN position

and the choke starts moving to the OFF position.

If the engine does not start before the choke moves to the OFF

position, repeat steps 2 and 3, then continue starting.

Electric Starter Types

Turn the starter switch (located on equipment) to the START

position, and hold it there until the engine starts. When the engine

starts, allow the engine switch to return to its normal position.

NOTICE

Do not use the starter for more than 5 seconds or starter motor

damage may occur. If the engine fails to start, release the switch

and wait 10 seconds before operating the starter again.

If the engine does not start before the choke moves to the OFF

position, repeat steps 2 and 3, then continue starting.

The throttle is preset on this type.

Stopping The Engine

1. Release the flywheel brake lever to activate the flywheel brake and

stop the engine.

2. Turn the fuel valve to the OFF position (see TYPE 1 Step 1 on

page 2).

OFF

CHOKE

LEVER

STOP

RUN

ON

FLYWHEEL

BRAKE LEVER

TYPE 5: MANUAL CHOKE/FIXED THROTTLE

Starting The Engine

1. Turn the fuel valve to the ON

position (see TYPE 1

Step 1 on page 2).

2. Pull the choke rod to the ON

position (cold engine).

3. Turn the engine stop switch

to the ON position.

4. Pull the starter grip lightly

until resistance is felt, then

pull briskly (see TYPE 1 Step 4 on page 3).

5. If the choke was used to start the engine, move the choke rod to

the OFF position as soon as the engine warms up enough to run

smoothly without use of the choke.

The engine speed is preset on this type.

Stopping The Engine

1. Move the engine switch to the OFF position.

2. Turn the fuel valve to the OFF position (see TYPE 1 Step 1 on

page 2).

ENGINE STOP SWITCH

OFF

ON

CHOKE

ROD

ON

TYPE 6: REMOTE THROTTLE/BLADE BRAKE CLUTCH

Starting The Engine

1. Turn the fuel valve to the ON position (see TYPE 1 Step 1 on

page 2).

2. Move the choke/

throttle/stop lever to

STOP

SLOW

the CHOKE position

(cold engine).

Make sure the blade

control lever is

disengaged (see

equipment manual).

CHOKE/

THROTTLE/

STOP

LEVER

3. Start the engine.

Recoil Starter Types

Pull the starter grip

lightly until

resistance is felt,

then pull briskly (see

TYPE 1 Step 4 on

page 3).

Electric Starter Types

Turn the starter switch (located on equipment) to the START

position, and hold it there until the engine starts. When the engine

starts, allow the engine switch to return to its normal position.

FAST

CHOKE

NOTICE

Do not use the starter for more than 5 seconds or starter motor

damage may occur. If the engine fails to start, release the switch

and wait 10 seconds before operating the starter again.

4. As soon as the engine starts, slowly move the choke/throttle/stop

lever to the FAST position.

5. Allow the engine to warm to operating temperature, then engage

the blade control lever (see equipment manual).

4

ENGLISH

Page 5

Throttle Setting

Position the choke/throttle/stop lever for the desired engine speed.

For best engine performance, it is recommended the engine be

operated with the choke/throttle/stop lever in the FAST (or high)

position.

Stopping The Engine

1. Disengage the blade brake clutch control lever (see equipment

manual).

2. Move the choke/throttle/stop lever to the SLOW position and allow

the engine to idle for a few seconds.

3. Move the choke/throttle/stop lever to the STOP position.

4. Turn the fuel valve OFF (see TYPE 1 Step 1 on page 2).

TYPE 7: ELECTRIC START WITH ENGINE-MOUNTED

STARTER SWITCH/MANUAL CHOKE CONTROL/

PRESET THROTTLE

Starting The Engine

1. Turn the fuel valve to the ON

position (see TYPE 1

Step 1 on page 2).

2. Pull the choke rod to the ON

position (see TYPE 5 Step 2

on page 4) (cold engine).

3. Electric Starter Types

Turn the starter switch to the

START position and hold it there until the engine starts. When the

engine starts, allow the starter switch to return to the ON position.

NOTICE

Do not use the starter for more than 5 seconds or starter motor

damage may occur. If the engine fails to start, release the switch

and wait 10 seconds before operating the starter again.

Recoil Starter Types

a. Turn the starter switch to the RUN position.

b. Pull the starter grip lightly until resistance is felt, then pull briskly

(see TYPE 1 Step 4 on page 3).

4. If the choke was used to start the engine, move the choke rod to

the OFF position as soon as the engine warms up enough to run

smoothly without use of the choke.

The engine speed is preset on this type.

Stopping The Engine

1. Move the starter switch to the STOP position.

2. Turn the fuel valve to the OFF position (see TYPE 1 Step 1 on

page 2).

STARTER

SWITCH

STOP

ON

START

TYPE 8: AUTOMATIC CHOKE/FIXED THROTTLE

Starting The Engine

1. Turn the fuel valve to the ON

position (see TYPE 1

Step 1 on page 2).

2. Move the flywheel brake lever

to the RUN position.

3. Pull the starter grip lightly until

resistance is felt, then pull

briskly (see TYPE 1 Step 4 on

page 3).

Stopping The Engine

1. Release the flywheel brake lever to activate the flywheel brake and

stop the engine.

2. Turn the fuel valve to the OFF position (see TYPE 1 Step 1 on

page 2).

FLYWHEEL BRAKE CONTROL CABLE

FUEL VALVE

LEVER

SERVICING YOUR ENGINE

THE IMPORTANCE OF MAINTENANCE

Good maintenance is essential for safe, economical and trouble-free

operation. It will also help reduce pollution.

WARNING

Improper maintenance, or failure to correct a problem

before operation, can cause a malfunction in which you

can be seriously hurt or killed.

Always follow the inspection and maintenance

recommendations and schedules in this owner’s manual.

To help you properly care for your engine, the following pages include

a maintenance schedule, routine inspection procedures, and simple

maintenance procedures using basic hand tools. Other service tasks

that are more difficult, or require special tools, are best handled by

professionals and are normally performed by a Honda technician or

other qualified mechanic.

The maintenance schedule applies to normal operating conditions. If

you operate your engine under severe conditions, such as sustained

high-load or high-temperature operation, or use in unusually wet or

dusty conditions, consult your servicing dealer for recommendations

applicable to your individual needs and use.

Maintenance, replacement, or repair of the emission control

devices and systems may be performed by any engine repair

establishment or individual, using parts that are “certified” to

EPA standards.

ENGLISH

5

Page 6

MAINTENANCE SAFETY

Some of the most important safety precautions follow. However, we

cannot warn you of every conceivable hazard that can arise in

performing maintenance. Only you can decide whether or not you

should perform a given task.

REFUELING

This engine is certified to operate on unleaded gasoline with a pump

octane rating of 86 or higher.

Refuel in a well-ventilated area with the engine stopped. If the engine

has been running, allow it to cool first. Never refuel the engine inside

a building where gasoline fumes may reach flames or sparks.

WARNING

Failure to properly follow maintenance instructions and

precautions can cause you to be seriously hurt or killed.

Always follow the procedures and precautions in this

owner’s manual.

SAFETY PRECAUTIONS

You may use regular unleaded gasoline containing no more than 10%

Ethanol (E10) or 5% Methanol by volume. In addition, Methanol must

contain cosolvents and corrosion inhibitors. Use of fuels with content

of Ethanol or Methanol greater than shown above may cause starting

and/or performance problems. It may also damage metal, rubber, and

plastic parts of the fuel system. Engine damage or performance

problems that result from using a fuel with percentages of Ethanol or

Methanol greater than shown above are not covered under warranty.

• Make sure the engine is off before you begin any maintenance or

repairs. This will eliminate several potential hazards:

– Carbon monoxide poisoning from engine exhaust.

Be sure there is adequate ventilation whenever you operate

the engine.

– Burns from hot parts.

Let the engine and exhaust system cool before touching.

– Injury from moving parts.

Gasoline is highly flammable and explosive, and you can

be burned or seriously injured when refueling.

• Stop engine and keep heat, sparks, and flame away.

• Refuel only outdoors.

• Wipe up spills immediately.

WARNING

Do not run the engine unless instructed to do so.

• Read the instructions before you begin, and make sure you have

the tools and skills required.

• To reduce the possibility of fire or explosion, be careful when

working around gasoline. Use only a nonflammable solvent, not

gasoline, to clean parts. Keep cigarettes, sparks, and flames away

from all fuel-related parts.

Remember that an authorized Honda servicing dealer knows your

engine best and is fully equipped to maintain and repair it.

To ensure the best quality and reliability, use only new genuine Honda

parts or their equivalents for repair and replacement.

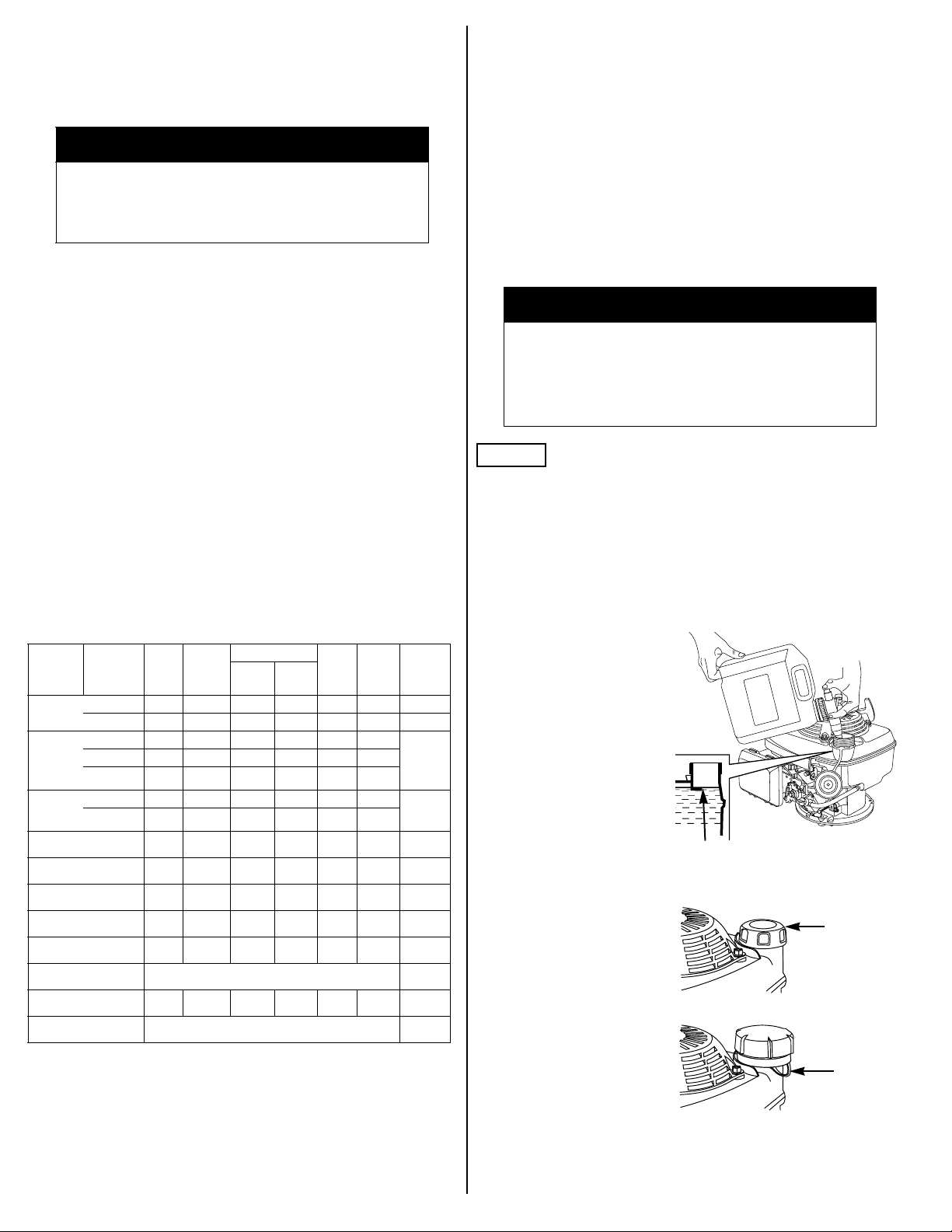

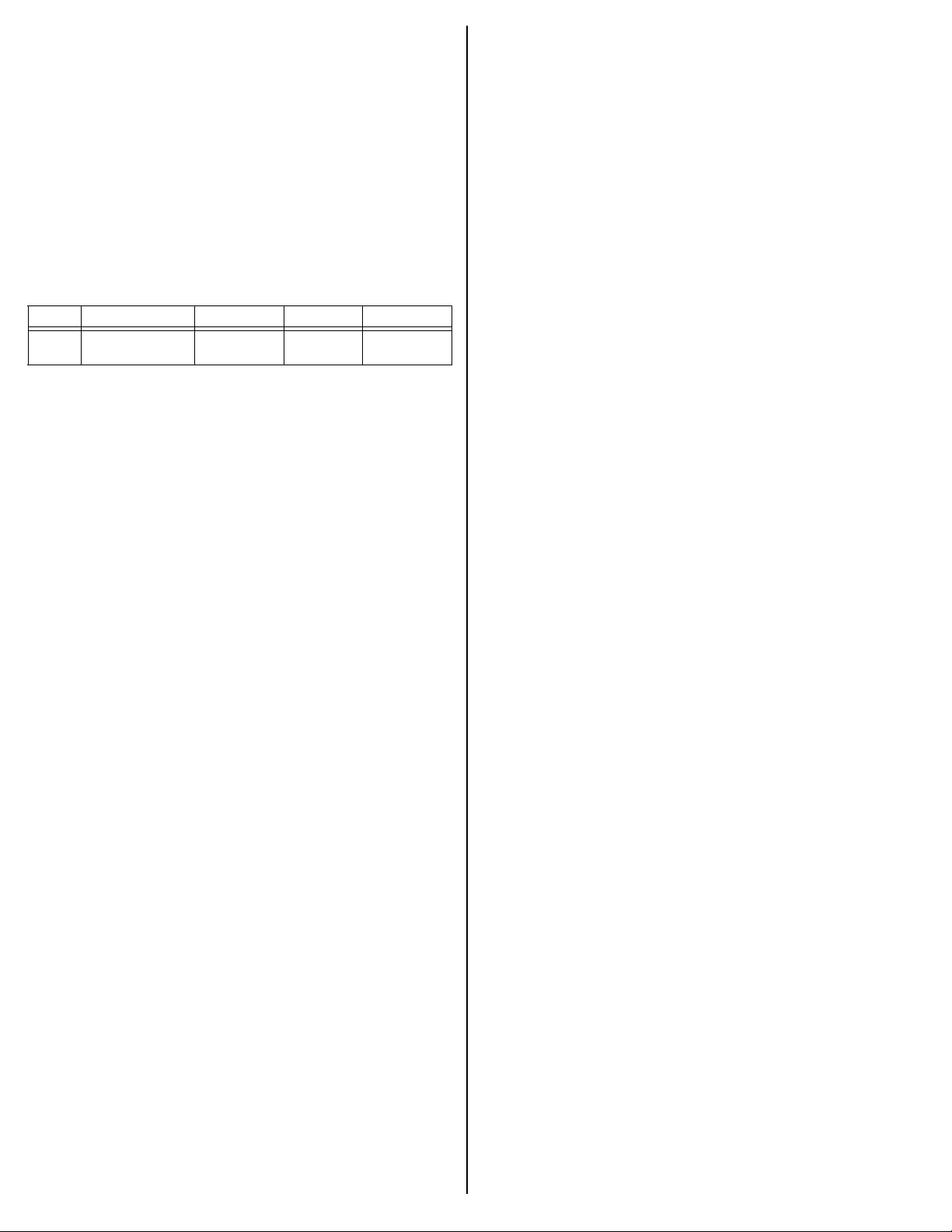

MAINTENANCE SCHEDULE

Item (1) Action Each

Engine oil Check O7

Change O O (3) 7

Air cleaner Check OO7

Clean O (2)

Replace O

Spark plug Check-Adjust O7

Replace O

Blade brake

clutch

Flywheel

brake pad

Spark

arrester

Idle

speed

Fuel tank

and filter

Fuel line Check Every 2 years (4) Shop

Valve

clearance

Combustion

chamber

(1) For commercial use, log hours of operation to determine proper maintenance

(2) Service more frequently when used in dusty areas.

(3) Change engine oil every 25 hours when used under heavy load or in high ambient

(4) These items should be serviced by an authorized Honda servicing dealer, unless

* See your equipment manual or Honda engine shop manual.

Failure to follow this maintenance schedule could result in non-warrantable failures.

Check O

Check O8

Clean O8

Adjust O (4) Shop

Check O (4) Shop

Check-Adjust O (4) Shop

Clean After every 250 hours (4) Shop

intervals.

temperatures.

you have the proper tools and are mechanically proficient. Refer to the Honda shop

manual for service procedures.

Use

or 5

Hrs.

First

Month

or

5 Hrs.

or

25 Hrs.or50 Hrs.

Every Season Every

100

Hrs.

Every

150

Hrs.

(200 Hrs.)

(200 Hrs.)

Page

*

manual

manual

manual

manual

manual

NOTICE

Fuel can damage paint and some types of plastic. Be careful not to

spill fuel when filling your fuel tank. Damage caused by spilled fuel is

not covered under your DISTRIBUTOR’S LIMITED WARRANTY (see

page 13).

Never use stale or contaminated gasoline or oil/gasoline mixture.

Avoid getting dirt or water in the fuel tank.

Move at least 3 meters (10 feet) away from the fueling source and site

before starting the engine.

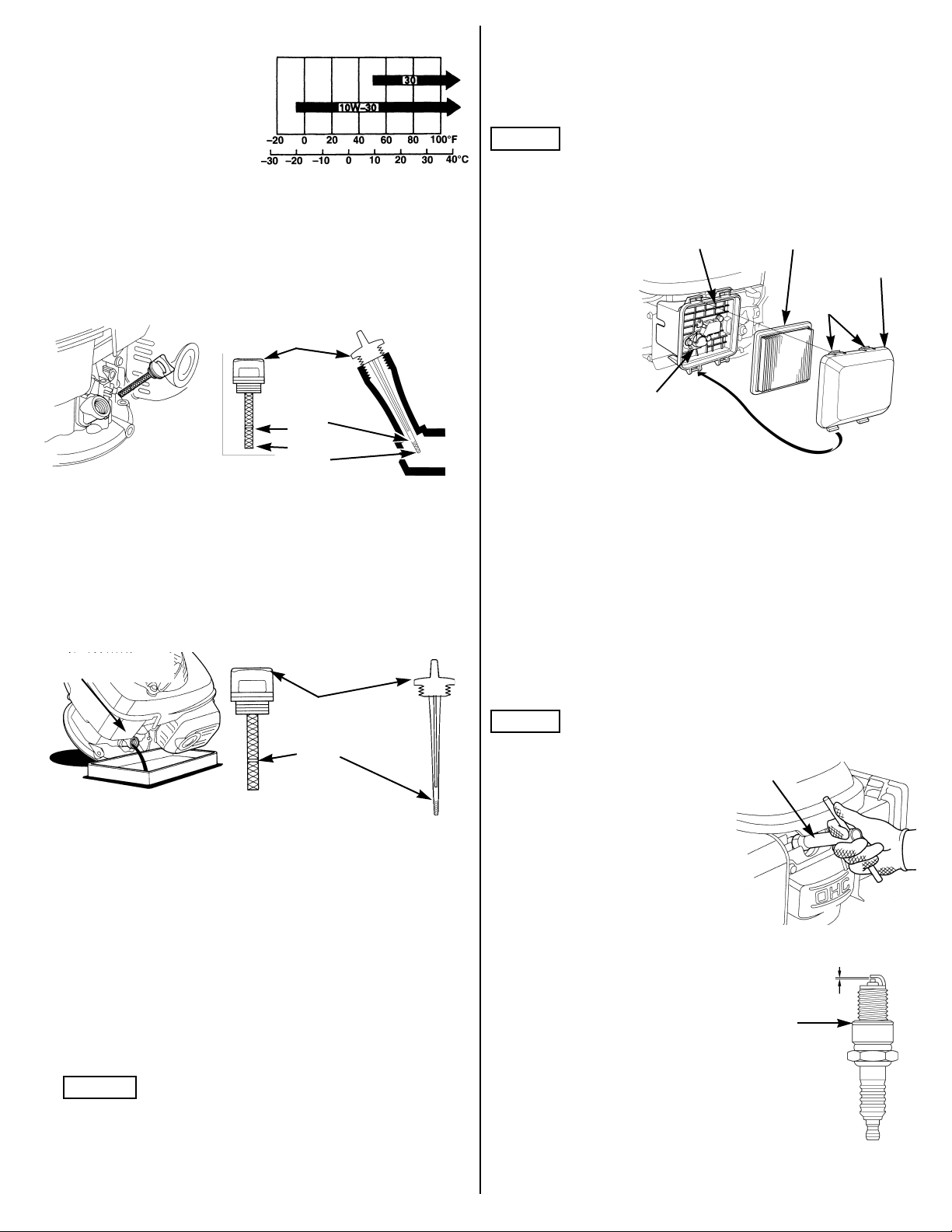

Adding Fuel

1. Remove the fuel tank cap.

2. Add fuel to the bottom of the

fuel level limit in the neck of

the fuel tank. Do not overfill.

Wipe up spilled fuel before

starting the engine.

3. Secure the fuel tank cap.

a. Non-tether type:

Tighten the cap securely.

b. Tether type:

Tighten the cap until it

clicks.

MAXIMUM FUEL LEVEL

FUEL TANK

CAP

TETHER

6

ENGLISH

Page 7

ENGINE OIL

Recommended Oil

Use 4-stroke motor oil that meets

or exceeds the requirements for

API service classification SJ or

later. Always check the API

service label on the oil container

to be sure it includes the letters

SJ or later.

SAE 10W-30 is recommended for general use. Other viscosities

shown in the chart may be used when the average temperature in

your area is within the indicated range.

Oil Level Check

1. Check the oil with the engine stopped and level.

2. Remove the oil filler cap/dipstick and wipe it clean.

OIL FILLER CAP/DIPSTICK

UPPER

LIMIT

LOWER

LIMIT

3. Insert the oil filler cap/dipstick into the oil filler neck as shown, but

do not screw it in, then remove it to check the oil level.

4. If the oil level is near or below the lower limit mark on the dipstick,

remove the oil filler cap/dipstick, and fill with the recommended oil

to the upper limit mark. Do not overfill.

5. Reinstall the oil filler cap/dipstick.

Oil Change

Drain the engine oil when the engine is warm. Warm oil drains quickly

and completely.

OIL FILLER NECK

OIL FILLER

CAP/

DIPSTICK

UPPER

LIMIT

(ELECTRIC

STARTER

TYPES)

(ELECTRIC

STARTER

TYPES)

AIR CLEANER

A dirty air filter will restrict air flow to the carburetor and cause poor

engine performance. Inspect the filter each time the engine is

operated. You will need to clean the filter more frequently if you

operate the engine in very dusty areas.

NOTICE

Operating the engine without a filter, or with a damaged filter, will

allow dirt to enter the engine, causing rapid engine wear. This type of

damage is not covered under your DISTRIBUTOR’S LIMITED

WARRANTY (see page 13).

Inspection

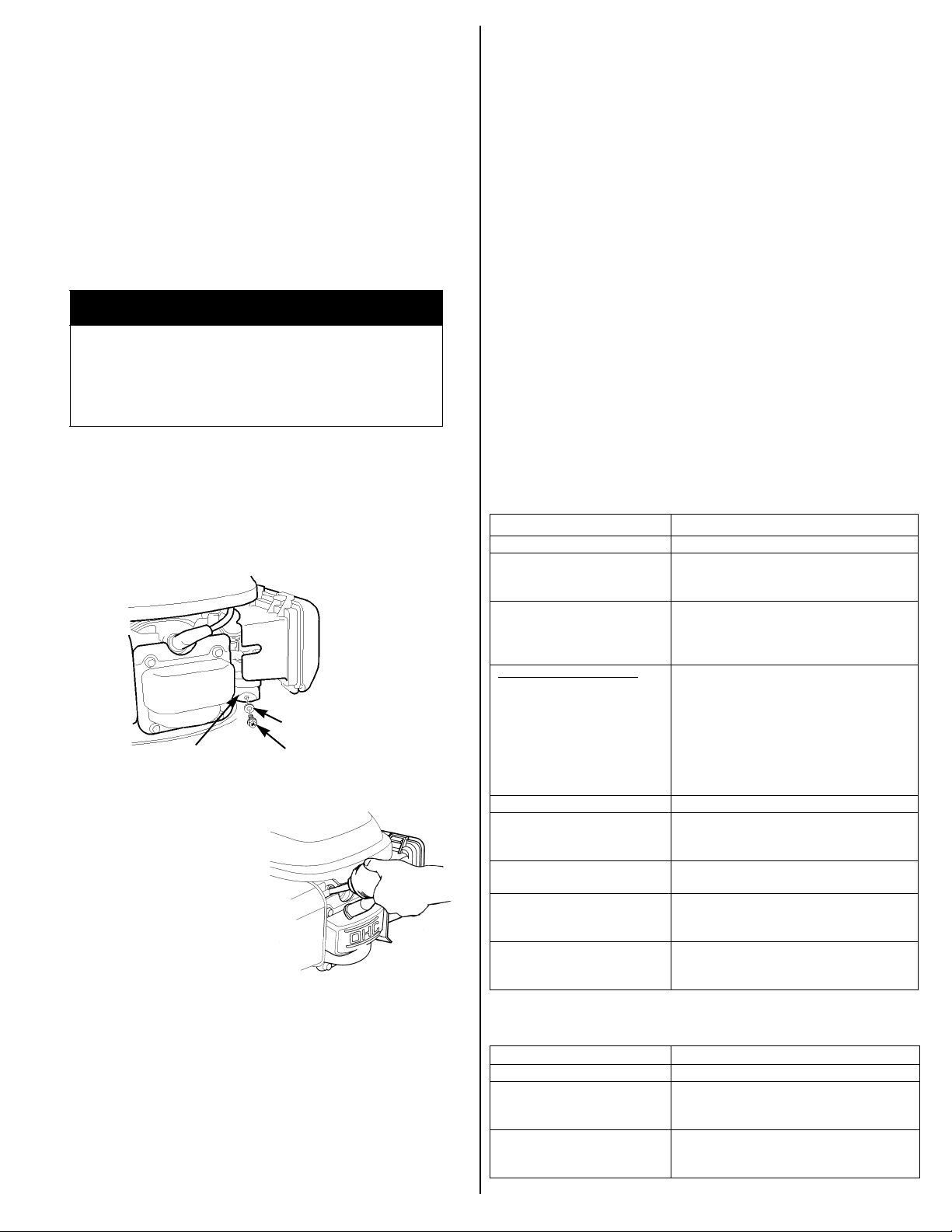

1. Press the latch

tabs on the top of

AIR CLEANER BODY

FILTER

AIR

CLEANER

COVER

the air cleaner

cover and remove

LATCH TABS

the cover. Check

the filter to be sure

it is clean and in

good condition.

2. Reinstall the filter

AIR DUCT

and air cleaner

cover.

Cleaning

1. Tap the filter several times on a hard surface to remove dirt, or

blow compressed air [not exceeding 30 psi (207 kPa, 2.1 kg/cm²)]

through the filter from the clean side that faces the engine. Never

try to brush off dirt. Brushing will force dirt into the fibers.

2. Wipe dirt from the air cleaner body and cover using a moist rag. Be

careful to prevent dirt from entering the air duct that leads to the

carburetor.

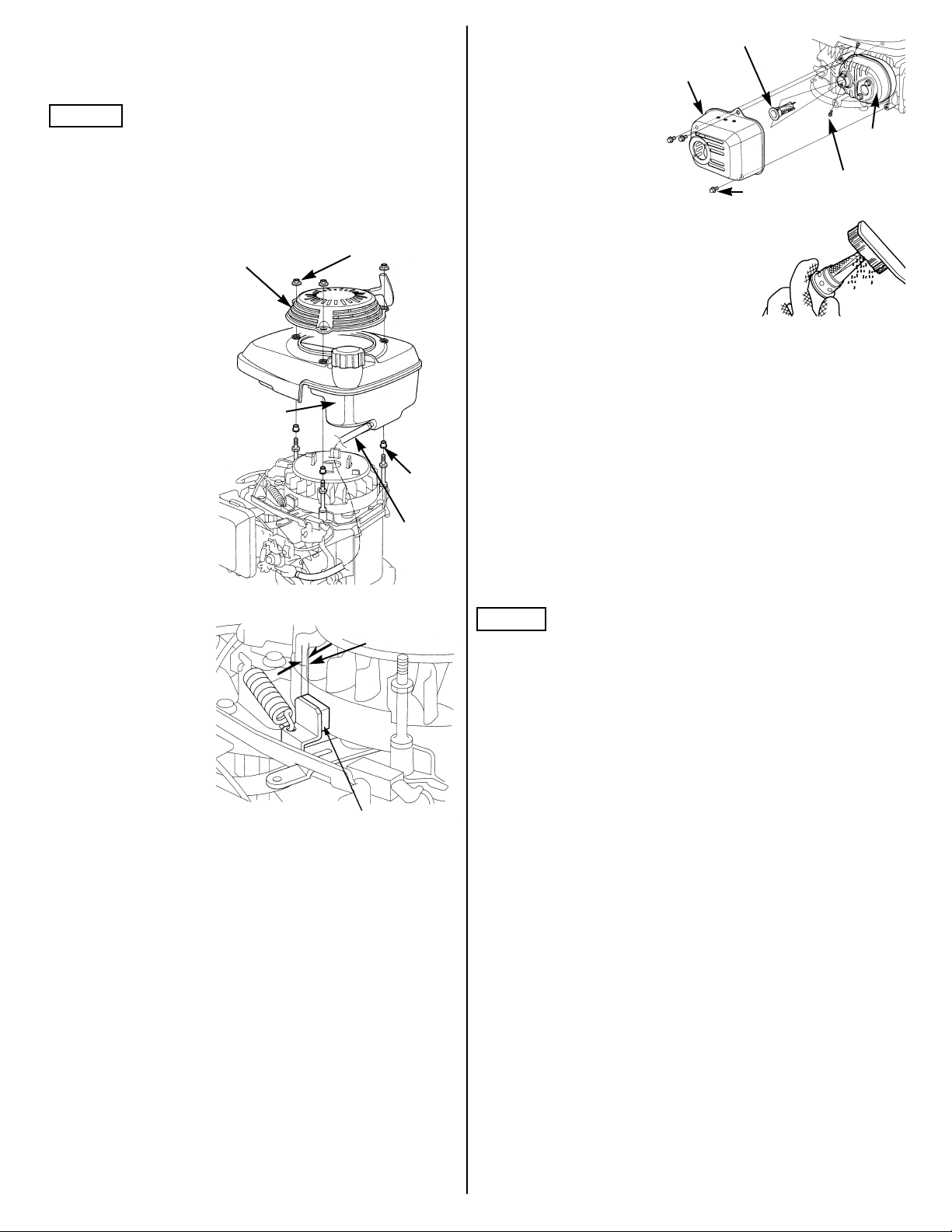

SPARK PLUG

Recommended Spark Plug: NGK BPR6ES

The recommended spark plug is the correct heat range for normal

engine operating temperatures.

NOTICE

Incorrect spark plugs can cause engine damage.

For good performance, the spark

plug must be properly gapped and

free of deposits.

SPARK PLUG

WRENCH

1. Turn the fuel valve to the OFF position to reduce the possibility of

fuel leakage (see TYPE 1 Step 1 on page 2).

2. Place a suitable container next to the engine to catch the used oil.

3. Remove the oil filler cap/dipstick and drain the oil into the container

by tipping the engine toward the oil filler neck.

Please dispose of used motor oil in a manner that is compatible

with the environment. We suggest you take used oil in a sealed

container to your local recycling center or service station for

reclamation. Do not throw it in the trash, pour it on the ground, or

pour it down a drain.

4. With the engine in a level position, fill to the upper limit mark on the

dipstick with the recommended oil (see page 7).

NOTICE

Running the engine with a low oil level can cause engine damage.

5. Reinstall the oil filler cap/dipstick securely.

ENGLISH

1. Disconnect the cap from the

spark plug, and remove any dirt

from the spark plug area.

2. Use a 13/16" spark plug wrench

to remove the spark plug.

3. Inspect the spark plug. Replace it if damaged, badly fouled, if the

sealing washer is in poor condition, or if the electrode is worn.

4. Measure the electrode gap with a

suitable gauge. The correct gap is

0.70 ~ 0.80 mm

(0.028 ~ 0.031 in)

0.70 ~ 0.80 mm (0.028 ~ 0.031 in).

If adjustment is needed, correct the

gap by carefully bending the side

SEALING

WASHER

electrode.

5. Install the spark plug carefully, by

hand, to avoid cross-threading.

6. After the spark plug is seated,

tighten with a spark plug wrench to

compress the washer.

7

Page 8

When installing a new spark plug, tighten 1/2 turn after the spark

plug seats to compress the washer. When reinstalling the original

spark plug, tighten 1/8 ~ 1/4 turn after the spark plug seats to

compress the washer.

NOTICE

Properly tighten the spark plug. A loose spark plug can become

very hot and can damage the engine. Overtightening the spark

plug can damage the threads in the cylinder head.

7. Attach the spark plug cap to the spark plug.

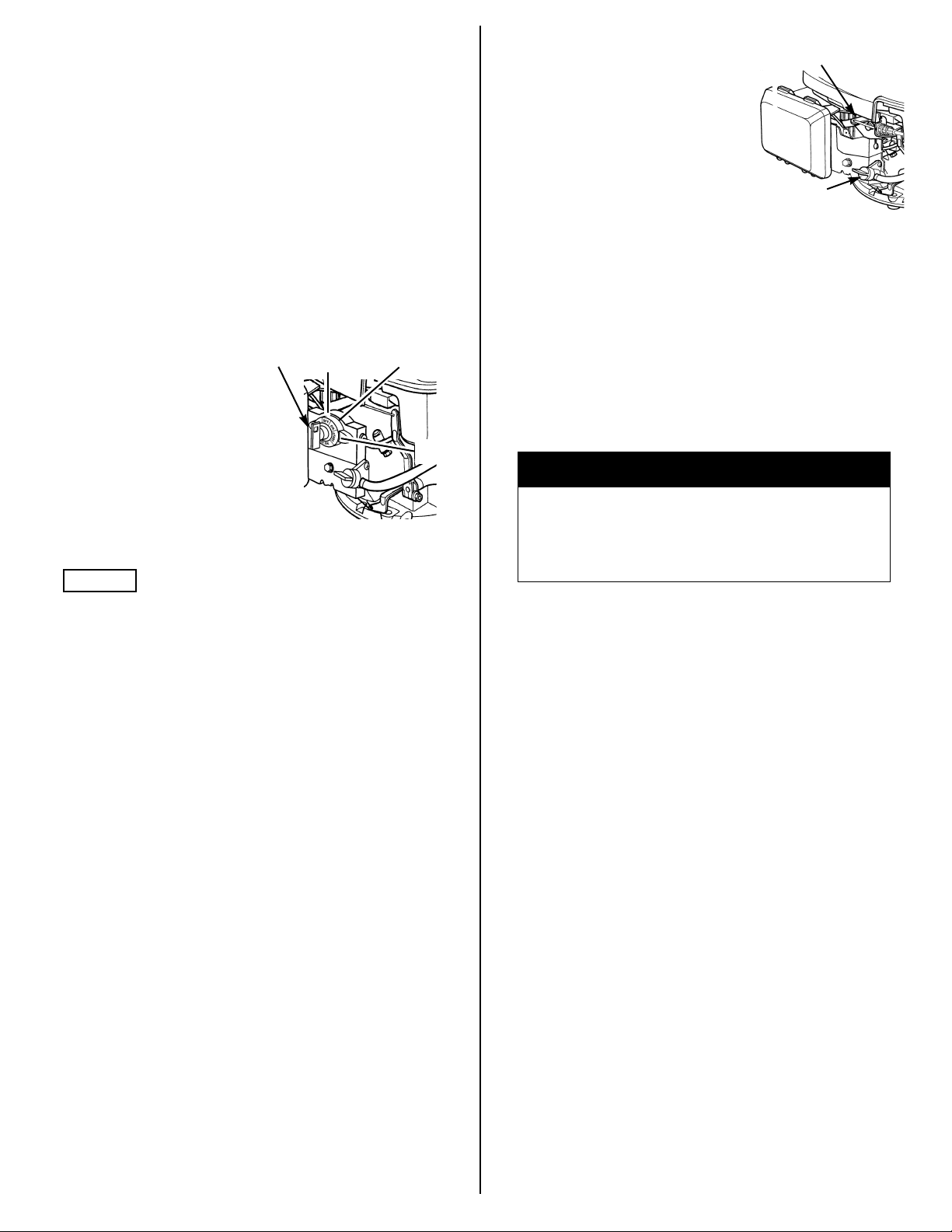

FLYWHEEL BRAKE INSPECTION

1. Remove the three flange

nuts from the recoil

starter, and remove the

recoil starter from the

engine.

2. Remove the fuel tank from

the engine without

disconnecting the fuel

tube. If the fuel tank

contains fuel, keep it level

as you remove it and set it

beside the engine in a

level position.

RECOIL

STARTER

FUEL TANK

FLANGE NUT (3)

SPACER (3)

FUEL

TUBE

Spark Arrester Removal

1. Remove the three 6 mm

bolts from the muffler

SPARK ARRESTER

MUFFLER

PROTECTOR

protector, and remove

the muffler protector.

2. Remove the two special

screws from the spark

MUFFLER

arrester, and remove

the spark arrester from

the muffler.

6 mm BOLT (3)

SPECIAL

SCREW (2)

Spark Arrester Cleaning & Inspection

1. Use a brush to remove carbon deposits

from the spark arrester screen. Be careful

not to damage the screen. Replace the

spark arrester if it has breaks or holes.

2. Install the spark arrester in the reverse

order of removal.

HELPFUL TIPS & SUGGESTIONS

STORING YOUR ENGINE

Storage Preparation

Proper storage preparation is essential for keeping your engine

trouble-free and looking good. The following steps will help to keep

rust and corrosion from impairing your engine’s function and

appearance, and will make the engine easier to start when you use it

again.

Cleaning

If the engine has been running, allow it to cool for at least half an hour

before cleaning. Clean all exterior surfaces, touch up any damaged

paint, and coat other areas that may rust with a light film of oil.

3. Check the brake shoe

thickness. If it is less than

BRAKE SHOE

THICKNESS

3 mm (0.12 in), take the

engine to your authorized

Honda servicing dealer.

4. Install the fuel tank and

recoil starter, and tighten

the three nuts securely.

BRAKE SHOE

SPARK ARRESTER (OPTIONAL EQUIPMENT)

In some areas, it is illegal to operate an engine without a USDA

(United States Department of Agriculture)-qualified spark arrester.

Check local laws and regulations. A USDA-qualified spark arrester is

available from an authorized Honda servicing dealer.

The spark arrester must be serviced every 100 hours to keep it

functioning as designed.

If the engine has been running, the muffler will be hot. Allow it to cool

before servicing the spark arrester.

NOTICE

Using a garden hose or pressure washing equipment can force water

into the air cleaner or muffler opening. Water in the air cleaner will

soak the air filter, and water that passes through the air filter or muffler

can enter the cylinder, causing damage.

Fuel

Gasoline will oxidize and deteriorate in storage. Deteriorated gasoline

will cause hard starting, and it leaves gum deposits that clog the fuel

system. If the gasoline in your engine deteriorates during storage, you

may need to have the carburetor, and other fuel system components,

serviced or replaced.

The length of time that gasoline can be left in your fuel tank and

carburetor without causing functional problems will vary with such

factors as gasoline blend, your storage temperatures, and whether

the fuel tank is partially or completely filled. The air in a partially filled

fuel tank promotes fuel deterioration. Very warm storage

temperatures accelerate fuel deterioration. Fuel problems may occur

within a few months, or even less if the gasoline was not fresh when

you filled the fuel tank.

Fuel system damage or engine performance problems resulting from

neglected storage preparation are not covered under your engine

warranty (see page 13).

You can extend fuel storage life by adding a gasoline stabilizer that is

formulated for that purpose, or you can avoid fuel deterioration

problems by draining the fuel tank and carburetor.

8

ENGLISH

Page 9

ADDING A GASOLINE STABILIZER TO EXTEND FUEL STORAGE LIFE

When adding a gasoline stabilizer, fill the fuel tank with fresh gasoline.

If only partially filled, air in the tank will promote fuel deterioration

during storage. If you keep a container of gasoline for refueling, be

sure that it contains only fresh gasoline.

1. Add gasoline stabilizer following the manufacturer’s instructions.

2. After adding a gasoline stabilizer, run the engine outdoors for

10 minutes to be sure that treated gasoline has replaced the

untreated gasoline in the carburetor.

3. Stop the engine, and turn the fuel valve to the OFF position (see

TYPE 1 Step 1 on page 2).

DRAINING THE FUEL TANK AND CARBURETOR

WARNING

Gasoline is highly flammable and explosive, and you can

be burned or seriously injured when handling fuel.

• Stop engine and keep heat, sparks, and flame away.

• Refuel only outdoors.

• Wipe up spills immediately.

1. Place an approved gasoline container below the carburetor, and

use a funnel to avoid spilling fuel.

2. Remove the drain bolt, then move the fuel valve lever to the ON

position (see TYPE 1 Step 1 on page 2).

3. After all the fuel has drained into the container, reinstall the drain

bolt and washer. Tighten the drain bolt securely.

WASHER

FLOAT BOWL

Engine Oil

1. Change the engine oil

(see page 7).

2. Remove the spark plug

(see page 7).

3. Pour a tablespoon (5 ~ 10 cc) of

clean engine oil into the

cylinder.

4. Pull the starter grip several

times to distribute the oil.

5. Reinstall the spark plug.

Storage Precautions

If your engine will be stored with gasoline in the fuel tank and

carburetor, it is important to reduce the hazard of gasoline vapor

ignition. Select a well-ventilated storage area away from any

appliance that operates with a flame, such as a furnace, water heater,

or clothes dryer. Also avoid any area with a spark-producing electric

motor, or where power tools are operated.

If possible, avoid storage areas with high humidity, because that

promotes rust and corrosion.

DRAIN BOLT

If there is gasoline in the fuel tank, leave the fuel valve in the OFF

position (see TYPE 1 Step 1 on page 2).

Keep the engine level in storage. Tilting can cause fuel or oil leakage.

With the engine and exhaust system cool, cover the engine to keep

out dust. A hot engine and exhaust system can ignite or melt some

materials. Do not use sheet plastic as a dust cover. A nonporous

cover will trap moisture around the engine, promoting rust and

corrosion.

Removal From Storage

Check your engine as described in the BEFORE OPERATION

CHECKS section of this manual (see page 2).

If the fuel was drained during storage preparation, fill the tank with

fresh gasoline. If you keep a container of gasoline for refueling, be

sure it contains only fresh gasoline. Gasoline oxidizes and

deteriorates over time, causing hard starting.

If the cylinder was coated with oil during storage preparation, the

engine will smoke briefly at startup. This is normal.

TRANSPORTING

Keep the engine level when transporting to reduce the possibility of

fuel leakage. Turn the fuel valve to the OFF position (see TYPE 1

Step 1 on page 2).

TAKING CARE OF UNEXPECTED PROBLEMS

ENGINE WILL NOT START

Possible Cause Correction

Fuel valve OFF Move lever to ON.

Choke OFF Move the choke/throttle lever, choke rod, or

choke lever to the ON position unless the

engine is warm.

Ignition switch or engine stop

switch OFF

Electric Starter types only

Battery under-charged.

Battery cables are loose or

corroded.

Fuse is blown.

If starter motor operates but

the engine does not start, go to

Out of fuel (below).

Out of fuel Refuel.

Bad fuel; engine stored without

treating or draining gasoline, or

refueled with bad gasoline

Spark plug faulty, fouled, or

improperly gapped

Spark plug wet with fuel

(flooded engine)

Fuel filter clogged, carburetor

malfunction, ignition

malfunction, valves stuck, etc.

ENGINE LACKS POWER

Possible Cause Correction

Air filter clogged Clean or replace the air filter (p. 7).

Bad fuel; engine stored without

treating or draining gasoline, or

refueled with bad gasoline

Fuel filter clogged, carburetor

malfunction, ignition

malfunction, valves stuck, etc.

Move the flywheel brake lever to the RUN

position. (TYPES 2 & 6: Throttle lever to

FAST position. TYPE 5: Engine stop switch

to ON.)

Refer to the equipment manufacturer’s

instructions for servicing the battery and

related components.

Drain the fuel tank and carburetor (p. 9).

Refuel with fresh gasoline.

Adjust or replace the spark plug (p. 7).

Dry and reinstall spark plug. Start engine

with choke/throttle lever in FAST position.

(TYPES 4 & 5: Choke OFF position).

Replace or repair faulty components as

necessary.

Drain the fuel tank and carburetor (p. 9).

Refuel with fresh gasoline.

Replace or repair faulty components as

necessary.

ENGLISH

9

Page 10

TECHNICAL INFORMATION

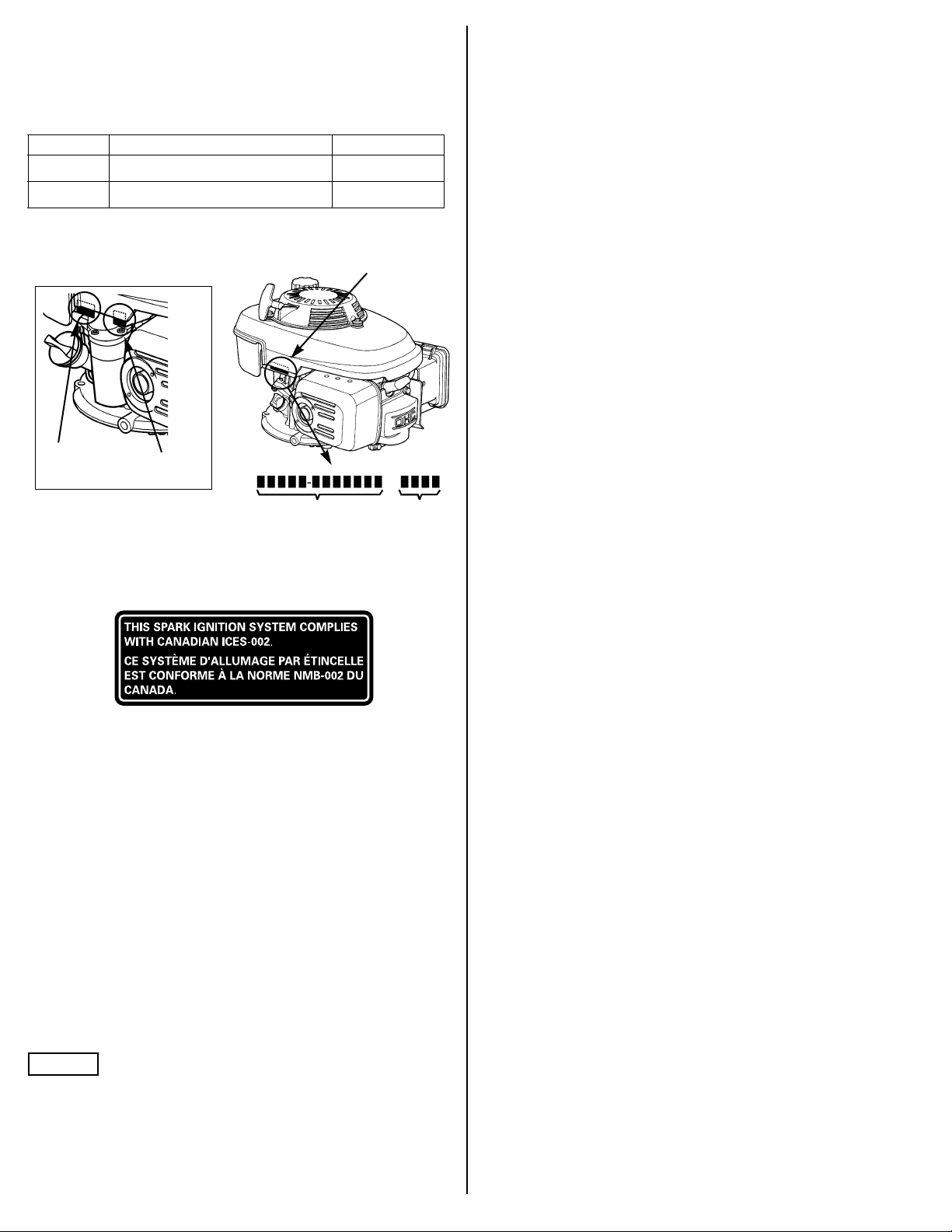

SERIAL NUMBER AND TYPE LOCATION

Record the engine serial number and type in the space below. You will

need this information when ordering parts and when making technical

or warranty inquiries.

MODEL SERIAL NUMBER ENGINE TYPE

GCV160

GCV190

Date purchased: ____________________

ELECTRIC STARTER TYPES

SERIAL

NUMBER

LOCATION

RADIO FREQUENCY INTERFERENCE LABEL (CANADA)

This engine complies with Canadian radio frequency interference

regulations, ICES-002.

CARBURETOR MODIFICATIONS FOR HIGH ALTITUDE OPERATION

At high altitude, the standard carburetor air-fuel mixture will be too

rich. Performance will decrease, and fuel consumption will increase. A

very rich mixture will also foul the spark plug and cause hard starting.

Operation at an altitude that differs from that at which this engine was

certified, for extended periods of time, may increase emissions.

High altitude performance can be improved by specific modifications

to the carburetor. If you always operate your engine at altitudes above

1,500 meters (5,000 feet), have your servicing dealer perform this

carburetor modification. This engine, when operated at high altitude

with the carburetor modifications for high altitude use, will meet each

emission standard throughout its useful life.

Even with carburetor modification, engine horsepower will decrease

about 3.5% for each 300-meter (1,000-foot) increase in altitude. The

effect of altitude on horsepower will be greater than this if no

carburetor modification is made.

NOTICE

When the carburetor has been modified for high altitude operation,

the air-fuel mixture will be too lean for low altitude use. Operation at

altitudes below 1,500 meters (5,000 feet) with a modified carburetor

may cause the engine to overheat and result in serious engine

damage. For use at low altitudes, have your servicing dealer return

the carburetor to original factory specifications.

__ __ __ __ __– __ __ __ __ __ __ __ __ __ __ __

__ __ __ __ __– __ __ __ __ __ __ __ __ __ __ __

SERIAL NUMBER AND

TYPE LOCATION

TYPE

LOCATION

SERIAL NUMBER

TYPE

EMISSION CONTROL SYSTEM INFORMATION

Source of Emissions

The combustion process produces carbon monoxide, oxides of

nitrogen, and hydrocarbons. Control of hydrocarbons and oxides of

nitrogen is very important because, under certain conditions, they

react to form photochemical smog when subjected to sunlight. Carbon

monoxide does not react in the same way, but it is toxic.

Honda utilizes appropriate air/fuel ratios and other emissions control

systems to reduce the emissions of carbon monoxide, oxides of

nitrogen, and hydrocarbons. Additionally, Honda fuel systems utilize

components and control technologies to reduce evaporative

emissions.

The U.S., California Clean Air Act, and Environment Canada

EPA, California, and Canadian regulations require all manufacturers

to furnish written instructions describing the operation and

maintenance of emission control systems.

The following instructions and procedures must be followed in order to

keep the emissions from your Honda engine within the emission

standards.

Tampering and Altering

Tampering with or altering the emission control system may increase

emissions beyond the legal limit. Among those acts that constitute

tampering are:

• Removal or alteration of any part of the intake, fuel, or exhaust

systems.

• Altering or defeating the governor linkage or speed-adjusting

mechanism to cause the engine to operate outside its design

parameters.

Problems That May Affect Emissions

If you are aware of any of the following symptoms, have your engine

inspected and repaired by your servicing dealer.

• Hard starting or stalling after starting.

• Rough idle.

• Misfiring or backfiring under load.

• Afterburning (backfiring).

• Black exhaust smoke or high fuel consumption.

Replacement Parts

The emission control systems on your Honda engine were designed,

built, and certified to conform with EPA, California, and Canadian

emission regulations. We recommend the use of genuine Honda parts

whenever you have maintenance done. These original-design

replacement parts are manufactured to the same standards as the

original parts, so you can be confident of their performance. The use

of replacement parts that are not of the original design and quality

may impair the effectiveness of your emission control system.

A manufacturer of an aftermarket part assumes the responsibility that

the part will not adversely affect emission performance. The

manufacturer or rebuilder of the part must certify that use of the part

will not result in a failure of the engine to comply with emission

regulations.

Maintenance

Follow the maintenance schedule on page 6. Remember that this

schedule is based on the assumption that your machine will be used

for its designed purpose. Sustained high-load or high-temperature

operation, or use in unusually wet or dusty conditions, will require

more frequent service.

10

ENGLISH

Page 11

Air Index

An Air Index Information hang tag/label is applied to engines certified

to an emission durability time period in accordance with the

requirements of the California Air Resources Board.

The bar graph is intended to provide you, our customer, the ability to

compare the emissions performance of available engines. The lower

the Air Index, the less pollution.

The durability description is intended to provide you with information

relating the engine’s emission durability period. The descriptive term

indicates the useful life period for the engine’s emission control

system. See your EMISSION CONTROL SYSTEM WARRANTY

(page 14) for additional information.

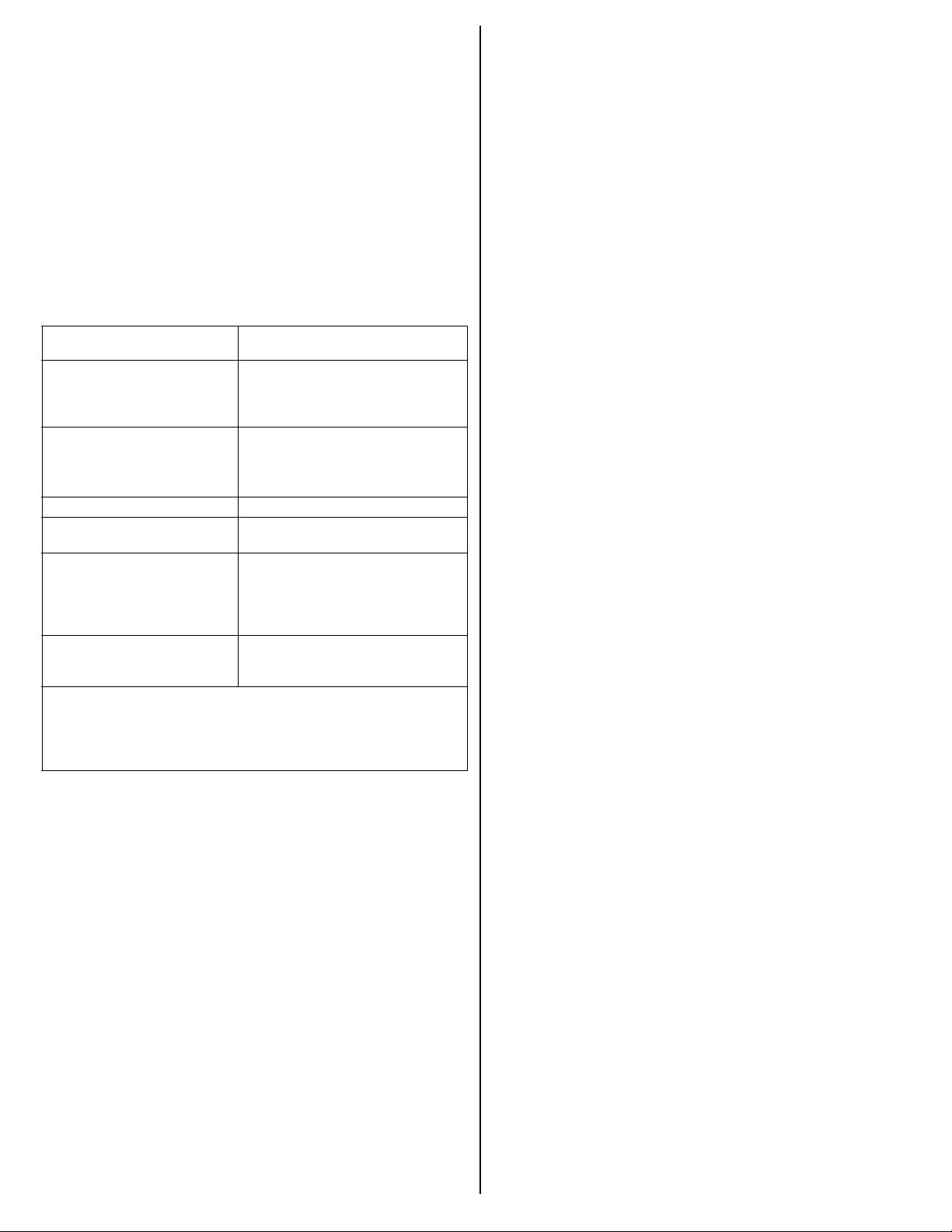

Descriptive Term Applicable to Emission

Durability Period

Moderate 50 hours (0–80 cc inclusive)

125 hours (greater than 80 cc)

Intermediate 125 hours (0–80 cc inclusive)

250 hours (greater than 80 cc)

Extended 300 hours (0–80 cc inclusive)

500 hours (greater than 80 cc)

1000 hours (225 cc and greater)

The Air Index Information hang tag/label must remain on the engine

until it is sold. Remove the hang tag before operating the engine.

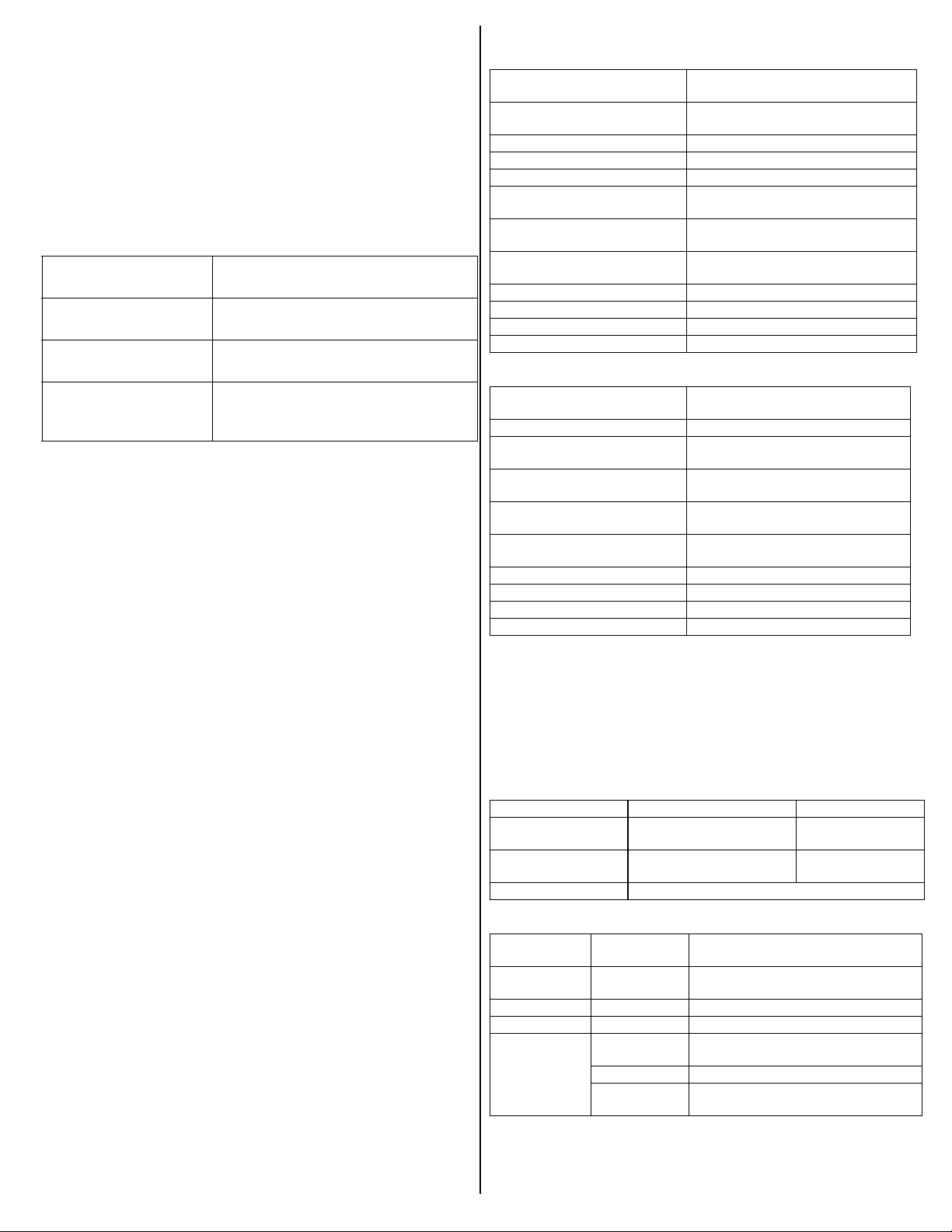

Specifications

GCV160

Length x Width x Height

(without electric start)

Length x Width x Height

(with electric start)

Dry weight (without electric start) 9.8 kg (22 lb)

Dry weight (with electric start) 11.6 kg (26 lb)

Engine type 4-stroke, overhead cam, single cylinder

Displacement

[Bore x Stroke]

Net power *

(in accordance with SAE J1349)

Max. net torque

(in accordance with SAE J1349)

Fuel tank capacity 0.93 (0.25 gal)

Cooling system Forced air

Ignition system Transistorized magneto

PTO shaft rotation Counterclockwise

367 x 331 x 360 mm

(14.4 x 13.0 x 14.2 in)

367 x 354 x 360 mm

(14.4 x 13.9 x 14.2 in)

3

(9.8 cu in)

161 cm

[64 x 50 mm (2.5 x 2.0 in)]

3.3 kW (4.4 hp) at 3,600 rpm

9.4 N•m (6.9 ft-lb) at 2,500 rpm

GCV190

Length x Width x Height 367 x 331 x 368 mm

Dry weight 12.3 kg (27.1 lb)

Engine type 4-stroke, overhead cam, single

Displacement

[Bore x Stroke]

Net power *

(in accordance with SAE J1349)

Max. net torque

(in accordance with SAE J1349)

Fuel tank capacity 0.93 (0.25 gal)

Cooling system Forced air

Ignition system Transistorized magneto

PTO shaft rotation Counterclockwise

* The power rating of the engine indicated in this document is the net

power output tested on a production engine for the engine model and

measured in accordance with SAE J1349 at 3600 rpm. Mass production

engines may vary from this value. Actual power output for the engine

installed in the final machine will vary depending on numerous factors,

including the operating speed of the engine in application, environmental

conditions, maintenance, and other variables.

(14.4 x 13.0 x 14.5 in)

cylinder

3

187 cm

[69 x 50 mm (2.7 x 2.0 in)]

3.8 kW (5.1 hp) at 3,600 rpm

11.3 N•m (8.3 ft-lb) at 2,500 rpm

(11.4 cu in)

Tuneup

ITEM SPECIFICATION MAINTENANCE

Spark plug gap 0.7 ~ 0.8 mm

(0.028 ~ 0.031 in)

Valve clearance (cold) IN: 0.15 ± 0.04 mm

EX: 0.20 ± 0.04 mm

Other specifications No other adjustments needed.

Refer to page 7.

See your authorized

Honda dealer.

Quick Reference Information

Fuel Type Unleaded gasoline with a pump octane

rating of 86 or higher (page 6).

Engine Oil Type SAE 10W-30, API SJ for general use.

Refer to page 7.

Carburetor Idle Speed 1,400 ± 150 rpm

Spark plug Type BPR6ES (NGK)

Maintenance Before each

use

First 5 hours Change engine oil. Refer to page 7.

Subsequent Refer to the maintenance schedule on

ENGLISH

Check engine oil level. Refer to page 7.

Check air filter. Refer to page 7.

page 6.

11

Page 12

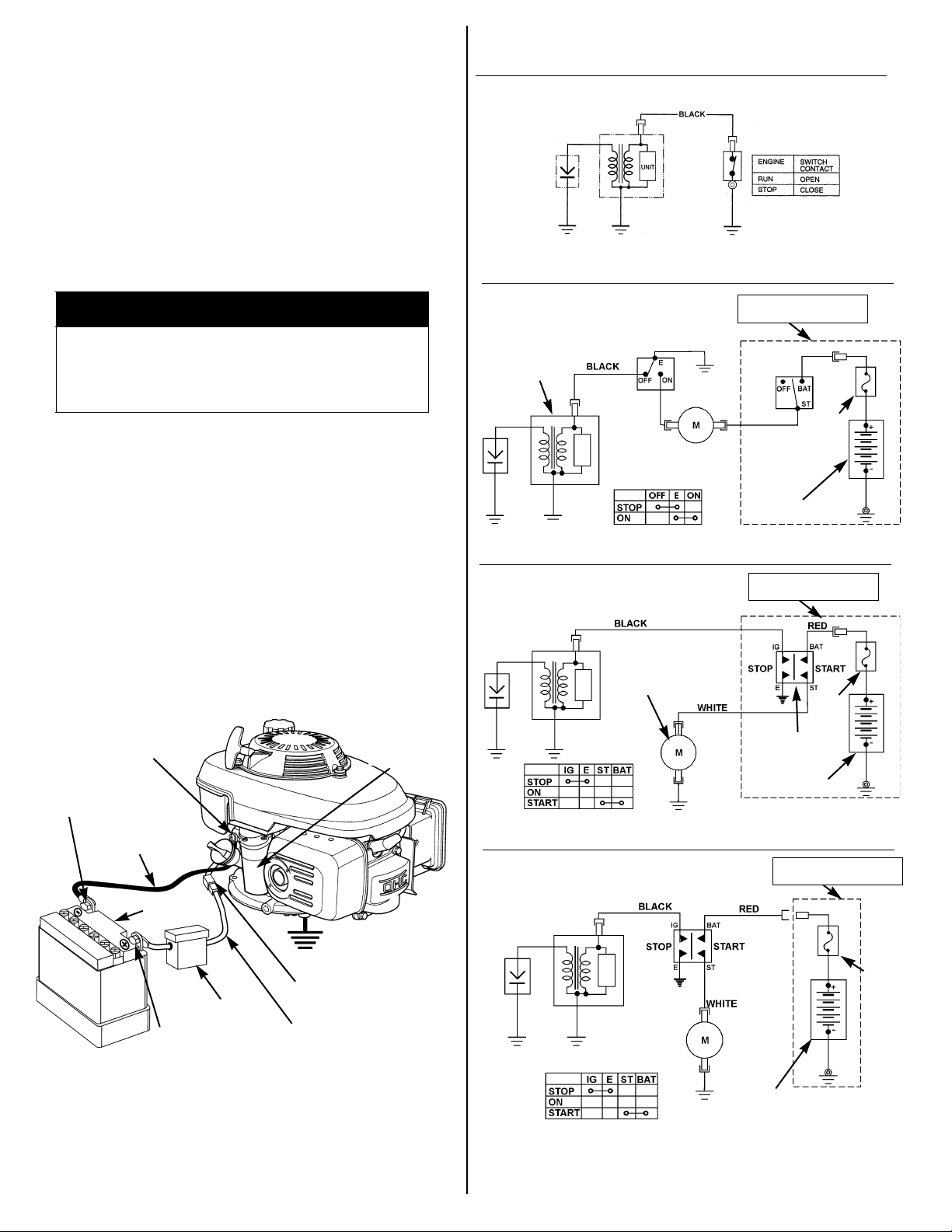

Battery Connections

Use the following materials to connect a 12-volt battery to the starter

on TYPE 7 units (electric start with engine-mounted starter switch/

manual choke control/preset throttle):

• Battery – 12-volt lead acid battery with a recommended ampere-hr

rating of 3 Ah or a 14.4-volt NiCd battery with a recommended

ampere-hr rating of 1.7 Ah.

• Wire – 12-gauge (minimum) wire with a maximum length of 10 ft

(3 meters).

• Fuse – 40-ampere blade type fuse.

• Termin al – Delphi 56 series male connector and terminal to

connect to the starter motor.

Coat the battery terminals and cable ends with dielectric grease. Be

careful not to connect the battery in reverse polarity.

WARNING

A battery can explode if you do not follow the correct

procedure, seriously injuring anyone nearby.

Keep all sparks, open flames, and smoking materials away

from the battery.

WARNING: Battery posts, terminals and related accessories contain

lead and lead compounds. Wash hands after handling.

1. Connect the battery positive (+) cable using the appropriate

connector and insulator to the supplied starter connector.

2. Connect the battery negative (-) cable to an engine mounting bolt,

frame bolt, or the provided ground position on the starter motor

(requires 5 x 8 mm screw).

3. Connect the battery positive (+) cable to the battery positive (+)

terminal as shown.

4. Connect the battery negative (-) cable to the battery negative (-)

terminal as shown.

The following diagram only shows connections for TYPE 7 units

(electric start with engine-mounted starter switch/manual choke

control/preset throttle). Connections are different for the other

electric starter types (TYPES 4 and 6).

STARTER GROUND (-)

CONNECTION

BATTERY

NEGATIVE (-)

TERMINAL

BATTERY

NEGATIVE (-)

CABLE

STARTER

MOTOR

Wiring Diagrams

RECOIL STARTER

(All Types)

SPARK

PLUG

IGNITION

COIL

ELECTRIC STARTER

(TYPE 4 with Flywheel Brake)

ENGINE STOP

SWITCH

IGNITION

COIL

SPARK

PLUG

STARTER

MOTOR

ELECTRIC STARTER

(TYPE 6 with Blade Brake Clutch)

SPARK

PLUG

STARTER

MOTOR

IGNITION

COIL

ELECTRIC STARTER

(TYPE 7 with Starter Switch on the engine)

ENGINE STOP

SWITCH

Supplied by equipment

manufacturer.

STARTER

SWITCH

FUSE

(40A)

BATTERY

Supplied by equipment

manufacturer.

FUSE

(40A)

STARTER

SWITCH

BATTERY

Supplied by equipment

manufacturer.

BATTERY

STARTER MOTOR

POSITIVE (+) CONNECTOR

(from starter switch)

40 AMP FUSE

BATTERY POSITIVE

(+) TERMINAL

BATTERY POSITIVE (+)

CABLE

This engine is not equipped with a charging system to keep the

battery charged during engine operation. The battery will loose

charge during starter motor operation only. There is no drain on the

battery once the engine is running.

The battery must be charged by an external battery charging system.

Refer to the equipment manufacturer’s instructions or the battery

manufacturer for specific external battery charging recommendations.

12

ENGLISH

SPARK

PLUG

IGNITION

COIL

STARTER SWITCH

STARTER

SWITCH

STARTER

MOTOR

BATTERY

FUSE

(40A)

Page 13

CONSUMER INFORMATION

HONDA PUBLICATIONS

Shop

Manual

Parts

Catalog

DISTRIBUTOR/DEALER LOCATOR INFORMATION

United States, Puerto Rico, and U.S. Virgin Islands:

Call (800) 426-7701

or visit our website: www.honda-engines.com

Canada:

Call (888) 9HONDA9

or visit our website: www.honda.ca

CUSTOMER SERVICE INFORMATION

United States, Puerto Rico, and U.S. Virgin Islands:

Servicing dealership personnel are trained professionals. They should

be able to answer any question you may have. If you encounter a

problem that your dealer does not solve to your satisfaction, please

discuss it with the dealership's management. The Service Manager,

General Manager, or Owner can help. Almost all problems are solved

in this way.

If you are dissatisfied with the decision made by the dealership's

management, contact the Honda Regional Engine Distributor for your

area. You can find their name, address, and phone number using the

dealer/distributor locator on our website at www.honda-engines.com

or by calling 1-800-426-7701.

If you are still dissatisfied after speaking with the Regional Engine

Distributor, you may contact the Honda Power Equipment Customer

Relations Office for your area. You can write to:

American Honda Motor Co., Inc.

Power Equipment Division

Customer Relations Office

4900 Marconi Drive

Alpharetta, GA 30005-8847

Telephone: (770) 497-6400, 8:30 am - 8:00 pm ET

Honda Canada, Inc.

715 Milner Avenue

Toronto, ON

M1B 2K8

Telephone: (888) 9HONDA9 Toll free

Facsimile: (877) 939-0909 Toll free

This manual covers complete maintenance and overhaul

procedures. It is intended to be used by a skilled technician.

Available through your Honda dealer or through Helm Inc. at

1 888-292-5395 or visit www.Honda-engines.com > product

manuals.

This manual provides complete, illustrated parts lists. Available

through your Honda dealer.

(888) 946-6329 Toll free

(416) 284-8110 Local Toronto dialing area

(416) 287-4776 Local Toronto dialing area

DISTRIBUTOR’S LIMITED WARRANTY

The applicable warranty is the warranty policy in effect in the country

where the warranty service is provided.

Distributor’s Limited Warranty

United States, Puerto Rico, or the U.S. Virgin Islands

PRODUCTS COVERED BY THIS

PRODUCT APPLICATIONS NONCOMMERCIAL/

GCV Series Engines All 24 months 3 months*

* Honda GCV general purpose engines are not covered by this warranty when installed on

concession type vehicles.

To Qualify for this Warranty:

The Honda general purpose engine must be purchased from a Honda general purpose

engine dealer or distributor authorized to sell that product in the United States, Puerto

Rico, or the U.S. Virgin Islands. This limited warranty applies to first retail purchaser and

each subsequent owner during the applicable warranty time period.

What American Honda Will Repair or Replace Under Warranty:

American Honda will repair or replace, at its option, any part that is proven to be defective

in material or workmanship under normal use during the applicable warranty time period.

Warranty repairs and replacements will be made without charge for parts or labor.

Anything replaced under warranty becomes the property of American Honda Motor

Company, Inc. All parts replaced under warranty will be considered as part of the original

product and any warranty on those parts will expire coincident with the original product

warranty.

To Obtain Warranty Service:

You must take your Honda general purpose engine, or the equipment in which it is

installed, together with proof of original retail purchase date, at your expense, to a Honda

engine dealer or distributor authorized to sell that product in the United States, Puerto

Rico, or the U.S. Virgin Islands, during their normal business hours. Many Honda engine

dealers and distributors are listed in the yellow pages of the telephone directory under

gasoline engines, lawn & garden equipment & supplies, etc.

If you are unable to obtain warranty service, or are dissatisfied with the warranty service

you receive, take the following steps: First contact the owner of the dealership or

distributor involved. Normally this should resolve the problem. However, if you are

dissatisfied with the decision made by the dealership's management, contact the Honda

Regional Engine Distributor for your area. You can find their name, address, and phone

number using the dealer/distributor locator on our website at (www.honda-engines.com)

or by calling 1-800-426-7701. If you are still dissatisfied after speaking with the Regional

Engine Distributor, you may contact the Honda Power Equipment Customer Relations

Department of American Honda Motor Co., Inc. Refer to page 13 for contact information.

Exclusions:

This warranty does not extend to parts affected or damaged by the product in which the

engine is installed, or by accident and/or collision, misuse, neglect, parts worn beyond

service limits due to normal wear/normal service life, parts affected or damaged by the

conversion to or use of fuel other than the fuel(s) which the engine is originally

manufactured to use, poor operation related to fuel contamination or fuel quality, parts

damaged by fuel contamination, the incorporation of, or use of, unsuitable attachments or

parts, the unauthorized alteration of any part or any causes other than defects in material

or workmanship of the engine. Use of the Honda general purpose engine for racing or

competition will void this warranty.

Disclaimer of Consequential Damage and Limitation of Implied

Warranties:

American Honda disclaims any responsibility for loss of time or use of the engine, or the

equipment in which the engine is installed, transportation, commercial loss, or any other

incidental or consequential damage. Any implied warranties are limited to the duration of

this written limited warranty. Some states do not allow limitations on how long an implied

warranty lasts and/or do not allow the exclusion or limitation of incidental or consequential

damages, so the above exclusions and limitations may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

WARRANTY:

LENGTH OF WARRANTY:

(FROM DATE OF ORIGINAL

PURCHASE)

NONRENTAL

COMMERCIAL/

RENTAL

When you write or call, please provide this information:

• Equipment manufacturer’s name and model number that the

engine is mounted on

• Engine model, serial number, and type (see page 10)

• Name of dealer who sold the engine to you

• Name, address, and contact person of the dealer who services

your engine

• Date of purchase

• Your name, address and telephone number

• A detailed description of the problem

ENGLISH

13

Page 14

Distributor’s Limited Warranty

Canada

Honda Canada Inc., 715 Milner Avenue, Toronto, Ontario for and on behalf of Honda

Motor Co. Ltd., Tokyo, Japan, gives the following written warranty on each new General

Purpose Engine manufactured by Honda Motor Co. Ltd., Japan, distributed in Canada by

Honda Canada Inc. and sold as part of the original equipment of machinery or equipment

when such machinery or equipment is manufactured in Canada. Whenever used herein,

the word “Honda” refers to Honda Canada Inc. and/or Honda Motor Co. Ltd. as

appropriate from the context.

Honda warrants that each new Honda General Purpose Engine will be free, under normal

use and maintenance, from any defects in material or workmanship for the relevant

warranty period set forth below. If any defects should be found in a Honda General

Purpose Engine within the relevant warranty period, necessary repairs and replacements

with a new part or the Honda equivalent shall be made at no cost to the consumer for

parts and labour (except for labour charges due to the presence of an attachment), when

Honda acknowledges that such defects are attributable to faulty material or workmanship

at the time of manufacture.

Warranty period

Warranty coverage commences from the original date of sale or when the unit is first put

into use as a demonstrator.

MODEL NON-COMMERCIAL COMMERCIAL RENTAL CONCESSION

GCV160

GCV190

NOTE: CONCESSION USE REFERS TO GO KARTS ETC.

This Warranty covers:

a) Any Honda General Purpose Engine purchased from a Honda general purpose

engine dealer or distributor authorized to sell that product in Canada.

b) Any factory installed part (except normal maintenance parts referred to in “THIS

WARRANTY DOES NOT COVER”); and

c) Any General Purpose Engine on which required maintenance services have been

performed as prescribed in the Owner's Manual.

This warranty does not cover:

a) Any repairs required as a result of collision, accident, striking any object, racing,

misuse or lack of required maintenance.

b) Any repairs required as a result of any attachments, parts or devices installed by or

repairs done by a party other than the Original Equipment Manufacturer or an

authorized Honda Power Products dealer.

c) Any Honda General Purpose Engine modified, altered, disassembled or remodeled.

d) Normal maintenance services, including tightening of nuts, bolts and fittings and

engine tune-up and the replacement of parts made in connection with normal

maintenance services including filters, spark plugs and wires, fuses, belts, lubricants

and other expendables susceptible to natural wear.

The owner’s obligation

In order to maintain the validity of this DISTRIBUTOR'S LIMITED WARRANTY, the

required maintenance services as set forth in the Owner's Manual must be performed at

the proper intervals and detailed receipts and records retained as proof.

To obtain warranty service

You must take your Honda General Purpose Engine, at your expense, during normal

service hours, to the authorized Honda Power Products dealer or the dealer designated

by the manufacturer of the machinery or equipment powered by the Honda engine. If you

are unable to obtain or are dissatisfied with the warranty service you receive, first contact

the owner of the dealership involved; this should resolve the problem. If you require

further assistance, contact Honda Canada Inc., at the address shown under Customer

Service Information (page 13).

Replacement parts warranty

New genuine Honda replacement parts sold to a consumer or installed by an authorized

Honda power equipment dealer which are not covered by the DISTRIBUTOR'S

WARRANTY are warranted for a period of one year from date of purchase for normal use,

or 3 months for rental or concession use provided, however, that this Replacement Parts

Warranty does not apply to any replacement parts modified, used with, or installed on a

power product for which the replacement parts were not intended. Electrical components

that are not installed by the dealer (sold over the counter) are not covered by warranty.

Entire written warranty

This DISTRIBUTOR'S WARRANTY is the only and the entire written warranty given by

Honda for Honda General Purpose Engines. No dealer or his agent or employee is

authorized to extend or enlarge on these warranties on behalf of Honda by any written or

verbal statement or advertisement.

Disclaimer

To the extent the law permits, Honda disclaims any responsibility for loss of time or use of

the General Purpose Engine, transportation or towing costs or any other indirect,

incidental or consequential damage, inconvenience or commercial loss.

Notice to consumer

The provisions contained in these written warranties are not intended to limit, modify, take

away from, disclaim or exclude any warranties set forth in or the operation of The

Consumer Products Warranties Act, 1977 (Saskatchewan), The Consumer Product

Warranty and Liability Act (New Brunswick), The Consumer Protection Act (Quebec), or

any other similar provincial or federal legislation.

24 months 3 months 3 months NONE

EMISSION CONTROL SYSTEM WARRANTY

Your new Honda Power Equipment engine complies with the U.S. EPA, Environment

Canada and State of California emission regulations. American Honda Motor Co., Inc.

provides the emission warranty coverage for engines in the United States, and its

territories. Honda Canada Inc. provides the emission warranty for engines in the 13

provinces and territories of Canada. In the remainder of this Emission Control System

Warranty, American Honda Motor Company Inc. and Honda Canada Inc. will be referred

to as Honda.

Your Warranty Rights And Obligations:

California

The California Air Resources Board and Honda are pleased to explain the emission

control system warranty on your Honda Power Equipment engine. In California, new

spark-ignited small off-road equipment engines must be designed, built and equipped to

meet the State's stringent anti-smog standards.

Other States, U.S. Territories, and Canada

In other areas of the United States and in Canada, your engine must be designed, built,

and equipped to meet the U.S. EPA and Environment Canada emission standards for

spark-ignited engines at or below 19 kilowatts.

All of the United States and Canada

Honda must warrant the emission control system on your power equipment engine for the

period of time listed below, provided there has been no abuse, neglect or improper

maintenance of your power equipment engine. Where a warrantable condition exists,

Honda will repair your power equipment engine at no cost to you including diagnosis,

parts and labor.

Your emission control system may include such parts as the carburetor or fuel injection

system, the ignition system, and catalytic converter. Also included may be hoses,

connectors and other emission-related assemblies.

Manufacturer's Warranty Coverage:

The 1995 and later power equipment engines are warranted for two years. If any

emission-related part on your engine is defective, the part will be repaired or replaced by

Honda.

Owner's Warranty Responsibility:

As the power equipment engine owner, you are responsible for the performance of the

required maintenance listed in your owner's manual. Honda recommends that you retain

all receipts covering maintenance on your power equipment engine, but Honda cannot

deny warranty coverage solely for the lack of receipts or for your failure to ensure the

performance of all scheduled maintenance.

As the power equipment engine owner, you should however be aware Honda may deny

you warranty coverage if your power equipment engine or a part has failed due to abuse,

neglect, improper maintenance, or unapproved modifications.

You are responsible for presenting your power equipment engine to a Honda Power

Equipment dealer as soon as a problem exists. The warranty repairs should be completed

in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should

contact the Honda Office in your region:

American Honda Motor Co., Inc.

Power Equipment Customer Relations

4900 Marconi Drive

Alpharetta, Georgia 30005-8847

Telephone: (770) 497-6400

Warranty Coverage:

Honda power equipment engines manufactured after January 1, 1995 and sold in the

State of California, U.S. EPA certified engines manufactured on or after September 1,

1996 and sold in all of the United States, and Canadian certified engines manufactured on

or after January 1, 2005 are covered by this warranty for a period of two years from the

date of delivery to the original retail purchaser. This warranty is transferable to each

subsequent purchaser for the duration of the warranty period.

Warranty repairs will be made without charge for diagnosis, parts or labor. All defective

parts replaced under this warranty become the property of Honda. Warranted parts are

listed under Emission Control System Warranty Parts later on this page. Normal

maintenance items, such as spark plugs and filters, that are on the warranted parts list are

warranted up to their required replacement interval only.

Honda is also liable for damages to other engine components caused by a failure of any

warranted part during the warranty period.

Only Honda approved replacement parts may be used in the performance of any warranty

repairs and must be provided without charge to the owner. The use of replacement parts

not equivalent to the original parts may impair the effectiveness of your engine emission

control system. If such a replacement part is used in the repair or maintenance of your

engine, and an authorized Honda dealer determines it is defective or causes a failure of a

warranted part, your claim for repair of your engine may be denied. If the part in question

is not related to the reason your engine requires repair, your claim will not be denied.

To Obtain Warranty Service:

You must take your Honda Power Equipment engine or the product on which it is installed,

along with your sales registration card or other proof of original purchase date, at your

expense, to any Honda Power Equipment dealer who is authorized by Honda to sell and

service that Honda product during his normal business hours. Claims for repair or

adjustment found to be caused solely by defects in material or workmanship will not be

denied because the engine was not properly maintained and used.

If you are unable to obtain warranty service, or are dissatisfied with the warranty service

you received, contact the owner of the dealership involved. Normally this should resolve

your problem. However, if you require further assistance, write or call the Honda Power

Equipment Customer Relations Department in your region.

Honda Canada Inc.

Power Equipment Customer Relations

or

715 Milner Avenue

Toronto, ON M1B 2K8

Telephone: (888) 946-6329

14

ENGLISH

Page 15

Exclusions:

Failures other than those resulting from defects in material or workmanship are not

covered by this warranty. This warranty does not extend to emission control systems or

parts which are affected or damaged by owner abuse, neglect, improper maintenance,

misuse, misfueling, improper storage, accident and/or collision, the incorporation of, or

any use of, any add-on or modified parts, unsuitable attachments, or the unauthorized

alteration of any part.

This warranty does not cover replacement of expendable maintenance items made in

connection with required maintenance services after the item's first scheduled

replacement as listed in the maintenance section of the product owner's manual, such as:

spark plugs and filters.

Disclaimer of Consequential Damage and Limitation of Implied

Warranties:

American Honda Motor Co., Inc. and Honda Canada Inc. disclaim any responsibility for

incidental or consequential damages such as loss of time or the use of the power

equipment, or any commercial loss due to the failure of the equipment; and any implied

warranties are limited to the duration of this written warranty. This warranty is applicable

only where the California, U.S. EPA, or Environment Canada emission control system

warranty regulation is in effect.

Emission Control System Warranty Parts:

SYSTEMS COVERED

BY THIS WARRANTY:

PAR TS

DESCRIPTION:

Fuel Metering Carburetor assembly, (includes starting

enrichment system), Engine temperature

sensor, Engine control module, Fuel

regulator, Intake manifold

Evaporative Fuel tank, Fuel cap, Fuel hoses, Vapor

hoses, Carbon canister, Canister

mounting brackets, Fuel strainer, Fuel

cock, Fuel pump, Fuel hose joint, Seal

cap, Canister purge hose joint

Exhaust Catalyst, Exhaust manifold

Air Induction Air filter housing, Air filter element*,

Crankcase breather tube

Ignition Flywheel magneto, Ignition pulse

generator, Crankshaft position sensor,

Power coil, Ignition coil assembly,

Ignition control module, Spark plug cap,

Spark plug*

Miscellaneous Parts Tubing, fittings, seals, gaskets, and

clamps associated with these listed

systems.

Note: This list applies to parts supplied by Honda and does not cover parts

supplied by the equipment manufacturer. Please see the original equipment

manufacturer’s emissions warranty for non-Honda parts.

* Covered up to the first required replacement only. See the Maintenance

Schedule (page 6).

ENGLISH

15

Page 16

16

ENGLISH

Page 17

INTRODUCTION

Merci d’avoir acheté un moteur Honda. Ce manuel vous aidera à

obtenir les meilleurs résultats de votre nouveau moteur et à l’utiliser

sans danger. Il contient tous les renseignements nécessaires ;

veuillez le lire attentivement avant de faire fonctionner le moteur. En

cas de problème ou pour toute question concernant votre moteur,

veuillez consulter un concessionnaire Honda.

Toute l’information contenue dans ce document est basée sur les

données les plus récentes au moment de l’impression. American

Honda Motor Co., Inc. se réserve le droit d’apporter des modifications

à tout moment sans préavis ni obligation. Toute reproduction, même

partielle, de ce document est interdite sans autorisation écrite.

Ce manuel fait partie intégrante du moteur et doit l’accompagner en

cas de revente.

Pour tout renseignement supplémentaire concernant le démarrage,

l’arrêt, le fonctionnement, les réglages ou toute opération d’entretien