Honda Automobiles FR600, FR6OO User Manual

Owner’s Manual

TILLER

FR600 / FRSOO

I!

!!!!I

I I I I I I I

I

!!I! !JW!

I I I I I I

I III I I I 11

I I I I I I I I I I I

01992 American Honda Motor Co., Inc. - All Rights Reserved

The engine exhaust from this product

contains chemicals known to the State

defects or other reproductive harm.

Thank you for purchasing a Honda tiller.

This manual describes operation and maintenance of your tiller:

Honda FR600 and FR800.

All information in this publication is based on the latest product

information available at the time of printing.

The illustrations in this manual are based on: Honda FR800

Honda Motor Co., Ltd. reserves the right to make changes at any time

without notice and without incurring any obligation.

No part of this publication may be reproduced without written

ermission.

7

his manual is considered a permanent part of the tiller and it must

stay with the tiller if resold.

READ THIS OWNER’S MANUAL CAREFULLY.

Pay special attention to these symbols and any instructions that

follow:

m

Indicates serious injury or death WILL result if instructions

are not followed.

B

Indicates a strong possibility that serious injury or death

could resultif instructions are not followed.

.B

Indicates a possibility that minor injury can result if

instructions are not followed.

(-1

Indicates that equipment or property damage can result if

instructions are not followed.

NOTE: Gives helpful information.

HONDA tillers are designed to give safe and dependable service if

operated according to instructrons. Operating this trller requires

;xx~l effort on your part to ensure your safety and the safety of

Using this product for a purpose not intended may cause inju 7 or

property dama B e. Read and understand this Owner’s Manual be ore

operating the ti ler.

If a problem should arise, or if you have any questions about your

tiller, consult an authorized Honda tiller dealer.

HONDA MOTOR CO.,LTD. 1991, ALL RIGHTS RESERVED

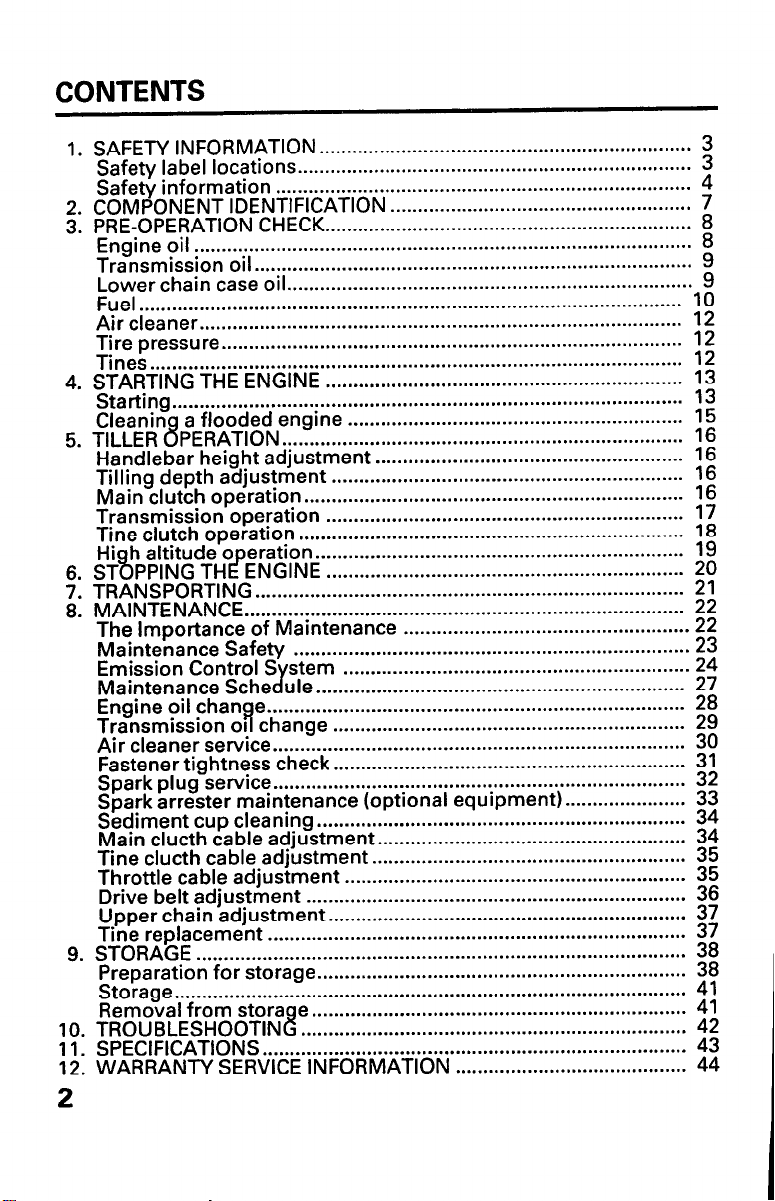

CONTENTS

1. SAFETY INFORMATION..

Safety label locations

Safety information

2. COMPONENT IDENTIFICATION

3. PRE-OPERATION CHECK

Engine oil

Transmission oil

Lower chain case oil

Fuel

Air cleaner

Tfreespressure

4. ;;T;R$NG THE ENGINE

Cleanin a flooded engine

5. TILLER OPERATION

Handlebar height adjustment..

Tilling depth adjustment

Main clutch operation

Transmission operation

Tine clutch operation

Hi h altitude o eration

6 STbPPING THE!ENGlNE

7: TRANSPORTING

8. MAINTENANCE

The Importance

Maintenance Safety

Emission Control S stem

Maintenance Sche

Engine oil than e

Transmission OI change

Air cleaner service

Fastener tightness check

Spark plug service

Spark arrester maintenance (optional

Sediment cup cleaning

Main clucth cable adjustment

Tine clucth cable adjustment

Throttle cable adjustment

Drive belt adjustment

Upper chain adjustment

Tine replacement

9. STORAGE

Preparation for storage

Storage

Removal from stora 8 e

10. TROUBLESHOOTIN

11. SPECIFICATIONS

12. WARRANTY SERVICE INFORMATION

...........................................................................................

................................................................................

...................................................................................................

........................................................................................

....................................................................................

.................................................................................................

............................................................................................. 13

.............................................................................. 22:

................................................................................

of Maintenance

............................................................................

9

............................................................................

.........................................................................................

............................................................................................. i:

.............................................................................

..................................................................

........................................................................

............................................................................

...................................................................

..........................................................................

.................................................................

.........................................................................

.....................................................................

.................................................................

......................................................................

...................................................................

.................................................................

........................................................................

...................................................................

cr

ule

...........................................................................

...........................................................................

...................................................................

.....................................................................

.................................................................

...................................................................

....................................................................

......................................................................

.......................................................

.............................................................

......................................................

................................................................

....................................................

...............................................................

................................................................

................................................................

........................................................

.........................................................

..............................................................

2

equipment). .....................

..........................................

:

;

8

8

9

9

:02

12

if

E

16

::

17

1;

zs

23

;;

28

::

z:

33

34

2

::

:;

38

41

2

44

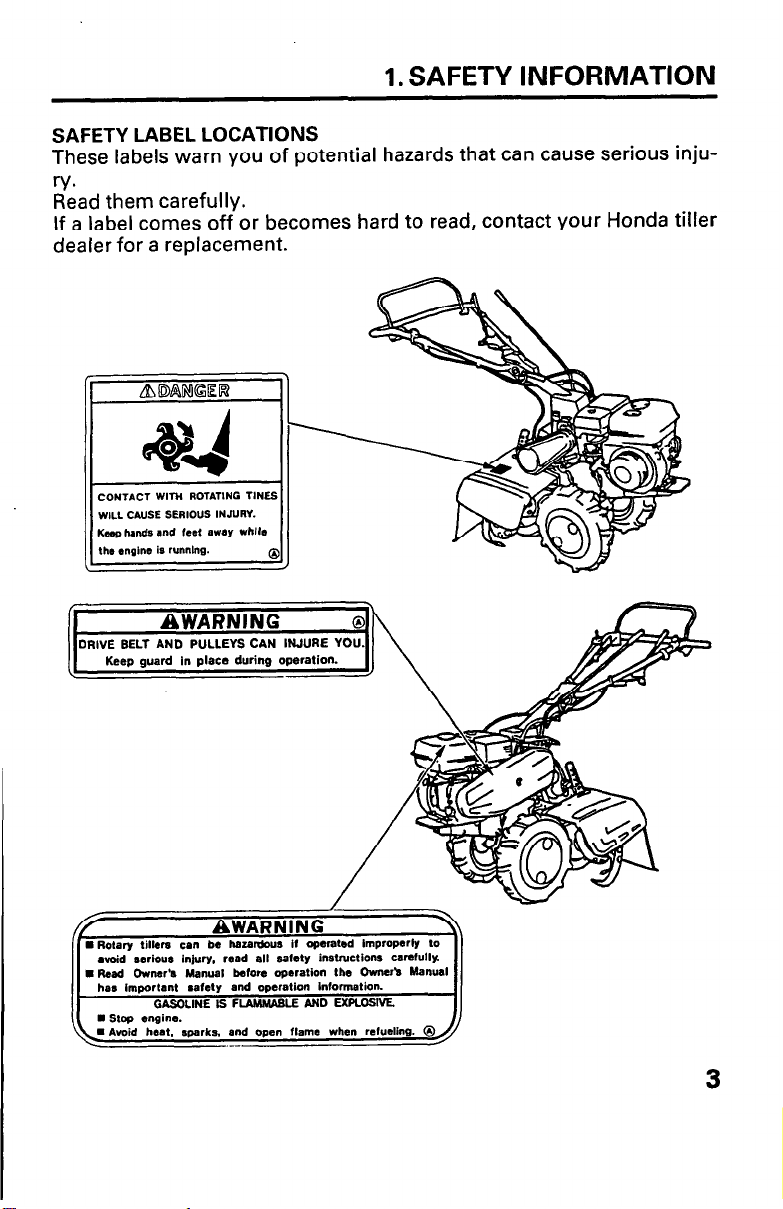

1. SAFETY INFORMATION

SAFETY LABEL LOCATIONS

These labels warn you of potential hazards that can cause serious inju-

ry.

Read them carefully.

If a label comes off or becomes hard to read, contact your Honda tiller

dealer for a replacement.

To ensure safe operation -

For your safety and the safety of others, pay special attention to these

precautions:

Operator responsibility

l Keep the tiller in good operating condition. Operating a tiller in poor

or questionable condition could result in serious injury.

l Be sure all safety devices are in working order and warning labels

are in place. These items are installed for your safety.

l Be sure the safety covers (V-belt cover, chain cover and recoil starter

cover) are in place.

l Know how to stop the engine and tines quickly in case of emergency.

Understand the use of all controls.

l Be very cautious when operating the tiller in REVERSE, especially if

attachments are being used.

l Keep a firm hold on the handlebars. They may tend to lift during

clutch engagement.

l Allowing anyone to operate this tiller without proper instruction may

result in injury.

l Wear sturdy, full-coverage footwear. Operating this tiller barefoot or

with open toe shoes or sandals increases your risk of injury.

l Dress sensibly. Loose clothing may get caught in moving parts,

increasing your risk of injury.

l Be alert. Operating this tiller when you are tired, ill or under the

influence of alcohol or drugs may result in serious injury.

l Keep all persons and pets away from the tilling area.

l Be sure the drag bar is in place and properly adjusted.

4

Child safety

l Keep children indoors and supervised at all times when any outdoor

power equipment is being used nearby. Young children move

quickly and are attracted especially to the tiller and the tilling activity.

l Never assume children will remain where you last saw them. Be

alert and turn the tiller off if children enter the area.

l Children should never be allowed to operate the tiller, even under

adult supervision.

Rotating tines hazard

The rotating tines are sharp and they turn at high speed. Accidental

contact can cause serious injury.

l Keep your hands and feet away from the tines while the engine is

running.

l Stop the engine and.disengage the tine clutch before inspection or

maintenance of tines.

l Disconnect the spark plug cap to prevent any possibility of

accidental starting. Wear heavy gloves to protect your hands when

cleaning the tines or when inspecting or replacing the tines.

Thrown object hazard

Objects hit by the rotating tines can be thrown from the tiller with

great force, and may cause serious injury.

. Before tilling, clear the tilling area of sticks, large stones, wire, glass,

etc. Till only in daylight.

l Always inspect the tiller for damage after striking a foreign object.

Repair or replace any damaged parts before continuing use.

l Pieces thrown from worn or damaged tines can cause serious injury.

Always inspect the tines before using the tiller.

5

Fire and burn hazard

Gasoline is extremely flammable, and gasoline vapor can explode.

Use extreme care when handling gasoline. Keep gasoline out of reach

of children.

l Refuel in a well-ventilated area with the engine stopped.

l Allow the engine to cool before refueling. Fuel vapor or spilled fuel

may ignite.

l The engine and exhaust system become very hot during operation

and remain hot for a while after stopping. Contact with hot engine

components can cause burn injuries and can ignite some materials.

l Avoid touching a hot engine or exhaust system.

l Allow the engine to cool before performing maintenance or storing

the tiller indoors.

Carbon monoxide poisoning hazard

Exhaust contains poisonous carbon monoxide, a colorless and

odorless gas. Breathing exhaust can cause loss of consciousness and

may lead to death.

l If you run the engine in an area that is confined or even partially

enclosed, the air you breathe could contain a dangerous amount of

exhaust gas. To keep exhaust gas from building up, provide

adequate ventilation.

Operation on slope

l When tilling on slopes, keep the fuel tank less than half full to

minimize fuel spillage.

l Till across the slope (At equally spaced intervals) rather than up and

down it.

l Be very careful when changing the direction of the tiller on a slope.

l Do not use the tiller on a slope of more than IO”.

The maximum safe grade angle shown is for reference purpose only

and should be determined according to the type of the tool. Before

starting the engine, check that the tiller is not damaged and in good

condition. For your safety and safety of others, exercise extreme

care when using the tiller on up or down hill.

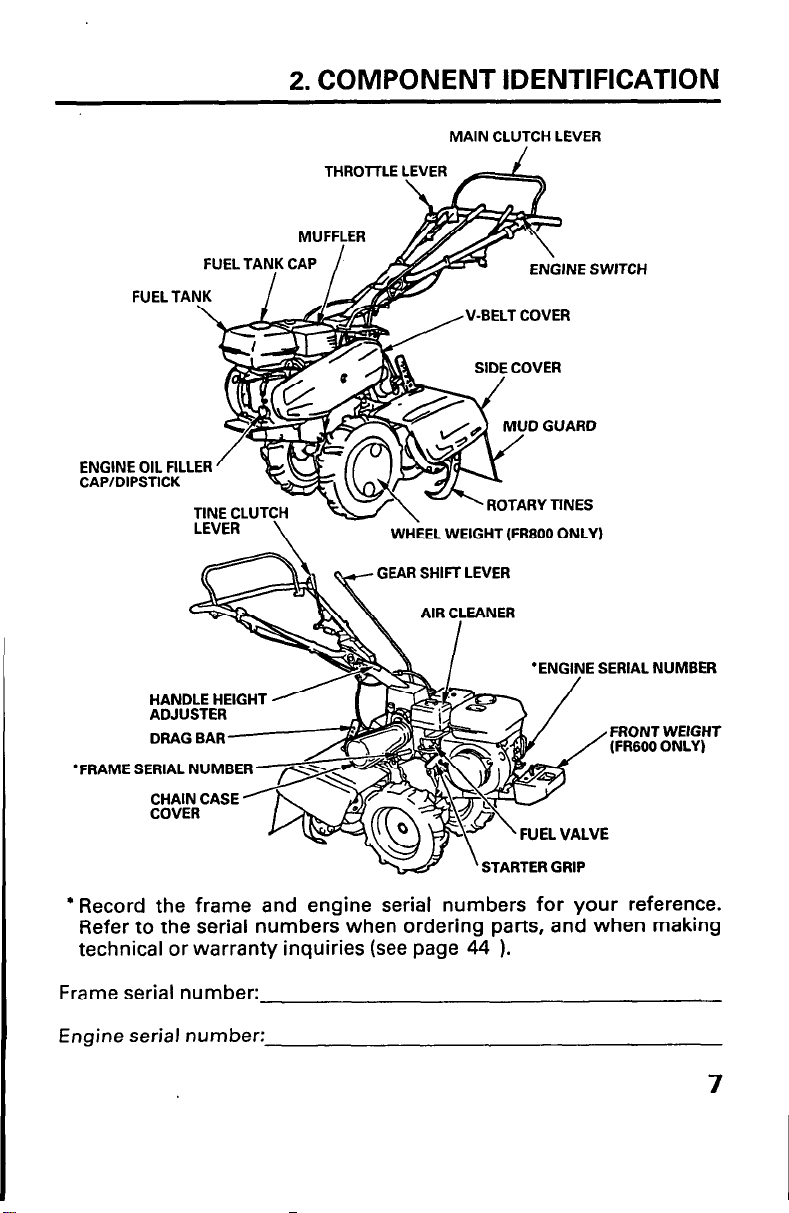

2. COMPONENT IDENTIFICATION

MAIN CLUTCH LEVER

THRO-ITLE

FUEL TANa

ENGINE OIL FILLER ’

CAP/DIPSTICK

HANDLE HEIGHT

‘FRAME

SERIAL NUMBE

LEVER

MI IFFI FP

,..-. . --..

\ -

i!

WH‘EEL WEIGHT (FRSOO ONLY)

I

‘ENGINE

SERIAL NUMBER

FRONT WEIGHT

(FR600 ONLY)

l Record the frame and engine serial numbers for your reference.

Refer to the serial numbers when ordering parts, and when making

technical or warranty inquiries (see page 44 ).

Frame serial number:

Engine seriaJ number:

7

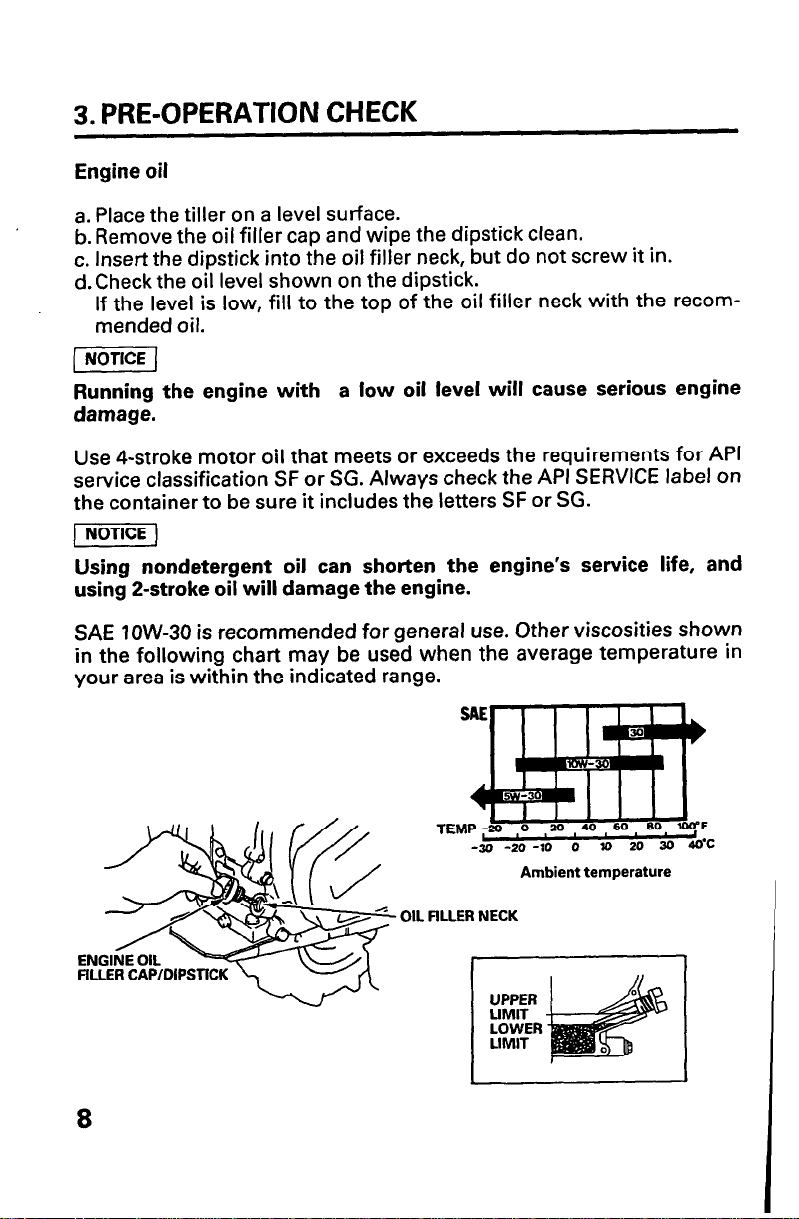

Engine oil

a. Place the tiller on a level surface.

b. Remove the oil filler cap and wipe the dipstick clean.

c. Insert the dipstick into the oil filler neck, but do not screw it in.

d. Check the oil level shown on the dipstick.

If the level is low, fill to the top of the oil filler neck with the recommended oil.

I

Running the engine with a low oil level will cause serious engine

damage.

Use 4-stroke motor oil that meets or exceeds the requirements for API

service classification SF or SG. Always check the API SERVICE label on

the container to be sure it includes the letters SF or SG.

piiEiE-]

Using nondetergent oil can shorten the engine’s service life, and

using P-stroke oil will damage the engine.

SAE low-30 is recommended for general use. Other viscosities shown

in the following chart may be used when the average temperature in

your area is within the indicated range.

FILLER CAP/DIPSTICK

OIL

FlLLER NECK

Ambient temperature

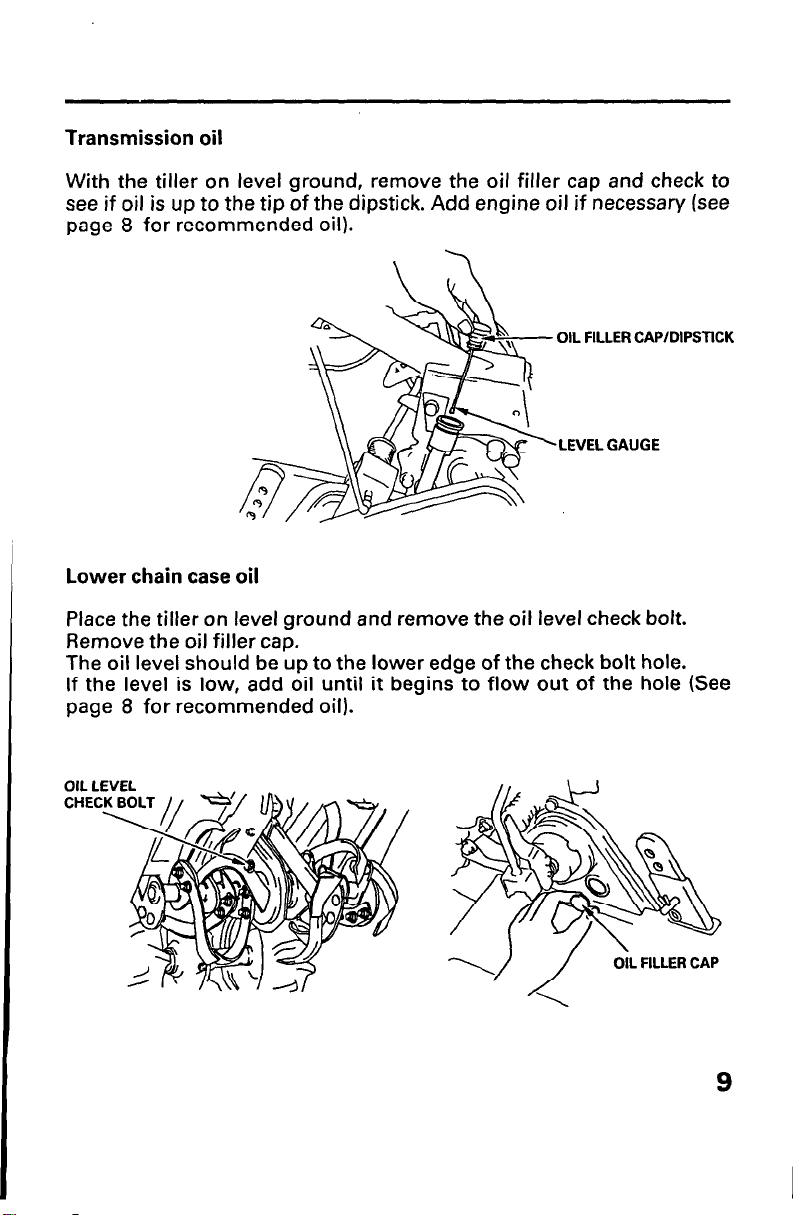

Transmission oil

With the tiller on level ground, remove the oil filler cap and check to

see if oil is up to the tip of the dipstick. Add engine oil if necessary (see

page 8 for recommended oil).

OIL FILLER CAP/DIPSTICK

LEVEL GAUGE

Lower chain case oil

Place the tiller on level ground and remove the oil level check bolt.

Remove the oil filler cap.

The oil level should be up to the lower edge of the check bolt hole.

If the level is low, add oil until it begins to flow out of the hole (See

page 8 for recommended oil).

9

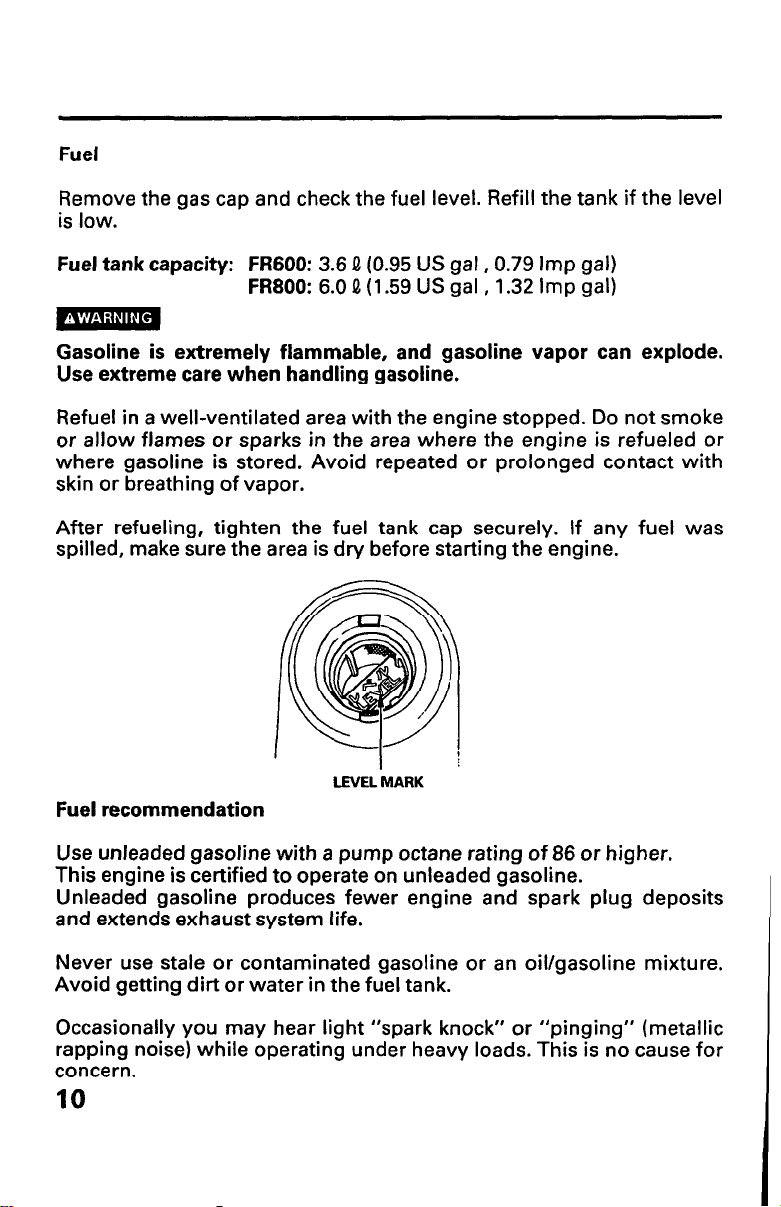

Fuel

Remove the gas cap and check the fuel level. Refill the tank if the level

is low.

Fuel tank capacity: FR600: 3.6 Q (0.95 US gal, 0.79 Imp gal)

FR800: 6.0 Q (1.59 US gal , 1.32 Imp gal)

Gasoline is extremely flammable, and gasoline vapor can explode.

Use extreme care when handling gasoline.

Refuel in a well-ventilated area with the engine stopped. Do not smoke

or allow flames or sparks in the area where the engine is refueled or

where gasoline is stored. Avoid repeated or prolonged contact with

skin or breathing of vapor.

After refueling, tighten the fuel tank cap securely. If any fuel was

spilled, make sure the area is dry before starting the engine.

LEVEL MARK

Fuel recommendation

Use unleaded gasoline with a pump octane rating of 86 or higher.

This engine is certified to operate on unleaded gasoline.

Unleaded gasoline produces fewer engine and spark plug deposits

and extends exhaust system life.

Never use stale or contaminated gasoline or an oil/gasoline mixture.

Avoid getting dirt or water in the fuel tank.

Occasionally you may hear light “spark knock” or “pinging” (metallic

rapping noise) while operating under heavy loads. This is no cause for

concern.

10

If spark knock or pin

normal load, than e

persists, see an aut orized Honda tiller dealer.

jiiEiq

Running the engine with persistent spark knock or pinging can cause

engine damage.

NOTE:

Running the engine with persistent spark knock or pinging is

considered misuse, and the Distributor’s Limited Warranty does not

cover parts damaged by misuse.

Oxygenated fuels

ing occurs at a steady engine speed, under

%

rands of gasoline. If spark knock or pinging

it

Some conventional gasolines are being blended with alcohol or an

ether compound. These

enated fuels. To meet c ean air standards, some areas of the United

8

tates and Canada use oxy enated fuels to help reduce emissions.

If you use an oxygenated uel, be sure it is unleaded and meets the

minimum octane rating requirement.

Before using an oxygenated fuel, try to confirm the fuel’s contents.

Some states/provinces require this information to be posted on the

‘; P F! dllowing are the EPA approved percentages of oxygenates:

I

I

ETHANOL- (ethyl or grain alcohol) 10% by volume

You may use gasoline containing up to 10% ethanol

by volume. Gasoline containin ethanol may be mar-

keted under the name “Gasoho 9

MTBE- (methyl tertiary butyl ether) 15% by volume

You may use gasoline containing up to 15% MTBE by vol-

asolines are collectively referred to as oxy-

B

9

“.

ume.

METHANOL- (methyl or wood alcohol) 5% by volume

If you notice any undesirable operating symptoms, try another service

station or switch to another brand of gasoline.

Fuel system dama e or performance problems resulting from the use

of an oxygenated

genates mentioned above are not covered under warranty.

You may use gasoline containing up to 5%

methanol by volume as long as it also contains

cosolvents and corrosion inhibitors to protect the fuel system. Gasoline containing more than 5%

methanol by volume may cause starting and/or performance roblems. It may also damage metal, rubber, and p astic parts of your fuel system. P

7 uel containing more than the percentages of oxy-

11

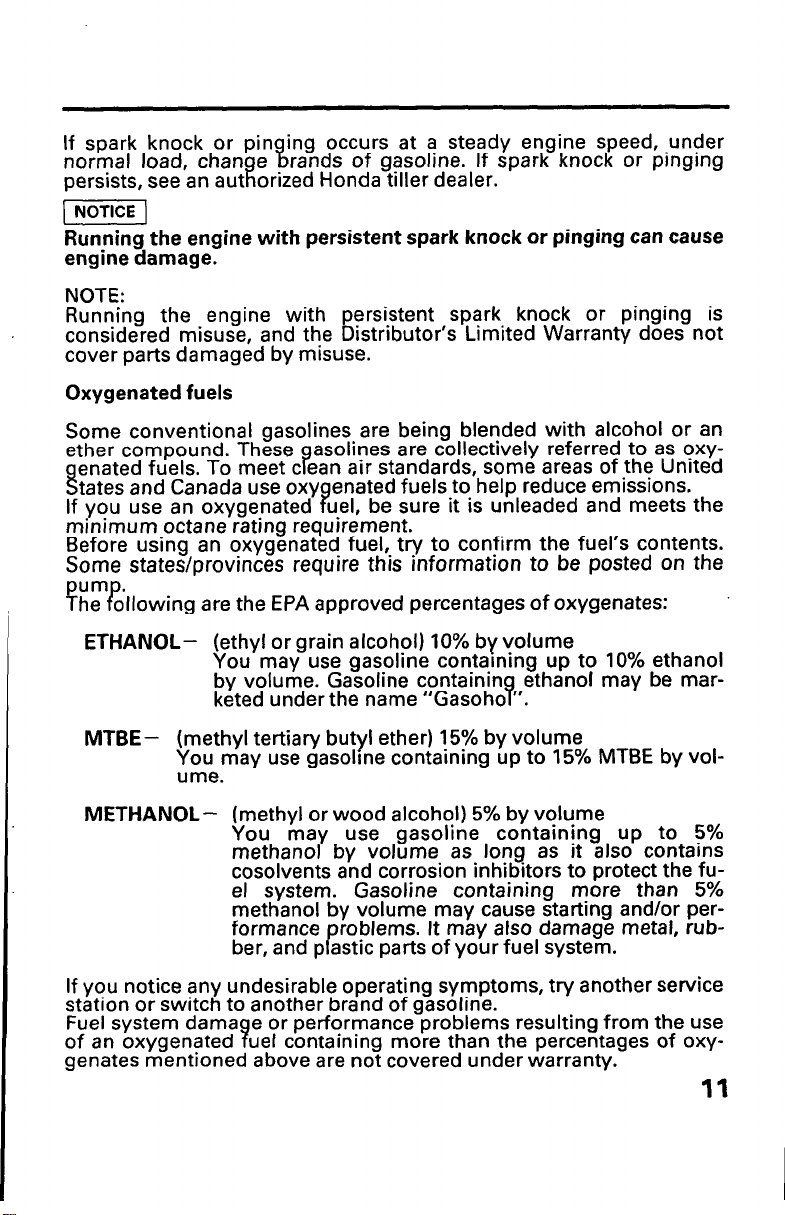

Air cleaner

Remove the cover and inspect the elements; clean them if necessary

(see page 30 1.

[NOTlCE(

Operating the engine with no air filter, or a damaged air filter, will

cause rapid engine wear.

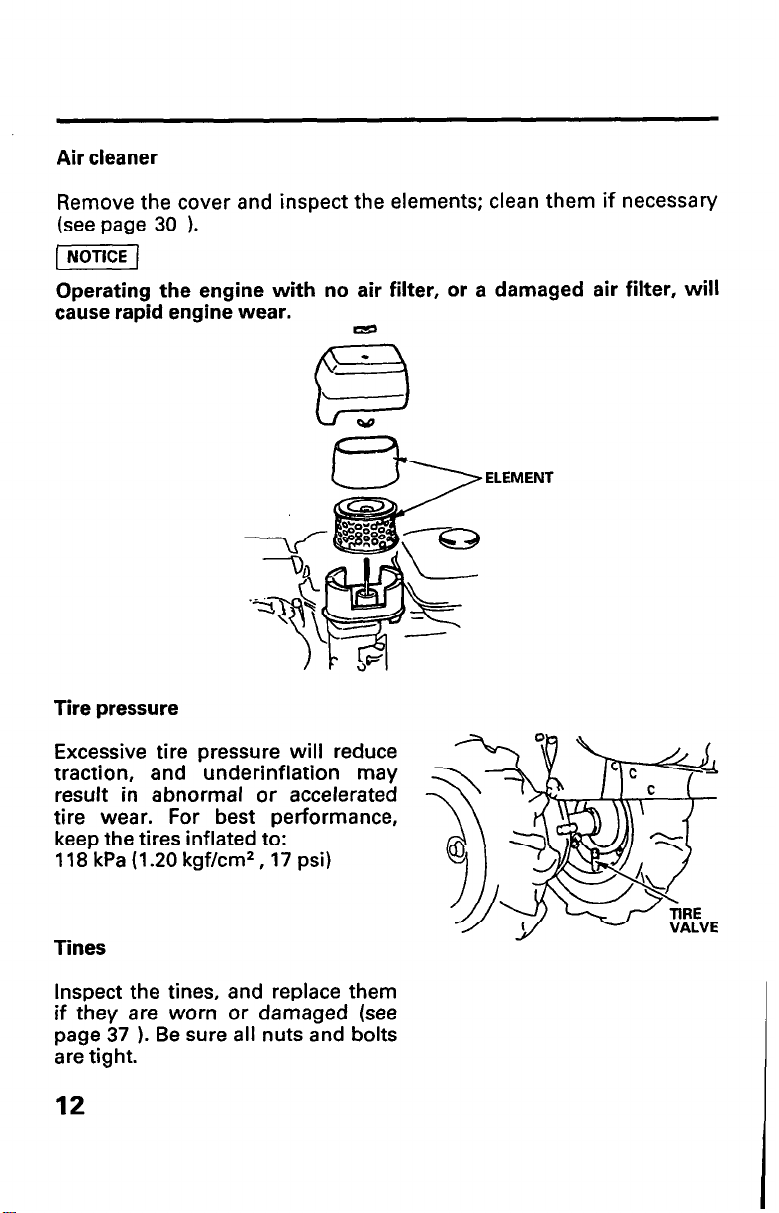

Tire pressure

tzs

ELEMENT

Excessive tire pressure will reduce

traction, and underinflation may

result in abnormal or accelerated

tire wear. For best performance,

keep the tires inflated to:

118kPa(1.20kgf/cm2,17psi)

Tines

Inspect the tines, and replace them

if they are worn or damaged (see

page 37 ). Be sure all nuts and bolts

are tight.

12

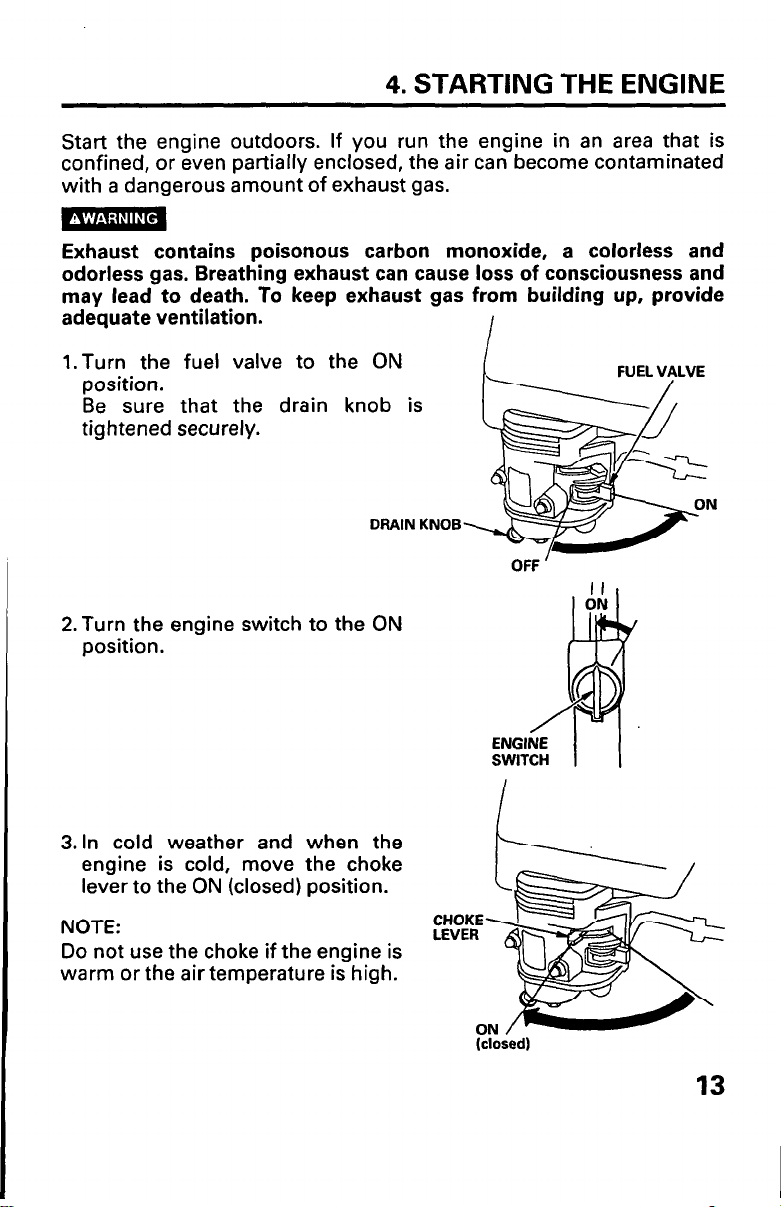

4. STARTING THE ENGINE

Start the engine outdoors. If you run the engine in an area that is

confined, or even partially enclosed, the air can become contaminated

with a dangerous amount of exhaust gas.

Exhaust contains poisonous carbon monoxide, a colorless and

odorless gas. Breathing exhaust can cause loss of consciousness and

may lead to death. To keep exhaust gas from building up, provide

adequate ventilation.

l.Turn the fuel valve to the ON

position.

Be sure that the drain knob is

tightened securely.

DRAIN KNOB

2.Turn the engine switch to the ON

position.

3. In cold weather and when the

engine is cold, move the choke

lever to the ON (closed) position.

NOTE:

Do not use the choke if the engine is

warm or the air temperature is high.

(closed)

Loading...

Loading...