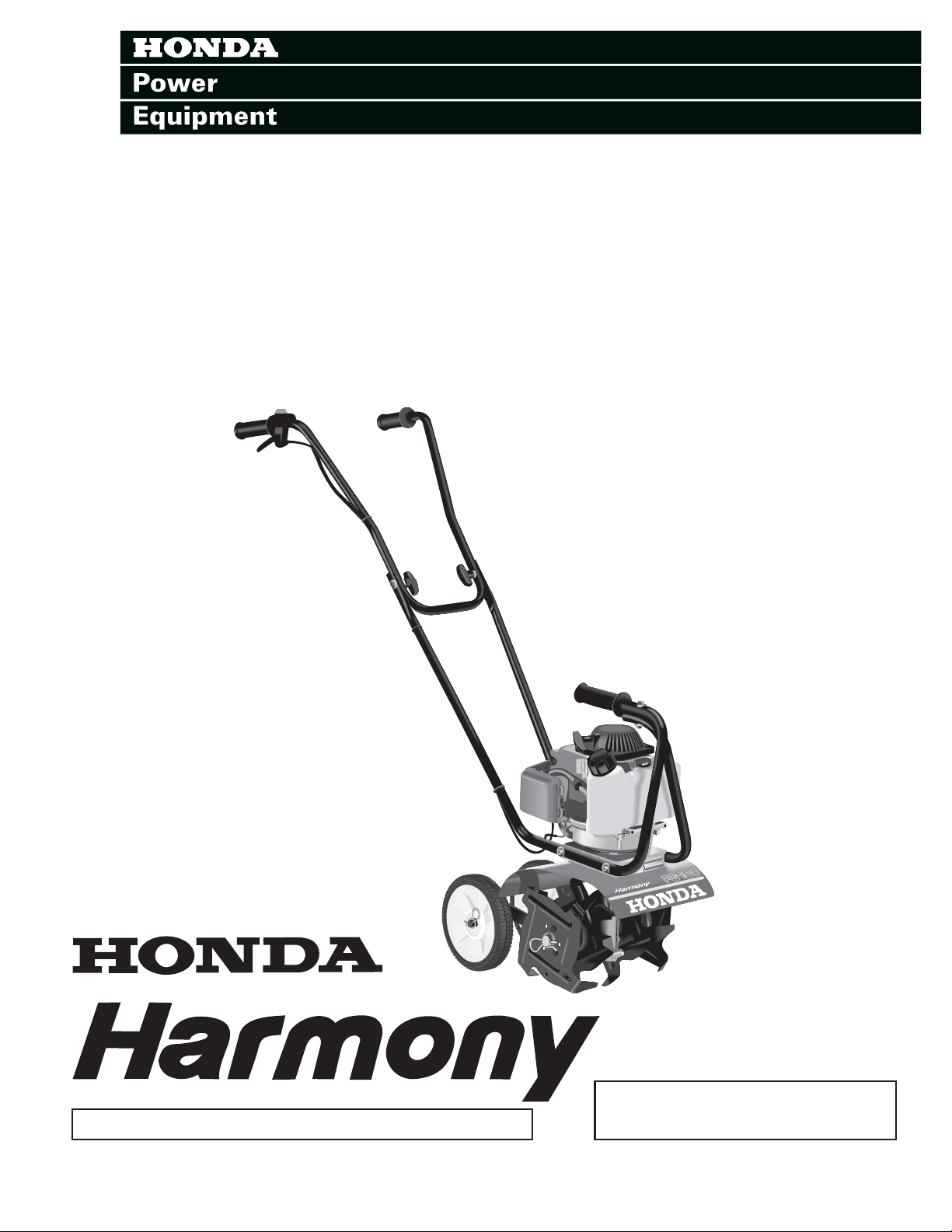

Honda Automobiles FG100 User Manual

OWNER'S MANUAL

Mini-Tiller

FG100

¿Necesita un manual en Español? Vea a la página 44.

©1997 American Honda Motor Co., Inc. All Rights Reserved

See page 28 for instructions on

assembling your FG100 Mini-Tiller.

B WARNING: B

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

Keep this owner’s manual handy so you can refer to it at any time. This should remain with the tiller if

resold.

The information and specifications included in this publication were in effect at the time of approval for

printing. American Honda Motor Co., Inc. reserves the right, however, to discontinue or change

specifications or design at any time without notice and without incurring any obligation whatever. No part

of this publication may be reproduced without written permission.

FG100 TILLER

INTRODUCTION

Congratulations on your selection of a Honda Harmony FG100 Tiller. We are certain you will be pleased

with your purchase of one of the finest tillers on the market.

We want to help you get the best results from your new tiller and to operate it safely. This manual

contains the information on how to do that; please it carefully.

As you read this manual, you will find information preceded by a symbol. That information

is intended to help you avoid damage to your tiller, other property, or environment.

We suggest you read the warranty policy to fully understand its coverage and your responsibilities of

ownership.

When your tiller needs scheduled maintenance, keep in mind that your Honda servicing dealer is

specially trained in servicing Honda tillers. Your Honda servicing dealer is dedicated to your satisfaction

and will be pleased to answer your questions and concerns.

Left and right sides of this unit are determined from the operator’s position, standing behind the tiller

handlebars, facing the direction of forward travel.

Best Wishes,

Power Equipment Division

American Honda Motor Co., Inc.

NOTICE

1

FG100 TILLER

A FEW WORDS ABOUT SAFETY

Your safety and the safety of others are very important. And using this tiller is an important responsibility.

To help you make informed decisions about safety, we have provided operating procedures and other

information on labels in this manual. This information alerts you to potential hazards that could hurt you or

others.

Of course, it is not practical or possible to warn you about all the hazards associated with operating or

maintaining a tiller. You must use your own good judgment.

You will find important safety information in a variety of forms, including:

• Safety Labels - on the tiller

• Safety Messages - preceded by a safety alert symbol B and of the following three words; DANGER,

WARNING, or CAUTION.

These signal words mean:

B DANGER You WILL be Killed or SERIOUSLY HURT if you don’t

follow instructions.

B WARNING You CAN be KILLED or SERIOUSLY HURT if you don’t

follow instructions.

B CAUTION You CAN BE HURT if you don’t follow instructions.

• Safety Headings - such as IMPORTANT SAFETY INFORMATION.

• Safety Section - such as TILLER SAFETY.

• Instructions - how to use this tiller correctly and safely.

This entire book is filled with important safety information - please read it carefully.

2

CONTENTS

FG100 TILLER

SAFETY ............................................................4

IMPORTANT SAFETY INFORMATION .........4

ATTACHMENTS AND MODIFICATIONS ......5

IMPORTANT MESSAGE TO EMPLOYERS ..5

IMPORTANT MESSAGE TO PARENTS .......5

SAFETY LABEL LOCATIONS .......................6

CONTROLS ......................................................7

COMPONENT IDENTIFICATION ..................7

DESCRIPTION OF CONTROLS....................8

Throttle Lever . . . . . . . . . . . . . 8

Engine Switch . . . . . . . . . . . . . 8

Handle Bar Adjustment . . . . . . . . . . 8

Choke Lever . . . . . . . . . . . . . . 8

Priming Bulb . . . . . . . . . . . . . . 8

Transport Wheels . . . . . . . . . . . . 9

Carrying Handle . . . . . . . . . . . . 9

Recoil Starter Grip . . . . . . . . . . . 9

Drag Bar . . . . . . . . . . . . . . . 9

BEFORE OPERATION .....................................10

GENERAL......................................................10

CHECK TILLING AREA .................................11

CHECK TILLER .............................................11

OPERATION.....................................................12

SAFETY PRECAUTIONS ..............................12

MOVING THE TILLER ...................................12

HANDLEBAR ADJUSTMENT ........................12

STARTING/STOPPING THE ENGINE ..........13

TILLER OPERATION.....................................14

MAINTENANCE & ADJUSTMENTS .................17

THE IMPORTANCE OF MAINTENANCE ......17

MAINTENANCE SAFETY ..............................17

MAINTENANCE SCHEDULE ........................18

Engine Oil . . . . . . . . . . . . . . . 19

AirFilter ...............20

Spark Plug . . . . . . . . . . . . . . 22

Spark Arrester . . . . . . . . . . . . . 23

Cooling Fins . . . . . . . . . . . . . . 24

Throttle Cable . . . . . . . . . . . . . 24

Idle Speed . . . . . . . . . . . . . . . 24

Fuel System . . . . . . . . . . . . . . 25

Transmission . . . . . . . . . . . . . 27

ASSEMBLY ...................................................... 28

THE IMPORTANCE OF ASSEMBLY ............ 28

UNPACKING .................................................29

LOOSE PARTS .............................................29

TILLER ASSEMBLY ...................................... 30

TRANSPORTING/STORAGE........................... 34

TRANSPORTING .......................................... 34

STORAGE ..................................................... 34

TAKING CARE OF UNEXPECTED

PROBLEMS...................................................... 37

STARTING PROBLEMS................................ 37

ENGINE OPERATING PROBLEMS .............. 37

SPECIFICATIONS............................................ 38

TECHNICAL & CONSUMER

INFORMATION................................................. 39

SERIAL NUMBER LOCATIONS.................... 39

HONDA PUBLICATIONS ..............................39

OPTIONS....................................................... 39

WARRANTY .................................................. 40

EMISSION CONTROL

SYSTEM WARRANTY ..................................42

WARRANTY SERVICE INFORMATION ....... 44

OXYGENATED FUELS ................................. 45

HIGH ALTITUDE OPERATION ..................... 45

EMISSION CONTROL

SYSTEM INFORMATION .............................. 46

QUICK REFERENCE..........................Back Cover

Maintenance.....................................Back Cover

Tuneup..............................................Back Cover

3

SAFETY

IMPORTANT SAFETY INFORMATION

Most accidents with this product can be prevented if you follow all instructions in this manual and on the

product. The most common hazards, according to accident statistics, are discussed below, along with the

best way to protect yourself and others.

Honda Tiller Usage

Honda tillers are designed to give safe and dependable service if operated according to instructions and

intended use.

Honda tillers are intended to be used by an experienced, trained, operator who is familiar with the use of

power equipment. Do not allow a child or an inexperienced, untrained operator to use this tiller. Operating

this equipment requires special effort on your part to ensure your safety and the safety of others. Read

and understand this owner’s manual.

Avoid Rotating Tines

The rotating tines can cause injury. Keep away from the tine shield whenever the engine is running. If you

need to adjust the tines, or work around the tines for any reason, always stop the engine. Disconnect the

spark plug cap if you need to clean or handle the tines.

Clear Tilling Area

The tiller tines can throw rocks and other objects with enough force to cause injury. Before tilling, carefully

inspect the area and remove all large debris.

Keep Shields in Place

Guards and shields are designed to protect you from being hit by thrown objects and from hot engine

parts and moving components. For your safety and the safety of others, keep all shields in place when

operating the tiller.

Refuel with Care

Gasoline is extremely flammable and gasoline vapor can explode. Refuel only outdoors, in a

well-ventilated area, with the engine off. Never smoke near gasoline, and keep other flames and sparks

away. Always store gasoline in an approved container.

Wear Protective Clothing

Wearing protective clothing will reduce your risk of injury. Long pants and eye protection reduce the risk

of injuries from thrown objects. Sturdy shoes with aggressive soles will help protect your feet and give

you better traction on slopes or uneven ground. Clothing worn by the operator should be fairly tight and

belted. Loose clothing should not be permitted because of the danger of getting into moving parts. Tie up

or restrain long hair.

Turn Engine Off When Not Tilling

If you need to leave the tiller for any reason, even just to inspect the area ahead, always stop the engine .

4 FG100 TILLER

SAFETY

ATTACHMENTS AND MODIFICATIONS

Do not make any modifications to your tiller. Modifying your tiller, or installing non-Honda attachments,

can make your tiller unsafe.

If you need attachments for your tiller, use only genuine Honda attachments. These products have been

designed for your tiller and are covered by warranty.

Non-Honda attachments are usually designed for universal applications. Although aftermarket attachments

may fit on your tiller, they may not meet factory specifications and could make your tiller unsafe.

IMPORTANT MESSAGE TO EMPLOYERS

As an employer, you have special responsibilities to the people who work for you.

Before you ask anyone to operate this tiller, you need to determine whether the person is old enough,

large enough, and strong enough to safely handle and control the tiller.

If you decide they are, make sure the employee reads and understands all instructions and warnings in

this manual, and on the labels before operating the tiller.

Allow adequate time for hands-on training by a qualified instructor, and personally supervise practice

sessions until you feel sure the employee is ready to operate the tiller.

Also be sure employees wear proper clothing and have eye protection and any other gear that may be

required by local ordinances or your insurance company.

Remember, too, that you are responsible for keeping the tiller properly maintained and in safe operating condition.

Your commitment to safety on the job can help prevent accidents and result in longer and more

productive years of service.

IMPORTANT MESSAGE TO PARENTS

Your child’s safety is very important to Honda. Read this message if you decide to permit your youngster

to operate this tiller. Tillers are tools, not toys. As with any equipment, bad judgments can result in

serious injuries. You can prevent accidents by making good decisions about if, when, and how your

youngster operates this equipment.

The first question you’ll need to ask is whether your youngster is capable of operating this tiller safely.

Remember, young people vary widely, and AGE IS NOT THE ONLY FACTOR. Physically, a youngster must

be LARGE ENOUGH AND STRONG ENOUGH to easily start the tiller and control its direction. The

youngster also needs enough size, strength, and coordination to comfortably reach and operate the controls.

Another, tougher question you need to ask is if your youngster has enough MATURITY AND

RESPONSIBILITY to safely operate this tiller. Does the young person think through problems and come

to logical solutions? Be honest! Anyone who takes unnecessary risks and doesn’t obey rules should not

operate this tiller.

If you decide that your son or daughter can handle the tiller safely, carefully read the owner’s manual with

your youngster. Make sure you both understand all instructions and safety information. Also, be sure your

youngster wears sturdy shoes and other protective clothing when operating or handling the tiller.

SUPERVISION is important. Walk behind your youngster during the first few minutes of tilling. Even after

the youngster is confident, do not let them use the tiller without supervision. An adult should also be

present during refueling and maintenance. Be sure the tiller is properly maintained and kept in safe

operating condition.

By always placing safety first, your youngster will acquire useful skills and a sense of accomplishment,

and you’ll both get the best results from your tiller.

FG100 TILLER 5

SAFETY

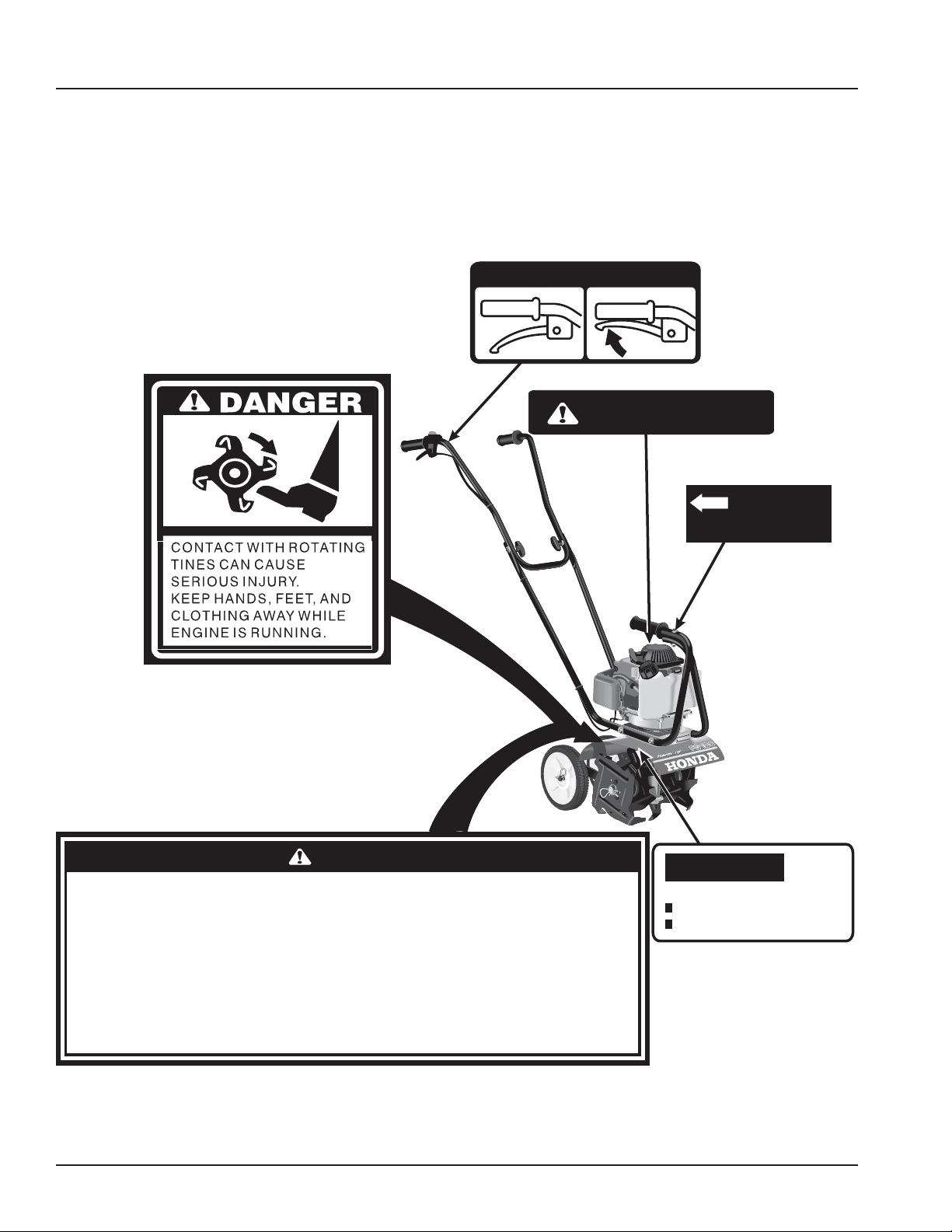

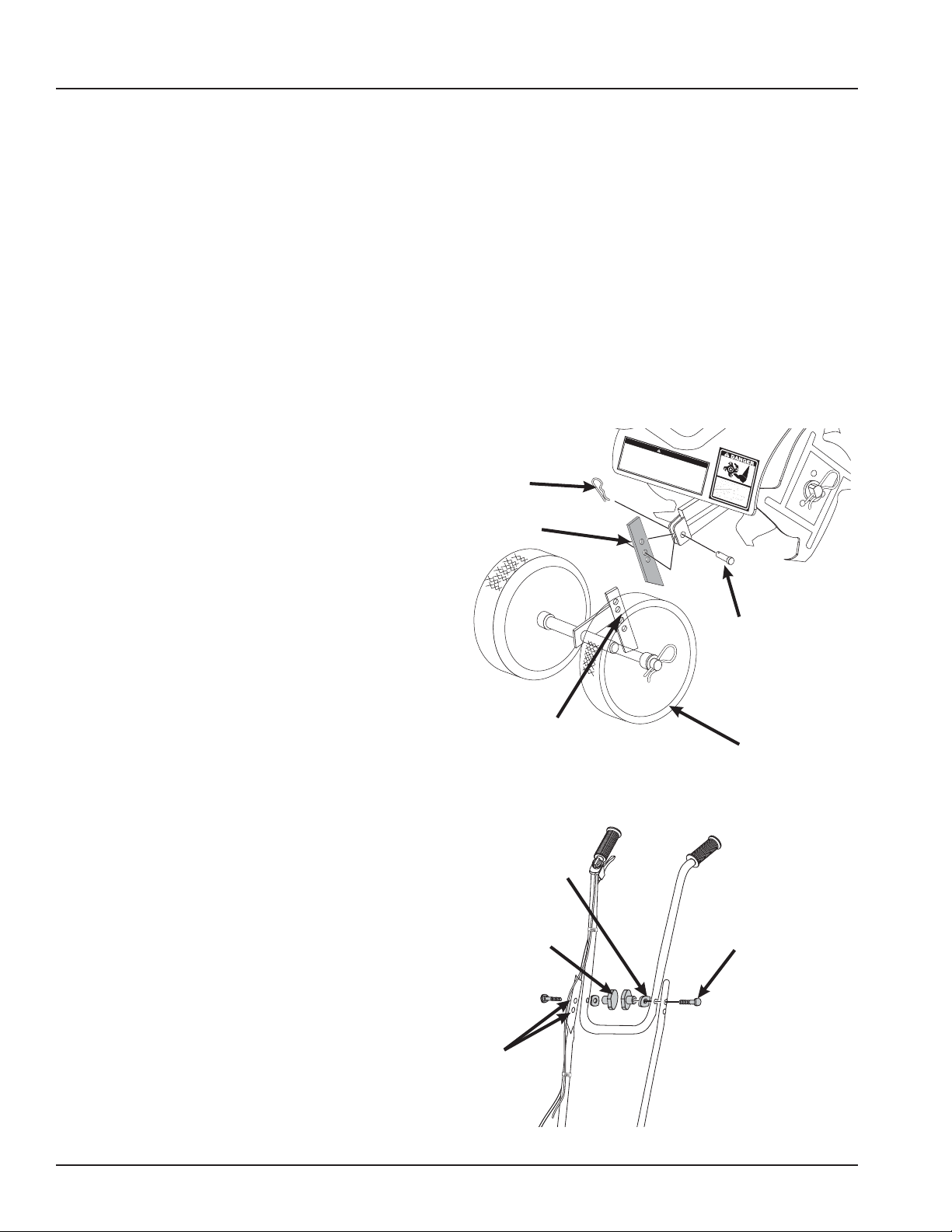

SAFETY LABEL LOCATIONS

The labels shown here contain important safety information. Please read them carefully. These labels are

considered permanent parts of your Honda tiller. If a label comes off or becomes hard to read,

immediately contact a Honda tiller servicing dealer for a replacement label.

DISEN GA GE ENGAGE

HOT / CHAUD

HOLD HERE

WHEN STARTING

CONTACT WITH ROTATING

TINES CAN CAUSE

SERIOUS INJURY.

KEEP HANDS, FEET AND

CLOTHING AWAY WHILE

ENGINE IS RUNNING.

WARNING

!

READ THE OWNER'S MANUAL CAREFULLY BEFORE OPERATION.

!

KNOW LOCATION AND FUNCTIONS OF ALL CONTROLS.

!

KEEP ALL SAFETY DEVICES AND SHIELDS IN PLACE AND WORKING.

!

NEVER ALLOW CHILDREN OR UNINSTRUCTED ADULTS TO OPERATE MACHINE.

!

SHUT OFF ENGINE BEFORE MANUALLY UNCLOGGING TINES OR MAKING

REPAIRS.

!

KEEP BYSTANDERSAWAY FROM MACHINE.

!

KEEP AWAY FROM ROTATING PARTS WHILE ENGINE IS RUNNING.

!

USE EXTREME CAUTION WHEN REVERSING OR PULLING THE MACHINE

TOWARDS YOU.

TO AVOID SERIOUS INJURY

NOTICE

To avoid damaging engine:

Check oil before operation.

Do not use gas/oil mix.

6 FG100 TILLER

COMPONENT IDENTIFICATION

ENGINE

SWITCH

HANDLE

HEIGHT

ADJUSTER

THROTTLE LEVER

CONTROLS

SPARK PLUG

RECOIL STARTER

CARRYING HANDLE

ENGINE OIL FILLER CAP/

ENGINE OIL DRAIN

CHOKE LEVER

AIR CLEANER

PRIMING BULB

TRANSPORT WHEEL

OR DRAG BAR

TINE

SHIELD

FUEL CAP

TILLING TINES

FG100 TILLER 7

CONTROLS

DESCRIPTION OF CONTROLS

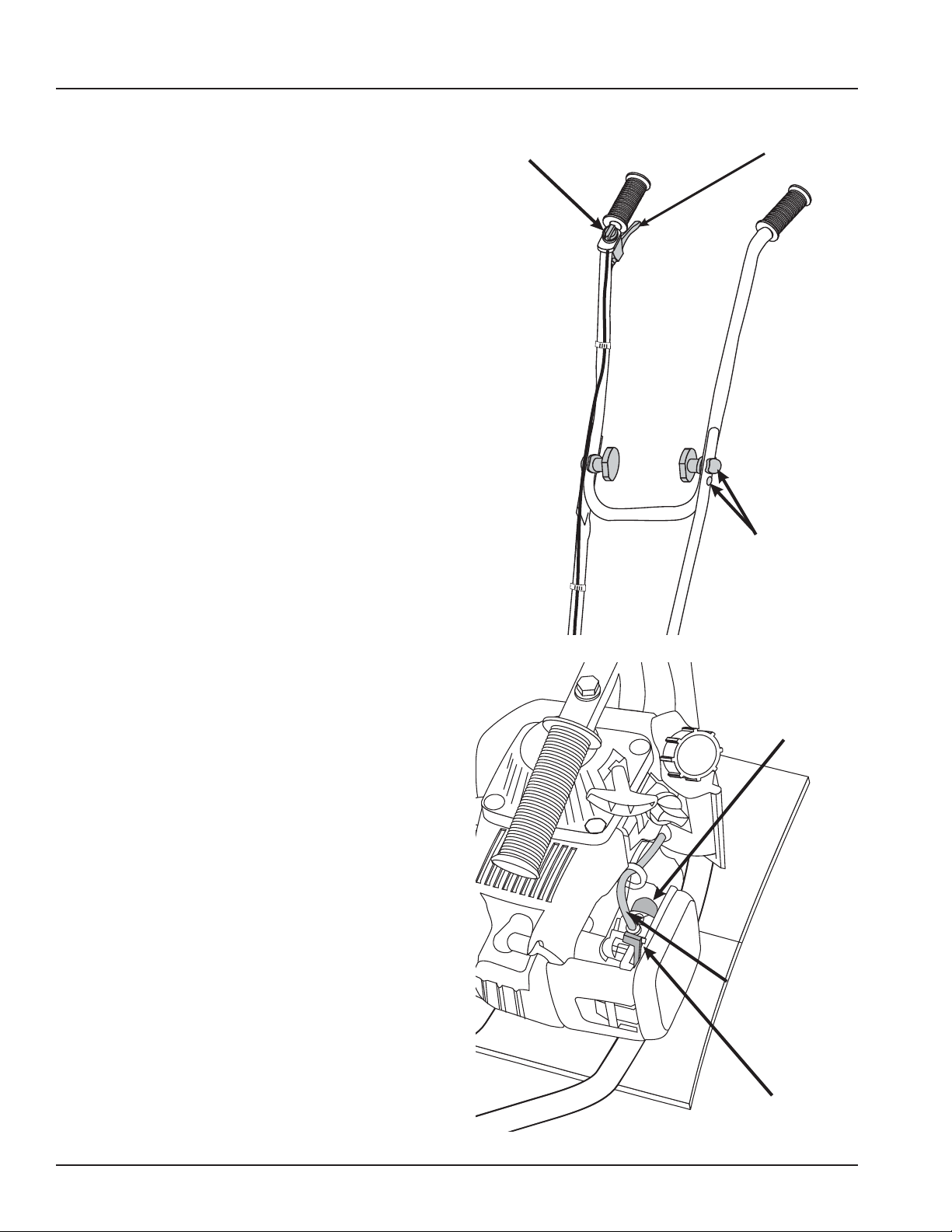

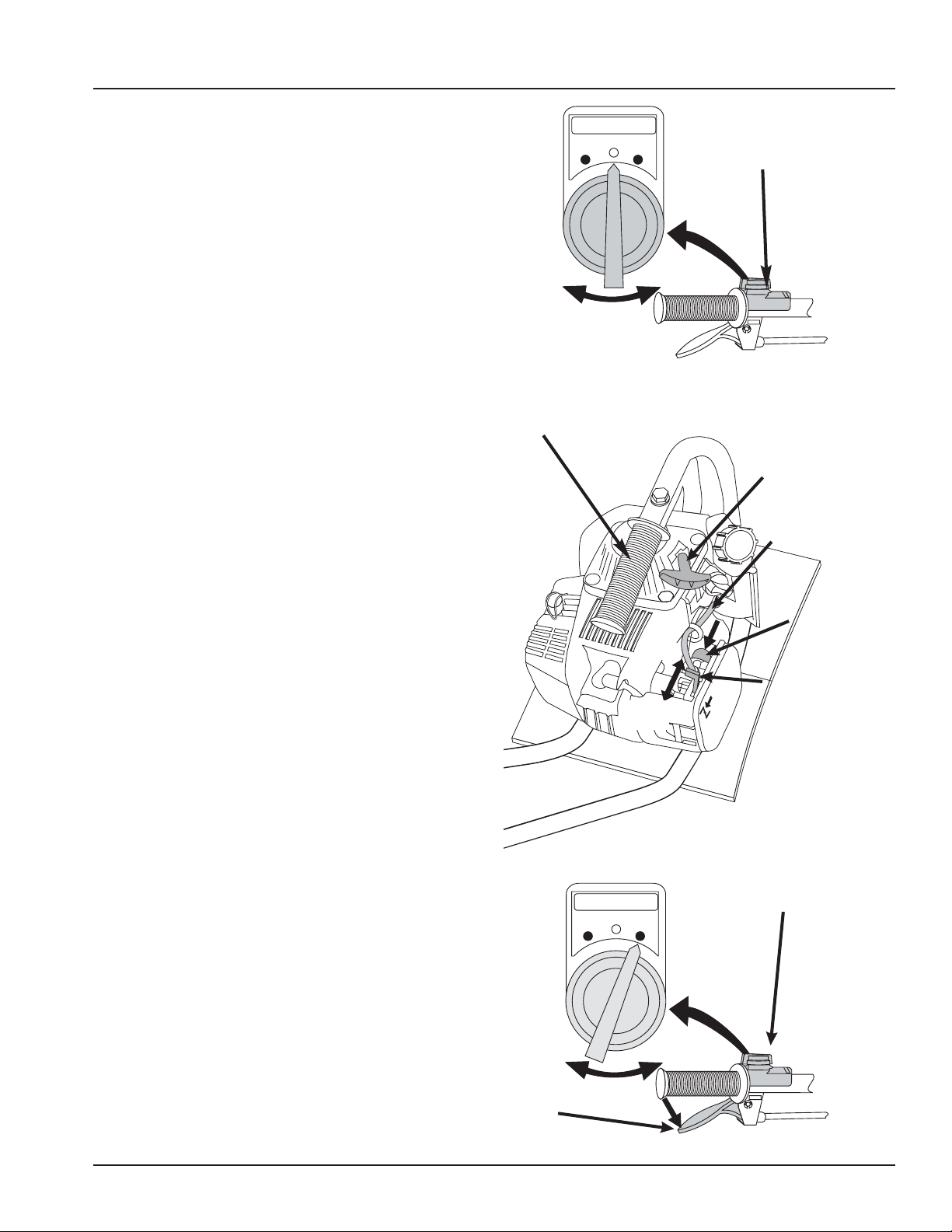

Throttle Lever

The throttle lever controls engine speed and tiller

tine rotation.

Pulling the throttle lever towards the grip increases

the engine speed which causes the tines to turn.

Releasing the throttle lever reduces engine speed

and stops the tiller tines from turning.

The tiller will have the greatest tilling force at

maximum engine speed. At idle, the tilling tines

should stop rotating.

Engine Switch

The engine switch controls the ignition system.

The engine switch must be in the ON position for

the engine to start and run. Moving the engine

switch to the OFF position stops the engine.

ENGINE SWITCH

THROTTLE LEVER

HANDLE BAR

ADJUSTMENT

(2-positions)

Handle Bar Adjustment

There are two positions that the handlebars can be

adjusted to best suit the height of the operator.

Choke Lever

The choke lever opens and closes the choke valve

in the carburetor.

The CLOSED position enriches the fuel mixture for

starting a cold engine. The OPEN position provides

the correct fuel mixture for operation after starting,

and for restarting a warm engine.

Priming Bulb

Pressing the priming bulb pumps fuel from the fuel

tank to the carburetor. This procedure is necessary

for starting a cold engine and after refueling an

engine that has run out of fuel.

To ensure that fuel has reached the carburetor,

press the priming bulb repeatedly until fuel can be

seen in the clear-plastic fuel-return tube.

PRIMER

BULB

FUEL-RETURN TUBE

(clear plastic)

CHOKE LEVER

8 FG100 TILLER

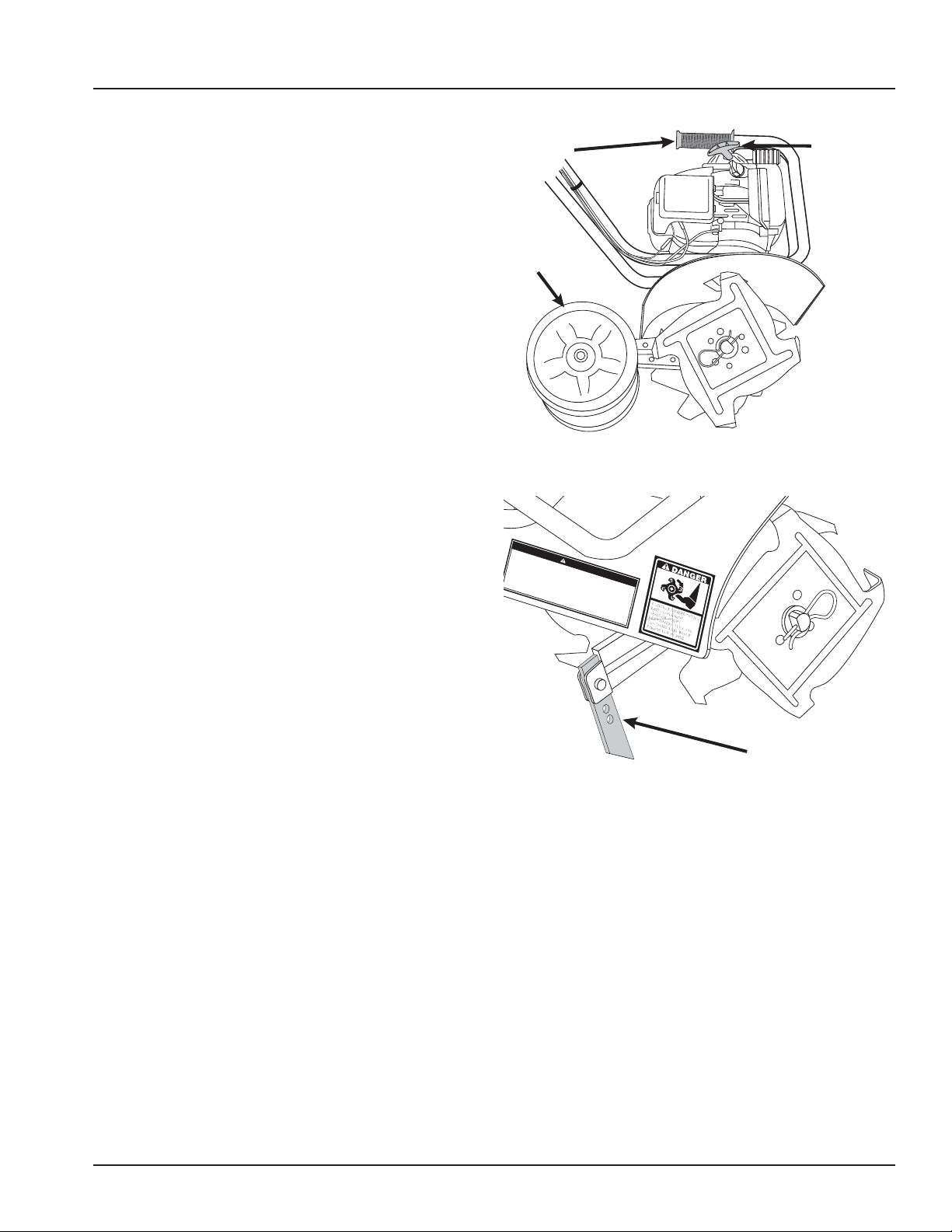

Transport Wheels

The transport wheels are used to move the tiller

around. Before tilling, the transport wheels must be

removed and the drag bar installed in their place.

CARRYING

HANDLE

CONTROLS

RECOIL

STARTER

Carrying Handle

The carrying handle rubber grip is used to hold the

tiller when starting the engine.

The carrying handle can be used to load/unload

the tiller, and to assist in certain engine

maintenance procedures.

Recoil Starter Grip

Pulling the starter grip operates the recoil starter to

crank the engine for starting.

Drag Bar

The drag bar is used to control the forward action

of the turning tiller tines. The drag bar can be

adjusted to control the tilling depth of the tines.

TRANSPORT

WHEELS

•

READTHE OWNER'S MANUAL CAREFULLYBEFORE OPERATION.

•KNOW LOCATION ANDFUNCTIONS OF ALL CONTROLS.

•KEEP ALL SAFETY DEVICES ANDSHIELDS IN PLACE ANDWORKING.

•NEVER ALLOW CHILDREN OR UNINSTRUCTEDADULTS TO OPERATEMACHINE.

•SHUT OFF ENGINE BEFORE MANUALLYUNCLOGGING TINES OR MAKINGREPAIRS.

•KEEP BYSTANDERS AWAYFROM MACHINE.

•KEEP AWAYFROM ROTATING PARTSWHILE ENGINE IS RUNNING.

•USE EXTREME CAUTION WHEN REVERSINGOR PULLING THE MACHINE TOWARDS

YOU.

WARNI NG

TOAVOID SERIOUS INJURY

DRAG BAR

FG100 TILLER 9

BEFORE OPERATION

ARE YOU READY TO OPERATE THE TILLER?

Your safety is your responsibility. A little time spent in preparation will significantly reduce your risk of

injury.

Knowledge

Read and understand this manual. Know what the controls do and how to operate them.

Familiarize yourself with the tiller and its operation before you begin to use it. Know what to do in case of

emergencies.

Physical and Mental Readiness

You must be alert and in good physical condition to operate the tiller. Do not operate the tiller if you are

tired, ill, or under the influence of alcohol, medication, or any substance that might impair your vision,

dexterity, or judgment.

If you have any physical problem that may be aggravated by strenuous work, consult your physician

before operating the tiller.

Protective Clothing

Wearing protective clothing will reduce your risk of injury. Do not wear loose clothing, jewelry, short pants,

sandals, or go barefoot. Secure hair so it is above shoulder level.

Eye, Face, and Head Protection

Always wear safety glasses or goggles that comply with ANSI standard Z87.1 to protect your eyes from

thrown objects. Prescription glasses may be worn under the safety glasses or goggles.

Wearing a dust mask will help to reduce the amount of pollens and dust inhaled.

Hearing Protection

Hearing protectors will help to protect your ears from noise. Earmuff-style hearing protectors can also

protect your ears from thrown objects.

Hand and Body Protection

Wear gloves, a long-sleeved shirt, and long pants made of heavy material. Clothing should fit closely but

allow freedom of movement, and should have no strings, straps, etc. that could catch on brush or the

tiller. Keep clothing fastened.

Foot Protection

Wear sturdy work boots with good toe protection and nonslip soles.

10 FG100 TILLER

BEFORE OPERATION

IS YOUR WORKING AREA READY?

Objects thrown by the tiller can cause serious injury. Be especially careful when crossing gravel drives,

walks or roads. Before operating the tiller, carefully inspect the area, and remove all objects that could be

thrown by, or entangled in, the tilling attachment, such as rocks, broken glass, nails, wire, or string.

Never operate the tiller without good visibility or light.

Clear the area of children, bystanders, and pets. Keep all children, bystanders, and pets at least

50 feet (15 meters) away from where the tiller is being operated.

If anyone approaches you while you are operating the tiller, release the throttle lever and stop the engine.

IS YOUR TILLER READY TO GO?

For your safety, and to maximize the service life of your equipment, it is very important to take a few

moments before you operate the tiller to check its condition. Be sure to take care of any problem you find,

or have your servicing dealer correct it, before you operate the tiller.

B WARNING

Improperly maintaining this tiller, or failing to correct a

problem before operation, could cause a malfunction

in which you could be seriously injured.

Always perform a pre-operation inspection before each

operation, and correct any problem.

Safety Inspection

Look around the engine for signs of oil or gasoline leaks. Wipe up any spills before starting the engine.

•

• Replace any damaged parts.

• Check that all fasteners are in place and secure. Tighten as necessary.

Tiller Tine Inspection

Look for signs of damage to the tilling tines (or any accessory installed). Replace any tiller tines and

•

parts that are worn out, bent, cracked, chipped, or damaged in any way.

• Make sure the tiller accessory is properly installed and securely fastened (see accessory operators

manual).

• Check that the debris shield is securely installed and in good condition.

Maintenance Inspection

Check the oil level (see page 19). Running the engine with a low oil level can cause engine damage.

Check the air filter (see page 20). A dirty air filter will restrict air flow to the carburetor, reducing engine

and tiller performance.

Check throttle operation (see page 24). The throttle must operate smoothly for good throttle control.

Check the fuel level (see page 25). Starting with a full tank will help to eliminate or reduce operating

interruptions for refueling.

FG100 TILLER 11

OPERATION

SAFETY PRECAUTIONS

Before operating the tiller for the first time, please review the IMPORTANT SAFETY INFORMATION (see

page 4) and the chapter titled BEFORE OPERATION (see page 10).

Even if you have operated other tillers, take time to become familiar with the operation of this tiller’s

controls and handling.

For your safety, avoid starting or operating the engine in an enclosed area, such as a garage. Your

engine’s exhaust contains poisonous carbon monoxide gas which can collect rapidly in an enclosed area

and cause illness or death.

If the tiller starts to shake or vibrate, stop the engine immediately. After the tiller tines have completely

stopped, inspect them to determine the cause of the vibration. Sudden vibration is a sign of a hazardous

problem, such as loose or damaged tilling tines (or tiller accessory), hidden objects in the soil, or the

ground that is too hard to till. Do not operate the tiller until the problem is corrected.

•

READTHE OWNER'SMANUAL CAREFULLYBEFOREOPERATION.

•KNOW LOCATIONANDFUNCTIONS OF ALLCONTROLS.

WARNING

•KEEP ALLSAFETY DEVICESAND SHIELDSIN PLACEAND WORKING.

TOAVOID SERIOUSINJURY

•NEVER ALLOWCHILDREN ORUNINSTRUCTED ADULTSTO OPERATEMACHINE.

Moving The Tiller

The tiller has transport wheels to allow easy

maneuvering to and from the work area. There are

four holes that the transport wheels can be set at.

Select the hole that sets the handlebars at a height

that provides comfortable tiller maneuvering.

LOCK PIN

DRAG BAR

•SHUT OFFENGINE BEFOREMANUALLY UNCLOGGINGTINES ORMAKING REPAIRS.

•KEEP BYSTANDERSAWAYFROM MACHINE.

•KEEP AWAYFROM ROTATINGPARTSWHILE ENGINEIS RUNNING.

•USE EXTREMECAUTION WHENREVERSING ORPULLING THEMACHINE TOWARDS

YOU.

Do not move the tiller with the engine running.

Before tilling, remove the transport wheels and

install the drag bar.

Drag Bar Installation

1. Make sure the engine is OFF before installing

the drag bar.

2. Remove the lock pin and the 5/16 x 7/8 inch

clevis pin. Remove the wheel assembly.

3. Install the drag bar with the pointed edge of the

drag bar towards the tiller tines using the

5/16 x 7/8 inch clevis pin and lock pin.

4. When your tilling job is completed, reinstall the

transport wheels in the reverse order of

removal.

Handlebar Adjustment

To adjust the handlebar height, remove the two

handlebar knobs, 5/16-18 x 1 1/2 inch handlebar

bolts, and curved washers. Move the upper

handlebar hole to align with either the upper or

lower holes in the lower handlebar assembly.

TRANSPORT

CURVED

HANDLEBAR

LOWER

HANDLEBA

R

5/16 x 7/8

in CLEVIS

TRANSPOR

5/16-18 X 1 1/2 in

12 FG100 TILLER

OPERATION

Starting The Engine

1. Move the engine switch to the ON position.

2. To start a cold engine, move the choke lever to

the CLOSED (E) position.

To restart a warm engine, leave the choke

lever in the OPEN position.

3. To start a cold engine, or after refueling an

engine that has run out of fuel, press the

priming bulb repeatedly until fuel can be seen

in the clear plastic fuel-return tube.

To restart a warm engine, it is not necessary to

press the priming bulb.

4. Place your left hand on the carrying handle

rubber grip and hold it firmly. Make sure your

feet are away from the tiller tines. With your

right hand, pull the starter grip lightly until you

feel resistance, then pull briskly. Return the

starter grip gently.

5. If the choke lever was moved to the

CLOSED (E) position, gradually move it to the

OPEN position as the engine warms up.

Allow the engine to warm up for a few minutes

after starting the engine cold.

The tiller tines should not rotate with the engine

idling. If there is rotation at idle, adjust the idle

speed correctly before using the tiller (see

page 24).

Stopping The Engine

1. Release the throttle lever.

2. Move the engine switch to the OFF position.

OFF OFF

CARRYING

ENG. SW.

ON

OPEN

CLOSE

ENG. SW.

ON

OFF OFF

ENGINE

STARTER

FUEL-RETURN

PRIMING

CHOKE

ENGINE

THROTTL

FG100 TILLER 13

OPERATION

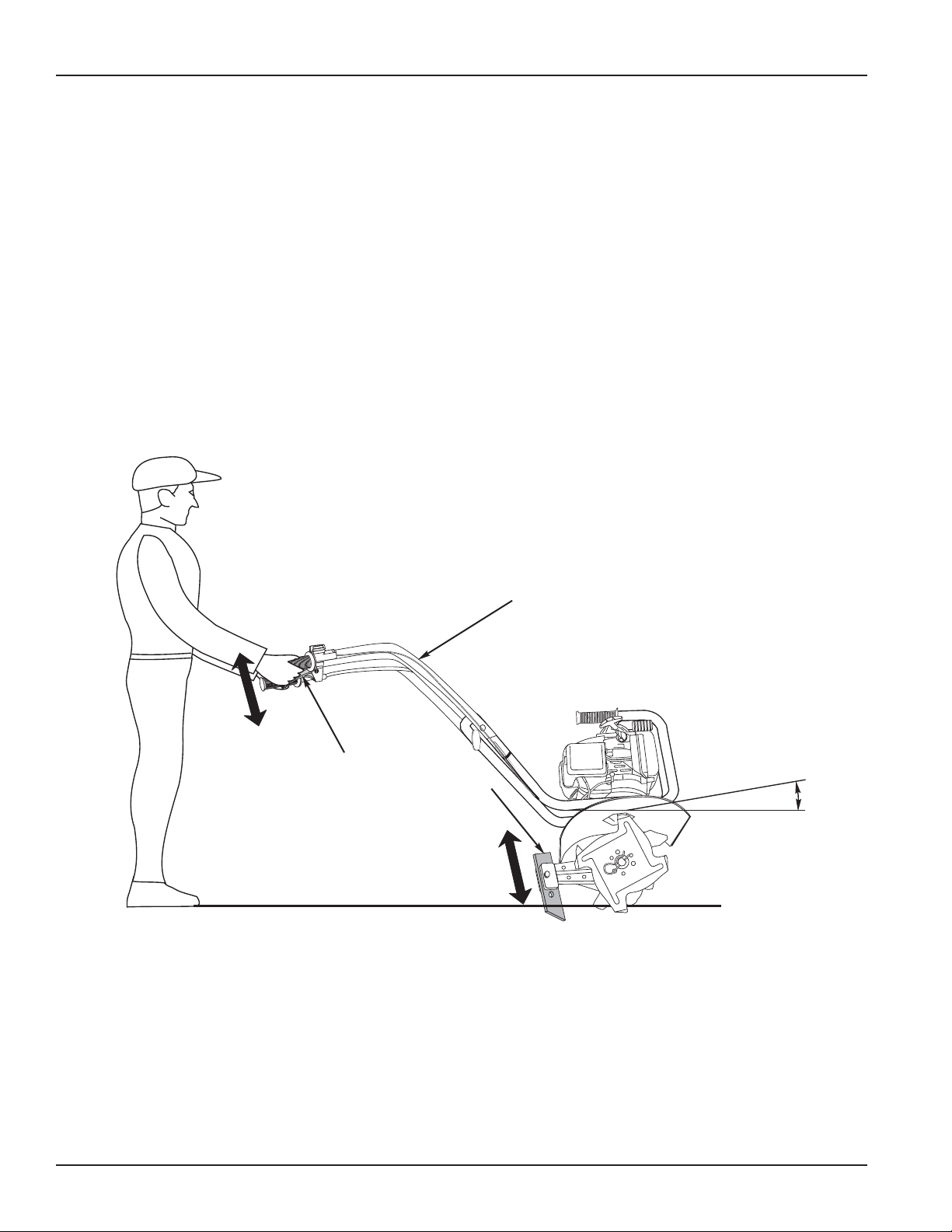

TILLER OPERATION

1. Install the drag bar (see page 12). Honda recommends using the drag bar when tilling. The tiller can be

difficult to control without the drag bar installed.

2. Adjust the handlebar to a comfortable position around waist height for normal tilling (see page 12).

3. Set the tilling depth by moving the drag bar up or down (see page 12).

The ideal height of the drag bar will depend on the type of soil being tilled, and soil conditions at the

time of tilling. In general, however, the drag bar should be adjusted so that the tiller is tilted slightly

backward.

4. Start the engine (see page 13).

5. Tilt the tiller back until the tines are off the ground. Squeeze the throttle lever to full speed position

(lever tight against the grip).

6. Lower the front of the tiller until the tines begin to dig into the ground.

7. Lower the handle slightly so the front of the tiller is raised about 6 - 8°. To get the maximum advantage

from the tiller, hold the tiller at this angle while you are tilling the ground.

HANDLEBARS

THROTTLE LEVER

DRAG BAR

6 - 8°

Handling Tips

If the tiller tends to move forward rapidly, push down on the handlebars to allow the drag bar to

•

penetrate the soil and slow the forward motion of the tiller. Continue to press down until the tiller tines

have dug to a desired depth that allows easy tiller handling.

• If the tines dig in but the tiller will not move forward, ease up on the handlebars and move the

handlebars from side-to-side. If the tiller still digs in, but will not move forward, raise the drag bar up a

hole.

• When turning, push down on the handlebars to bring the tiller’s weight to the rear; this will make turning

easier.

14 FG100 TILLER

Loading...

Loading...