Honda Automobiles Accessories C100 User Manual

Honda Super Cub Etc.

Frame & Forks

Introduction

This section is all about how to strip, servioce and rebuild the frame and forks of the Honda Super Cub and

other bikes using the same frames, plus all the anciliary components not covered in the Engine, Electrics, or

Maintenance Sections. This page is still under construction

All the models using the Super Cub frame are covered here, although models such as the CT50 will have far

fewer components. The only area or real difference between models is the forks - some use leading link and

others use telescopic types. Note that although the frames may appear to be the same, there are any number of

detail differences that, although the stripping and rebuilding methods are the same, many components are not

interchangeable. Frames fall into 4 main groups:

A - Pre 1968 (C100/C102/C105)

B - 1968 to 1983 Small (C50/C70/CT50/CT90)

C - 1968 to 1983 Large (C90)

D - 1982 to present (C50/C70/C90)

Note that the CT series used telescopic forks even though the C50/C70 used leading link forks with basically the

same frame. Note also the CT70 is not part of the same family, it used an ST type of frame.

Remember to disconnect the battery if you intend disconnecting any electrical items, and to reconnect it again

later.

Contents

Section Component

1 Engine

2 Front Wheel & Brake Assembly

3 Front Fork Assembly - Leading Link types

4 Front Fork Assembly - Telescopic types

5 Rear Wheel & Brake Assembly

6 Rear Suspension

7 Seat, Rear Mudguard, & Air-Cleaner

1.0 Engine

How many parts you remove while dropping the engine out of the frame depends on the reason for taking the

engine out. If it is to work on the frame, many components can remain attached to the engine, the fewer

components you remove then the less chance there is of loosing something. There is always the time factor to be

considered as well.

1.1 Lean the bike against a wall, but make sure it will not fall as you work on it.

1.2 Remove the left hand side cover, held on by three screws. Disconnect the wiring loom. Disconect the

carburettor overflow pipe, a plastic pipe usually attached forward of the generator.

1.3 Remove the chain from the engine either by splitting the chain at its split link, or by removing the 2 bolts

holding the engine sprocket on. Once the engine sprocket bolts are removed you will have to rotate the sprocket

retention plate until it comes off the splines. Remove the sprocket (screw the retention plate to the sprocket to

keep everything together).

1.4 Remove the screw holding on the carburettor access panel (the black plastic panel on top of the frame above

the engine.

1.5 Remove the 2 bolts fixing the inlet manifold to the engine cylinder head. (Only remove the carburettor if

you intend to work on it or the frame, see the carburettor section). Stuff some clean kitchen towel or cloth into

the intake port of the engine to stop things falling into it.

1.6 Remove the bolts holding on the plastic legshield, if fitted. Also remove the 2 straps, one each side of the

engine, rhat form part of the legshield mount.

1.7 Move to the right hand side of the bike and remove the muffler/exhaust system. There are 2 nuts at the

engine end and one bolt on the frame. Remove the spark plug lead.

1.8 Remove the upper and rear engine hanger bolts, these are the large bolts that hold the engine in, one is at the

top of the transmission housing and the other is near where the engine sprocket is mounted. Slacken Remove the

nuts and washers from both first, then you will have to try and lift the engine slightly to pull out the upper bolt

(you may need to tap it lightly with a soft mallet to start it. Gently lower the front od the engine down to the

ground. By supporting the engine on the footpeg you should be able to remove the rear engine mounting bolt.

You may have to wriggle the engine to pull it out from the frame.

1.9 (If stripping the engine) Remove the footpeg bar, held on by 4 bolts underneath the transmission, and the

gear pedal. Note that you might have to use an old screwdriver to open out the clamp a bit to pull the gear pedal

off its splines.

Give the engine a clean off as it will probably have accumulated a quantity of road dirt. Don't let anything enter

where the air intake manifold was bolted.

For stripping the engine, see the 'Horizontal OHC 49-86cc Engine' page.

Refitting the engine is basically a reversal of the removal.

1.10 Fit the footpeg bar.

1.11 Lift the back of the engine into the frame and slide the rear mounting bolt through.

1.12 Lift the front of the engine and slide the upper engine mount bolt through.

1.13 Fit the nuts on the rear and upper mounting bolts and tighten.

1.14 Fit the muffler, making sure that a gasket ring is fitted.

1.15 Remove your paper bung out of the intake port, check that there is a gasket fitted and refit the carburettor.

1.16 Refit the front engine mounting straps and the legshields. Note that the straps are marked with an 'L' or 'R'

to show you which side they go on.

1.17 Refit the chain, and the engine sprocket if it was removed. Check the chain tension and adjust if necessary.

1.18 Refit the carburettor overflow pipe and the engine loom.

1.19 Refit the left hand side cover.

1.20 Refit the gear pedal if it has been removed.

1.21 Start the engine and check that everything is working, that there are no leaks from the exhaust or into that

air intake system. Make sure that the engine revs freely (although be careful here if the engine has been rebuilt.

The engine may smoke an awful lot if you have had it apart, but do not worry unduly as it is just oil in the

combustion chamber and around the rings that is burning off. It may take 10 minutes for the smoke to

disappear).

1.22 Refit the plastic carburettor access panel.

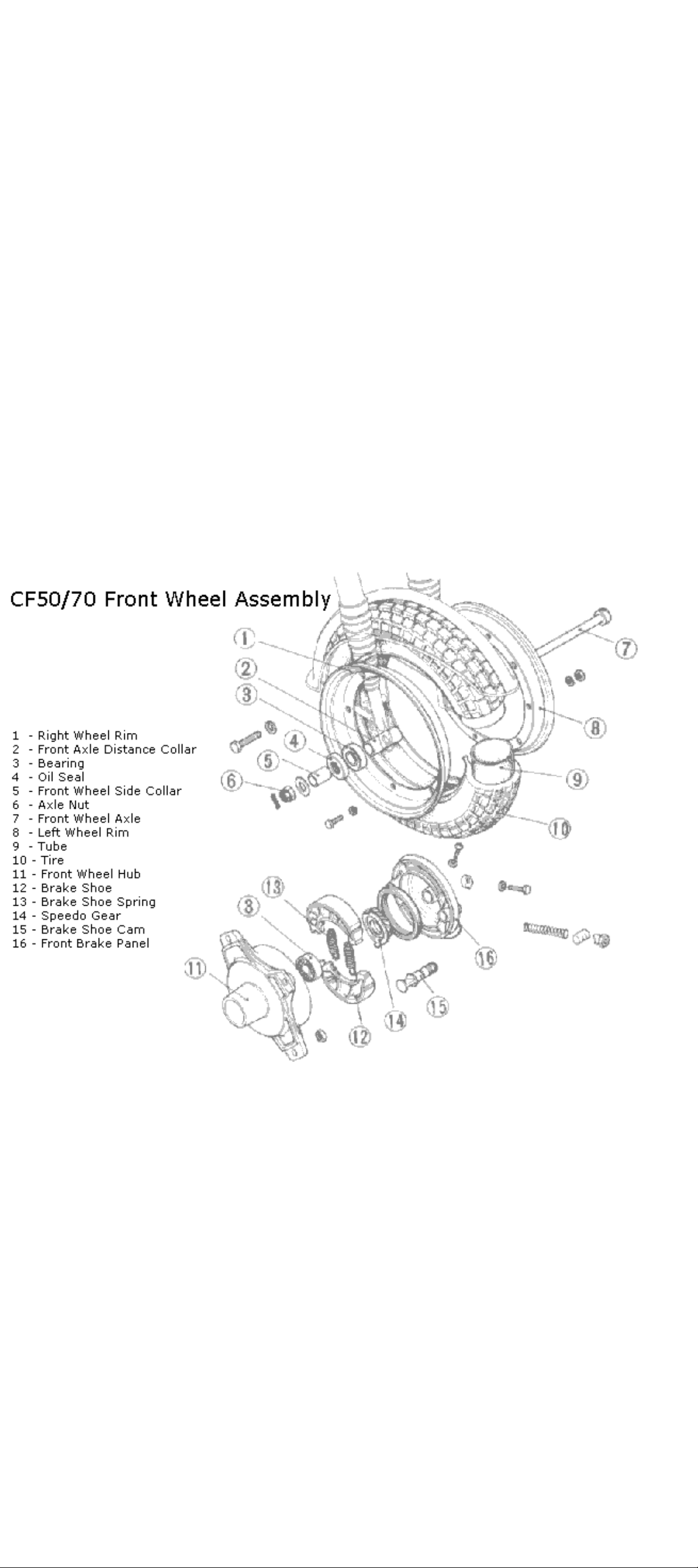

2.0 Front Wheel & Brake Assembly

This is quite an easy job as the wheel assembly is quite light. Note that it is important to note where the wheel

spacer goes, and that the brake shoes are the same as the Honda C50 & C70 Cub/Passport. Generally it is easier

to buy Cub/Passport parts.

Not all the operations below may be necessary if you just want to work on one particular component.

2.1 Put some kind of stand/strong box/bottle crate under the engine so that the front wheel is off the ground.

2.2 Disconnect the front brake cable by removing the adjuster nut, and the speedometer cable. Note: This does

not have to be done if you are not going to work on the brake.

2.3 Pull out the cotter pin/split pin and remove the axle nut.

2.4 Pull the axle spindle out, this may require a few taps with a soft mallet.

2.5 Remove the front wheel, catching the side collar if it falls off the front wheel (the side collar is only held in

by the oil seal).

2.6 Remove the side collar and the brake, be careful as the speedometer gear may fall out of the brake.

2.7 Remove the brake shoes by pulling the shoes against the force of the springs to get them off the mounting

pivots.

2.8 Remove the external brake operating arm and push the brake shoe cam through from the outside.

2.9 Remove the oil seal and bearings, if required.

2.10 Deflate the tyre.

2.11 Remove the 4 bolts attaching the wheel to the hub and remove the hub.

2.12 Remove the remaining bolts holding the 2 rim halves together, and remove the wheel rims from the tyre.

Check the wheel rims for damage, examine both the inside and outside of the tyre to make sure no stones or

metal are embedded in the rubber. Measure the brake linings and check they are in good condition. Examine the

hub part of the brake to make sure the metal is not scored or worn unevenly.

2.13 To assmble the front wheel it is necessary to have the tube inflated just enough to give it shape. Put the

tube in the tyre.

2.14 Fit the wheel rims, feeding the tube valve through the valve hole in one of the rims. Make sure that you do

not pinch the tube.

2.15 Fit the four 6 mm bolts through the rim and do them up but not tight.

Loading...

Loading...