Page 1

2006 ST1300/A

SET-UP

INSTRUCTIONS

Set-up and pre-delivery service

must be performed by an authoriz ed

Honda motorcycle dealer.

©2006 American Honda Motor Co., Inc. - All Rights Reserved

MPD 11396 (0601 )

Issued: January 2006

Page 2

IMPORTANCE OF PROPER SET-UP AND PRE-DEL IVERY SERVICE

FOR YOUR CUSTOMER'S SAFETY

Proper set-up and pre-delivery service are essential to rider safety and the reliability of the

machine. Any error or oversight ma de by the t echnician as sembling and ser vicing a ne w machine

can result in faulty operation, damage to the machine, or injury to the rider.

WARNING

Improper set-up or pre-delivery service can

create an unsafe condition that can cause

your customer to be seriously hurt or killed.

Follow the procedures and precautions in

this manual and the service manual carefully.

FOR YOUR SAFE T Y

Some of the most important safety precautions are given below. However, we cannot warn you

of every conceivable hazard that can arise in performing set-up and pre-delivery service. Only

you can decide whether or not you should perform a given task.

WARNING

Failure to properly follow instructions and

precautions can cause you to be seriously

hurt or killed.

Follow the procedures and precautions in this

manual carefully.

IMPORTANT SAFETY PRECAUTIONS

Make sure you have a clear understanding of all basic shop safety practices and that you are

wearing appropriate clothing and safety equipment. When performing the set-up or pre-delivery

service, be especially careful of the following:

• Read the instructions before you begin, a nd make sure you have the tools and skills required to

perform the tasks safely.

• To prevent the machine from falling on you, park it on a firm, level surface, using the proper

stand(s) to provide firm support.

Make sure the engine is off before you begin any servicing procedures. This will help eliminate

several potential hazards:

• Carbon monoxide poisoning from engine exhaust—be sur e th ere is adequ ate ventilati o n

whenever you run the engine.

• Burns from hot parts—let the engine and exhaust system cool before touching.

• Injury from moving parts—do not run the engine unless the instruction tells you to do so. Even

then, keep your hands, fingers, and clothing away.

To reduce the possibility of a fire or explosion, be careful when working around gasoline or

batteries. Use only a nonflammable solvent, not gasoline, to clean parts. Keep all cigarettes,

sparks an d fl am es away fro m the battery and all fuel- re l ated parts.

©2006 American Honda Motor Co., Inc. - All Rights Reserved i

Page 3

2006 ST1300/A

How To Use This Manual

Follow the complete sequence of steps as shown. Do not short-cut any steps. The sequence has

been established to ensure the unit is properly assembled.

The individual steps are composed of three components:

• Sub-heading—The large sub-headings are a brief description of the step. They are intended

to be used by the experienced technician, one who only needs a brief reminder of the

set-up sequence.

• Descriptive text—The descriptive text explains in detail what is to be done during that step.

This explanation is intended as a guide for the technician needing additional information.

• Photographs/Line art—The photographs or line art support both the sub-headings and the

detailed text.

Indicates the set-up section Indicates the pre-deliver y section

Modifications and Accessories

Modifications that you may have made, or should make in the future , to any Honda product, shall

be deemed by our company to have been performed at your sole risk and responsibility, and

without our company's or the manufacturer's approval, or consent, implied or expressed. We

further discla im a ny and al l liability, obligation, or re sponsibility for a ny defe cts of modif ie d pa rt s

or of the modified product, and for any claims, demands, or causes of action for damage to

property or for personal injuries resulting from the modification of said Honda product.

Torque Table

ITEM SIZE TORQUE

Reflector nut 6 mm 12 N·m (1.2 kgf·m, 9 lbf·ft)

Front fender bolt 6 mm 12 N·m (1.2 kgf·m, 9 lbf·ft)

Front axle bolt -------- 79 N·m (8.1 kgf·m, 58 lbf·ft)

Pinch bolt 8 mm 22 N·m (2.2 kgf· m, 16 l bf ·ft)

Caliper bolt 8 mm 31 N·m (3.2 kgf·m, 23 lbf·ft)

Mirror bolt 6 mm 12 N·m (1.2 kgf·m, 9 lbf·ft)

Windscreen bol t 6 mm 12 N·m (1.2 kgf·m, 9 lbf·ft)

Windscreen cover screws 4 mm 1.0 N·m (0.1 kgf·m, 0.7 lbf·ft)

Handlebar cover 6 mm 1.2 N·m (0.12 kgf·m, 0.9

Engine guard cover 6 mm 9.0 N·m (0.9 kgf·m, 6.6 lbf·ft)

Oil filler cap ----- --- 12 N·m (1.2 kgf·m, 9 lbf·ft)

lbf·ft)

ii ©2006 American Honda Motor Co., Inc. - All Rights Reserved

Page 4

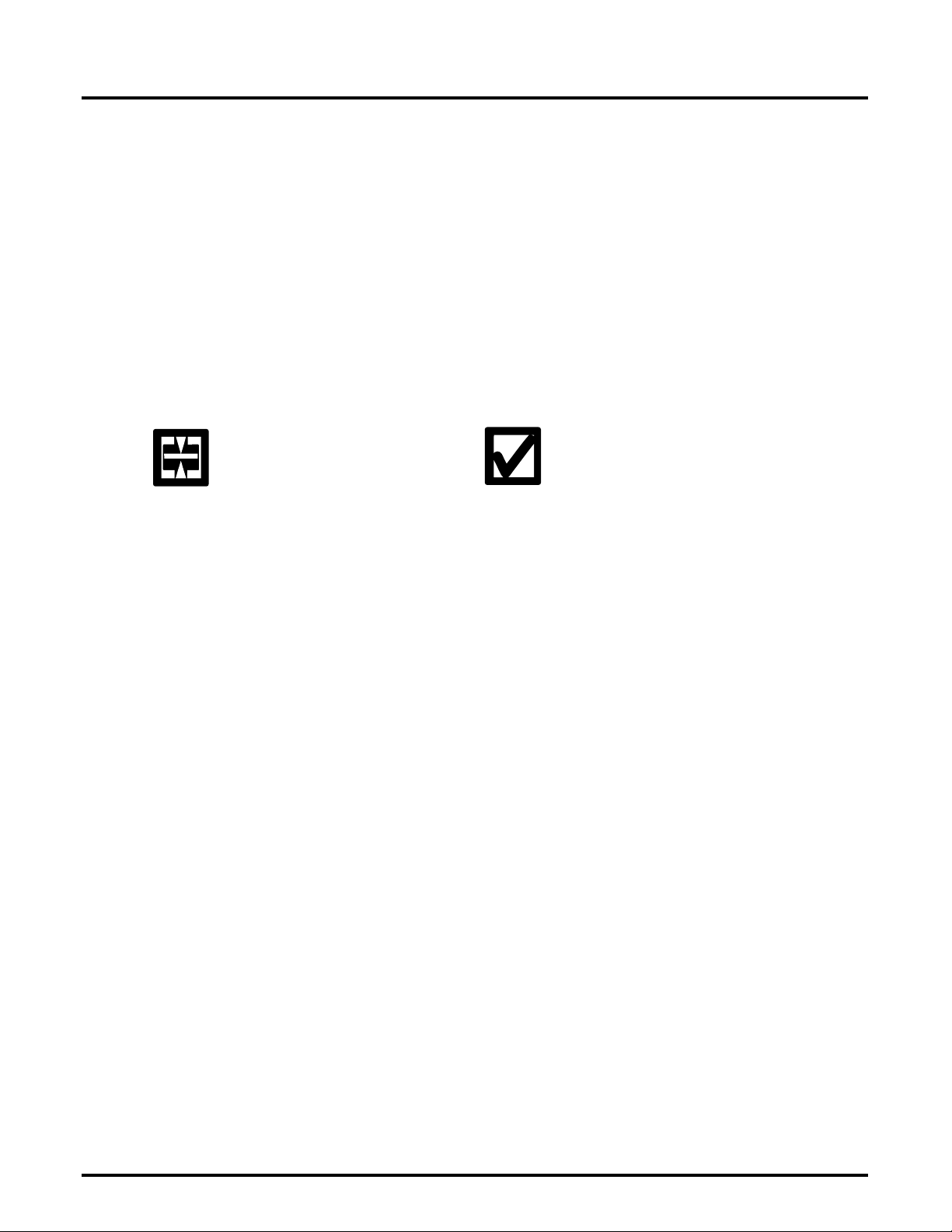

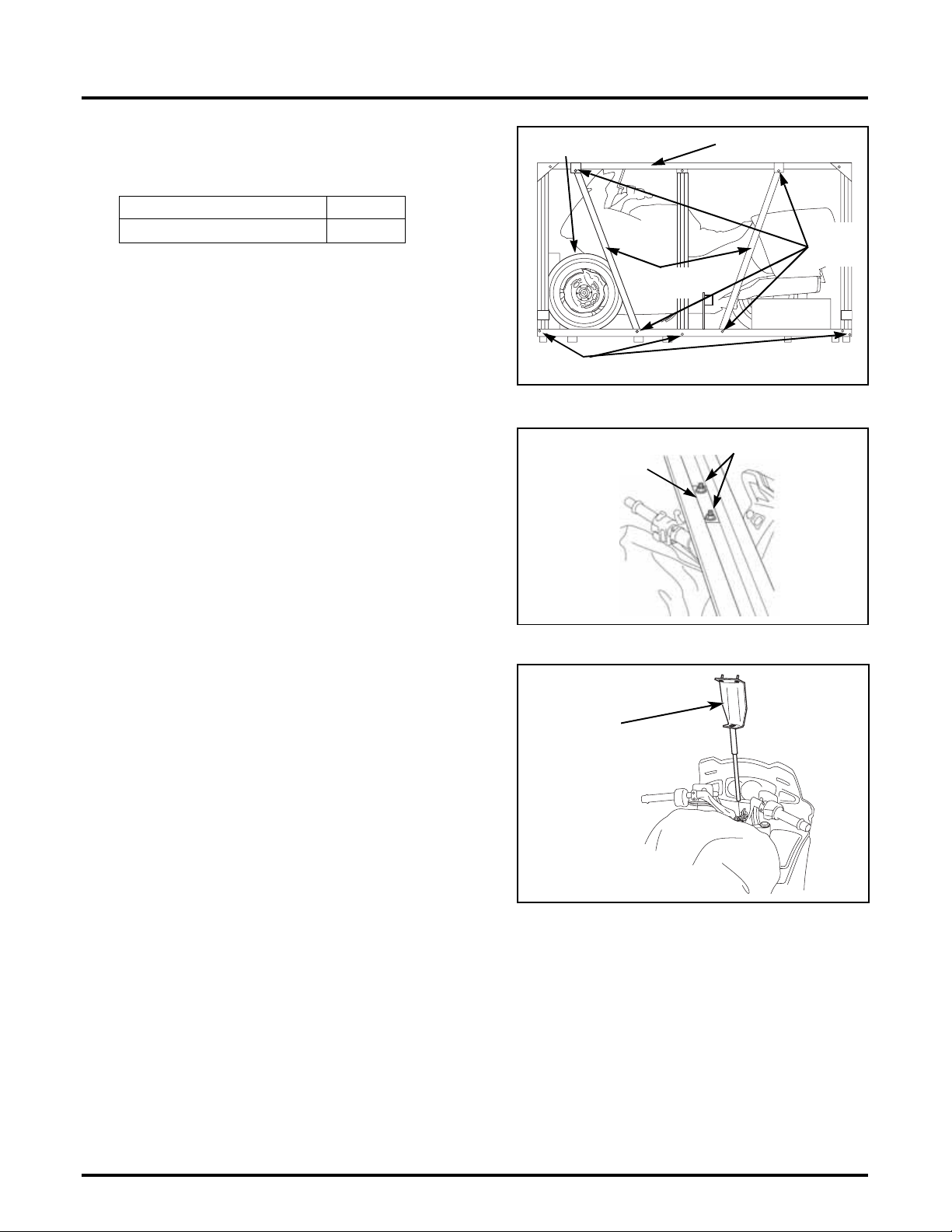

1.Remove the carton cover.

The ST1300/A is crated in one of two ways.

You may r ec ei ve either on e .

Cover ed c r ate:

Cut the strap and remove the carton cover.

Remove the inner cardboard frame cover.

STRAP

COVERED CRATE

Uncovered crate:

When stacking crates, protect the motorcycle

from falling objects and bad weather.

2.Check for damage.

Check the unit for hidden damage.

If you find damage, follow the instructi ons on

the Delivery and Damage Claims Guidelines

wall chart (Reorder No. S0477) before

proceeding.

3.Remove the side braces, wheel, loose

parts cartons, and crate frame.

UNCOVERED CRATE

Remove the ties securing the front whee l and

loose parts cartons.

PARTS

CARTON

©2006 American Honda Motor Co., Inc. - All Rights Reserved 1

TIE

TIES

PARTS

CARTON

TIE

Page 5

2006 ST1300/A

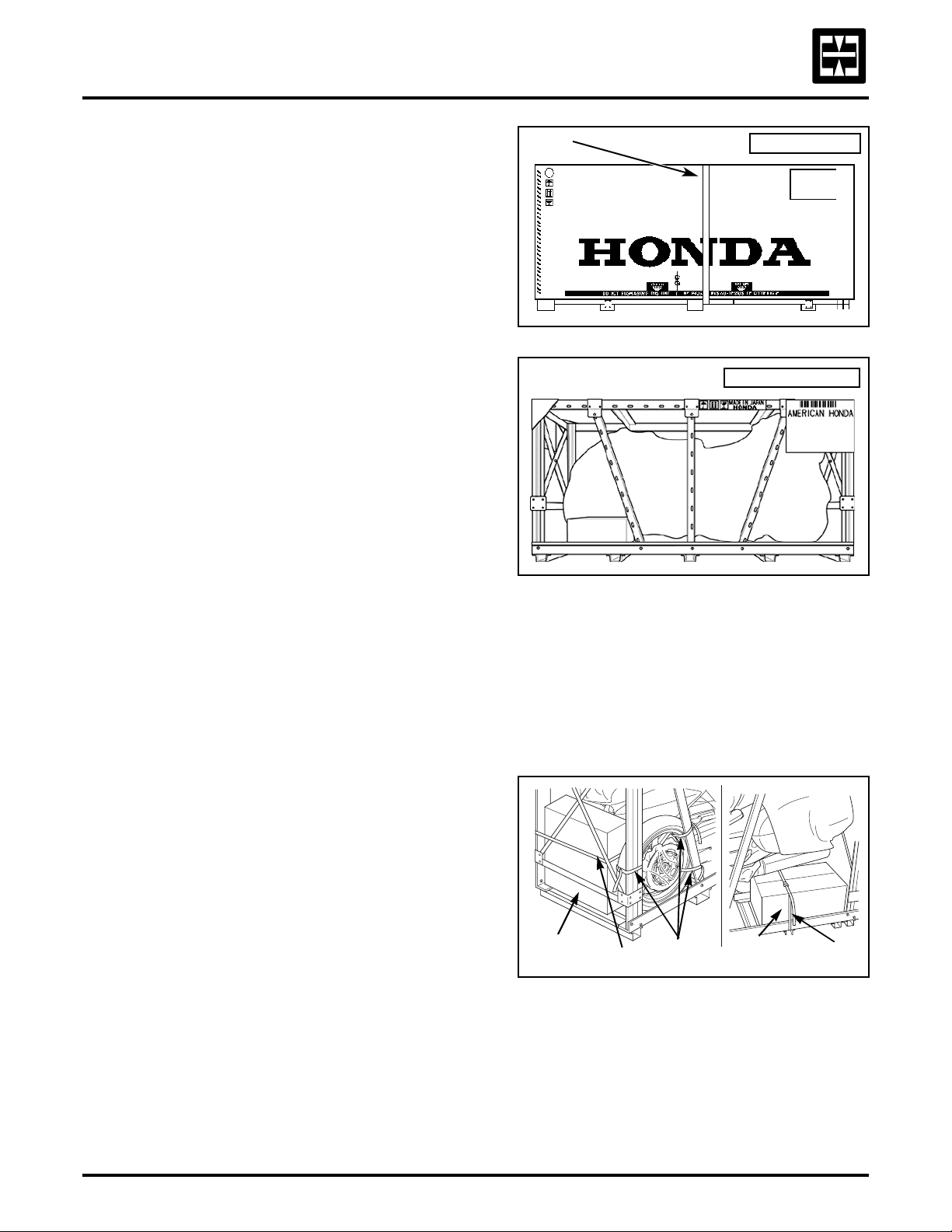

3.Remove the side braces, wheel,

loose parts cartons, and crate

frame (cont.).

PARTS QTY

Riding Tips & Practice Guide 1

Remove the bolts and side braces, being

careful not to damage the front wheel.

Remove the loose parts cartons.

Keep the You and Your Motorcycle Riding

Tips & Practice Guide and hand deliver to the

customer at the time of delivery.

Remove the nuts, plate, and bolts.

Using two people, carefully remove the

crate frame, being careful not to damage

the motorcycle.

FRONT WHEEL

FRAME BOLTS

CRATE FRAME

SIDE

BRACE

BOLTS

SIDE

BRACES

NUT S AN D B O LTS

PLATE

Remove the front shipping brace, being

careful not to damage the motorcycle.

FRONT

SHIPPING

BRACE

2 ©2006 American Honda Motor Co., Inc. - All Rights Reserved

Page 6

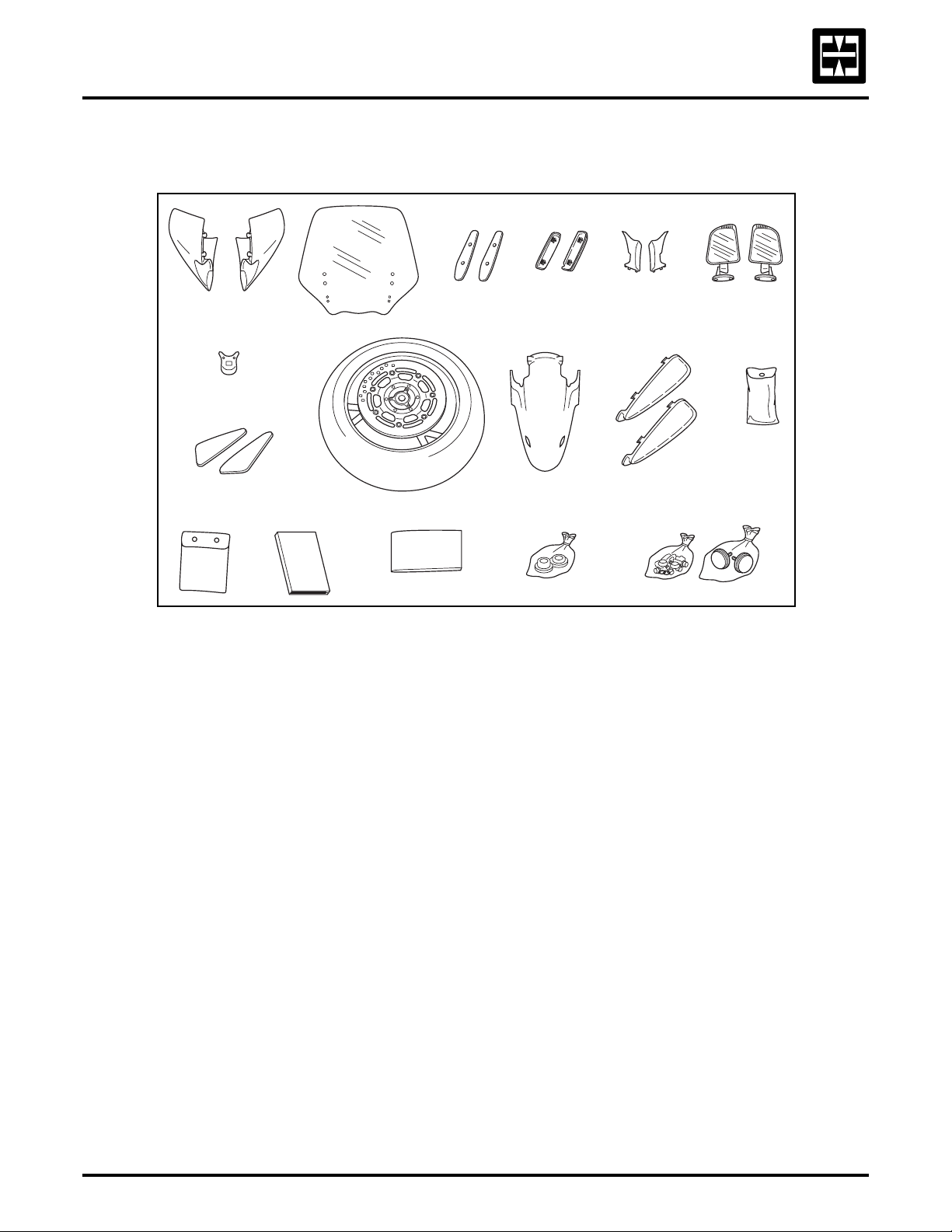

4.Loose Parts Information.

Unpack the remaining loose parts and check them against this illustration.

1.

2.

3.

4.

5.

7.

8.

11.

9.

13.

15.

14.

DESCRIPTION QTY PART NUMBER STEP

1. Right mirror cover 1 88111-MCS-G00ZJ 8

Left mirror cover 1 88121-MCS-G00ZJ 8

2. Windscreen 1 64150-MCS-G00 9

3. Windscreen cover 2 64151-MCS-G00 9

4. Right windscreen brack et cover 1 64183-MCS-G00 9

Left windscreen bracket cover 1 64188-MCS-G00 9

5. Right mirror cover rubber 1 88112-MCS-G00 8

Left mirror cover rubber 1 88122-MCS-G00 8

6. Right rear view mirror 1 88110-MCS-G01 8

Left rear view mirror 1 88120-MCS-G01 8

7 . Handlebar cover 1 53115-MCS-G00ZA 10

8. Right knee grip pad* 1 17506-MCS-G01 15

Left knee grip pad* 1 17507-MCS-G01 15

9. Front wh e e l assembly 1 ----------- ----------- -- 7

10. Front fender 1 61100-MCS-G00ZH 6

11. Right engine guard cover 1 64260-MCS-G01 14

Left engine guard cover 1 64265-MCS-G01 14

10.

16.

(Continued on next page .)

6.

12.

17.

* Optional parts. Hand the knee pads to the customer at the time of delivery or install if the

customer wants them installed (see step 15).

©2006 American Honda Motor Co., Inc. - All Rights Reserved 3

Page 7

2006 ST1300/A

4.Loose parts information (cont.).

DESCRIPTION QTY PART NUMBER STEP

12. Tool kit 1 ------ ----------- ------- 12

13. Owner’s Manual bag 1 83642-MN5-000 12

14. Owner’s Manual 1 31MCS630** 12

15. You and Your Motorcycle

Riding Tips & Practice Guide

16. Right front wheel side col lar 1 44311-MCS-G00 7

Left front wheel side collar 1 44312-MCS-G00 7

1 7. Attaching parts:

Front fender:

Rubber washer 2 18325-MBV-0 00 6

Pan screw 6 x 20 mm 2 90138-MCS-G00 6

Socket bolt 6 x 18 mm 2 96600-06018- 00 6

Flange bolt 6 x 16 mm 2 96001-06016-07 6

Front reflector 2 33742-HB9-641 6

Front reflector stay 2 33742-MCS-L00 6

Flange nut 6 mm 2 94050-06000 6

Mirrors:

Flange bolt 6 x 20 mm 4 96001-06020-00 8

Hose clip 4 95002-02100 8

Windscreen:

Plastic retainer 4 64509-MK4-000 9

Collar, side cover 4 61104-435-000 9

Flange bolt 6 x 18 mm 4 96001-06018-07 9

Pan screw 4 x 25 mm 4 90126-MCS-G00 9

Adjuster rubber 2 64175-MCS-G00 9

Handlebar cover:

Special screw 4 x 6.5 mm 2 90136-MCS-G00 10

Engine guard covers:

Pan screw 6 x 11 mm 2 90106-KY2-701 14

1 G0045*** 3

** If missing, order from Helm Inc.

*** If missing, order from Resolve Corp.

Missing Parts or Shipping Damage

Identify missing parts by referring to the Loose Parts Information section. Order the parts

using normal parts ordering procedures. Claims for missing loose parts or those damaged

during transit should be submitted to American Honda, not the carrier. After completing

repairs, submit a Transportation Claim via iN. For complete details, please refer to the

Warranty Policy and Procedures Manual.

4 ©2006 American Honda Motor Co., Inc. - All Rights Reserved

Page 8

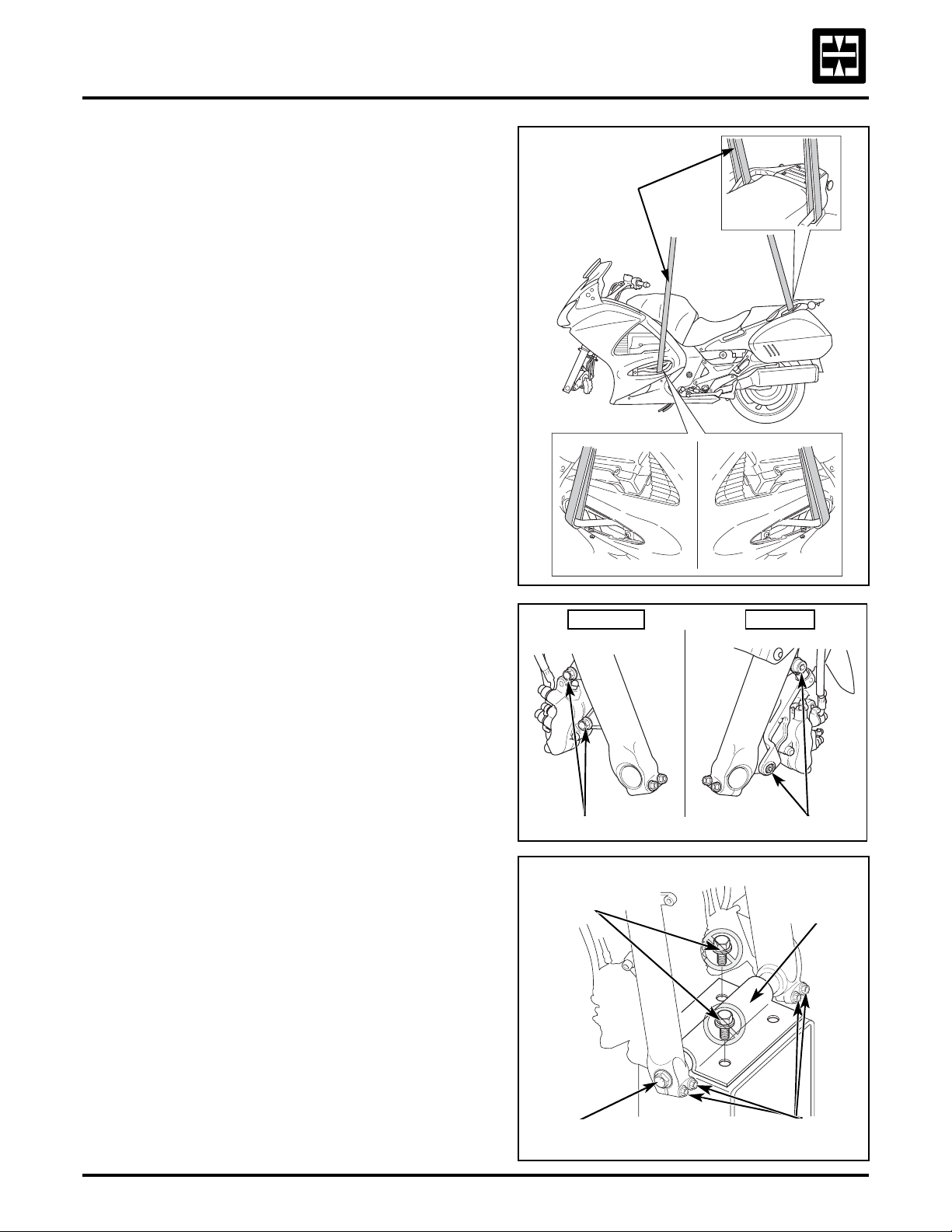

5.Remove the motorcycle from the

crate base.

Install lifting slings on the engine guards and

grab rails as shown.

If necessary, use a spreader board to prevent

the slings from damaging the motorcycle.

Lift the slings just enough to remove

the slack.

Loosen the caliper bolts, axle bolt, and axle

pinch bolts. Remove the washer bolts, and

lower shipping bracket from the crate base.

SLINGS

RIGHT SIDE

LEFT SIDE

Discard the washer bolts.

CALIPER BOLTS

WASHER BOLTS

(discard)

AXLE BOLT

CALIPER BOLTS

LOWER

SHIPPING

BRACKET

PINCH BOLTS

©2006 American Honda Motor Co., Inc. - All Rights Reserved 5

Page 9

2006 ST1300/A

5.Remove the motorcycle from the crate

base (cont.).

Remove the shipping braces, nuts, and

protective covering from the foot pegs on

both sides of the motorcycle.

Lift the motorcycle free from the crate base

and remove the base.

On a firm, level surface, lower the centerstand

and lower the motorcycle until it is resting on

its rear wheel and centerstand.

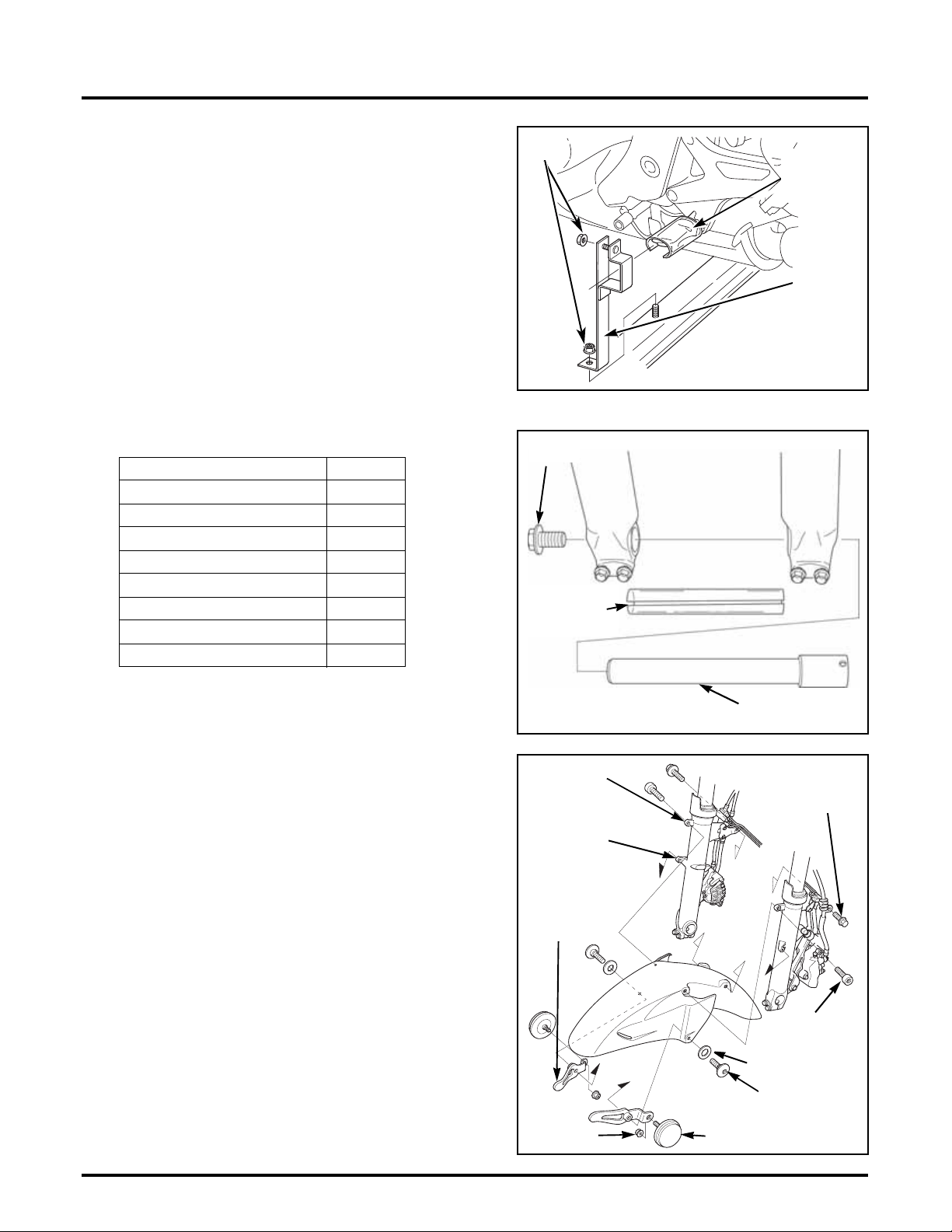

6.Install the front fender.

PARTS QTY

Front fender 1

Rubber washer 2

Pan screw 6 x 20 mm 2

Socket bolt 6 x 18 mm 2

Flange bolt 6 x 16 mm 2

Front reflector 2

Front reflector stay 2

Flange nut 6 mm 2

NUTS

AXLE

BOLT

PROTECTIVE

COVERING

(discard)

PROTECTIVE

COVERING

(discard)

SHIPPING

BRACE

Remove the axle bolt.

Remove the axle protective covering and the

axle shaft.

Position the reflector stays on the inside of

the front fender by aligning them with the

projections on the front fender. Install the

reflector stays with two 6 x 20 mm pan

screws and rubber washers.

Secure the reflectors to the stays with two

6 mm nuts.

Torque the nuts.

Torque: 12 N·m (1.2 kgf·m, 9 lbf·ft)

Position the front fender between the fork

legs and attach it to the fork stays with two

6 x 18 mm socket bolts. Secure the brake

hose stays with two 6 x 16 mm flange bolts.

Torque the bolts.

Torque: 12 N·m (1.2 kgf·m, 9 lbf·ft)

FORK STAY

UPPER

FORK STAY

LOWER

REFLECTOR

STAY

6 mm NUT

AXLE SHAFT

6 x 16 mm

FLANGE

BOLT

6 x 18 mm

SOCKET BOLT

RUBBER WASHER

6 x 20 mm

FLANGE BOLT

REFLECTOR

6 ©2006 American Honda Motor Co., Inc. - All Rights Reserved

Page 10

7.Install the front wheel.

PARTS QTY

Front wheel assembly 1

Right front wheel side col lar 1

Left front wheel side collar 1

Clean both sides of the front and rear brake

discs with a clean shop towel and Pro Honda

Brake Cleaner or equivalent.

Remove the caliper mounting bolts. Be

careful not to get dust and dirt on the ends of

the mounting bolts.

Support both calipers with a piece of wire,

or similar method, so they do not hang from

the brake hoses. Be careful not to twist the

brake hos es .

Do not operate the brake lever or pedal after

the brake calipers are removed.

Note that the shoulders on each wheel collar

are different sizes. It is important to install

them with th e correct sid es facing the wheel.

RIGHT SIDE

CALIPER

BOLTS

LEFT SIDE

CALIPER

BOLT

8 x 45 mm

CALIPER

BOLT

Install the 16.5 mm left-side collar with the

10 mm deep shoulder side facing the wheel.

Install the 27.5 mm right-side collar with the

34 mm outside diameter shoulder facing

the wheel .

Position the front wheel between the

fork legs.

Slide the axle shaft through the left fork leg,

the 16.5 mm left-side collar, front wheel,

27.5 mm right-side collar, and right fork leg.

Push in on the axl e s haft so t he le f t end of the

axle shaft i s flus h w i th th e s u r face of the left

fork leg.

While holding the axle, install a nd t ight en the

axle bolt to the specified torque.

Torque: 79 N·m (8.1 kgf·m, 58 lbf·ft)

Tighten the right axle pinch bolts to the

specified torque.

Torque: 22 N·m (2.2 kgf·m, 16 lbf·ft)

AXLE BOLT

27.5 mm

RIGHT SIDE

COLLAR

PINCH

BOLTS

AXLE

SHAFT

16.5 mm

LEFT SIDE

COLLAR

©2006 American Honda Motor Co., Inc. - All Rights Reserved 7

Page 11

2006 ST1300/A

7.Install the front wheel (cont.).

Reinstall the right and left front brake

calipers, being careful not to damage the

front wheel and related components.

Install the caliper bolts and tighten to the

specified torque.

Torque: 31 N·m (3.2 kgf·m, 23 lbf·ft)

Operate the front brake and pump the forks

several times to seat the axle.

Check the brake operation by applying the

brake lever and pedal.

Check th e w h eel for free ro tation after th e

brake is released. If the brake drags or the

wheel does not rotate freely, recheck the

wheel and brake caliper installation.

RIGHT SIDE

CALIPER

BOLTS

LEFT SIDE

8 x 45 mm

CALIPER

BOLT

CALIPER

BOLT

Visually check the positio n of the brake disc in

relation to the brake caliper; it should be

DISC

centered. If not, recheck the wheel and brake

caliper installation.

CALIPER BRACKET

8 ©2006 American Honda Motor Co., Inc. - All Rights Reserved

Page 12

7.Install the front wheel (cont.).

Make sure the axle end is flush with the front

fork leg outer surface as shown.

Tighten the left axle pinch bolts to the

specified torque.

Torque: 22 N·m (2 .2 k g f· m , 16 lbf·ft)

AXLE

PINCH BOLTS

On th e ST13 00A, v erif y the cle aranc e bet ween

the ABS front pulser ring and sensor.

Clearance specification:

0.4 - 1.2 mm (0.02 - 0.05 in)

If outside the clearance specification range,

recheck the wheel installation.

8.Install the mirrors.

PARTS QTY

Right mirror cover 1

Left mirror cover 1

Right mirror cover rubber 1

Left mirror cover rubber 1

Right rear view mirror 1

Left rear view mirror 1

Flange bolt 6 x 20 mm 4

Hose clip 4

SENSOR

PULSER RING

HOSE CLIPS

PULSER RING

SENSOR

0.4 - 1.2 mm (0.02 - 0.05 in)

6 x 20 mm FLANGE BOLTS

Remove and discard the shipping bolts.

Install the rig h t and left rear vi ew mirrors

using two 6 x 20 mm flange bolts on

each side.

Torque the bolts.

Torque: 12 N·m (1.2 k g f· m , 9 l b f· ft)

Install the two hose clips as shown.

SHIPPING BOLTS

(discard)

©2006 American Honda Motor Co., Inc. - All Rights Reserved 9

Page 13

2006 ST1300/A

8.Install the mirrors (cont.).

Align the retaining tabs, located on the ends

of the mirror cover rubber, with the indentations on the fairing.

Push the end of the retainer strap into th e

hole in the body.

Connect the wiring harness terminals colorto-color: right side wires are colored light

blue and white, left side wires are colored

orange and white.

HOLE

MIRROR

COVER

RUBBER

RETAINER

STRAP

TERMINALS

MIRROR COVER

Carefully install the mirror covers by pressing

the cover prongs into the grommets on the

bracket, and mirror bracket ends into the

cover as shown.

MIRROR COVER

10 ©2006 American Honda Motor Co., Inc. - All Rights Reserved

Page 14

9.Install the windscreen.

PARTS QTY

Windscreen 1

Windscreen cover 2

Right windscreen bracket cover 1

Left windscreen bracket cover 1

Plastic re ta iner 4

Side cover collar 4

Flange bolt 6 x 18 mm 4

Pan screw 4 x 25 mm 4

Adjuster rubber 2

Note that th e w i n dscreen adj u s ter s ar e

installed as shown, however, they can be

reinstalled according to rider preference.

To install the windscreen, use two people

to carefully install the following parts in the

order indicated below:

• Windscreen bracket covers

WINDSCREEN

COVER

WINDSCREEN

BRACKET

COVERS

6 x 18 mm

FLANGE BOLT

4 x 25 mm

PAN SCREWS

SIDE

COVER

COLLARS

6 x 18 mm

FLANGE

BOLT

• Adjuster rubbers

• Windscreen

• Plastic retainer

• Side cover collars

• 6 x 18 mm flange bolts

Torque the bolts.

Torque: 12 N·m (1 .2 k g f· m , 9 l b f· ft)

Then, install the following:

• Windscreen covers

• 4 x 25 mm pan screws

Torque the pan screws.

Torque: 1.0 N·m (0. 1 kgf·m, 0. 7 l b f· ft)

ADJUSTER RUBBERS

PLASTIC RETAINERS

©2006 American Honda Motor Co., Inc. - All Rights Reserved 11

Page 15

2006 ST1300/A

10.Install the handlebar cover and saddlebag

lever lock.

PARTS QTY

Handlebar cover 1

Special screw 4 x 6.5 mm 2

Remove the ignition key from the ignition.

Remove th e p r o t ec tive tape.

Attach the handlebar cover using two

4 x 6.5 mm special screws.

Torque the screws.

Torque: 1.2 N·m (0.12 kgf·m, 0.9 lbf·ft)

Open the left fairing pocket with the

ignition key.

4 x 6.5 mm SPECIAL SCREWS

IGNITION

KEY

HANDLEBAR

COVER

PROTECTIVE

TAPE

FAIRING POCKET

Take out the saddlebag lever locks from the

left fairing pocket.

Insert the ignition key into the saddlebag

lever lock and turn it clockwise to the position

shown.

Push in on the saddlebag lever lock while

aligning it with t he c utout in the saddlebag

as shown.

IGNITION

KEY

SADDLEBAG

LEVER LOCKS

SADDLEBAG

LEVER LOCK

CUTOUT

12 ©2006 American Honda Motor Co., Inc. - All Rights Reserved

Page 16

11.Remove the rear seat.

Insert the ignition key and turn it clockwise to

open the latch lever.

Pull the rear seat back and up while

depressing the seat opener.

REAR SEAT

LATCH LEVER

SEAT OPENER

12.Store the tool kit and Owner’s Manual.

PARTS QTY

Tool kit 1

Owner’s Manual bag 1

Owner’s Manual 1

Place the tool kit under the rear seat and

secure it with the tool band.

Place the Owner’s Manual into its bag and

place it on top of the tool kit.

13.Install the rear seat.

Note: If the pre-delivery steps will be

completed directly afte r set- up, le a ve the re ar

seat off until after step 17.

Insert the prong into the recess under the

frame cross member, then push down on the

rear of the re ar se at.

Close the latch lever and turn the ignition

key counterclockwise.

Be sure the seat i s locked secure ly in posi tion.

Place the ignition key into the ignition.

OWNER’S

MANUAL

AND BAG

PRONG

TOOL BAND

TOOL KIT

REAR SEAT

LATCH LEVER

IGNITION

KEY

©2006 American Honda Motor Co., Inc. - All Rights Reserved 13

Page 17

2006 ST1300/A

14.Install the engine guard covers.

PARTS QTY

Right engine guard cover 1

Left engine guard cover 1

Pan screw 6 x 11 mm 2

Install the engine guard covers and secure

them with a 6 x 11 mm pan screw.

Torque the screws.

Torque: 9.0 N·m (0.9 kgf·m, 6.6 lbf·ft)

15.Install the fuel tank knee grip pads.

PARTS QTY

Right knee grip pad 1

Left knee grip pad 1

Install the optional knee pads if the customer

requests them to be installed.

If the unit has not been sold, store the pads in

the right saddlebag.

Clean the mating surfaces of the fuel tank

with a clean shop towel and isopropy l alcohol

or equivalent.

Peel off the backing sheets and attach the

pads to the sides of the fu el tan k 30 mm

(1-13/16 in) from the low er front edg es o f th e

tank, as shown in the illustration.

If the ambient temperature is 77

warm the mating surfaces of the tank and

the pad’s adhesive side with a hair dryer

before attaching.

°F or below,

6 x 11 mm

PAN SCREW

30 mm

(1-13/16

FUEL TANK

30 mm

(1-13/16 in)

KNEE GRIP PADS

After attaching the pads, press down firmly

over the en tire area of the pad to ens u r e

maximum adhesion.

Avoid washing the motorcycle or riding in

wet conditions for 24 hours after attaching

the pads.

14 ©2006 American Honda Motor Co., Inc. - All Rights Reserved

Page 18

16.Verify the proper routing of the cables, hoses, and wire harnesses.

POSITIVE (+)

BATTERY TERMINAL

NEGATIVE (-) CABLE

NEGATIVE (-)

BATTERY TERMINAL

BATTERY BOX

RIGHT

RUNNING

LIGHT

CONNECTOR

RIGHT TURN

SIGNAL 2P

(SKY BLUE)

CONNECTOR

LEFT TURN

SIGNAL 2P

(ORANGE)

CONNECTOR

LEFT RUNNING LIGHT

CONNECTOR

©2006 American Honda Motor Co., Inc. - All Rights Reserved 15

Page 19

2006 ST1300/A

17.Service and install the battery.

Service the battery only if the unit is sold or

will be used as a demonstrator.

Remove the seats:

If the rear seat is installed, follow the

instructions for seat removal in step 11.

Remove the front seat by pulling it back

and up.

Remove the right saddlebag:

Insert the ignition key and turn it cloc kwise to

open the latch lever.

Remove the right side saddlebag by lifting up

and pulling it out.

FRONT SEA T

LATCH LEVER

Close the latch lever.

Remove the right side cover:

Remove the screws and the right side cover.

SADDLEBAG

5 mm SCREWS

16 ©2006 American Honda Motor Co., Inc. - All Rights Reserved

5 mm SCREW

SIDE COVER

Page 20

17.Service and install the battery (cont.).

Remove th e b attery cover .

Remove the battery holder by removing

the bolt.

Pull the battery out of the battery box.

Remove the cap and the packed battery nuts

and bolts.

The battery in this motorcycle is a pre-

charged, maintenance-free type. The

electrolyte has been added at the factory.

Follow the instructions included in Service

Letter #48.

Make sure the ignition switch is in the

OFF position.

Lower the battery into the battery box.

NUTS AND BOLTS

CAP

BATTERY COVER

BATTERY

HOLDER

BATTERY

BOLT

Connect the positive (+) battery cable to

the positive (+) battery terminal. Then

connect the negative (-) battery cable to the

negative (-) battery terminal using t he special

bolts and nuts.

Tighten the bolts securely.

Coat both terminals with clean dielectric

grease and pull the red cover over the

pos itive t erminal.

Allowing the positive (+) cable to rest on any

metal parts could wear throug h the insulation

and cause a short circuit. Do not allow the

positive (+) cable to contact any metal parts.

Verify the correct battery cable routing by

referring to step 16.

Reinstall the battery holder, bolts, battery

cover, and s i de cover in th e r everse ord er

of removal.

POSITIVE (+)

CABLE

NUTS

BOLTS

NEGATIVE

(-) CABLE

©2006 American Honda Motor Co., Inc. - All Rights Reserved 17

Page 21

2006 ST1300/A

17.Service and install the battery (cont.).

Reinstall the front seat:

Insert the seat prong under the tank a nd a lign

the two recesses with the prongs at the rear

of the tank. Make sure that the seat adjustment guides align with the holes in the seat

and push down on the rear of the seat to

secure it into position.

Reinstall the rear seat:

Reinstall the rear seat by following the

instructions in step 13.

FRONT SEAT

RECESSES

PRONGS

HOLES

PRONG

SEAT ADJUSTMENT

GUIDES

Install the right saddlebag:

Use the ignition key to open the latch lever.

Position the three slots of the saddlebag

on the three hooking points on the

motorcycle as shown. Check that the

saddlebag engages securely.

Close the latch lever and lock it with the

ignition key.

Remove the ignition key and place it in the

ignition switch in the OFF position.

SADDLEBAG

LATCH

LEVER

HOOKING

POINTS

SLOTS

18 ©2006 American Honda Motor Co., Inc. - All Rights Reserved

Page 22

18.Check the coolant level.

Check the coolant level at the coolant reserve

tank. If the level is low, remove the coolant

reserve tank cap and add Pro Honda HP

coolant or a 1:1 mixture of a high-quality

ethylene glycol anti-freeze containing

corrosion inhibitors and distilled water to

restore the level to the UPPER mark. Do not

spill coolant on painted or plastic surfaces as

it can damage the finish.

UPPER

LEVEL MARK

LOWER

LEVEL MARK

RESERVE

TANK

RESERVE

TANK CAP

19.Verify the throttle freeplay.

Operate th e th r o ttl e to confirm th at it moves

smoothl y an d re tu r n s automatica lly fr o m an y

open position to the fully closed positi on in all

steering positions.

Confirm the throttle grip freeplay:

Throttle freeplay:

2 – 6 mm (1/16 – 1/4 in)

Make adjustments at the throttle grip

adjuster by loosening the lock nut and

turning the adjuster. Tighten the lock nut

after adju s tm ent.

20.Check the oil level.

Before starting the engine, remove the antirust coating from the engine and exhaust

system using a mild detergent and water.

Rinse with clean water.

Support the motorcycle in an upr ight position

on a firm, level surface.

Check that the oil level is between the

upper and lower level marks in the

inspection window.

2 – 6 mm (1/16 – 1/4 in)

INSPECTION WINDOW

UPPER LE VEL MARK

LOCK NUT

ADJUSTER

LOWER LEVEL MARK

©2006 American Honda Motor Co., Inc. - All Rights Reserved 19

Page 23

2006 ST1300/A

20.Check the oil level (cont.).

If the oil level is below the lower level mark,

remove the right cylinder head over-head

cover and oil filler cap, and add the recommended oil until it is visible in the inspection

window. Replace the oil filler cap.

Start the engine and let it idle for 3 – 5

minutes. Make sure the low oil pressure

indicator goes of f. If the indicator re mains on,

stop the engine and troubleshoot the cause.

Stop the engine and wait 2 – 3 minute s. Check

the oil level using the above procedure and, if

necessary, add the recommended oil until it

reaches the upper level mark. Do not add oil

above the upper level mark.

• Oil recommendation: Pro Honda GN4 or

HP4 (without molybdenum additives) 4stroke oil or equivalent motor oil

• Viscosity: SAE 10W-40

• Classification: SG or higher. Do not use oils

labeled as energy conserving on the circular

API service label.

FILLER CAP

• JASO 4T Service Classification: MA

• Crankcase capacity (after draining): 3.6

Liters (3.8 US Quarts)

Reinstall the oil filler cap and right cylinder

head over-head cover.

21.Check the final drive oil level.

Place the motorcycle on its centerstand on a

firm, lev el surface.

Remove the oil filler cap and check the oil

level, it shou ld be flus h with the l ower edge o f

the oil filler hole. If the level is low, check for

oil leaks. Add the recommended oil through

the oil filler hole until it reaches the lower

edge of the opening.

Recommended oil: Pro Honda Shaft Drive Oil

or equivalent SAE 80 hypoid gear oil

Reinstall and torque the oil filler cap.

Torque: 12 N·m (1.2 kgf·m, 9 lbf·ft)

OIL FILLER CAP

LOWER ED G E

20 ©2006 American Honda Motor Co., Inc. - All Rights Reserved

Page 24

22.Check the front and rear brake reservoir

fluid levels.

Turn the handlebar so the front brake

reservoir is level and check the fluid level.

FRONT BRAKE

LOWER LEVEL MARK

SCREWS

Support the motorcycle in an upr ight position

on a firm, level surface and check the rear

brake flui d le vel .

If the fluid level is low in either reservoir,

remove the screws, reservoir cover, and

diaphragm or cap.

Add Pro Honda DOT 4 brake fluid or

equivalent from a sealed container to bring

the level up to the upper level mark.

Reinstall the cap or the diaphragm, cover,

and screws.

Operate the hand lever and foot pedal. If the

free play is excessive or the brake feels

spongy and the reservoir fluid level is cor rect,

bleed the system.

23.Check the idle speed.

Start the engine and warm it up to its normal

operating temperature.

Place the motorcycle on its centerstand on a

firm, level surface.

REAR BRAKE

UPPER LEVEL MARK

LOWER

LEVEL MARK

Connect a tachometer to the engine

according to the manufacturer’s instructions.

Verify the idle speed (rpm).

Idle speed: l,000

± 100 rpm

THROTTLE

STOP

SCREW

DECREASE

If an adjustment is needed, turn the

throttle stop screw to set the idle speed

INCREASE

using a screwdriver.

Stop the engine and remove the tachometer.

©2006 American Honda Motor Co., Inc. - All Rights Reserved 21

Page 25

2006 ST1300/A

24.Check the tire pressure.

Front and rear: 42 psi.

25.Check the clutch lever and sidestand

ignition cut-off switches.

When the transmission is in gear, the starter

should not work unless the clutch lever is

pulled in and the sidestand is up.

Position the motorcycle securely with the rear

wheel raised off the ground.

Clutch lever ignition cut-off switch test:

Shift the tr ansmissio n into g ear.

Raise the sidestand and without pulling the

clutch lever in, turn on the ignition, set the

engine stop switch to the RUN position, and

press the starter button.

If the engine starts, there is a problem with

the clutch lever ignition cut-off switch.

Troubleshoot the cause.

Sidestand ignition cut-off switch test:

Shift the tr ansmissio n into g ear.

Lower the sidestand and pull the clutch lever

in. Turn on the ignition, set the engine stop

switch to the RUN position, and press the

starter button.

If the engine starts, there is a problem with

the sidestand ignition cut-off switch.

Troubleshoot the cause.

22 ©2006 American Honda Motor Co., Inc. - All Rights Reserved

Page 26

26.Adjust the front seat height.

The front seat height of the ST1300/A can be

adjusted for rider preference.

Remove the rear seat by referring to the

instructions in step 11.

Remove the front seat by following the

instructions in step 17.

Move the seat height adjuster into one of the

three positions on the guide as shown.

SEAT HEIGHT ADJUSTER

Be sure to alig n th e h o l es i n t h e r ear o f th e

front seat with the adjuster when installing

the seat.

Reinstall the front seat by referring to the

instructions in step 17.

Reinstall the rear seat by following the

instructions in step 13.

GUIDE

HIGH POSITION

MIDDLE POSITION

LOW POSITION

27.Complete the Set-up/Pre-delivery form.

Complete an On-Road Motorcycle Set-up/Predelivery Checklist (Reorder No. S0299, also

availabl e o n iN) by checking the boxes

confirming the steps were done.

©2006 American Honda Motor Co., Inc. - All Rights Reserved 23

Page 27

2006 ST1300/A

Wiring Diagram - ST1300

24 ©2006 American Honda Motor Co., Inc. - All Rights Reserved

Page 28

Wiring Diagram - ST1300A

©2006 American Honda Motor Co., Inc. - All Rights Reserved 25

Loading...

Loading...